Energy-saving agent special for gear of textile machine and preparation method thereof

An energy-saving agent and gear technology, which is applied in the fields of additives, petroleum industry, lubricating compositions, etc., can solve the problems of inconvenient use, difficulty in meeting the requirements of spinning gear lubrication and energy saving, and chemical and physical stability of nano-metal particle additives. Wear, energy saving effect is obvious, the effect of avoiding serious abrasive wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

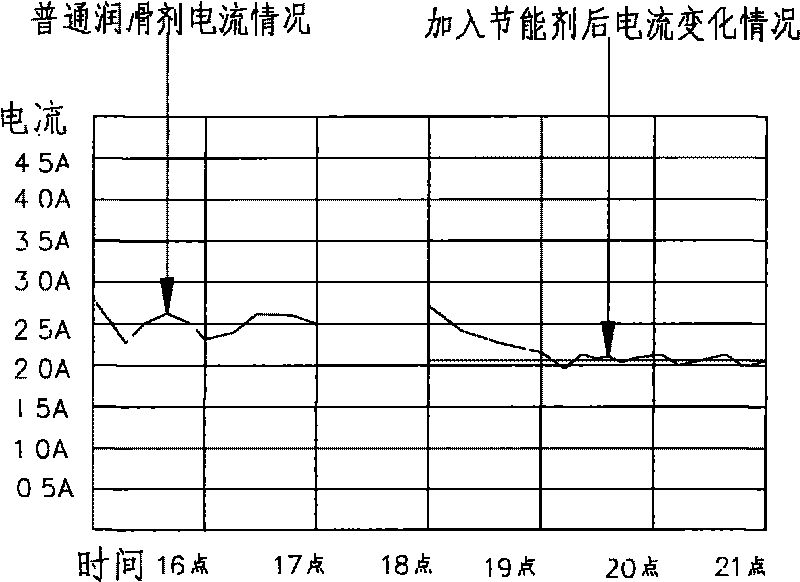

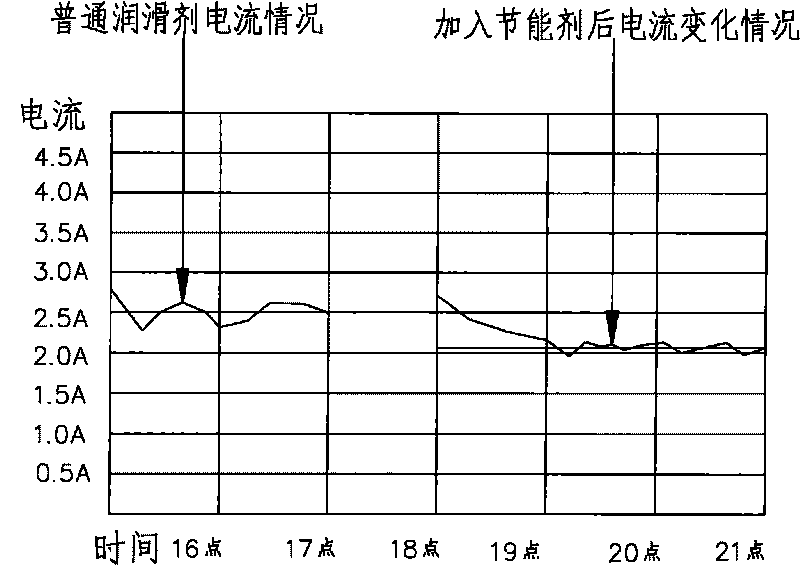

Image

Examples

Embodiment 1

[0026] Embodiment 1 A special energy-saving agent for textile machinery gears, containing 0.8kg of nano-copper powder (particle size 10-80nm, available in large quantities on the market), 950kg of Caltex Cepheus 68 base oil, 1kg of succinimide, and long-chain primary alkanes Zinc dithiophosphate (T203, produced by Nanjing Mingliang Oil Additive Co., Ltd.) 30kg, 10% polyvinyl alcohol 17-88 (polymerization degree 1700, alcoholysis degree 88%) solution 60kg.

[0027] The preparation method of the above-mentioned special energy-saving agent for spinning machine gears: get 0.8kg of nano-copper powder, 1kg of succinimide (50-100nm particle size) and 60kg of polyvinyl alcohol solution (10%, degree of polymerization 1700, degree of alcoholysis 88%) Add in a mixer, adjust the temperature to 40°C, stir and disperse at a speed of 5000r / min for 2 hours, then pump into an ultrasonic generator, and add 30kg of long-chain primary alkyl zinc dithiophosphate for forced dispersion. Then add the...

Embodiment 2

[0028] Example 2 A special energy-saving agent for textile machinery gears, containing 1.2kg of nano-copper powder, 900kg of Caltex Cepheus68 base oil, 1kg of succinate, and tetrapolyoxypropylene derivatives of amines (T1001, produced by Nanjing Lianrun Petrochemical Co., Ltd.) 35kg, chitosan derivative solution 50kg.

[0029]The preparation method of the above special energy-saving agent for textile machinery gears: take 1.2kg of nano-copper powder, 1.1kg of succinate and 50kg of chitosan derivative solution and add them to the mixer, adjust the temperature to 45°C, stir and disperse at a speed of 5800r / min for 2h , and then pumped into the ultrasonic generator, adding 35 kg of tetrapolyoxypropylene derivatives for forced dispersion. Then add the treated material to 900kg of Caltex Cepheus 68 base oil, heat up to 85°C to dissolve and make a solution, put it into a mixing tank, and start stirring for 1 to 2 hours.

[0030] The preparation method of the above-mentioned chitosa...

Embodiment 3

[0031] Embodiment 3 A special energy-saving agent for textile machinery gears, containing 0.1kg of nano-copper powder, 900kg of Caltex Cepheus68 base oil, 0.5kg of succinimide, 20kg of long-chain primary alkyl zinc dithiophosphate, and 10% polyvinyl alcohol 17-88 solution 20kg. The preparation method is basically the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size distribution | aaaaa | aaaaa |

| particle size distribution | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com