Keratin hairspray for hair and modeling products for hair

A technology of keratin and styling agent, which is applied in the direction of dressing preparations, cosmetics, hair care, etc., to achieve the effect of easy cleaning, moderate hair hardness, and long styling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1: Preparation of keratin

[0040] Wash the human hair (or wool) and pulverize it, and pretreat it with a sodium thioglycolate solution (sodium hydroxide to adjust the pH) with a pH value of 11 and a concentration of 0.5 mol / L at normal pressure and room temperature (20°C to 30°C) for 3 hours, then add urea to the solution, the amount of urea added is such that the concentration in the solution reaches 7mol / L, and then the reduction reaction is carried out at normal pressure and room temperature (20°C to 30°C) for 25 hours. After the reaction time expires, drop in Acetic acid adjusts the pH value of the reaction solution to 6-8, then feeds oxygen into the solution, and reacts at room temperature (20°C-30°C) for 0.5 hours. 80kD dialysis bag for dialysis, centrifugal separation to obtain the primary keratin solution with a molecular weight of 60,000 to 150,000 Daltons, salting out the primary keratin solution to obtain keratin solids, and vacuum (5-10mmHg colum...

Embodiment 2

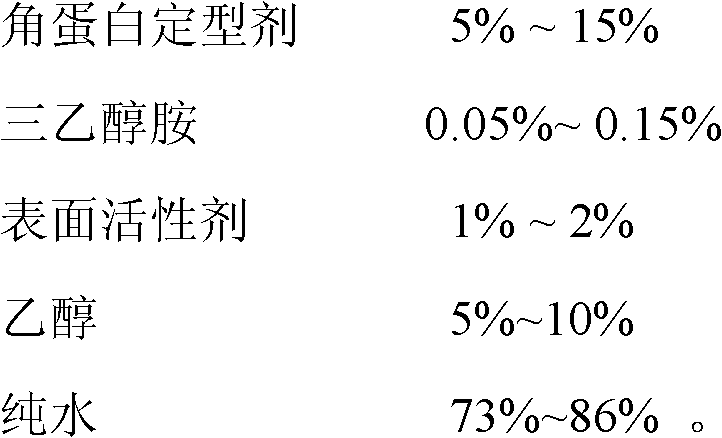

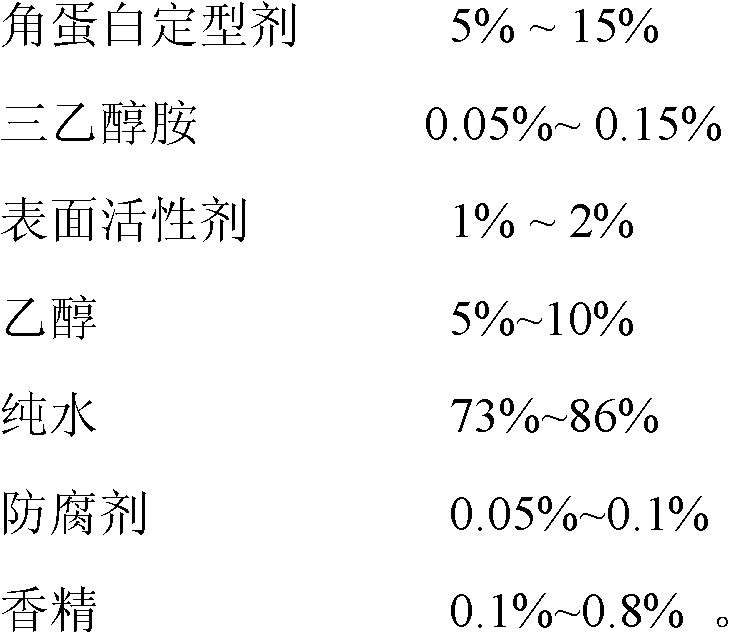

[0041] Embodiment 2: prepare jelly water

[0042] In this embodiment, the jelly water is prepared from keratin fixative for hair, triethanolamine, laureth-9, hydrogenated castor oil, ethanol, essence, methylchloroisothiazolinone and deionized water. The weight percent of component is as follows:

[0043]

[0044]

[0045] Preparation:

[0046] 1. Preparation of hair keratin fixative

[0047] The keratin prepared in Example 1 and the vinylpyrrolidone / vinyl acetate copolymer are metered at 1:4 (weight ratio), and the keratin is mixed with the vinylpyrrolidone / vinyl acetate copolymer at room temperature and normal pressure Uniform, that is, the formation of keratin fixative for hair;

[0048] 2. Preparation of jelly water

[0049] Add 824.5Kg of deionized water into the batching pot at room temperature and normal pressure, then add 80Kg of ethanol, 50Kg of hair keratin fixative, 10Kg of laureth-9, 10Kg of hydrogenated castor oil, 1Kg of triethanolamine, methyl 0.5Kg of...

Embodiment 3

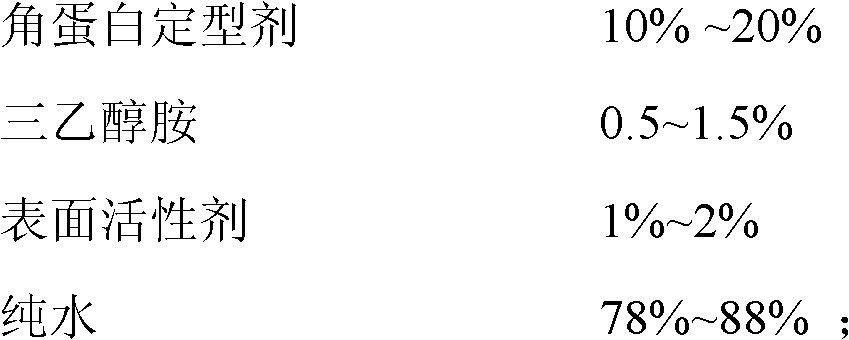

[0050] Embodiment 3: prepare jelly water

[0051] In this example, the jelly water is prepared from hair keratin fixative, triethanolamine, lauryl glucoside, hydrogenated castor oil, ethanol and distilled water, and the weight percentages of the above-mentioned components are as follows

[0052]

[0053] Preparation:

[0054] 1. Preparation of hair keratin fixative

[0055] The keratin prepared in Example 1 and the vinylpyrrolidone / vinyl acetate copolymer are measured at 1:1 (weight ratio), and the keratin is mixed with the vinylpyrrolidone / vinyl acetate copolymer at room temperature and normal pressure Uniform, that is, the formation of keratin fixative for hair;

[0056] 2. Preparation of jelly water

[0057] Add 859.5Kg of distilled water to the batching pot at room temperature and normal pressure, then add 50Kg of ethanol, 80Kg of hair keratin fixative, 5Kg of lauryl glucoside, 5Kg of hydrogenated castor oil, and 0.5Kg of triethanolamine and stir until uniform , filte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com