Biphase multi-shaft drive system

A technology of multi-axis transmission and intermediate shaft, applied in the direction of transmission chain, transmission device, belt/chain/gear, etc., can solve the problems of high rigid shock and vibration, vibration of chain transmission system, low fatigue life, etc., to reduce shock and Vibration, improved fatigue life, improved overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

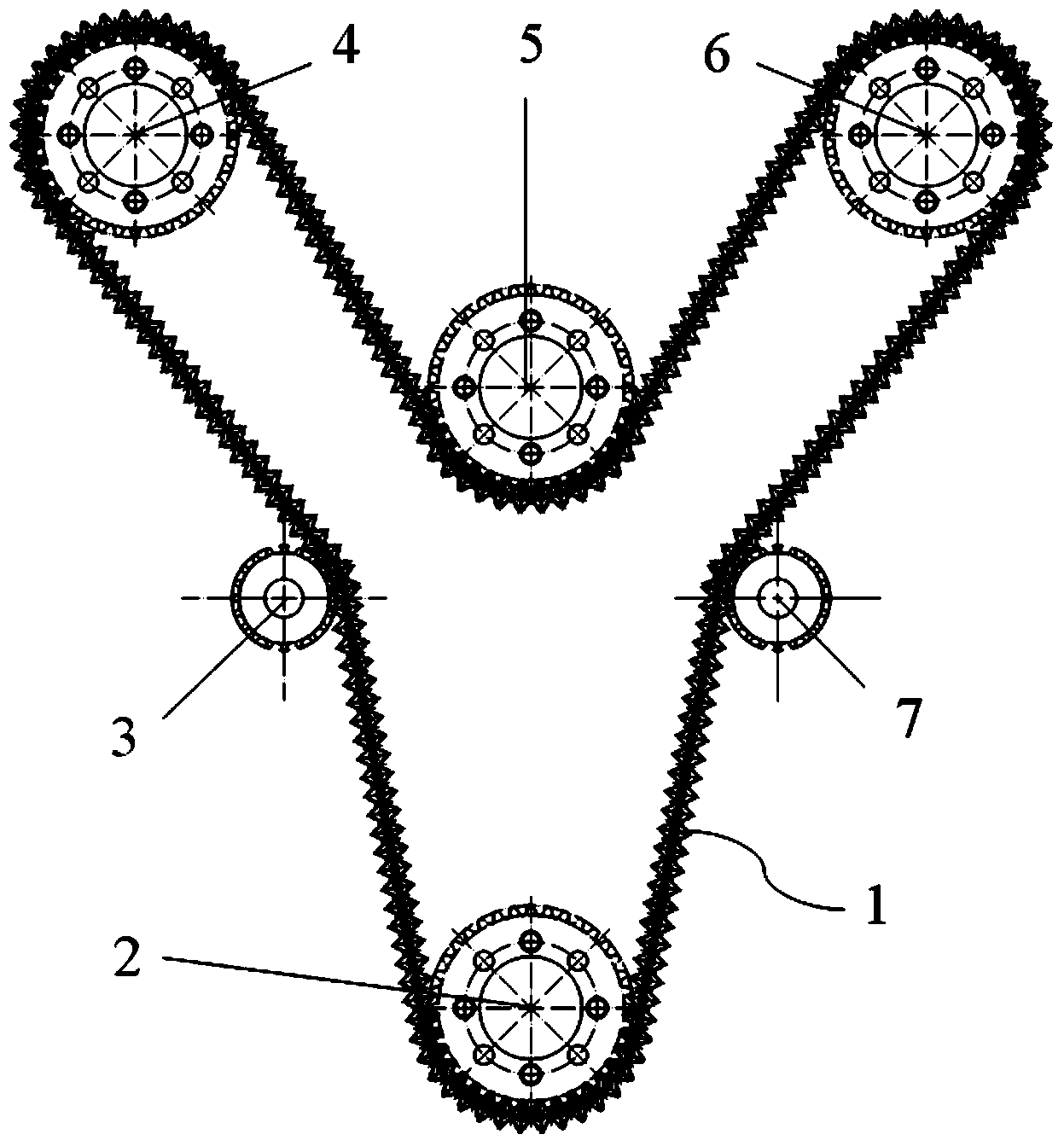

[0038] figure 1 It is the overall assembly drawing of the present invention, and it can be seen that a kind of dual-phase multi-axis transmission system of the present invention consists of Hy-Vo toothed chain 1, driving sprocket 2, tensioning sprocket A 3, driven sprocket B 4 and the middle Shaft sprocket 5, driven sprocket C 6 and tensioning sprocket D 7 form. The Hy-Vo toothed chain 1 meshes with the driving sprocket 2, the tensioning sprocket A 3, the driven sprocket B 4 and the intermediate shaft sprocket 5, the driven sprocket C 6 and the tensioning sprocket D 7 transmission;

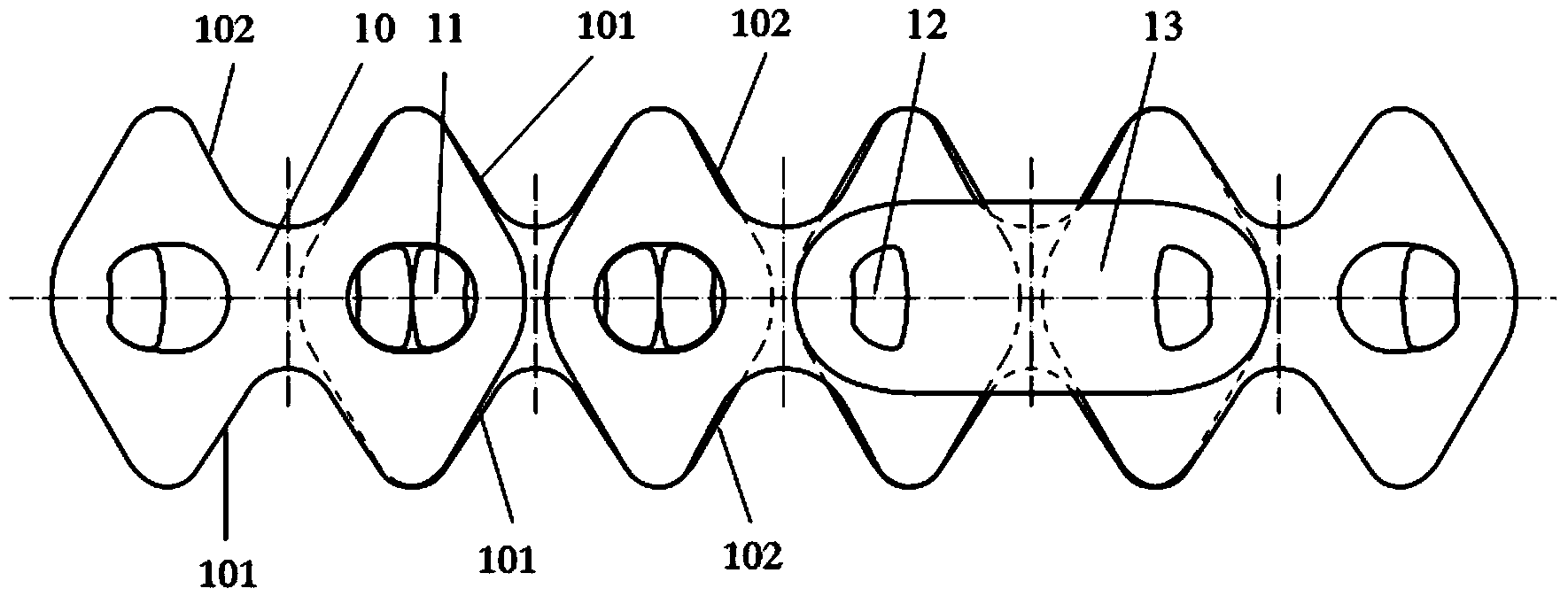

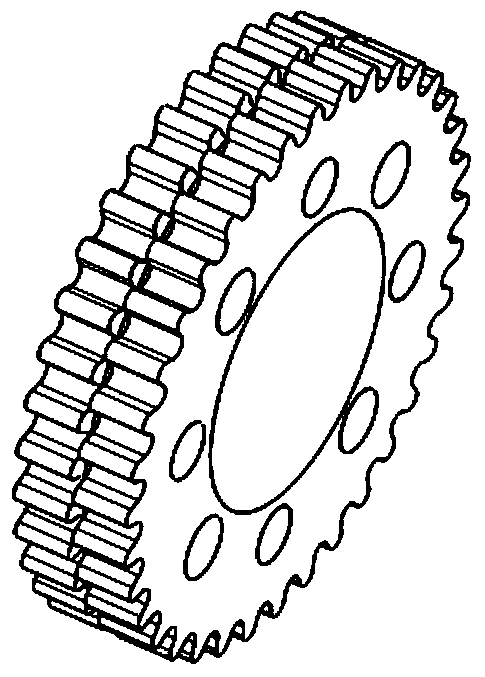

[0039] Referring to Figure 3(a)-Figure 3(c), it can be seen that the driving sprocket 2, tensioning sprocket A 3, driven sprocket B 4, intermediate shaft sprocket 5, driven sprocket C 6 and tension sprocket Tight sprocket wheels 7 are two-phase sprocket wheels, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com