Scroll drive type multi-axle drive mechanism

A multi-axis transmission and transmission technology, which is applied in transmission devices, gear transmission devices, mechanical equipment, etc., can solve the problems of large structure and difficult realization of adjustment mechanism.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific content and working process of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

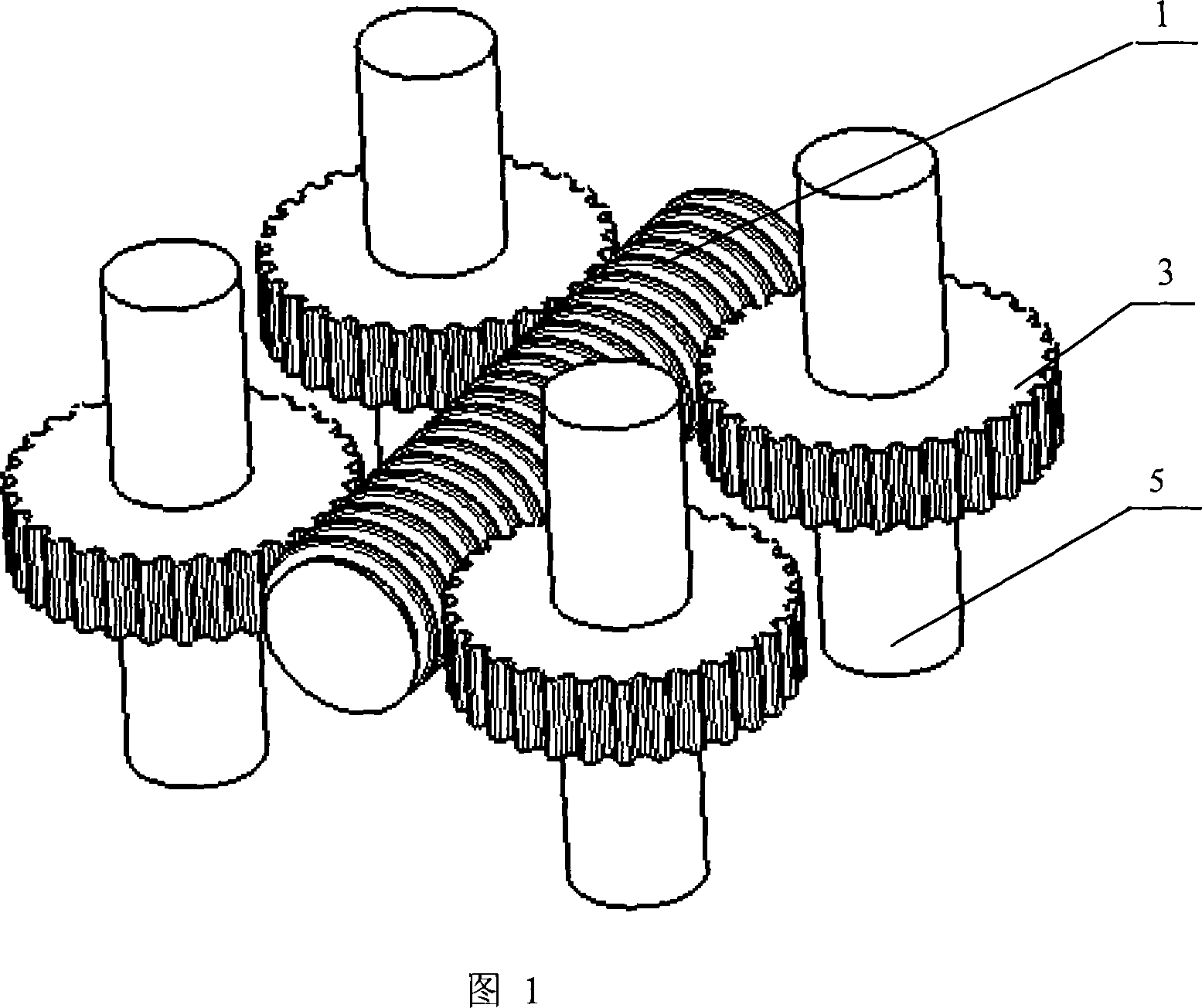

[0033] Refer to Figure 1: The worm drive type multi-axis transmission mechanism consists of one or more worms 1; one worm is arranged with a row of multiple worm gears or multiple rows of multiple worm gears, and one worm simultaneously meshes with multiple worm gears to achieve multi-axis transmission; changing the worm The direction of rotation can change the direction of rotation of the output shaft 5 . The worm 1 in the figure is an active input shaft, which can rotate in both positive and negative directions; it drives two rows (4) of worm gears. These worm gears are independent of each other and can rotate freely. The direction of rotation of the worm gear is controlled by the direction of rotation of the worm.

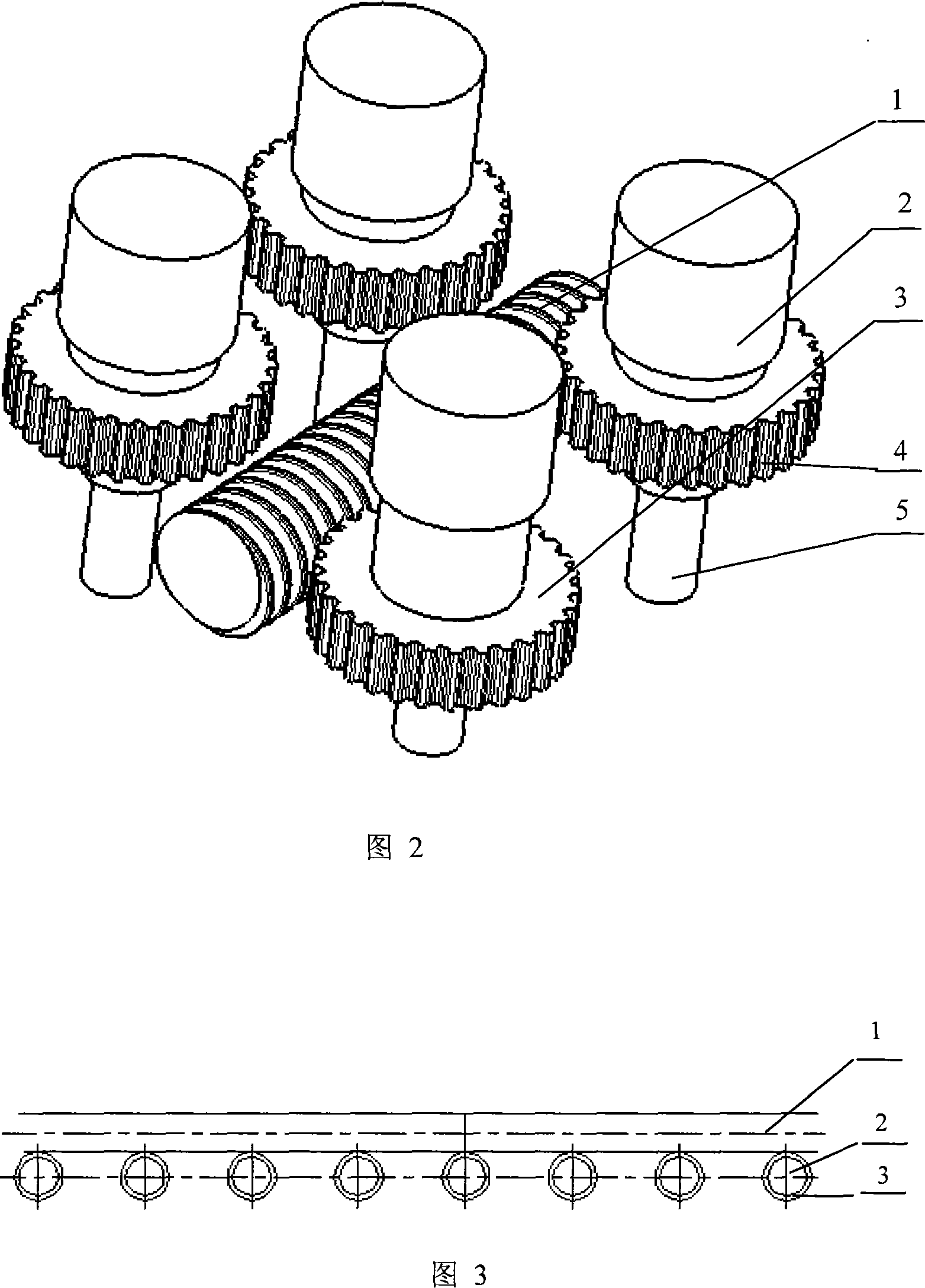

[0034] Refer to Fig. 2: The worm drive type multi-axis transmission mechanism is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com