Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54results about How to "Reduce jam frequency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flow alarming method and system of network equipment

InactiveCN103546319AReduce jam frequencyImprove failure response capabilitiesData switching networksEngineeringFalse alarm

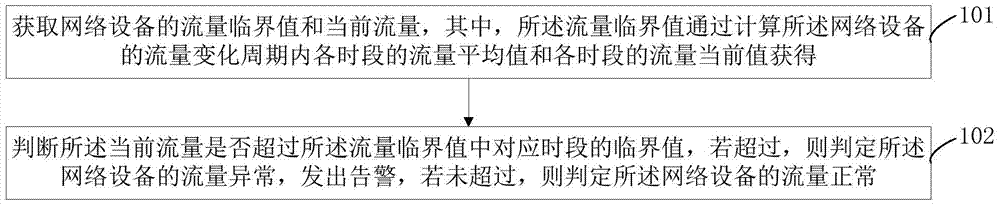

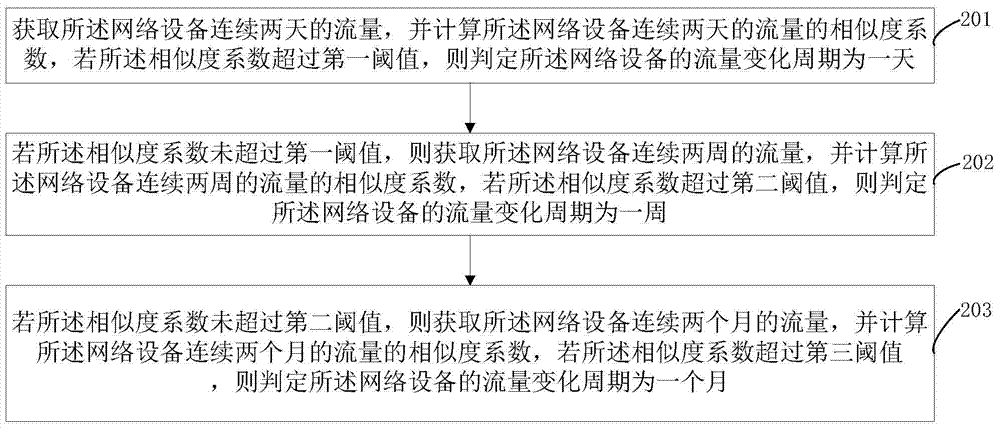

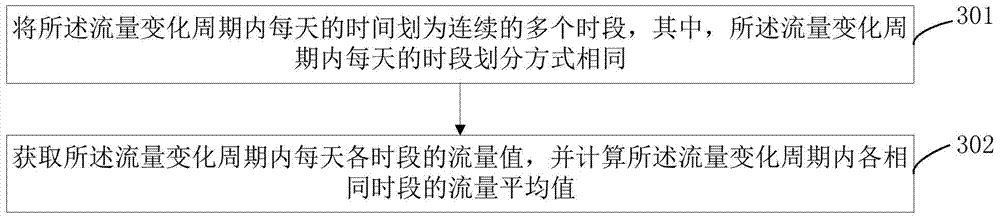

The invention discloses a flow alarming method and system of network equipment. The flow alarming method includes acquiring a flow critical value and a current flow of the network equipment; judging whether the current flow exceeds a critical value of the corresponding moment in the flow critical value or not, if yes, judging that the flow of the network equipment is abnormal and sending an alarm, and if not, judging the flow of the network equipment is normal, wherein the flow critical value is obtained by calculating average flow value of time frames within a flow varying period of the network equipment and the current flow value of the time frames. By the aid of the flow alarming method and system, whether the flow of the network equipment is normal or not is judged by comparing the current flow of the network equipment and the critical value calculated by the average flow value of the time frames within the flow varying period of the network equipment and the current flow value of the time frames, report missing rate and false alarm rate can be decreased, and effectiveness and sensitivity of flow analysis are improved.

Owner:CHINA SOUTHERN POWER GRID COMPANY +1

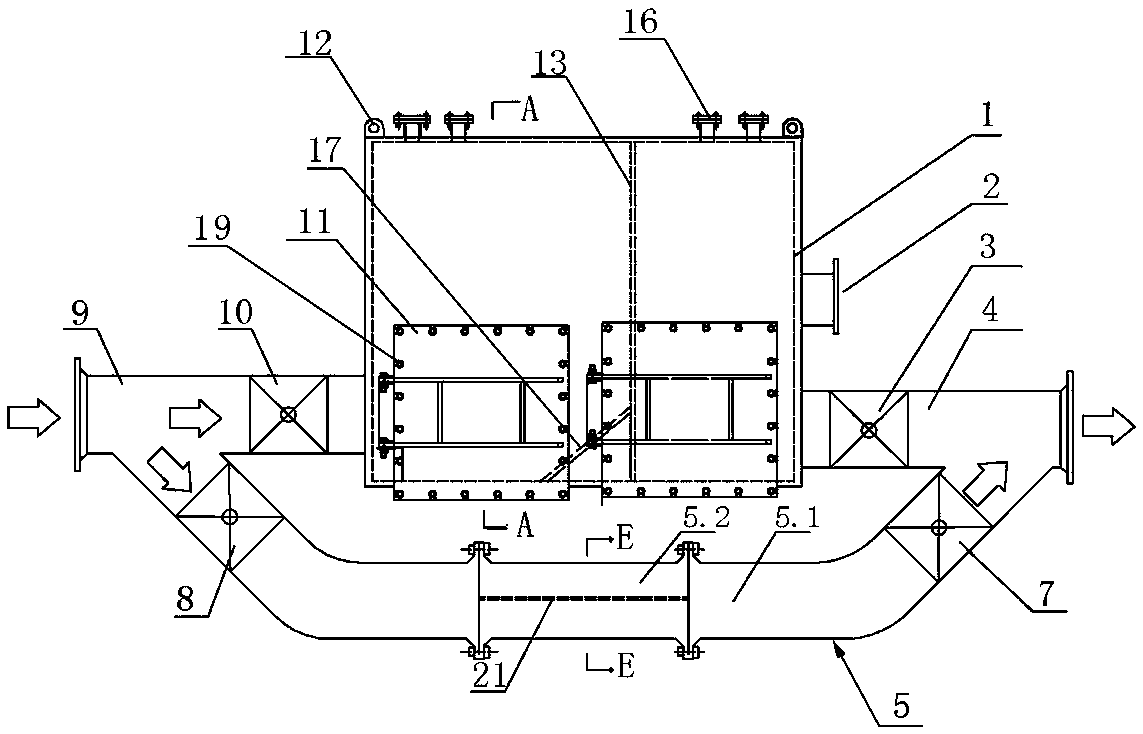

Filtering type plate heat exchanger

InactiveCN104567490AAvoid enteringReduce jam frequencyCorrosion preventionLaminated elementsPlate heat exchangerImpurity

The invention discloses a filtering type plate heat exchanger, including a movable pressing plate, a fixed pressing plate and a plurality of plates with corner pores, wherein the plurality of plates are arranged between the movable pressing plate and the fixed pressing plate; the movable pressing plate is provided with an installing hole A and an installing hole B, the installing hole A is aligned with a primary inlet, and the installing hole B is aligned with a secondary inlet; the filtering type plate heat exchanger also includes a filter screen A and a filter screen B, the filter screens A and B pass through the movable pressing plate, the plates and the fixed pressing plate respectively from the installing hole A and the installing hole B, and a blank flange A and a blank flange B are respectively arranged at the installing holes A and B. According to the filtering type plate heat exchanger, the filter screens are inserted from the sides of the movable pressing plate, thus being capable of preventing impurities in fluid from entering runners among the plates, and reducing the blocking efficiency of the plate heat exchanger; in addition, when the filter screens are increased in impurities and fluid resistance, the filter screens can be drawn out to clean, thus being low in labor intensity and high in efficiency.

Owner:上海艾克森股份有限公司 +1

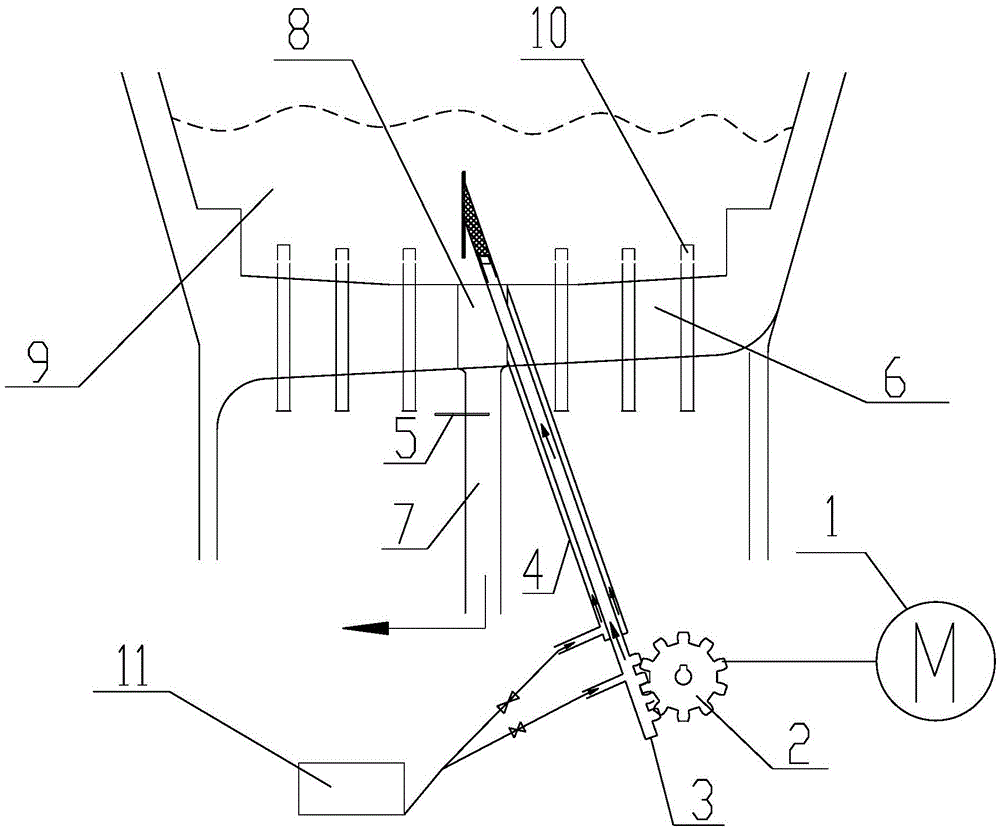

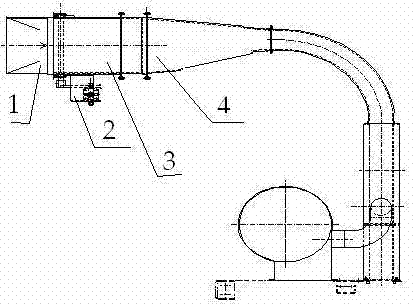

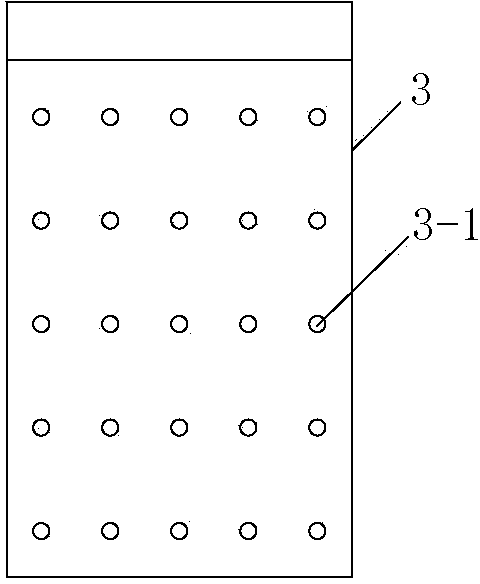

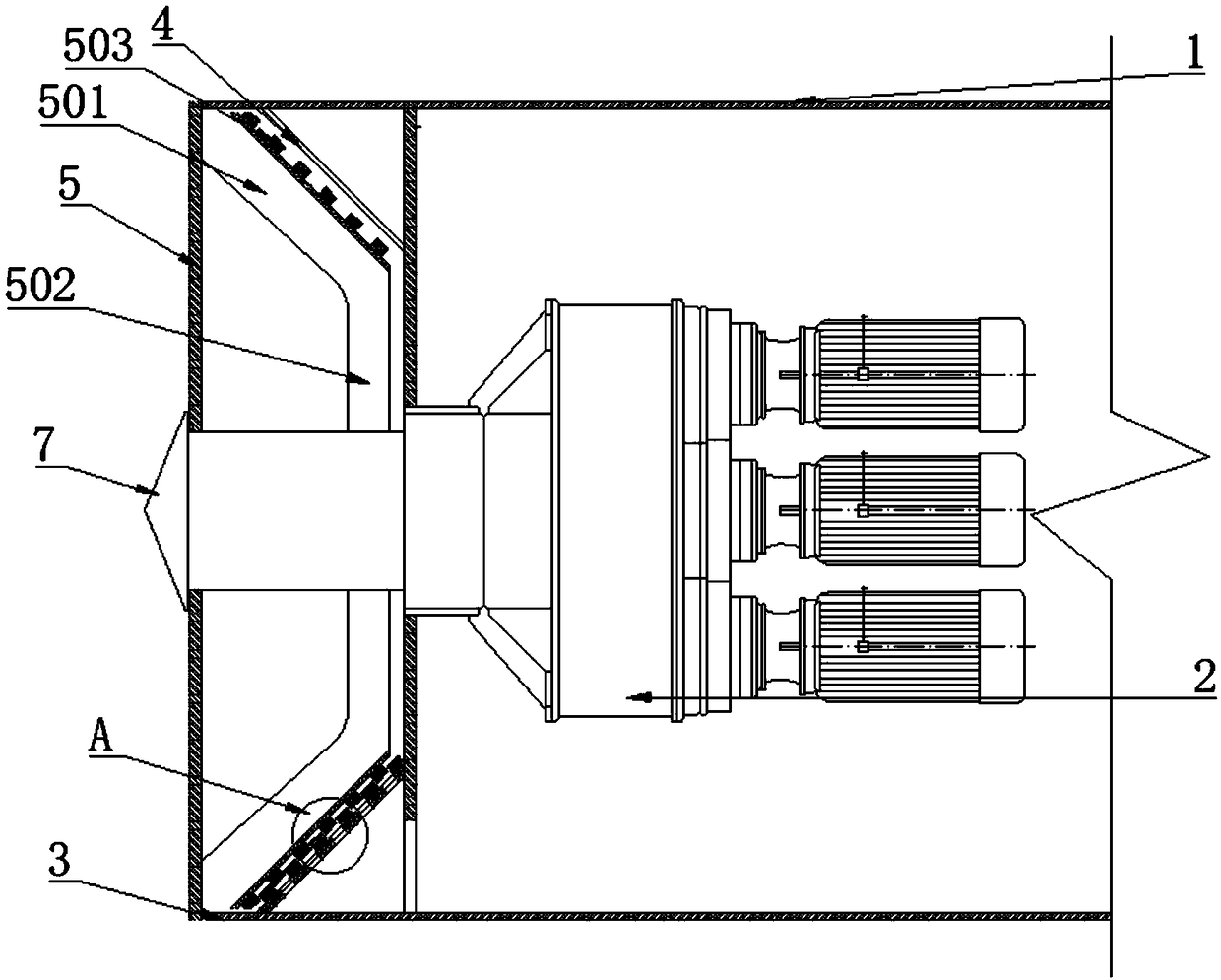

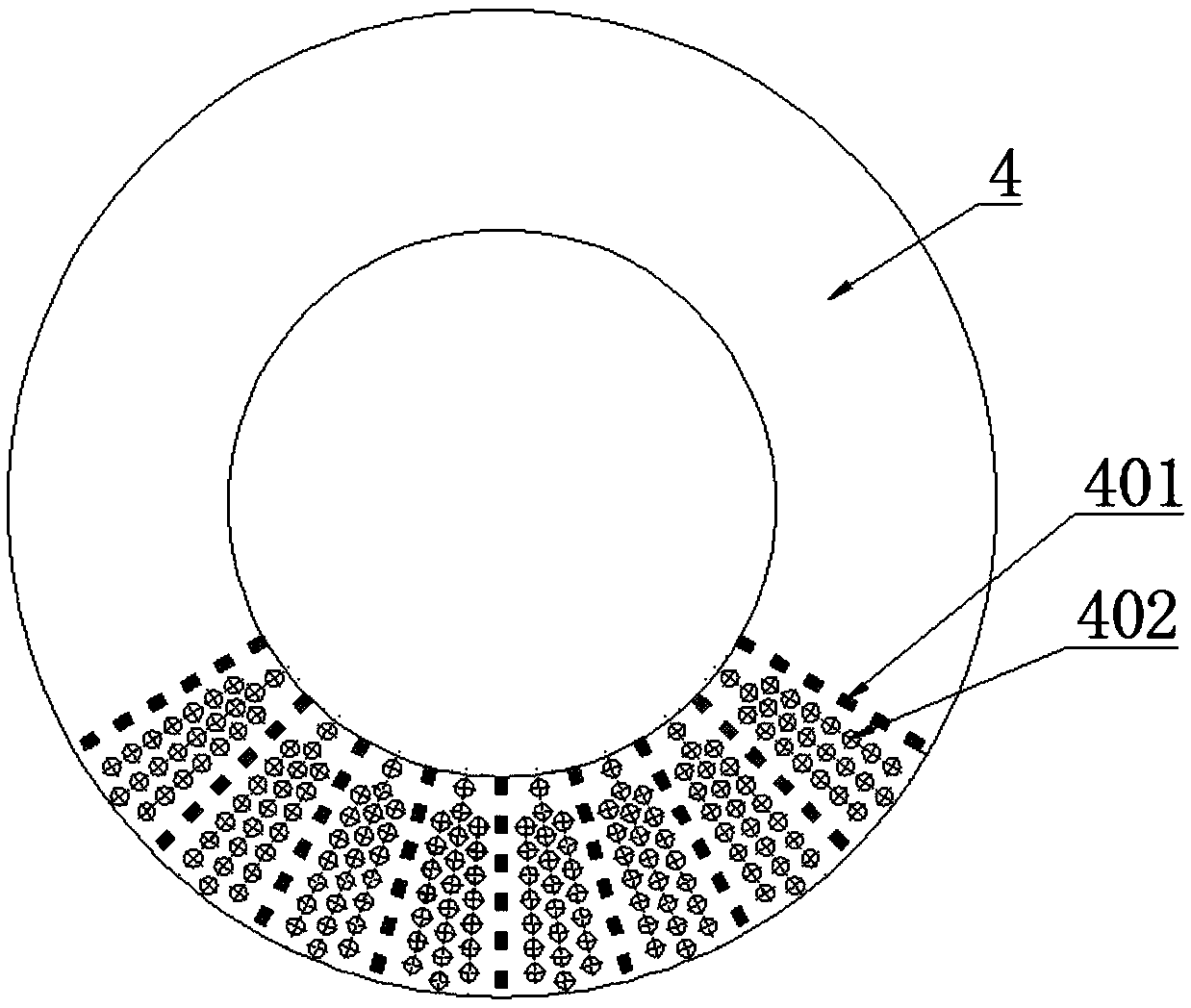

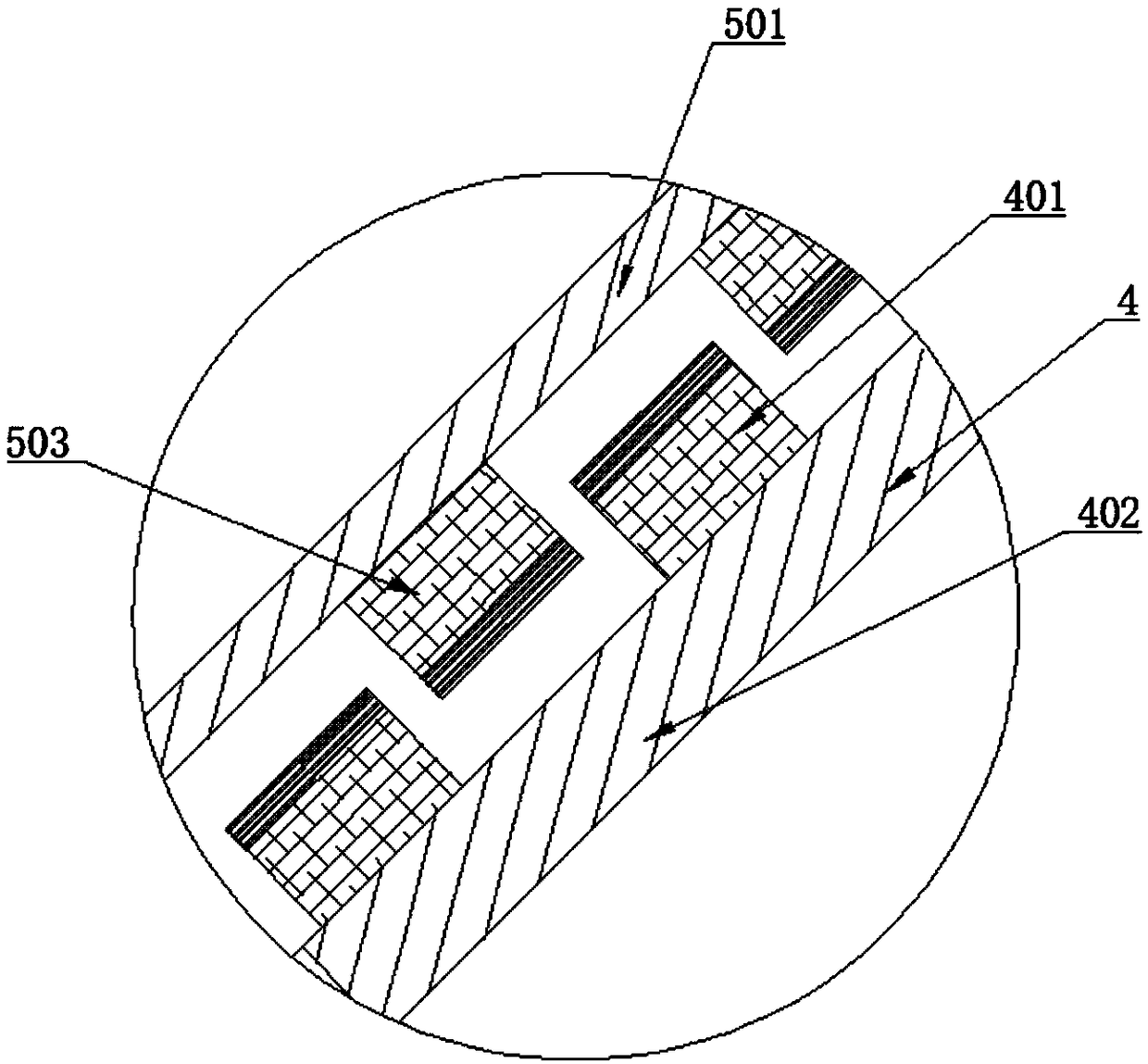

Automatic residue poking method and device for wind distribution plate of biomass circulating fluidized bed boiler

ActiveCN105485672AImprove fluidizationReduce accumulationFluidized bed combustionApparatus for fluidised bed combustionBiomassCirculating fluidized bed boiler

The invention discloses an automatic residue poking method and device for a wind distribution plate of a biomass circulating fluidized bed boiler. According to the technical scheme of the automatic residue poking method and device, an outer sleeve connected with a side wall opening of a residue discharging hole is arranged at the side wall opening of the residue discharging hole of the wind distribution plate and inclines relative to a residue discharging pipe, and a telescopic fluidization wind pipe with a residue poking head and fluidization wind outlets is arranged in an inner cavity of the outer sleeve. When the boiler operates normally, the residue poking head extends into a bed material above the residue discharging hole, and fluidization wind is injected to the periphery of the residue discharging hole through the fluidization wind outlets. When the residues need to be discharged from the boiler, the residue poking head draws back into the inner cavity of the outer sleeve so that the top of the residue poking head can be matched with the side wall opening of the residue discharging hole in a sealed manner. When the residues are blocked in the boiler in the discharging process, the residue poking head stretches out and draws back in the bed material above the residue discharging hole to finish physical stirring, large blocks of residues are broken, and meanwhile ash near the residue discharging hole can be continuously blown by injecting the fluidization wind, so that automatic residue poking is achieved. By the adoption of the automatic residue poking method and device, the defects brought by traditional manual residue poking are effectively overcome.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

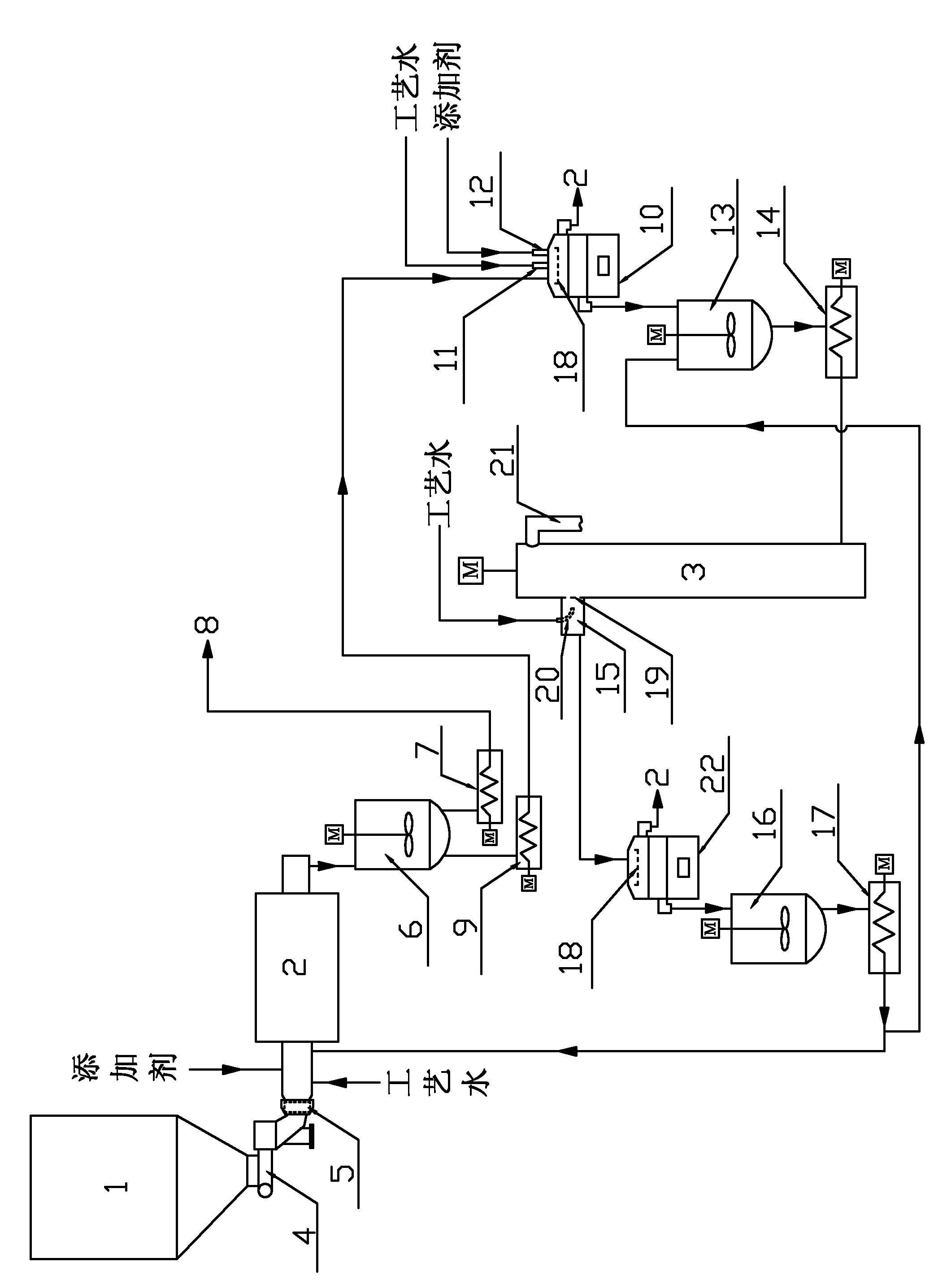

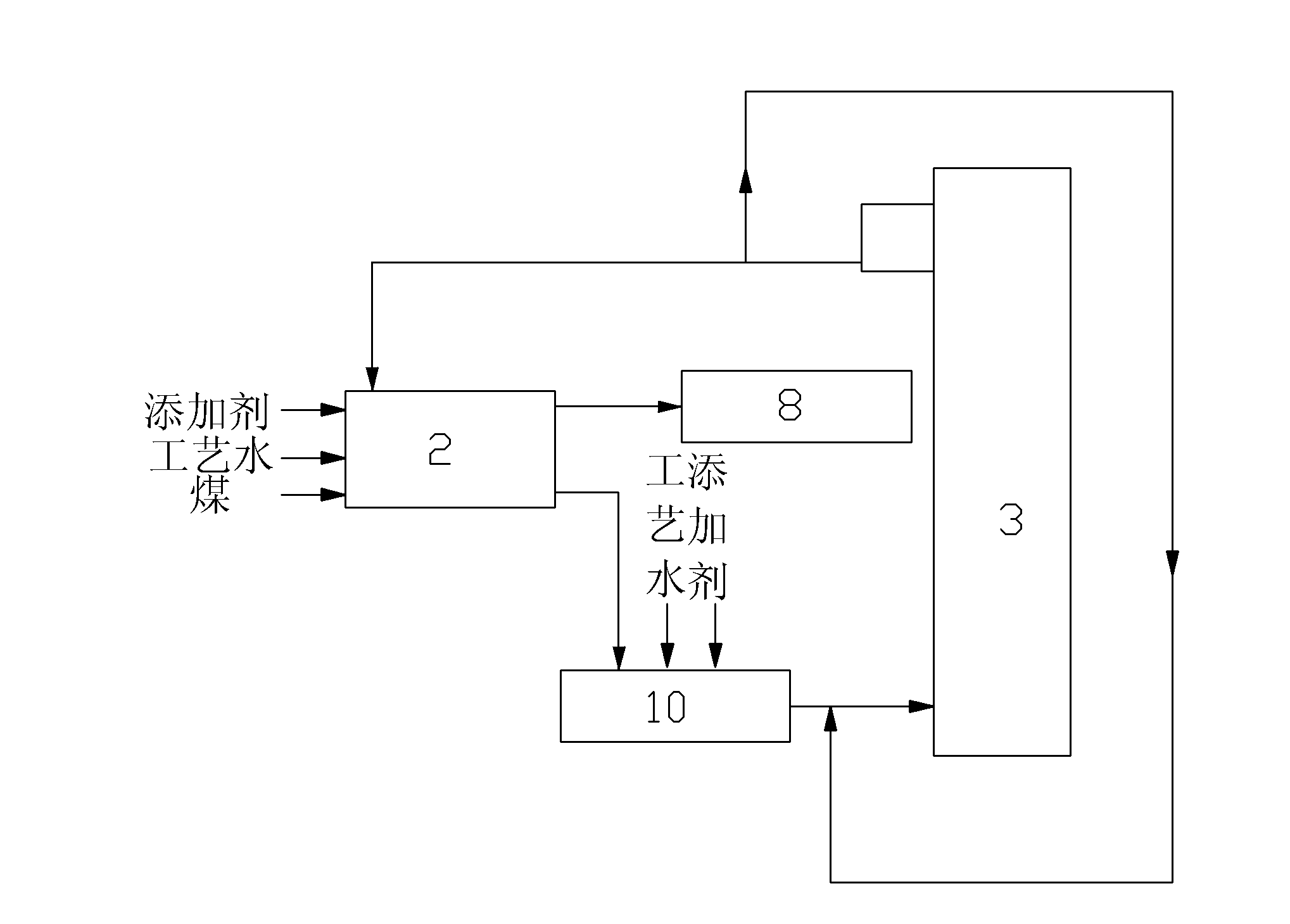

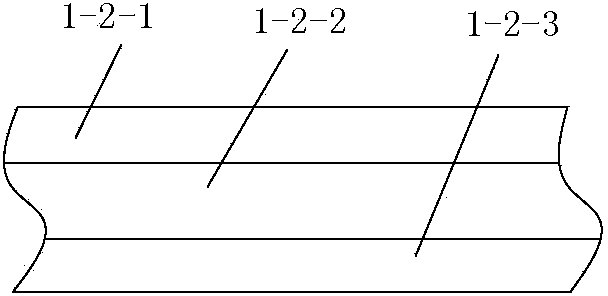

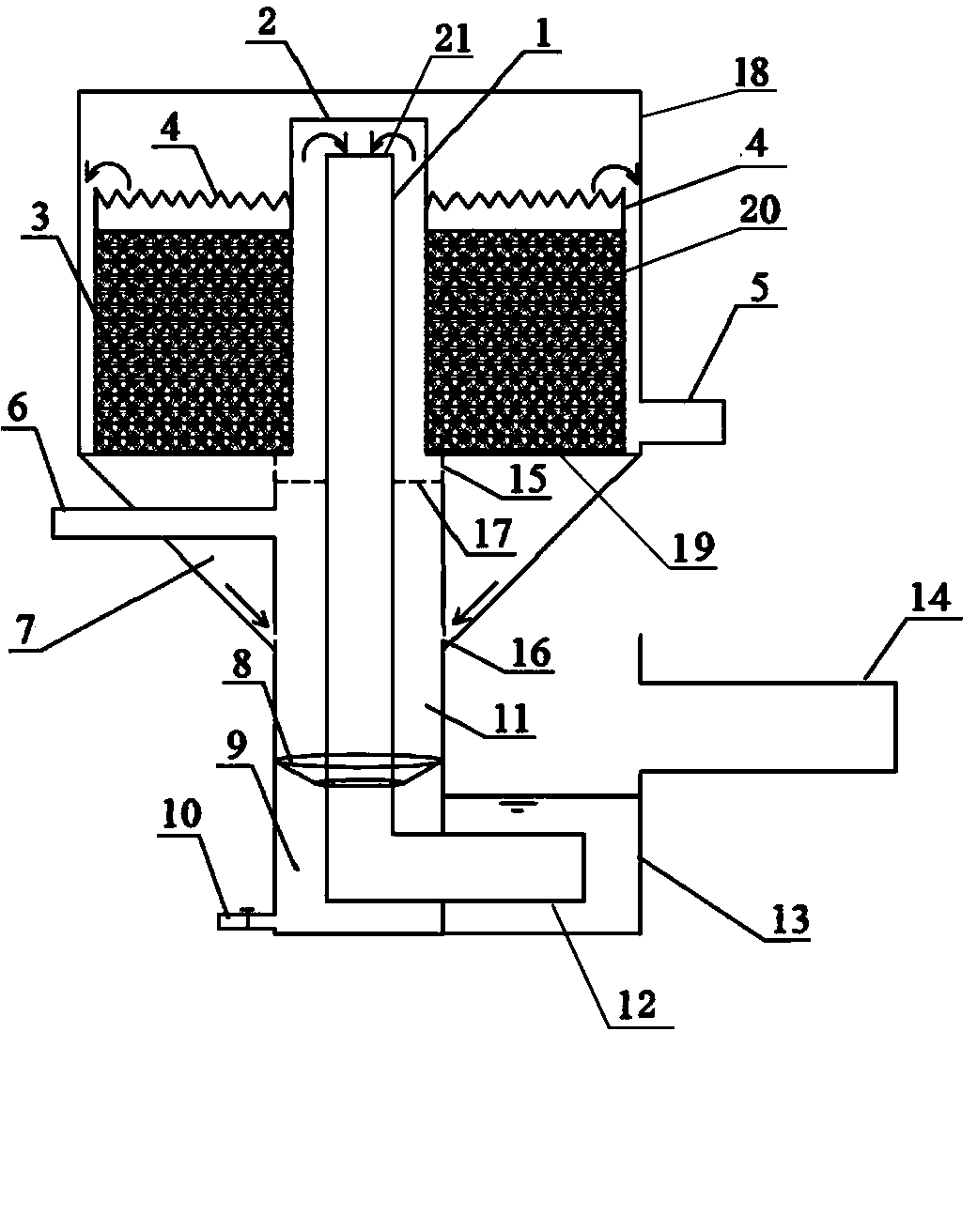

Gasified coal-water-slurry preparation process and corresponding production line

ActiveCN103184085ALarge opening areaImprove passing abilityLiquid carbonaceous fuelsGranular/pulverulent flues gasificationCoal waterDrive motor

The invention relates to a novel rotation-vibration sieve. When coal-water-slurry is processed by using an existing rotation-vibration sieve, the coal-water-slurry containing a large amount of coal particles directly scours a sieve mesh, and the sieve mesh should be replaced every 2-3 days, such that the machine is frequently shut down, and long-period stable operation is affected. Also, an upper sieve cylinder and a lower sieve cylinder are fastened by using bundle buckles. When the rotation-vibration sieve works, constant vibration is carried out, and buckle disengagement accident frequently happens. Therefore, the rotation-vibration sieve provided by the invention comprises a cylindrical pedestal and a sieve cylinder. A vibration generation device and a driving motor are arranged in the cylindrical pedestal. A crude material outlet and a fine material outlet are arranged outside a sieve cylinder. A sieve mesh and a fine material plate are arranged in the sieve cylinder. A sieve cover is arranged on the sieve cylinder. A feeding port is provided on the sieve cover. A buffering mixer is arranged in the sieve cylinder and is positioned above the sieve mesh. The buffering mixer faces a matching feeding pipe. The novel rotation-vibration sieve provided by the invention has the advantages of simple structure, convenient assembly and disassembly, long sieve mesh life, and long working period. The novel rotation-vibration sieve provided by the invention is suitable to be used for sieving various slurries and especially coal-water-slurry.

Owner:YANKUANG GRP CO LTD

Tunneling method of slurry shield passing through anchor cable zone in long distance

A tunneling method of a slurry shield passing through an anchor cable zone in a long distance comprises the following steps that 1, reinforcing is conducted on soil masses within the range of 5 m-6 mon the two sides of the central line of a to-be-excavated tunnel; 2, drilling and anchor distributing are conducted on the reinforcing areas; 3, a manual gate valve is mounted between a quarrying boxof a shield mechanism and a slurry discharging gate valve of a soil bin; 4, the quarrying box of the shield mechanism is transformed; 5, a slurry parameter used by the shield mechanism is set; and 6,a shield tunneling parameter is set, till excavation of a designed shield route is completed, and construction is ended. The tunneling method solves the technical problems that a slurry discharging pipe and the quarrying box are clamped deadly or blocked by an anchor cable, a cutter disc is wound, the aperture ratio of the cutter disc is decreased, and a cutter tool is damaged in the long distanceanchor cable zone passing through construction process of a traditional slurry shield.

Owner:CHINA CONSTR COMM ENG GRP UNITED

Anti-blocking device of sewage cyclone

ActiveCN110882570AReduce filter pressureReduce jam frequencyStationary filtering element filtersFiltrationWastewater

Belonging to the technical field of blockage prevention of sewage cyclones, the invention discloses an anti-blocking device of a sewage cyclone. The anti-blocking device comprises a box body with an open top, and an inlet and an outlet that are respectively disposed at the front end and rear end of the box body, the outlet is connected to the sewage cyclone, the box body is internally equipped with a filter screen unit comprising a plurality of filter screens, two sides of the box body are respectively equipped with an auxiliary filter unit communicated with the box body, water inlets of the auxiliary filter units are communicated with the front side of the filter screen unit, and water outlets of the auxiliary filter units are communicated with the rear side of the filter screen unit; impurity discharge ports of the auxiliary filter units are communicated with impurity treatment boxes; and a filter screen at the most front end in the filter screen unit has guide parts adjacent to thewater inlets of the auxiliary filter units at both ends close to the side wall of the box body. The anti-blocking device provided by the invention can perform auxiliary filtration while filtering wastewater in the box body through the filter screens, reduces the filtration pressure of the first filter screen, and effectively reduces the occurrence rate of blockage.

Owner:HAITIAN WATER GRP CO LTD

Cotton feeding box cotton distributing system

InactiveCN104264293AReduce cloggingReduce jam frequencyFibre feedersAgricultural engineeringMechanical engineering

The invention relates to a cotton feeding box cotton distributing system which is provided with a swing cotton distributing mechanism and a cotton delivery channel. An air cylinder and a connecting rod are arranged in the swing cotton distributing mechanism, a steel plate capable of swinging is arranged on the cotton delivery channel, a piston of the air cylinder is connected with the connecting rod, the connecting rod is connected with the steel plate through a fixing mechanism, and an adjustable device is arranged on the connecting rod. The cotton feeding box cotton distributing system improves automation degree and a control process, decreases pipe blockage frequencies, reduces the labor intensity of workers and improves production efficiency and product quality. Practical application proves that the system is reliable in operation and simple and convenient to operate.

Owner:杨配媛

Horizontal subsurface wetland system for intensifying denitrification of micro-polluted water in winter

ActiveCN104326574AReasonable structural designImprove denitrification effectWater treatment compoundsBiological treatment apparatusWater levelWetland

The invention relates to a horizontal subsurface wetland system for intensifying denitrification of micro-polluted water in winter, which effectively solves the problem that the denitrification effect of the wetland in winter is affected by low BOD5 / NO<3->, dissolved oxygen, substrate clogging and the like. The method comprises the following steps: forming a water distributing room between a water distributing plate which is arranged on the inner face at the water inlet end of a substrate bed body and an inner face at the water inlet end; forming a water receiving room between a water receiving plate which is arranged on the inner face at the water outlet end and the inner face at the water outlet end; arranging a plurality of sampling tubes at the front and middle sections in the substrate bed body between the water distributing plate and the water receiving plate; forming ventilating holes in each sampling tube; arranging a corncob layer at the rear section in the substrate bed body; forming limber holes in the water distributing plate and the water receiving plate, wherein the substrate bed body between the water distributing plate and the water receiving plate is internally filled with a gravel layer, a zeolite layer and a gravel scrap iron layer from top to bottom; installing a water inlet pipe on the end face at the water inlet end of the substrate bed body; installing a water outlet pipe used for adjusting the water level on the end face at the water outlet end; and covering the surface of the wetland system with a thin film. The system provided by the invention is simple to maintain, low in substrate clogging frequency and low in operating cost, and the denitrification percent is not less than 40%.

Owner:ZHENGZHOU UNIV

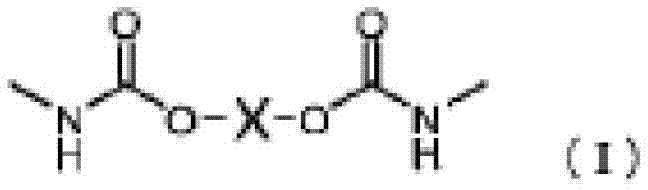

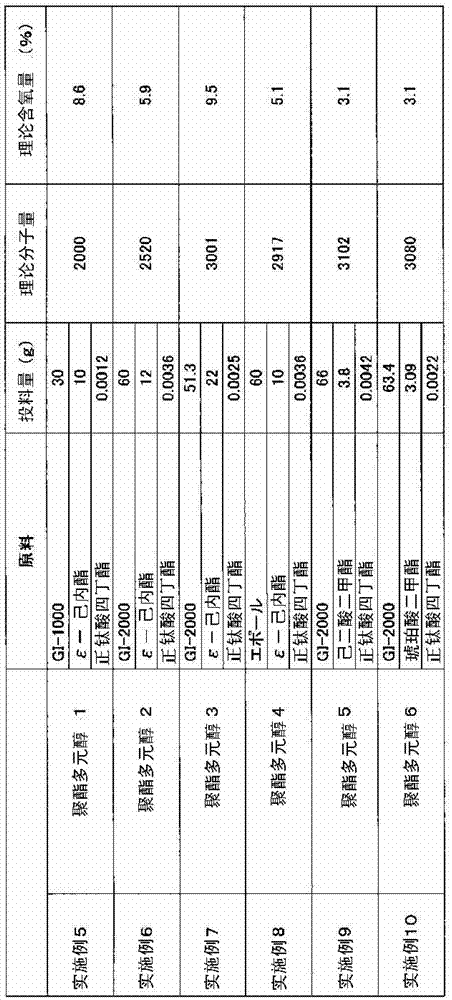

Process for production of polyurethane and uses of polyurethane produced thereby

ActiveCN103172816AReduce adhesionGood peeling effectMonocomponent polyurethanes artificial filamentPolyolSolvent

Owner:MITSUBISHI RAYON CO LTD

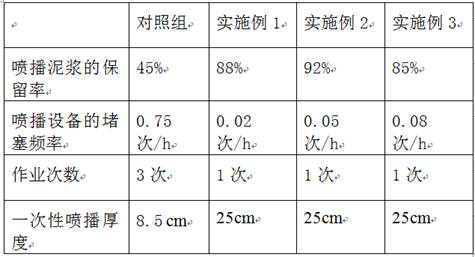

Fiber soil mixed spray-seeding method

ActiveCN109804861AStrong adhesionImprove adhesionHops/wine cultivationGrowth substratesFiberHeat treated

The invention provides a fiber soil mixed spray-seeding method. According to the fiber soil mixed spray-seeding method, an adopted spray-seeding matrix comprises heat-treated wood fibers. The heat-treated wood fibers are 1.5-2.5 cm in length and 0.05-0.15 mm in diameter. According to the heat-treated wood fibers, the content of the fibers with the lengths of 2 cm is larger than or equal to 50%. Onthe basis of not using the means such as cement, concrete and wire meshes which destroy the soil structure, the adhesive force of a matrix layer on a slope is strong, and the thickness of the matrixsprayed by one time is increased by 2 to 3 times compared with that of traditional spray-seeding.

Owner:JOFO GREEN CO LTD

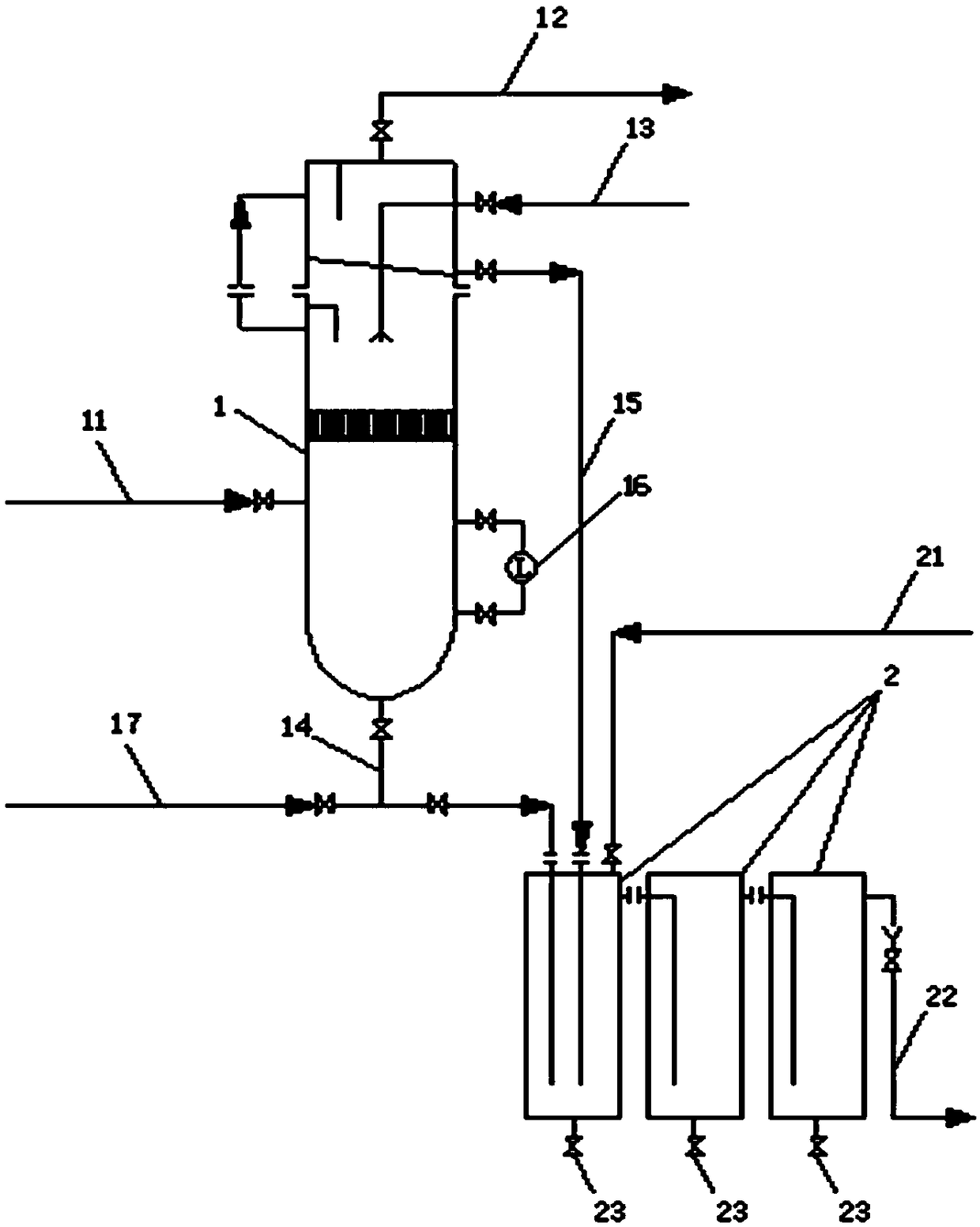

Fluorine absorption system used for wet-process phosphoric acid

ActiveCN109647137AReduce jam frequencyNo increase in total hydrationGas treatmentDispersed particle separationPhosphoric acidHexafluorosilicic acid

The invention provides a fluorine absorption system used for wet-process phosphoric acid. The system comprises a Venturi scrubbing device, a primary washing device, a pipe washing device, a secondarywashing device and a tertiary washing device which are arranged in sequence. According to the fluorine absorption system used for the wet-process phosphoric acid, waste gas containing fluorine passesthrough the Venturi scrubbing device, the primary washing device, the pipe washing device, the secondary washing device and the tertiary washing device in sequence for multi-stage washing, the washingdevices are provided with circulating tanks respectively, circulating fluid in the Venturi circulating tank and the primary washing tower circulating tank is continuously pumped out to enter a firstplate-and-frame filter press and a second plate-and-frame filter press, silica gel precipitation in the fluorine absorption system is removed, and the blocking frequency is reduced. The recycled watersupplement path is changed, the temperature of exhaust and the concentration of the circulating fluid are reduced, and therefore, the fluosilicic acid absorbing efficiency is improved.

Owner:襄阳泽东化工集团股份有限公司

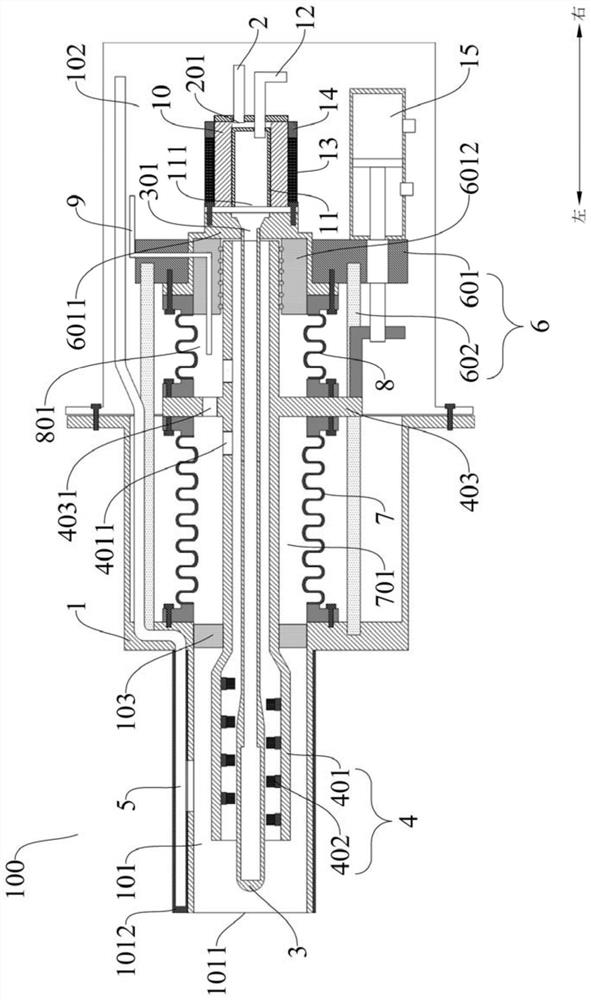

Liquid-state lag tapping device of slack coal slag gasifier

InactiveCN103215086AAvoid damageReduce high temperature thermal shockCombustible gas productionThermal impactLiquid state

The invention relates to a liquid-state lag tapping device of a slack coal slag gasifier. The liquid-state lag tapping device comprises a main body, a cooling agent flowing pipeline and a slag tapping channel, wherein the cooling agent flowing pipeline is buried in the main body; the slag tapping channel penetrates through the main body, extends to the bottom end of the main body from the top end of the main body, and is symmetrically arranged around the longitudinal axis of the main body; and through the slag tapping channel, the upside of the liquid-state slag tapping device is communicated with a coal gasification pressure container and the downside of the liquid-state slag tapping device is communicated with a chilling chamber; the main body comprises a main body upper part and a main body lower part, the slag tapping channel limited by the inner surface of the main body upper part is downward converged along with the longitudinal axis of the main body; and the slag tap of the liquid-state slag tapping device is limited by the inner surface of the main body lower part. The liquid-state lag tapping device for the slack coal slag gasifier can avoid or withstand the invasion and corrosion of molten slag and ferrum as well as thermal impact influence, and is long in service life and convenient to disassemble and maintain.

Owner:SHANGHAI ZEMAG MINDAC MACHINERY EQUIP

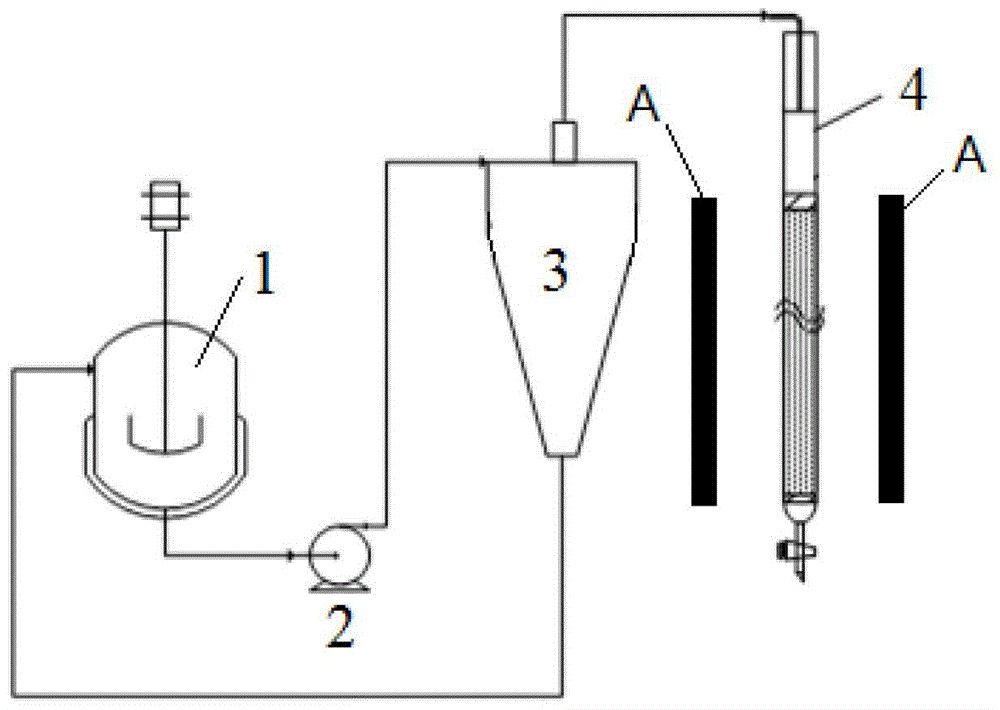

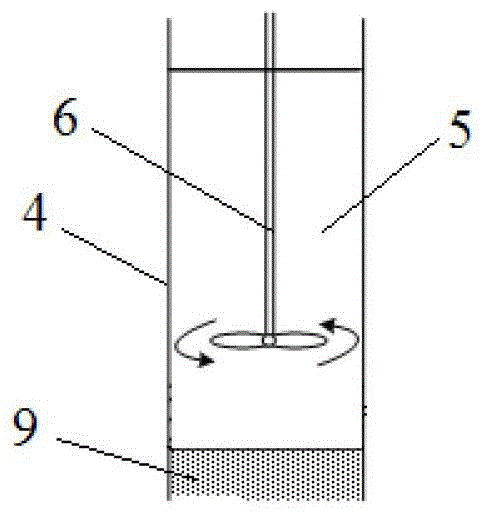

Self-cleaning circulating oil tank

InactiveCN102734624AGuaranteed qualityReduce jam frequencyLubrication containersThree levelFuel tank

The invention discloses a self-cleaning circulating oil tank which comprises a cylindrical tank body, the cylindrical tank body is provided with an oil inlet (close to the upper end part of the tank body) and an oil outlet (close to the lower end part of the tank body), the oil inlet direction of the oil inlet extends along the tangential direction of the inner wall of the cylindrical tank body, and the end face of the lower part of the cylindrical tank body is of a reversed conical structure. According to the invention, the oil inlet of the oil tank extends along the tangential direction, and as the bottom of the oil tank is of a reversed conical structure, fed lubricating oil is in a rotational flow state; because the density of impurities is higher than the density of the lubricating oil, the impurities can be fed into the conical bottom and accumulated in the process of rotational flow, therefore, the lubricating oil in the space of the upper part of the conical bottom of the oil tank contains less impurities, thereby achieving the purpose of automatically removing impurities in the lubricating oil, and ensuring the quality of the lubricating oil, so that the normal operation of each friction pair of power equipment can be ensured; meanwhile, the jamming frequency of three-level filtering system such as a filtering device and a filter screen and the like can be reduced, and the problems that the pressure of an outlet of a circulating pump is excess and the oil supply of the power equipment is not enough can be avoided, thereby avoiding accident of the equipment, and reducing the maintenance cost.

Owner:TIANJIN QIXING PRECISION MACHINERY

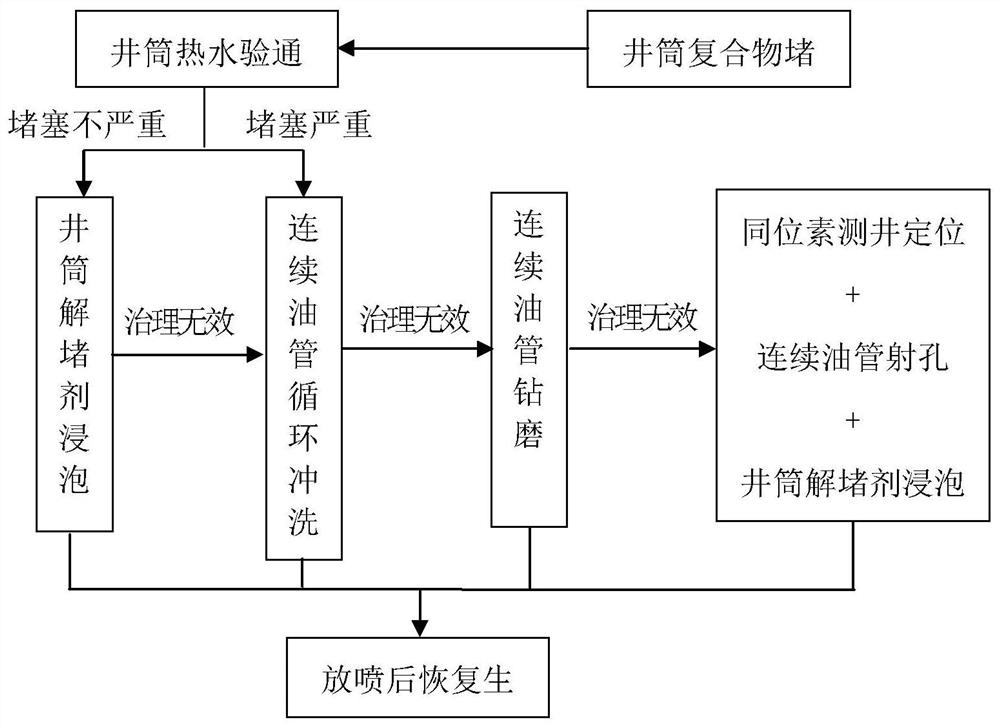

Gas well shaft compound blockage treatment method

ActiveCN112627773ACongestion managementReduce jam frequencyCleaning apparatusCoiled tubingEngineering

The invention discloses a gas well shaft compound blockage treatment method. The method comprises the following specific steps that 1, shaft blockage is verified through hot water, the hot water is pumped into a shaft from a well mouth, the displacement in the pumping process is smaller than or equal to 1m< 3 > / min, the pump pressure change condition is observed in the pumping process, and the shaft blockage throttling severity degree is judged; 2, if the pump pressure change condition is that the pump pressure is gradually decreased in the hot water pumping process in the step 1, a blockage removal agent injection soaking process is adopted for blockage removal treatment; and 3, if the pump pressure change condition is that the pump pressure is kept stable or even increased in the hot water pumping process in the step 1, a coiled tubing is adopted for cyclic flushing firstly, and then the blockage removal agent injection soaking process is adopted for blockage removal treatment.

Owner:CHINA PETROLEUM & CHEM CORP +1

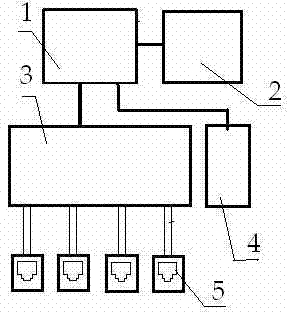

Control system for continuous cotton feeding

InactiveCN104267624AReduce cloggingReduce jam frequencyProgramme control in sequence/logic controllersControl systemControl engineering

The invention relates to a control system for continuous cotton feeding. The control system comprises a central controller, a carding machine interface device, an information interface device, a fan and sensor groups. The central controller is connected with the carding machine interface device and the information interface device through signal lines, the central controller is connected with the fan through a control line, and the information interface device is connected with the sensor groups through signal lines. The automation degree of the system is increased, the control technology is improved, the frequency of pipeline blocking is decreased, the labor intensity of workers is relieved, production efficiency and product quality are improved, and the practical application proves that the system is reliable in operation and easy and convenient to operate.

Owner:杨配媛

Granulator comprising double tubular reactors and application thereof in diammonium phosphate production

ActiveCN104860283AAvoid wear and tearExtended service lifePhosphatesAlkali orthophosphate fertiliserNuclear engineeringDiammonium phosphate

The invention provides a granulator comprising double tubular reactors. A main beam is arranged on the upper part of the granulator. A No.1 tubular reactor and a No.2 tubular reactor are respectively arranged on the two opposite sides of the granulator. According to the No.1 tubular reactor, an ammonia distributor is inserted into a granulator feed layer through a plow-type steel part welded on the main beam. A liquid ammonia delivery pipe is arranged on the end of the No.1 tubular reactor positioned on the outer side of the granulator. According to the No.2 tubular reactor, an ammonia distributor is inserted into a granulator feed layer through a plow-type steel part welded on the main beam. A liquid ammonia delivery pipe is arranged on the end of the No.2 tubular reactor positioned on the outer side of the granulator. A washing liquid circulation tank is respectively connected to the upper parts of the No.1 tubular reactor and the No.2 tubular reactor through tubular reactor feeding pumps. The working pressure of the equipment is lower than that of single tubular reactors. A blocking frequency is substantially reduced. Single tubular reactor purging frequency is reduced to once per shift. A cylinder scale phenomenon close to a spray point is inhibited.

Owner:HUBEI LIUGUO CHEM IND

Washing device of oxidation air pipe in desulphurization system

InactiveCN103007715AReduce jam frequencyRinse in timeDispersed particle separationWater flowDouche device

The invention discloses a washing device of an oxidation air pipe in a desulphurization system. The washing device comprises the oxidation air pipe, a washing pipe communicated with the oxidation air pipe and a water pump mounted at the water inlet end of the washing pipe. In the washing device provided by the invention, when the pipe orifice of the oxidation air pipe needs to be washed, the water pump at the end part of the washing pipe is directly opened, and pressure water flows into the oxidation air pipe along the washing pipe and passes through the pipe orifice of the oxidation air pipe finally, and when pressure water passes through the pipe orifice of the oxidation air pipe, the water pump applies certain impact force to the pressure water, so that the pressure water can impact the dirt at the pipe orifice of the oxidation air pipe; and the water pump is opened periodically, so that the pressure water can wash the dirt at the pipe orifice of the oxidation air pipe in time, as a result, the washing device can effectively reduce the frequency of blockage at the pipe orifice of the oxidation air pipe.

Owner:华润电力登封有限公司

Coal mill outlet anti-blocking sampling device and installation method

PendingCN114354284AImprove dust removal effectGuaranteed uptimeTransportation and packagingWithdrawing sample devicesFiltrationDust control

The invention provides a coal mill outlet anti-blocking sampling device and an installation method.The sampling device comprises a machine shell, a sampling pipe, a first-stage filter element, a dust sweeping assembly and a first air blowing pipe, the machine shell comprises a sampling part and a sealing part which are arranged in a separated mode, a sample inlet is formed in the first end of the sampling part, and a ceramic shell is installed on the peripheral wall of the sampling part; a sample gas inlet is formed in the first end of the sampling pipe, the first end of the sampling pipe is arranged in the sealing part, the primary filter element is arranged in the machine shell, the first end of the primary filter element is located in the sampling part and is adjacent to the sample inlet, the second end of the primary filter element is located in the sealing part, and the dust sweeping assembly is arranged in the machine shell and is used for sweeping the peripheral wall of the primary filter element; the first air blowing pipe is communicated with the inner cavity of the sampling part and is used for blowing dust in the sampling part out of the shell through the sample inlet. The embodiment of the invention is provided. The sampling device disclosed by the invention has the characteristics of multi-stage filtration, high-efficiency dust removal, difficulty in blockage and long service life.

Owner:TSINGHUA UNIV

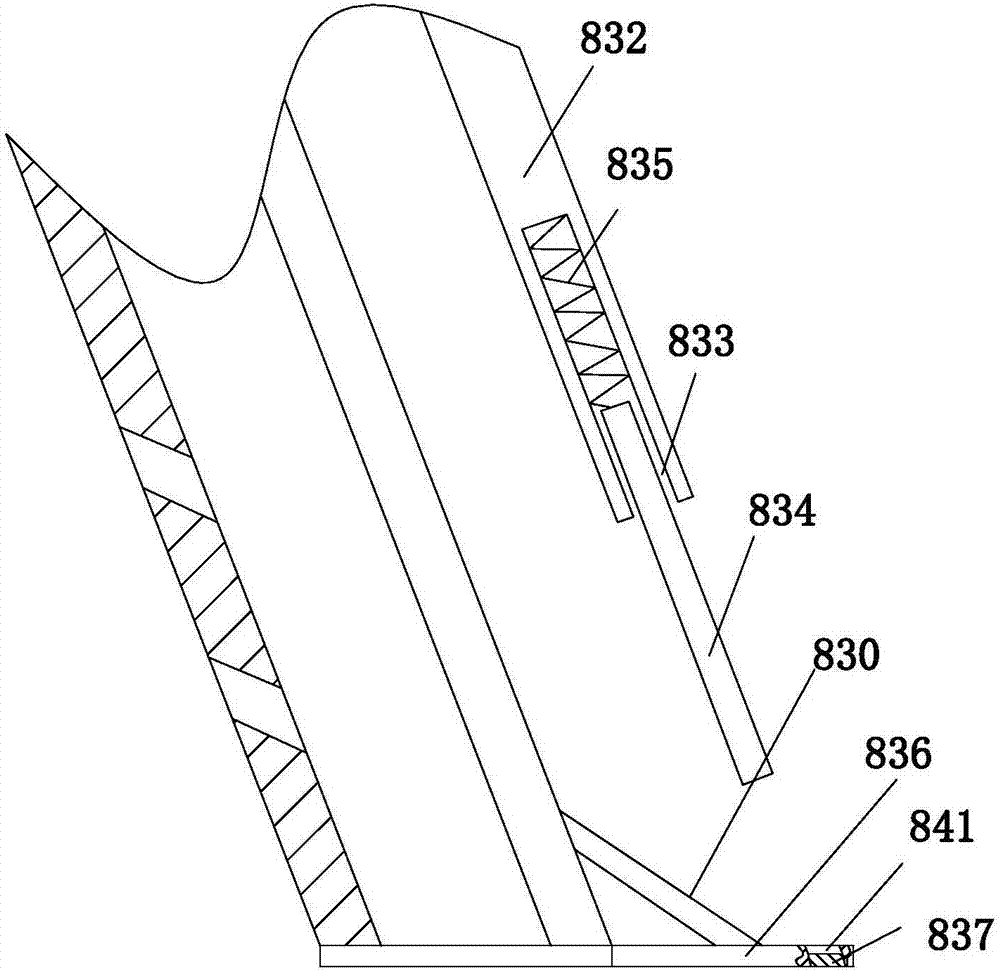

Cotton collection bucket of disc type plucker

InactiveCN106987928AAchieve adsorptionTo achieve the purpose of storageSafety devices for fibre treatmentFibre breaking machinesCircular discAgricultural engineering

The invention discloses a cotton collection bucket of a disc type plucker. The cotton collection bucket includes an outer shell (818) and an inner shell (819); a baffle plate (820) is arranged between the outer shell (818) and the inner shell (819), the inner side of the baffle plate (820) is an air guide layer (821), and the outer side of the baffle plate (820) is a debris storage layer (822); a fixed cover plate (823) and a movable iron plate (824) are arranged at the upper end of the debris storage layer (822), a top baffle plate (825) is arranged at the upper end of the air guide layer (821), a movable groove (839) corresponding to the position of the movable iron plate (824) is formed in the top baffle plate (825), and a movable spring (840) is arranged between the movable groove (839) and the movable iron plate (824); an electromagnet(826) is arranged above the movable iron plate (824) and is connected with a controller (827), a through hole (828) is formed in the inner shell (819), and an air inlet (829) is formed in the bottom of the air guide layer (821). The cotton collection bucket of the disc type plucker has the advantages of making scrap iron recycling convenient and reducing the occurrence frequency of blocking.

Owner:湖州南浔凯普纺织有限公司

Automatic cleaning oil tank

InactiveCN104747889AGuaranteed qualityReduce jam frequencyLubrication containersThermodynamicsFilter system

The invention discloses an automatic cleaning oil tank. The automatic cleaning oil tank comprises a cylindrical tank body, wherein an oil inlet near the upper end and an oil outlet near the lower end are formed in the cylindrical tank body; an oil inlet direction of the oil inlet is in the tangential direction of the inner wall of the cylindrical tank body; and the lower end surface of the cylindrical tank body is an inverted conical structure. The oil inlet of the oil tank is in the tangential direction and the bottom of the oil tank is the inverted conical structure, so that entering lubricant is in a cyclonal state. As the density of impurities is higher than the density of the lubricant, the impurities can enter the conical bottom and be accumulated in the cyclonal process, and the impurities of the lubricant in the upper space of the conical bottom of the oil tank are fewer. Accordingly, the purposes of automatically cleaning the impurities in the lubricant and guaranteeing the quality of the lubricant are achieved, and thus all frictional pairs of power equipment are normally operated; meanwhile, the blockage frequency of such three-level filter systems as filters and filter screens can be reduced; the problems of excess pressure in an outlet of a circulating pump and insufficient oil supply of the power equipment are prevented; the equipment accidents are prevented; and the maintenance cost is reduced.

Owner:TIANJIN QIXING PRECISION MACHINERY

Device for purifying WSA acid-making raw material acid gas

The invention discloses a device for purifying a WSA acid-making raw material acid gas. When the device is used, the acid gas in an acid gas pipeline behind a vacuum carbonate desulphurization vacuumpump enters a purifying segment of a purifying container through an acid gas inlet, is purified and washed by a purifying solution, entering from a purifying solution inlet, sprayed by a nozzle, and is washed by a filter screen to remove oils, naphthalene and a desulphurization solution entrained by the acid gas, and the washed acid gas goes upwards through a gas communicating pipeline, enters a separation segment from the purifying section, undergoes gas-liquid separation, and enters a burner of a WSA acid maker through an acid gas outlet. A purifying solution discharged from the purifying segment flows out from a purifying solution outlet and enters a discharging container, and a separation liquid obtained after the gas-liquid separation in the separation segment enters the discharging container through a separation liquid outlet, so the continuous discharge of the purifying solution and the separation liquid is achieved, acid gas leakage is avoided, the purification of the WSA acid-making raw material acid gas is achieved, the blockage frequency of the acid gas pipeline is reduced, the running period of an acid making system is prolonged, and the operating rate of the acid making system is improved.

Owner:攀钢集团西昌钢钒有限公司

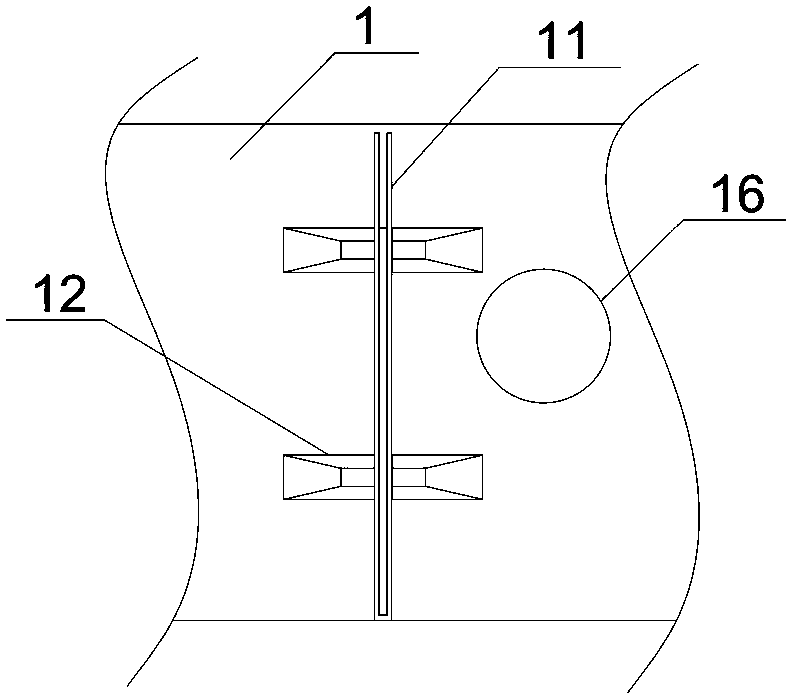

Circulating fluidized bed slagging pipe device and dredging method

ActiveCN107543153AMove up and down quicklyUnique secondary feed featureFluidized bed combustionApparatus for fluidised bed combustionFillet weldSlag

The invention relates to a circulating fluidized bed slagging pipe device and a dredging method. In the present, a power plant generally utilizes a site manual slag poking mode to solve the problem that a slagging pipe is plugged; generally, two operators must be needed to be specially responsible for operation in site; in the moment, slag spray, bed material self flow and other abnormal phenomenaendangering personal safety are prone to happening; an operation environment is severe, labor intensity is large, and labor cost is high; furthermore, overhaul efficiency for boiler shutdown caused by plug is higher, and safety and economy of a boiler are poorer. The circulating fluidized bed slagging pipe device disclosed by the invention comprises a slagging pipe (1), a hole is formed in the upper part of the slagging pipe, a connection pipe (5) is welded in the hole, the upper part of the connection pipe is in angle welding to a sealing device (21), the sealing device is connected with a slag breaking device (22), the slag breaking device is fixed to a fixed frame (2), and the fixed frame is respectively fixed to the ground and the connection pipe. The slagging pipe device and the dredging method disclosed by the invention are applied to a circulating fluidized bed.

Owner:大唐鸡西第二热电有限公司

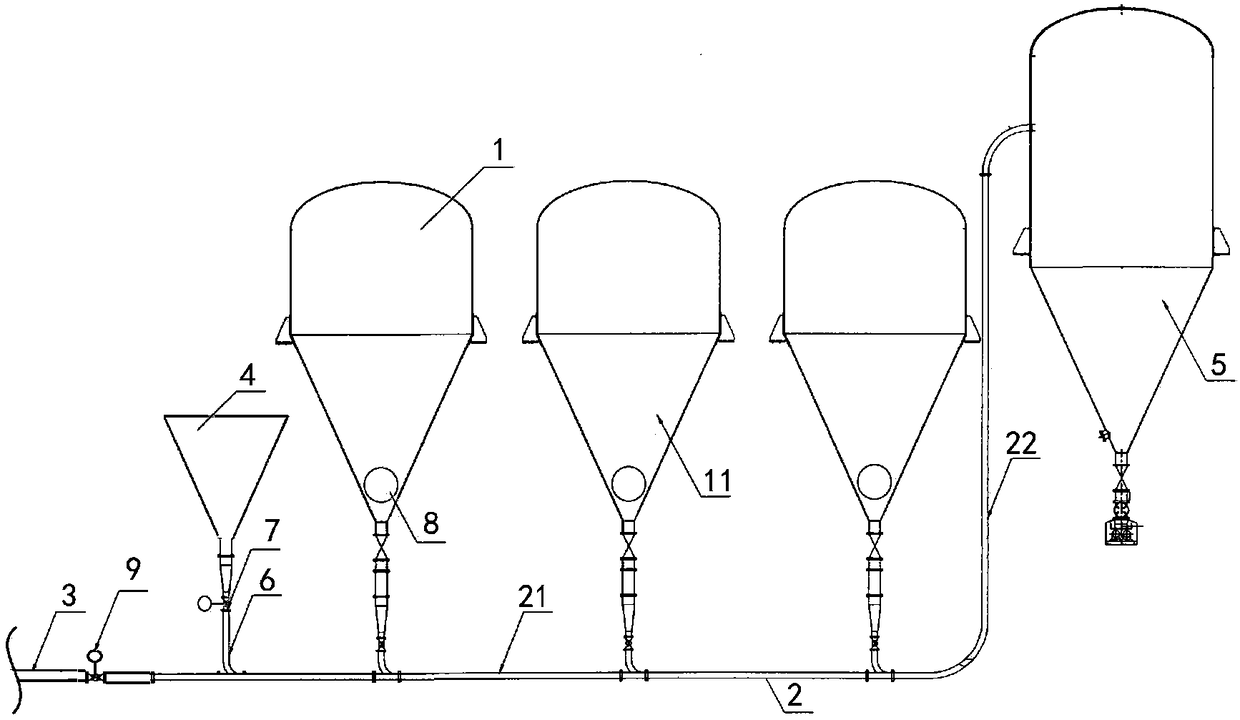

Blast furnace gas dust removing and discharging device

The invention discloses a blast furnace gas dust removing and discharging device. The blast furnace gas dust removing and discharging device comprises bag dust removing boxes, a dust conveying pipeline, a gas source pipeline connected to the dust conveying pipeline, and a funnel, wherein the dust conveying pipeline comprises a dust conveying main pipe and a dust conveying branch pipe, one end of the dust conveying main pipe is connected to the bag dust removing boxes and the other end is connected to one end of the dust conveying branch pipe; the other end of the dust conveying branch pipe isconnected to a dust bin; and the dust conveying main pipe is connected to the lower end of the funnel through a sandblast unblocking pipe on which an electric ball valve is arranged. The dust removingand discharging device can reduce the blocking frequency of the conveying pipeline, facilitate the timely unblocking of the dust conveying pipeline, reduce the labor intensity of post personnel, andensure the stable operation of pneumatic conveying.

Owner:SICHUAN DESHENG GRP VANADIUM & TITANIUM CO LTD

A kind of fiber soil mixed spraying method

ActiveCN109804861BStrong adhesionImprove adhesionHops/wine cultivationGrowth substratesSoil scienceSoil mixing

The invention provides a fiber-soil mixed spraying method. In the spraying method, the spraying matrix adopted includes heat-treated wood fibers. The heat-treated wood fibers: length 1.5-2.5cm, diameter 0.05-0.15mm. The heat-treated wood fibers: the content of fibers with a length of 2 cm is ≥50%. On the basis of not using cement, concrete, barbed wire and other means to destroy the soil structure, the substrate layer has strong adhesion on the slope, and the substrate thickness of one spraying is 2 to 3 times higher than that of traditional spraying.

Owner:JOFO GREEN CO LTD

A kind of ion exchange method

ActiveCN104338566BNo pollutionDoes not increase operational difficultyIon-exchange column/bed processesMolecular sieve catalystsMolecular sieveIon exchange

The invention provides an ion exchange method. According to the method, a slurry comprising a solid substance with exchangeable groups flows through an ion exchange column filled with an ion exchange resin bed layer, such that the exchangeable groups in the solid substance is subjected to ion exchange with ion exchange groups in the ion exchange resin in the ion exchange resin bed layer; and solid-substance-containing slurry flowing out from the ion exchange column is collected. At least part of the ion exchange resin is magnetic ion exchange resin. Also, when the slurry flows through the ion exchange column, the ion exchange column is positioned in a transversal rotation magnetic field. With the method provided by the invention, after ion exchange, no or substantially no molecular sieve is adhered to the surface of the ion exchange resin, such that ion exchange column service period can be effectively prolonged, and washing and regeneration frequencies can be reduced. Under a same condition of ion exchange, with the method provided by the invention, higher ion exchange efficiency can be achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Tilting furnace for smelting ferrovanadium through electro-aluminothermic process

ActiveCN111485104AEasy to operateIncrease the cross-sectional area of the tapholeCharge manipulationIndustrial engineeringManufacturing engineering

The invention discloses a tilting furnace, particularly discloses a tilting furnace for smelting ferrovanadium through an electro-aluminothermic process, and belongs to the technical field of design and manufacturing of metallurgical production equipment. The tilting furnace for smelting ferrovanadium through the electro-aluminothermic process is remarkably reduced in blocking frequency and more convenient in blockage clearing operation. The tilting furnace comprises a tilting furnace body and further comprises an open type tapping chute system, wherein the open type tapping chute system is arranged in the middle of the tilting furnace body in a downward-inclined mode.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES

Secondary crushing device of pipe jacking machine

The invention discloses a secondary crushing device of a pipe jacking machine. The secondary crushing device of the pipe jacking machine comprises a pipe jacking machine body. The pipe jacking machinebody comprises a shell and a cabin barrel coaxially and fixedly arranged with the end portion of the shell. The secondary crushing device of the pipe jacking machine is characterized by comprising asecondary crushing mechanism, wherein the secondary crushing mechanism comprises a hollow circular-truncated-cone-shaped crushing bin with a large end opening, one end of the crushing bin is coaxiallyand fixedly connected with the end portion of the shell, and the other end of the crushing bin is fixedly connected with the inner side wall of the cabin barrel; a plurality of groups of crushing assemblies are fixedly arranged on the lower portion of the side wall of the crushing bin at intervals, and each group of crushing assembly comprises a plurality of first crushing tools which are weldedat equal intervals; and each group of crushing assembly are located on different bus bars of the crushing bin, and the central angle of the vertical section where the crushing assemblies are located is 100-120 degrees, and the angular bisector of the central angle is located directly below the central axis of the crushing bin. Secondary crushing can be carried out on the crushed objects entering the pipe jacking machine body, the particle size of the crushed objects is reduced, the phenomenon of "delayed discharging" caused by blockage of a slurry discharging pipeline is reduced, and the effect of continuous slurry discharging is achieved.

Owner:中铁隧道局集团建设有限公司

A carding machine control device

The invention relates to a carding machine control device comprising a central controller, a carding machine interface device, an information interface device, a fan and a sensor group. The central controller is connected with the carding machine interface device and the information interface device via signal lines; the central controller is connected with the fan via a control line; the information interface device is connected with the sensor group via a signal line. The carding machine control device has the advantages of increasing the degree of automation of systems, improving control technology, reducing the frequency of pipeline jam, reducing the labor intensity of workers, and improving the production efficiency and product quality; practical application proves that the system can run reliably and the operation is simple.

Owner:杨配媛

Integral purification device and method for particles in rain and sewage

InactiveCN102774896BImprove removal efficiencyAvoid easy cloggingWater/sewage treatment by centrifugal separationWater/sewage treatment by flocculation/precipitationParticulatesWater discharge

The invention relates to an integral purification device and an integral purification method for particles in rain and sewage. The device consists of three parts including a rotational flow riffling unit, a diameter change precipitation unit and an up-flow filter unit in vertical overlapped arrangement, wherein the rotational flow riffling unit comprises a rotational flow riffling tube, a water inlet pipe, a sand discharge pipe, a siphon cover, a siphon pipe, a water sealing groove, a water discharge pipe, a first perforation plate, a second perforation plate and a third perforation plate, the diameter change precipitation unit comprises a diameter change precipitation pool, the up-flow filter unit comprises a filter chamber case, a filter chamber base plate, a filter pool, filter materials and a filter water outlet. The device and the method provided by the invention have the characteristics that the particle removal efficiency is high, the blockage is avoided, the energy is saved, the efficiency is high, the water load impact capability is high, the occupied area is small, the investment and operation management cost are low, and the like. The method and the device can be widely applied to the particle purification in water discharge pipelines with greater slope and the rainfall runoff of roofs, elevated roads and the like.

Owner:北京建筑工程学院

Rural domestic sewage integrated advanced treatment device and sewage treatment method

PendingCN113354209AReduce drug costsImprove denitrification effectSpecific water treatment objectivesWater contaminantsSewageElectron donor

The invention discloses a rural domestic sewage integrated advanced treatment device. The rural domestic sewage integrated advanced treatment device comprises a grit tank, an anaerobic tank, an anoxic tank, an aerobic tank, a membrane biological reaction tank and a baffling type autotrophic denitrification filter tank which are sequentially connected along the sewage treatment direction; the baffling type autotrophic denitrification filter tank comprises a sewage treatment area for filtering sewage and a clean water tank communicated with a water outlet of the sewage treatment area, and partition plates are arranged in the sewage treatment area in the vertical direction so as to divide the sewage treatment area into a plurality of treatment chambers; and each treatment chamber is filled with an autotrophic functional filler for providing electron donors for microorganisms in the sewage, each partition plate is provided with a connecting section for communicating the adjacent treatment chambers, and the connecting sections on the adjacent partition plates are arranged in a staggered manner, so that the sewage in the sewage treatment area flows in an S-shaped flow direction. Under a same occupied area, the flow path of the sewage is maximized, the denitrification effect is improved, only a small filter material area is needed for completing the same water treatment amount, and the filter material cost is saved.

Owner:ANHUI ZHONGHUAN ENVIRONMENTAL PROTECTION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com