Blast furnace gas dust removing and discharging device

An ash unloading device and bag dust removal technology, applied in the direction of dust collectors, etc., can solve the problems of blockage of conveying pipelines, polluting the working environment, and affecting the stable operation of pneumatic conveying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

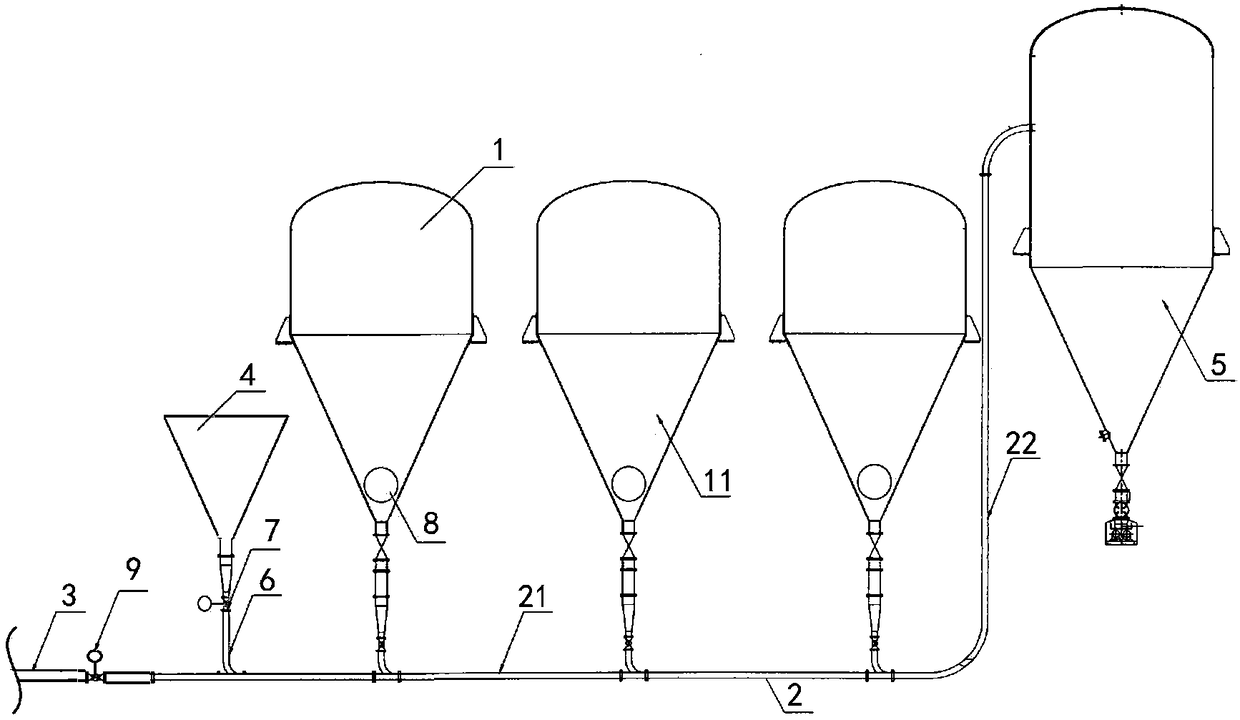

[0022] Such as figure 1 As shown, the present invention provides a blast furnace gas dust removal and ash unloading device, including: a bag dust removal box 1, an ash conveying pipe 2, a gas source pipe 3 and a funnel 4 connected to the ash conveying pipe 2, the ash conveying pipe 2 Including: an ash conveying main pipe 21 and an ash conveying branch pipe 22. One end of the ash conveying main pipe 21 is connected to the bag dust removal box 1 and the other end is connected to one end of the ash conveying branch pipe 22; the other end of the ash conveying branch pipe 22 is connected to the ash warehouse 5; The ash conveying main pipe 21 is connected to the lower end of the funnel 4 through a sandblasting cleaning pipe 6, and an electric ball valve 7 is provided on the sandblasting cleaning pipe 6.

Embodiment 2

[0024] Such as figure 1 As shown, the difference from Embodiment 1 is only:

[0025] The hopper 3 can hold and transport sinter particles, and the sandblasting cleaning pipe 6 can transport sinter particles. The ash branch pipe 22 is a straight pipe. The lower dust air chamber 11 of the bag dust removal box 1 is connected to the main ash conveying road 21, and the lower dust air chamber 11 of the bag dust removal box 1 is provided with an ash discharge hole 8. The number of the bag dust removal box 1 is several, preferably three. The gas source pipeline 3 is connected to the ash conveying main pipe 21, and the connection between the sandblasting cleaning pipe 6 and the ash conveying main pipe 21 is provided at the connection point of the bag dust removal box 1 and the ash conveying main pipe 21 Between the connection point of the gas source pipeline 3 and the ash conveying main pipe 21.

[0026] The gas source pipeline 3 is a nitrogen purge pipe, and a nitrogen purge valve 9 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com