Filtering type plate heat exchanger

A plate heat exchanger and filtering technology, applied in heat exchange equipment, heat exchanger types, indirect heat exchangers, etc., can solve the problem of reducing the blockage frequency of plate heat exchangers, the time-consuming and labor-intensive assembly of plate heat exchangers Large and other problems, to achieve the effect of low labor intensity, fast cleaning speed, and reducing the frequency of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The structure of the present invention will be explained in detail below in conjunction with the accompanying drawings.

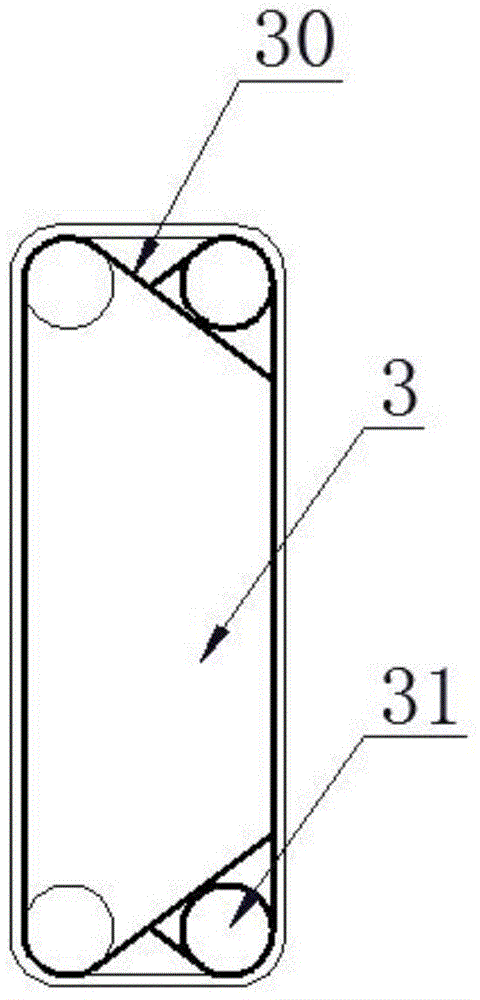

[0025] Such as Figure 4 , 6 , 7, a filter plate heat exchanger, including a movable compression plate 5, a fixed compression plate 2 and a plate 3. Such as figure 2 , 3 Plate 3 shown, figure 2 , 3 The way of embedding the rubber strip 30 in the plate 3 is different. There are four corner holes 31 on the plate 3, and a rubber strip 30 is embedded on one side of each plate 3. The part of the rubber strip 30 is the part of the thick line in the figure. The rubber strip 30 has a sealing effect and controls the flow direction of the fluid. figure 2 Pattern 3 in image 3 The plates 3 are arranged at intervals to form two intersecting inter-plate flow channels 6, which are respectively used for the flow of the heating medium and the heated medium, or the flow of the cooling medium and the cooled medium, the heating medium, the heated medium, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com