Secondary crushing device of pipe jacking machine

A technology of secondary crushing and pipe jacking, which is applied in mining equipment, tunnels, earthwork drilling, etc., and can solve problems such as pipe jacking stagnation, inability to chop, plastic drainage boards and hard rocks blocking the slurry discharge channel, etc. Achieve the effects of reducing weight, reducing workload and improving pulp discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0032] It should be understood that terms such as "having", "comprising" and "including" as used herein do not entail the presence or addition of one or more other elements or combinations thereof.

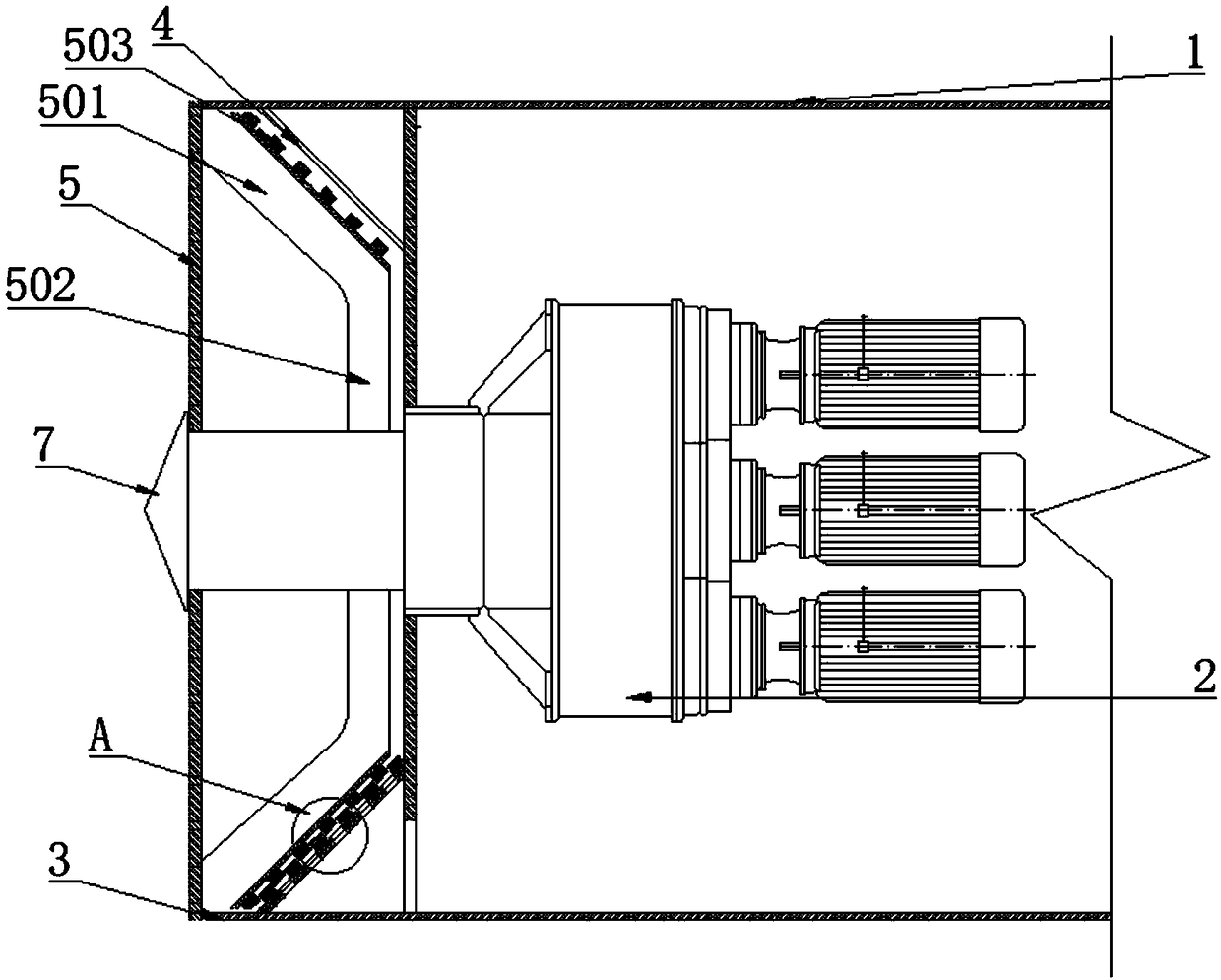

[0033] Such as Figure 1-6As shown, the present invention provides a secondary crushing device for a pipe jacking machine, which includes a pipe jacking machine body, the pipe jacking machine body includes a shell 1, and a cabin fixed coaxially with the end of the shell 1 3, including:

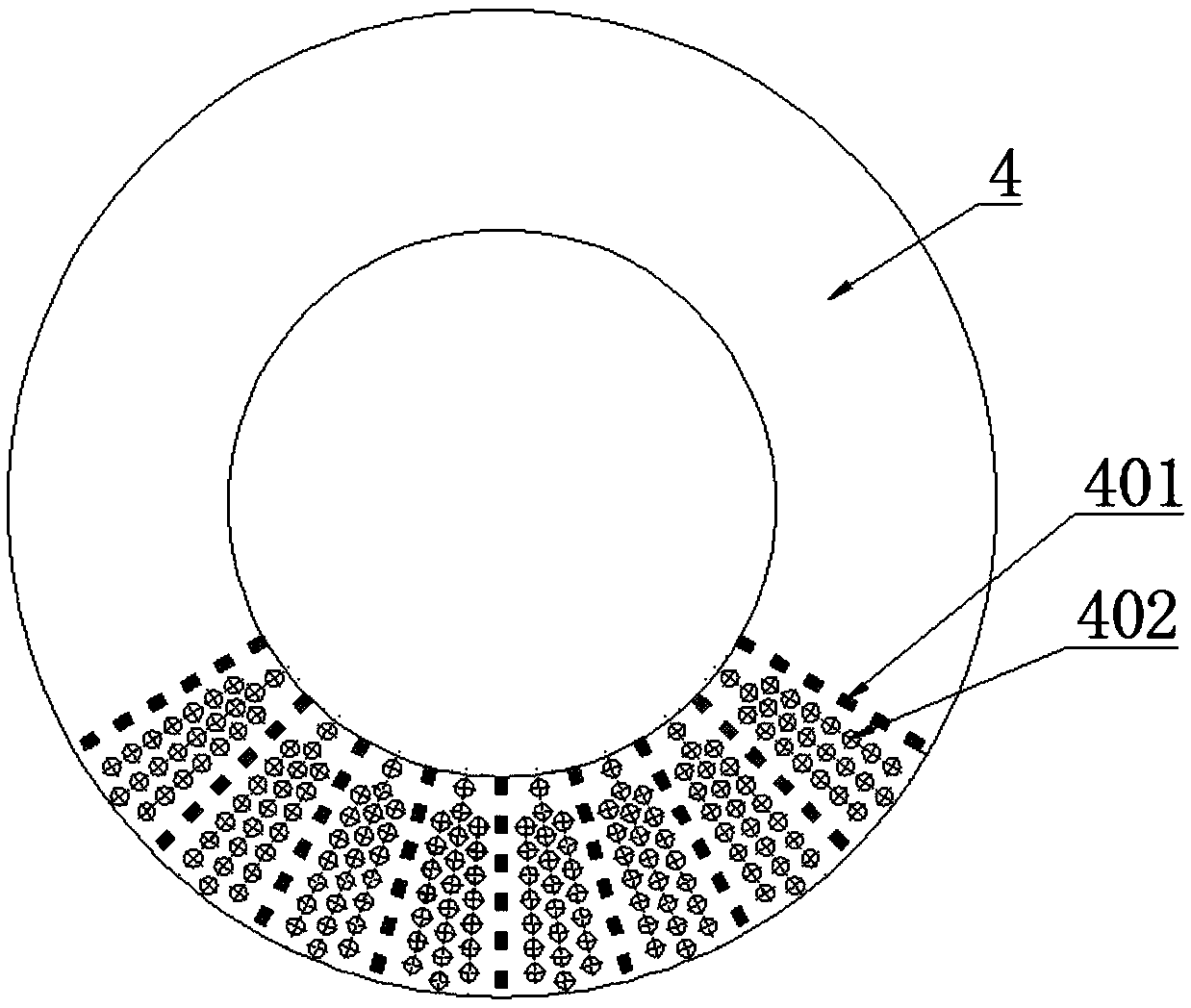

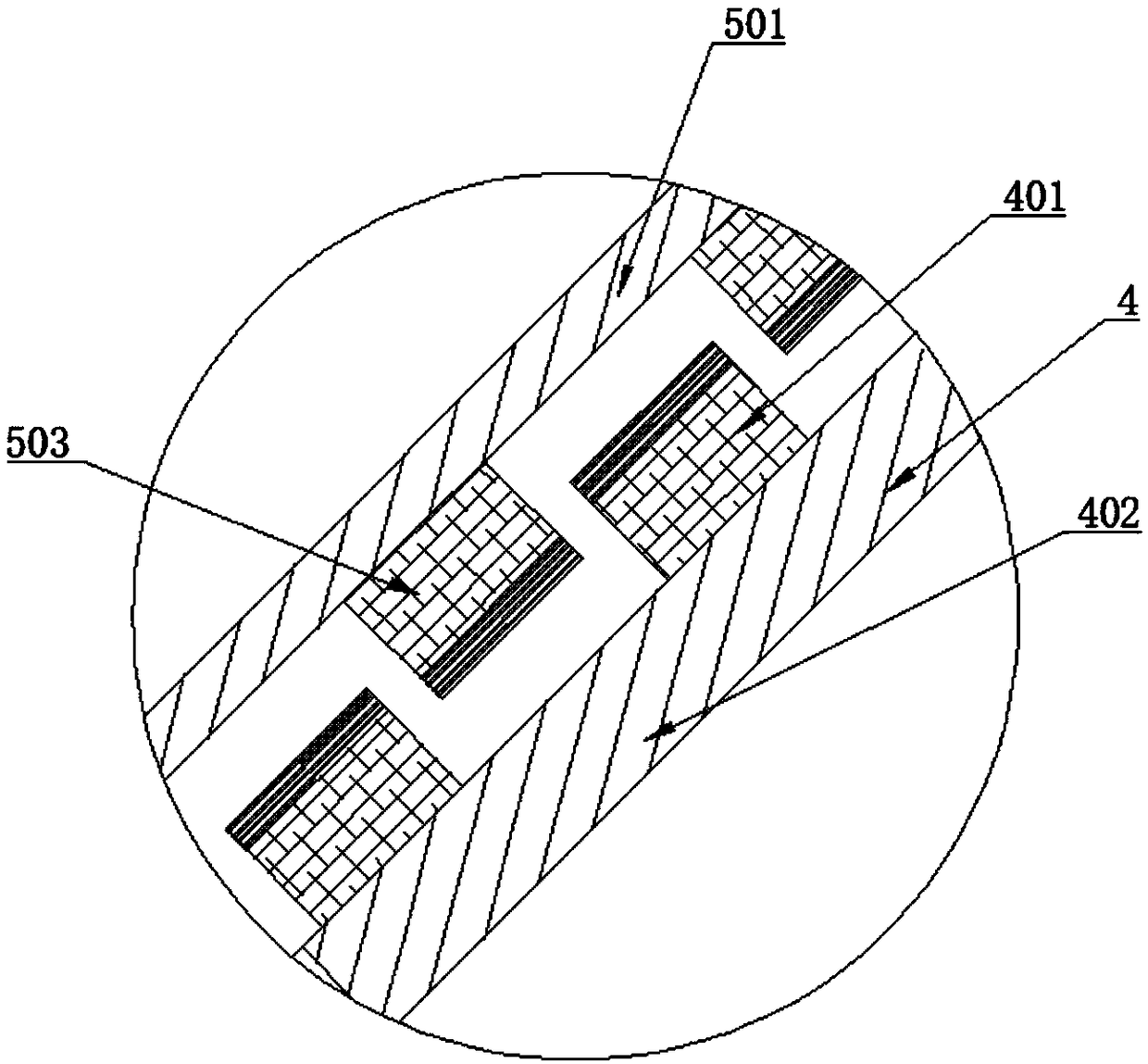

[0034] The secondary crushing mechanism includes a hollow conical crushing bin 4 with a large end opening, one end of the crushing bin 4 is coaxially fixed to the end of the casing 1, and the other end is fixed to the inner wall of the cabin 3. Then, the lower part of the side wall of the crush...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com