Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Reduce floating fiber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

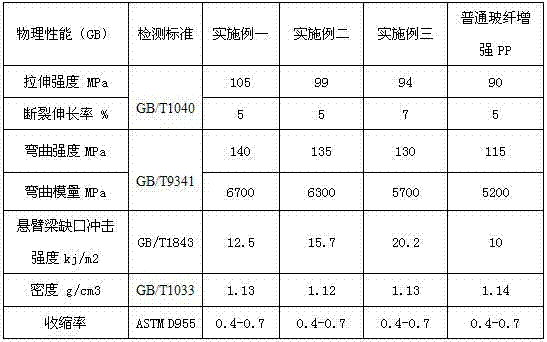

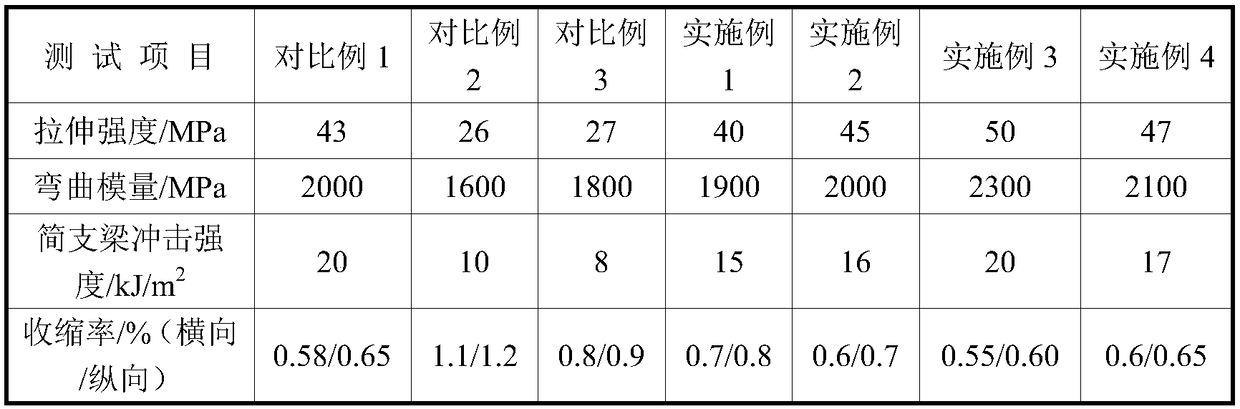

Reinforced polypropylene composite material and preparation method thereof

InactiveCN103589058ARaw materials are easy to getSolving Recycling ProblemsPolypropylene compositesGlass fiber

Owner:ORINKO NEW MATERIAL CO LTD

Long glass fiber enhanced polypropylene composite material and preparation method thereof

The invention relates to the technical field of polypropylene materials, and specifically relates to a long glass fiber enhanced polypropylene composite material and a preparation method thereof. Thelong glass fiber enhanced polypropylene composite material comprises a component A and a component B. The component A is prepared from following components in parts by weight: 30 to 90 parts of polypropylene resin, 10 to 60 parts of alkali-free continuous glass fibers, 0.5 to 2.0 parts of a lubricant, 0.01 to 0.1 part of peroxides, 0.5 to 3.0 parts of a silane coupling agent, and 0.2 to 0.7 part of an antioxidant. The component B is prepared from following components in parts by weight: 30 to 90 parts of polypropylene resin, 10 to 60 parts of alkali-free continuous glass fibers, 0.5 to 2.0 parts of a lubricant, 1.0 to 4.0 parts of a catalyst, 0.01 to 0.1 part of peroxides, and 0.2 to 0.7 part of an antioxidant. Peroxides decompose and functionalize polypropylene; during the infiltration process, polypropylene has high fluidity and excellent infiltration effect; after the material is moulded, the mechanical strength of the material is improved, and moreover, the prepared material has few fibers on the surface, is easy to mould, and has a high performance.

Owner:QINGDAO HAIER NEW MATERIAL R&D CO LTD

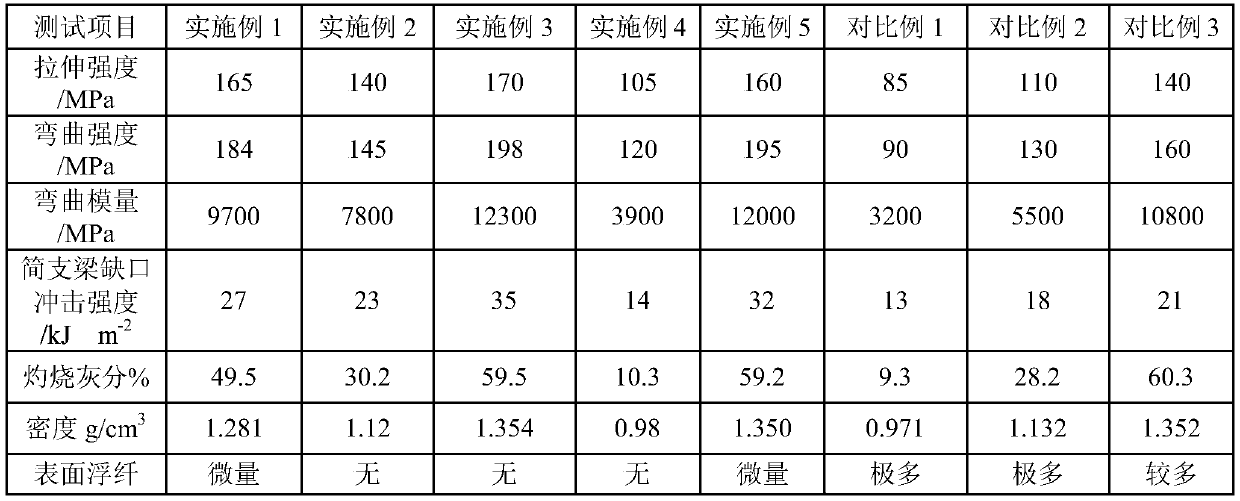

High-strength, high-weather-resistance and good-appearance PA6 composition and preparation method thereof

The invention relates to a high-strength, high-weather-resistance and good-appearance PA6 composition and a preparation method thereof. The high-strength, high-weather-resistance and good-appearance PA6 composition comprises the following components in parts by weight: 25-45 parts of PA6 resin; 5 -10 parts of amorphous nylon and 20 to 50 parts of glass fiber; 10-40 parts of mineral powder; 0.3-0.8part of carbon black; 0.3-0.8 part of a fluidity improver; 0.3-0.8 part of an antioxidant; 0.3-0.8 part of a lubricant; 0.5-1 part of weather-resistant agent. The PA6 composition disclosed by the invention has good comprehensive performance, and can be used for preparing a high-performance composite material to replace a traditional metal material to be used in automobile functional parts and structural parts.

Owner:SHANGHAI KINGFA SCI & TECH +1

Modified polypropylene material, preparation method and application thereof

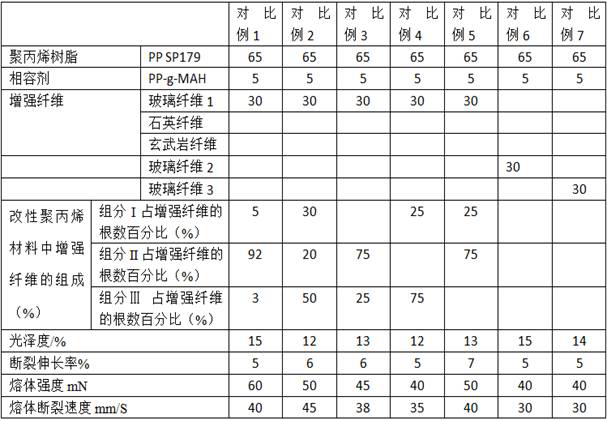

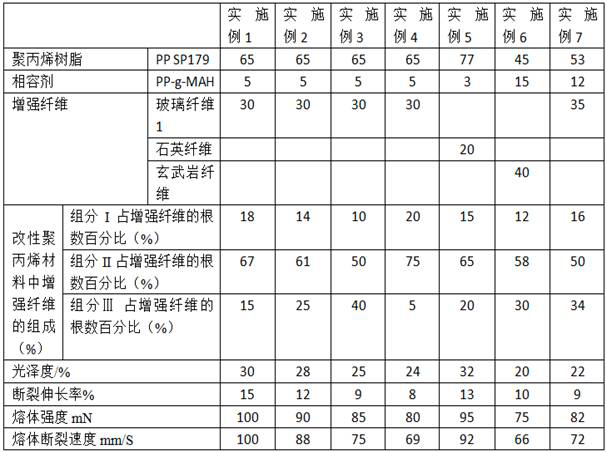

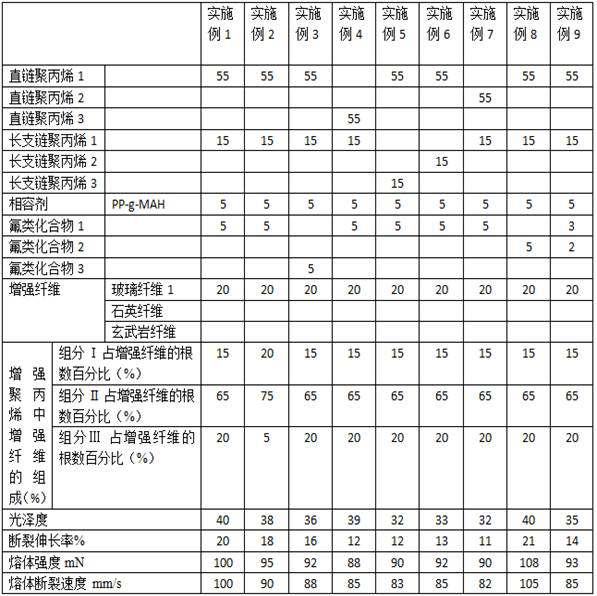

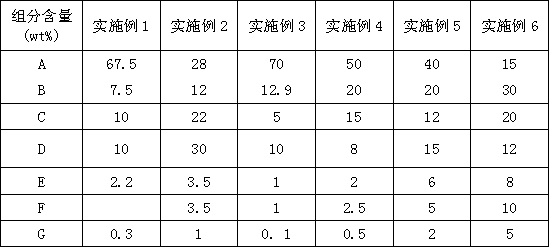

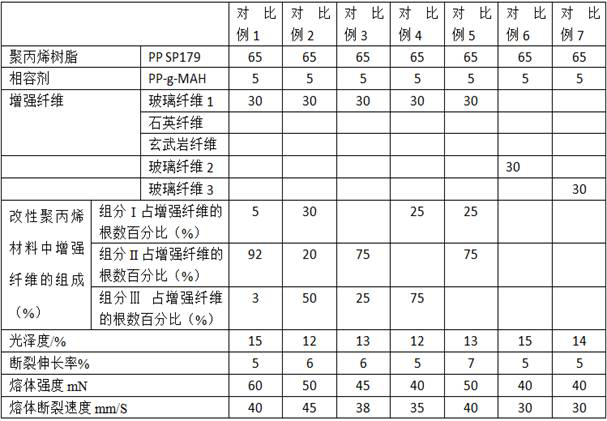

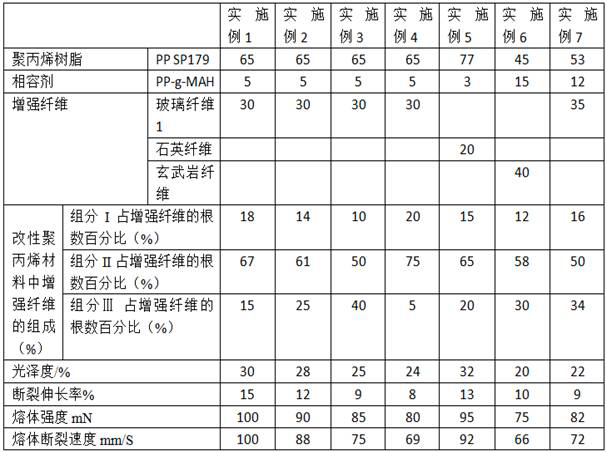

The invention discloses a modified polypropylene material, a preparation method and application thereof. The modified polypropylene material comprises the following components in parts by weight: a, 20-80 parts of a polypropylene resin, b, 1-20 parts of a compatilizer, and c, 10-40 parts of reinforcing fibers, wherein the reinforcing fibers comprise a component I, a component II and a component III, the component I consists of reinforced fibers with the length of less than 0.1 mm and accounts for 10-20% of the reinforing fibers, the component II is composed of reinforced fibers with the length of 0.1 mm-0. 3mm and accounts for 50-75% of the number of the reinforcing fibers, and the component III is composed of reinforced fibers with the length of 0.4 mm-0. 8mm, and accounts for 5-40% of the number of the reinforcing fibers. According to the invention, by controlling the length and content distribution of the reinforcing fibers in the modified polypropylene material, compared with a glass fiber material with a conventional length (0.4-0.6 mm), the surface gloss is high, and floating fibers are few; elongation at break is large, toughness is good, and tests such as ball falling are facilitated; and the melt elongation rate is high, and the modified polypropylene material is mainly suitable for blow molding, plastic suction and other occasions.

Owner:KINGFA SCI & TECH CO LTD

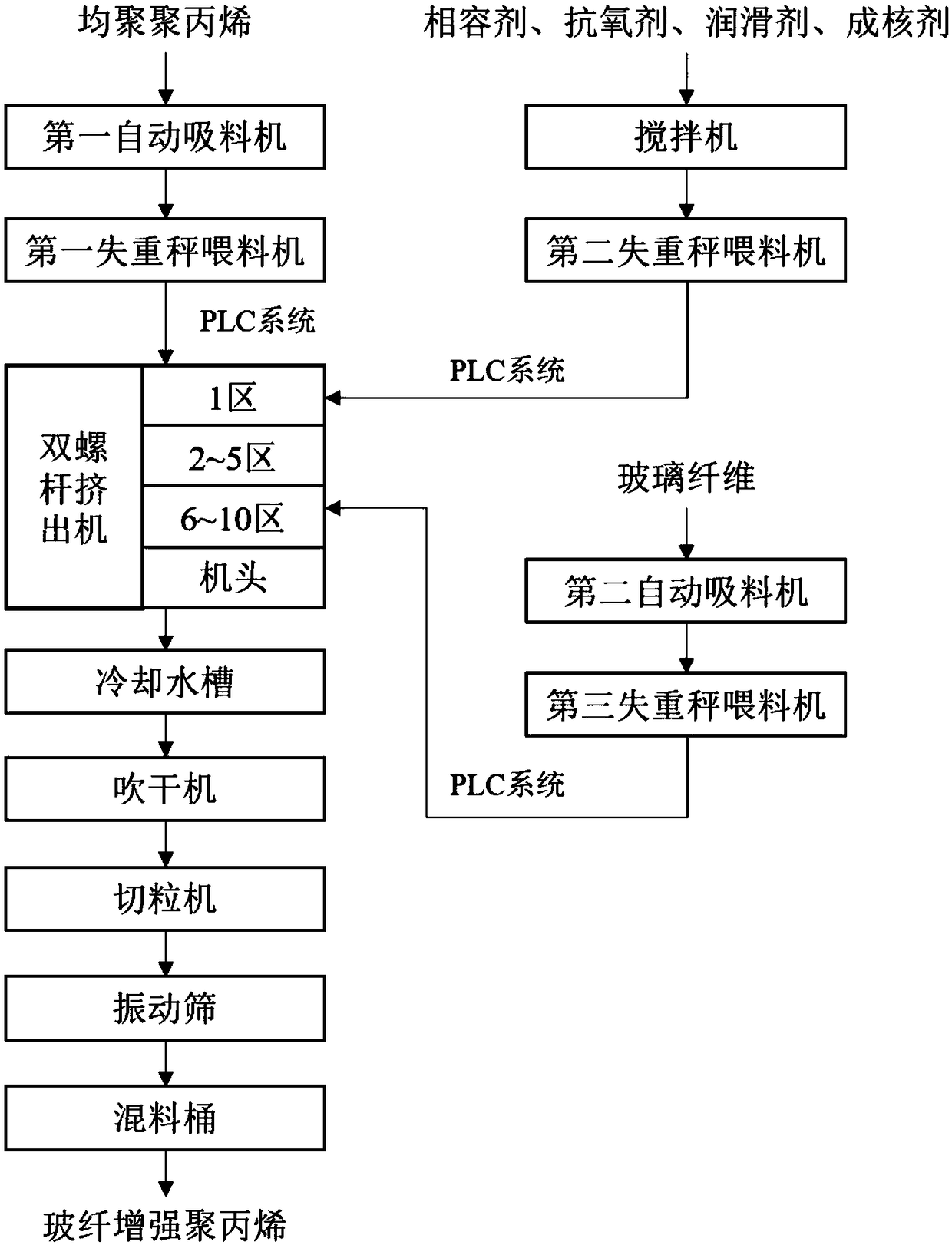

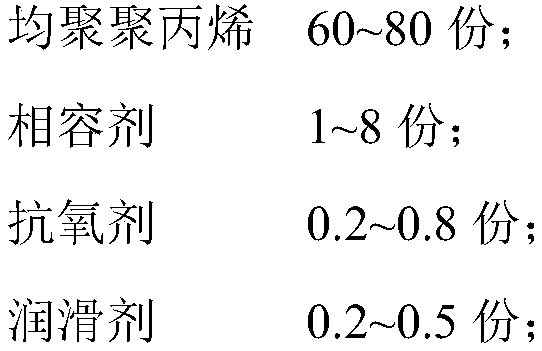

High-rigidity glass fiber reinforced polypropylene material and preparation equipment and preparation method thereof

The invention discloses a high-rigidity glass fiber reinforced polypropylene material and preparation equipment and a preparation method thereof. The high-rigidity glass fiber reinforced polypropylenematerial consists of the following raw materials: homo-polypropylene, a compatilizer, an antioxidant, a lubricating agent, a nucleating agent and glass fibers. Meanwhile, the invention discloses theequipment for preparing the polypropylene material and a method for preparing the high-rigidity glass fiber reinforced polypropylene material by using the equipment. In addition, the invention furtherdiscloses application of the high-rigidity glass fiber reinforced polypropylene material. The polypropylene material has high bending strength and modulus, is excellent in anti-impact property and good in thermal stability, resists hydrolysis, and can be widely applied to automotive panels, washing machine drums, handles of thermal jugs and the like.

Owner:GUANGDONG JUSHI CHEM CO LTD

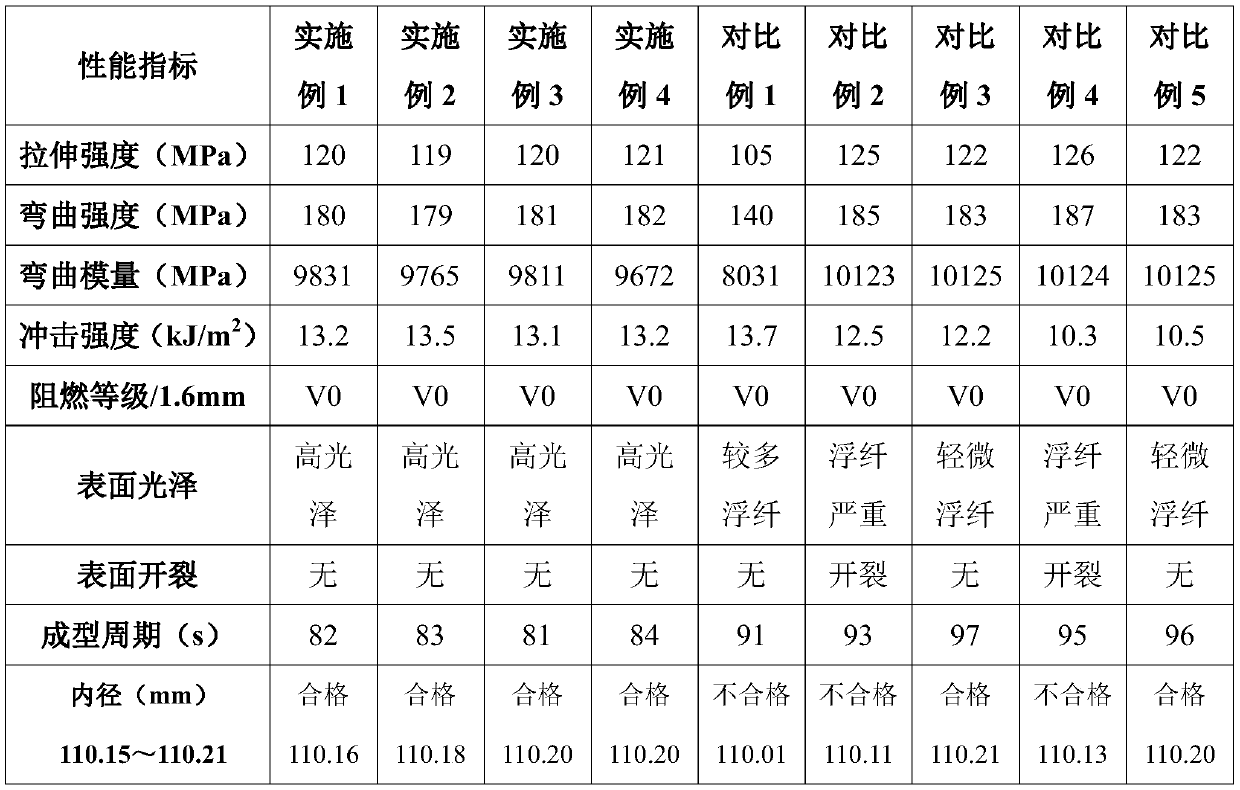

Flame-retardant reinforced PBT (polybutylene terephthalate) composite and preparation method thereof

The invention discloses a flame-retardant reinforced PBT (polybutylene terephthalate) composite and a preparation method thereof. The flame-retardant reinforced PBT composite comprises PBT resin, PET(polyethylene glycol terephthalate) resin, brominated epoxy resin, an antimony compound, glass fiber, glass beads, a dendritic hyperbranched polymer, a toughening agent, an anti-aging agent, a lubricant, a nucleating agent and color masterbatch. The preparation method includes: 1) pre-drying of the PBT resin and the PET resin; 2) pre-mixing of the PBT resin, the PET resin, the brominated epoxy resin, the antimony compound, the dendritic hyperbranched polymer, the toughening agent, the anti-aging agent, the lubricant, the nucleating agent and the color masterbatch; 3) extrusion granulation performed by adding the glass fiber and the glass beads. The flame-retardant reinforced PBT composite has the advantages of high gloss, good dimensional stability, low warpage, good weather resistance andthe like; the preparation process is simple, the production cost is low, and the flame-retardant reinforced PBT composite is suitable for pressure gauge housing materials.

Owner:聚石化学(苏州)有限公司

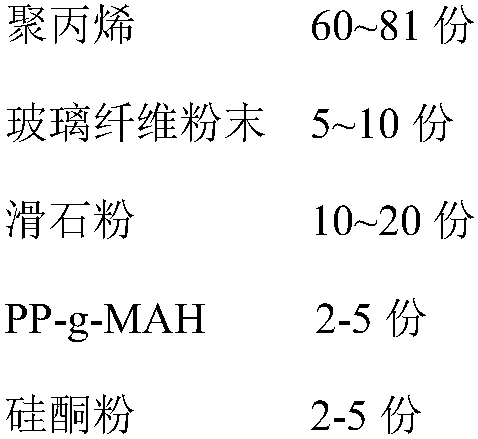

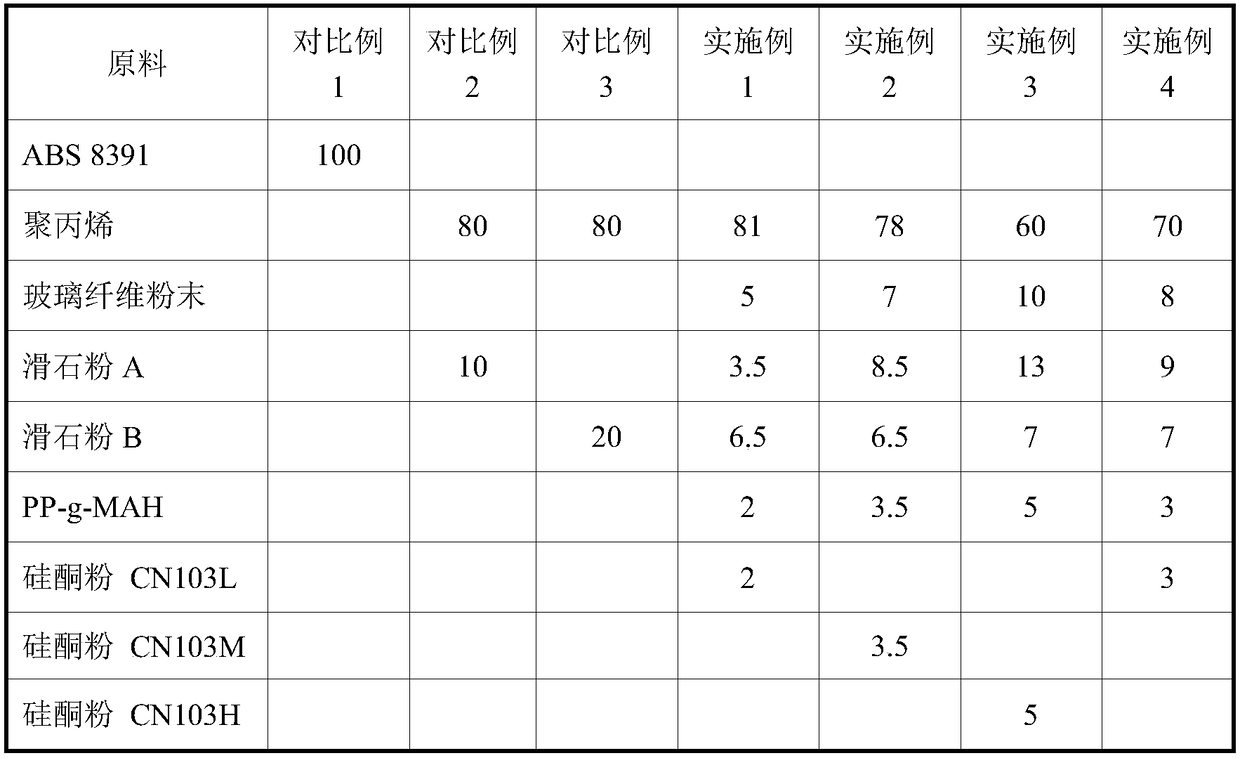

Reinforced polypropylene composite material capable of replacing ABS as well as preparation method and application of reinforced polypropylene composite material

The invention provides a reinforced polypropylene composite material capable of replacing ABS as well as a preparation method and application of the reinforced polypropylene composite material. The material is prepared from the following raw materials in parts by weight: 60 to 81 parts of polypropylene, 5 to 10 parts of glass fibers, 2 to 5 parts of PP-g-MAH and 2 to 5 parts of silicone powder; talcum powder is a mixture formed by mixing talcum powder A with talcum powder B according to the mass ratio ranging from 1:2 to 2:1; D50 of the talcum powder A is 1 to 2 microns and D50 of the talcum powder B is 10 to 15 microns. According to the preparation method disclosed by the invention, by adding glass fiber powder and the talcum powder with different particle sizes into the polypropylene, the strength and the toughness of a final material are close to those of an ABS material; in addition, by adding a special silicone powder additive, the surface of a product subjected to injection molding has no floating fibers and the reinforced polypropylene composite material can replace the ABS material.

Owner:合肥卡洛塑业科技有限公司

Reinforced polypropylene material, preparation method and application thereof

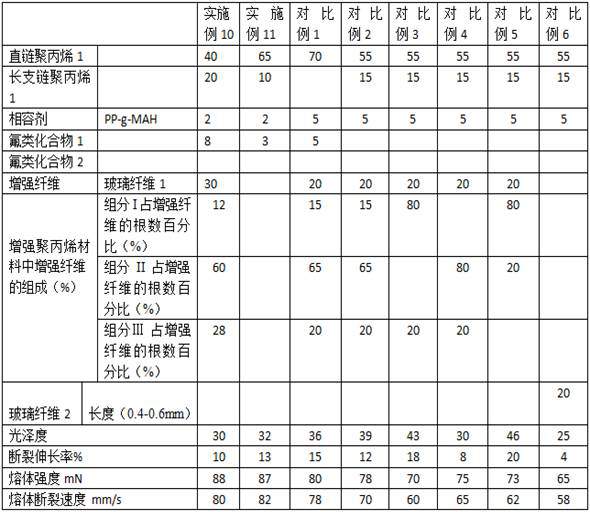

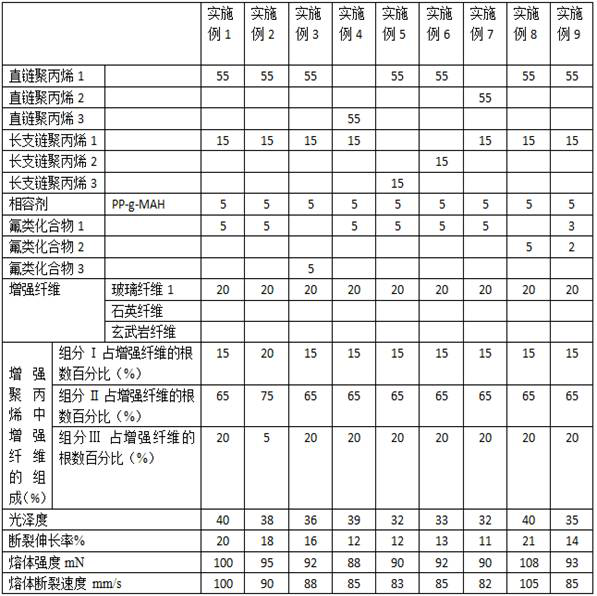

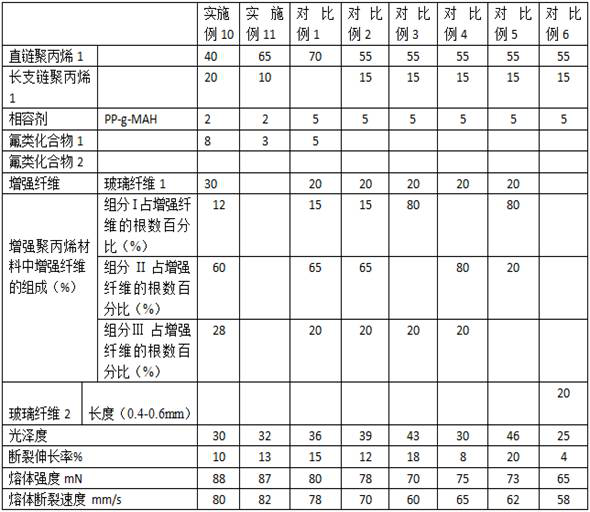

The invention discloses a reinforced polypropylene material, a preparation method and application thereof. The reinforced polypropylene material comprises the following components in parts by weight: 30-70 parts of straight-chain polypropylene, 2-50 parts of long branched chain polypropylene, 1-20 parts of a compatilizer, 5-60 parts of reinforcing fibers, 0.1-20 part of a fluorine compound. According to the invention, the polypropylene material prepared by the method is high in surface gloss, good in toughness and high in melt strength, and is mainly suitable for blow molding, plastic uptake and other occasions.

Owner:KINGFA SCI & TECH CO LTD

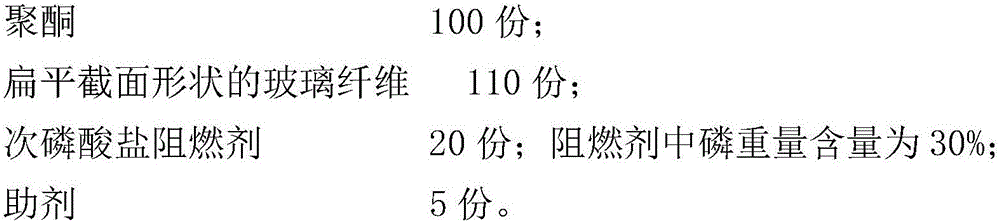

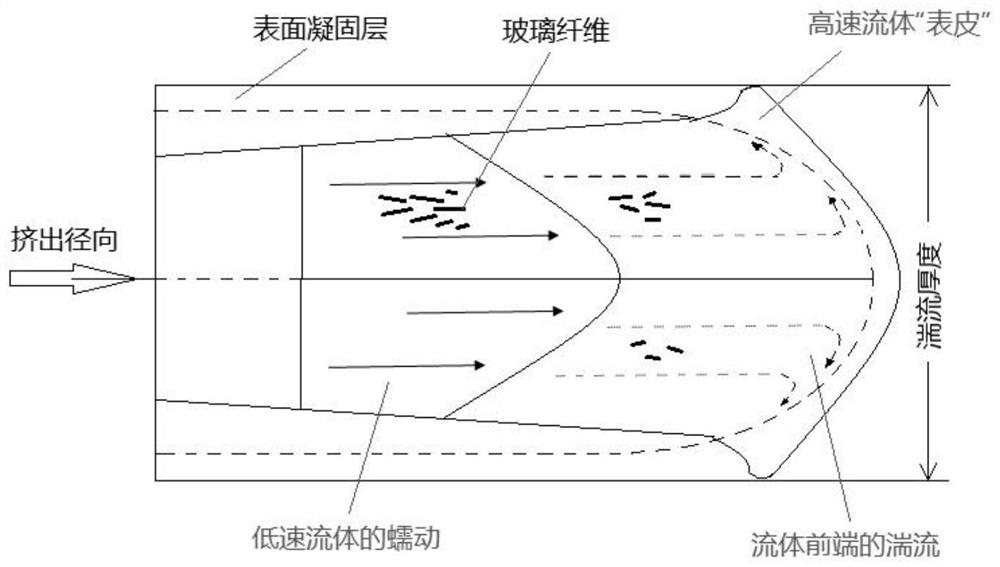

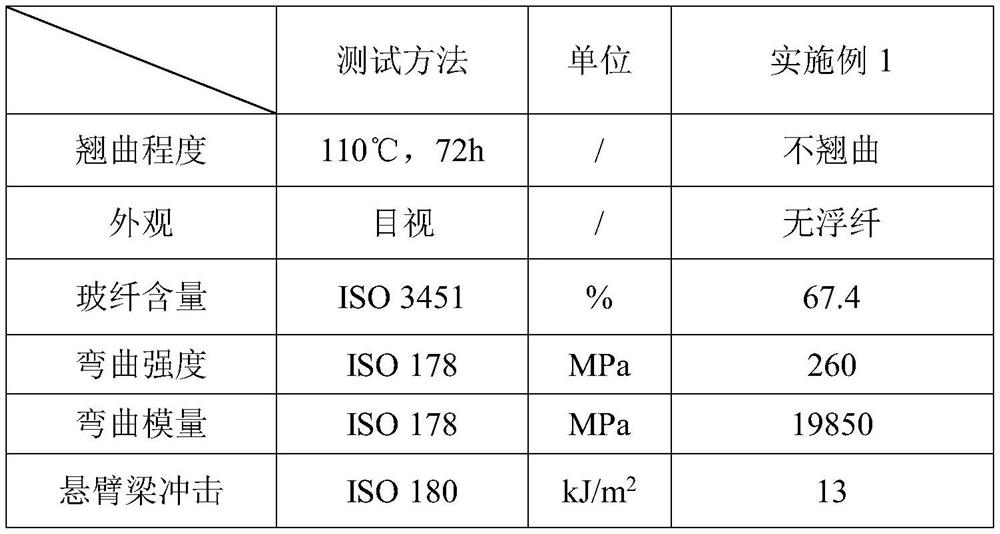

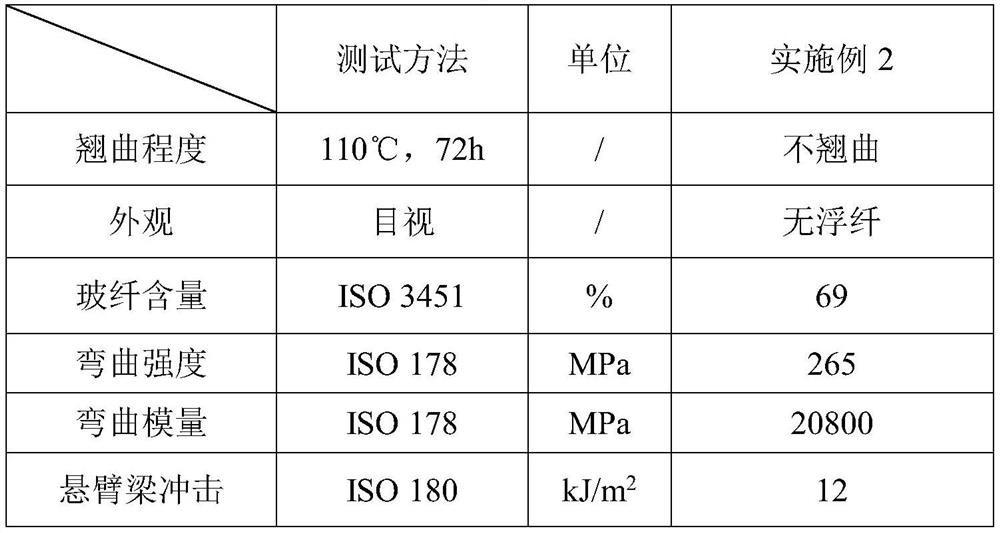

Flame-retardant glass fiber reinforced polyketone composite material capable of being used for vehicle fuel oil system

The present invention discloses a flame-retardant glass fiber reinforced polyketone composite material capable of being used for a vehicle fuel oil system, wherein 100 parts by weight of polyketone is added with 60-150 parts by weight of glass fibers having a flat cross-section shape, 5-30 parts by weight of a phosphorus-based flame retardant agent, and 0-5 parts by weight of other auxiliary agents. According to the present invention, the polyketone composite material has advantages of high strength and high rigidity, and can be used in engine covers, fuel oil tanks, fuel oil pipes and other products having high requirements on chemical resistance, hydrolysis resistance, fuel oil resistance and rigidity, wherein the product is easy to mold through the fluidity of the composition, and the floating fiber can be reduced.

Owner:5ELEM HI TECH CORP

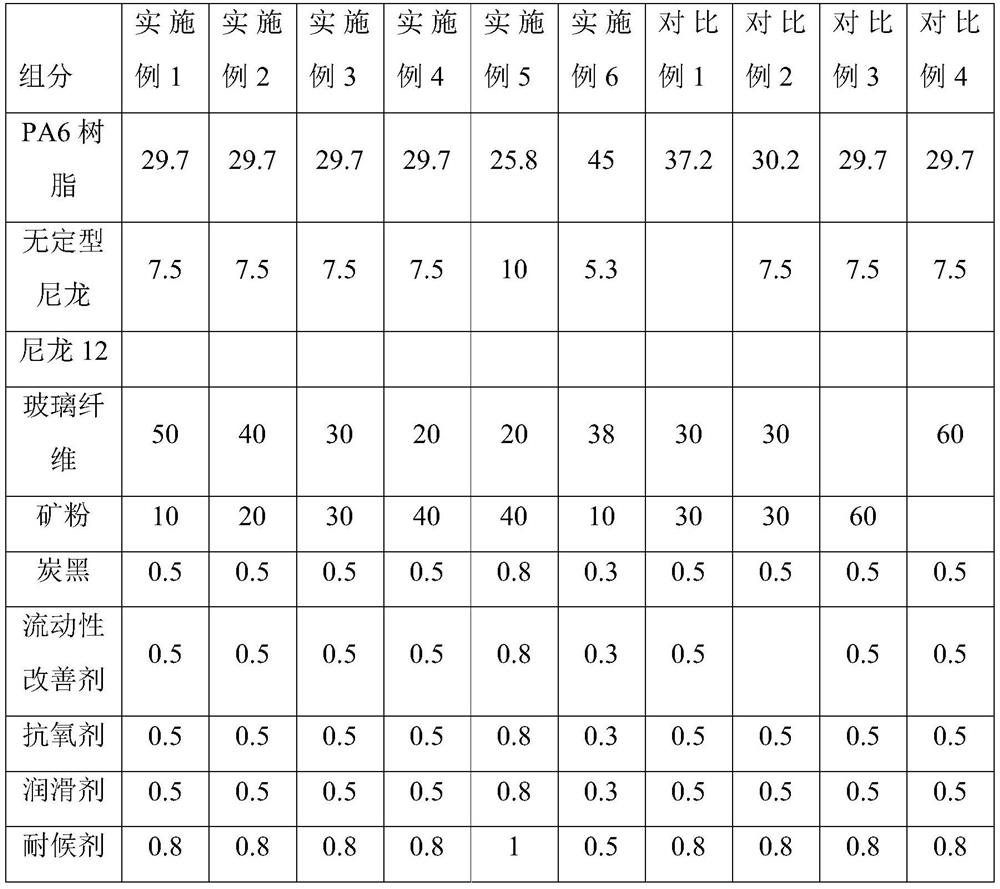

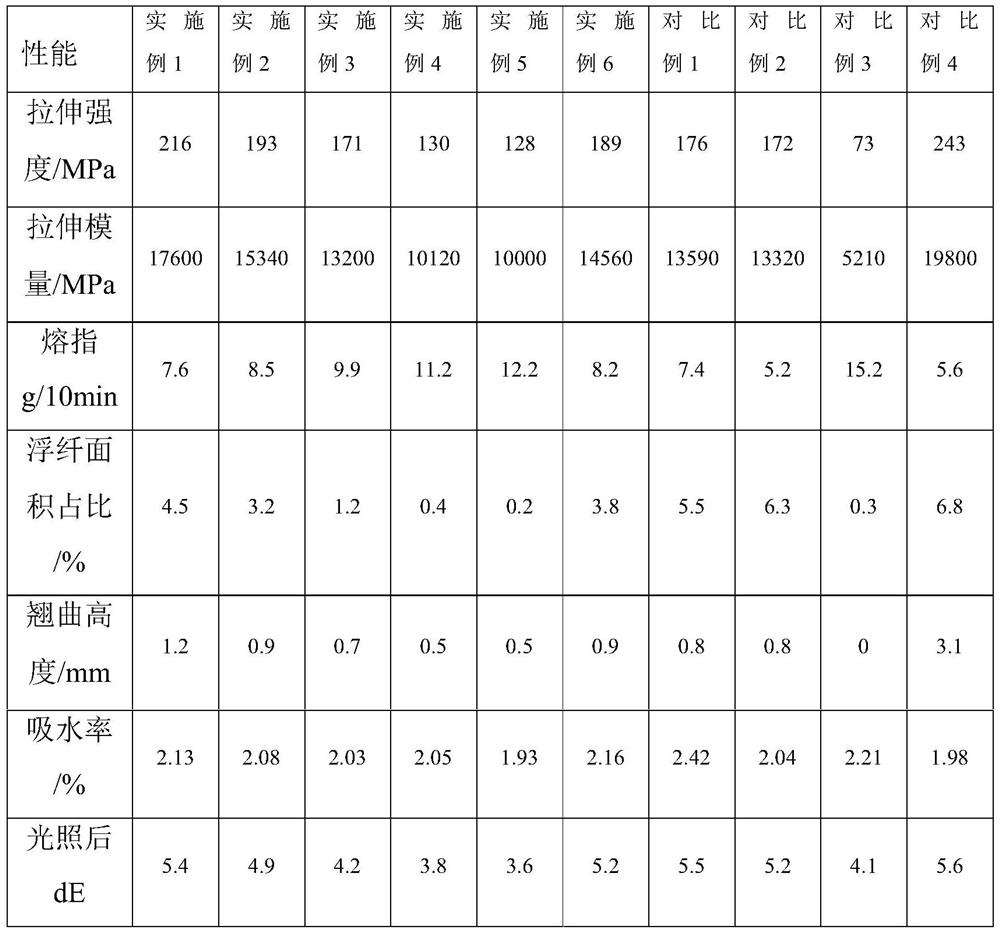

Ultrahigh-strength, low-warping and low-floating-fiber PA reinforced material and preparation process thereof

The invention provides an ultrahigh-strength, low-warpage and low-floating-fiber PA (polyamide) reinforced material. The ultrahigh-strength, low-warpage and low-floating-fiber PA reinforced material is prepared from 20-40 parts of PA6, 55-80 parts of glass fibers, 2-8 parts of mineral powder, 2-8 parts of a functional compatilizer, 0.2-0.6 part of a lubricant and 0.2-1.5 parts of an antioxidant, the functional compatilizer is a maleic anhydride grafted ethylene-octylene copolymer, a maleic anhydride grafted ethylene-propylene copolymer or a maleic anhydride grafted ethylene propylene diene monomer; the PA6 comprises PA6 with a high melt index and PA6 with a low melt index, the melt indexes of the PA6 with the high melt index are 70-100 g / 10 min and 30-50 g / 10 min respectively, the proportion of the PA6 with the high melt index is 40-50%, and the proportion of the PA6 with the low melt index is 40-60%. According to the invention, the ultrahigh glass fiber content (greater than 60%) provides excellent performances such as higher mechanical strength, heat resistance, dimensional stability and the like for the PA reinforced material, and also overcomes the defects of high warping, high floating fiber, low gloss and the like caused by high-content fibers.

Owner:广州仕天材料科技有限公司

High-toughness low-floating-fiber ABS resin composition and preparation method and application thereof

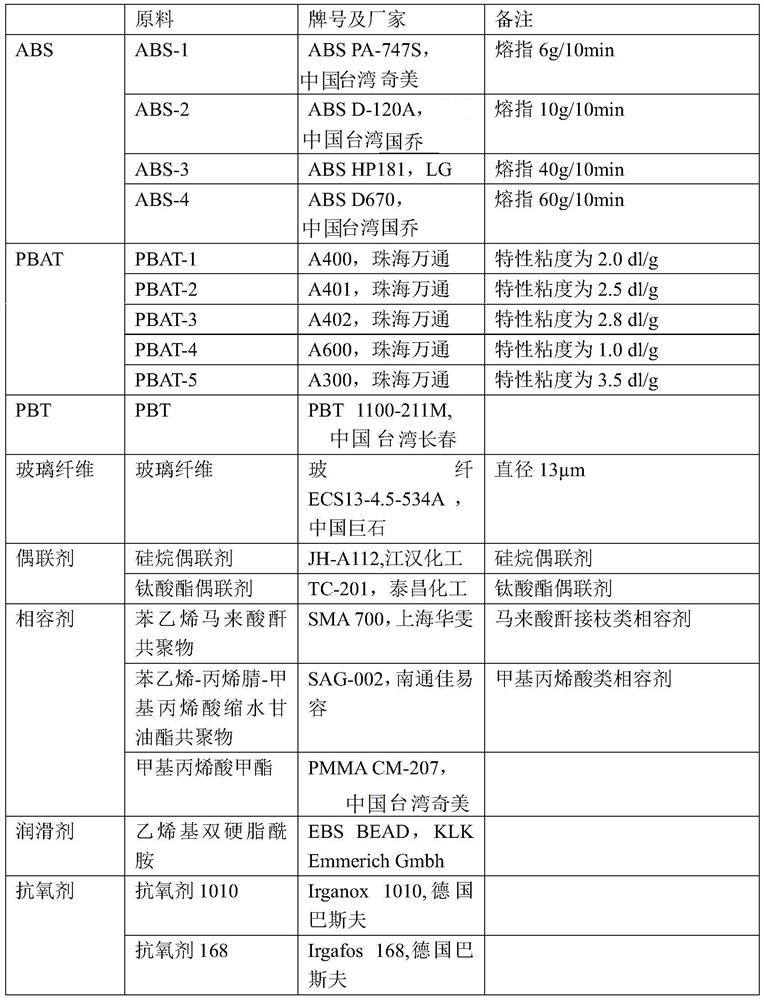

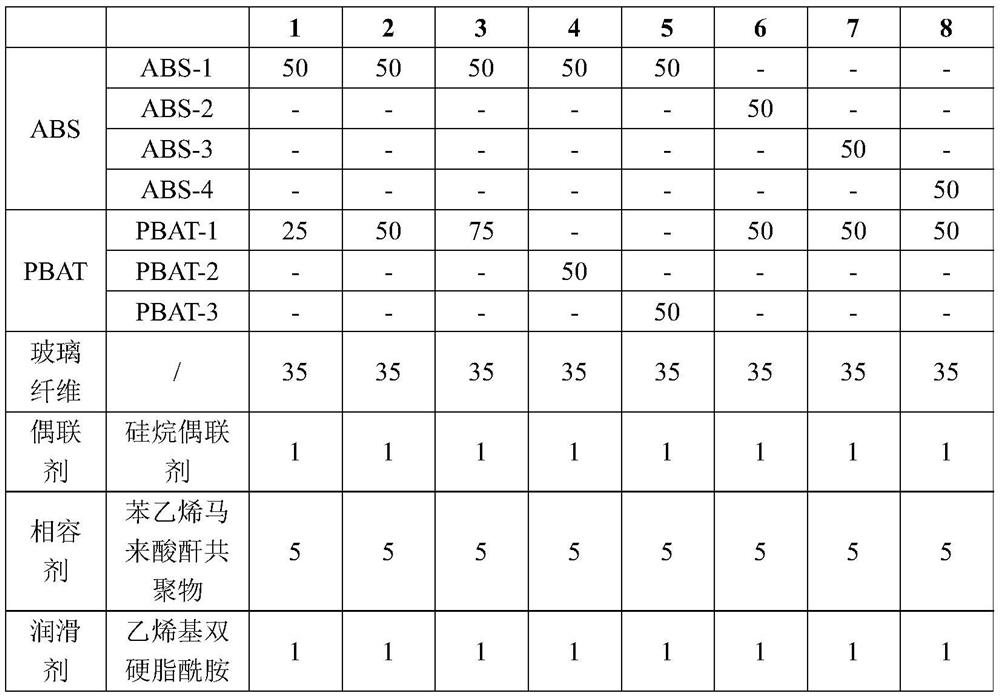

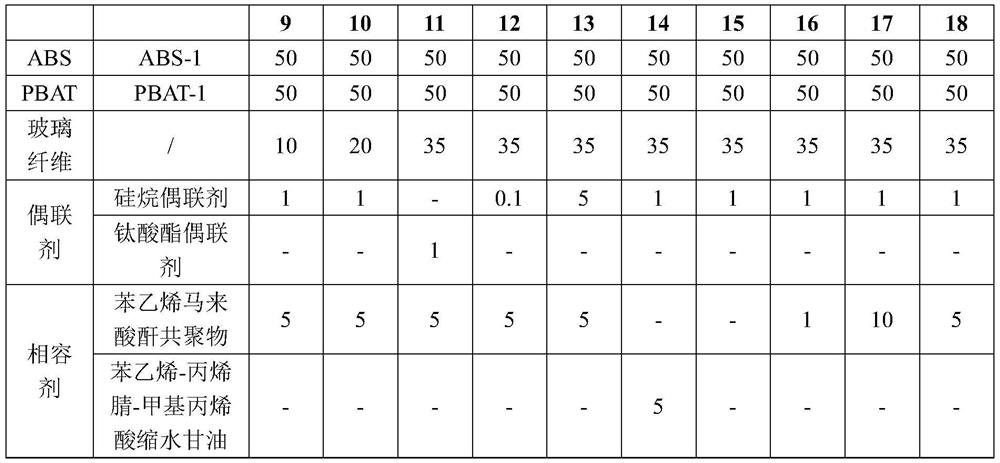

The invention discloses a high-toughness low-floating-fiber ABS resin composition. The ABS resin composition is characterized by comprising the following components: an acrylonitrile-butadiene-styrene copolymer, poly(butylene adipate-co-terephthalate), glass fibers, a compatilizer, a coupling agent, a lubricant and a processing aid, wherein the intrinsic viscosity of poly(butylene adipate-co-terephthalate) resin is 2.0 to 2.8 dl / g. According to the invention, a specific type of PBAT is added into an ABS resin matrix and cooperates with the compatilizer, the lubricant and the coupling agent, so the ABS resin composition with high toughness and low floating fiber content is obtained under the condition that the ABS resin composition contains the glass fibers. Under the condition that 30 wt% of the glass fibers is added, no obvious floating fiber exists on the surface of the ABS resin composition, and notch impact strength can reach 15KJ / m<2>.

Owner:KINGFA SCI & TECH CO LTD +1

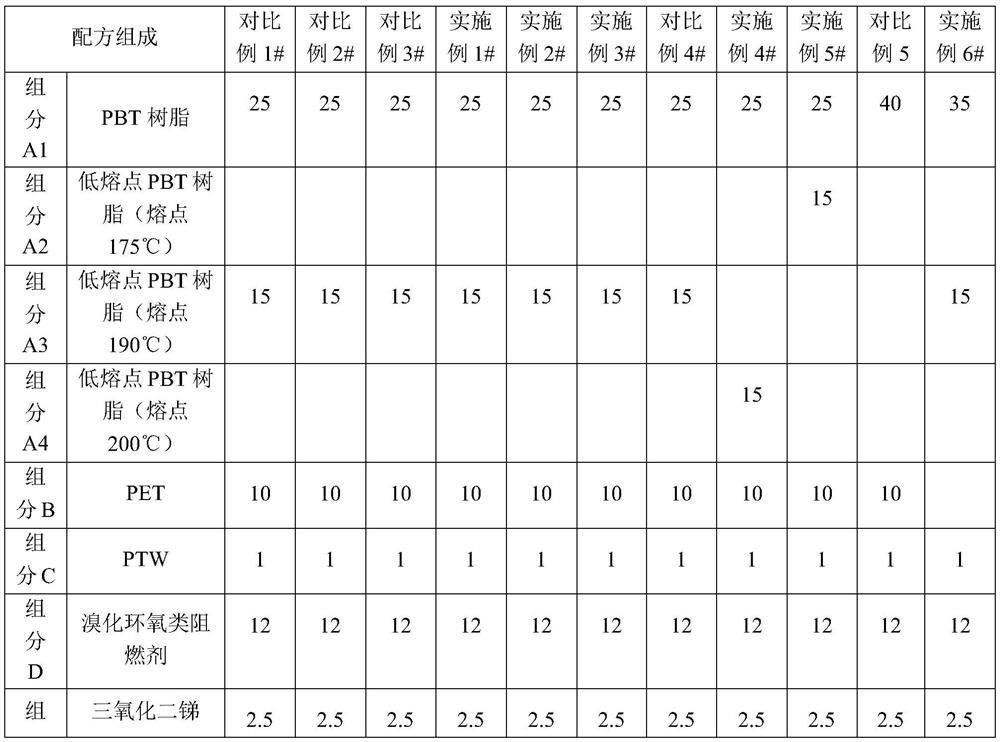

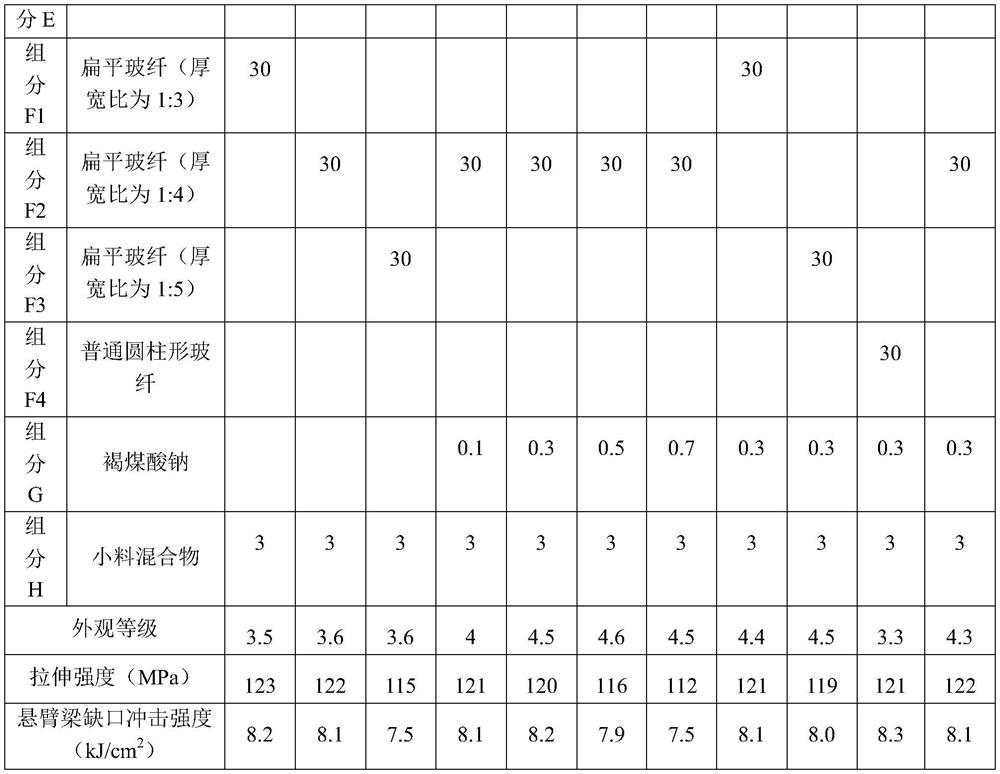

Glass fiber reinforced polybutylene terephthalate composition with low floating fiber effect

InactiveCN111909492AExcellent low floating fiber synergistic effectReduce floating fiberPolytetramethylene terephthalateGlass fiber

The invention relates to a glass fiber reinforced polybutylene terephthalate composition with a low floating fiber effect. A PBT resin is used as a base material, PET resin is used as an auxiliary base material, flat glass fiber is used as a reinforcing unit and sodium lignite is used as a floating fiber improving synergist, the low-melting-point PBT resin, the flat glass fiber and the sodium lignite have an excellent low-floating-fiber synergistic effect, and a prepared product is high in strength, high in surface gloss, less in floating fiber and good in mechanical property. Therefore, the use requirements of most appearance workpieces can be met.

Owner:JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD +1

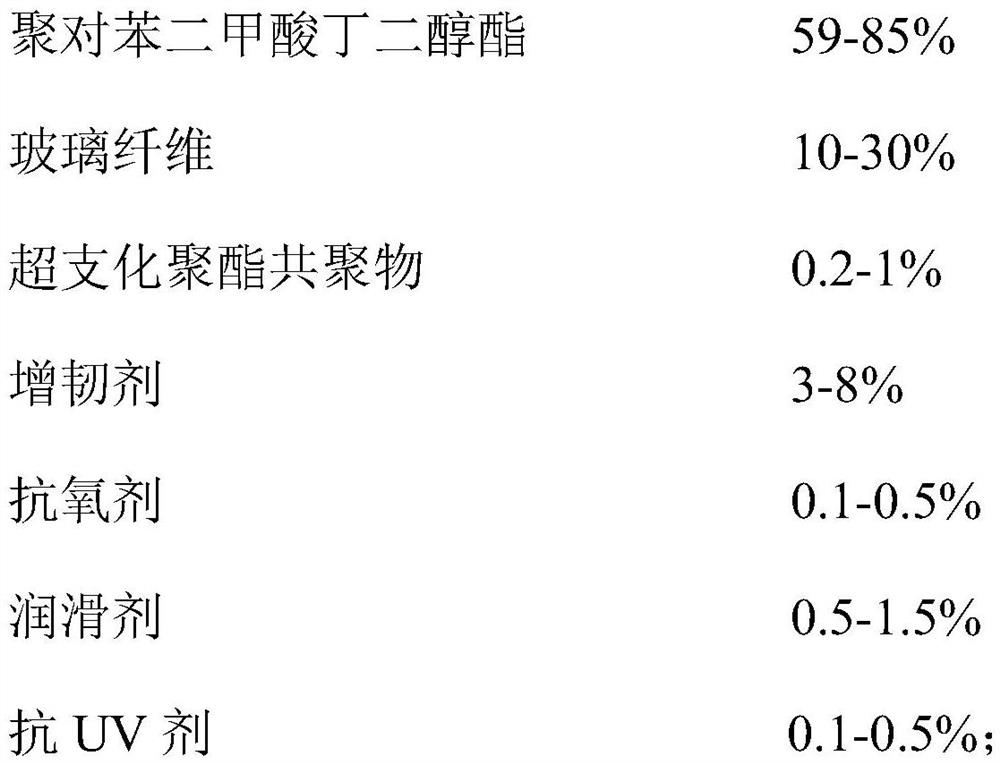

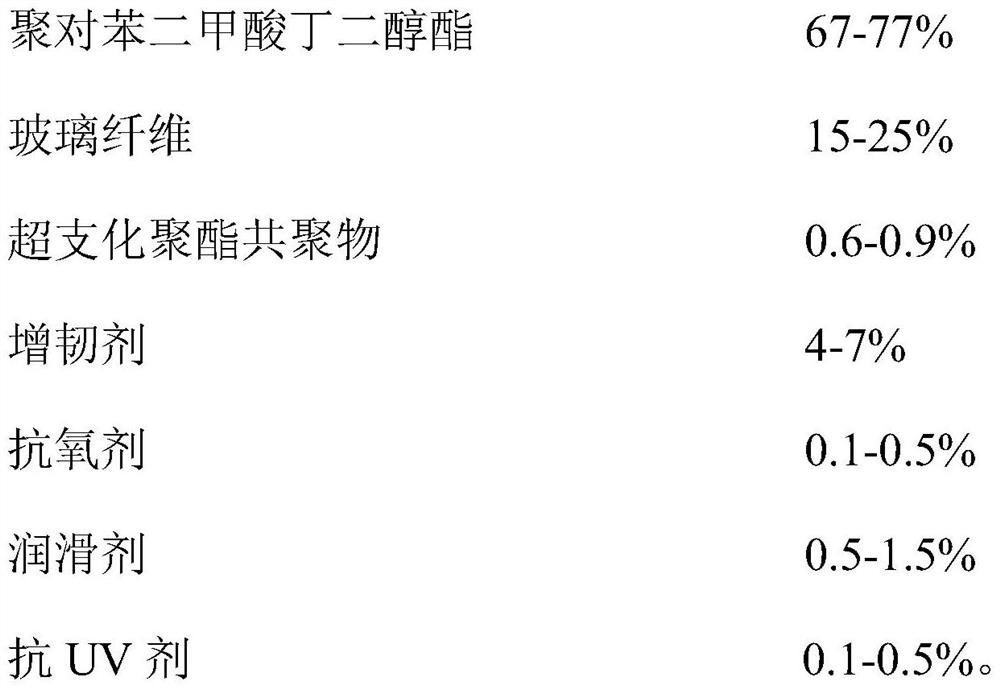

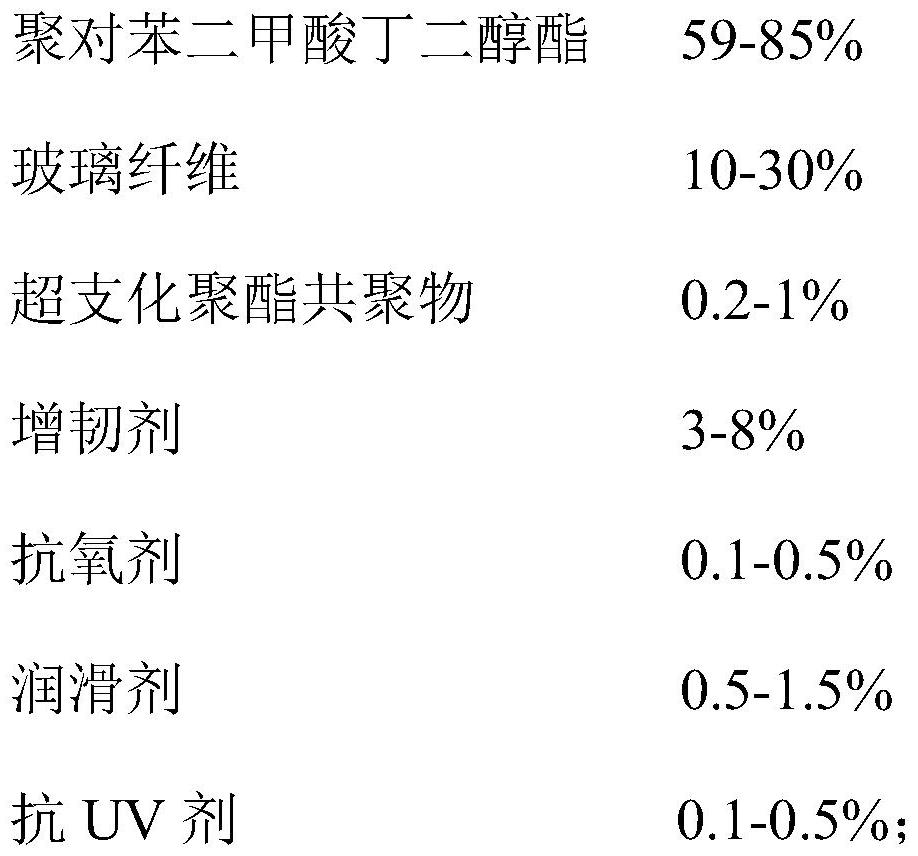

Spraying-free polybutylene terephthalate fiber-added composite material and preparation method thereof

The invention provides a spraying-free polybutylene terephthalate fiber-added composite material and a preparation method thereof. The spraying-free polycarbonate fiber-added composite material is prepared from the following raw materials in percentage by weight: 59-85 percent of polybutylene terephthalate, 10-30 percent of glass fiber, 0.2-1 percent of hyperbranched polyester copolymer, 3-8 percent of toughening agent, 0.1-0.5 percent of antioxidant, 0.5-1.5 percent of lubricating agent and 0.1-0.5 percent of anti-UV (Ultraviolet) agent. The hyperbranched polyester copolymer is a copolymer ofcarboxyl-containing hyperbranched polyester acrylate and glycidyl methacrylate; The carboxyl-containing hyperbranched polyester acrylate is obtained by modifying hyperbranched polyester with butanedioic anhydride, hexamethylene diisocyanate and hydroxyethyl acrylate. The spraying-free polybutylene terephthalate fiber-added composite material has the advantages of low floating fiber on the surface, high gloss, high hardness, excellent mechanical properties, excellent heat resistance and the like.

Owner:深圳市中塑新材料有限公司

Glass fiber reinforced polypropylene composition and preparation method thereof

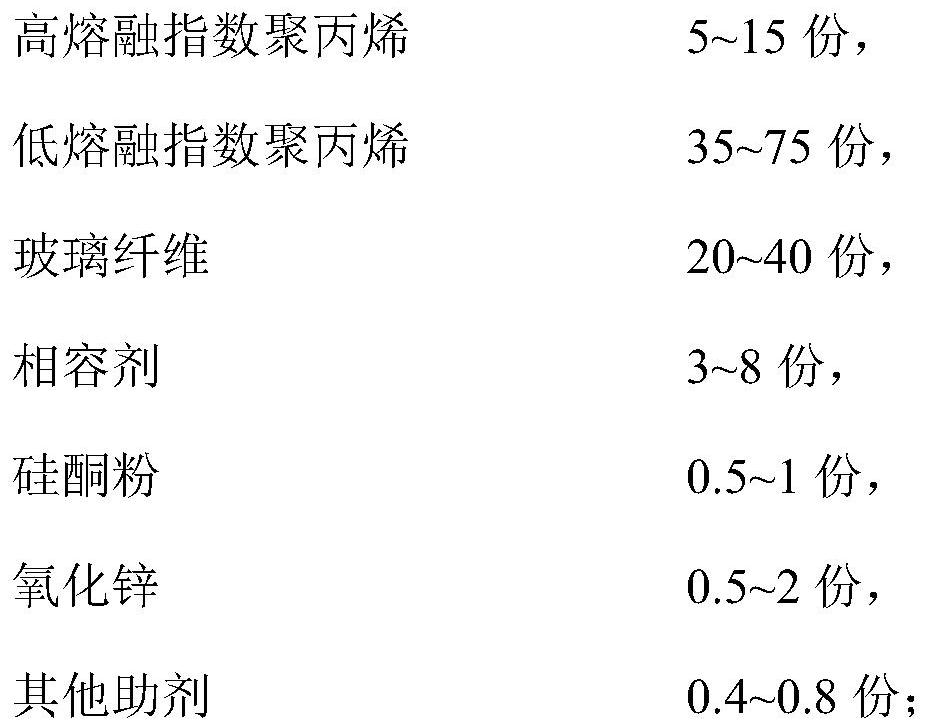

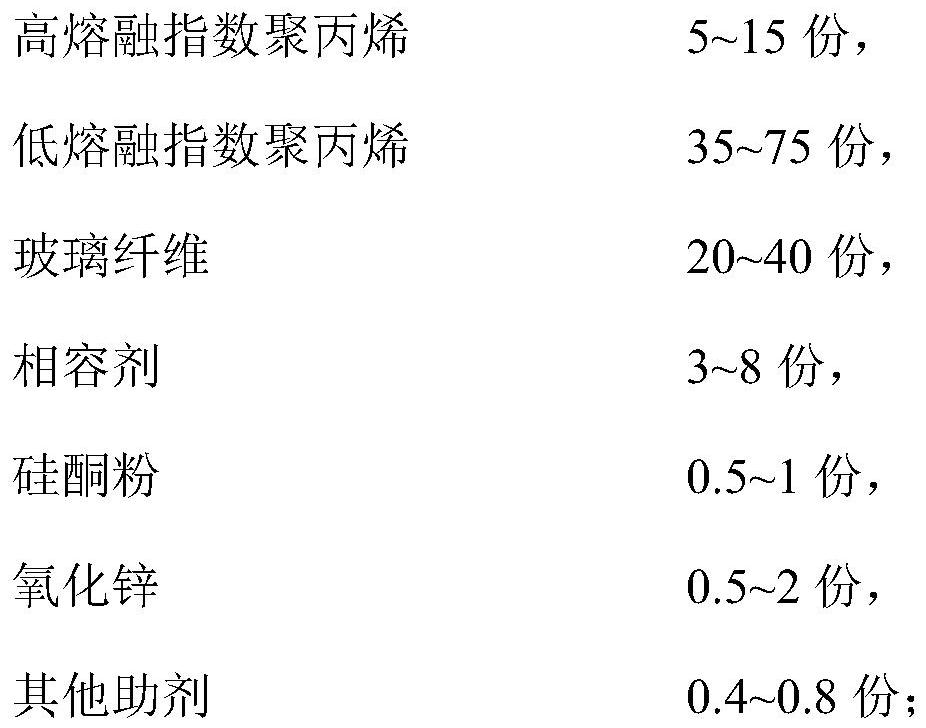

The invention discloses a glass fiber reinforced polypropylene composition and a preparation method thereof. The glass fiber reinforced polypropylene composition is prepared from the following components in parts by weight: 5-15 parts of high-melt-index polypropylene, 35-75 parts of low-melt-index polypropylene, 20-40 parts of glass fibers, 3-8 parts of a compatilizer, 0.5-1 part of silicone powder, 0.5-2 parts of zinc oxide and 0.4-0.8 parts of other assistants, wherein the melt index of the high-melt-index polypropylene under the conditions of the temperature of 230 DEG C and the load of 2.16 kg is 100-200 g / 10 min, and the melt index of the low-melt-index polypropylene under the conditions of the temperature of 230 DEG C and the load of 2.16 kg is 1-10 g / 10 min. The glass fiber reinforced polypropylene composition disclosed by the invention has excellent properties of high strength, high rigidity, dimensional stability and low floating fiber.

Owner:HEFEI GENIUS NEW MATERIALS

Modified polypropylene composite material with high wear resistance and preparation method of modified polypropylene composite material

InactiveCN107501727AHigh Rockwell hardnessImproved finger scratch resistanceGlass fiberPolypropylene composites

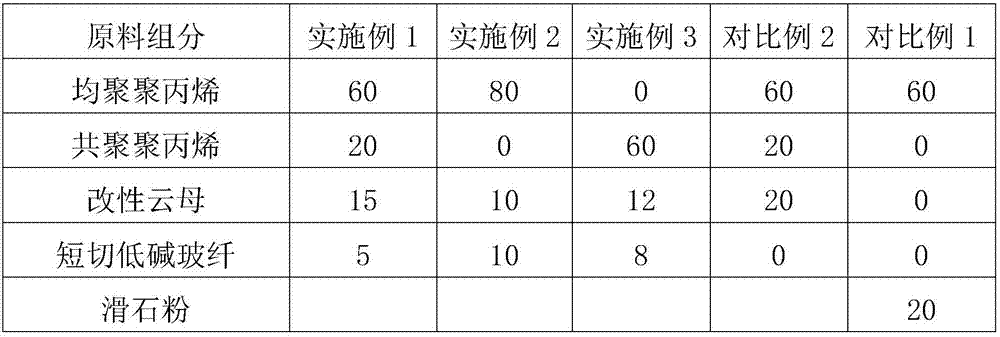

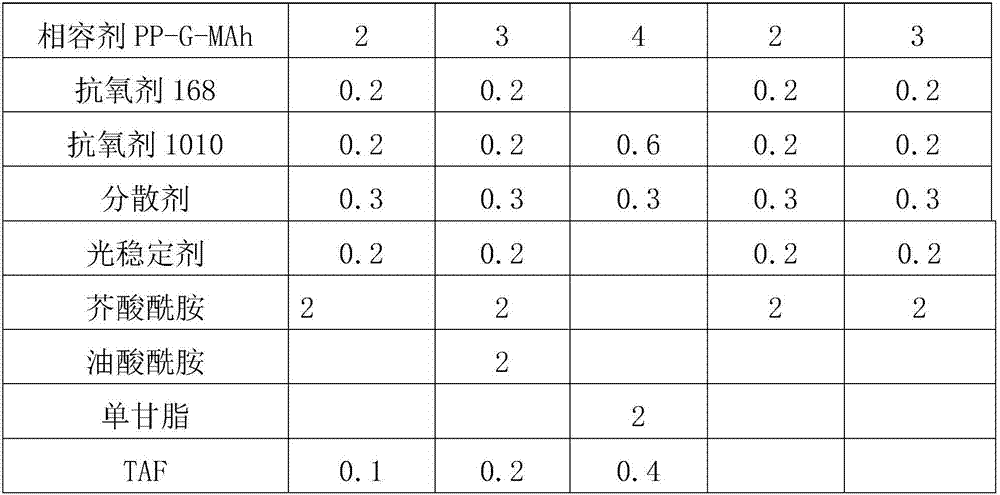

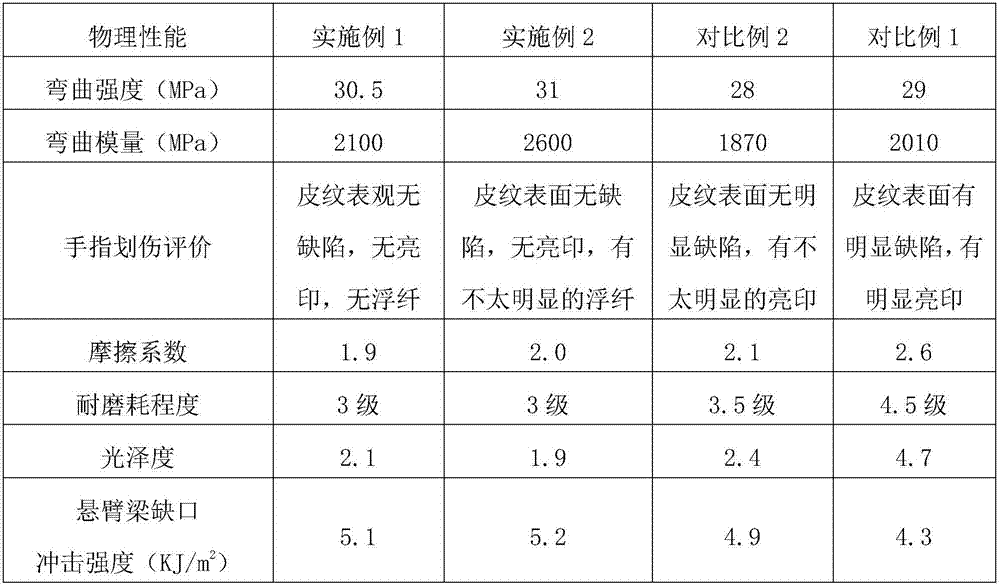

The invention discloses a modified polypropylene composite material with high wear resistance. The modified polypropylene composite material is prepared from raw materials in parts by weight as follows: 60-75 parts of polypropylene, 10-15 parts of modified mica, 5-10 parts of glass fibers, 2-4 parts of a compatilizer, 2 parts of a surface slipping agent, 0.2-0.4 parts of a surface floating fiber resisting auxiliary and 0.9 parts of other auxiliaries. With addition of modified mica, the glass fibers, the compatilizer and the other auxiliaries, the dispersion condition of the modified mica and the glass fibers in a matrix is better, and the matrix is combined with the material more stably, so that finger scratching resistance of the material is improved; the finger scratching resistance of the surface of the composite material is excellent, the surface has no obvious change after being scratched, notch impact strength is higher than 5 KJ / m<2>, bending modulus is higher than 2000 MPa, and the use range of the material is wide.

Owner:ORINKO NEW MATERIAL CO LTD

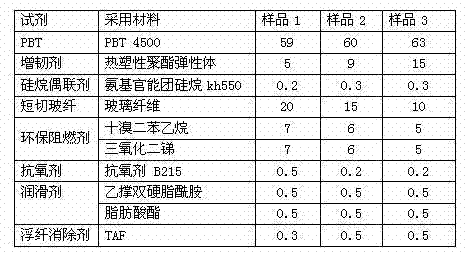

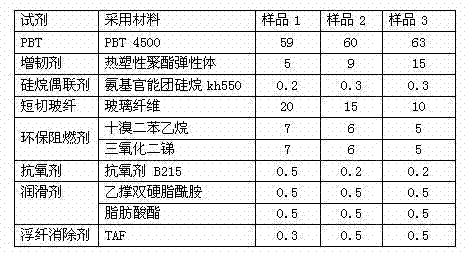

Low-floating fiber flame-retardant reinforced PBT (Polybutylece Terephthalate) composite material

The invention relates to a low-floating fiber flame-retardant reinforced PBT (Polybutylece Terephthalate) composite material, and belongs to the technical field of plastic modification. The material comprises the following components in percentage by weight: 55 to 70% of PBT, 5 to 15% of toughening agent, 0.2 to 0.5% of silane coupling agent, 10 to 20% of chopped glass fiber, 10 to 15% of environment-friendly fire retardant, 0.1 to 0.5% of antioxidant, 0.1 to 1% of lubricant, and 0.3 to 0.8% of floating fiber curing agent. The preparation method comprises the steps of mixing, extruding and injection molding. The prepared low-floating fiber flame-retardant reinforced PBT composite material has low floating fiber, fire retardance and reinforcement performance.

Owner:QINGDAO DADU NEW MATERIAL TECH

Low floating fiber flame-retardant reinforcing PBT (Polybutylece Terephthalate) composite material and preparation method thereof

The invention relates to the technical field of plastic modification, and particularly relates to a low floating fiber flame-retardant reinforcing PBT (Polybutylece Terephthalate) composite material and a preparation method thereof. The low floating fiber flame-retardant reinforcing PBT composite material comprises PBT, a toughening agent, a silane coupling agent, a chopped glass fiber, an environmental-friendly fire retardant, an antioxidant, a lubricating agent and a floating fiber remover, wherein the PBT accounts for 55%-70% of the total weight of a raw material in weight percentage, and the weight ratio of PBT to the toughening agent is (1-20):1. The preparation method comprises the steps of mixing, extrusion and injection moulding. The product prepared through the invention has the advantages of low floating fiber, fire retardance and reinforcement.

Owner:QINGDAO DADU NEW MATERIAL TECH

High-rigidity metal-like nylon composite material and preparation method thereof

The invention discloses a high-rigidity metal-like nylon composite material and a preparation method thereof. Raw materials include, by weight, 100 parts of nylon-610, 30-70 parts of nylon-6, 1-5 parts of an antioxidant, 1-5 parts of a lubricant, 1-5 parts of coupling agents, 30-100 parts of long glass fiber, and 70-450 parts of short glass fiber. According to the material formula, in the ultra-high filled composite material, the lubricant comprises a dendritic type nylon lubricant which can greatly reduce material degradation caused by shear heat, the compound of the dendritic nylon lubricantand zinc stearate has a strong complementation effect, use of the coupling agents can reduce floating fiber, and thus, mechanical performance of the composite material can be improved greatly.

Owner:DONGGUAN HONOUR E P

Glass fiber reinforced polyamide composition and its preparation method and application

The invention relates to a composition of a macromolecular compound, in particular to a glass fiber enhanced polyamide composition and a preparation method and application thereof. The glass fiber enhanced polyamide composition is prepared from polyamide 6 or polyamide 66, low-melting-point polyamide, aliphatic polyketone, alkali-free chopped glass fibers and POE-grafted maleic anhydride. By the adoption of unique formula design and a two-step extrusion process, the glass fiber enhanced polyamide composition with low melting point, high wear resistance, low floating fiber content and high size stability is prepared, and can be widely applied to the fields of automobiles, engineering structural members, electronic and electrical products and the like which have high appearance requirement and relatively high requirements on rigidity and toughness balance, wear resistance and size stability.

Owner:QINGDAO HAIER NEW MATERIAL R&D CO LTD

A kind of reinforced polypropylene material and its preparation method and application

The invention discloses a reinforced polypropylene material and a preparation method and application thereof, comprising: 30-70 parts of straight-chain polypropylene; 2-50 parts of long-chain branched polypropylene; 1-20 parts of a compatibilizer; 60 parts; 0.1-20 parts of fluorine compounds; the polypropylene material prepared by the invention has high surface gloss, good toughness and high melt strength, and is mainly suitable for blow molding and suction molding and other occasions.

Owner:KINGFA SCI & TECH CO LTD

A kind of modified polypropylene material and its preparation method and application

The invention discloses a modified polypropylene material and a preparation method and application thereof, comprising: a, 20-80 parts of polypropylene resin; b, 1-20 parts of a compatibilizer; c, 10-40 parts of reinforcing fibers ; The reinforcing fiber includes component I, component II and component III: component I: is composed of reinforcing fibers with a length of less than 0.1 mm, which accounts for 10-20% of the number of reinforcing fibers; component II : Consists of reinforcing fibers with a length of 0.1mm‑0.3mm, which account for 50‑75% of the reinforcing fibers; Component III: Consists of reinforcing fibers with a length of 0.4mm‑0.8mm, which account for 50‑75% of the reinforcing fibers The root percentage is 5‑40%. By controlling the length and content distribution of the reinforcing fibers in the modified polypropylene material, the invention has high surface gloss, less floating fibers, high elongation at break, Good toughness, which is conducive to testing such as falling balls; and high melt elongation, mainly suitable for blow molding and blister molding and other occasions.

Owner:KINGFA SCI & TECH CO LTD

Glass fiber reinforced polycarbonate composite material as well as preparation method and application thereof

ActiveCN113861654AImprove mechanical propertiesImprove technical defects of poor liquidityBio-packagingGlass fiberFiber

The invention discloses a glass fiber reinforced polycarbonate composite material which comprises the following components in parts by weight: 80 parts of polycarbonate; 50 to 100 parts of glass fibers; wherein the weight of the PBAT and / or PBSA is 0.01-0.3 time of the total weight of the glass fibers. According to the invention, by adding a certain amount of PBAT and / or PBSA, the technical defects that the glass fiber reinforced polycarbonate composite material highly filled with glass fibers is serious in fiber floating and easy to generate crazing due to poor fluidity of polycarbonate are improved, the defect of poor solvent resistance of polycarbonate is improved, and the mechanical properties can be well maintained.

Owner:SHANGHAI KINGFA SCI & TECH +1

A kind of glass fiber reinforced polypropylene composition and preparation method thereof

The invention discloses a glass fiber reinforced polypropylene composition and a preparation method thereof, which comprises 5-15 parts of high-melt-index polypropylene, 35-75 parts of low-melt-index polypropylene, 20-40 parts of glass fiber, 3~8 parts, 0.5~1 part of silicone powder, 0.5~2 parts of zinc oxide and 0.4~0.8 parts of other additives are prepared according to parts by weight; wherein, the high melt index polypropylene is prepared at a temperature of 230°C and a load of 2.16 The melt index under the condition of kg is 100-200g / 10min, and the melt index of the low melt index polypropylene under the condition of a temperature of 230°C and a load of 2.16kg is 1-10g / 10min. The glass fiber-reinforced polypropylene composition of the invention has excellent performances of high strength, high rigidity, dimensional stability and low floating fiber.

Owner:HEFEI GENIUS NEW MATERIALS

Low floating fiber high gloss glass fiber reinforced polypropylene composite material and preparation method thereof

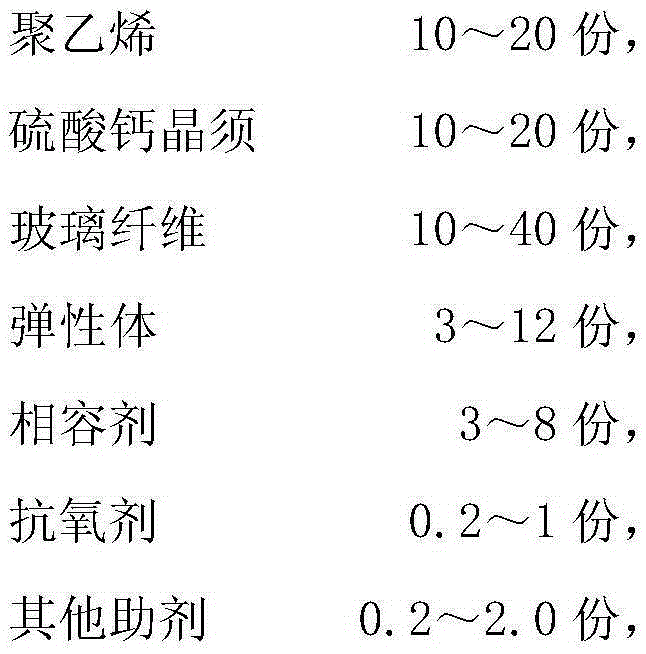

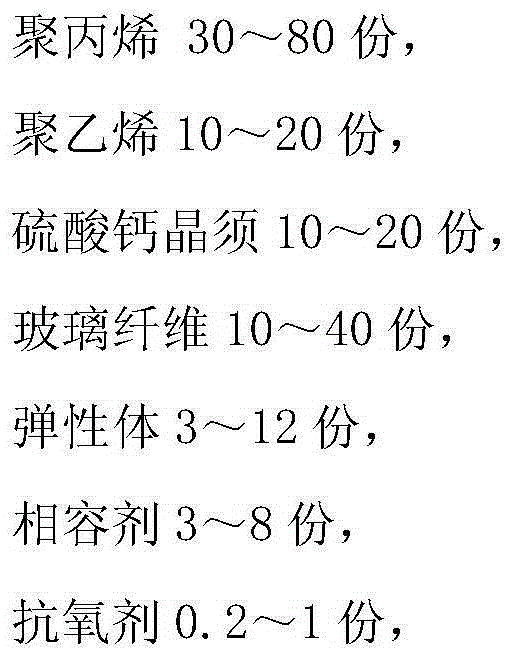

The invention provides a low-revealed high-gloss glass fiber reinforced polypropylene composite material and a preparation method thereof. The composite material comprises the following components in parts by weight: 30-80 parts of polypropylene, 10-20 parts of polyethylene, 10-20 parts of calcium sulfate whiskers, 0-40 parts of glass fibers, 3-12 parts of an elastomer, 3-8 parts of a compatilizer, 0.2-1 part of an antioxidant and 0.2-2.0 parts of other aids, wherein the particle size of the calcium sulfate whiskers is 3-15 microns, and the elastomer is one or a mixture of two of a thermoplastic elastomer and a thermosetting elastomer. The invention further relates to the preparation method of the composite material. According to the composite material, the glass fibers are partially replaced with the calcium sulfate whiskers, so that the inherent strength of the composite material is kept, the usage amount of the glass fibers is reduced, revealed fibers are reduced, and the surface gloss of the material is improved.

Owner:SHANGHAI SUNNY

Low floating fiber antiflaming reinforced PBT (polybutylece terephthalate) composite material

The invention relates to the technical field of plastic modification, and particularly relates to a low floating fiber antiflaming reinforced PBT (polybutylece terephthalate) composite material. The material comprises PBT, flexibilizer, silicon coupling agent, chopped glass fiber, environment-friendly fire retardant, antioxidant, lubricant and floating fiber remover, wherein the PBT accounts for 55-70 weight percent of the total amount of the raw material, and the weight ratio of the PBT to flexibilizer is (1-20):1. A preparation method of the material comprises steps of mixing, extruding and injection moulding. The product prepared by the method has low floating fiber, is inflaming retarding and is reinforced.

Owner:QINGDAO DADU NEW MATERIAL TECH

Low-emission, low-floating-fiber, low-warping and ultra-dispersed long glass fiber polyamide composite material and preparation method thereof

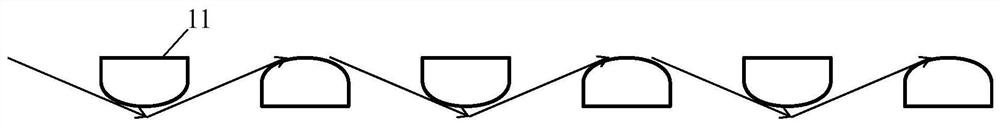

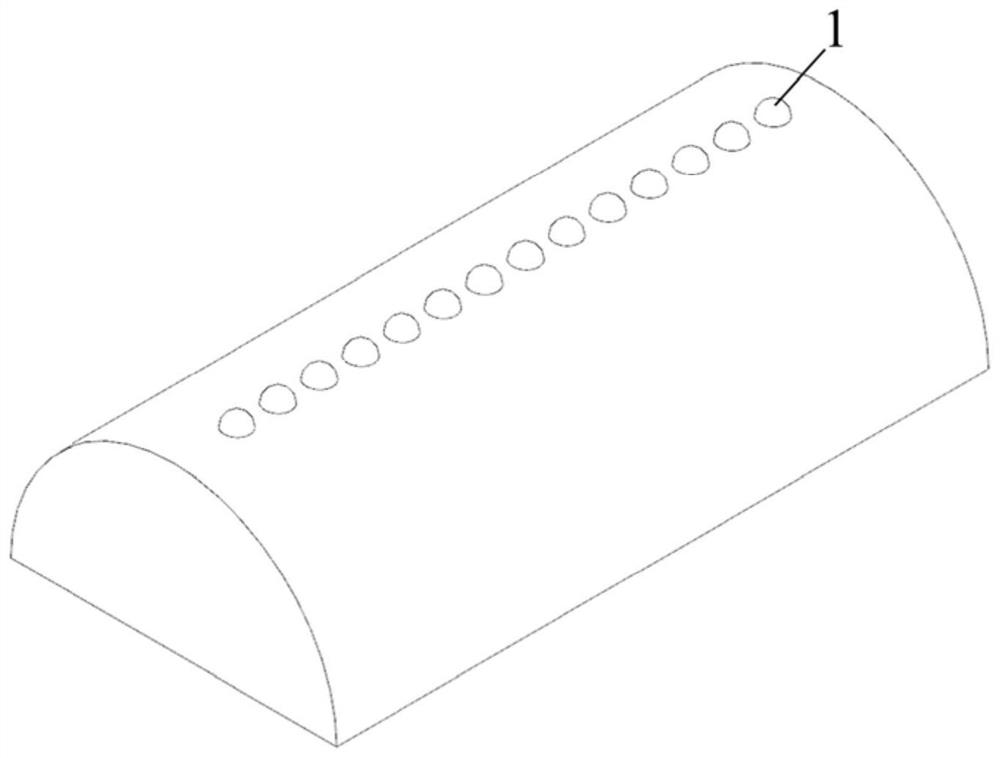

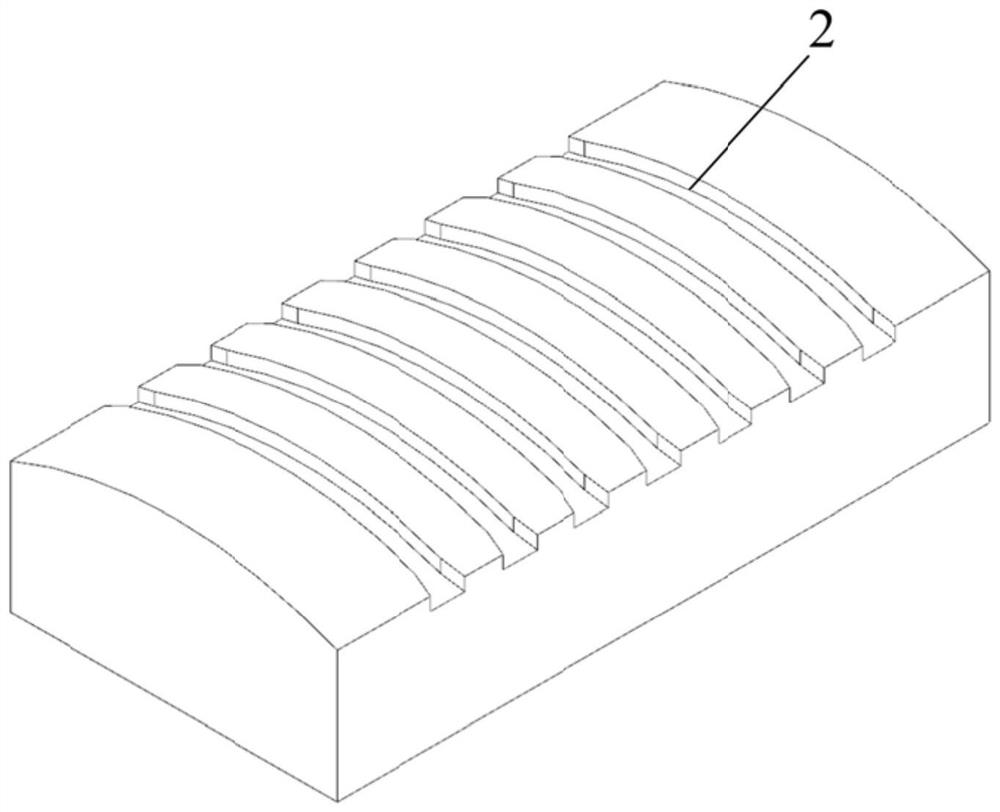

The invention discloses a low-emission, low-floating-fiber, low-warping and ultra-dispersed long glass fiber polyamide composite material and a preparation method thereof. The preparation method comprises the following steps: uniformly mixing all the raw materials except long glass fibers, and adding the mixture into a double-screw extruder from a main feeding hopper; enabling the long glass fibers to penetrate through a fiber adding hole; and performing melt impregnation extrusion in the double-screw extruder to obtain the low-emission, low-floating-fiber, low-warping and ultra-dispersed long glass fiber polyamide composite material. A melt impregnation section in the double-screw extruder is provided with a plurality of sequentially-arranged infiltration type extrusion compression bar groups; each infiltration type extrusion compression bar group comprises two compression bars which have opposite cambered surfaces and are arranged in a staggered mode; the cambered surfaces of the compression bars with the downward cambered surfaces are provided with a plurality of protrusions arranged and distributed in the direction perpendicular to the moving direction of the long glass fibers; and a plurality of grooves which are arranged and distributed in the direction perpendicular to the moving direction of the long glass fibers are formed in the cambered surfaces of the compression bars with the upward cambered surfaces.

Owner:中广核俊尔(浙江)新材料有限公司 +1

PC/ABS composition with ESD (Electro-Static Discharge) function and application thereof

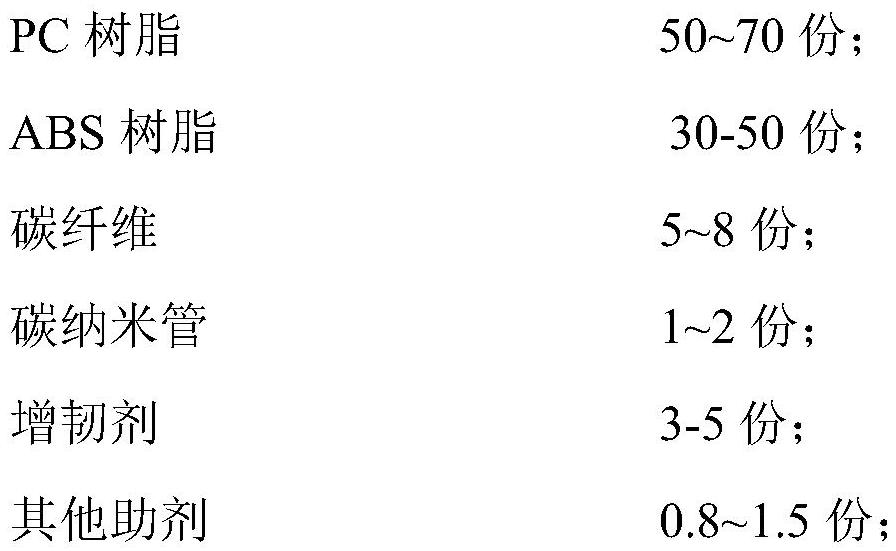

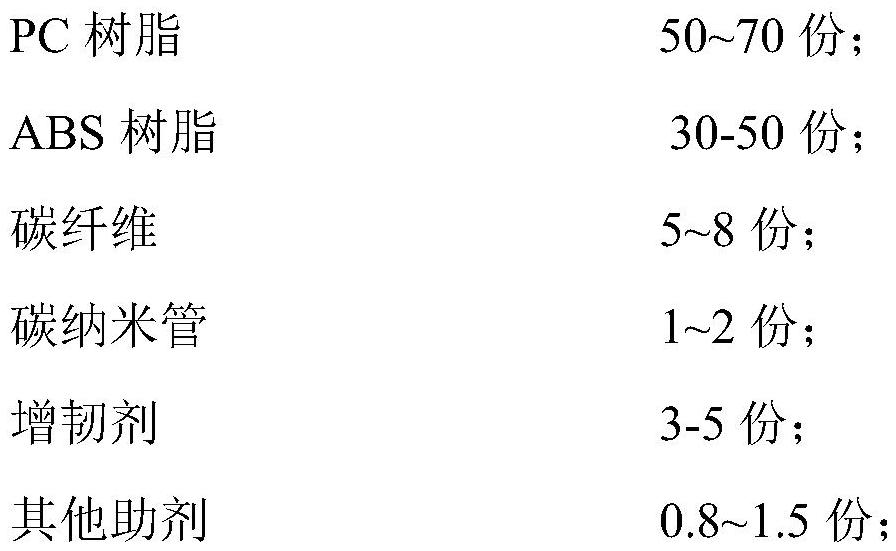

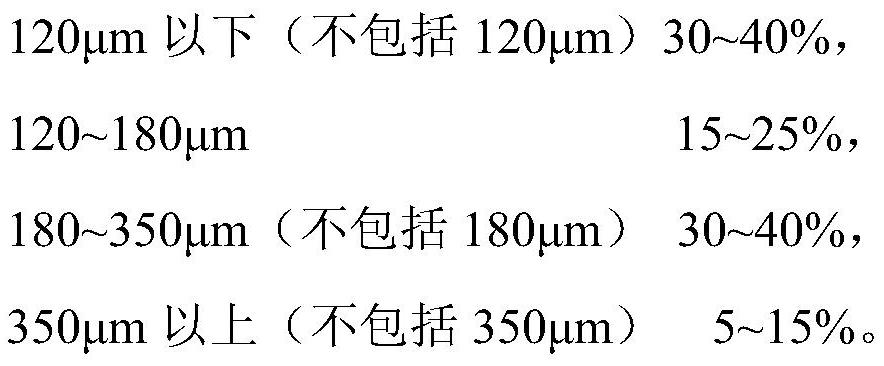

The invention discloses a PC (polycarbonate) / ABS (acrylonitrile butadiene styrene) composition with an ESD (electro-static discharge) function and application thereof. The PC / ABS composition with the ESD function is prepared from the following components: PC resin, ABS resin, carbon fibers, carbon nanotubes, a toughening agent and other auxiliaries, the length distribution of the carbon fibers comprises the following components in percentage by weight: 30-40% of carbon fibers with the particle size of less than 120 microns (not including 120 microns), 15-25% of carbon fibers with the particle size of 120-180 microns, 30-40% of carbon fibers with the particle size of 180-350 microns (not including 180 microns) and 5-15% of carbon fibers with the particle size of more than 350 microns (not including 350 microns). The PC / ABS composition with the ESD function is prepared through the synergistic effect of the carbon fibers with specific length distribution and the carbon nanotubes with a very small addition amount, the melt viscosity is proper, and the surface has low floating fibers.

Owner:KINGFA SCI & TECH CO LTD

Low-floating fiber flame-retardant reinforced PBT (Polybutylece Terephthalate) composite material and preparation method thereof

Owner:QINGDAO DADU NEW MATERIAL TECH

A kind of high rigidity imitation metal nylon composite material and preparation method thereof

The invention discloses a high-rigidity metal-like nylon composite material and a preparation method thereof. The raw materials include the following components in parts by weight: nylon 610 100; nylon 6 30-70; antioxidant 1-5; lubricant 1-5 ; Coupling agent 1‑5; Long glass fiber 30‑100; Short glass fiber 70‑450. In terms of material formulation of the present invention, the ultra-highly filled composite material includes dendritic nylon lubricant in the lubricant, which can greatly reduce the material degradation caused by shear heat. In addition, dendritic nylon lubricant and zinc stearate The combination of the two can play a strong complementary effect. The use of the formula coupling agent can reduce the floating fiber and greatly improve the mechanical properties of the material.

Owner:DONGGUAN HONOUR E P

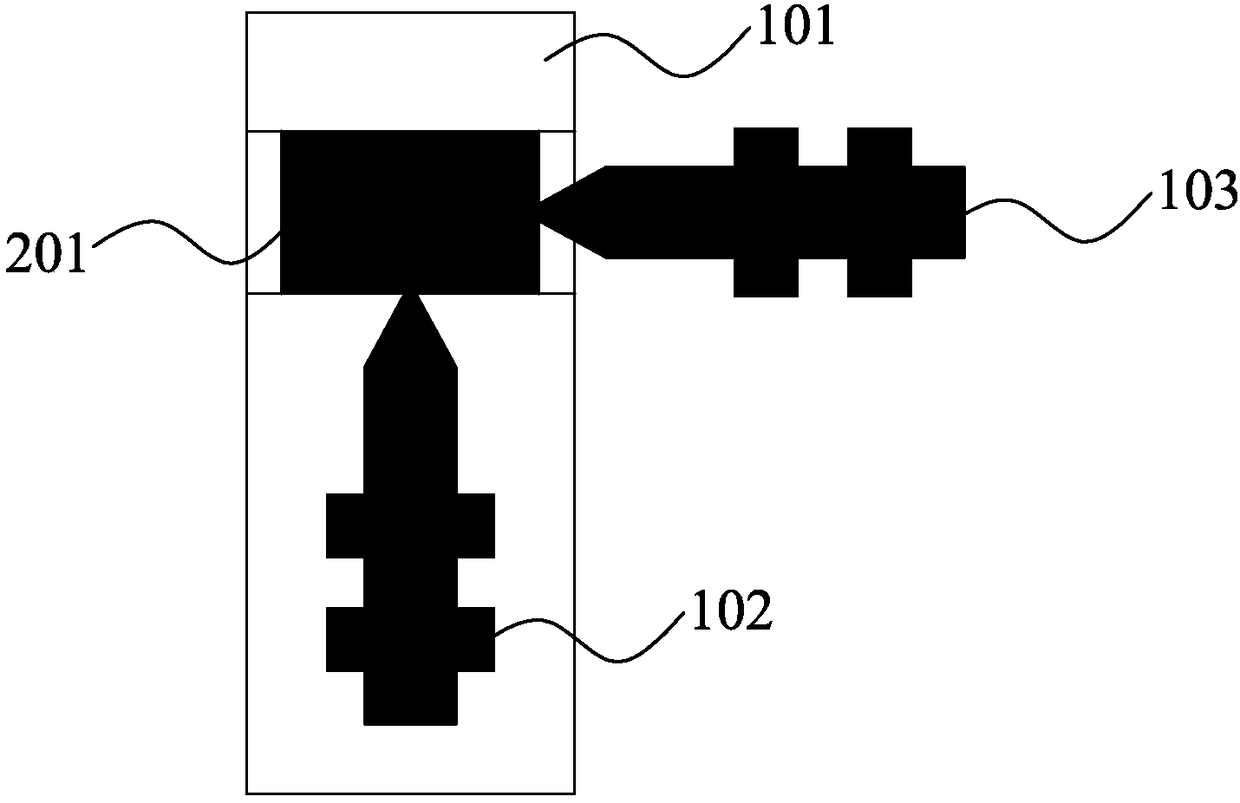

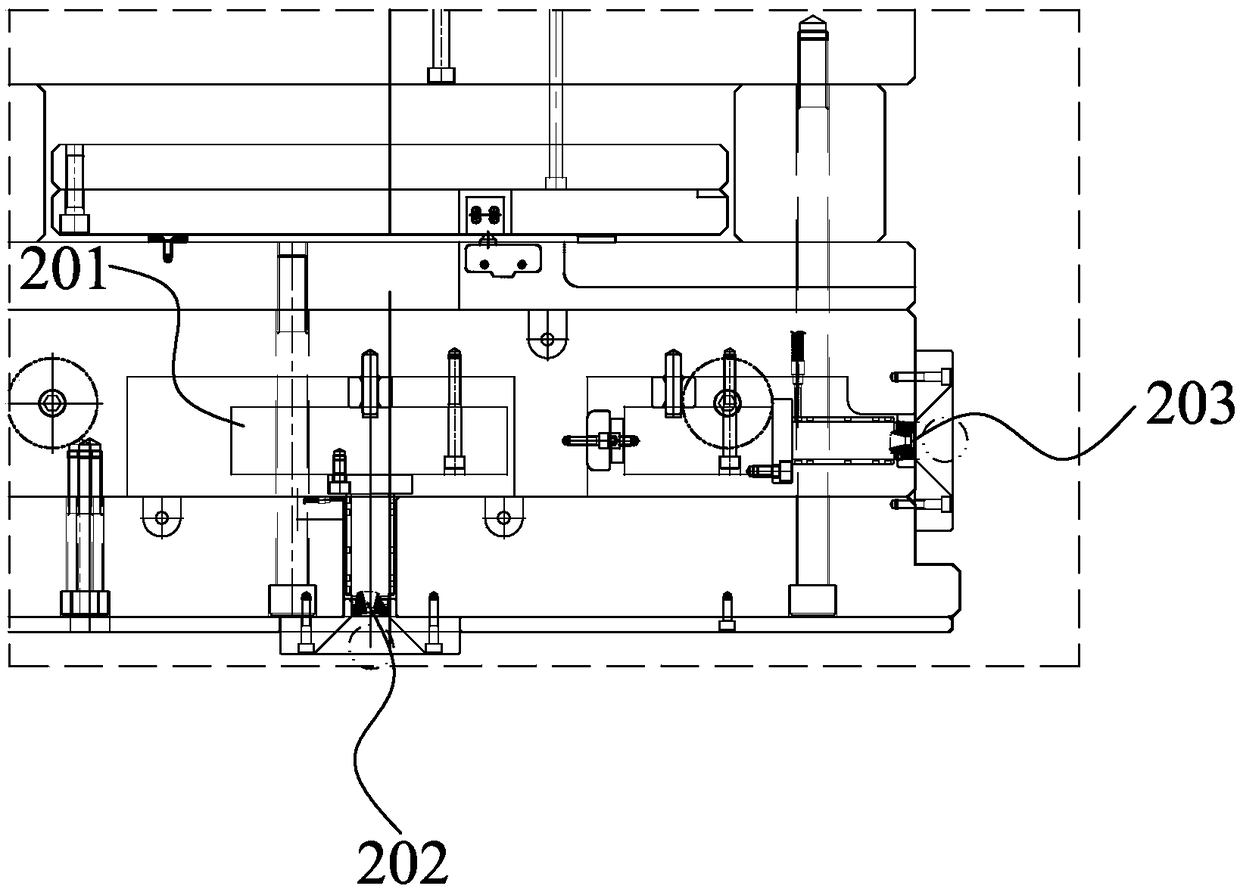

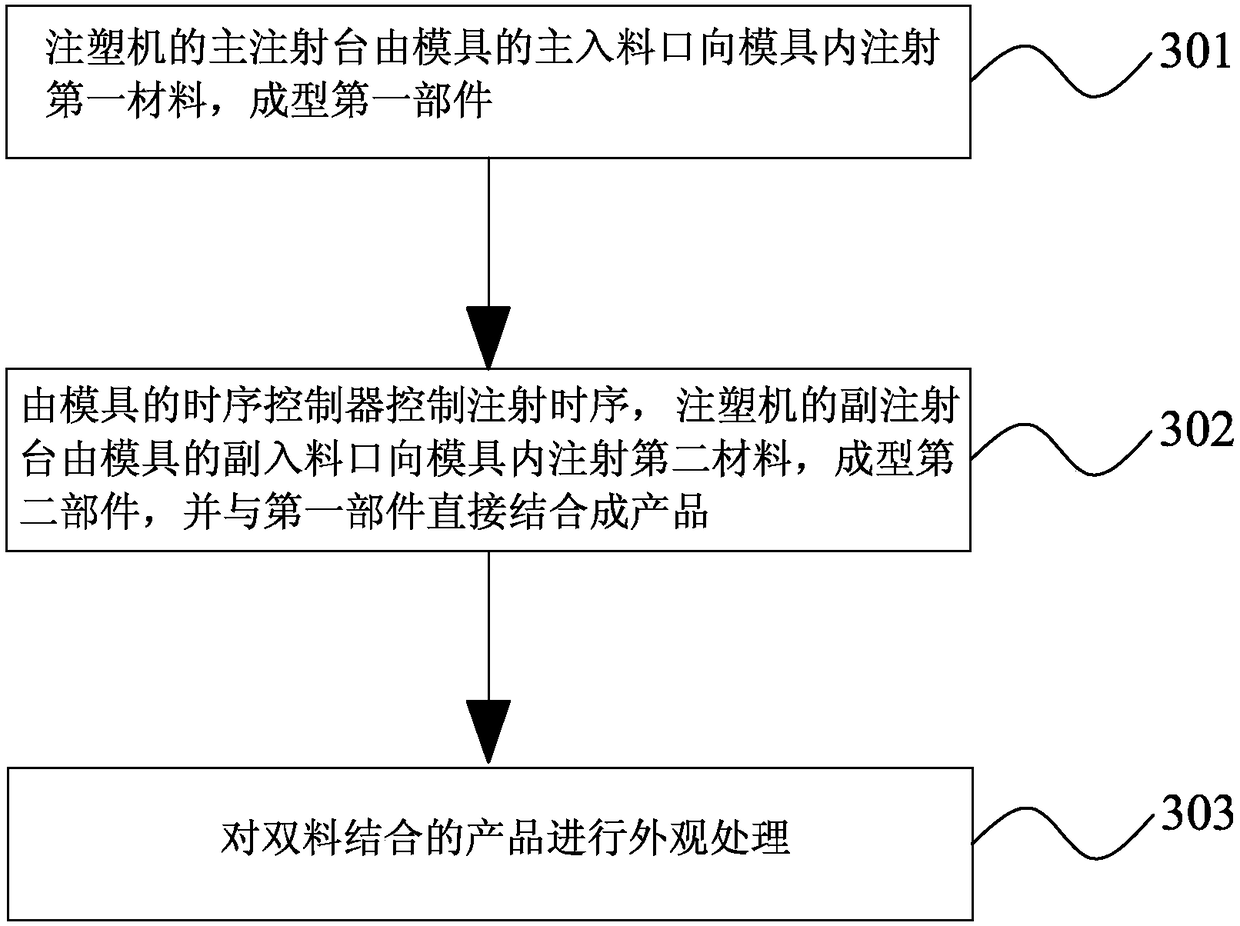

Two-material bonding apparatus, two-material bonding method and two-material bonding product

InactiveCN108454000AQuality improvementMeet diverse mass production needsDomestic articlesInjection molding machineWork time

The invention discloses a two-material bonding apparatus, a two-material bonding method and a two-material bonding product. The two-material bonding apparatus comprises: an injection molding machine,wherein the injection molding machine has a main injection table and a sub injection table, and the main injection table and the sub injection table are used for respectively injecting a first material and a second material to mold the first component and the second component of a product; a mold having a main material inlet and a sub material inlet, wherein the first component and the second component are molded in the mold and are directly combined into the product; and a mold temperature variable controller, wherein the mold further has a timing controller. The two-material bonding method comprises that the main injection table of the injection molding machine injects the first material into the mold through the main material inlet of the mold to mold the first component; the injectiontiming is controlled by the timing controller of the mold, and the sub injection table of the injection molding machine injects the second material into the mold through the sub material inlet of themold to mold the second component; and the first component and the second component are directly combined to form the product. The product is molded through the method. With the method and the apparatus of the present invention, the cost and the working time are saved, the appearance of the product is good, and the yield of the mass production is improved.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com