Low floating fiber high gloss glass fiber reinforced polypropylene composite material and preparation method thereof

A composite material and polypropylene technology, applied in the field of composite materials and their preparation, can solve the problems of not too much glass fiber content, poor appearance of parts, obvious floating fiber problems, etc., and achieve good dimensional stability and improve gloss. , Improve the effect of surface gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

[0031] Embodiments 1 to 6 relate to the present invention and also relate to the aforementioned low-floating fiber high-gloss glass fiber reinforced polypropylene composite material and a preparation method thereof; the method includes the following steps:

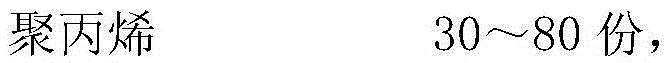

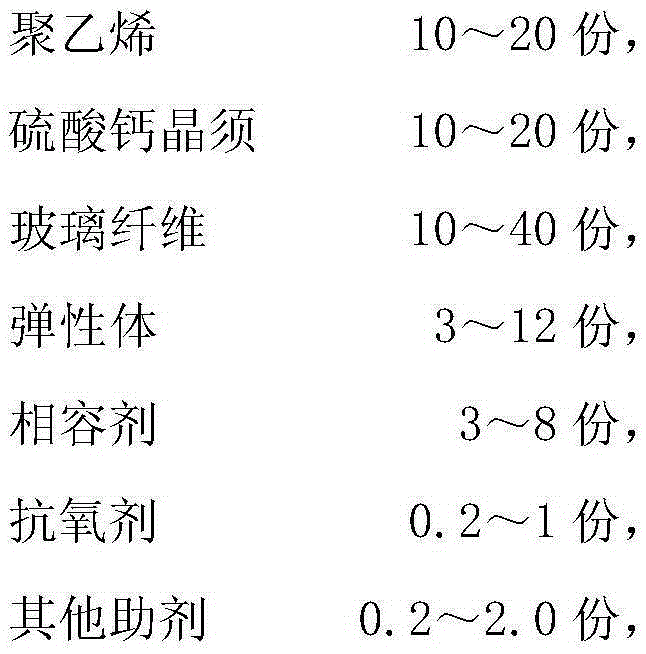

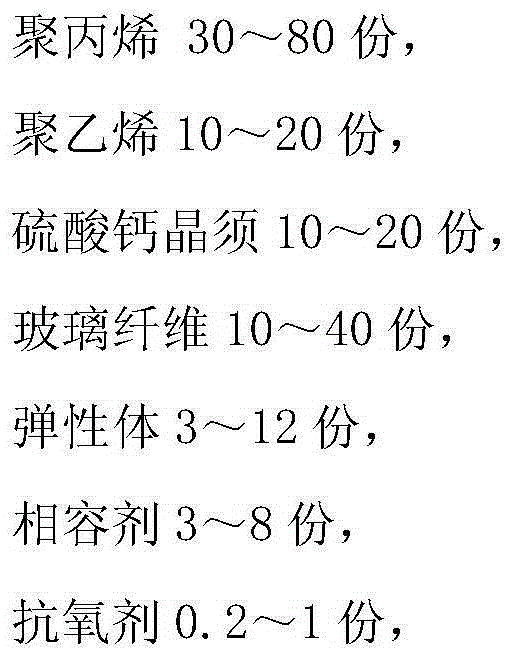

[0032] Step 1, weigh each component according to the ratio in Table 1:

[0033] Table 1

[0034] Unit:kg

[0035]

[0036] in FIG. 1:

Embodiment 1

[0037] In Example 1: the polypropylene is atactic polypropylene, the polypropylene has a mass melt flow rate of 2.0 to 50.0 g / 10 min at a temperature of 230° C. and a load of 21.17 N, and the tensile strength is ≥ 20 MPa;

[0038] The polyethylene is high-density polyethylene, and the polyethylene has a mass melt flow rate of 10.0-40.0g / 10min and a tensile strength of ≥15Mpa under the conditions of a temperature of 230°C and a load of 21.17N;

[0039] The glass fiber is alkali-free glass fiber, and its fiber diameter is 8-20 μm;

[0040] The particle size of calcium sulfate whiskers is 3-15 μm;

[0041] The elastomer is polybutadiene rubber;

[0042] The compatibilizer is polypropylene grafted acrylic acid;

[0043] The initiator is tert-butyl peroxyacetate;

[0044] The antioxidant is a hindered phenolic antioxidant;

[0045] Other additives are heat stabilizers.

Embodiment 2

[0046] In Example 2: the polypropylene is isotactic polypropylene, the polypropylene has a mass melt flow rate of 2.0 to 50.0 g / 10 min at a temperature of 230° C. and a load of 21.17 N, and the tensile strength is ≥ 20 Mpa;

[0047] The polyethylene is low-density polyethylene, and the polyethylene has a mass melt flow rate of 10.0-40.0g / 10min and a tensile strength of ≥15Mpa under the conditions of a temperature of 230°C and a load of 21.17N;

[0048] The glass fiber is alkali-free glass fiber, and its fiber diameter is 8-20 μm;

[0049] The particle size of calcium sulfate whiskers is 3-15 μm;

[0050] The elastomer is styrene-butadiene rubber;

[0051] The compatibilizer is polypropylene grafted maleic acid;

[0052] Initiator is dicumyl peroxide;

[0053] The antioxidant is a hindered phenolic antioxidant;

[0054] Other additives are lubricants;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com