Reinforced polypropylene composite material capable of replacing ABS as well as preparation method and application of reinforced polypropylene composite material

A composite material and polypropylene technology, applied in the field of reinforced polypropylene composite materials and its preparation, can solve the problems of large molding shrinkage, limited application, and low strength, and achieve the effects of increasing strength, reducing shrinkage, and promoting mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

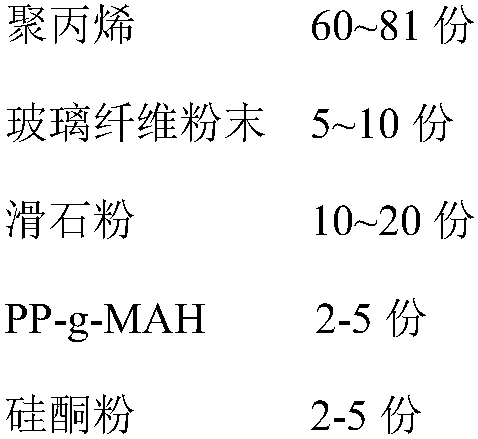

Method used

Image

Examples

Embodiment Construction

[0021] In order to better understand the technical characteristics of the present invention, the present invention will be further described by examples below.

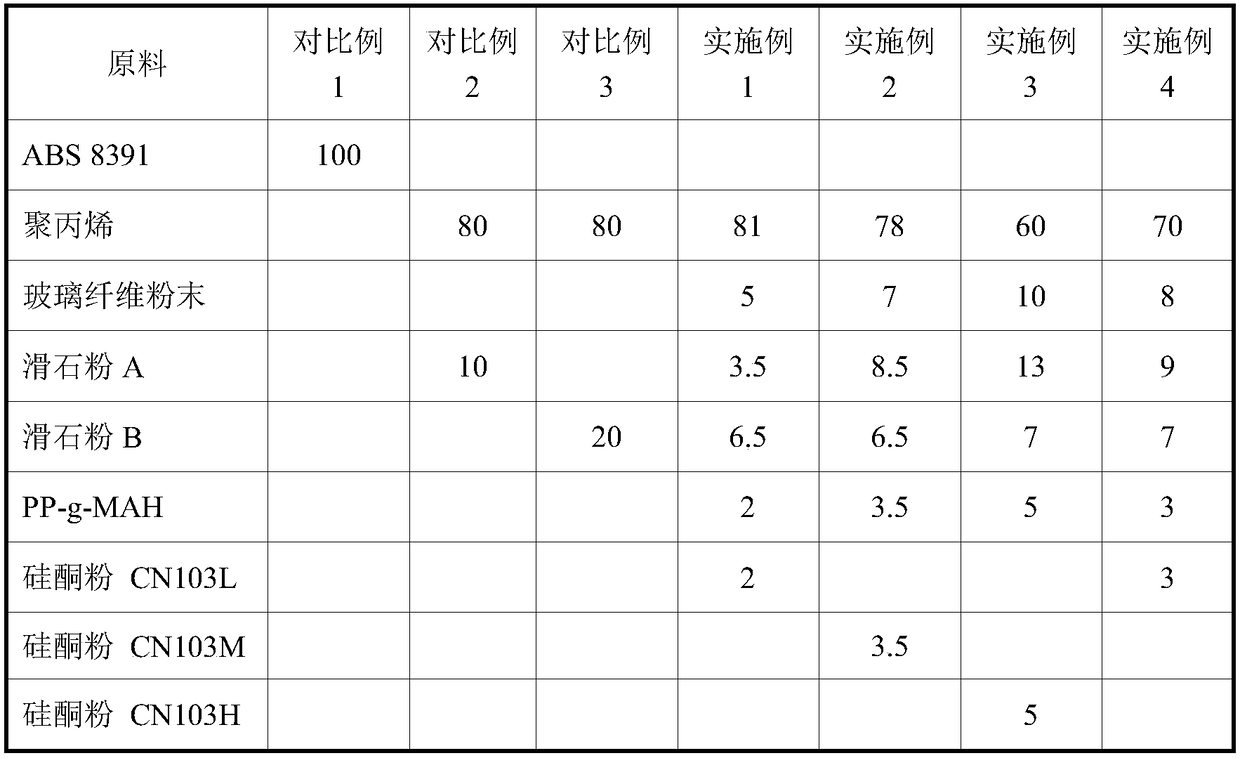

[0022] Table 1 shows the components of Examples 1-4 and their percentages by weight, wherein the D50 of talcum powder A is 1-2 microns, and the D50 of talc powder B is 10-15 microns.

[0023] The preparation method is as follows: mix polypropylene, talcum powder, PP-g-MAH, and silicone powder with a high-speed mixer for 8-15 minutes, then add to a twin-screw extruder; at the same time, pass glass fiber powder through the side feeding port Put into a twin-screw extruder, control the barrel temperature of the twin-screw extruder within the range of 180-220°C, mix and extrude and pelletize.

[0024] Table 1:

[0025]

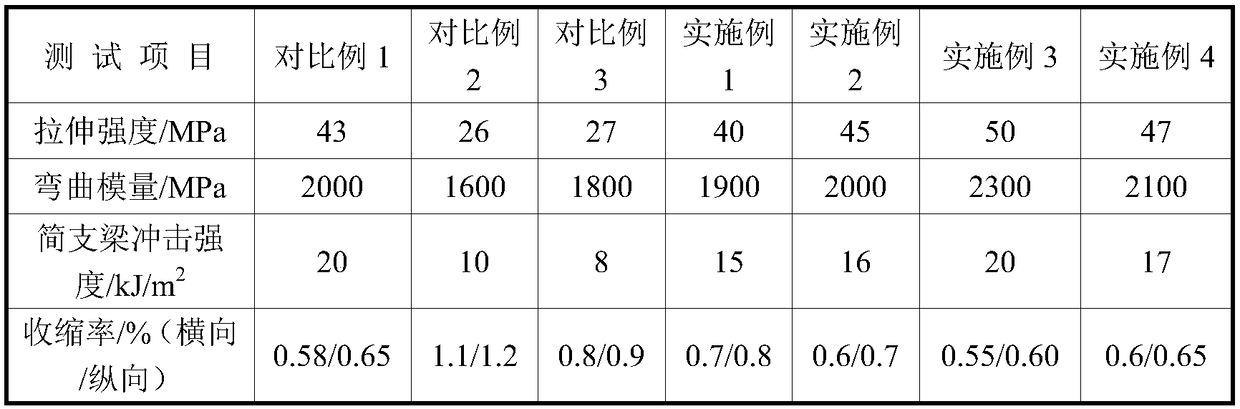

[0026] The polypropylene composite material prepared in Comparative Examples 1-3 and Examples 1-4 was injection molded into samples at 200-230°C, and then heated in a xenon lamp aging box with 0.55w / m ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com