High-strength, high-weather-resistance and good-appearance PA6 composition and preparation method thereof

A technology with high weather resistance and composition, applied in the field of polymer materials, can solve problems such as low water absorption PA6 composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

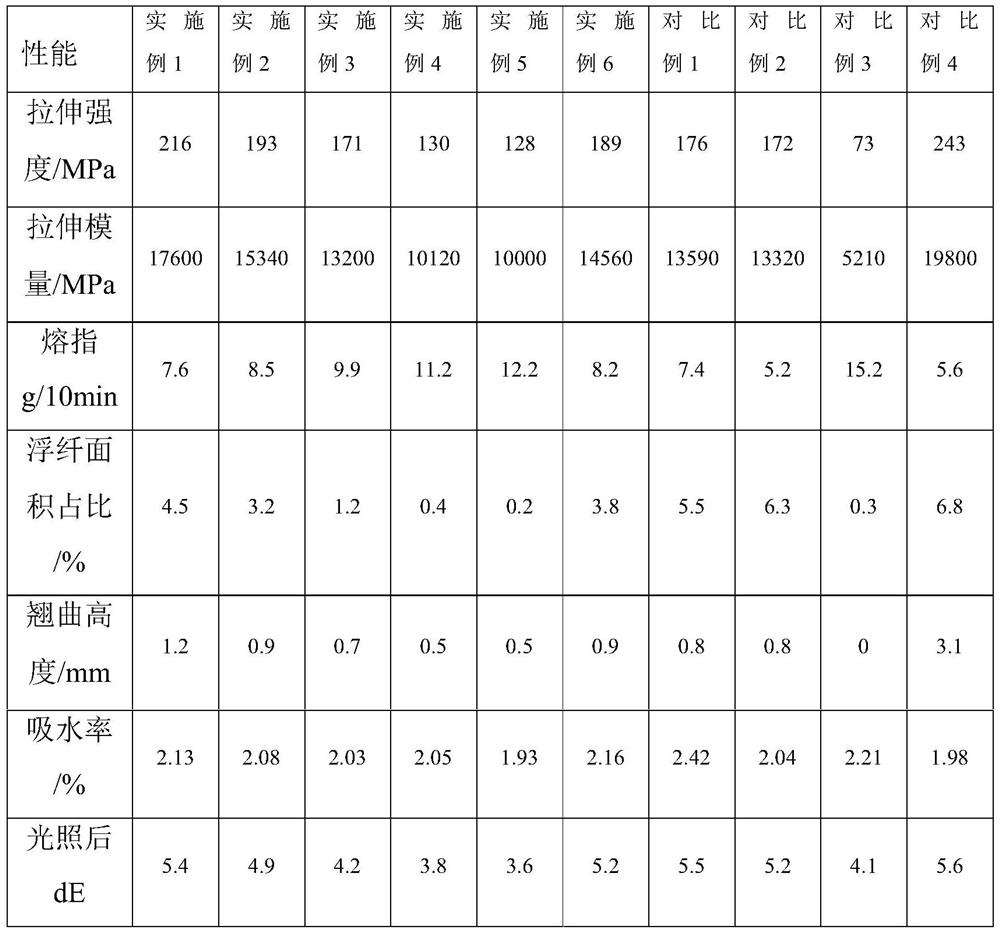

Examples

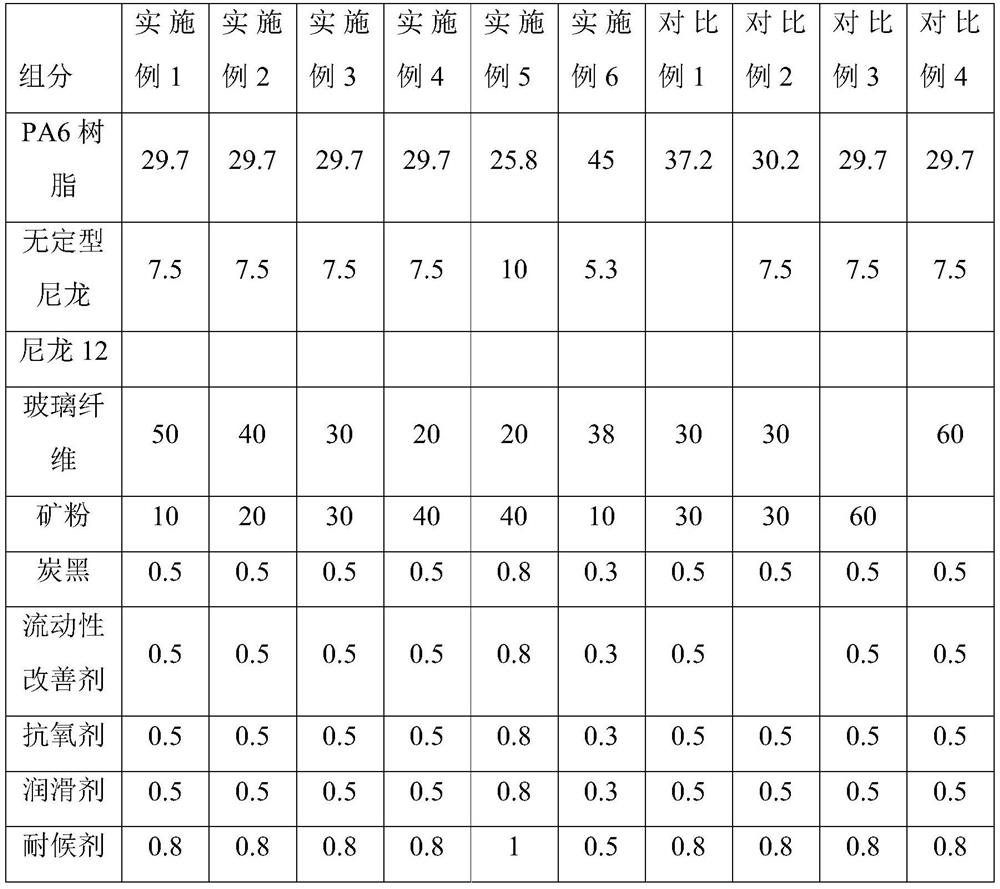

Embodiment 1-6

[0041] Weigh the raw materials according to the ratio shown in Table 1, premix the dried PA6 (drying condition 120°C, 6H), amorphous nylon, carbon black, fluidity improver, antioxidant, lubricant and weathering agent, It is plasticized by twin-screw, and glass fiber and mineral powder are fed in sequence from both sides in proportion. After traction, cooling, pelletizing and drying, pellets are obtained. The twin-screw extruder is set at a temperature of 220-240° C. and a screw speed of 300-400 rpm according to the conventional practice in the field such as the operation manual.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com