Flame-retardant glass fiber reinforced polyketone composite material capable of being used for vehicle fuel oil system

A fuel system and composite material technology, applied in the field of high physical property flame retardant composition, can solve the problems of low rigidity, low rigidity and high price of POK, and achieve the effect of reducing floating fiber and easy fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020]

[0021]

[0022] Each component is weighed with corresponding weight; then, each component is stirred by a single-shaft mixing barrel; the above mixture is respectively added into a twin-screw extruder to melt, extrude and granulate.

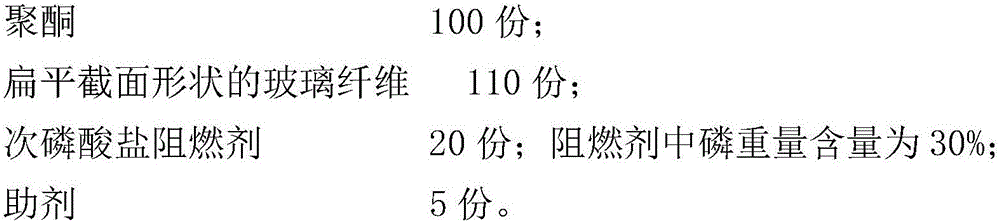

Embodiment 2

[0024]

[0025] Each component is weighed with corresponding weight; then, each component is stirred by a single-shaft mixing barrel; the above mixture is respectively added into a twin-screw extruder to melt, extrude and granulate.

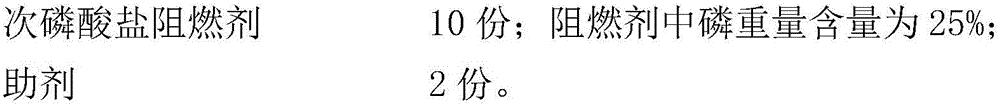

Embodiment 3

[0027]

[0028] Each component is weighed with corresponding weight; then, each component is stirred by a single-shaft mixing barrel; the above mixture is respectively added into a twin-screw extruder to melt, extrude and granulate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com