Long glass fiber enhanced polypropylene composite material and preparation method thereof

A technology of polypropylene materials and composite materials, applied in the field of polypropylene materials, can solve the problems of high price of high melting index materials, decreased mechanical properties of polymer substrates, unstable fluidity, etc., and can improve energy and polymer molecular weight, Increases interfacial strength and cladding ability, eliminates effects of low polymer strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

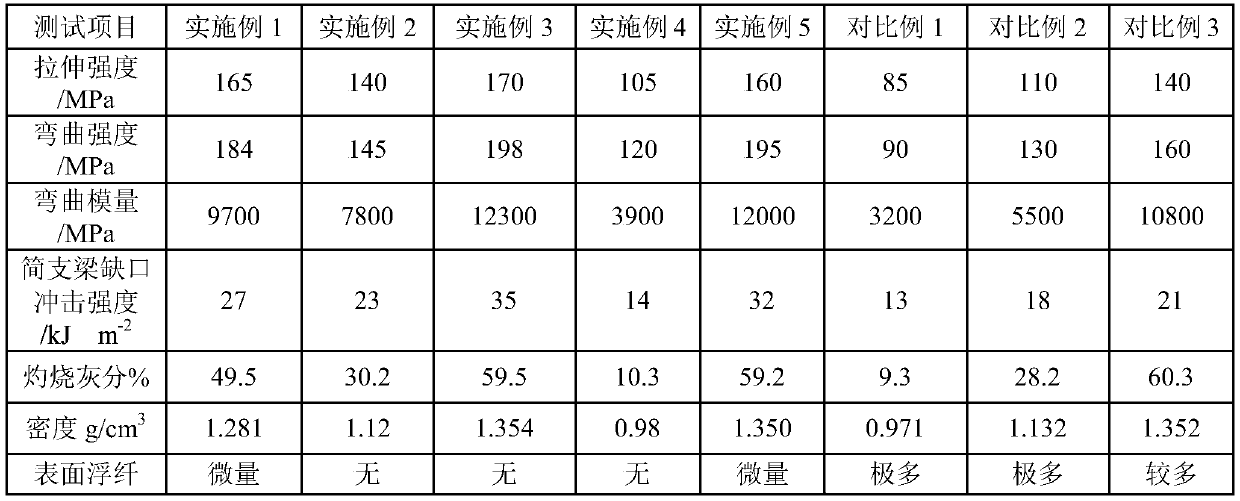

Examples

Embodiment 1

[0028] Weigh each component in component A and component B according to table 1, wherein, polypropylene resin is selected as the copolymerization polypropylene resin that melt index is 60-70g / 10min (230 ℃ / 2.16kg); Preparation steps are as follows:

[0029] (1) Dry the polypropylene resins of components A and B at 70°C for 2 hours to control the moisture content below 0.01% to obtain dry polypropylene resins;

[0030] (2) Add the weighed components A and B respectively into the mixer in proportion, set the speed range of the mixer to 400r / min, stir and mix for 1min, and mix well to obtain the polypropylene mixture A, polypropylene Mixture B, placed at room temperature for 18h;

[0031] (3) Set the screw temperature of the twin-screw extruder to be 240° C., and the rotating speed to be 500 rpm. The above-mentioned polypropylene mixtures A and B are extruded with the twin-screw extruder respectively, and directly enter the sol pool after extrusion, and set the sol The temperatur...

Embodiment 2

[0033] Weigh each component in Component A and Component B according to Table 1, wherein the polypropylene resin is selected as a copolymerized polypropylene resin with a melt index of 30-50g / 10min (230°C / 2.16kg); the preparation steps are as follows:

[0034] (1) Dry the polypropylene resins of components A and B at 85°C for 1 hour to control the moisture content below 0.01% to obtain dry polypropylene resins;

[0035] (2) Add the weighed components A and B into the mixer respectively in proportion, set the speed range of the mixer to 200r / min, stir and mix for 3min, and mix well to obtain polypropylene mixture A, polypropylene Mixture B, placed at room temperature for 24h;

[0036] (3) Set the screw temperature of the twin-screw extruder to be 200°C and the rotating speed to be 400 rpm, extrude the above-mentioned polypropylene mixtures A and B respectively with the twin-screw extruder, and directly enter the sol pool after extrusion, and set the sol The temperature of the po...

Embodiment 3

[0038] Weigh each component in component A and component B according to Table 1, wherein the polypropylene resin is selected as a homopolypropylene resin with a melt index of 90-100g / 10min (230°C / 2.16kg); the preparation steps are as follows :

[0039] (1) Dry the polypropylene resins of components A and B at 75°C for 1.5 hours to control the moisture content below 0.01% to obtain dry polypropylene resins;

[0040] (2) Add the weighed components A and B into the mixer in proportion, set the speed range of the mixer to 300r / min, stir and mix for 2min, and mix well to obtain the polypropylene mixture A, polypropylene Mixture B, placed at room temperature for 20h;

[0041] (3) Set the screw temperature of the twin-screw extruder to be 220°C and the rotating speed to be 300 rpm, extrude the above-mentioned polypropylene mixtures A and B respectively with the twin-screw extruder, and directly enter the sol pool after extrusion, and set the sol The temperature of the pool is 230°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com