Low-floating fiber flame-retardant reinforced PBT (Polybutylece Terephthalate) composite material

A composite material, low-floating fiber technology, used in the field of plastic modification, to achieve broad market prospects, smooth surface, and reduce the effect of surface floating fiber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific embodiments.

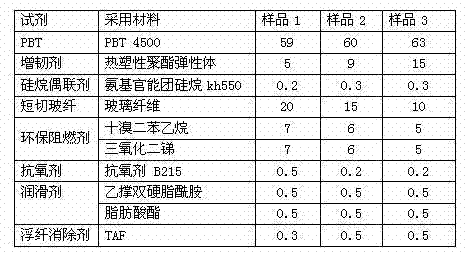

[0021] The technical solution of this embodiment is: a low-fiber flame-retardant reinforced PBT composite material, which is composed of the following components in mass percentage: PBT 55%~70%, toughening agent 5-15%, silane coupling agent 0.2 %~0.5%, chopped glass fiber 10%-20%, environmentally friendly flame retardant 10~15%, antioxidant 0.1%~0.5%, lubricant 0.1%~1%, floating fiber remover 0.3%~0.8% .

[0022] Wherein, the toughening agent adopts PBT-containing crystalline hard segment or polyester soft segment type.

[0023] Wherein, the toughening agent is a thermoplastic polyester elastomer.

[0024] Wherein, the environmentally friendly flame retardant uses decabromodiphenylethane and / or antimony trioxide.

[0025] Wherein, the lubricant adopts a mixture of fatty acid ester and ethylene bisstearamide, and the weight ratio of the two is 1-2:1.

[0026] Wherein, the floating fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com