Low-emission, low-floating-fiber, low-warping and ultra-dispersed long glass fiber polyamide composite material and preparation method thereof

A long glass fiber polyamide and composite material technology, applied in the direction of coating, etc., can solve the problems of difficult to achieve good dispersion of glass fiber, poor material wetting effect, etc., to increase the wetting effect and fluidity, easy to control, and good economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. It should be understood that these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention. The operating methods not indicated in the following examples are generally in accordance with conventional conditions, or in accordance with the conditions suggested by the manufacturer.

[0050] The raw material formulations of the following examples and comparative examples are shown in Table 1, and the figures are all mass percentages, in units of %. PA6 Xinhui Meida M2000 and M2400. The cross section of flat glass fiber ECS301HP-3-M3 is about 24 μm long and 8 μm wide, with an aspect ratio of 3. Coupling agent KH560. Lubricant, Zhonglan Chenguang GM-100. Black female, Cabot 3785.

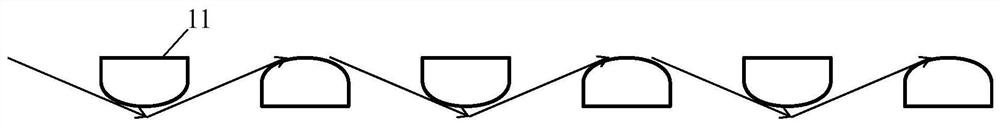

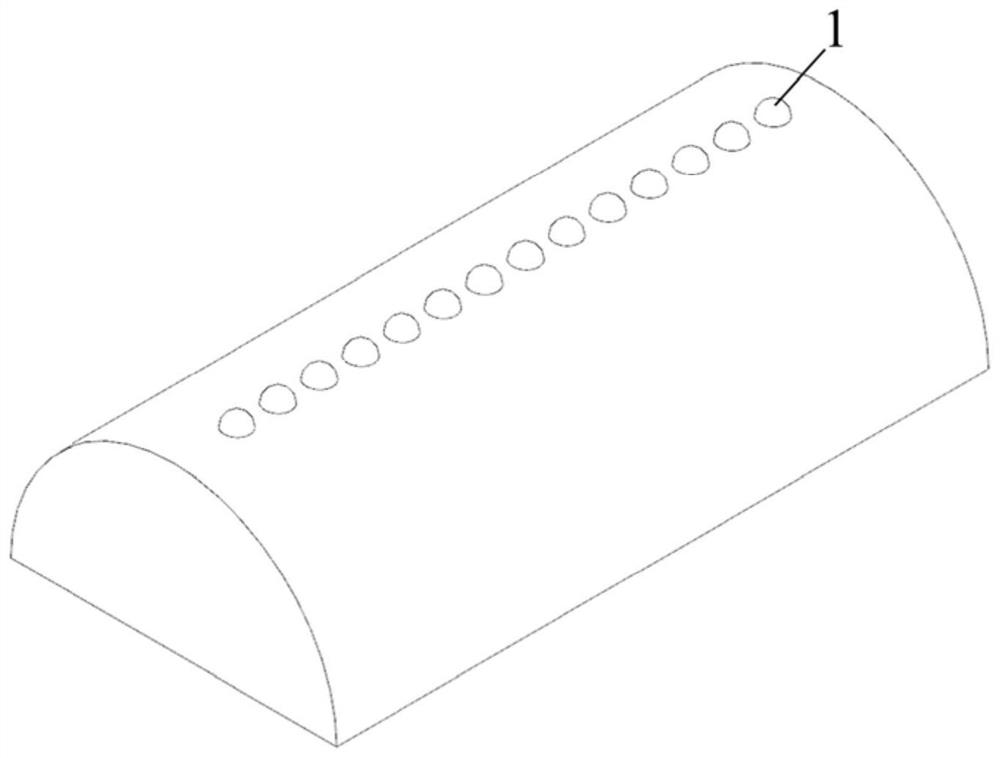

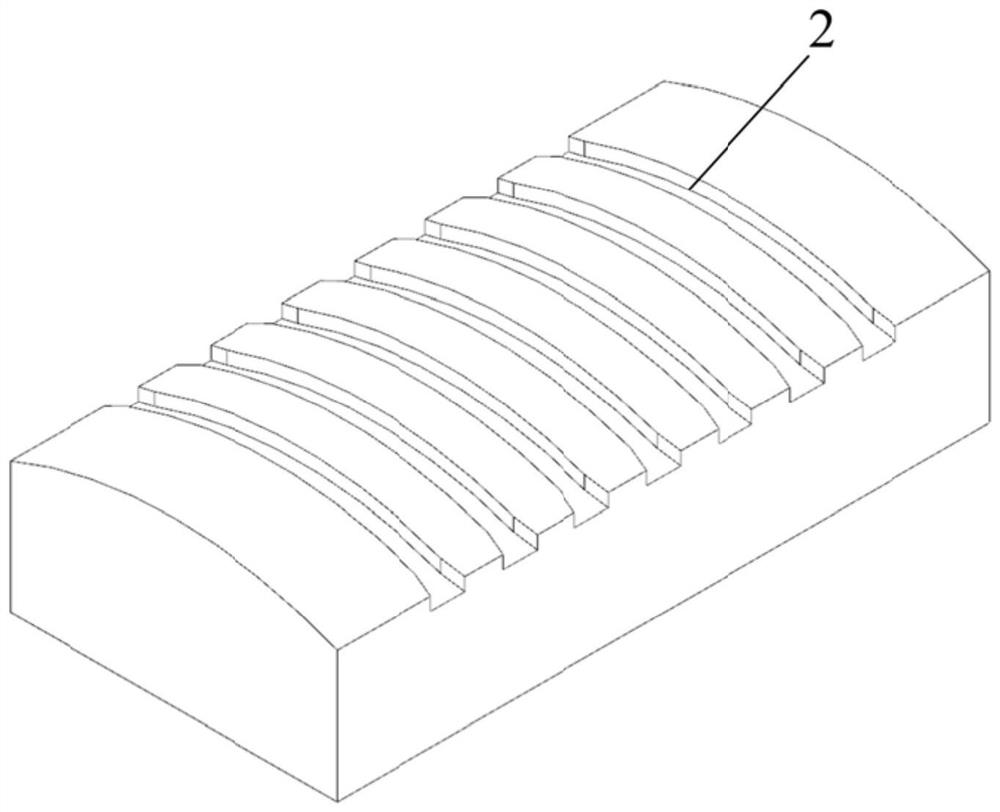

[0051] Following each embodiment, the equipment that comparative example adopts such as Figure 1~4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com