Glass fiber reinforced polyamide composition and its preparation method and application

A polyamide composition and polyamide technology, which are applied in the field of glass fiber reinforced polyamide composition and its preparation, can solve the problems of poor dimensional stability, "floating fiber weight, low water absorption rate, etc., and achieve good dimensional stability and low water absorption. The effect of floating fiber and low melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

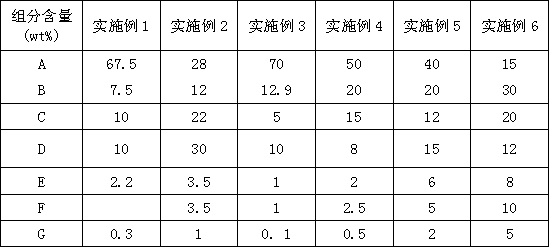

[0026] The preparation method of the glass fiber reinforced polyamide composition of the present invention is as follows: the first step is to mix polyamide 6 or polyamide 66 and low-melting polyamide uniformly in proportion, and then melt, extrude and granulate through extrusion equipment to obtain Low-melting polyamide composition; the second step, the low-melting polyamide composition prepared in the first step is uniformly mixed in proportion with aliphatic polyketone, alkali-free chopped glass fiber, POE grafted maleic anhydride, and extruded Equipment for melt extrusion granulation. In this case, the components polyamide 6 or polyamide 66, low melting point polyamide, aliphatic polyketone, E-chopped glass fiber, and POE grafted maleic anhydride should be varied within the range specified above, Such that all weight percentages always add up to 100%.

[0027] The above-mentioned technical scheme, further, in addition to polyamide 6 or polyamide 66, low-melting polyamide,...

Embodiment

[0047] Weigh polyamide PA6, polyamide with low melting point and additives according to the proportioning ratio of Examples 1-3 in Table 1, mix them in a high-speed mixer for 3 minutes, and add the mixed materials into the twin-screw extruder from the hopper, Melt extrusion and granulation to obtain a low-melting point polyamide composition. During extrusion, the temperature of each section of the twin-screw extruder is 220°C in the first zone, 230°C in the second zone, 240°C in the third zone, 240°C in the fourth zone, 240°C in the fifth zone, 240°C in the sixth zone, 240°C in the seventh zone, and 240°C in the head. °C, screw speed 300rpm.

[0048] The prepared low-melting polyamide composition, dendritic polyamide, aliphatic polyketone, chopped non-alkali glass fiber, POE grafted maleic anhydride, and auxiliary agent were mixed in a high-speed mixer for 2 minutes, and the mixed material was added by adding The hopper is fed into a twin-screw extruder, melted and extruded t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com