Modified polypropylene composite material with high wear resistance and preparation method of modified polypropylene composite material

A composite material, polypropylene technology, applied in the polymer field, can solve the problems of fingernail scratches and poor finger scratch resistance, and achieve the effects of improving compatibility, improving overall performance and reducing surface defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1-3 and comparative example 1-2

[0035] Weigh polypropylene, modified mica after treatment with silane coupling agent, chopped low-alkali glass fiber, compatibilizer, anti-floating fiber additive, surface slip agent and other additives into the high-speed In the mixer, mix at 80-150r / min for 5-10min to obtain the mixed material; then add the mixed material from the feeding port to a vacuum port with two vacuum ports, the screw speed is 100-300 rpm, and the long diameter of the screw The high wear-resistant polypropylene composite material is produced by melting, extruding, cooling and pelletizing in a twin-screw extruder with a ratio of 30-45:1 and an extruder temperature of 190-230°C.

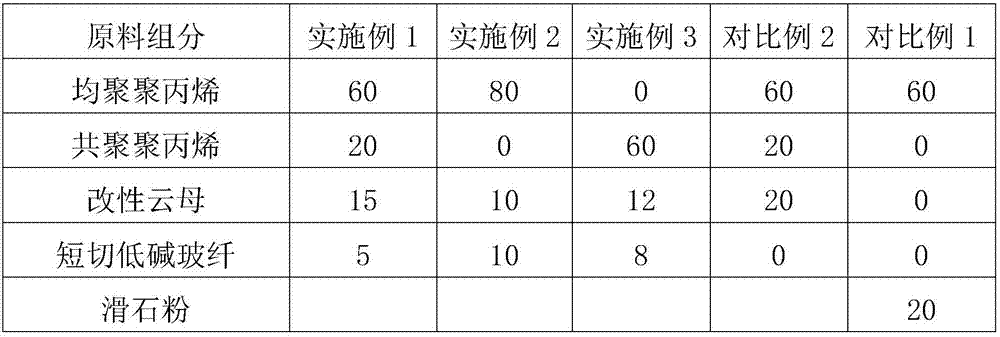

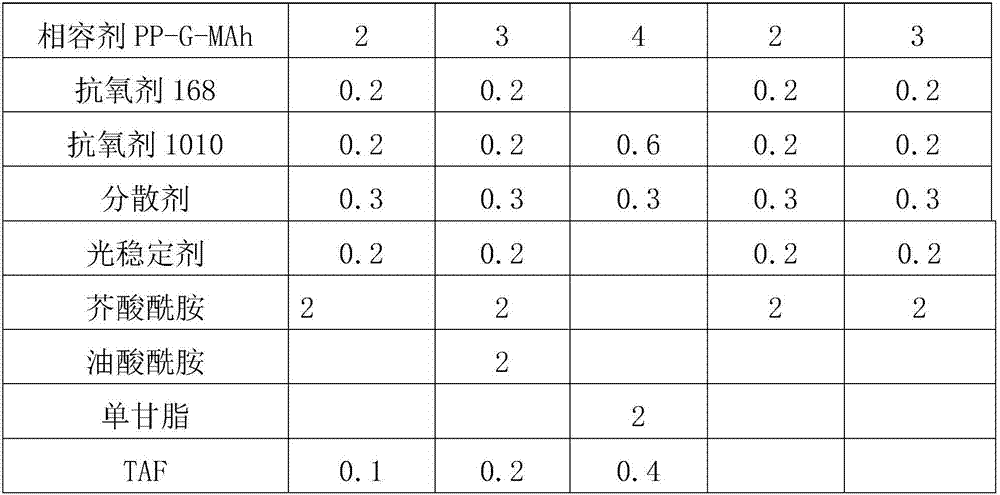

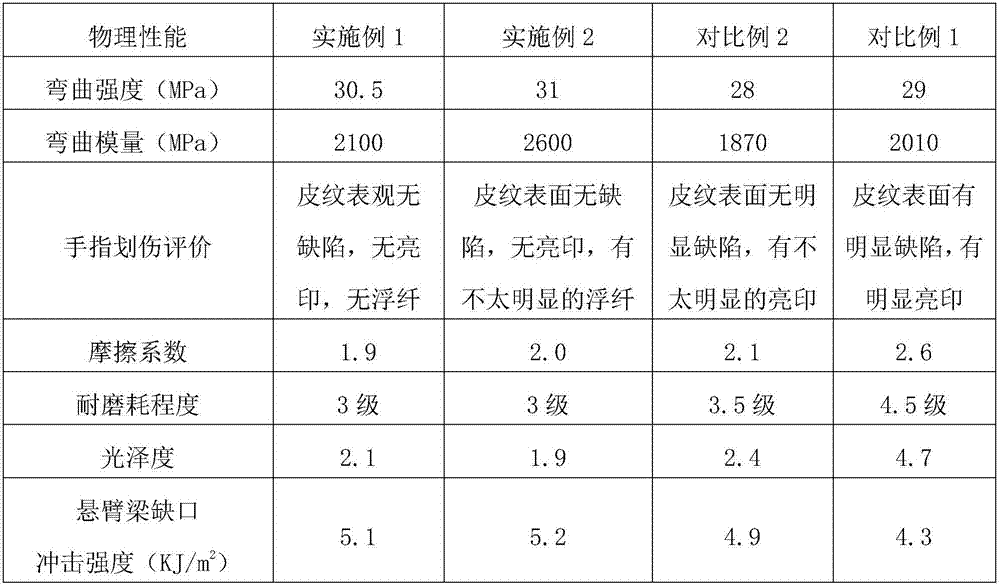

[0036] The composition of preparation raw material in table 1 embodiment 1-3 and comparative example 1

[0037]

[0038]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com