High-rigidity glass fiber reinforced polypropylene material and preparation equipment and preparation method thereof

A technology of polypropylene material and glass fiber, which is applied in the direction of coating, etc., can solve the problems that glass fiber cannot be effectively wetted by resin, the content of glass fiber is difficult to control and stabilize, and the length of glass fiber is damaged, etc., to achieve thermal stability protection and excellent hydrolysis resistance properties and extraction resistance, and the effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

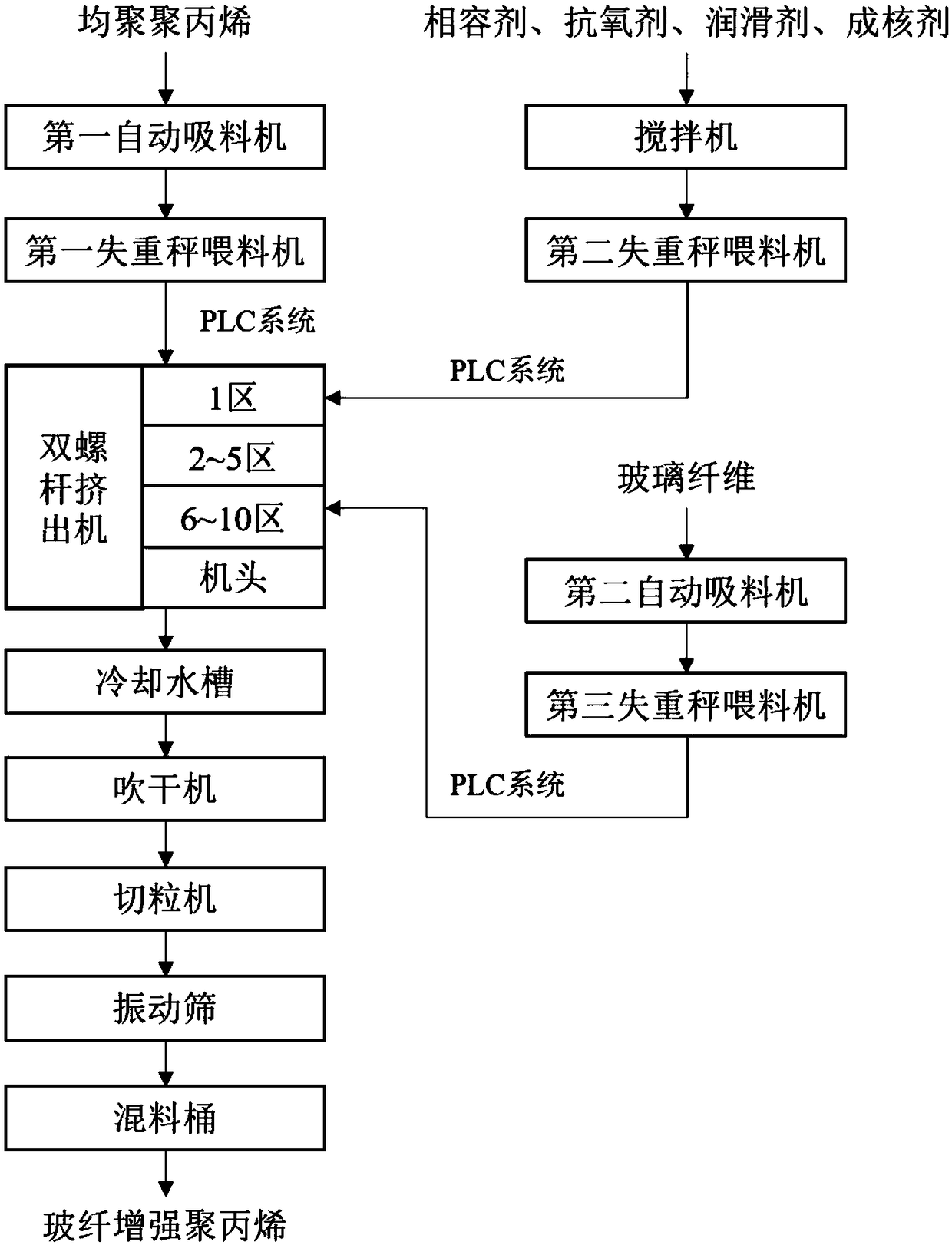

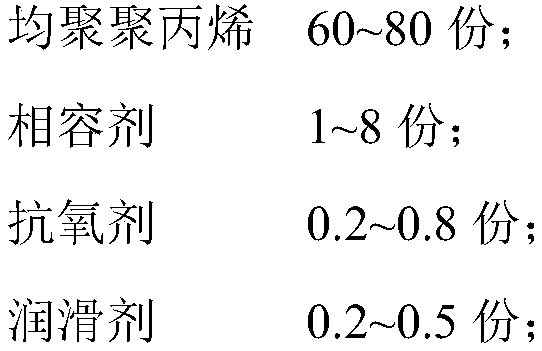

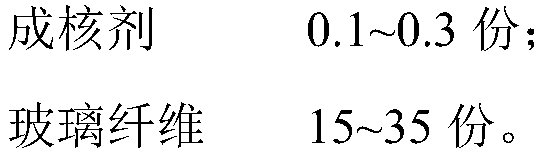

[0050] A kind of preparation method of high rigidity glass fiber reinforced polypropylene material, utilizes above-mentioned equipment to prepare, comprises the following steps:

[0051] 1) Transport the homopolypropylene to the first loss-in-weight feeder through the first automatic feeder; put the compatibilizer, antioxidant, lubricant and nucleating agent into the mixer, mix and stir, and transport to In the second loss-in-weight feeder; the glass fiber is transported to the third loss-in-weight feeder by the second automatic suction machine;

[0052] 2) The materials of the first loss-in-weight feeder and the second loss-in-weight feeder are put into the main feeding port of the twin-screw extruder respectively, and the materials of the third loss-in-weight feeder are put into the side of the twin-screw extruder. Feed port, extruded through twin-screw extruder;

[0053] 3) The extruded material is cooled in the cooling water tank in turn, dried by the blow dryer, pelletiz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com