Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Reduce film thickness variation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

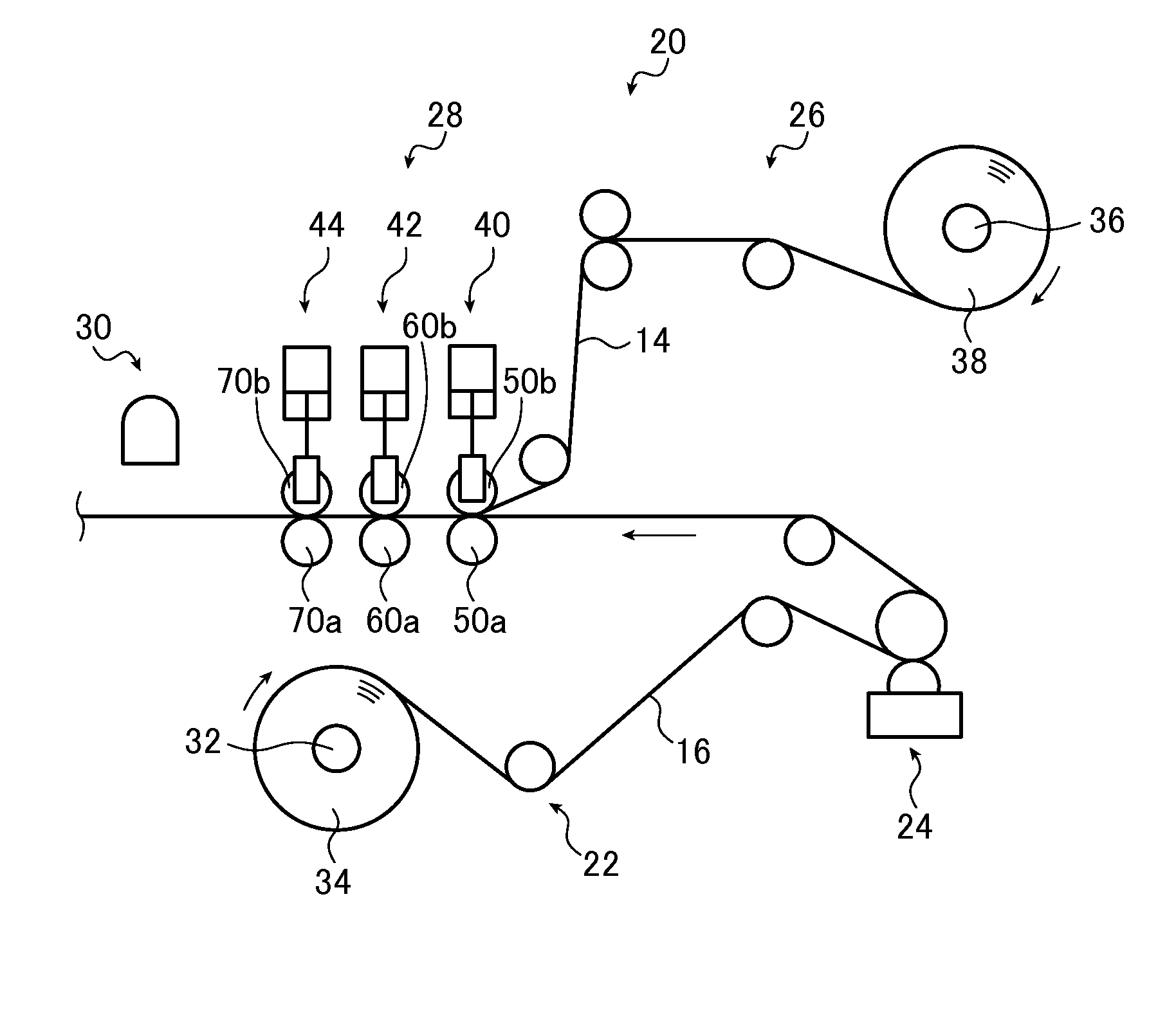

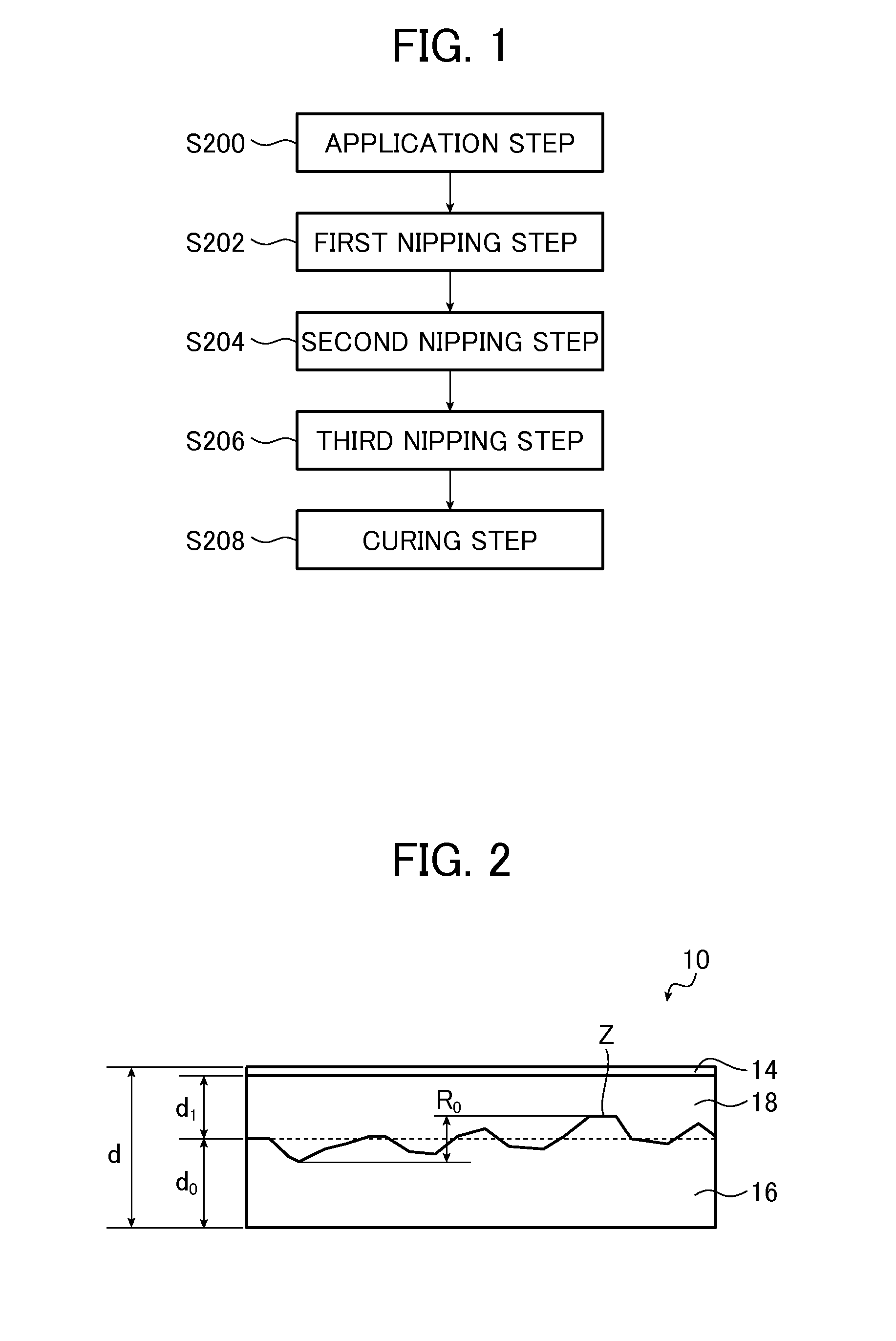

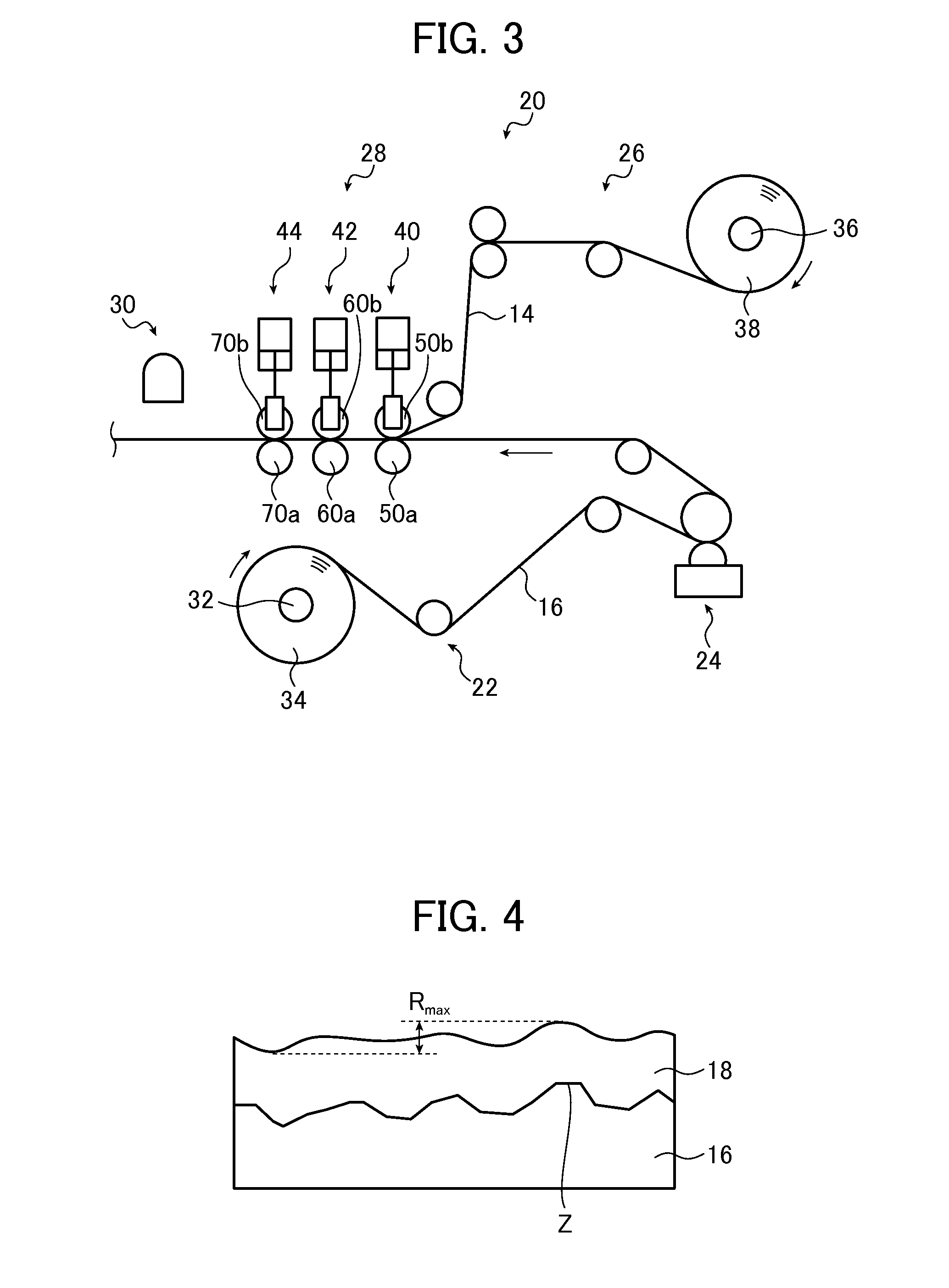

Lamination method and laminate

InactiveUS20150314580A1Reduce film thickness variationHigh film thickness accuracyAdhesive processesLayered product treatmentAdhesiveEngineering

A lamination method includes: a bonding step of bonding a support to a main surface of a substrate while transporting the substrate and the support along predetermined transport paths; and a curing step of curing an adhesive after the bonding step, and the bonding step is performed to bond the substrate and the support together while sequentially passing the substrate and the support through two or more nip roller pairs and, of the two or more nip roller pairs, a nip roller pair provided downstream has a nip distance set to be equal to or smaller than a nip distance of a nip roller pair provided upstream. The lamination method and a laminate obtained thereby can reduce film thickness variations in a substrate to achieve a high film thickness accuracy, ensures high versatility, and can suppress cost increases.

Owner:FUJIFILM CORP

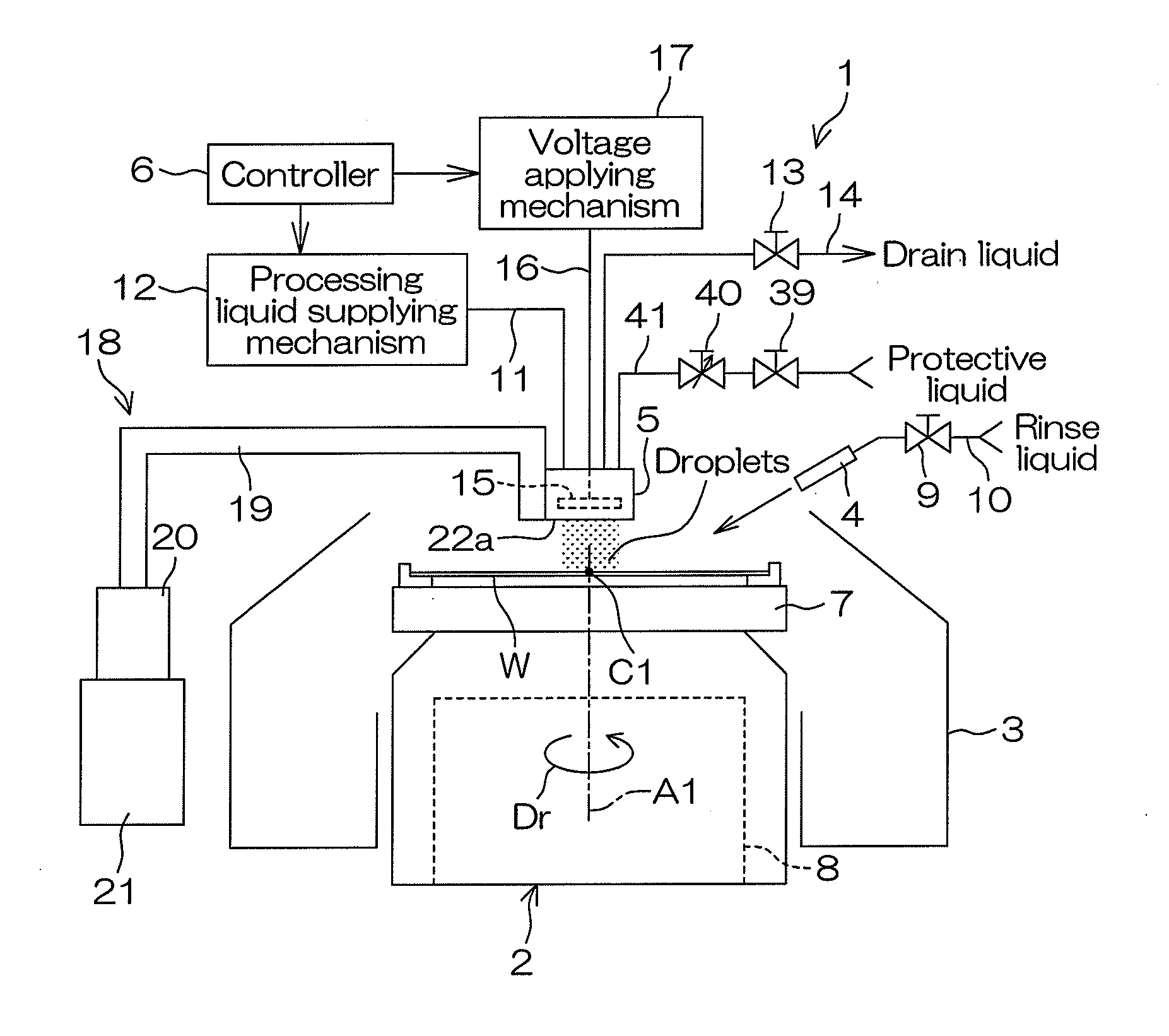

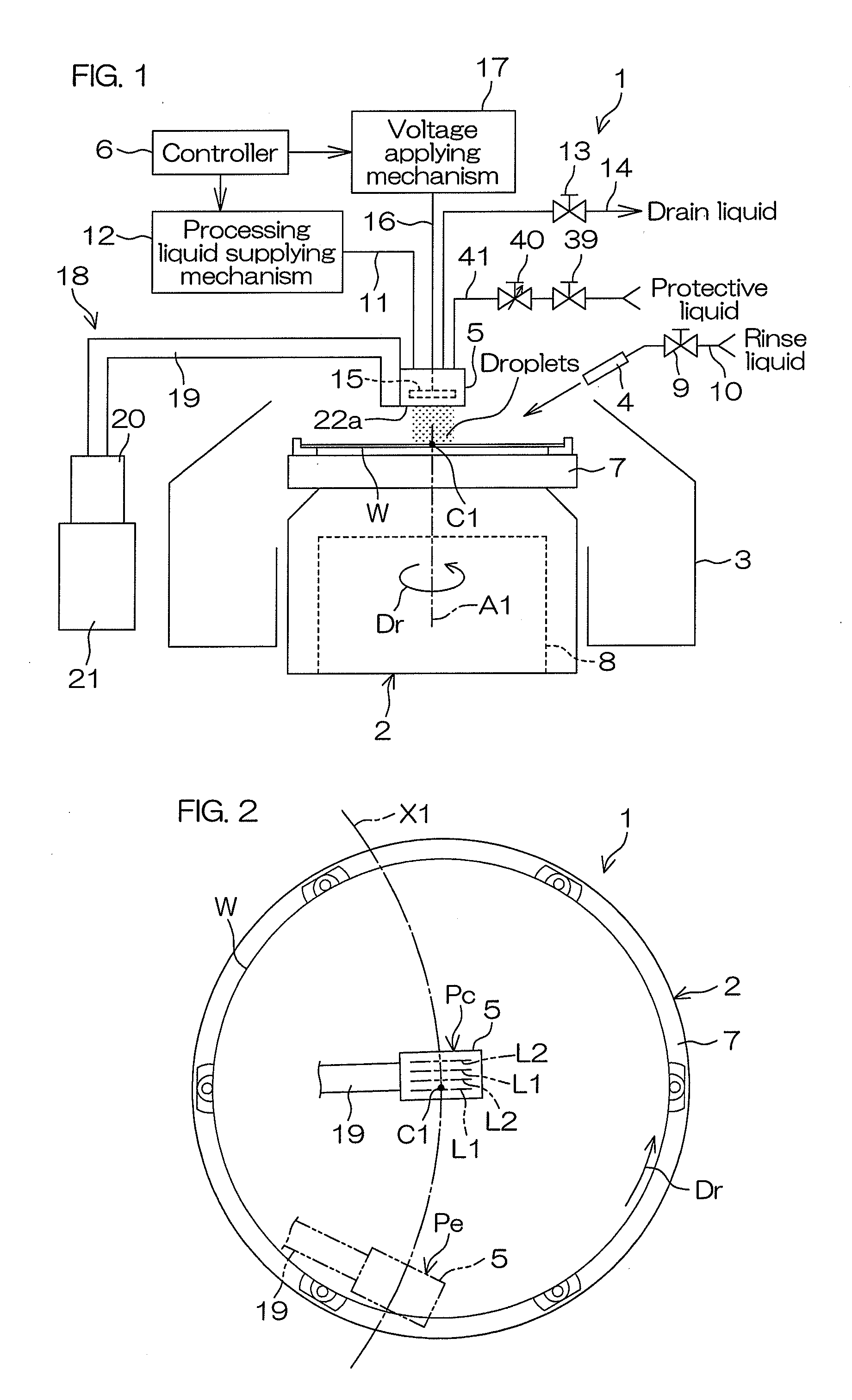

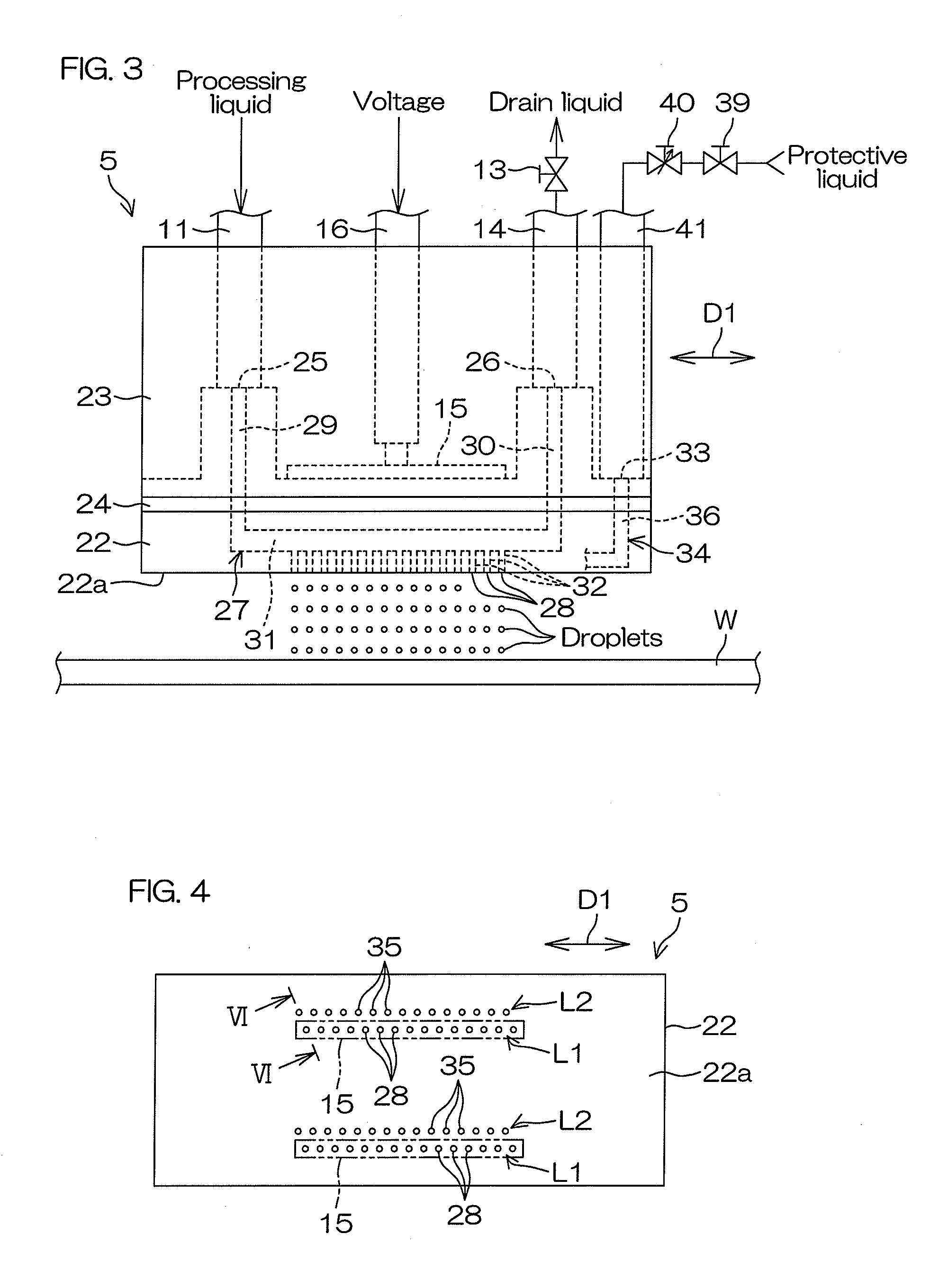

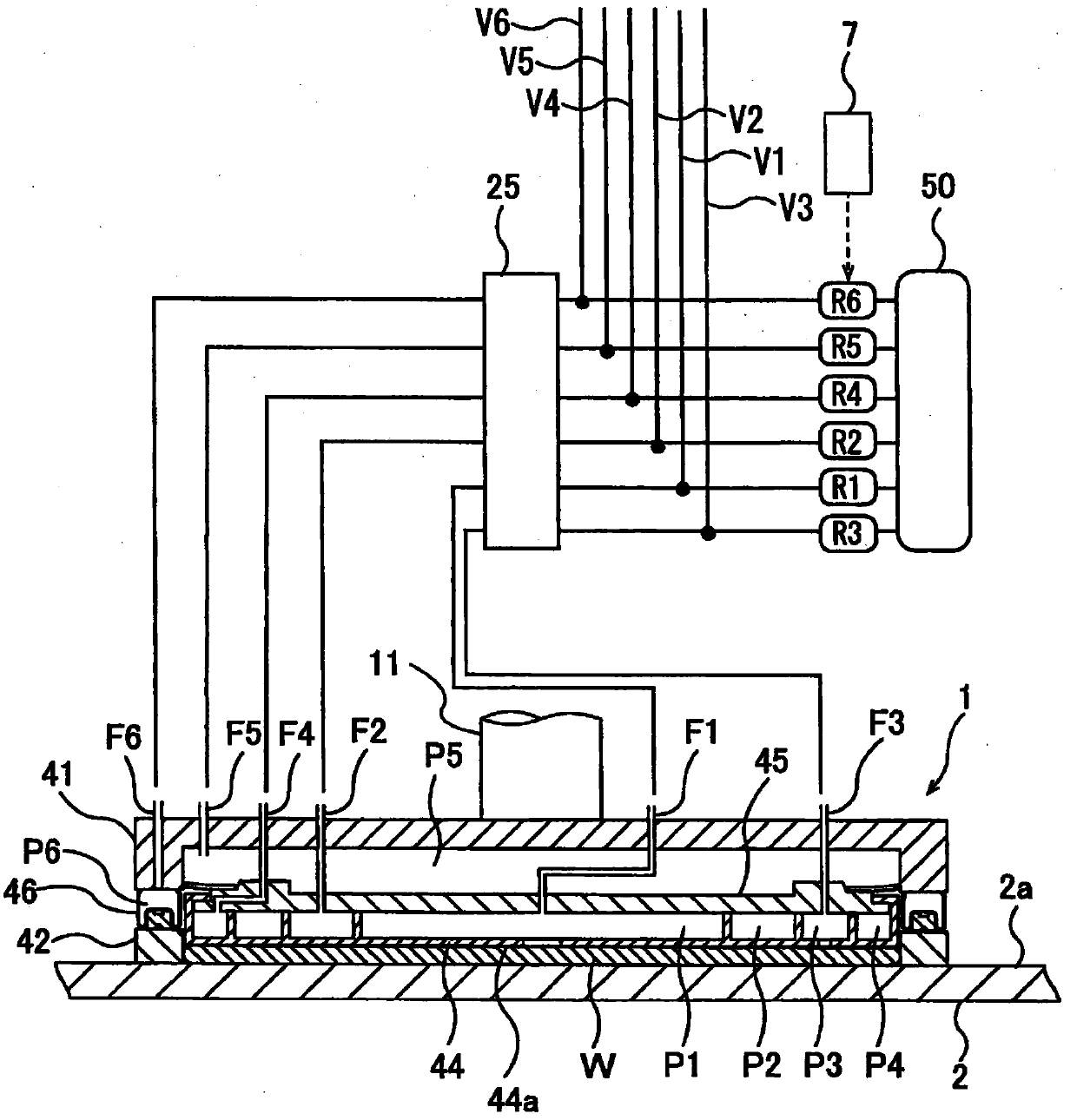

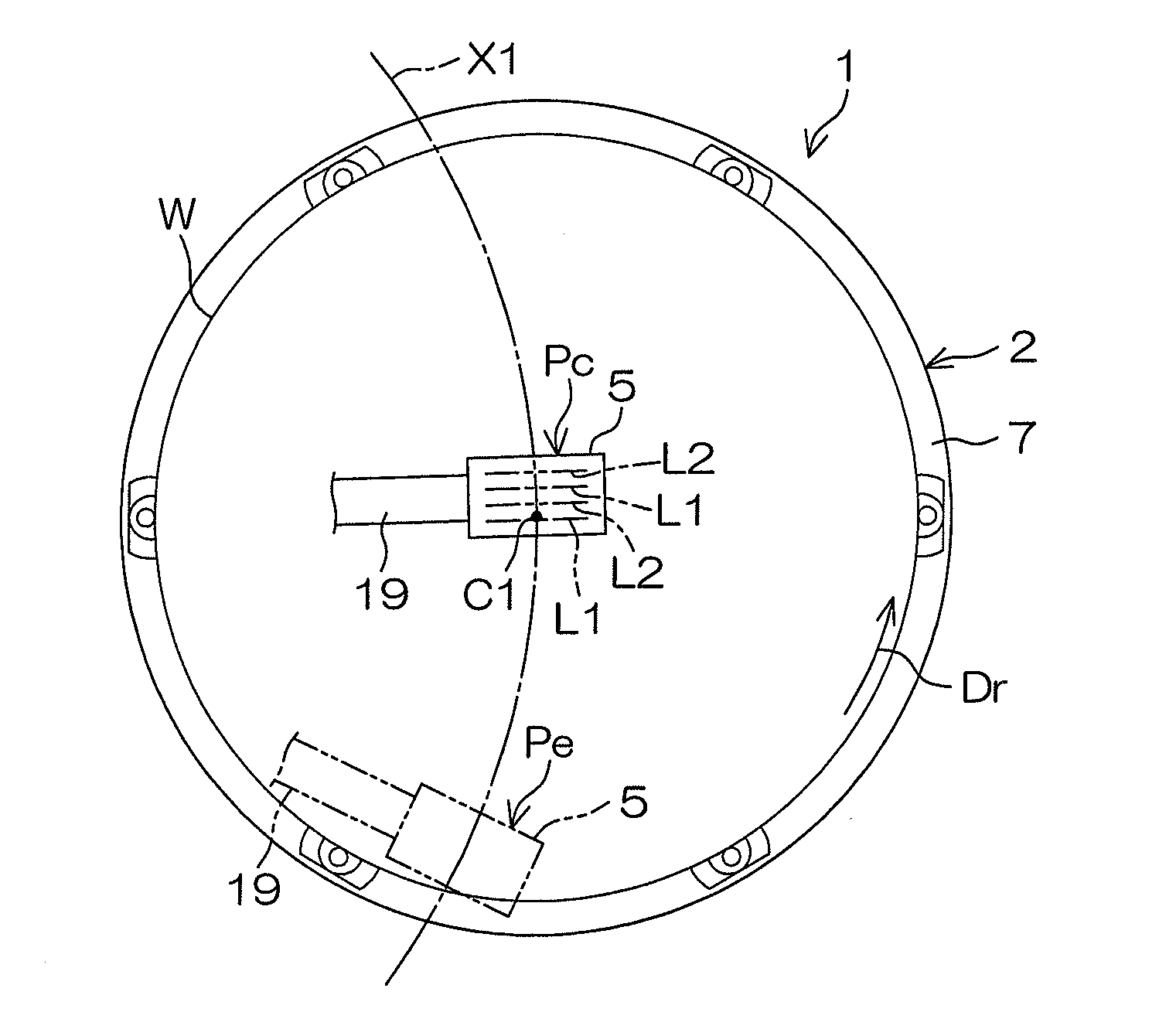

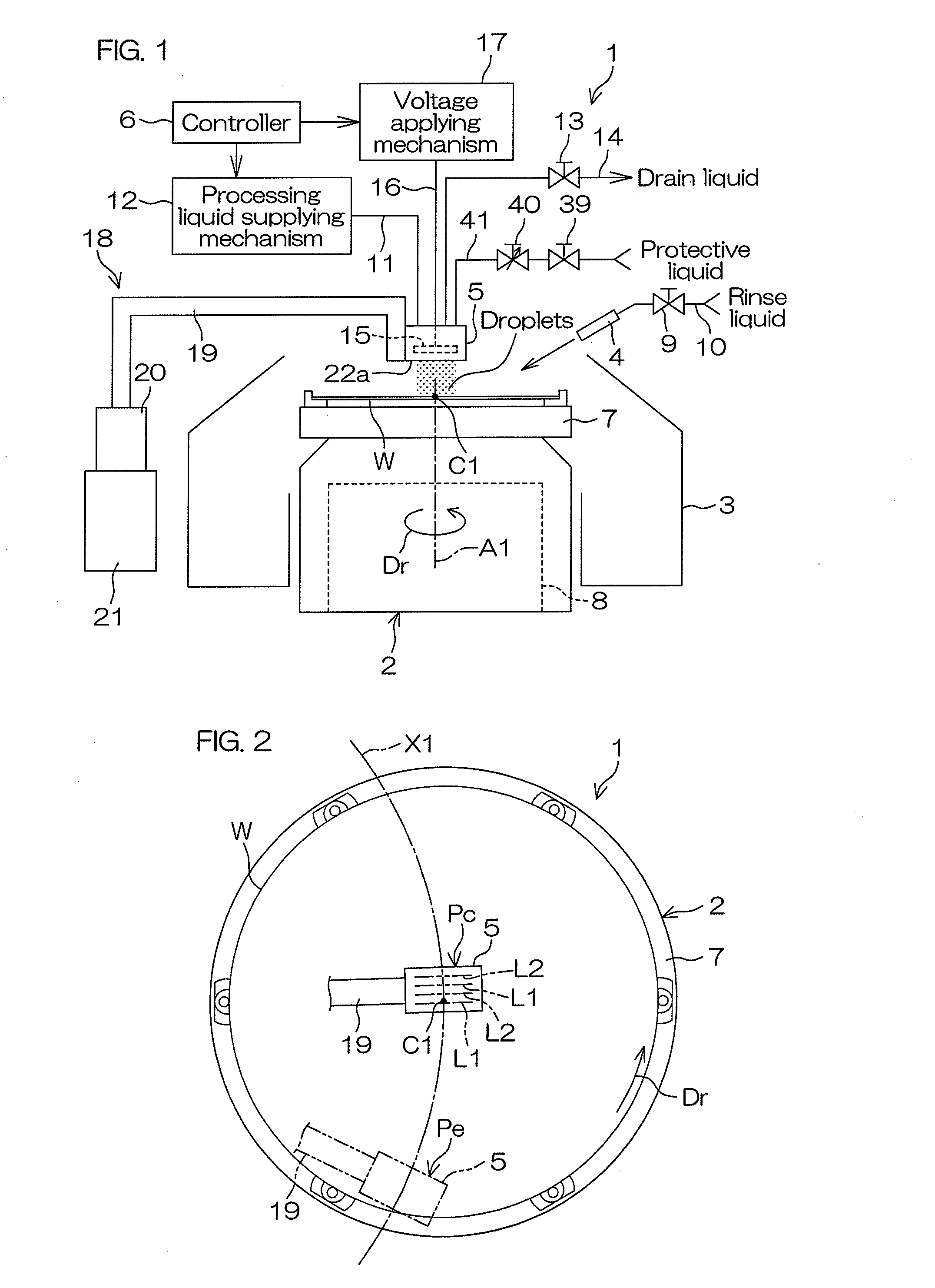

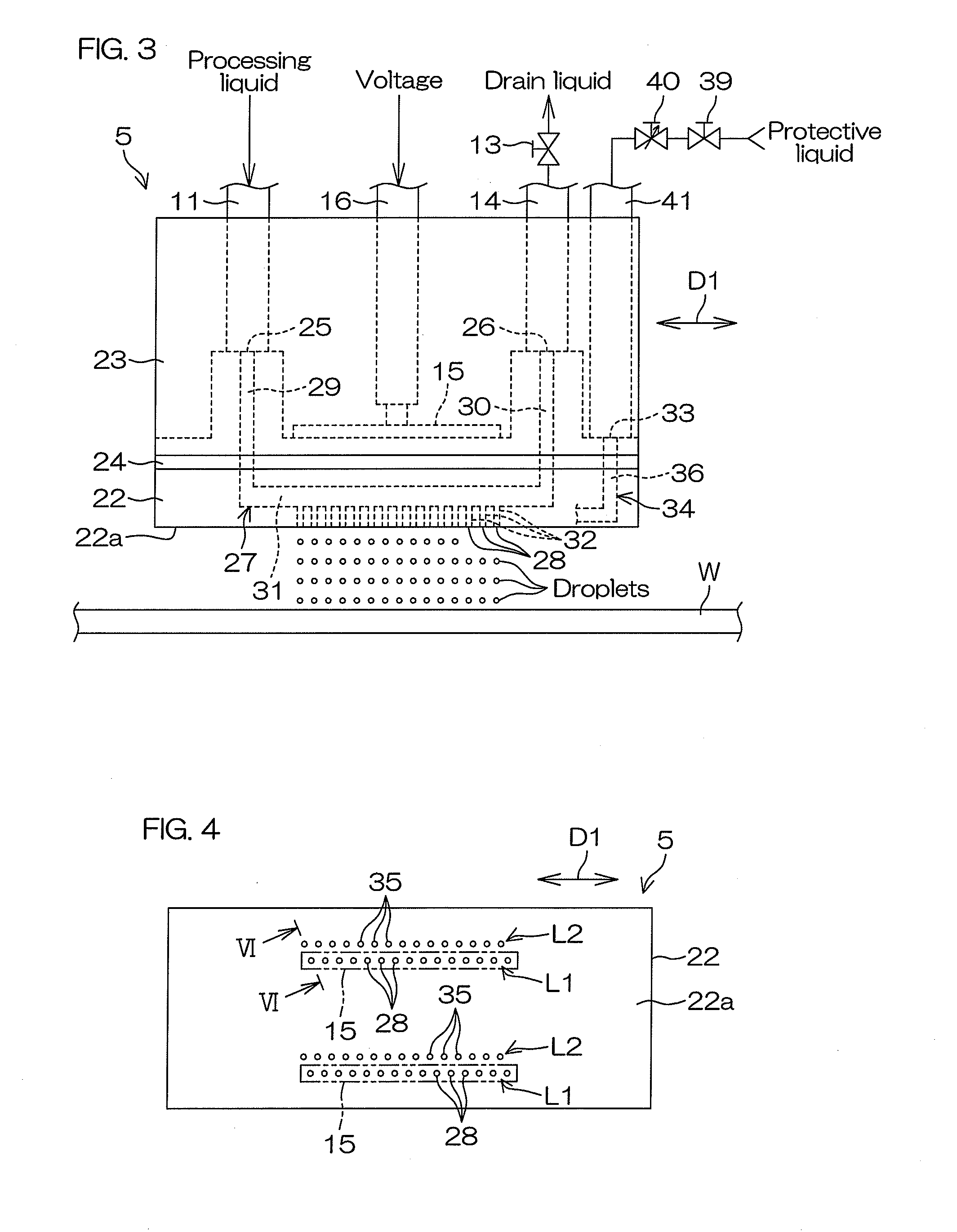

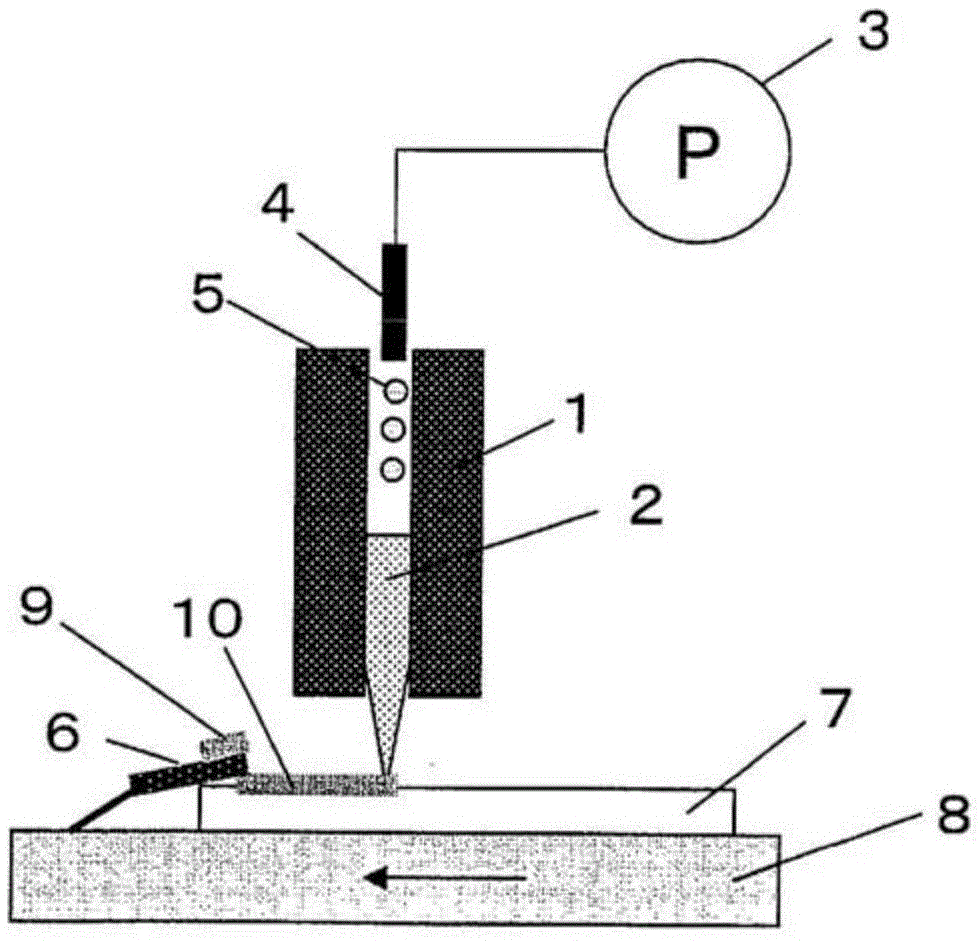

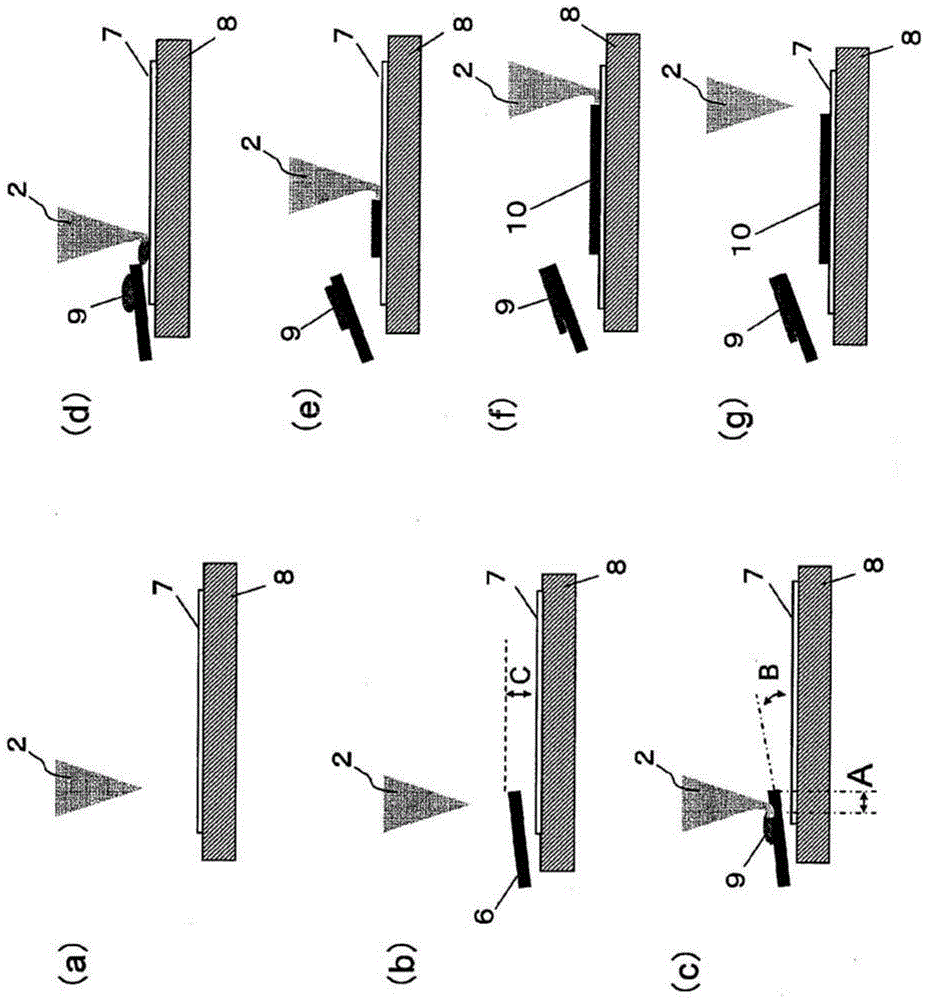

Substrate processing apparatus, substrate processing method, and nozzle

InactiveUS20130052360A1Reduce film thickness variationImprove processing qualityMovable spraying apparatusSpray nozzlesEngineeringContact position

A substrate processing apparatus includes a substrate holding unit that holds a substrate, an injection unit that injects droplets of a processing liquid from a plurality of injection ports respectively toward a plurality of collision positions within a principal surface of the substrate held by the substrate holding unit, and a liquid film forming unit. The liquid film forming unit discharges a protective liquid from a plurality of discharge ports respectively toward a plurality of liquid contact positions within the principal surface of the substrate held by the substrate holding unit to form a plurality of liquid films of the protective liquid that respectively cover different collision positions.

Owner:SCREEN HLDG CO LTD

Conductive porous layer for batteries and fabrication method for same

InactiveUS20140087272A1Improve adhesionReduce film thickness variationFuel and primary cellsHybrid cell detailsHigh densityPhysical chemistry

The conductive porous layer for batteries according to the present invention comprises a laminate comprising a first conductive layer and a second conductive layer. The first conductive layer includes at least a conductive carbon material and a polymer. The second conductive layer includes at least a conductive carbon material and a polymer. The conductive porous layer satisfies at least one of the following two conditions: “the polymer in the first conductive layer is present with a high density at the surface of the layer in contact with the second conductive layer than at the surface not in contact with the second conductive layer” and “the polymer in the second conductive layer is present with a higher density at the surface of the layer in contact with the first conductive layer than at the surface not in contact with the first conductive layer.”

Owner:DAI NIPPON PRINTING CO LTD

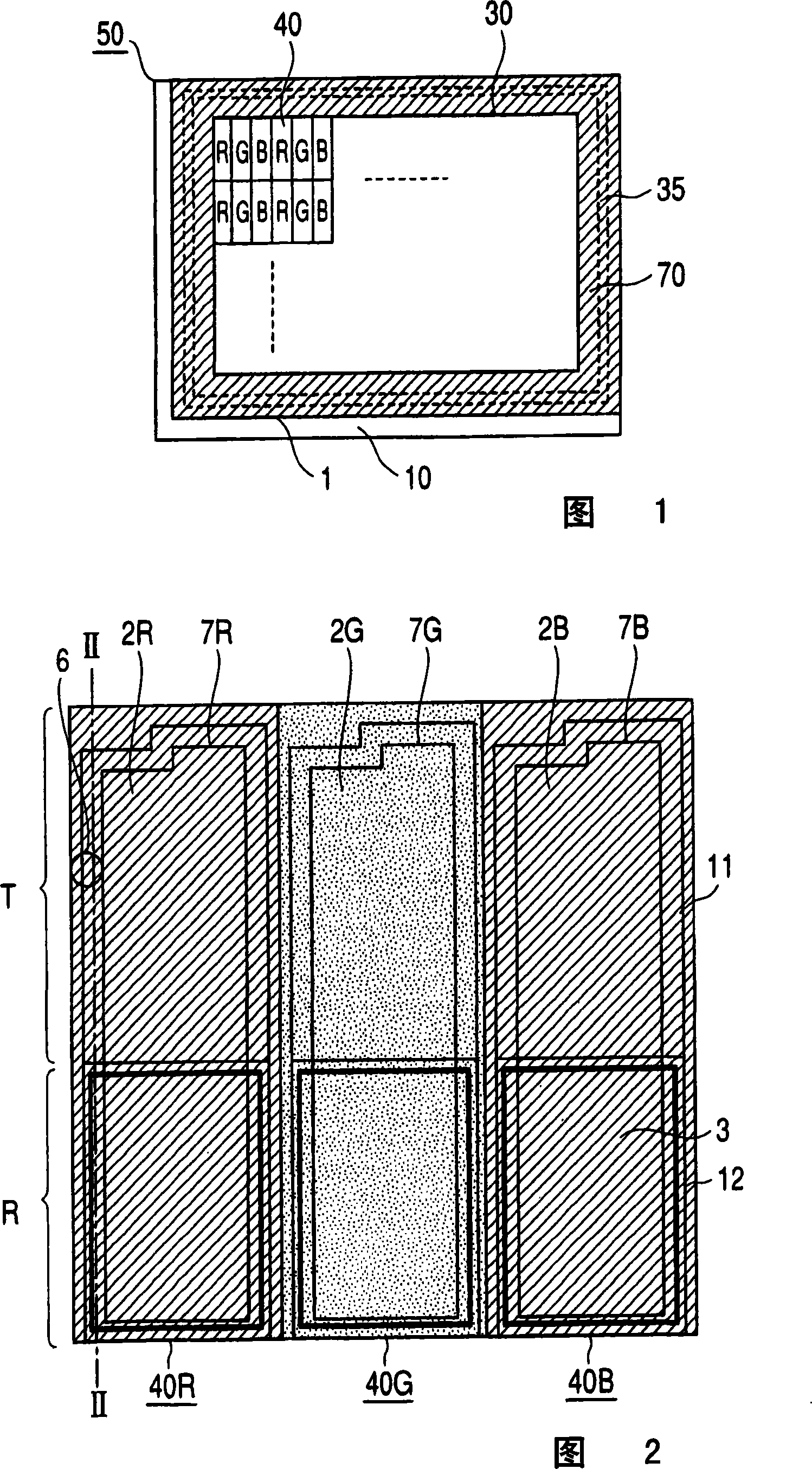

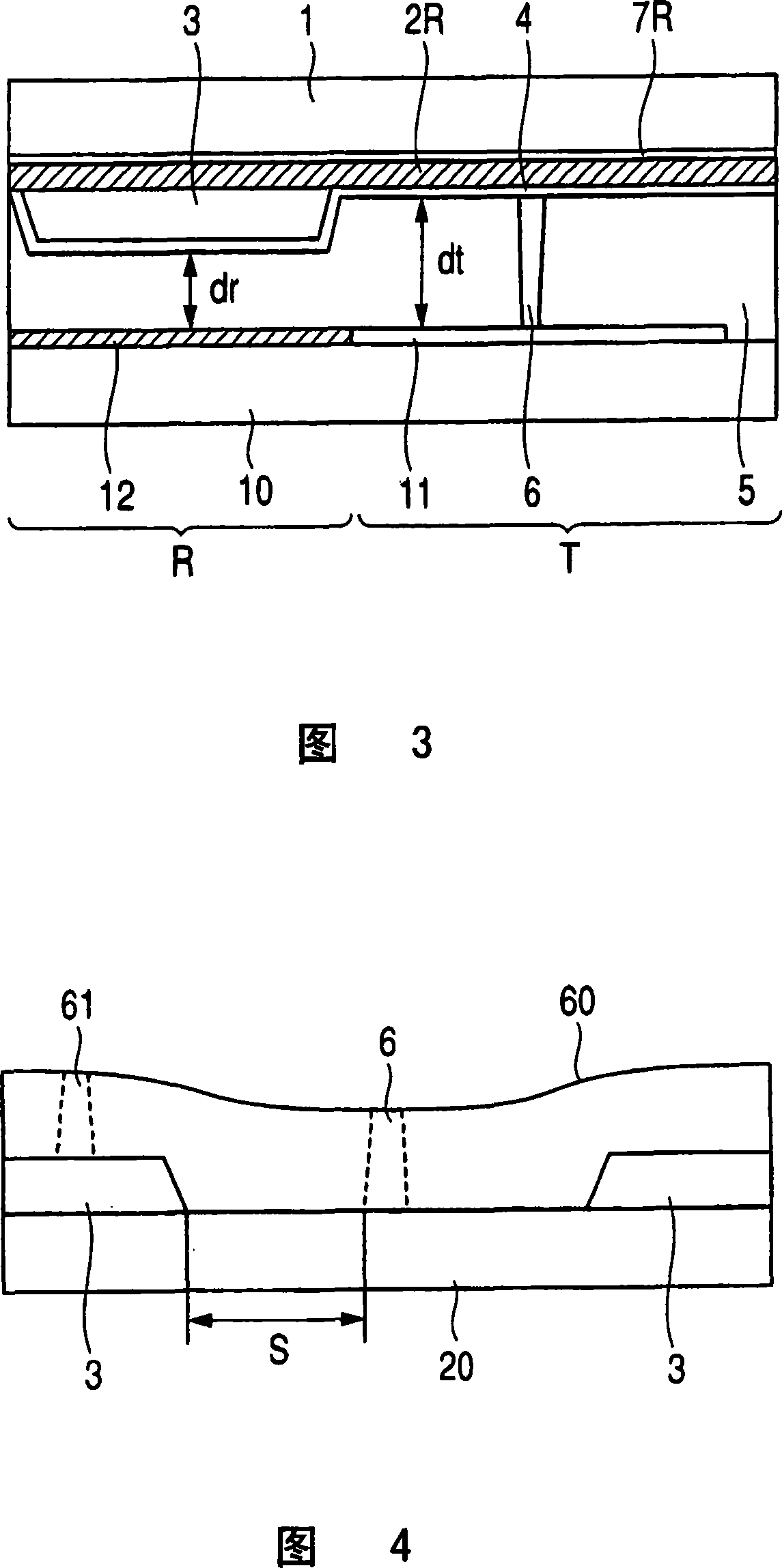

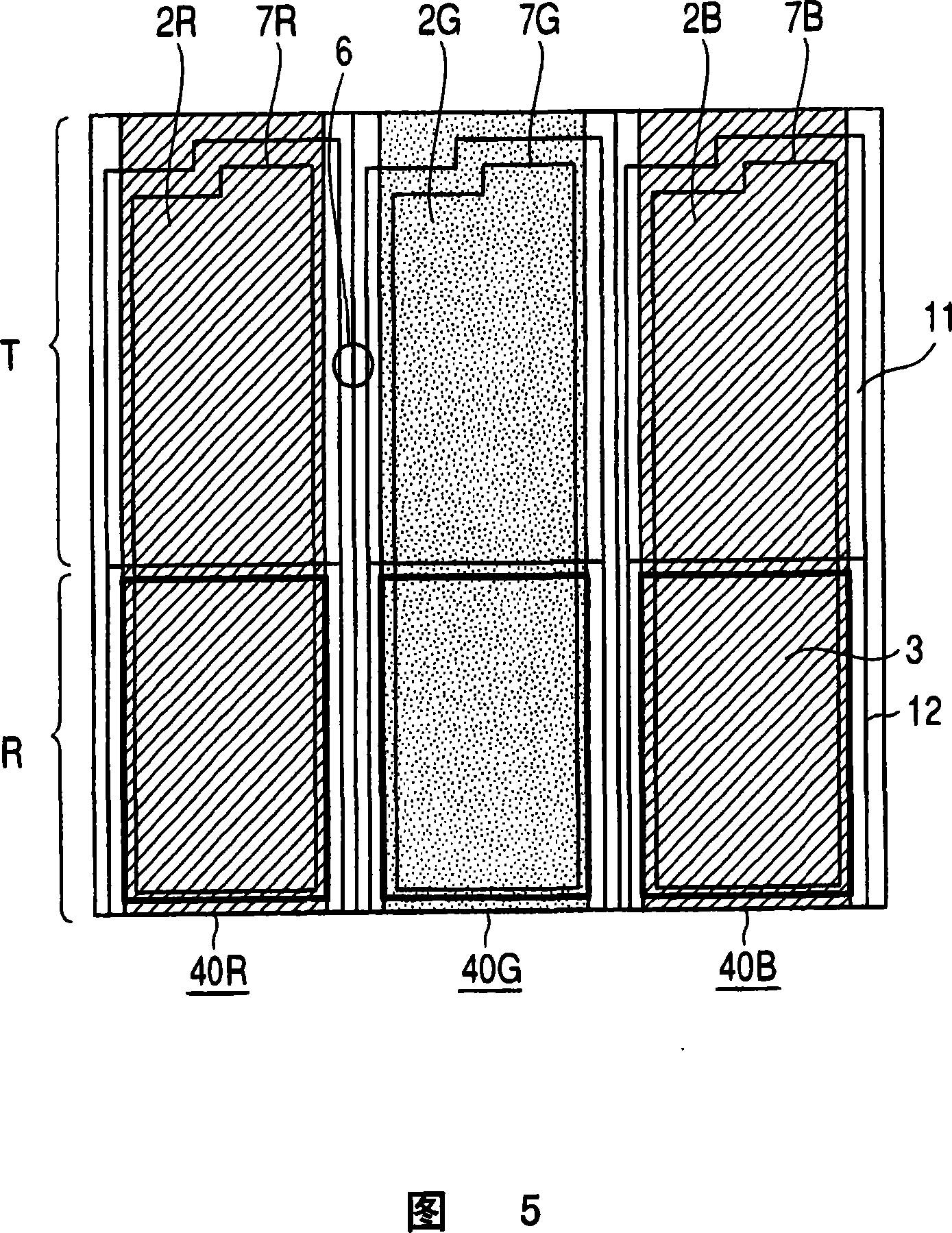

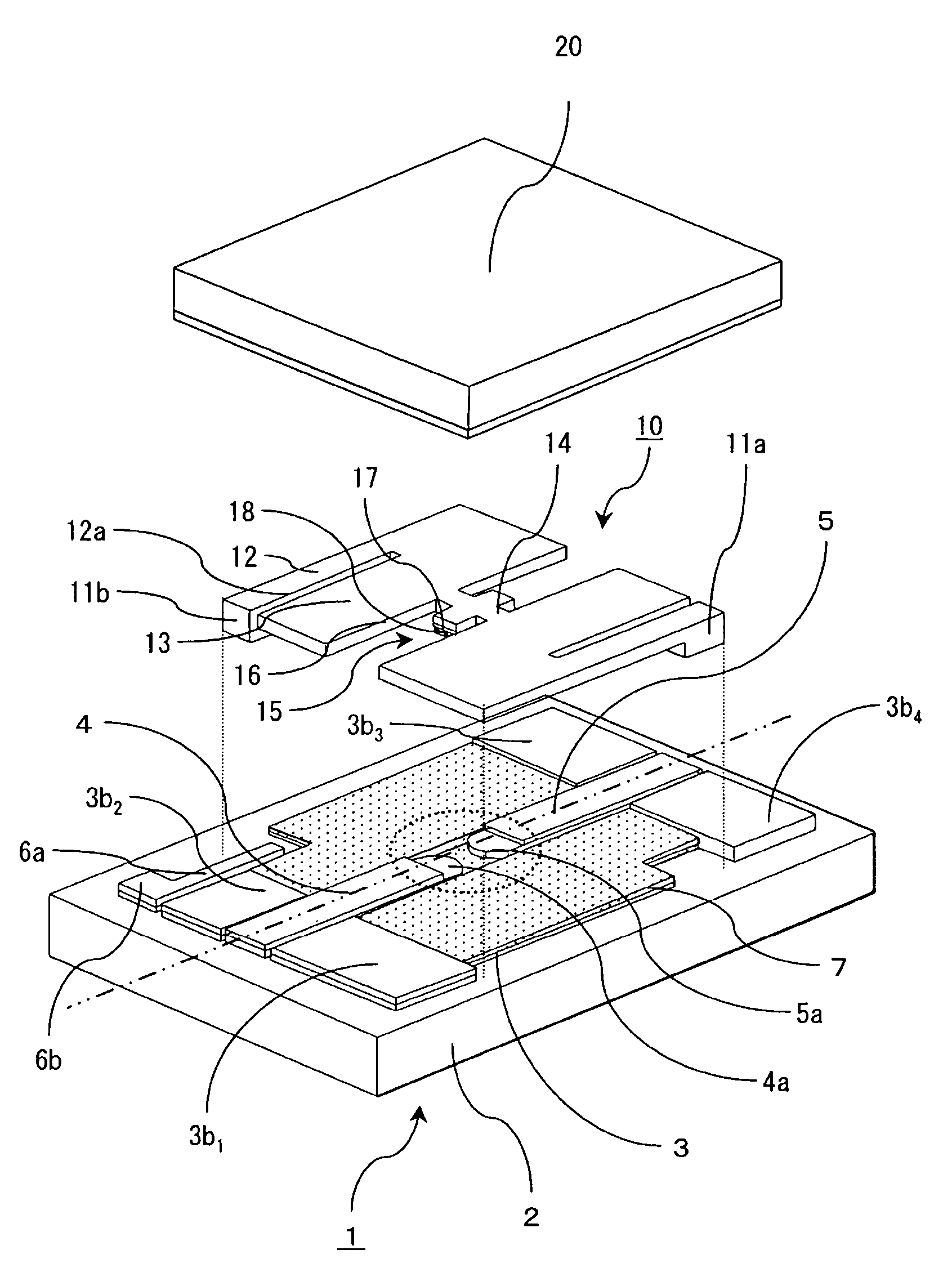

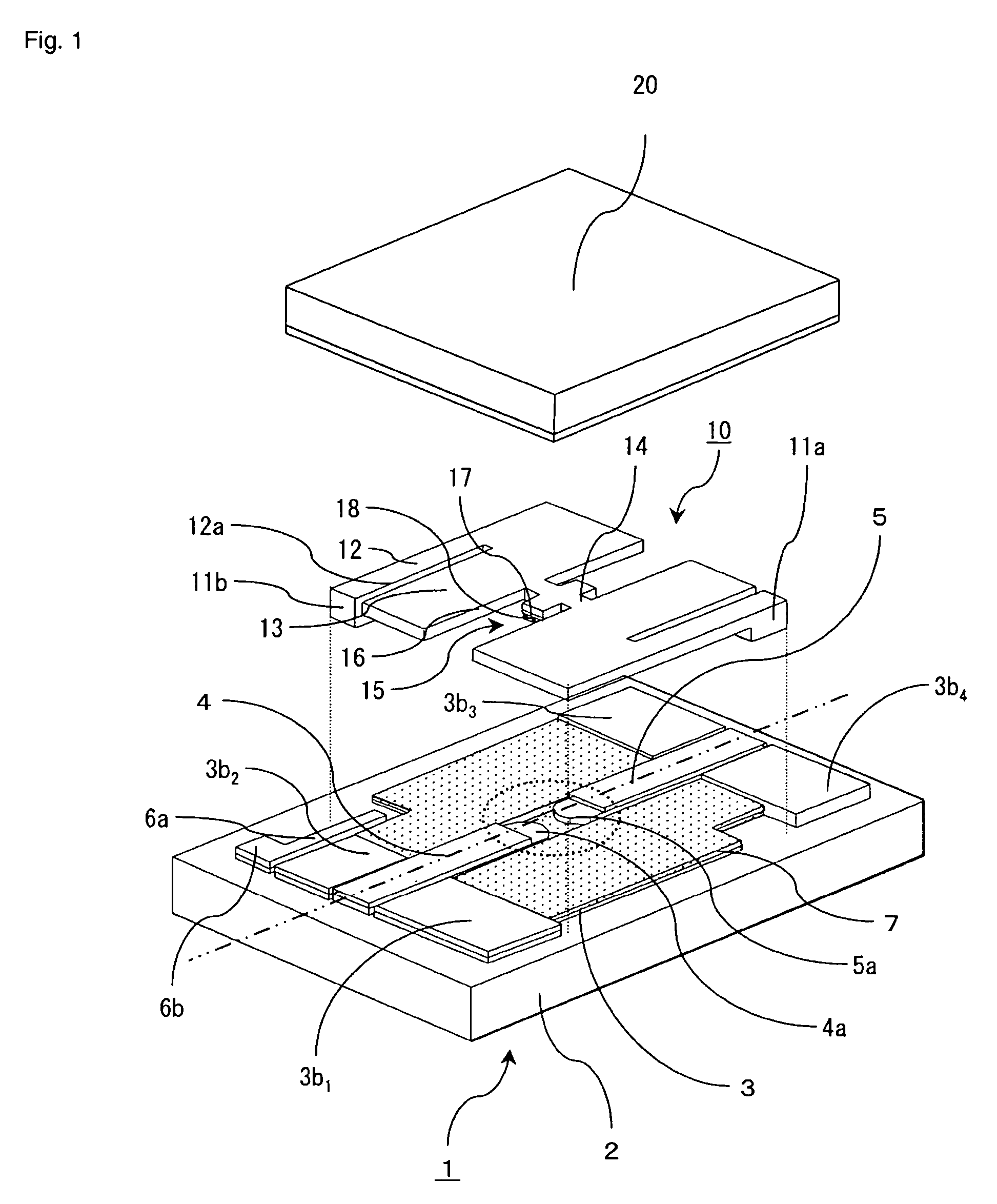

Liquid crystal display device

InactiveCN101097359AReduce film thickness variationLess uneven gapStatic indicating devicesNon-linear opticsLiquid-crystal displayComputer science

A liquid crystal display device includes: a liquid crystal layer interposed between a first substrate and a second substrate; a columnar spacer holding the liquid crystal layer; and a plurality of pixels arranged in matrix which constitutes a display unit, wherein: each of the pixels has a first display region and a second display region; the first display region has the liquid crystal layer thinner than the second display region; a protrusion portion is formed in the first display region of the first substrate; and the columnar spacer is formed only in the second display region in which the protrusion portion is not formed.

Owner:MITSUBISHI ELECTRIC CORP

Laminate body and method for manufacturing same

InactiveUS20150147675A1Improve adhesionReduce film thickness variationCell electrodesFinal product manufacturePolymer sciencePolymer chemistry

An object of the present invention is to provide a laminate having food adhesion between a support and a conductive layer. The laminate of the present invention comprises a conductive layer A formed on a support, the conductive layer A containing a conductive carbon material and a polymer, the polymer in the conductive layer A being dense at the surface in contact with the support.

Owner:DAI NIPPON PRINTING CO LTD

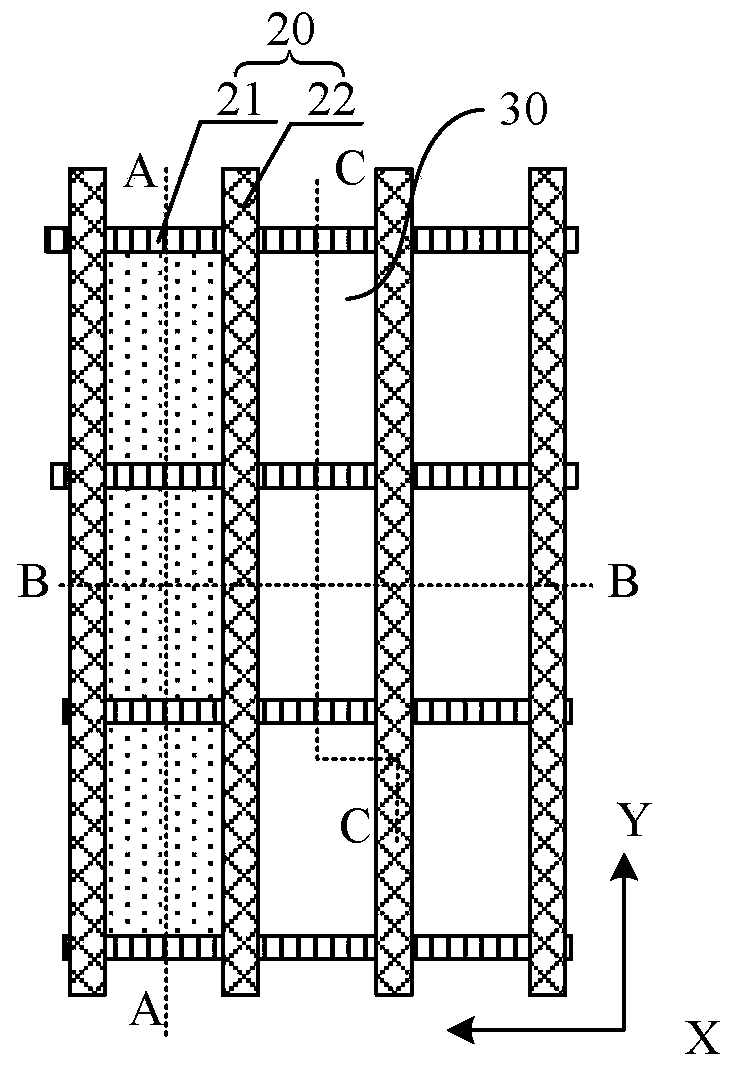

Contact switch for high frequency application

InactiveUS7038301B2Reduce lossSmall sizeElectrostatic/electro-adhesion relaysSemiconductor/solid-state device manufacturingEngineeringSignal lines

A plurality of fixed contacts and signal lines are provided on a fixed substrate. A movable contact which is closed or opened with the fixed contacts is provided on a movable substrate opposed to the fixed substrate. A film thickness of the fixed contacts is made to be smaller than that of the signal lines so that the movable contact is set in a concave portion constituted by the fixed contacts when the fixed contacts, and the movable contact are closed and the signal lines are linearly connected.

Owner:ORMON CORP

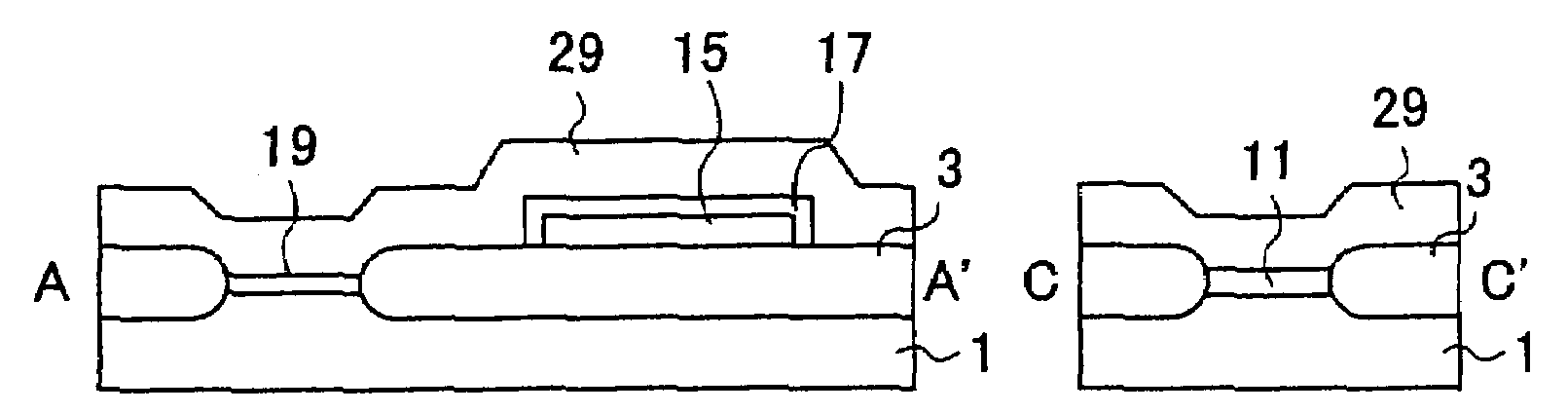

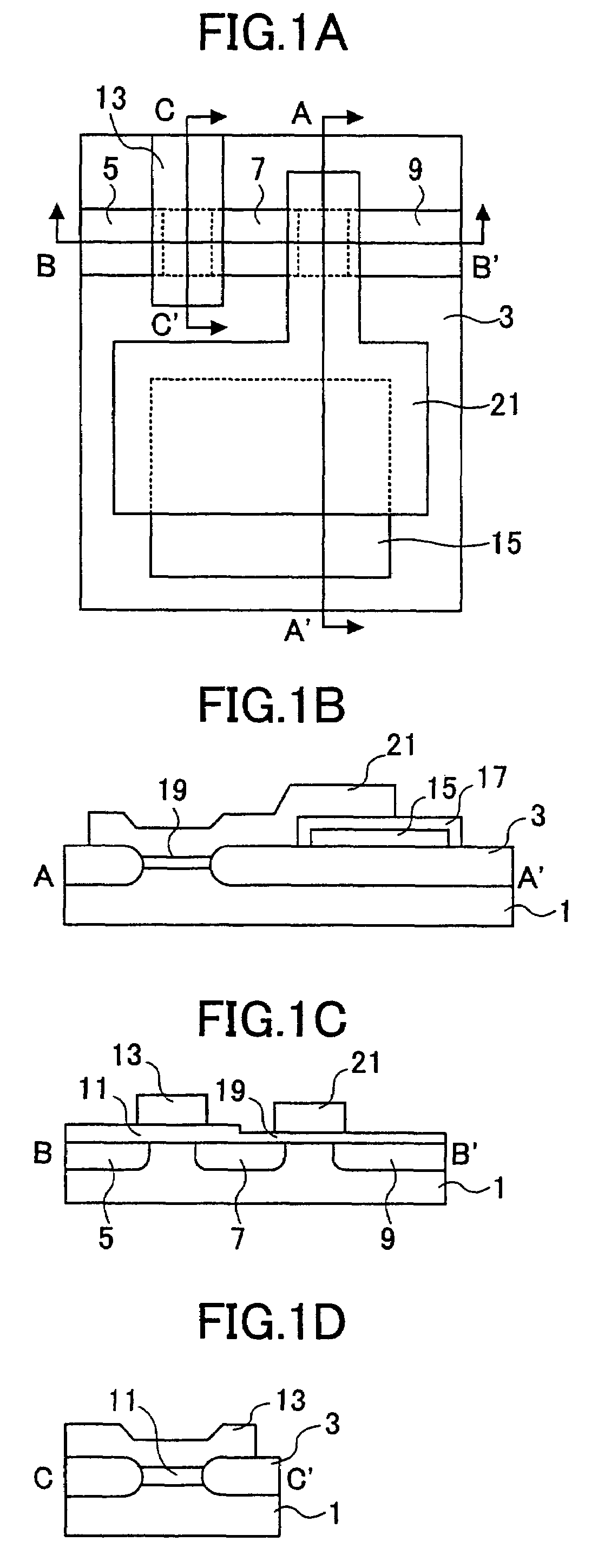

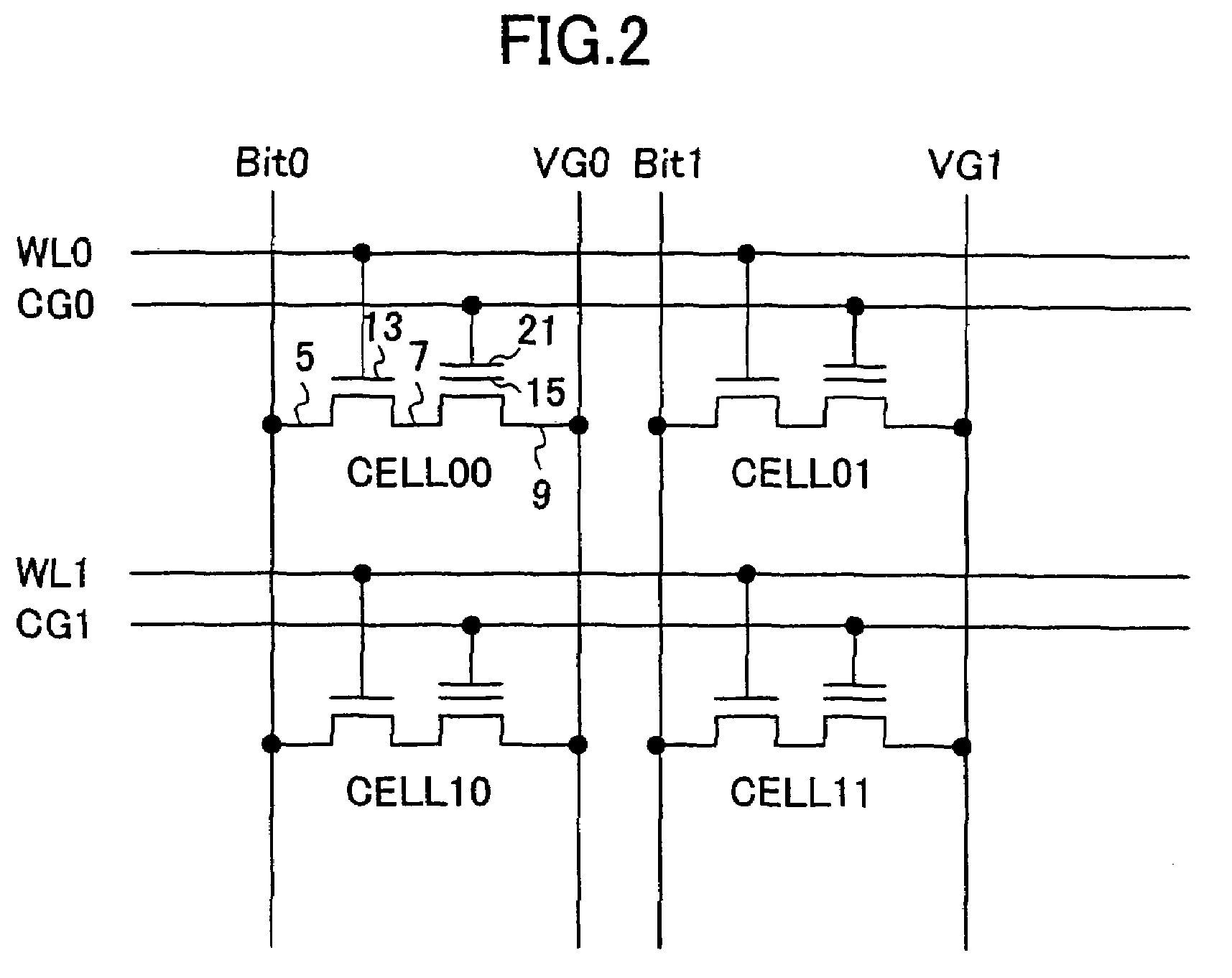

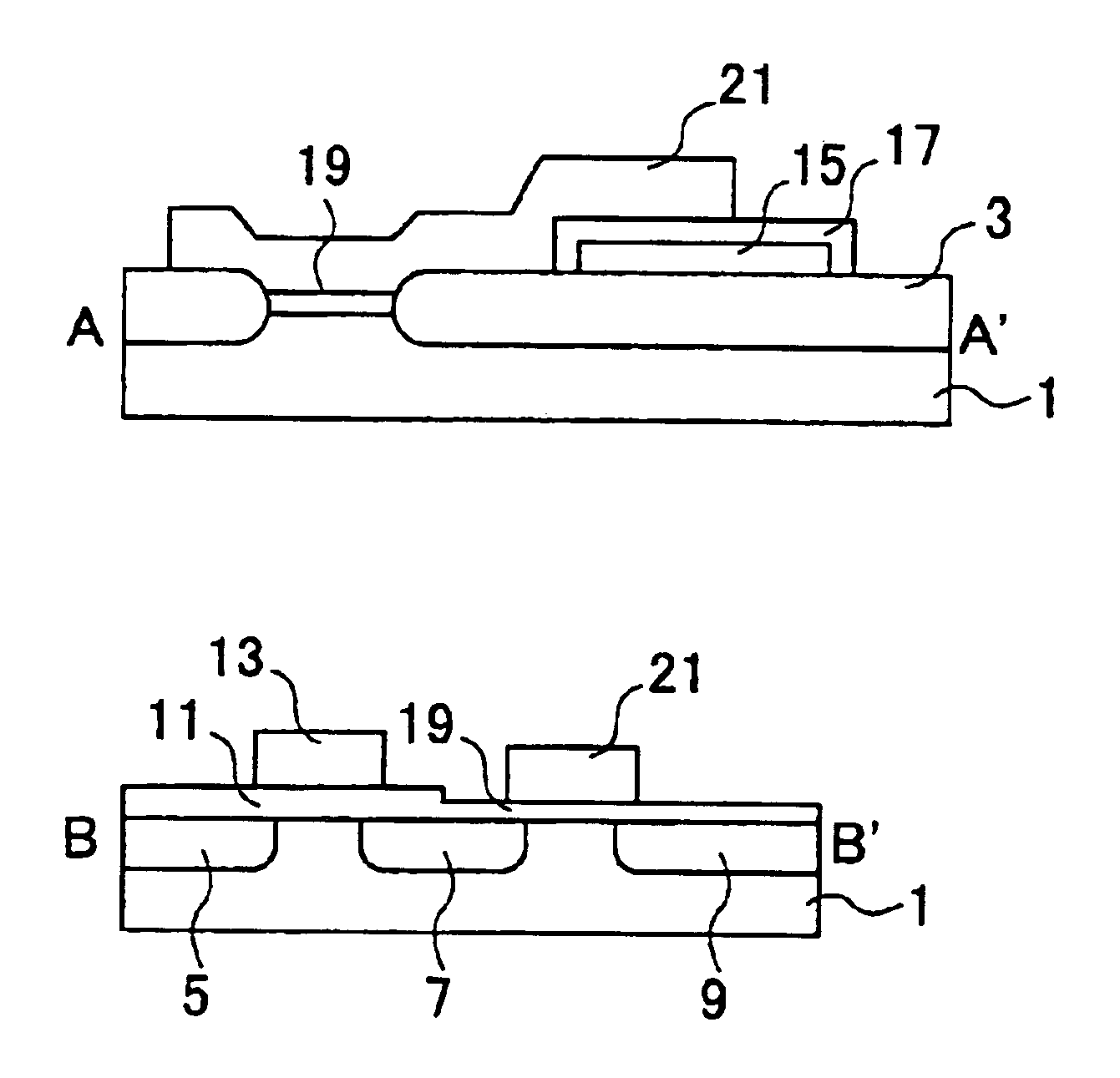

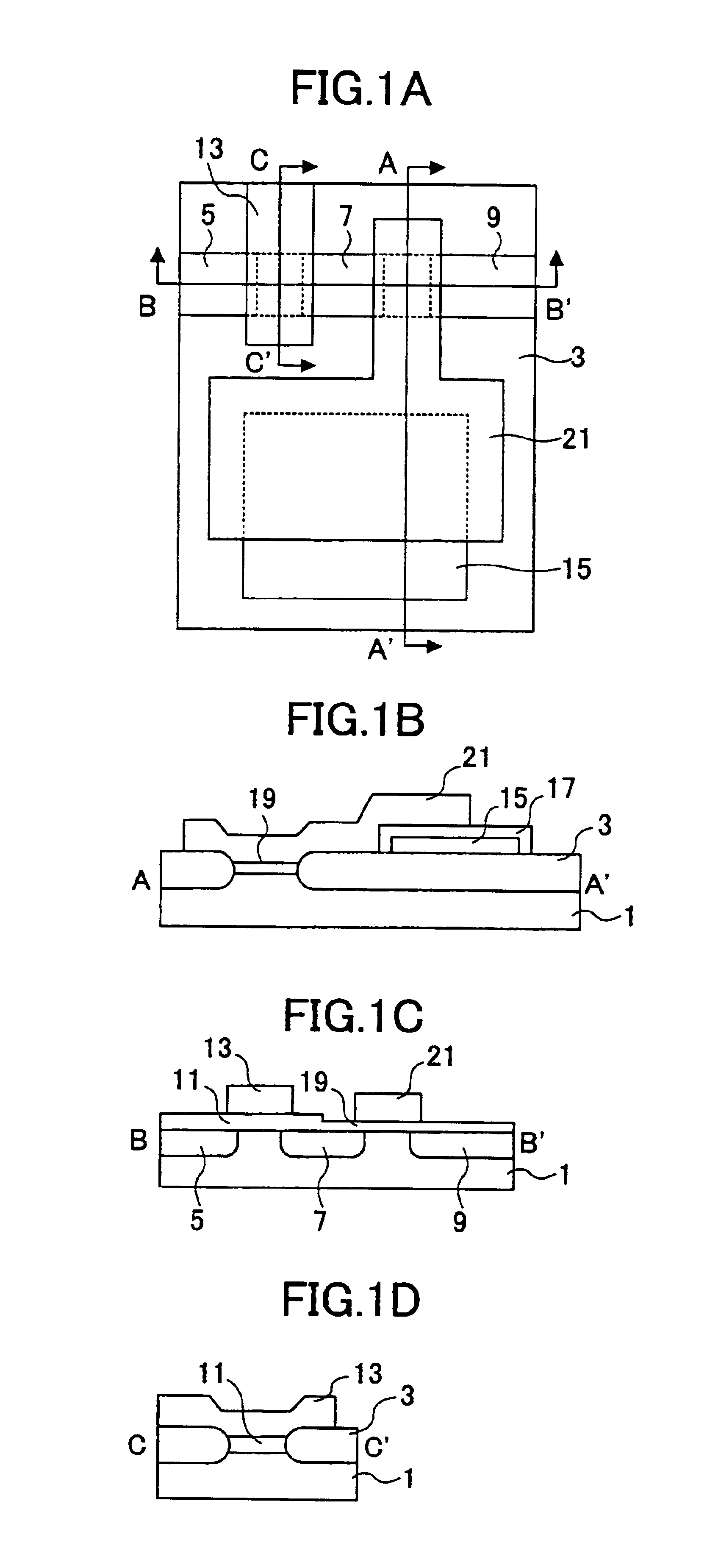

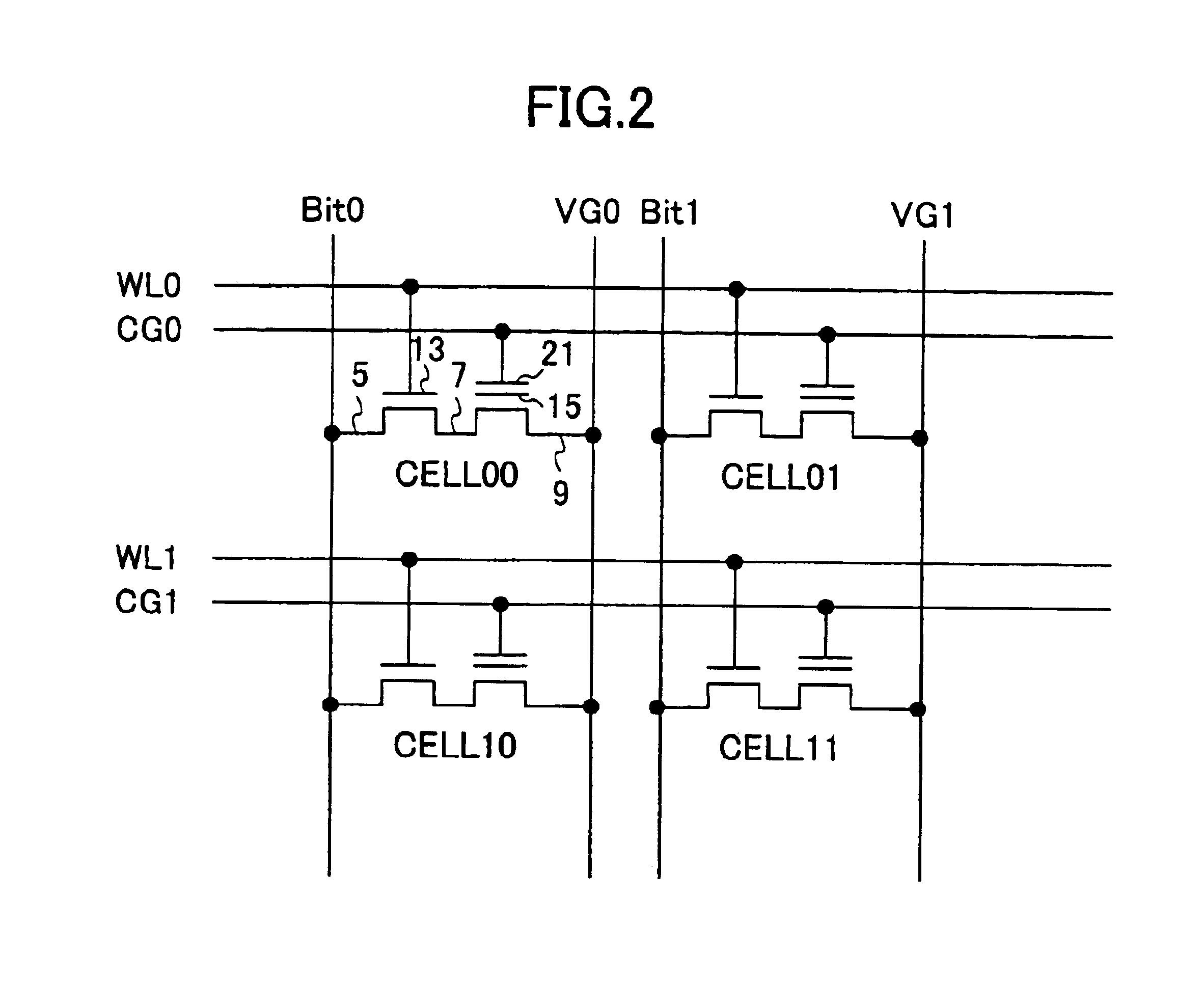

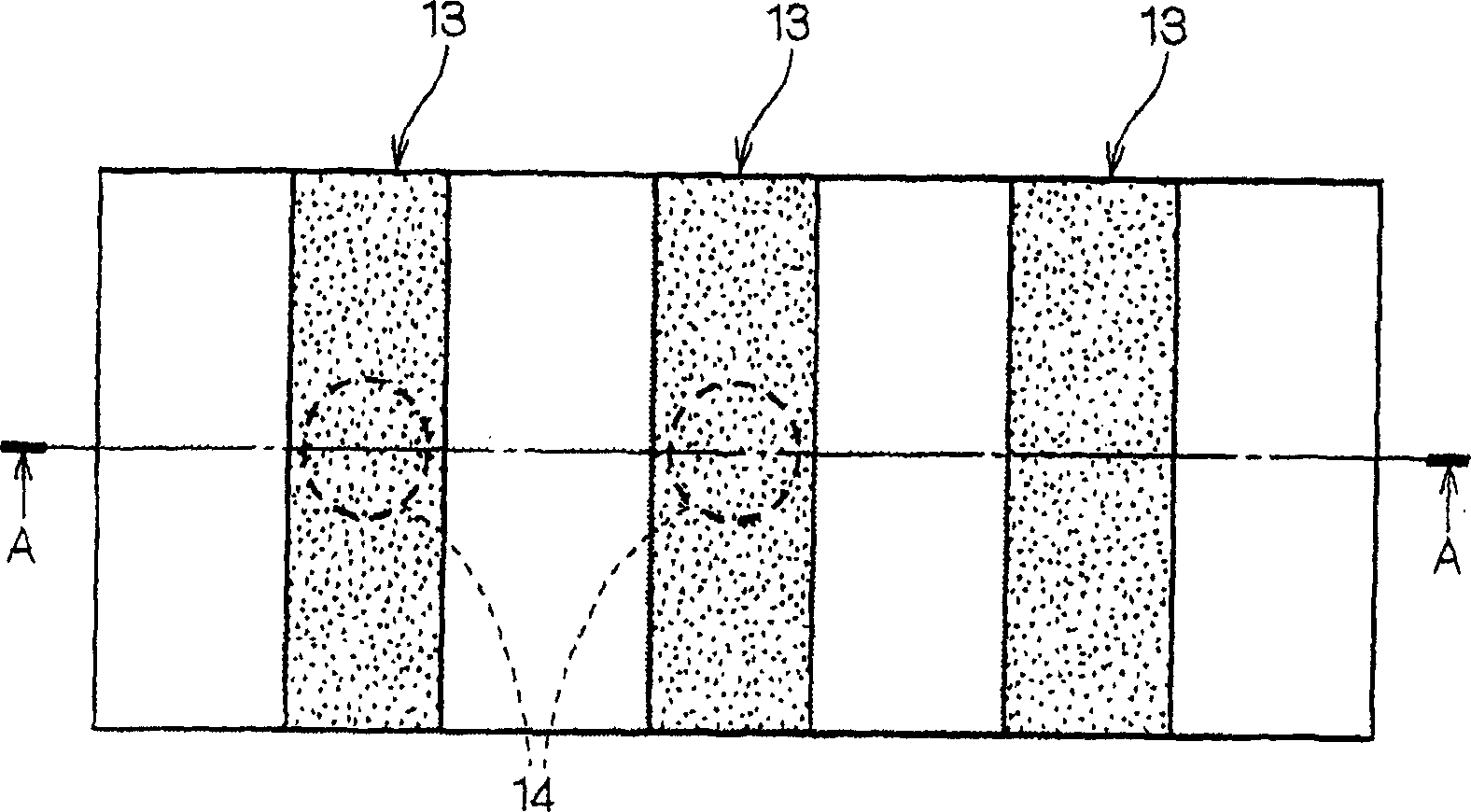

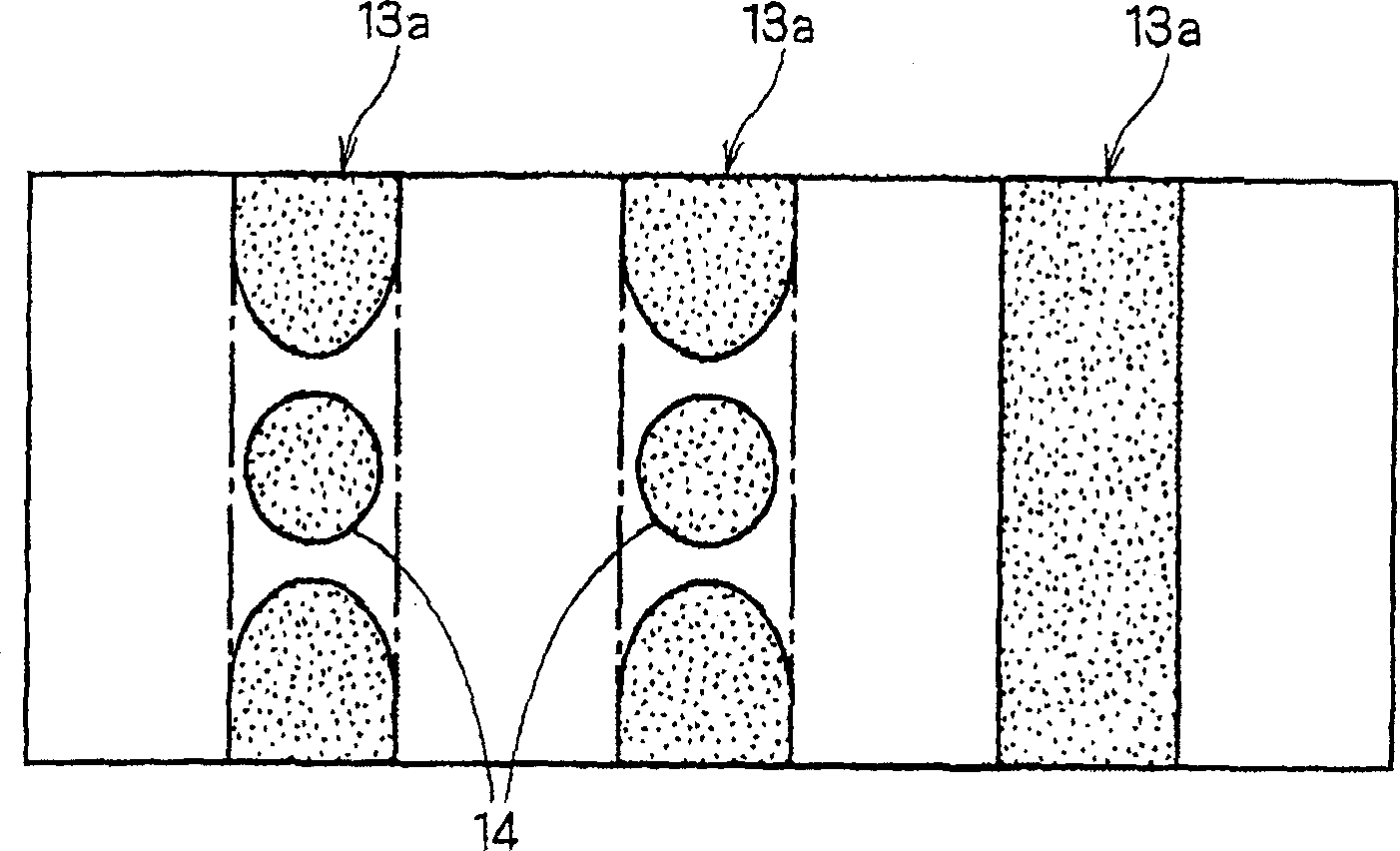

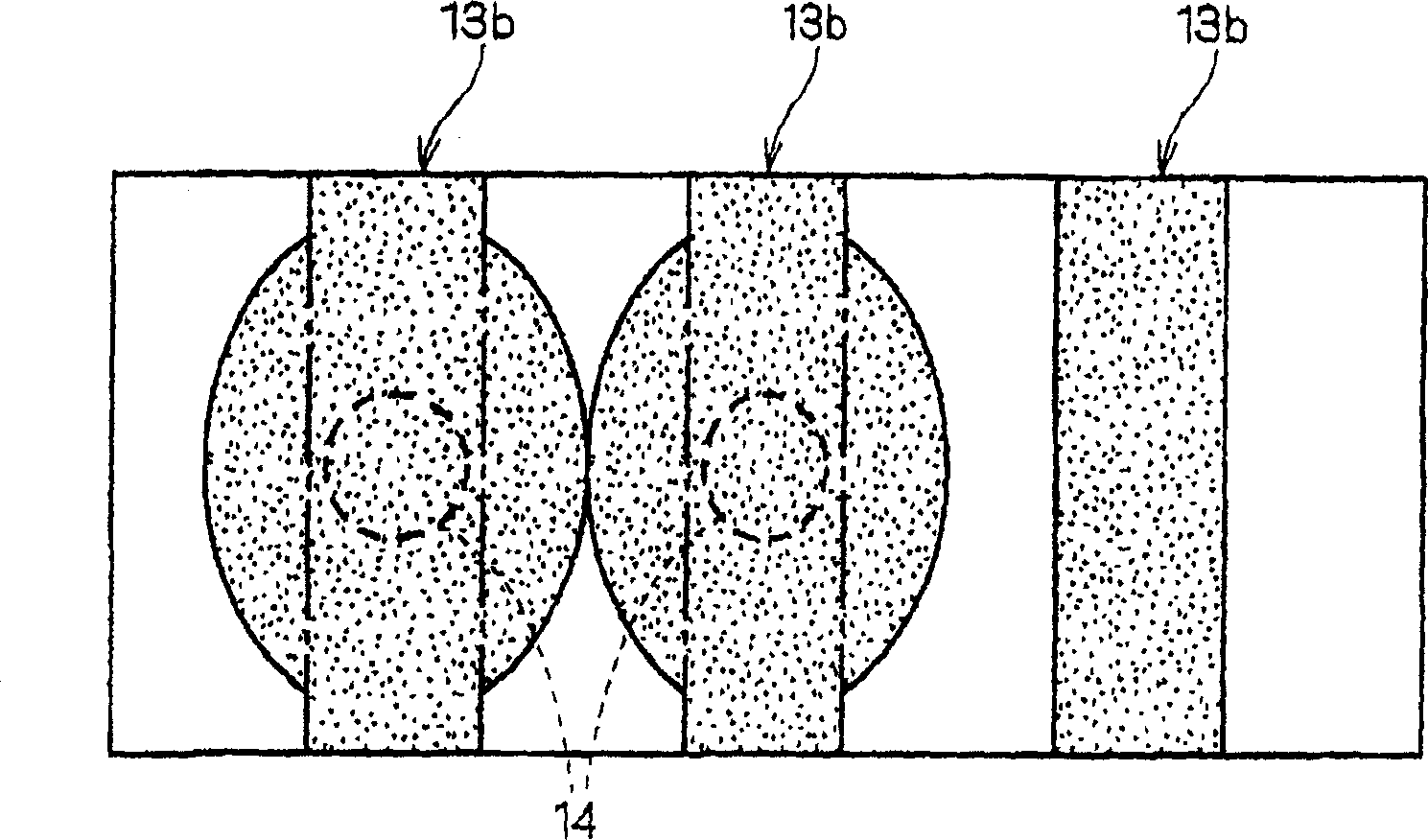

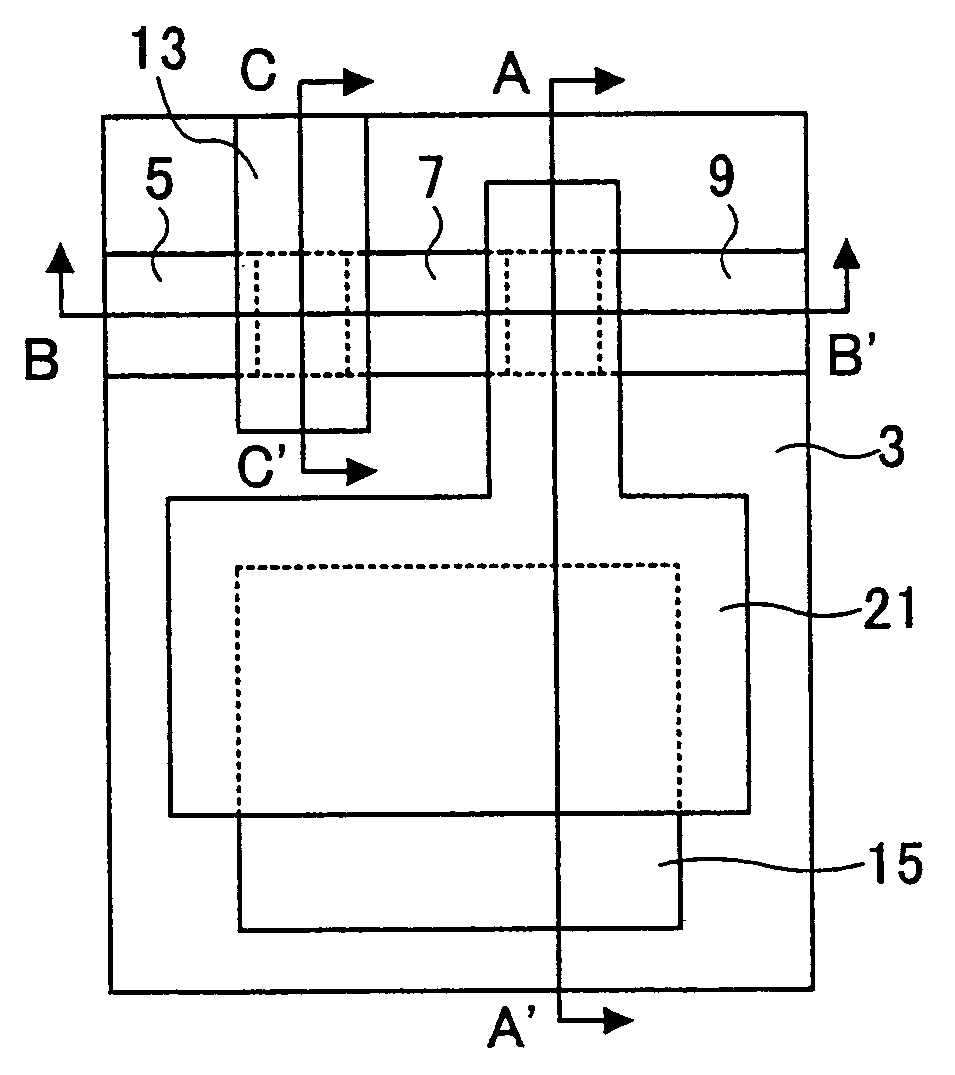

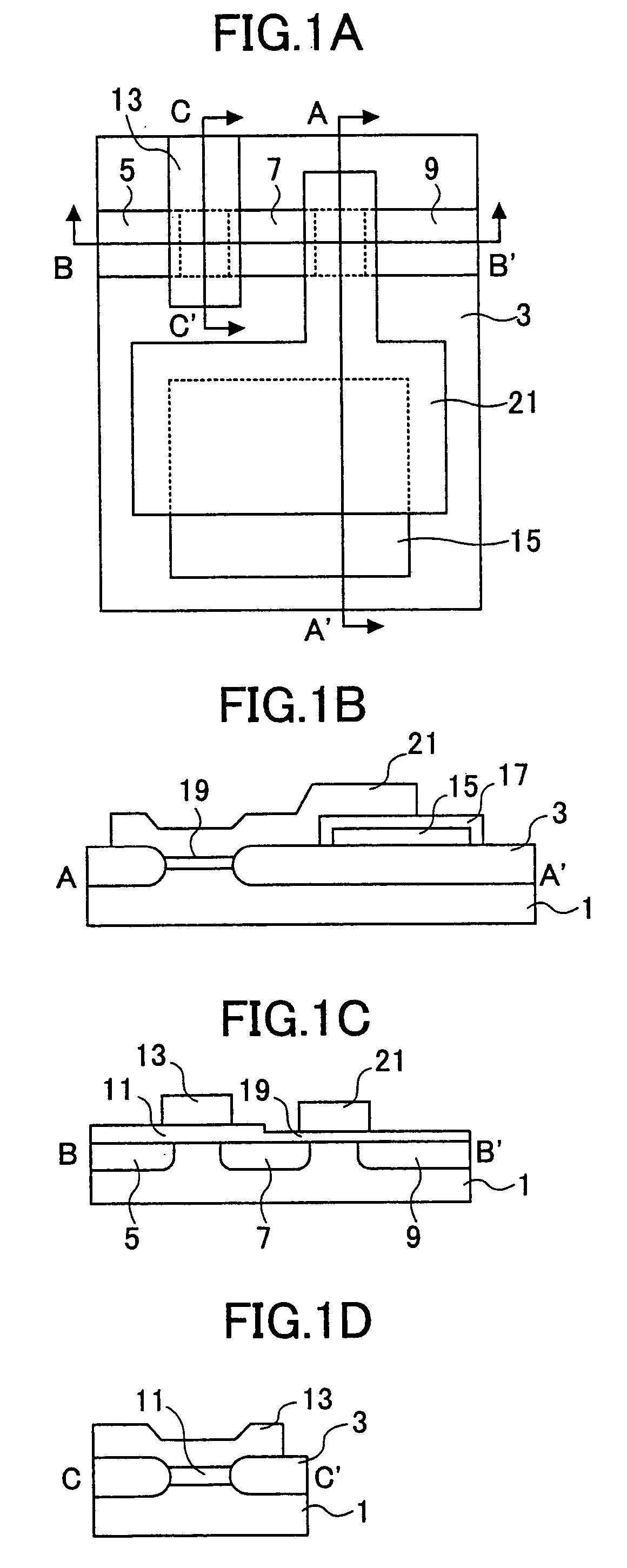

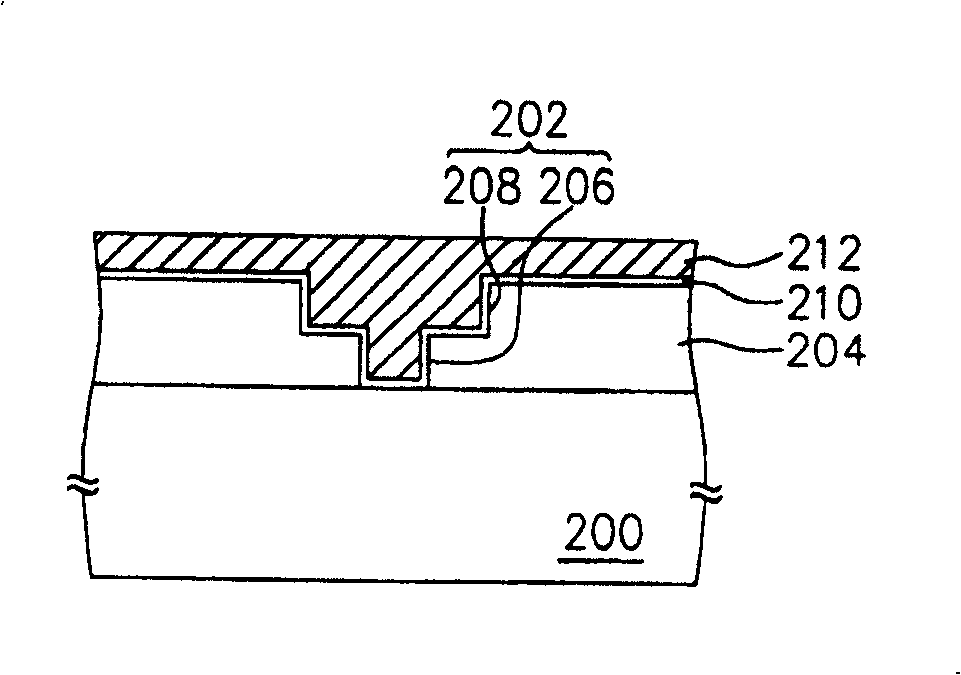

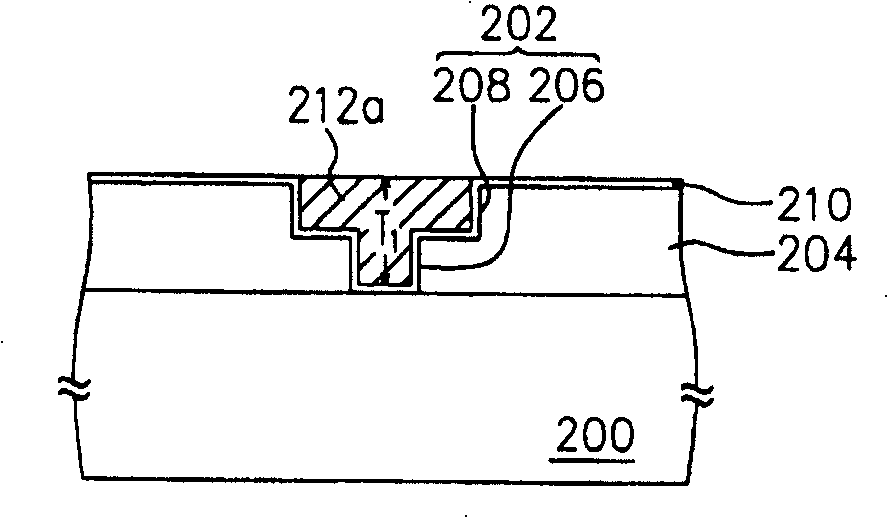

Semiconductor device and its manufacturing method

InactiveUS7314797B2Reduce film thickness variationImprove reliabilityTransistorSolid-state devicesInter layerLow voltage

A semiconductor device is capable of being applied with both a positive and a negative voltage to its control gate, and writing to its memory requires a low voltage. A control gate is formed on a memory unit region of a field oxide film, and an inter-layer silicon oxide film is formed on its surface. A gate oxide film for a non-volatile memory is formed on a P substrate between N type diffusion layers. The floating gate is formed on the inter-layer silicon oxide film, the field oxide film, and the gate oxide film for the non-volatile memory. Since a large coupling ratio between the control gate and the floating gate is available on the field oxide film, memory rewriting requires only a low voltage. Further, since the control gate is formed by a poly silicon film, both a positive voltage and a negative voltage can be applied to the control gate.

Owner:RICOH KK

Semiconductor device and its manufacturing method

InactiveUS6949790B2Reduce film thickness variationImprove reliabilityTransistorSolid-state devicesLow voltageSilicon oxide

A semiconductor device is capable of being applied with both a positive and a negative voltage to its control gate, and writing to its memory requires a low voltage. A control gate is formed on a memory unit region of a field oxide film, and an inter-layer silicon oxide film is formed on its surface. A gate oxide film for a non-volatile memory is formed on a P substrate between N type diffusion layers. The floating gate is formed on the inter-layer silicon oxide film, the field oxide film, and the gate oxide film for the non-volatile memory. Since a large coupling ratio between the control gate and the floating gate is available on the field oxide film, memory rewriting requires only a low voltage. Further, since the control gate is formed by a poly silicon film, both a positive voltage and a negative voltage can be applied to the control gate.

Owner:RICOH KK

Electronic device manufacturing method

InactiveCN1523658AReduce film thickness variationResidue reductionSemiconductor/solid-state device manufacturingConductive pattern formationResistSemiconductor

It is an object to provide a semiconductor device having a buried multilayer wiring structure in which generation of a resolution defect of a resist pattern is suppressed and generation of a defective wiring caused by the resolution defect is reduced. After a via hole (7) reaching an etching stopper film (4) is formed, annealing is carried out at 300 to 400 DEG C. with the via hole (7) opened. As an annealing method, it is possible to use both a method using a hot plate and a method using a heat treating furnace. In order to suppress an influence on a lower wiring (20) which has been manufactured, heating is carried out for a short time of approximately 5 to 10 minutes by using the hot plate. Consequently, a by-product staying in an interface of an upper protective film (6) and an interlayer dielectric film (5) having a low dielectric constant and a by-product staying in an interface of the etching stopper film (4) and the interlayer dielectric film (5) having a low dielectric constant are discharged so that an amount of the residual by-product can be decreased.

Owner:RENESAS ELECTRONICS CORP +1

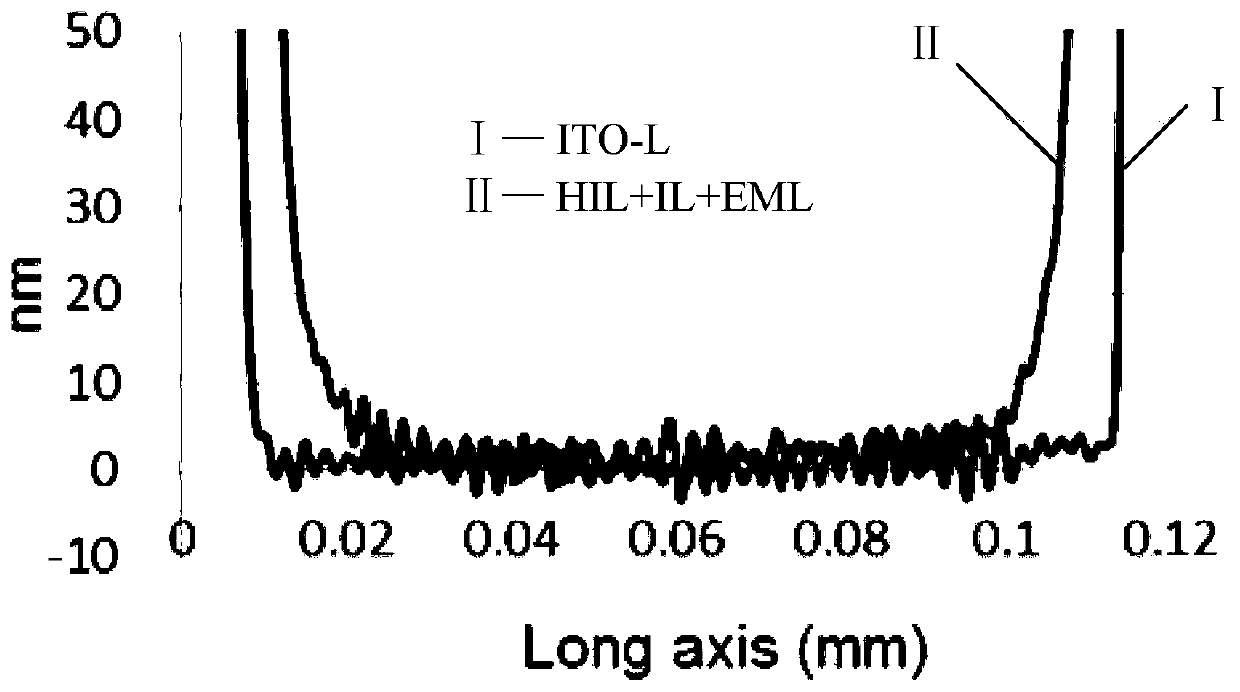

Display substrate, preparation method thereof and display device

ActiveCN111463353AImprove brightness uniformityUniform film thicknessSolid-state devicesSemiconductor/solid-state device manufacturingHole injection layerDisplay device

The invention discloses a display substrate, a preparation method thereof and a display device. The display substrate comprises an underlayer substrate, a pixel defining layer and a light-emitting structure layer, wherein the pixel defining layer is arranged on one side of the underlayer substrate, and a plurality of sub-pixel areas are defined by the pixel defining layer; and the light-emitting structure layer is arranged on the side, which is away from the underlayer substrate, of the pixel defining layer and located in the sub-pixel areas, the light-emitting structure layer comprises a holeinjection layer, and when hole injection ink is formed in the sub-pixel areas through an ink-jet printing method, the hole injection ink of at least two adjacent sub-pixel areas is communicated. According to the display substrate, the film thicknesses of the hole injection layers of at least two adjacent sub-pixel areas can be uniform, the film thickness difference between sub-pixels is reduced,and the brightness uniformity between the pixels is improved.

Owner:BOE TECH GRP CO LTD

Method for making ceramic electronic part, and plating bath

ActiveCN101128623AImproved solderabilitySmall film thickness deviationAnodisationFixed capacitor electrodesAdhesiveDissolution

A method for manufacturing a ceramic electronic component, comprising: a step of preparing an electronic component forming body composed of Ba-containing ceramics; and a step of forming an electrode on the outer surface of the electronic component forming body, and the electrode has a The Sn coating film is characterized in that, as the plating bath used when forming the Sn coating film, the Sn ion concentration A is 0.03 to 0.51 mol / L, the sulfate ion concentration B is 0.005 to 0.31 mol / L, and the molar ratio A plating bath with a B / A of less than 1 and a pH in the range of 6.1 to 10.5. According to the present invention, when the Sn plating film is formed, the elution of Ba from the electronic component formed body hardly occurs, not only the adhesion between the electronic component formed bodies caused by the Sn plating film hardly occurs, but also the solderability is good. Method for manufacturing ceramic electronic components.

Owner:MURATA MFG CO LTD

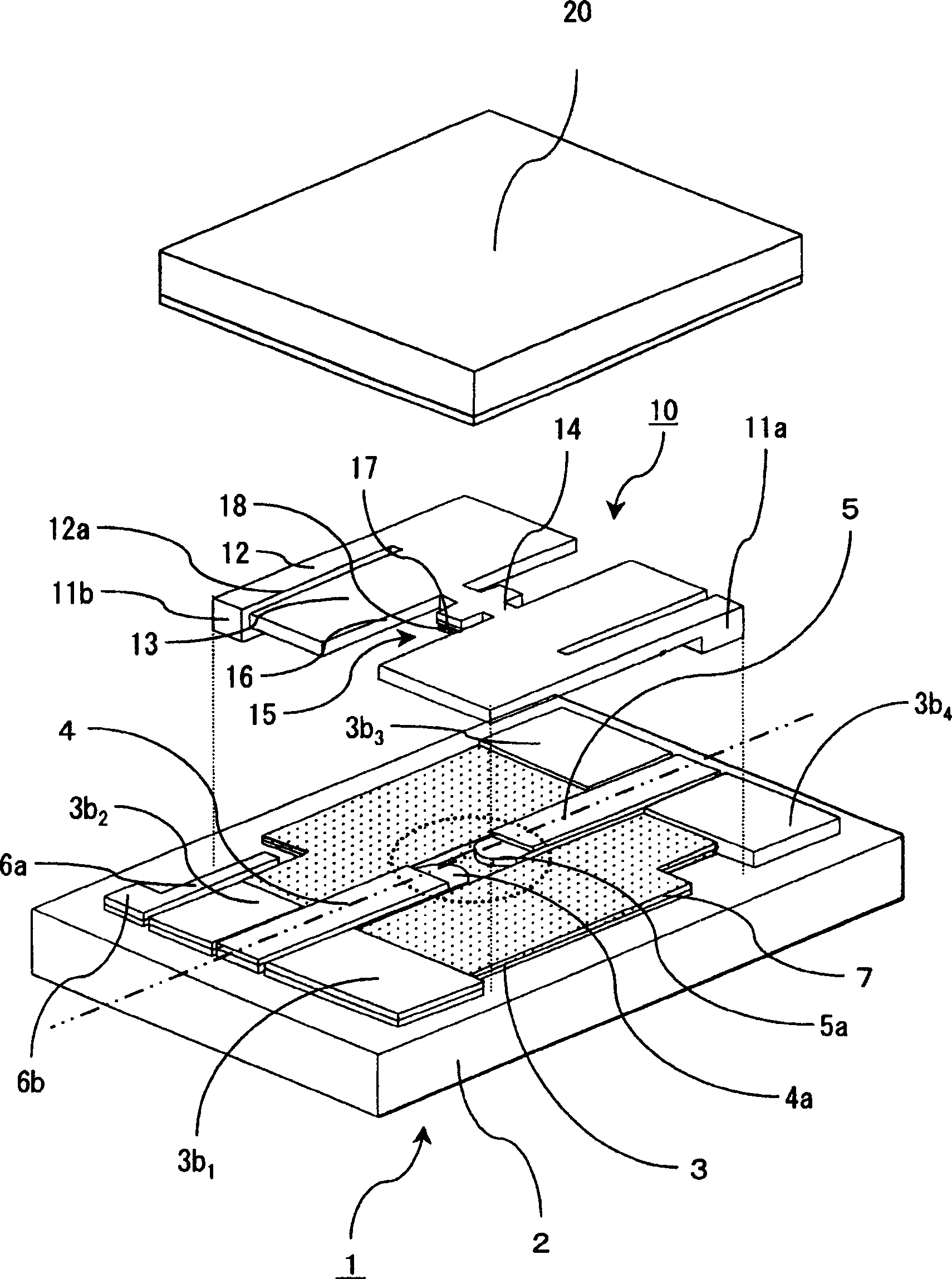

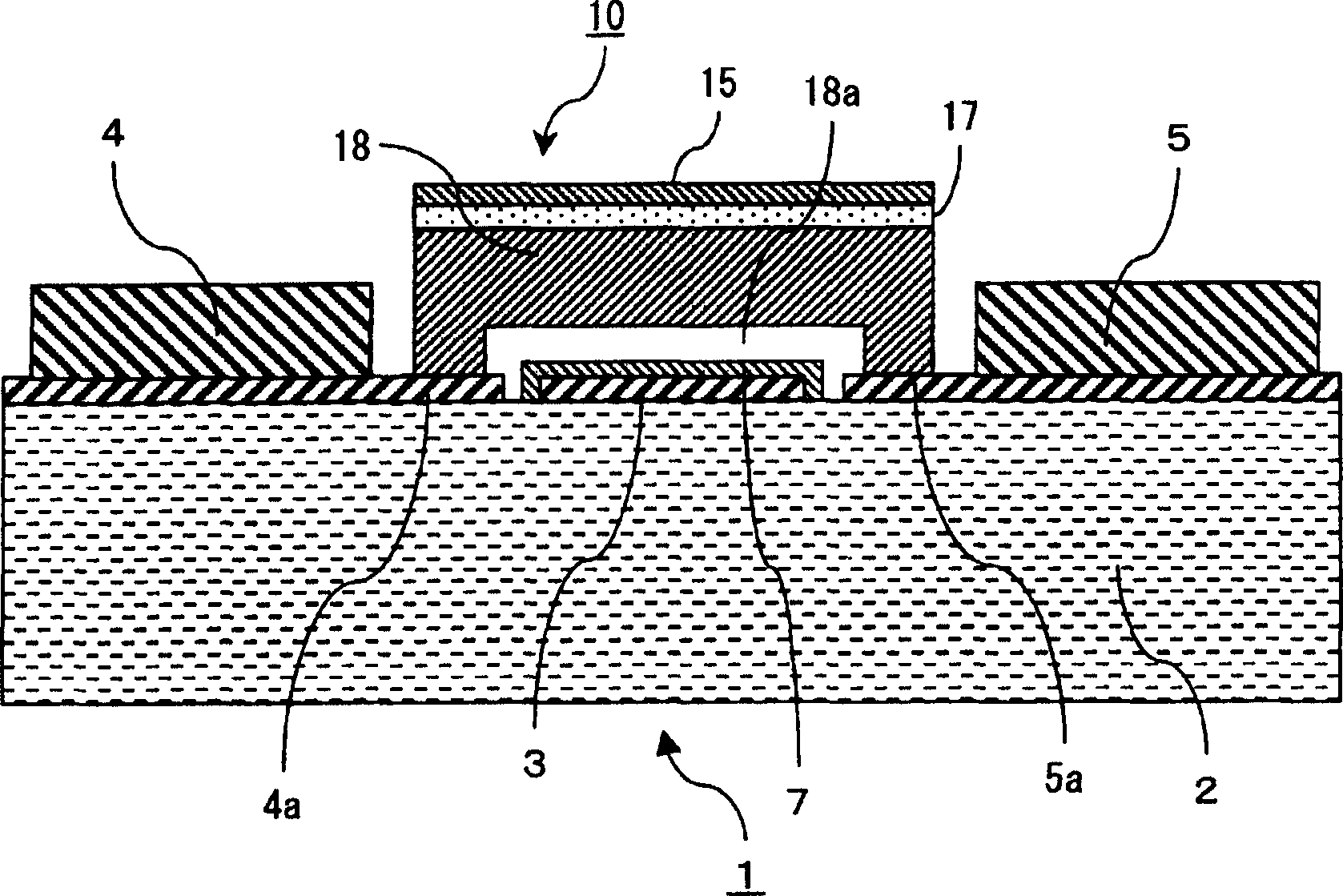

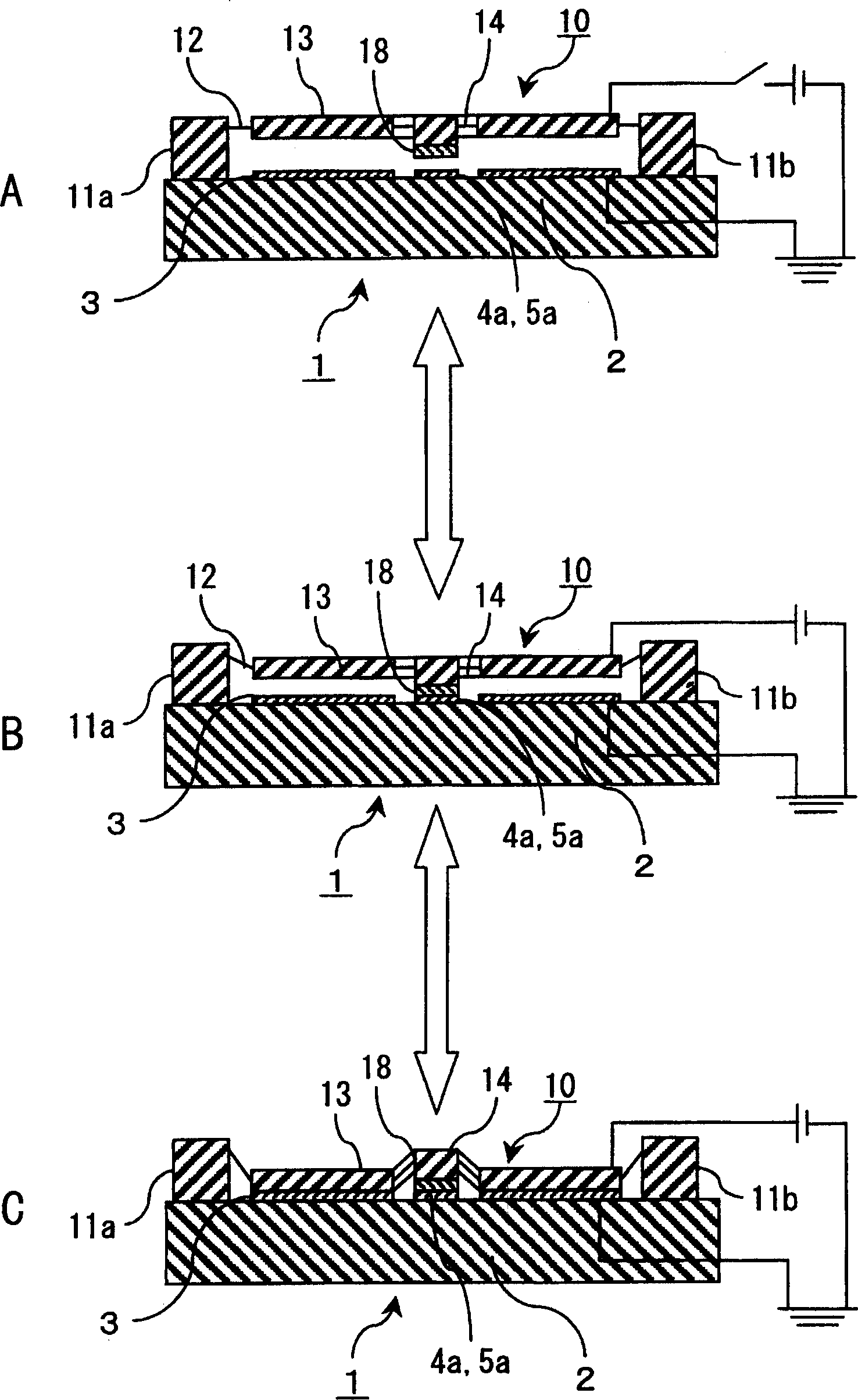

Contact switch and appts. provided with contact switch

InactiveCN1519877AGuaranteed contact reliabilityReduce film thickness variationElectrostatic/electro-adhesion relaysPiezoelectric/electrostrictive devicesEngineeringElectrical and Electronics engineering

To enable to reduce the film thickness variations at the contact point part by simple structural changes, and by reducing variations of gap amount between the contact points, stabilize actions at the time of closing of the contact points, and reduce propagation loss of a signal by improving the high frequency property. At a stationary substrate 1, a plurality of fixed contact points 4a, 5a and signal wires 4, 5 are arranged and installed. At a movable substrate 10 which counters the stationary substrate 1, the movable contact point 18 closed and separated from the fixed contact points 4a, 5a is installed. The film thickness of the fixed contact points 4a, 5a are made to be smaller than the film thickness of the signal wires 4, 5, and at the closing of the fixed contact points 4a, 5a and the movable point 18, the movable point 18 is made to enter into a recess part constituted of the fixed contact points 4a, 5a, and conduction of the signal wires 4, 5 is carried out linearly.

Owner:ORMON CORP

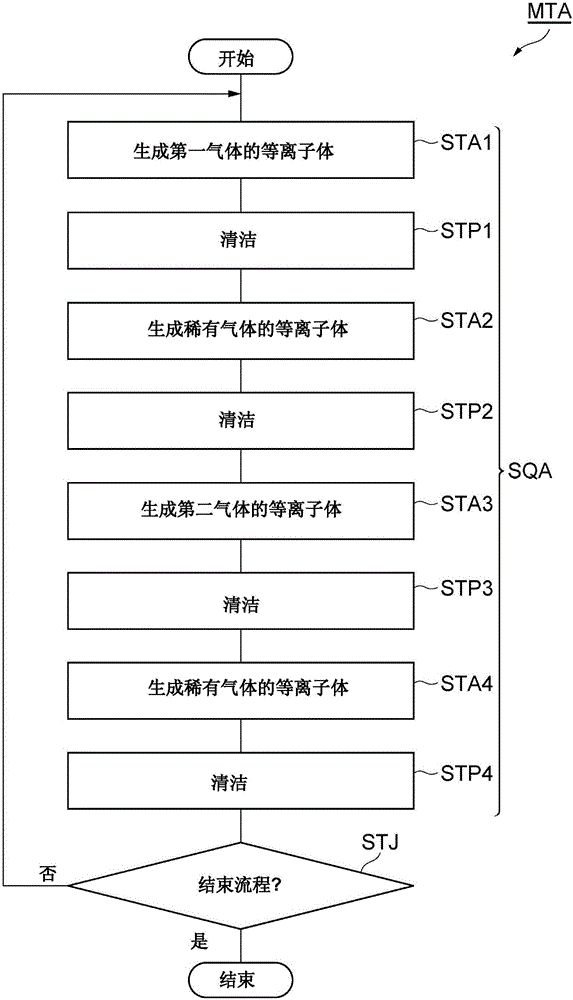

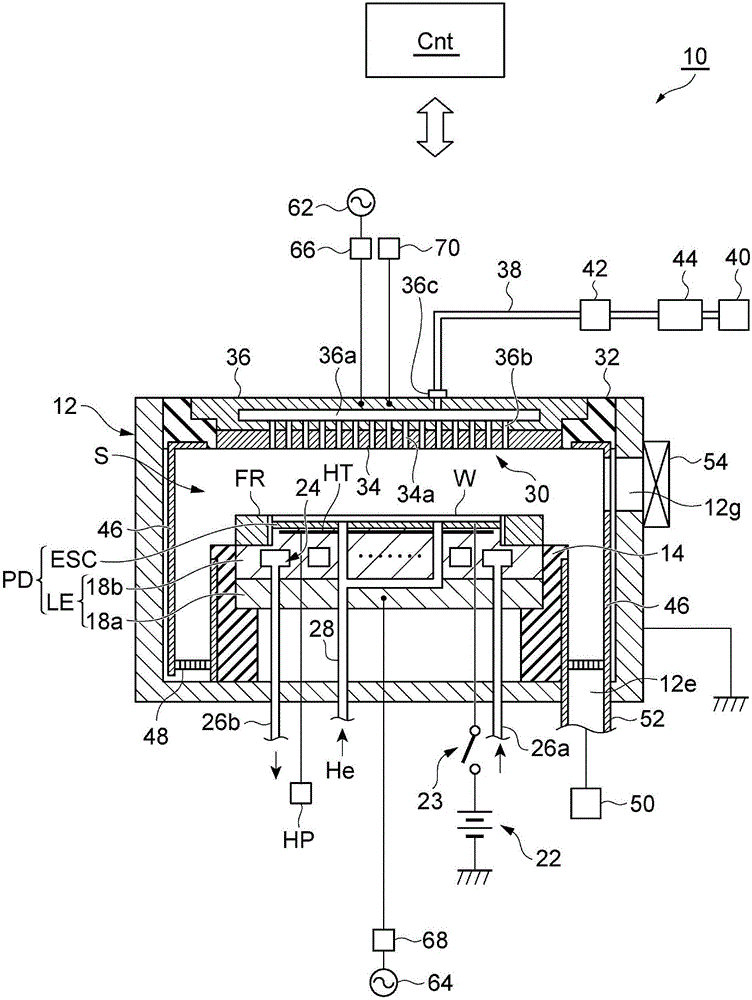

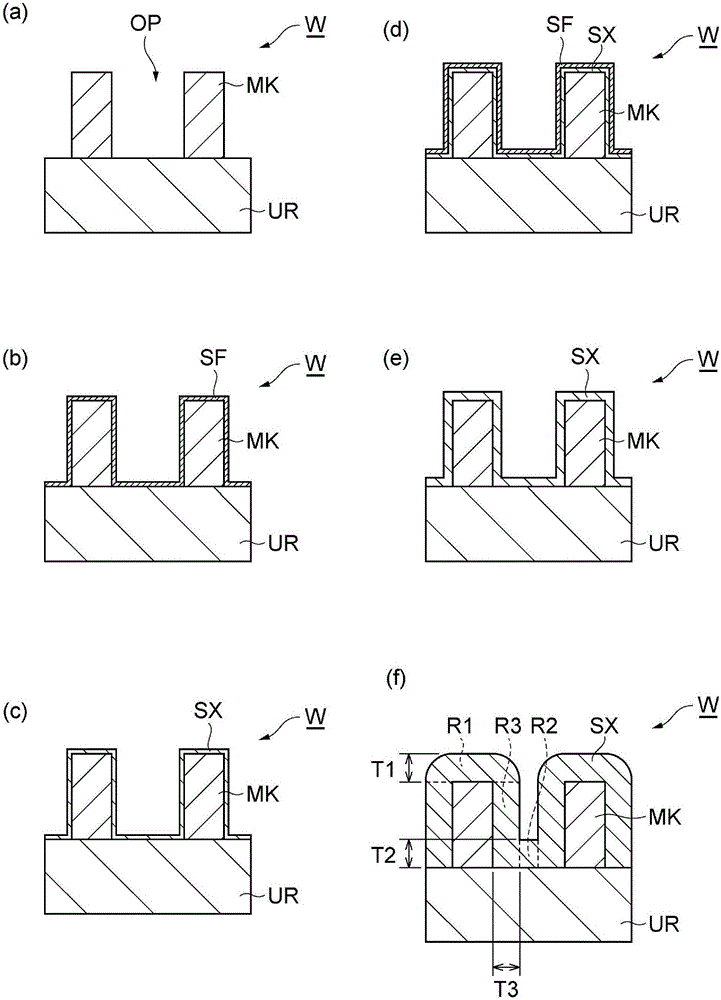

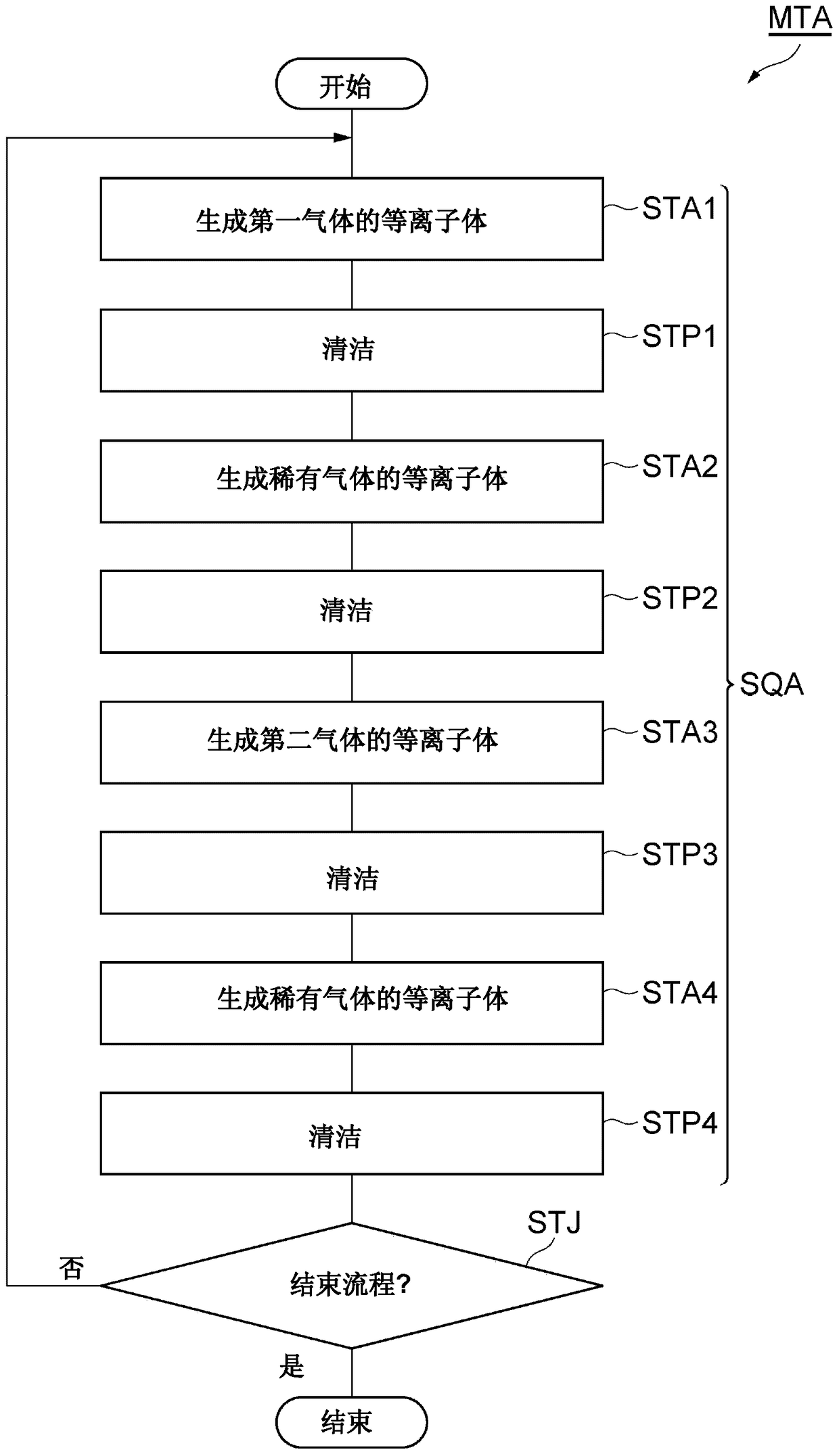

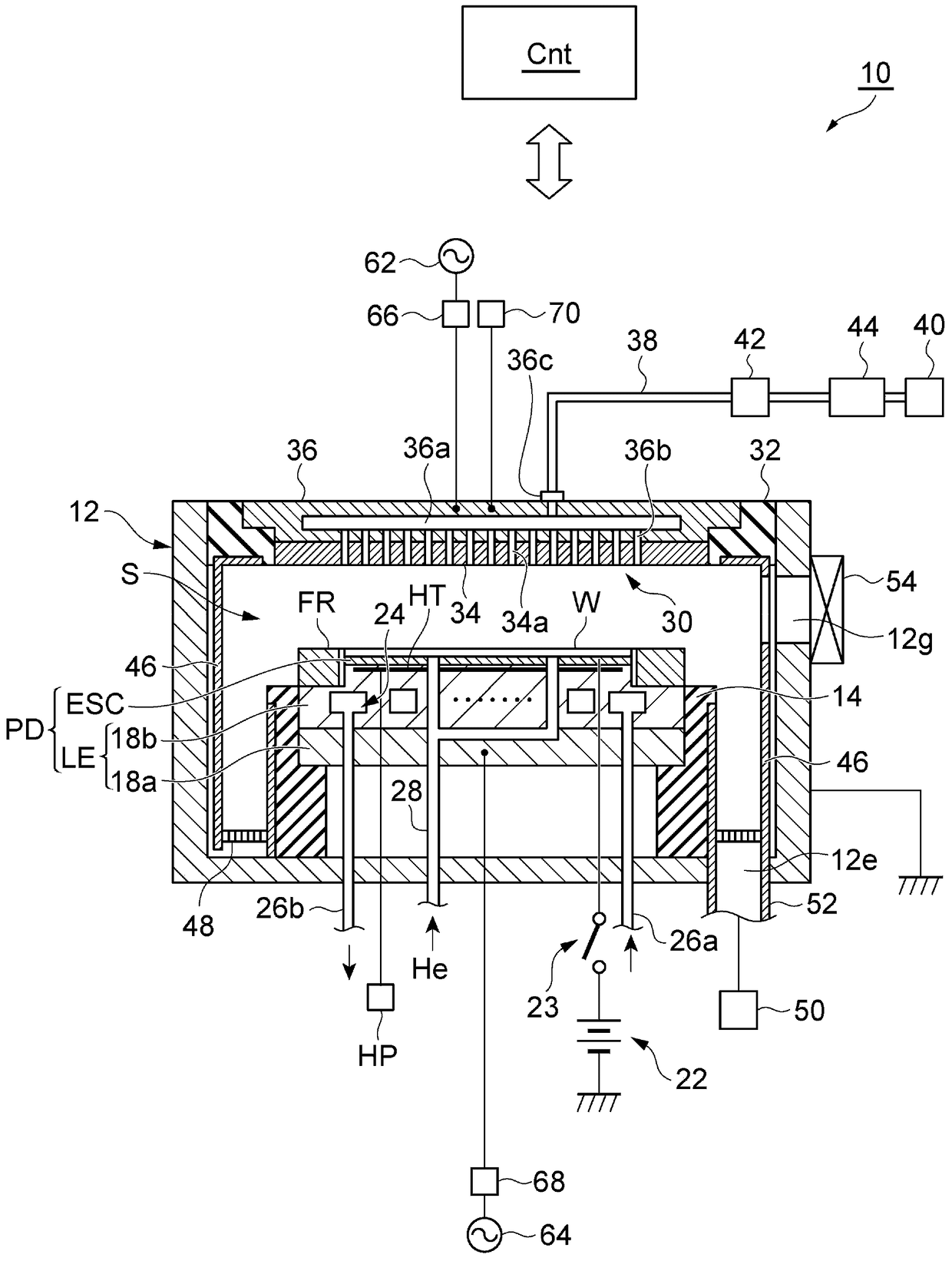

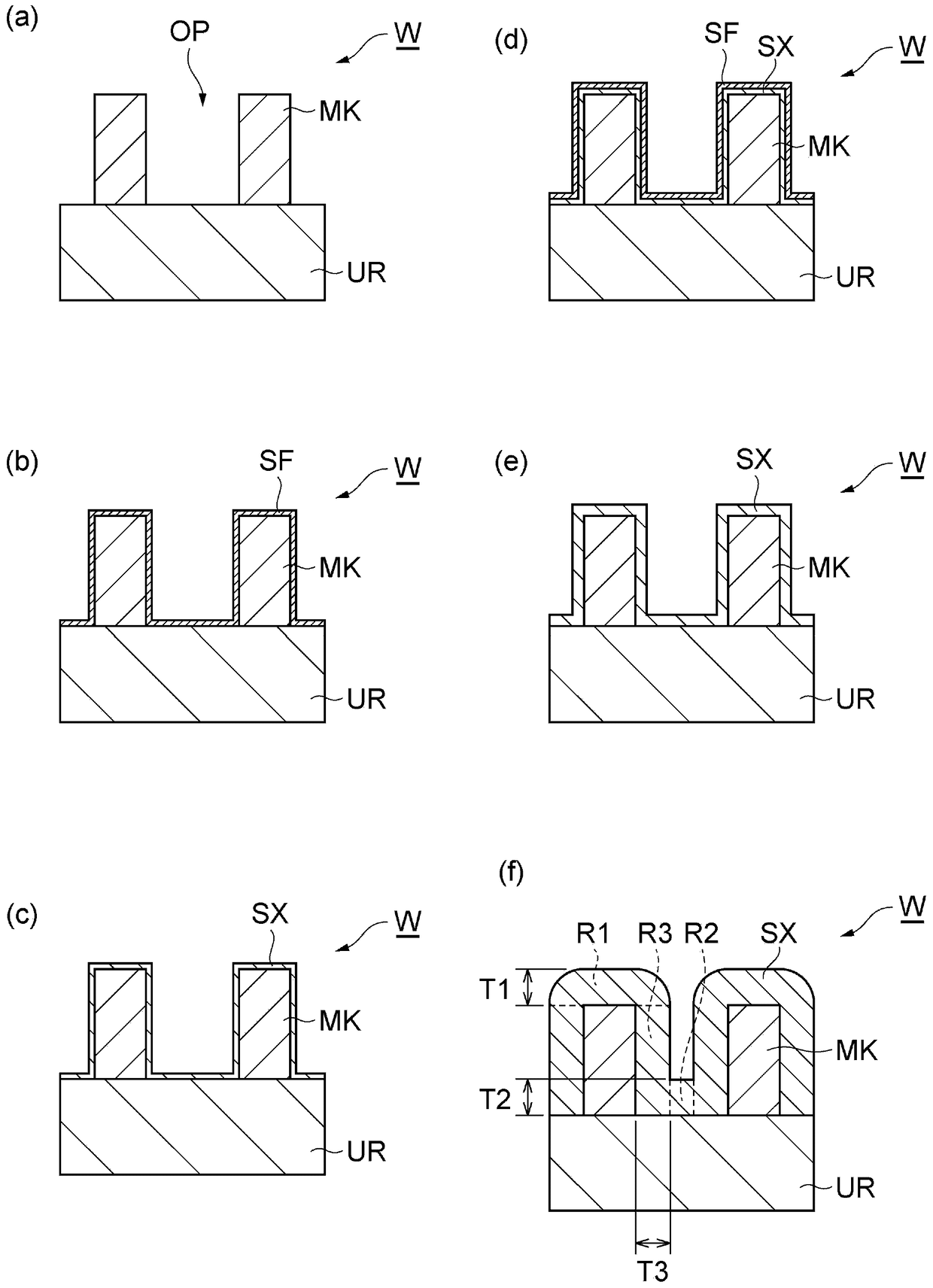

Method of processing a target object

ActiveCN105845550AReduce film thickness variationSemiconductor/solid-state device manufacturingNoble gasSilicon oxide

The invention provides a method of processing a target object. Non-uniformity in a thickness of a silicon oxide film formed on a processing target object can be reduced even when an aspect ratio of an opening of a mask is increased. In one implementation method, a silicon oxide film is formed by repeating a sequence including: (a) a first process of forming a reactant precursor on the processing target object by generating plasma of a first gas containing a silicon halide gas within a processing vessel of a plasma processing apparatus; (b) a second process of generating plasma of a rare gas within the processing vessel after the first process; (c) a third process of forming a silicon oxide film by generating plasma of a second gas containing an oxygen gas within the processing vessel after the second process; and (d) a fourth process of generating plasma of a rare gas within the processing vessel after the third process.

Owner:TOKYO ELECTRON LTD

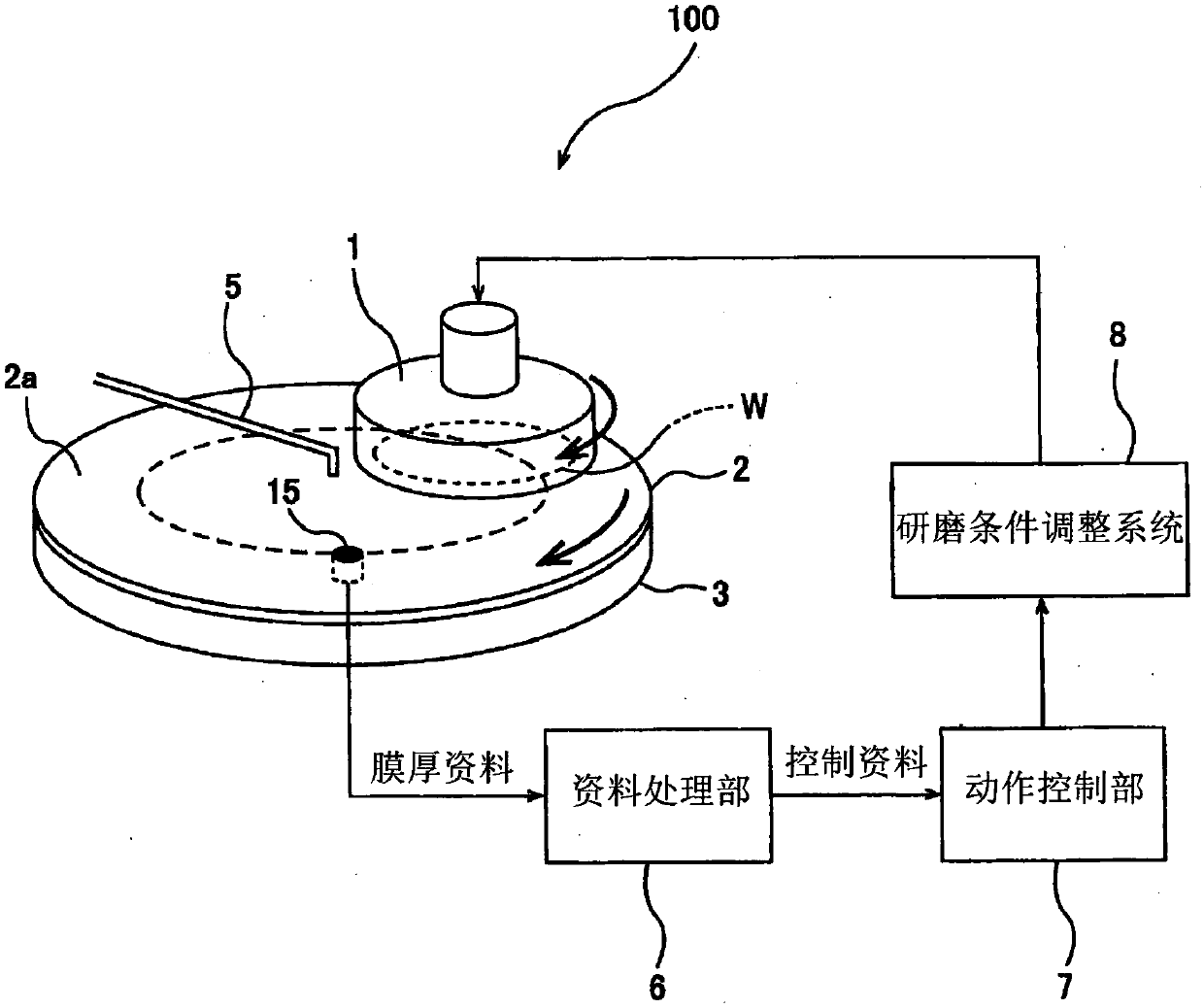

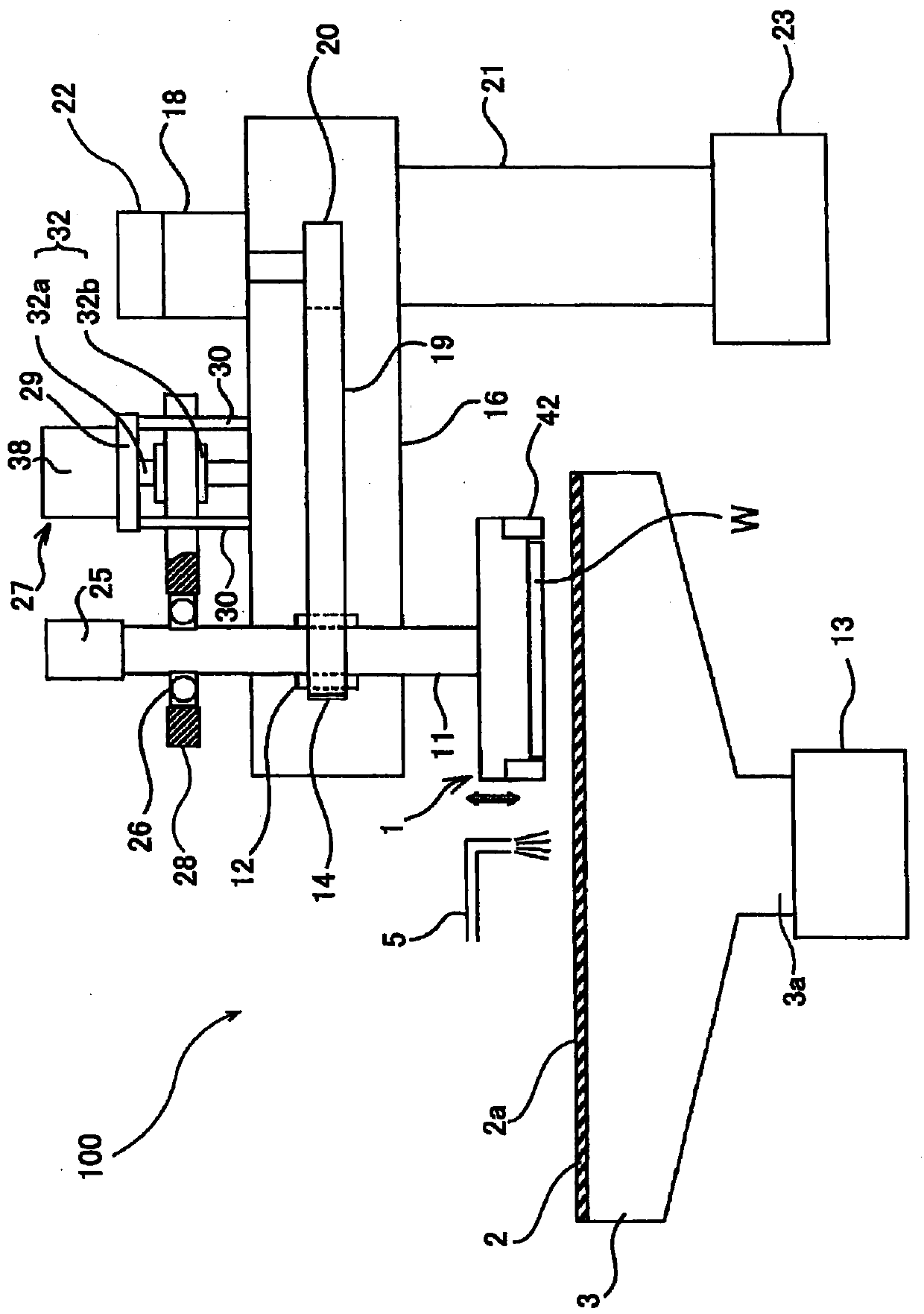

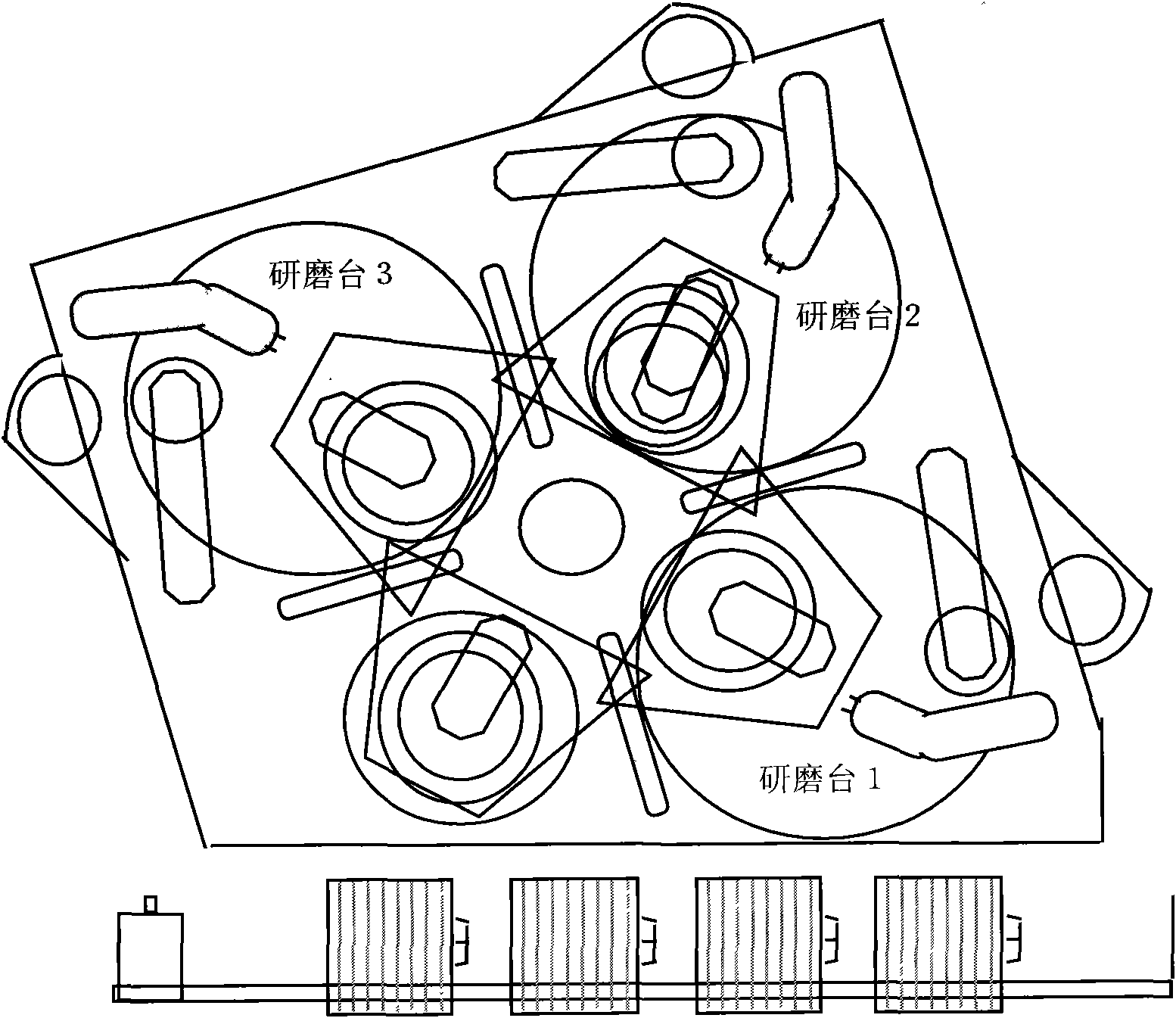

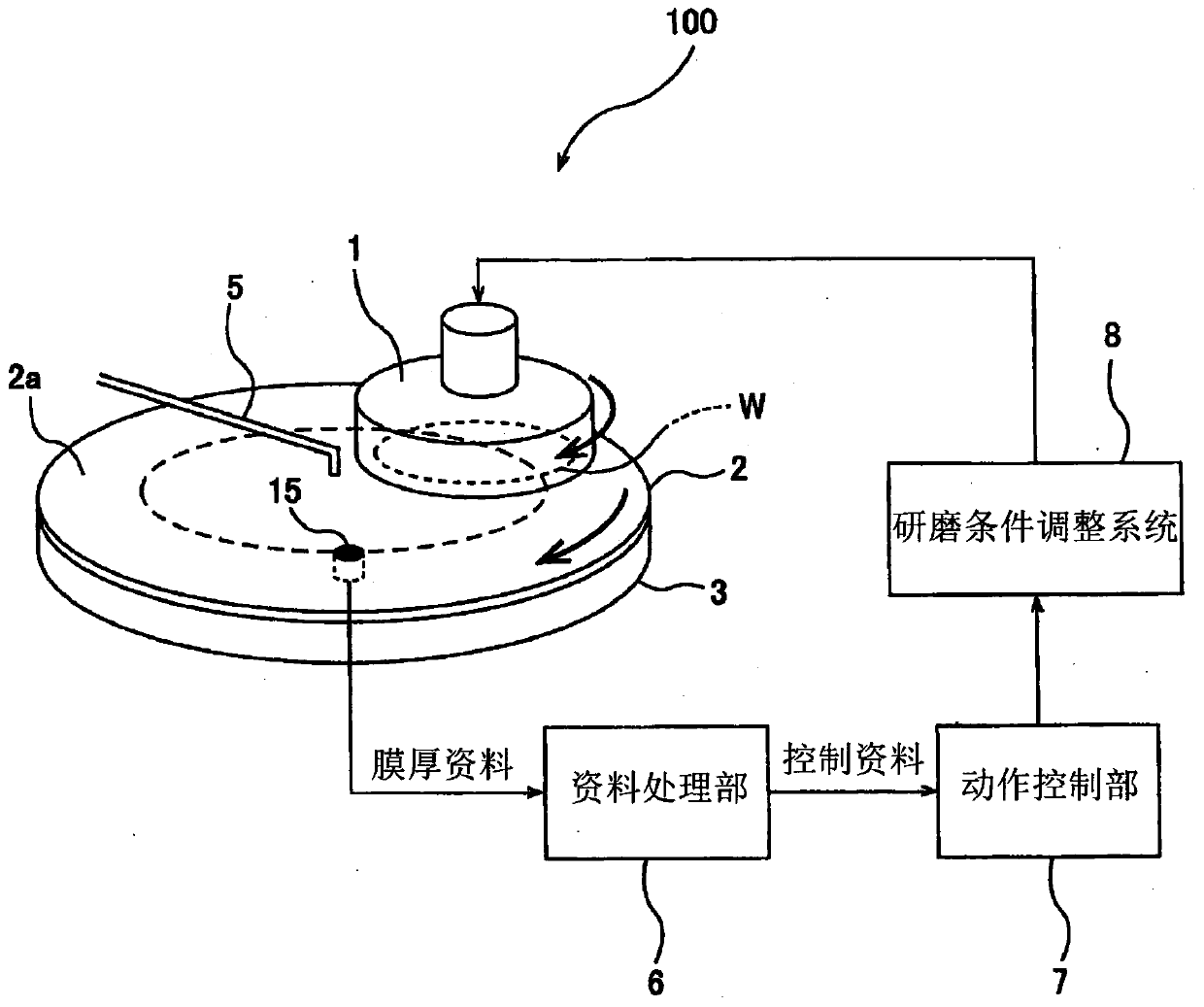

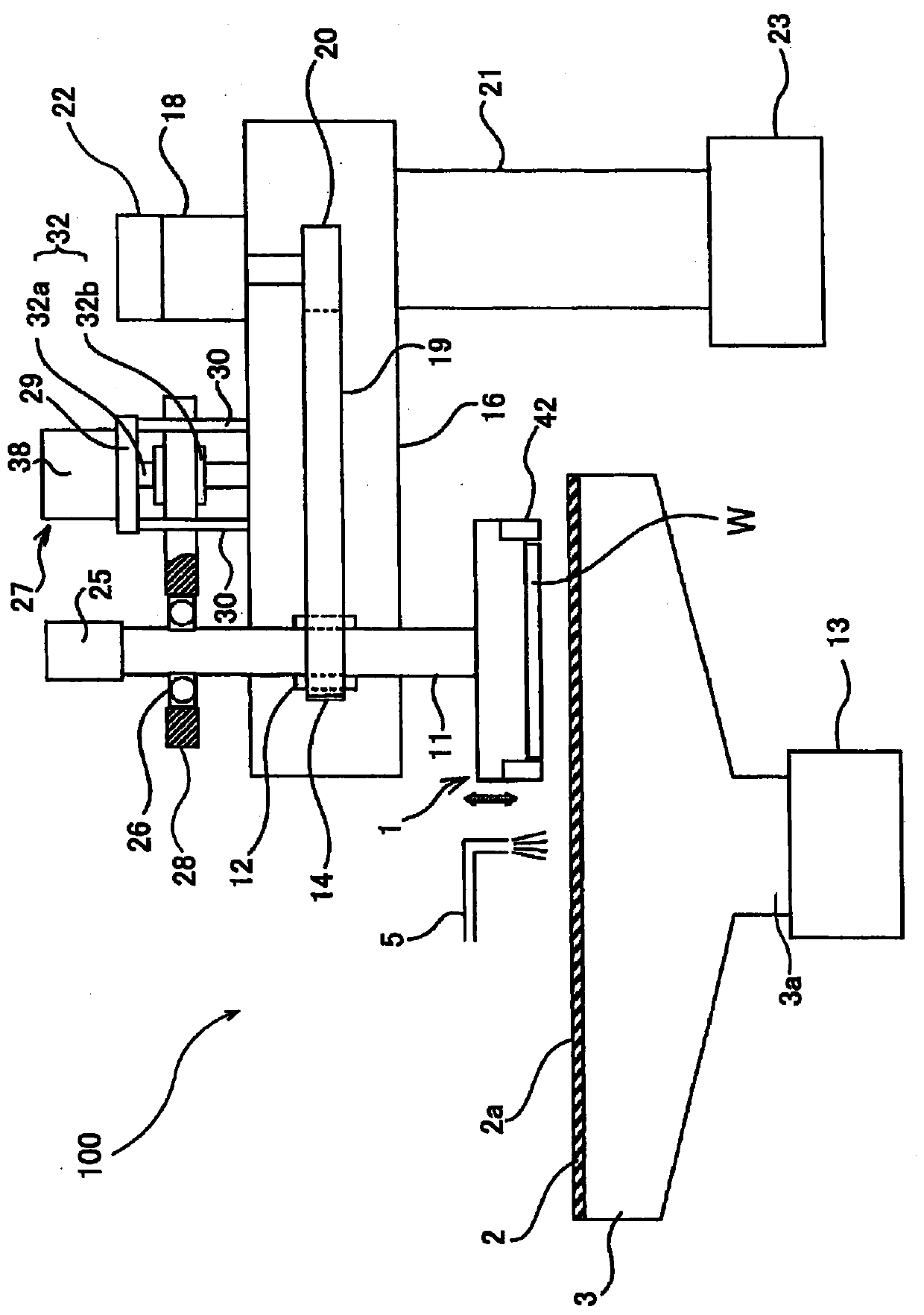

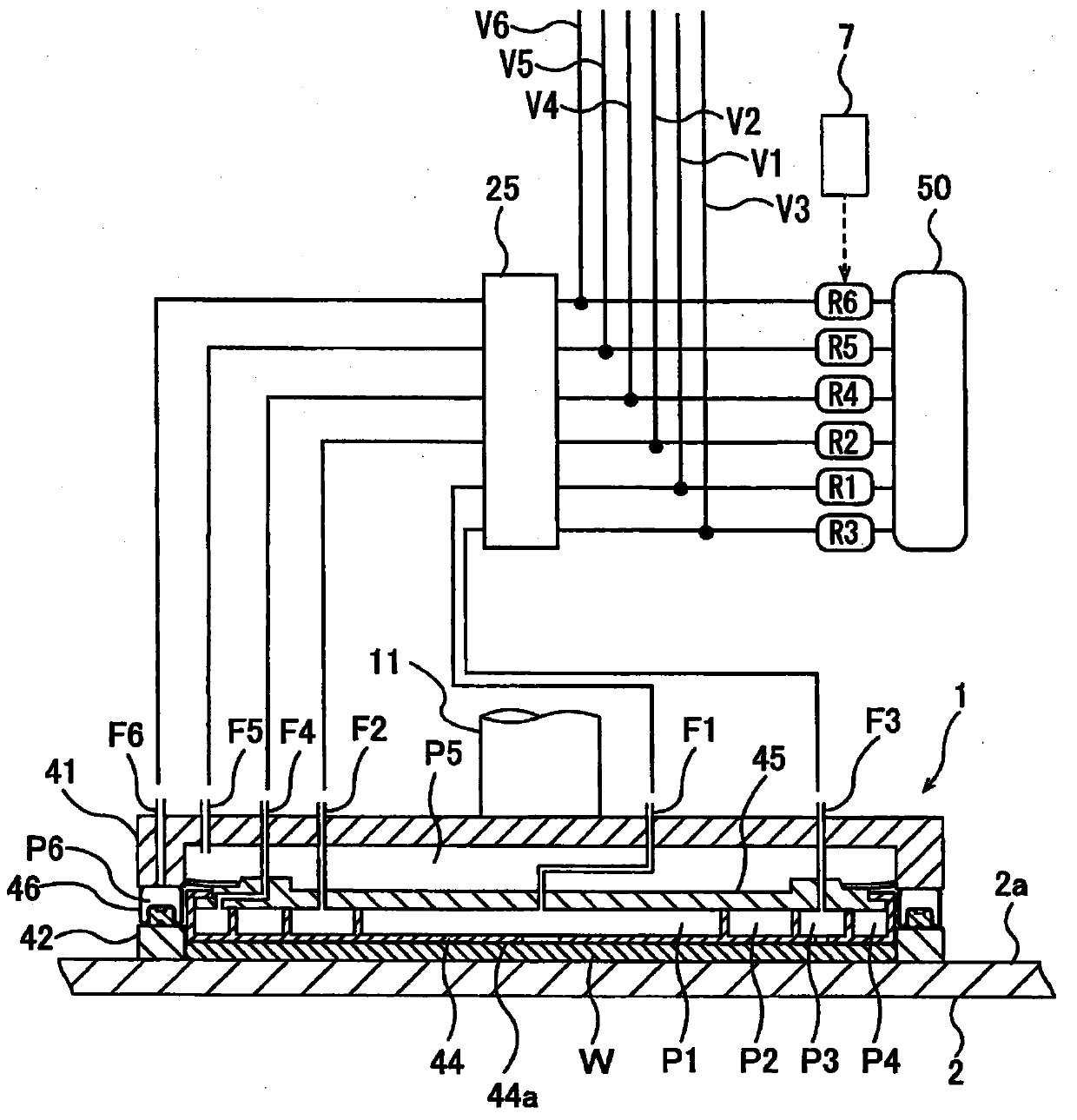

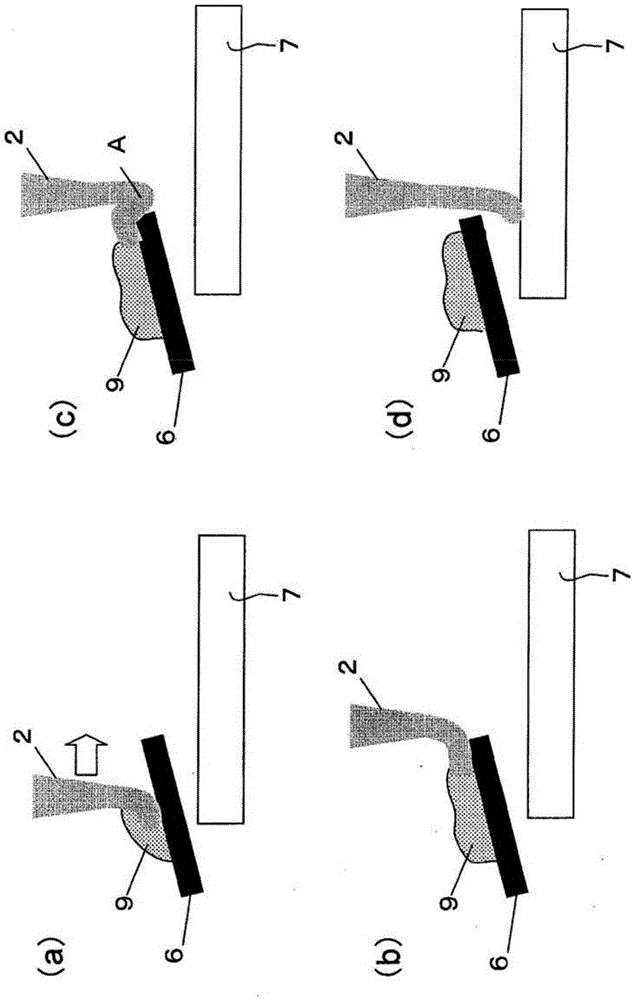

Polishing method and polishing device

ActiveCN108025419AMinimize film thickness differencesEliminates uneven film thicknessSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingComposite materialSi substrate

The present invention relates to a method and a device for polishing the surface of a substrate having film thickness unevenness in the circumferential direction of the substrate. Disclosed is a polishing method whereby: film thickness distribution in the circumferential direction of a substrate (W) is acquired; a first region having the largest or smallest film thickness is determined on the basis of the film thickness distribution; a polishing table (3) holding a polishing pad (2) is rotated; the surface of the substrate (W) is pressed to the polishing pad (2), while rotating the substrate by means of a polishing head (1); and the first region is polished at a removing rate that is different from the removing rate for a second region within the surface of the substrate (W).

Owner:EBARA CORP

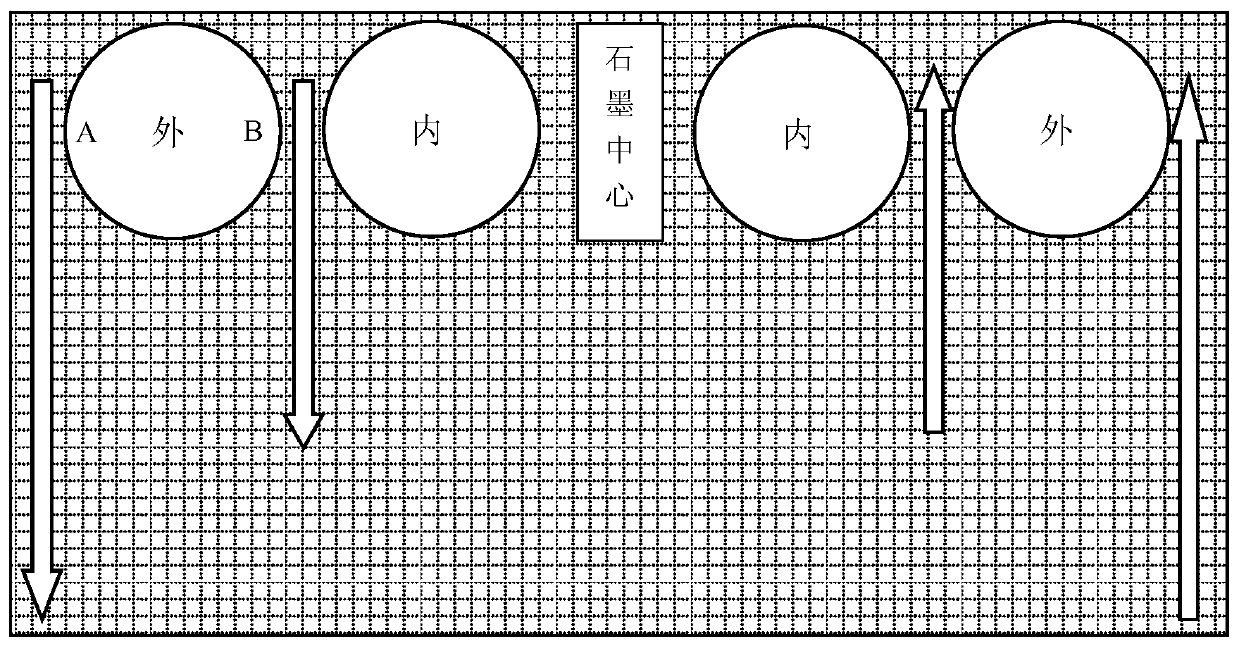

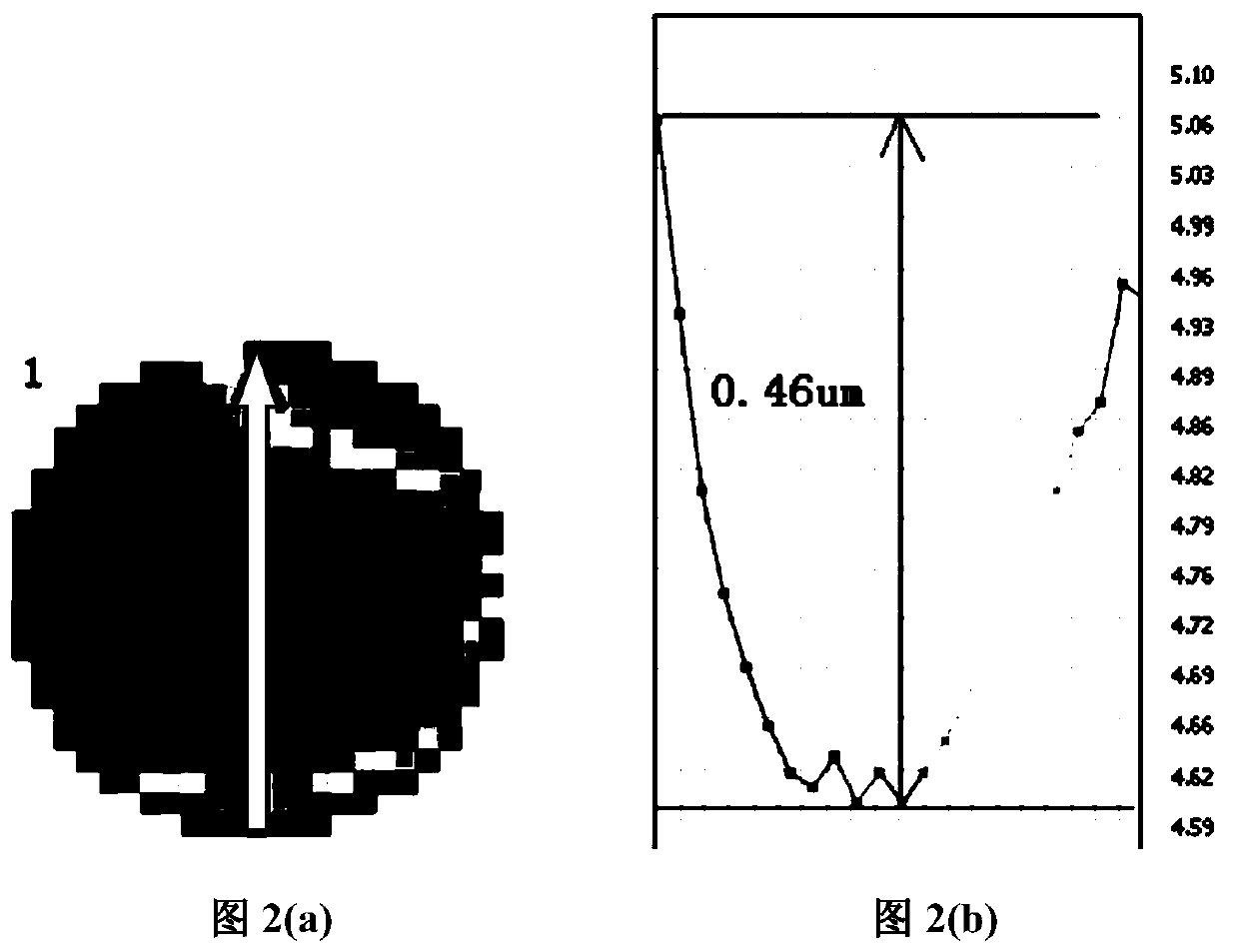

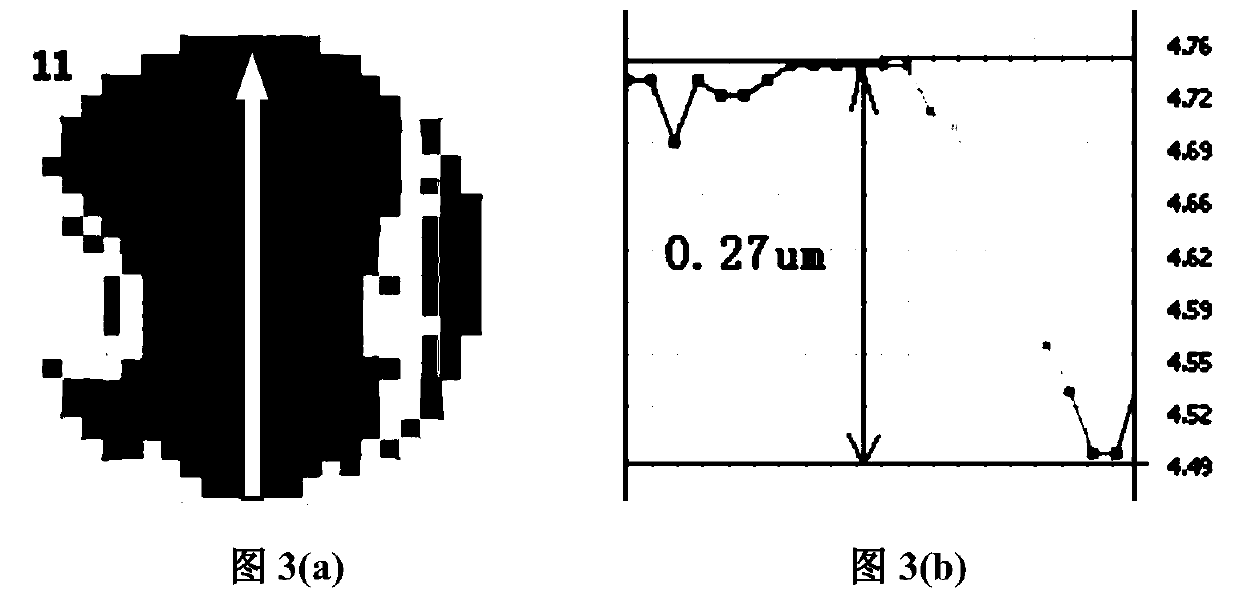

Improving method of thickness uniformity of silicon-based epitaxial wafer

ActiveCN109797375ASolve the technical problem of film thickness uniformityImprove thickness uniformityPolycrystalline material growthFrom chemically reactive gasesGraphiteTemperature and pressure

The invention provides an improving method of the thickness uniformity of a silicon-based epitaxial wafer. The improving method is characterized by being suitable for an MOCVD high-rotating-speed system and comprising the steps: in the process of epitaxial growth of a GaN layer on the surface of a silicon substrate, the rotating speed of a graphite disc is adjusted to be 500-1200 r / min, a matchedair flow is introduced according to the rotating speed of the graphite disc, and the corresponding temperature and pressure are controlled. According to the improving method, the thickness uniformityof the wafer can be improved, the technical problem of the film thickness uniformity of the silicon-based epitaxial wafer is effectively solved, and in practical application, the film thickness deviation improved through the improving method can be decreased by 40% or above.

Owner:LATTICE POWER (JIANGXI) CORP

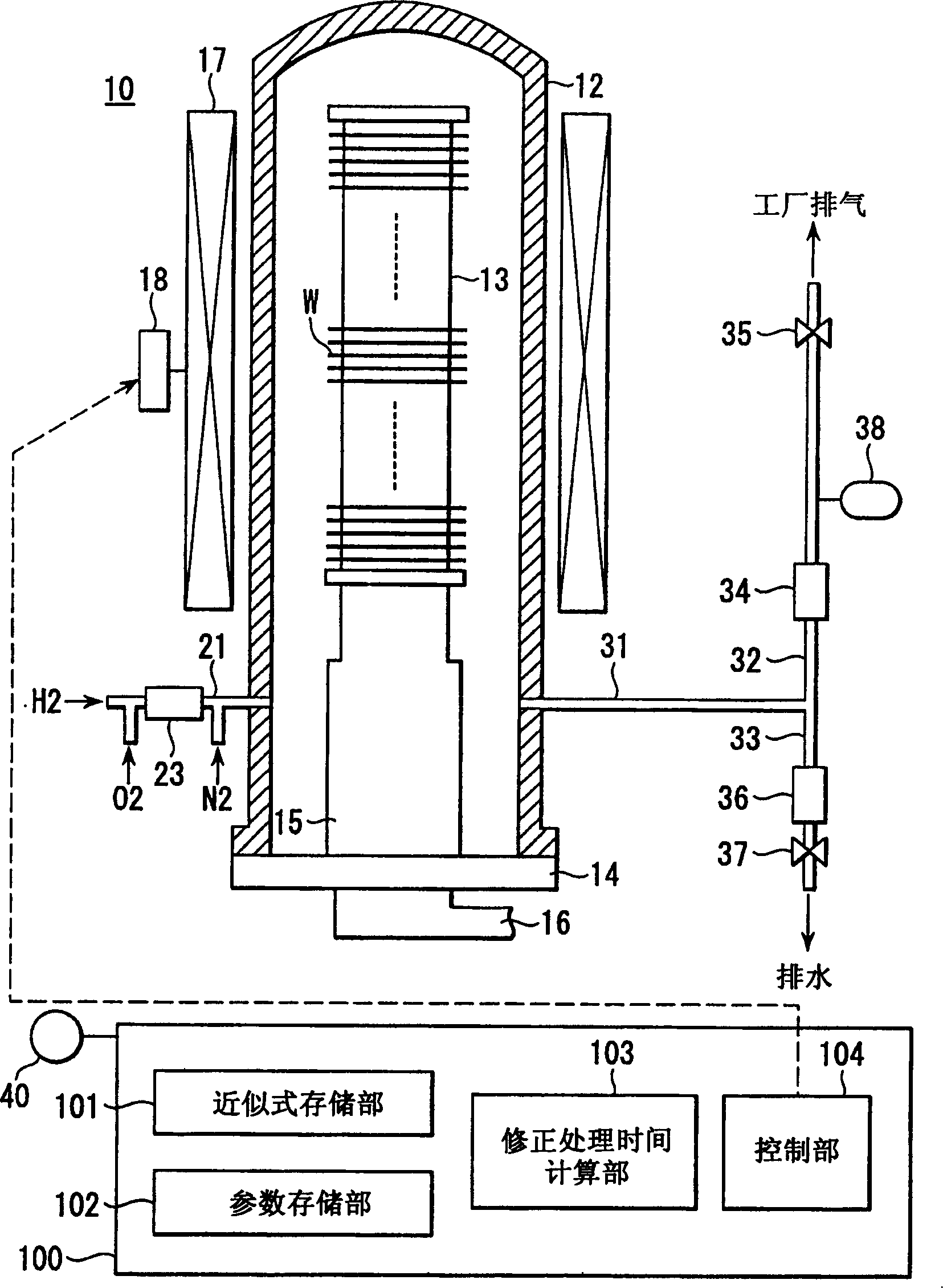

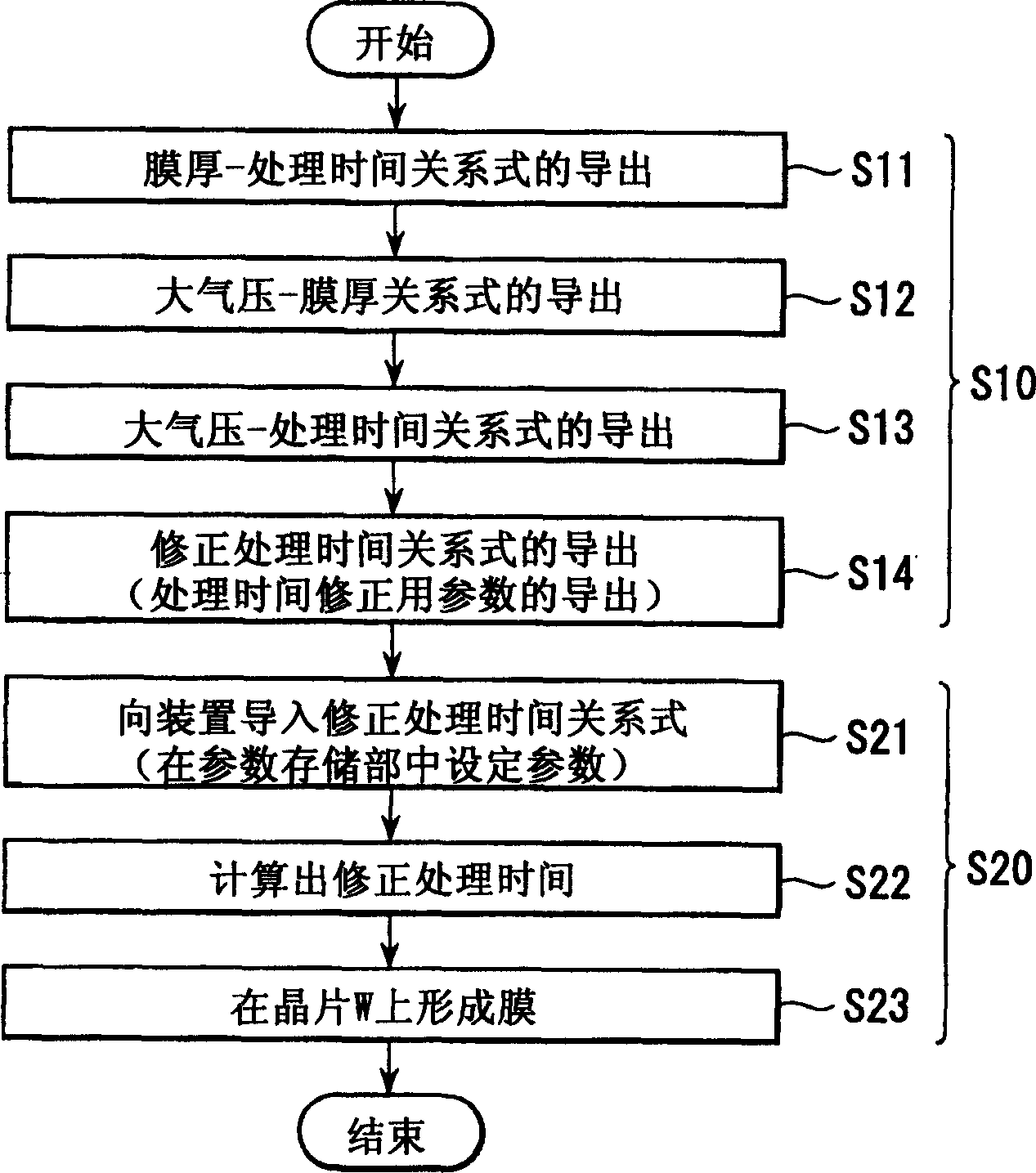

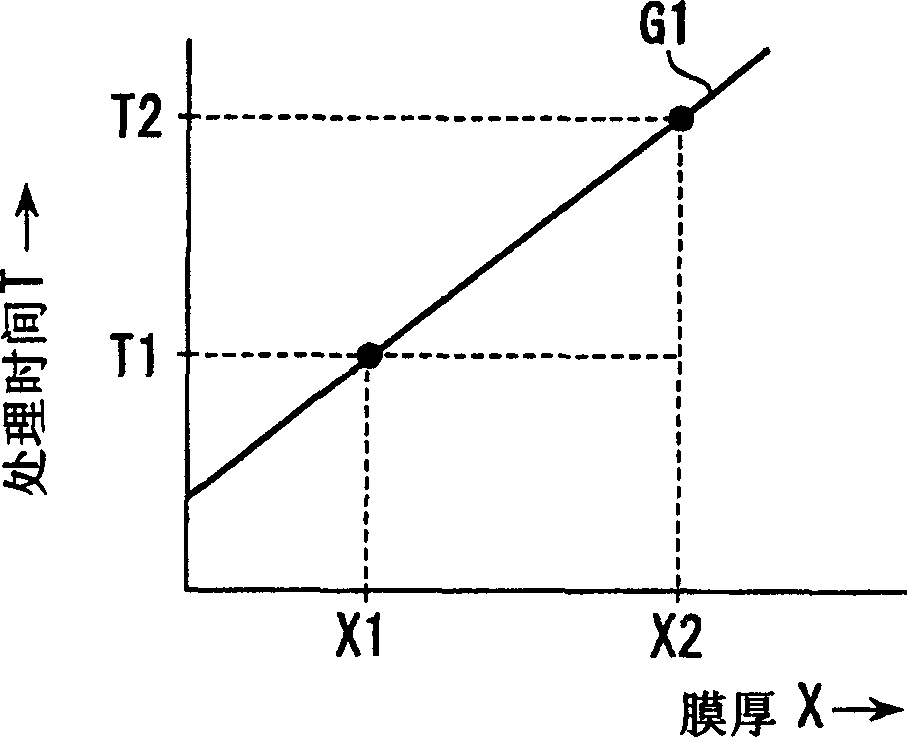

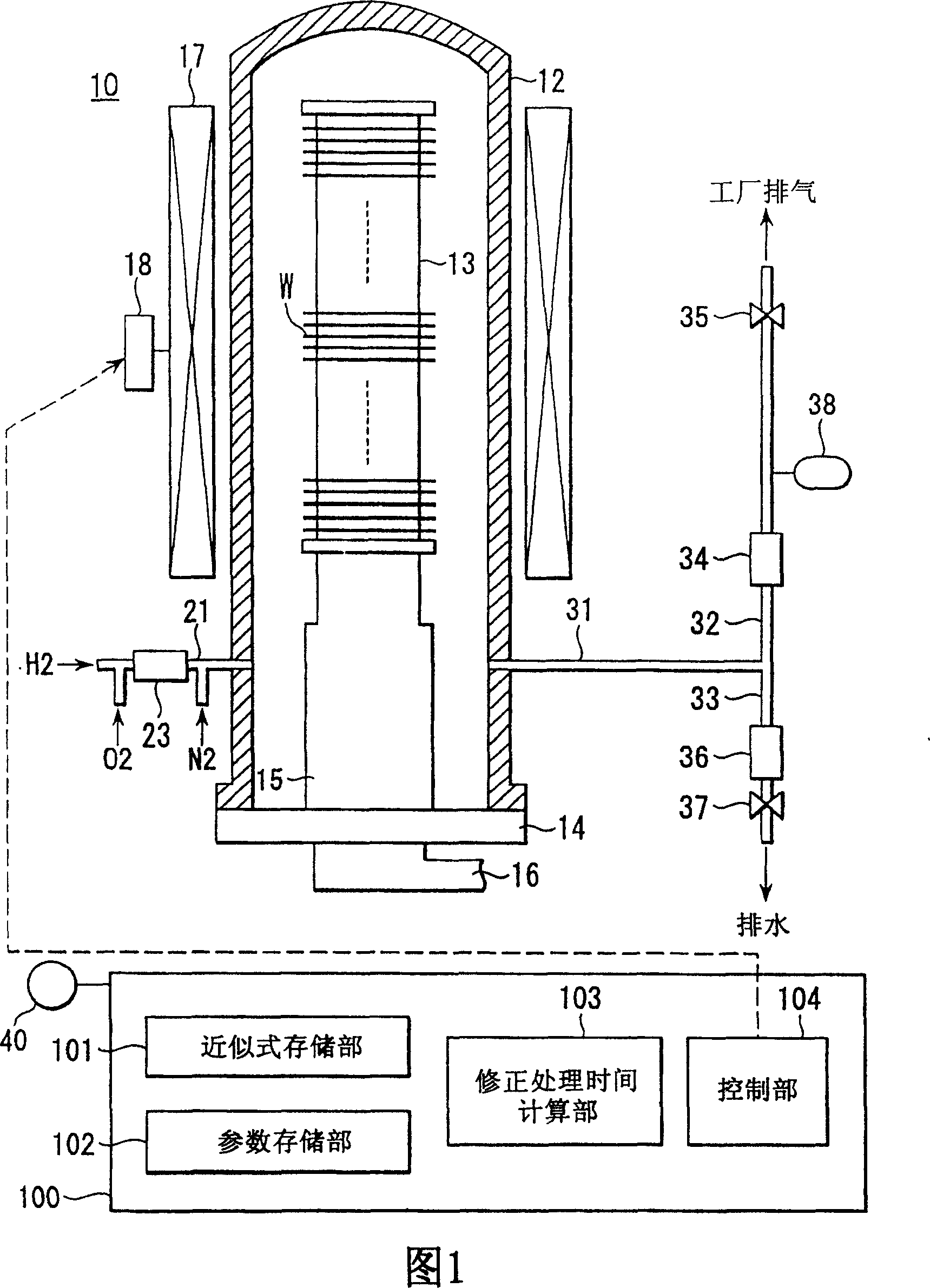

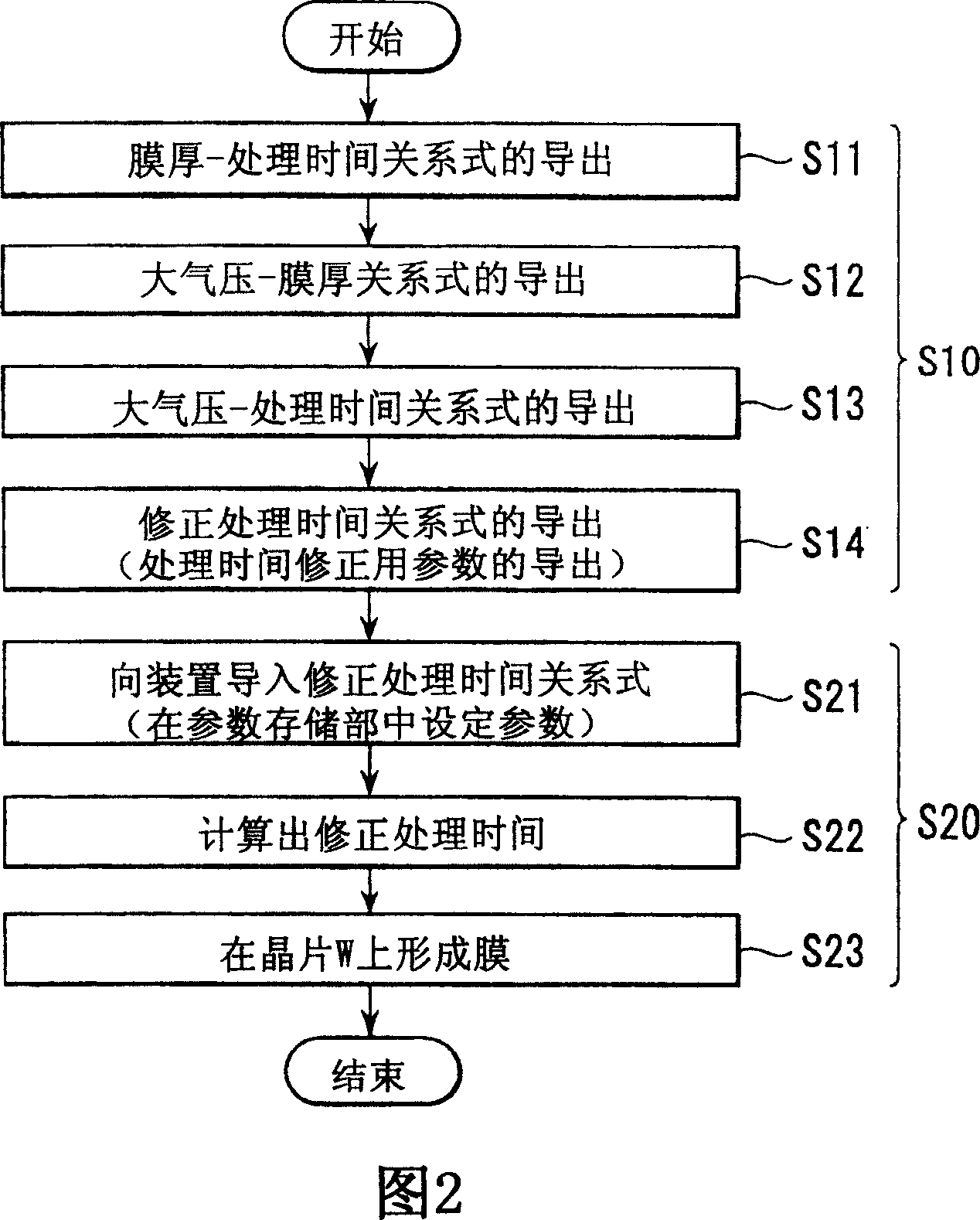

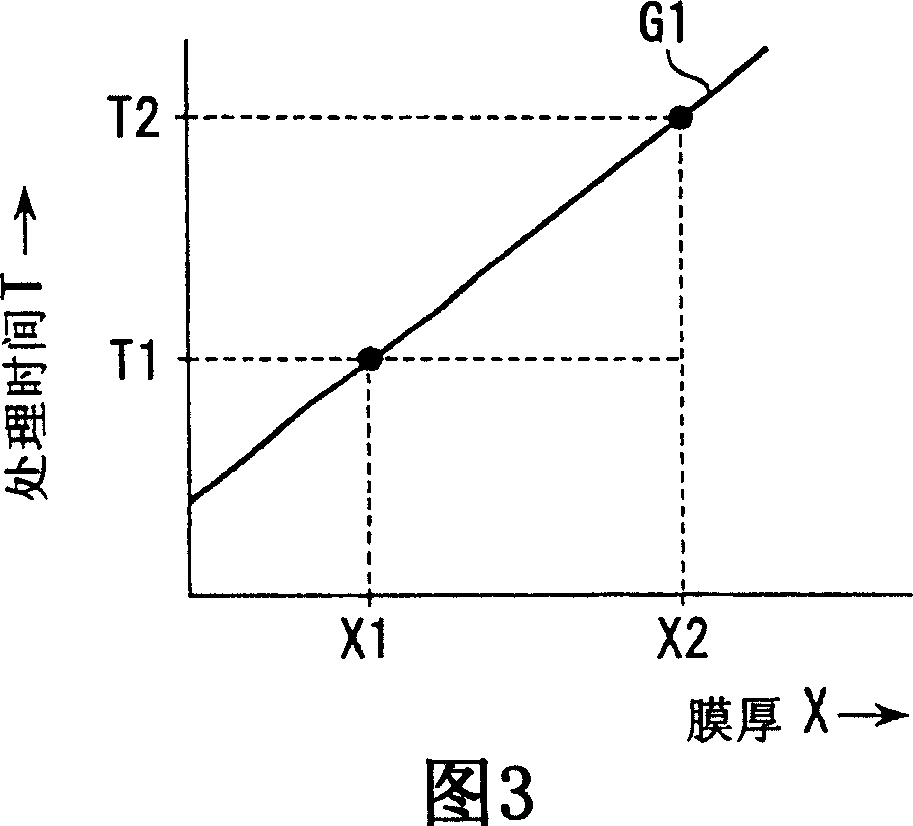

Film formation method

InactiveCN1643667AReduce film thickness variationSemiconductor/solid-state device manufacturingChemistryRelational equation

A film formation method includes a preparation stage (S 10 ) and a process stage (S 20 ). In the preparation stage (S 10 ), a process time correction equation prepared to correct process time in accordance with atmospheric pressure is derived, based on a first relational equation that expresses a relationship between film thickness and process time, and a second relational equation that expresses a relationship between atmospheric pressure and film thickness (S 11 to S 14 ). In the process stage (S 20 ), process time is corrected, based on the process time correction equation thus derived and a measurement result of current atmospheric pressure, and then film formation is performed, based on process time thus corrected (S 21 to S 23 ).

Owner:TOKYO ELECTRON LTD

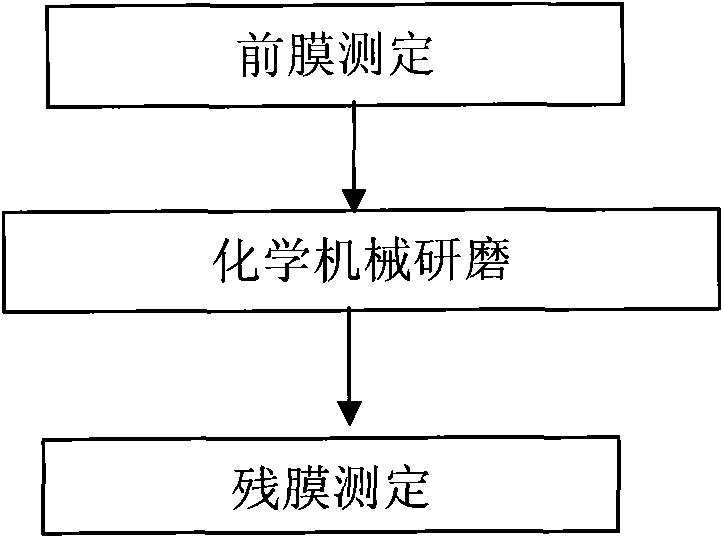

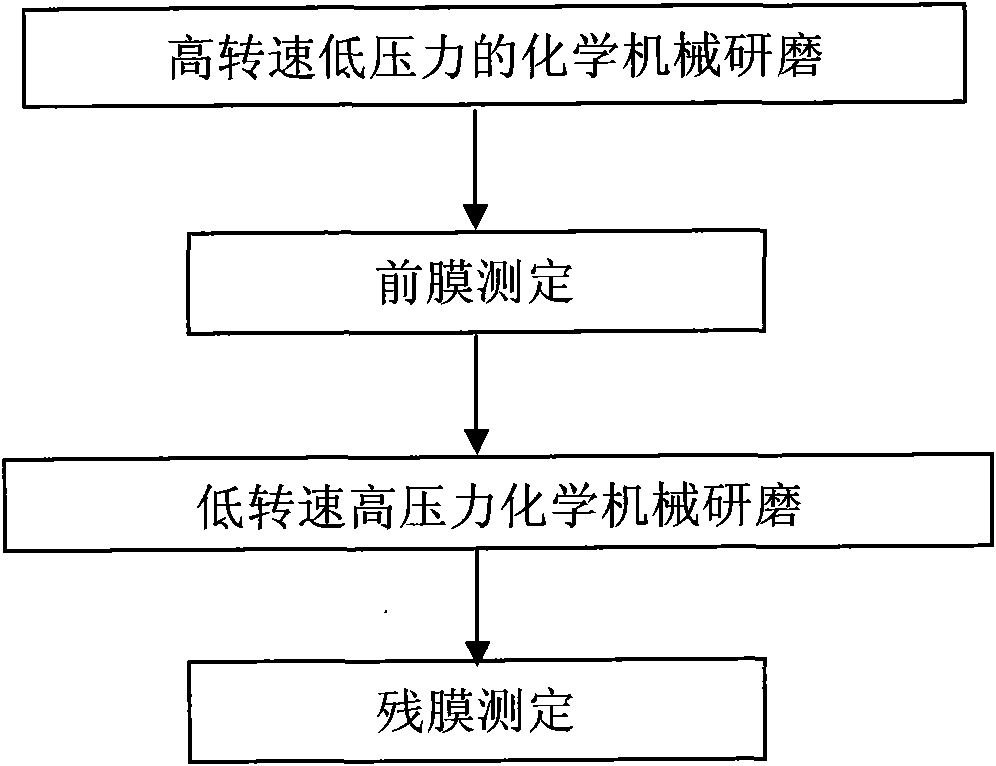

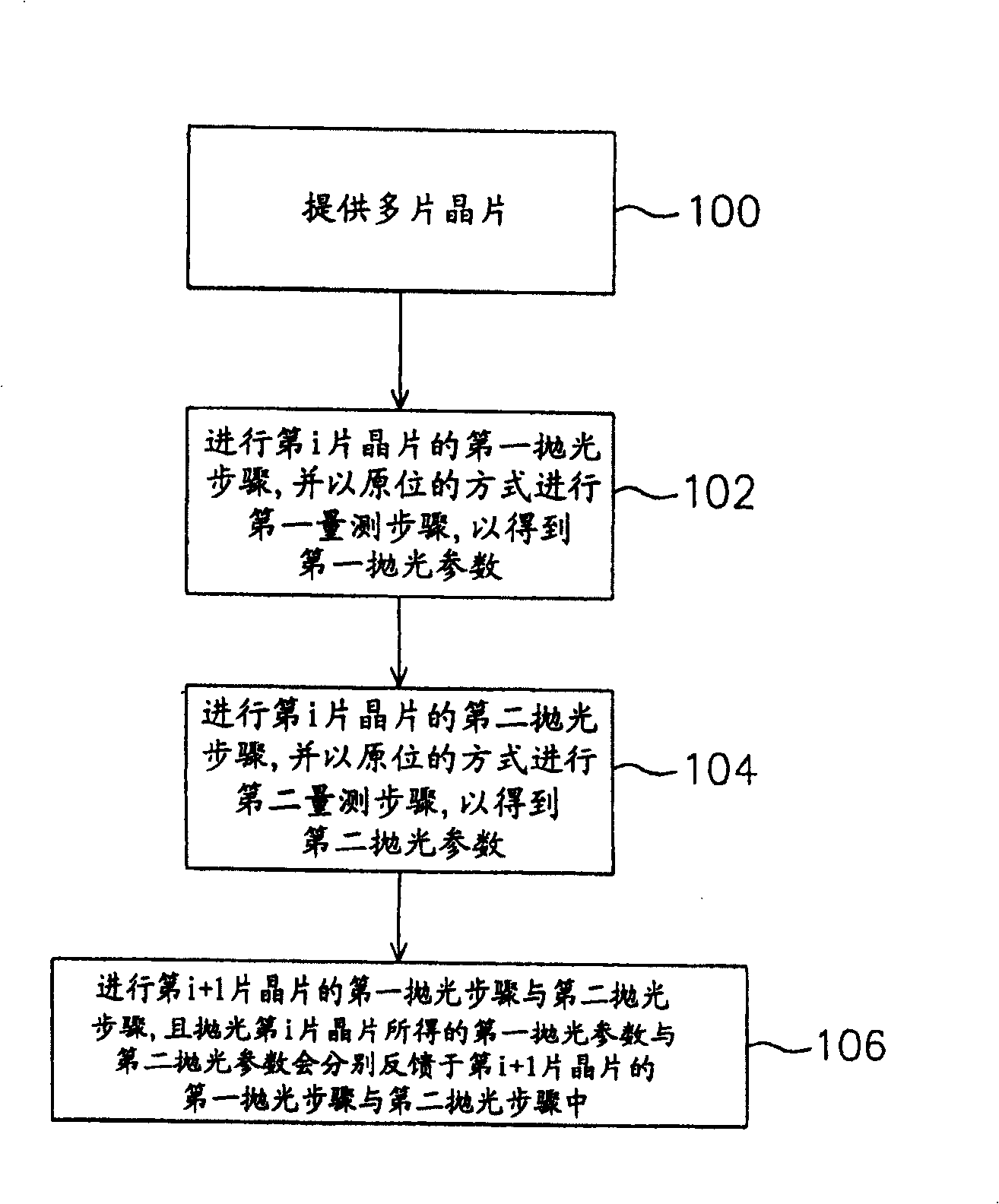

Chemical mechanical polishing (CMP) stepwise polishing method

InactiveCN102117746AReduce film thickness variationSemiconductor/solid-state device manufacturingCompound (substance)Engineering

The invention discloses a chemical mechanical polishing (CMP) stepwise polishing method. The method comprises the following steps: 1, polishing a product silicon wafer for the first time by adopting a chemical mechanical polishing condition with high rotating speed and low pressure so as to reduce the thickness of a front film and the difference caused by pattern distribution; 2, detecting the front film, and taking a detection result as basis of polishing for the second time; and 3, polishing the product silicon wafer for the second time by adopting the chemical mechanical polishing condition with low rotating speed and high pressure, and reducing the polishing time to reduce film thickness fluctuation caused by service life change of a consumables; and 4, detecting a residual film finally. By the method, the product difference or abnormal residual film thickness caused by fluctuation of polishing velocity can be reduced.

Owner:SHANGHAI HUA HONG NEC ELECTRONICS

Substrate processing apparatus, substrate processing method, and nozzle

ActiveUS20150246365A1Reduce film thickness variationImprove processing qualityLiquid surface applicatorsClosuresInjection portEngineering

A substrate processing apparatus includes a substrate holding unit, an injection unit that injects droplets of a processing liquid from a plurality of injection ports respectively toward a plurality of collision positions on the substrate, and a liquid film forming unit. The liquid film forming unit discharges a protective liquid from a plurality of discharge ports toward a plurality of liquid contact positions that respectively cover different collision positions. The plurality of injection ports and the plurality of discharge ports may be formed in a nozzle. A nozzle moving unit may be provided, to move the nozzle along the substrate.

Owner:DAINIPPON SCREEN MTG CO LTD

Conductive porous layer for batteries and fabrication method for same

InactiveUS9406940B2Improve adhesionReduce film thickness variationFuel and primary cellsHybrid cell detailsHigh densityPorous layer

The conductive porous layer for batteries according to the present invention comprises a laminate comprising a first conductive layer and a second conductive layer. The first conductive layer includes at least a conductive carbon material and a polymer. The second conductive layer includes at least a conductive carbon material and a polymer. The conductive porous layer satisfies at least one of the following two conditions: “the polymer in the first conductive layer is present with a high density at the surface of the layer in contact with the second conductive layer than at the surface not in contact with the second conductive layer” and “the polymer in the second conductive layer is present with a higher density at the surface of the layer in contact with the first conductive layer than at the surface not in contact with the first conductive layer.”

Owner:DAI NIPPON PRINTING CO LTD

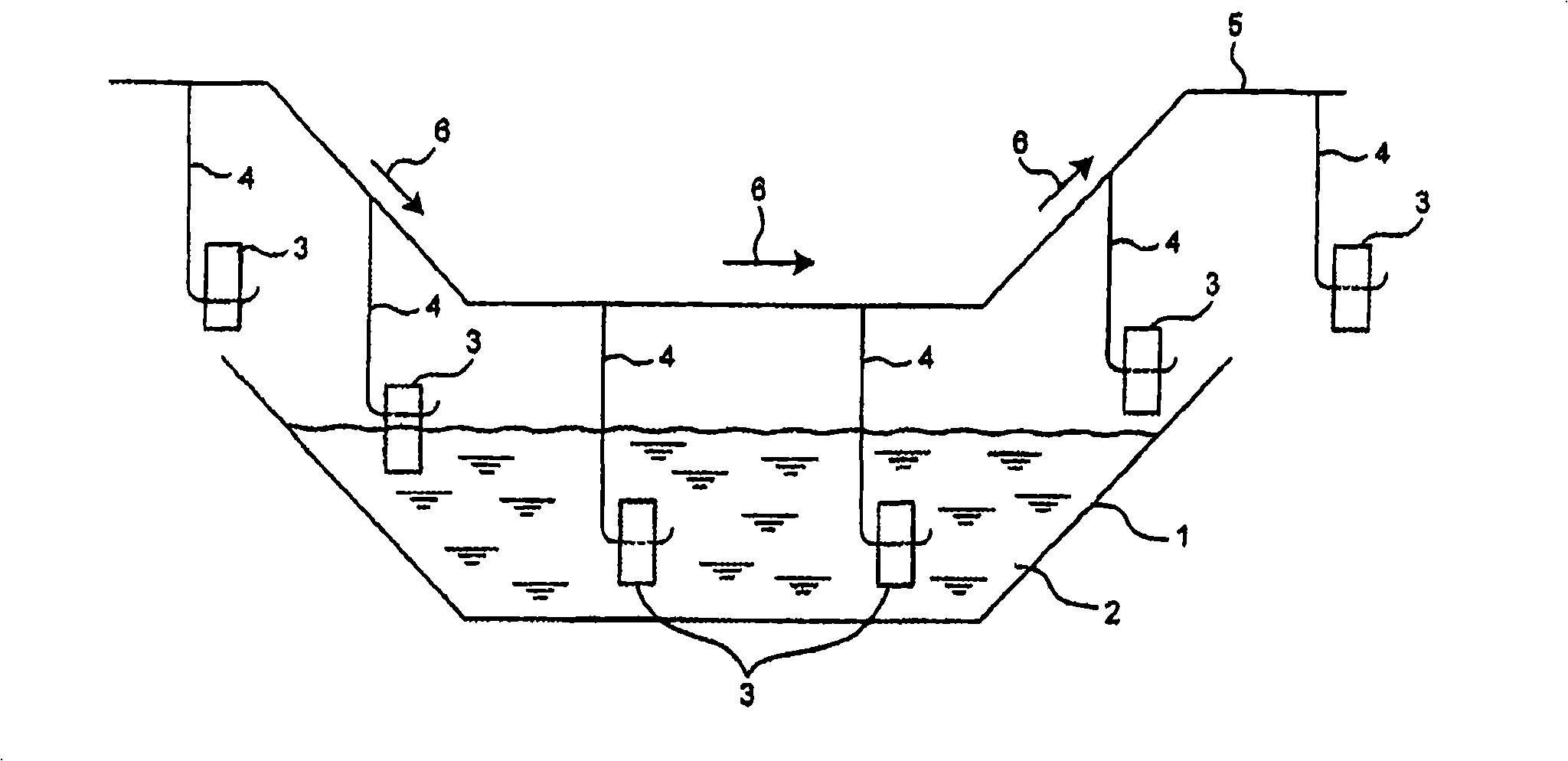

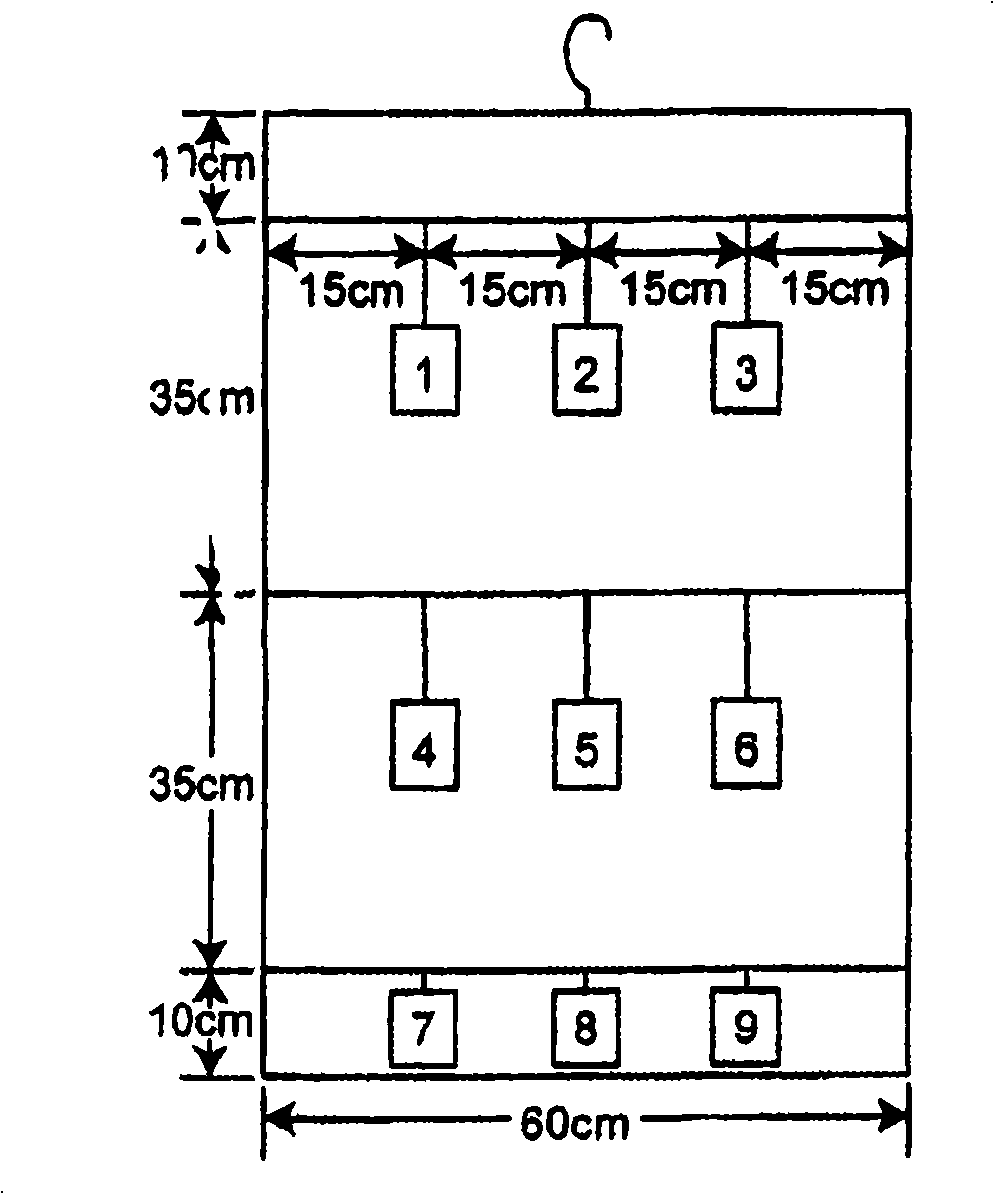

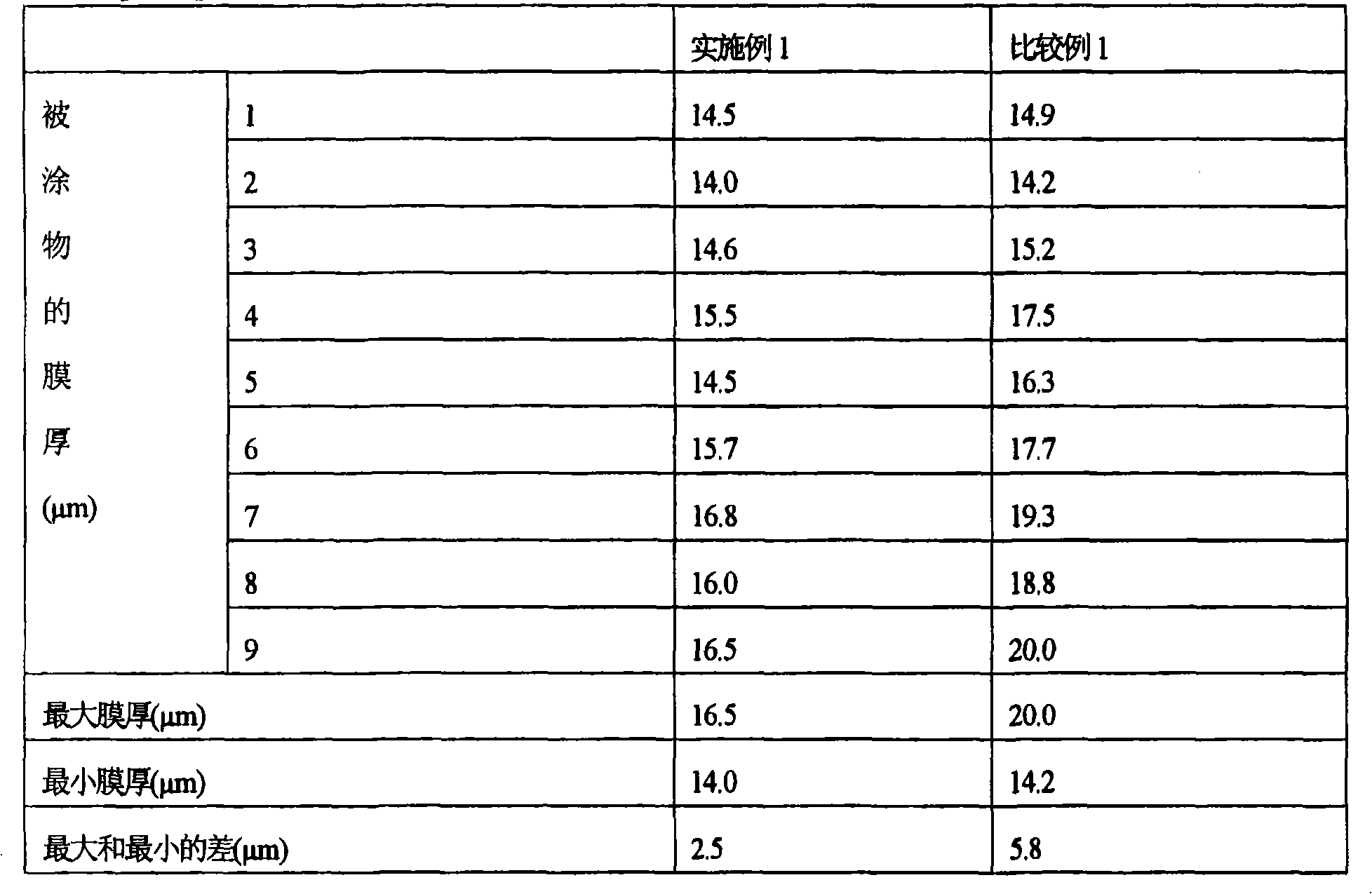

Cathode electrodeposition coating method

InactiveCN101285207AReduce the amount presentSave resourcesElectrophoretic coatingsFilm resistanceMetallurgy

The invention provides a cathode electrodeposition coating method which causes film thickness of an electrodeposition coating film as uniform as possible during cathode electrodeposition coating of transporting coated objects (in particular to components) with various shapes and sizes. The cathode electrodeposition coating method processes the electrodeposition coating in the state of mixing the coated components with different sizes and / or shapes in a cathode electrodeposition coating bath, which is characterized in processing to adjust in the cathode electrodeposition coating bath so that the electrodeposition coating film formed when the thickness of electrodeposition is coated to 15mum is provided with a film resistance in the range of 700kappa omega.cm<2> to 1,800kappa omega.cm<2>.

Owner:NIPPON PAINT CO LTD

Grinding method and grinding device

ActiveCN108025419BReduce film thickness variationEliminates uneven film thicknessSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingComposite materialSi substrate

The invention relates to a method and a device for grinding the surface of a substrate with uneven film thickness along the circumferential direction of the substrate. The polishing method is to obtain the film thickness distribution in the circumferential direction of the substrate (W), determine the first region with the largest or smallest film thickness according to the film thickness distribution, and rotate the polishing table (3) holding the polishing pad (2), The surface of the substrate (W) is pressed against the polishing pad (2) while the substrate is rotated by the polishing head (1), and the first region is polished with a removal rate different from that of the second region on the surface of the substrate (W).

Owner:EBARA CORP

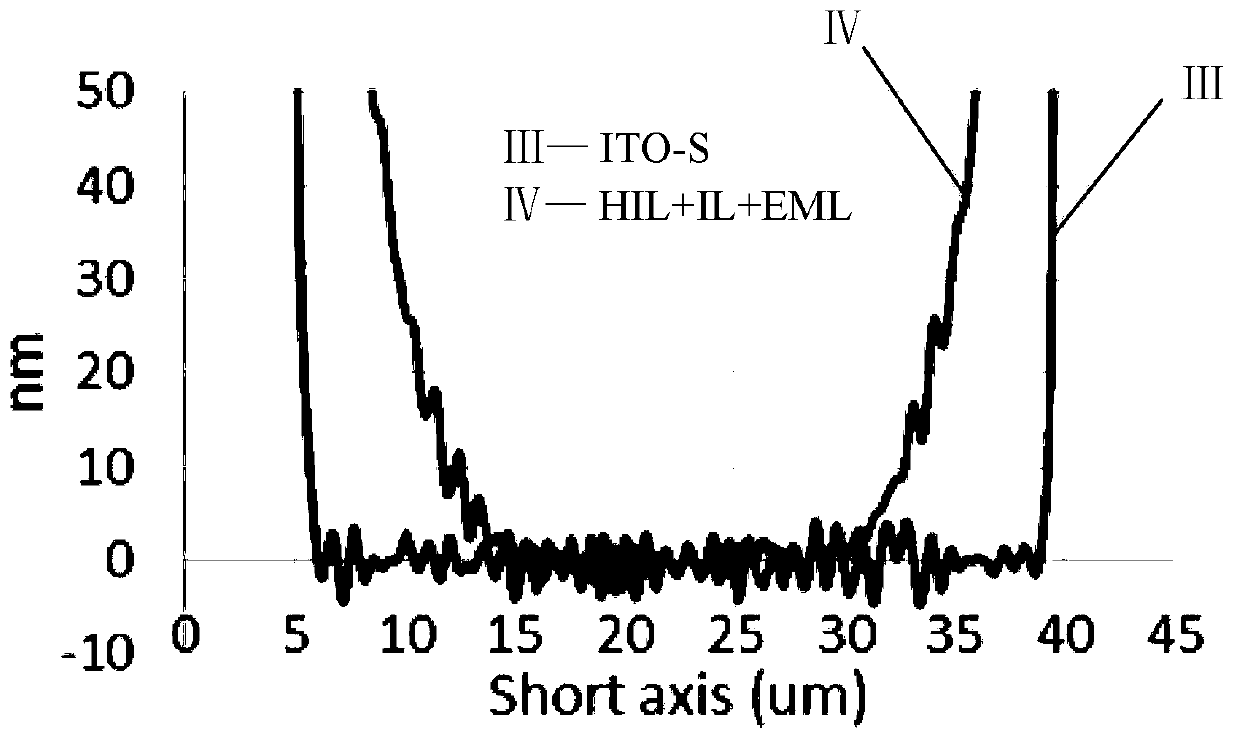

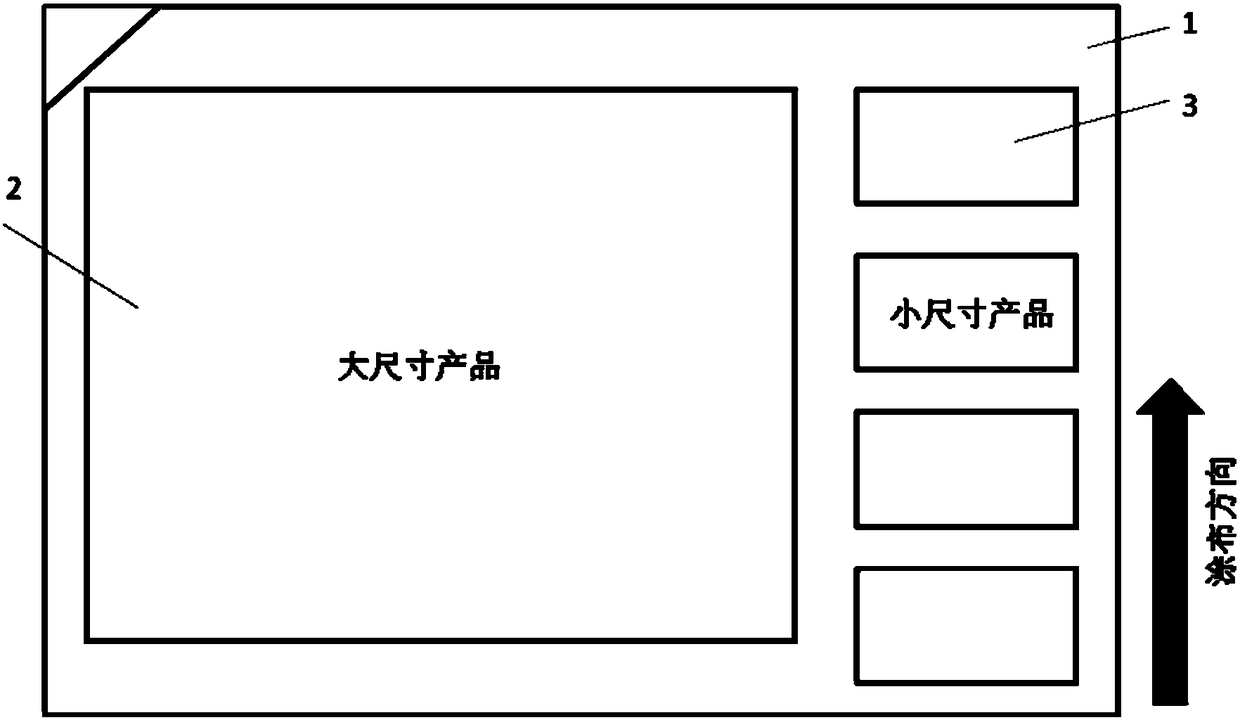

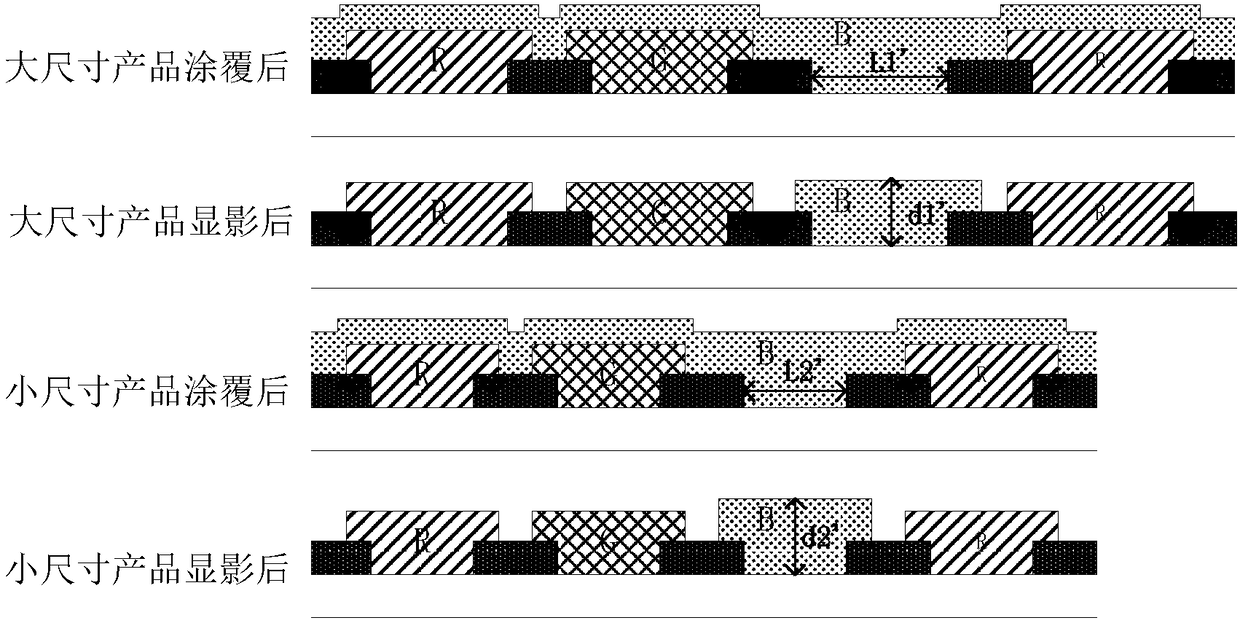

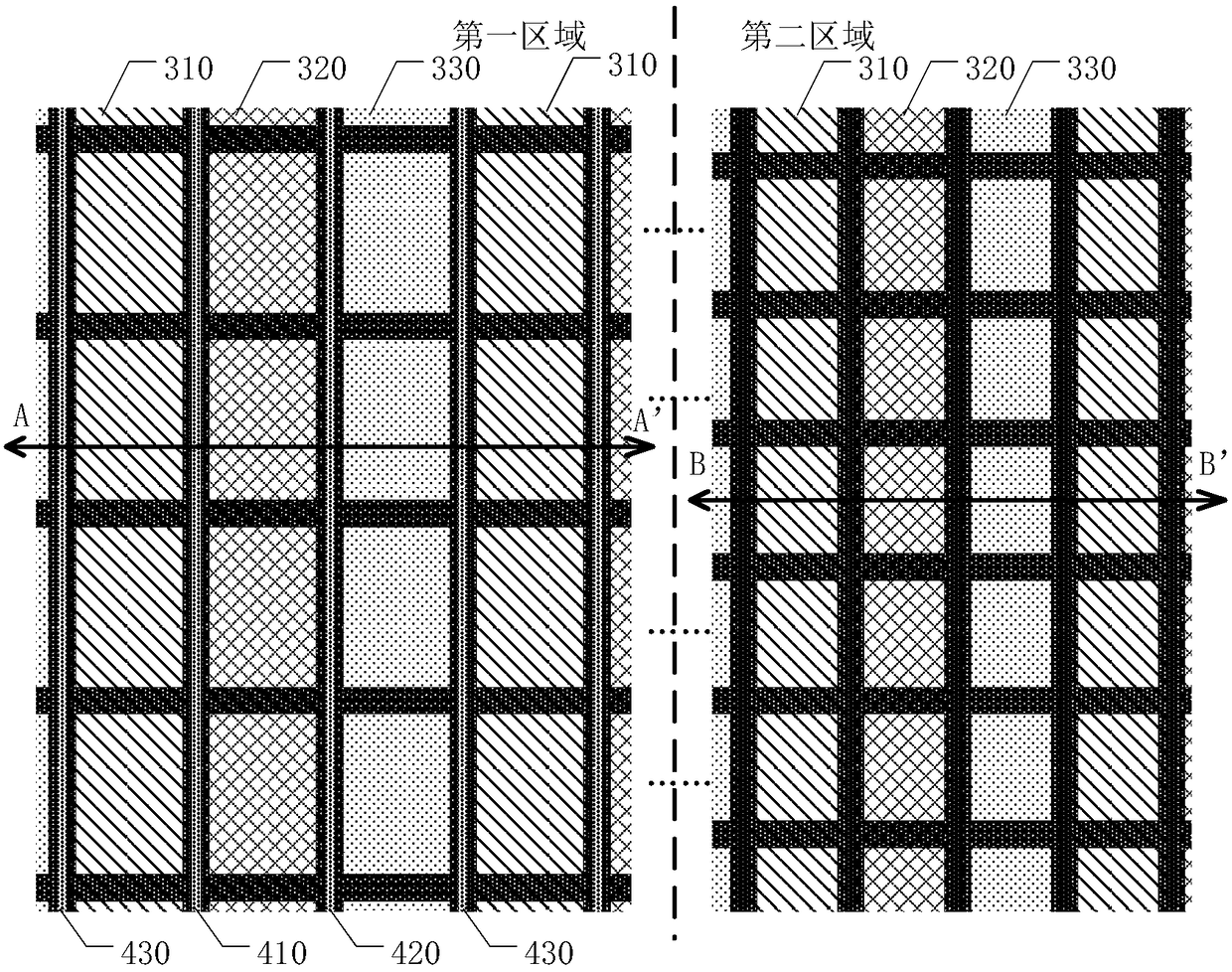

Display motherboard, manufacturing method thereof, and display device

ActiveCN105527746BReduce film thickness variationIncrease resistanceNon-linear opticsDisplay deviceEngineering

The invention provides a display motherboard, a production method thereof and a display device. The display motherboard comprises a substrate as well as a black matrix layer and a color filter layer which are arranged on the substrate, wherein the substrate comprises a first area and a second area; the size of each sub-pixel aperture area, formed in the first area, of the black matrix layer is larger than that of each sub-pixel aperture area, formed in the second area, of the black matrix layer; a retaining wall layer located on the black matrix layer is further arranged in the first area. According to the display motherboard, the retaining wall layer is arranged in the first area with larger sub-pixel apertures, so that the flowing resistance during photoresist coating can be increased through the retaining wall layer when the color filter layer is produced, and a film thickness difference of color filter layers in the same color due to a difference of pixel apertures of different sized products of MMG (multi-model glass) products can be reduced.

Owner:BOE TECH GRP CO LTD +1

Film formation method

InactiveCN1315161CReduce film thickness variationSemiconductor/solid-state device manufacturingRelational equationAtmospheric pressure

A film formation method includes a preparation stage (S 10 ) and a process stage (S 20 ). In the preparation stage (S 10 ), a process time correction equation prepared to correct process time in accordance with atmospheric pressure is derived, based on a first relational equation that expresses a relationship between film thickness and process time, and a second relational equation that expresses a relationship between atmospheric pressure and film thickness (S 11 to S 14 ). In the process stage (S 20 ), process time is corrected, based on the process time correction equation thus derived and a measurement result of current atmospheric pressure, and then film formation is performed, based on process time thus corrected (S 21 to S 23 ).

Owner:TOKYO ELECTRON LTD

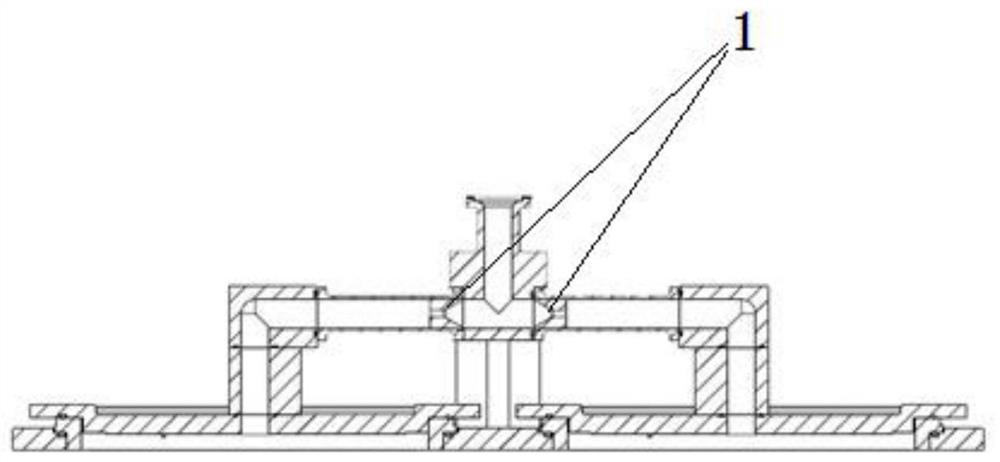

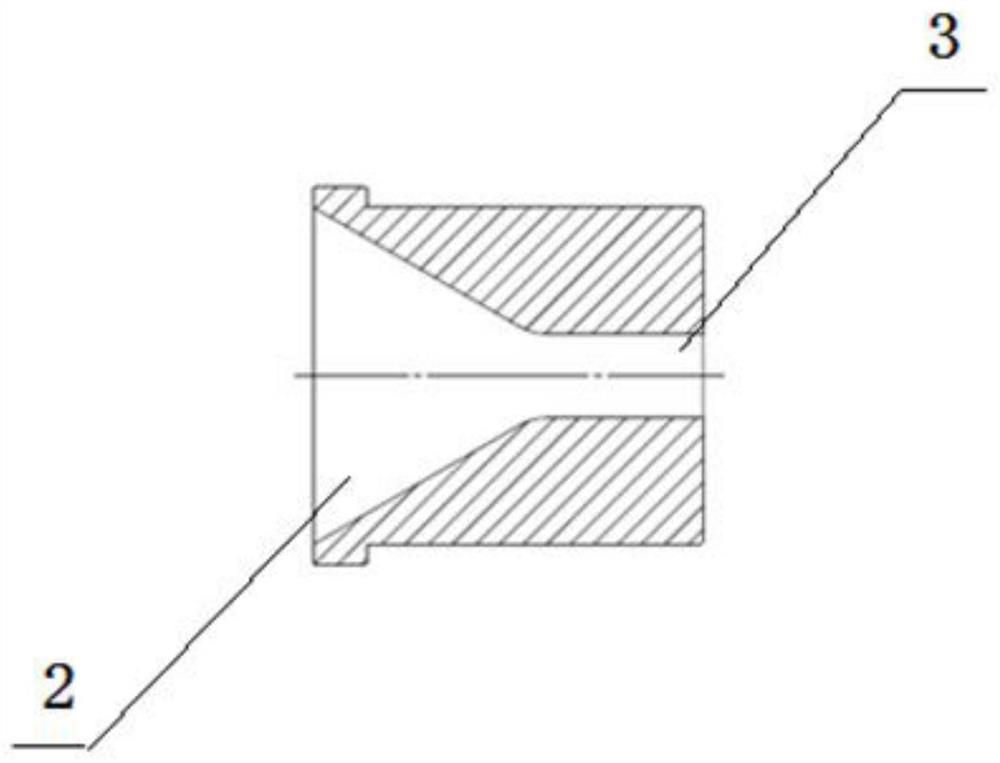

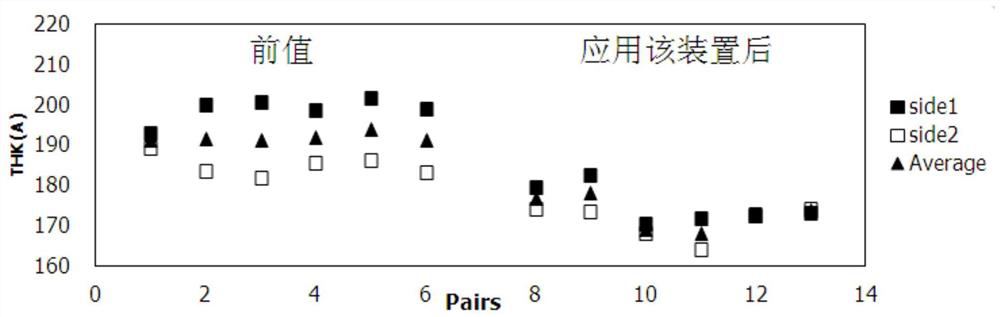

Device and method for improving process deviation of multi-cavity equipment

PendingCN113823545AThe problem of blocking channelingImprove yield rateElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringMaterials science

The invention provides a device and method for improving process deviation of multi-chamber equipment. The device is arranged on a multi-chamber reaction gas path, one end of the interior of the device adopts a conical surface structure, and the other end of the interior of the device adopts a straight hole structure. According to the device and the method provided by the invention, the structure / operation is simple, the price is low, the problem of high-efficiency blocking of gas channeling can be achieved by reasonably setting the internal aperture, finally, the thickness difference of the wafer surface film between the chambers is reduced, and the yield of the wafer is improved.

Owner:PIOTECH CO LTD

The processing method of the processed object

ActiveCN105845550BReduce film thickness variationSemiconductor/solid-state device manufacturingNoble gasSilicon oxide

The present invention provides a method of processing an object by which variation in film thickness of a silicon oxide film formed on an object to be processed can be reduced even if an opening of a mask has a high aspect ratio. In the method according to one embodiment, a silicon oxide film is formed by repeatedly performing a process including the steps of: (a) generating plasma of a first gas containing a silicon halide gas in a processing vessel of a plasma processing apparatus, thereby A first step of forming a reactive precursor on the treatment body; (b) after the first step, a second step of generating a plasma of a rare gas in the processing vessel; (c) after the second step, generating plasma of a second gas containing oxygen, a third step of forming a silicon oxide film; and (d) a fourth step of generating plasma of a rare gas in the processing vessel after the third step.

Owner:TOKYO ELECTRON LTD

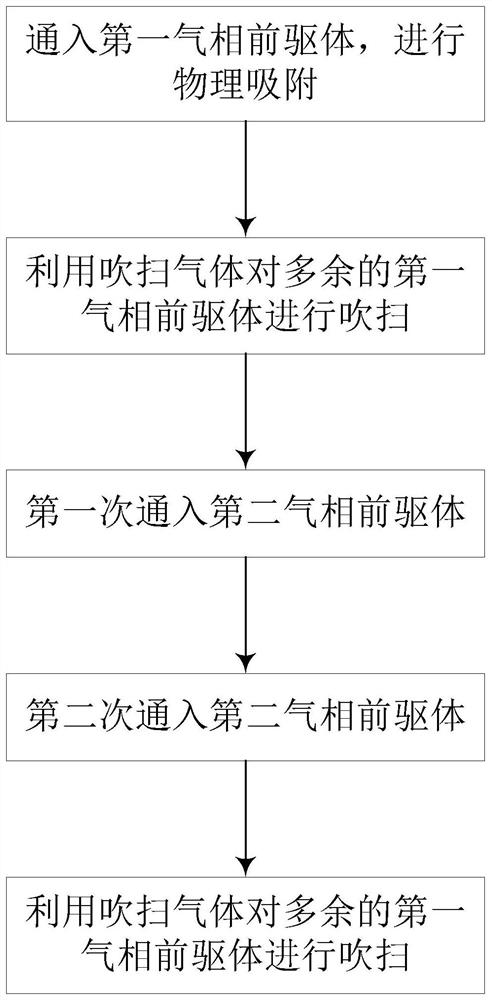

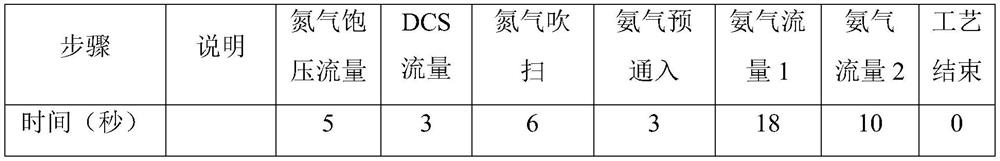

Method for reducing silicon wafer film thickness difference in furnace tube process

PendingCN111876749AReduce concentration differenceImprove thickness differenceChemical vapor deposition coatingPhysical chemistryThin membrane

The invention discloses a method for reducing silicon wafer film thickness difference in a furnace tube process. Each circulation process comprises the following steps of S1, introducing a first gas-phase precursor; S2, blowing the redundant first gas-phase precursor; S3, introducing a second gas-phase precursor for the first time; S4, introducing a second gas-phase precursor for the second time;and S5, blowing the redundant second gas-phase precursor; wherein the relationship, among the volume V0 of the second gas-phase precursors required in each circulation process, the flow S1 and the introduction time T1 of the second gas-phase precursor introduced for the first time, and the flow S2 and the introduction time T2 of the second gas-phase precursor introduced for the second time, is V0=S1xT1+S2xT2; and S1>S2. According to the method, on the premise of ensuring that the thickness of a thin film deposited in each circulation process is not changed, the concentration difference of precursor residual gas in a furnace tube is effectively reduced, the film thickness difference, caused by residual gas deposition, of silicon wafers at different positions in the furnace tube is reduced,and the thickness difference among the silicon wafers is improved.

Owner:SHANGHAI HUALI INTEGRATED CIRCUTE MFG CO LTD

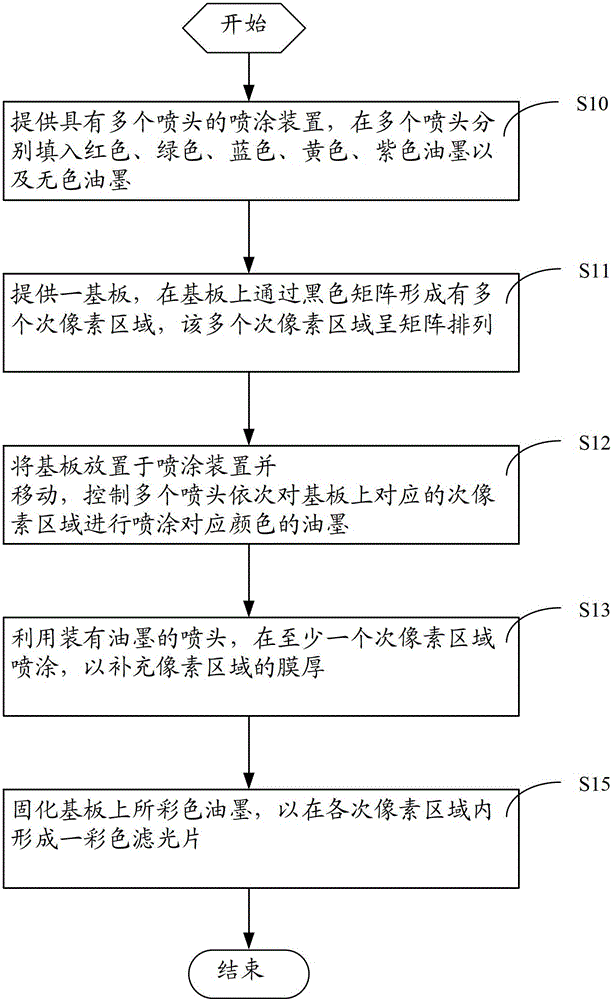

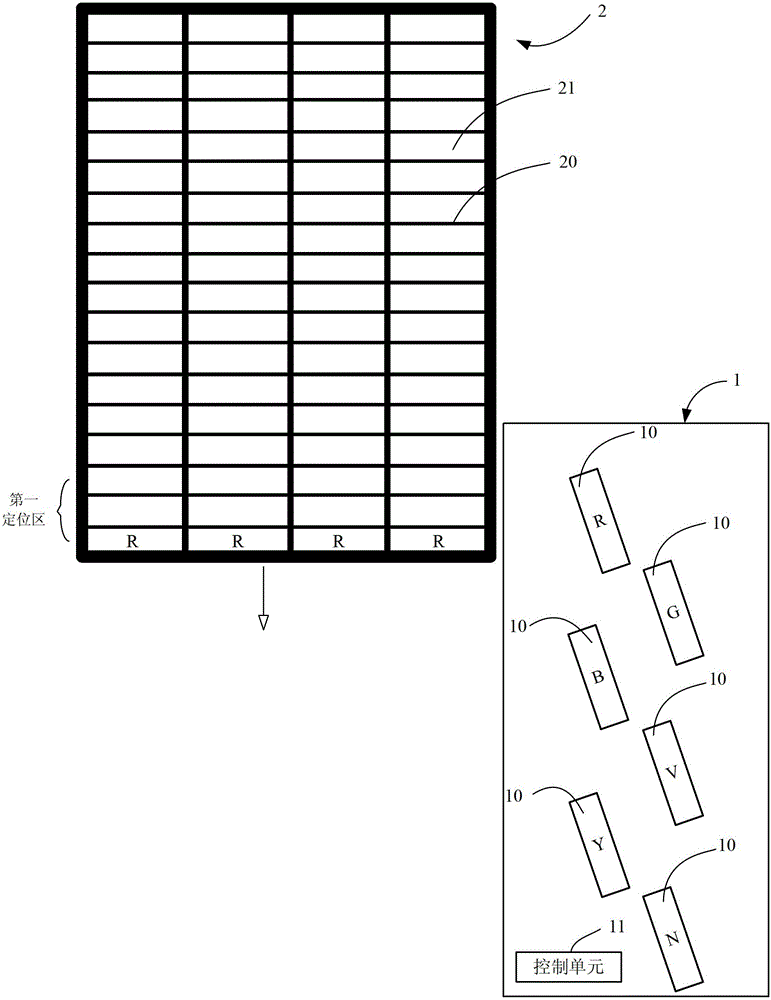

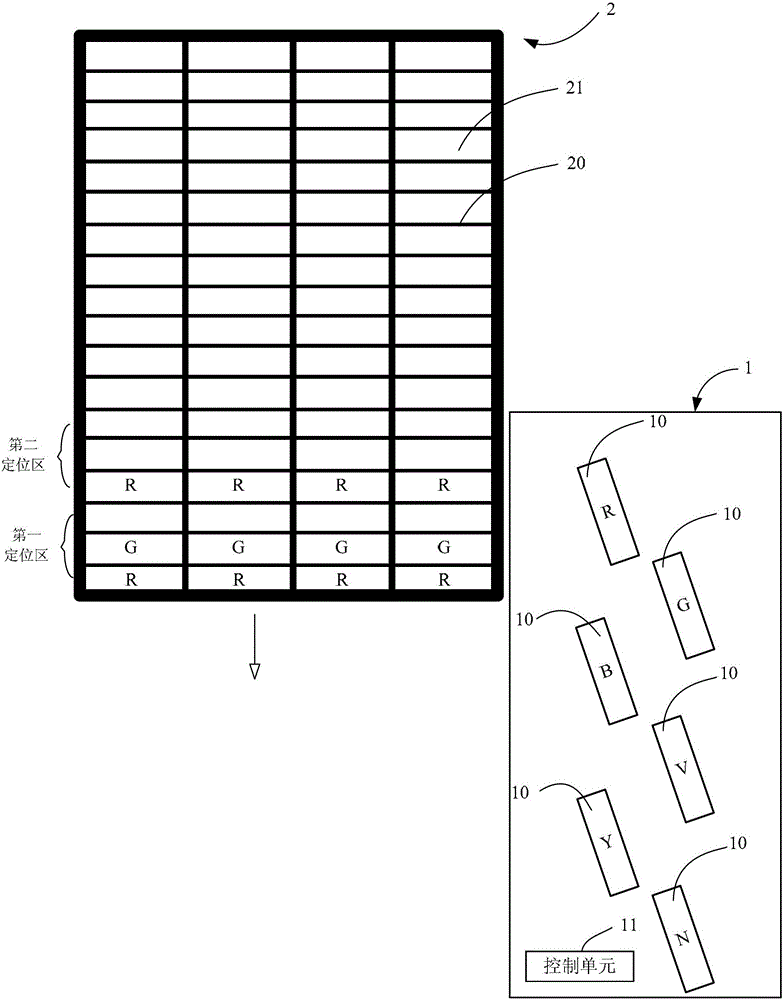

A method for forming a color filter substrate and corresponding spraying device

ActiveCN103435267BReduce film thickness variationPrevent display defectsNon-linear opticsOptical elementsColor gelPrinting ink

A method for forming a color filter substrate and a corresponding spraying device. The forming method comprises: providing a spraying device (1) having a plurality of spray heads (10), each spray head being filled with printing ink of one color; providing a substrate (2), and forming a plurality of subpixel regions (21) on the substrate, the plurality of subpixel regions being arranged in a matrix; and placing the substrate on the spraying device and moving same in one direction, and controlling the plurality of spray heads to sequentially spray printing ink of corresponding colors onto corresponding subpixel regions on the substrate once the substrate is moved a fixed distance, at least one row of subpixel regions being sequentially coated with printing ink of different colors. The product qualification rate of manufacturing color filter substrates can be improved, so that the production scheduling is more flexible.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Semiconductor device and its manufacturing method

InactiveUS20050275041A1Reduce film thickness variationImprove reliabilityTransistorSolid-state devicesDevice materialLow voltage

A semiconductor device is capable of being applied with both a positive and a negative voltage to its control gate, and writing to its memory requires a low voltage. A control gate is formed on a memory unit region of a field oxide film, and an inter-layer silicon oxide film is formed on its surface. A gate oxide film for a non-volatile memory is formed on a P substrate between N type diffusion layers. The floating gate is formed on the inter-layer silicon oxide film, the field oxide film, and the gate oxide film for the non-volatile memory. Since a large coupling ratio between the control gate and the floating gate is available on the field oxide film, memory rewriting requires only a low voltage. Further, since the control gate is formed by a poly silicon film, both a positive voltage and a negative voltage can be applied to the control gate.

Owner:RICOH KK

Coating device and coating method

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Chemical-mechanical polishing equipment and process

ActiveCN100475446CReduce film thickness variationInstant adjustment of polishing parametersSemiconductor/solid-state device manufacturingBurnishing machinesCompound (substance)Engineering

The chemico-mechanical polishing equipment consists of polishing machine, the first thickness measurer and the second thickness measurer connected to the polishing machine. Both the first thickness measurer and the second thickness measurer are used to complete the in-situ measurement of the thicknesses of the first material and the second material after polishing, and this can decrease the difference of chips in film thickness.

Owner:UNITED MICROELECTRONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com