Device and method for improving process deviation of multi-cavity equipment

A process deviation, multi-chamber technology, used in the manufacture of discharge tubes, electrical components, semiconductor/solid-state devices, etc., can solve the problems of film thickness difference on the wafer surface, increase the structure of the gas supply system, and affect the wafer yield. , to achieve the effect of reducing film thickness difference, efficient gas channeling, and improving wafer yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

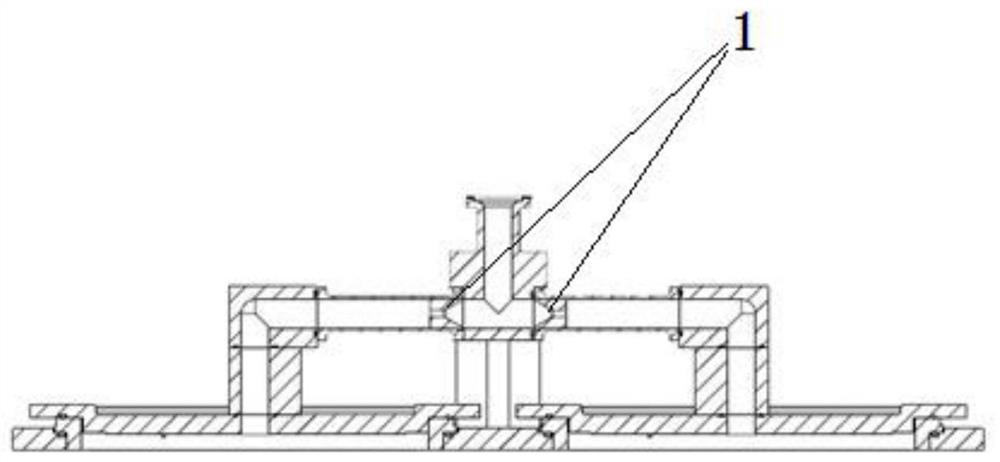

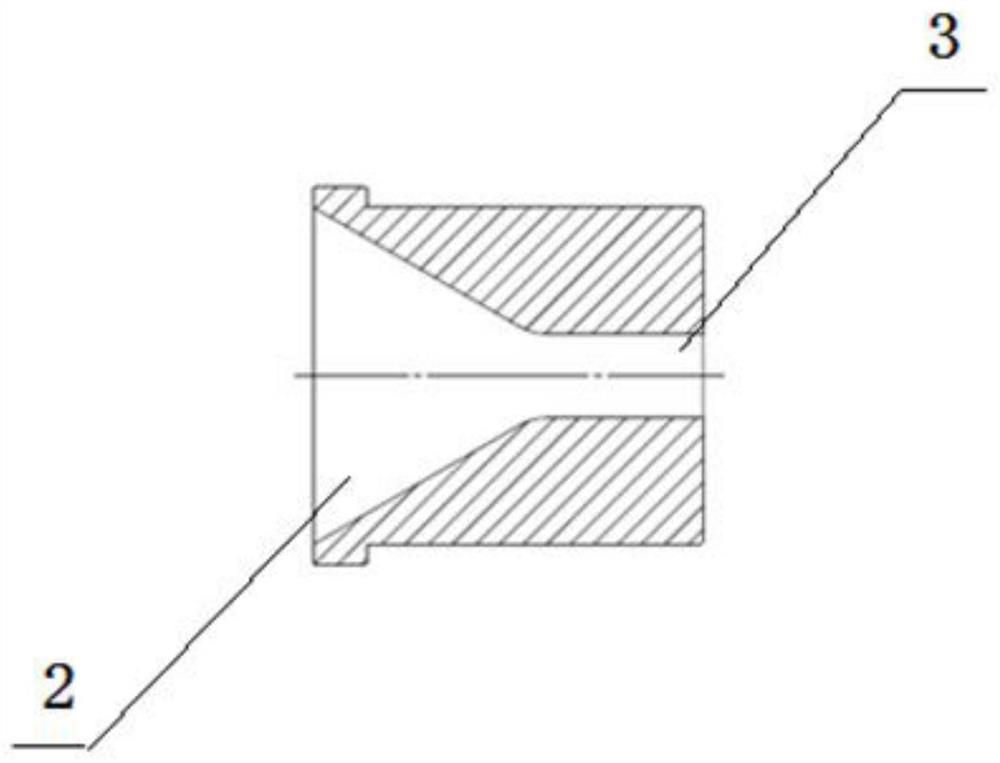

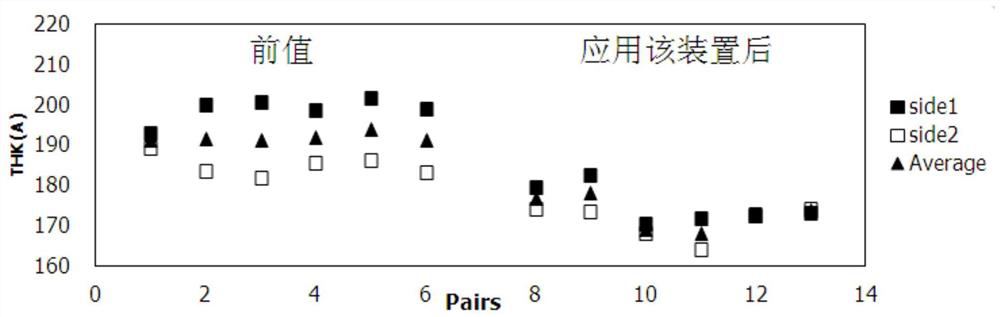

[0021] Such as figure 1 As shown, it is a schematic diagram of the installation position of the device. This embodiment aims at the problem of the difference in film thickness of the wafer surface between the chambers caused by the channeling of the process gas between the chambers in the prior art, and provides a method for reducing the thickness of the film between the chambers. The thickness difference device 1 mainly includes positioning steps, a tapered surface structure 2, and a straight hole structure 3; through this device, the difference in film thickness on the wafer surface between chambers is reduced, and the yield of wafers is improved.

[0022] The positioning step positions the device on the air path;

[0023] For further improvement, the thickness of the step meets the tolerance requirement of 0, -0.02. Reasonable tolerance requirements, on the one hand, prevent the O-ring seals on other gas paths from being compressed and fail to cause gas leakage due to ther...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com