Coating device and coating method

A coating device and a coating technology are applied in the coating device and the coating field, which can solve the problems of uneven texture, poor appearance, and uneven film thickness of the coating film, and achieve the effect of reducing the variation of the film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

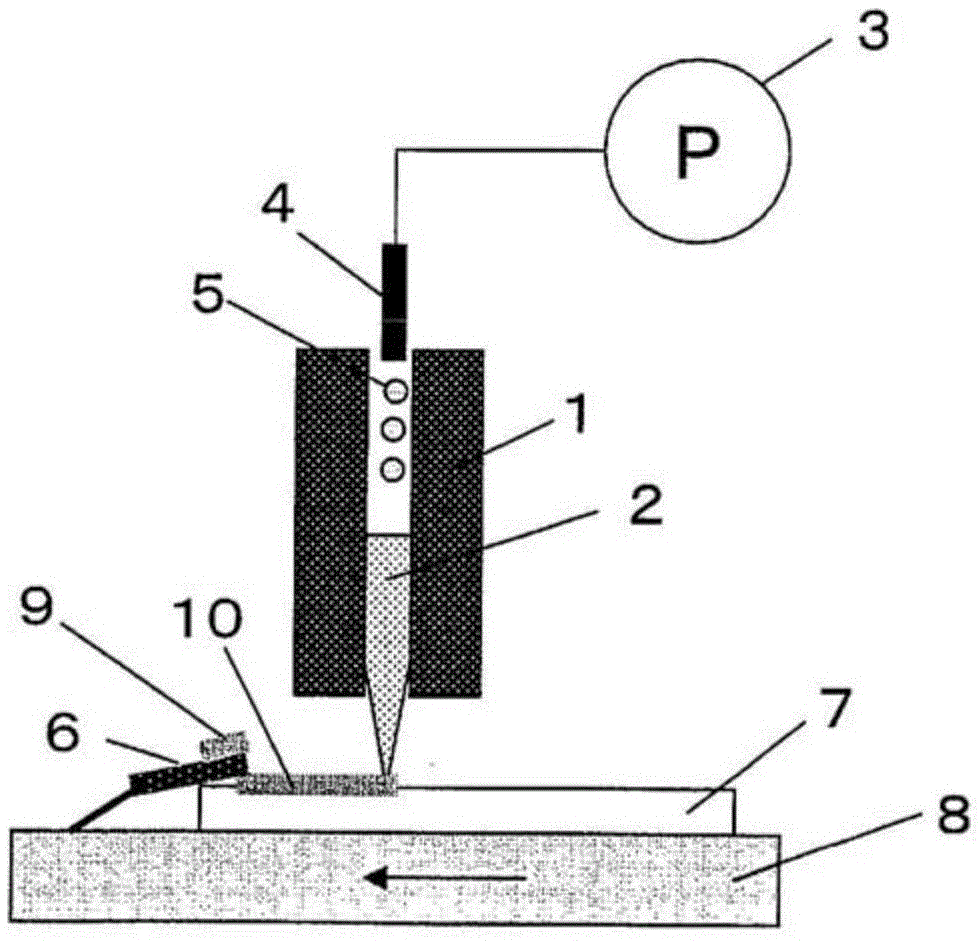

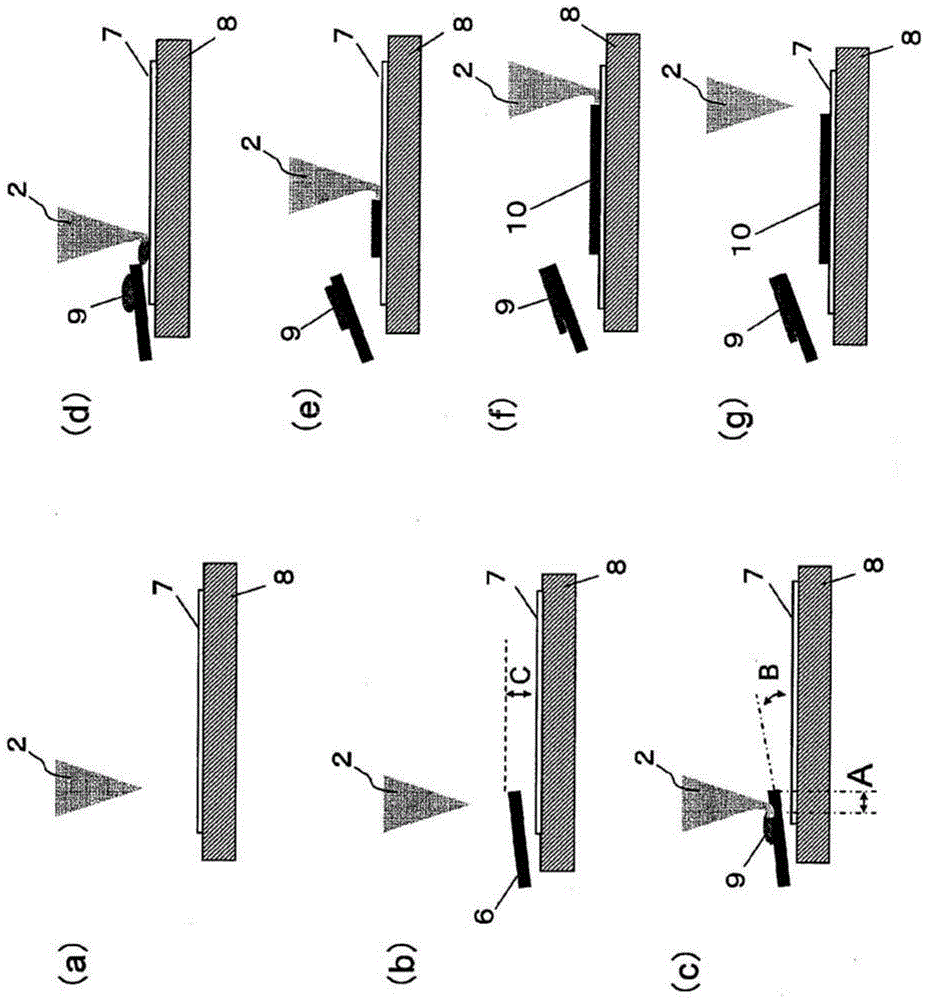

[0065] refer to figure 2 (a)~ figure 2 (g), yes figure 1 The coating operation of the coating device described in .

[0066] First, the substrate 7 is fixed on the transfer table 8 to such an extent that it does not shift due to transfer / coating by a decompression adsorption method, an electrostatic adsorption method, physical fixing, etc., and is moved below the porous member 2. ( figure 2 (a)).

[0067] Next, the spacer 6 is arranged on the coating start position of the substrate 7 ( figure 2 (b)). Then, the distance between the porous member 2 and the separator 6 is reduced by a vertical driving mechanism (not shown) of the porous member 2 , and the end of the porous member 2 is brought into contact with the surface of the separator 6 .

[0068] Here, the coating fluid accumulation 9 occurs at the end of the porous member 2 ( figure 2 (c)). In this state, the porous member 2 and the substrate 7 are relatively moved, and the porous member 2 is moved from the se...

Embodiment 2

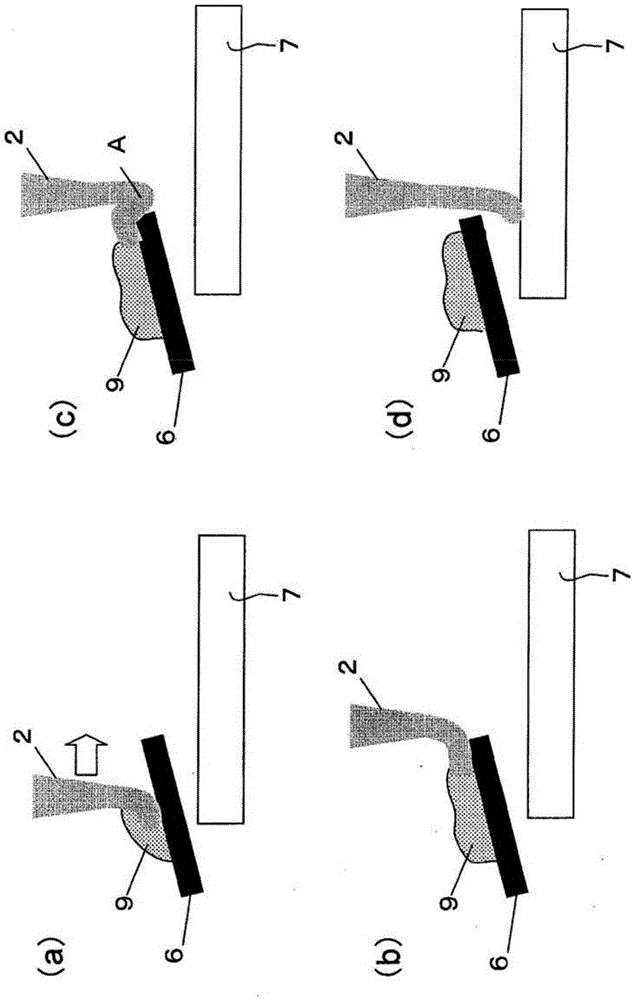

[0085] Next, the contents related to the shape of the separator will be described. in the aforementioned image 3 , taking into account the above image 3 (c)~ image 3 In (d), if the end of the porous member 2 is in contact with the substrate 7 in the coating width direction at the same time, air bubbles will be mixed between the end of the porous member 2 and the substrate 7 at a certain position in the width direction. If it is in such a state, it will apply|coat in the state mixed with air bubbles, and coating unevenness may generate|occur|produce.

[0086] This problem can be solved by the apparatus configuration shown below. Figure 5 It is a schematic diagram obtained by observing the positional relationship of the substrate 7 , the end of the porous member 2 , and the separator 6 in a plan view.

[0087] The end of the porous member 2 and the substrate 7 are arranged in a direction perpendicular to the relative movement direction of the end of the porous member 2 a...

Embodiment 3

[0090] Next, the shape of the separator will be described. Figure 6 It is a figure showing the overall shape of a separator. Figure 6 (a) represents a top view, Figure 6 (b) means Figure 6 (a) XX' profile, Figure 6 (c) means Figure 6 (a) YY' profile.

[0091] As described in Examples 1 and 2, the coating liquid oozes out at the position where the end of the porous member 2 is in contact with the separator 6 to generate a fluid accumulation. However, if mass production is considered, each cleaning of the partition plate 6 will increase the loss and cost due to production tact or components and solvents required for cleaning. Therefore, in order to easily remove the accumulated liquid generated on the surface of the separator 6 , a mechanism for removing unnecessary application liquid is provided on the separator 6 . use Figure 6 (a)~ Figure 6 (b) An example thereof will be described.

[0092] At a position closer to the upstream side (opposite to the direction in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com