A method for forming a color filter substrate and corresponding spraying device

A color filter, spraying device technology, applied in optics, optical components, nonlinear optics, etc., can solve the problems of difficult scheduling, uneven color, inconsistent spit out, etc., to reduce maintenance time and The steps of cleaning, the effect of improving production efficiency and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Preferred embodiments of the present invention will now be described with reference to the accompanying drawings.

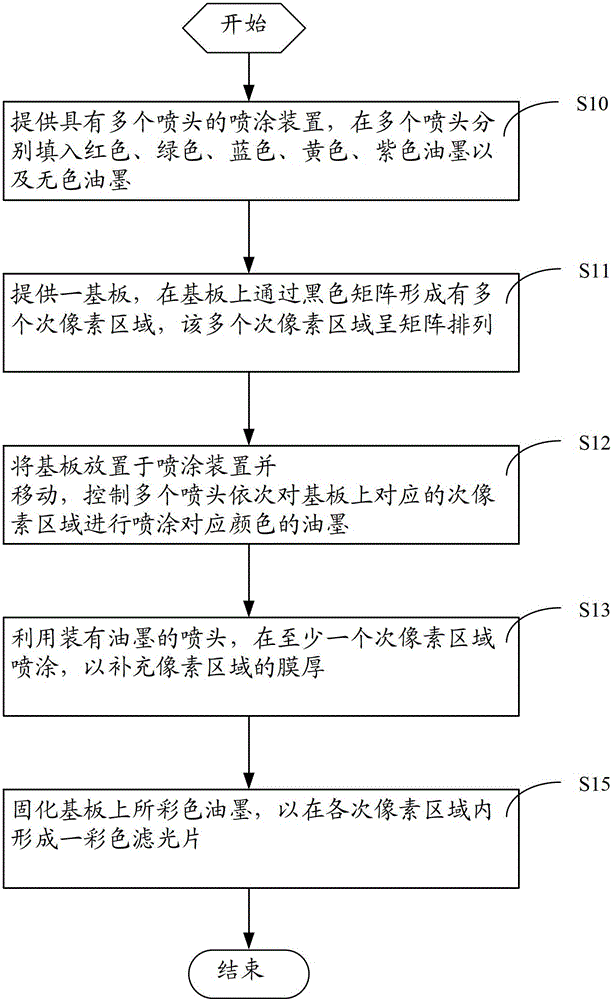

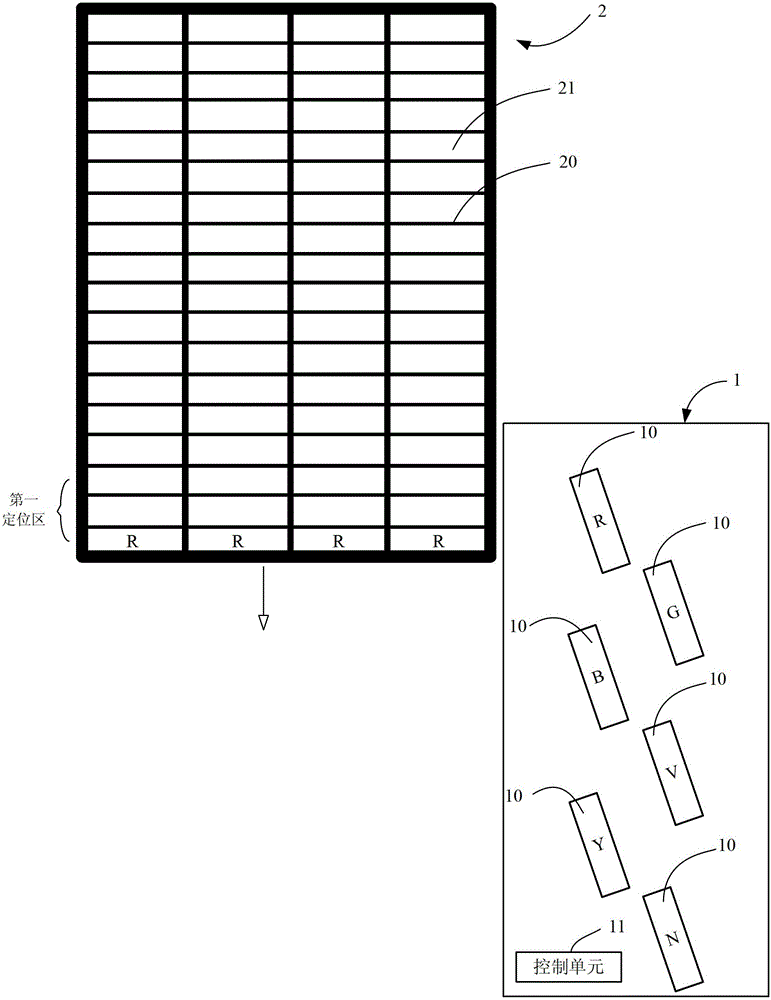

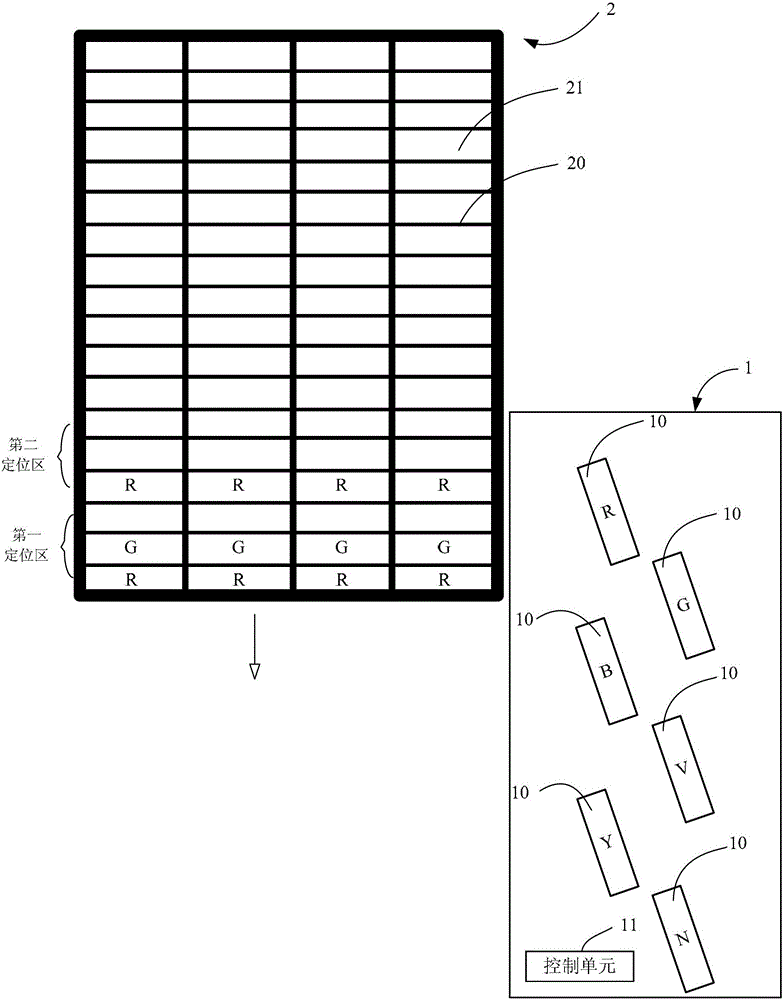

[0052] Such as figure 1 Shown is a schematic diagram of the main flow in an embodiment of a method for forming a color filter substrate provided by the present invention; for ease of understanding, it is combined with figure 2 The schematic diagram in .

[0053] Embodiments of the present invention provide a method for forming a color filter substrate, which includes the following steps:

[0054] Step S10, providing a spraying device 1 with a plurality of nozzles 10, filling the plurality of nozzles 10 with ink of one color, wherein the ink includes red, green, blue, yellow, purple ink and colorless ink, Respectively represented by R, G, B, Y, V and N in the figure;

[0055] Step S11, providing a substrate 2, such as a glass substrate, on which a plurality of sub-pixel regions 21 are formed through a black matrix 20, and the plurality of sub-pixel region...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com