Method for reducing silicon wafer film thickness difference in furnace tube process

A furnace tube process and film thickness technology, applied in metal material coating process, coating, gaseous chemical plating and other directions, can solve the problem of large difference in thickness of silicon wafers, reduce film thickness difference, improve thickness difference, reduce Effects of concentration differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

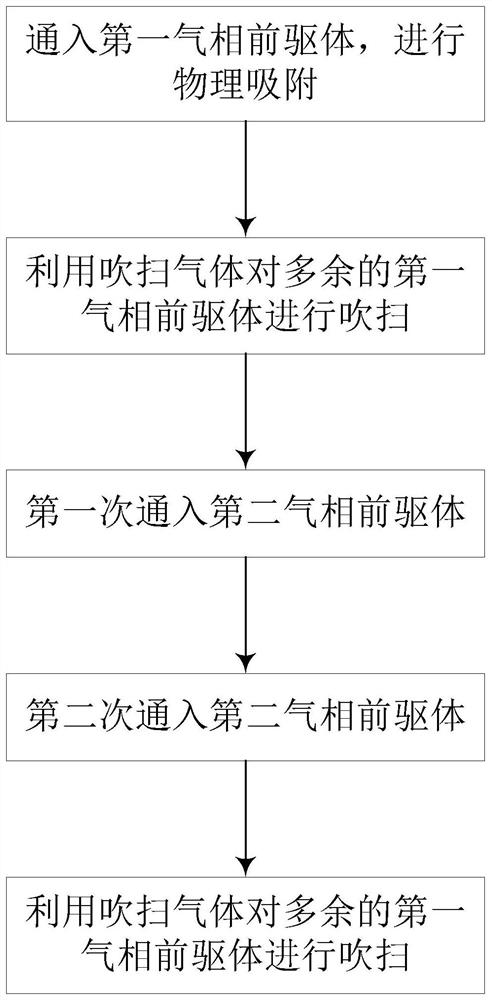

[0029] The method that the embodiment of the present invention provides to improve the difference in thickness of the silicon wafer film in the furnace tube process, such as figure 1 As shown, the growth of the film comprises several cyclic processes, and the steps of each cyclic process are as follows:

[0030] Step S1, introducing the first gas phase precursor for physical adsorption;

[0031] Step S2, using a purge gas to purge the redundant first gas phase precursor;

[0032] Step S3, the second gas-phase precursor is introduced for the first time, and the flow rate of the second gas-phase precursor is S 1 , the access time is T 1 ;

[0033] Step S4, the second gas-phase precursor is introduced for the second time, and the flow rate of the second gas-phase precursor is S 2 , the access time is T 2 ;

[0034] Step S5, using a purge gas to purge the excess second gas-phase precursor;

[0035] Wherein, the volume V of the second gas phase precursor required in each cyc...

Embodiment 2

[0044] On the basis of the first embodiment, this embodiment further defines in detail the method for improving the thickness difference of the silicon wafer film in the furnace tube process.

[0045] Wherein, the ratio of the flow rate S1 of the second gas-phase precursor introduced for the first time to the flow rate S2 of the second gas-phase precursor introduced for the second time is 5:1˜10:1.

[0046] In step S2 and step S5, the purge gas is nitrogen or inert gas.

[0047] In step S3 and step S4, the second gas-phase precursor and the first gas-phase precursor perform a chemical reaction to form a thin film.

[0048] The silicon nitride thin film formed by atomic layer deposition (ALD) process is taken as an example for illustration below.

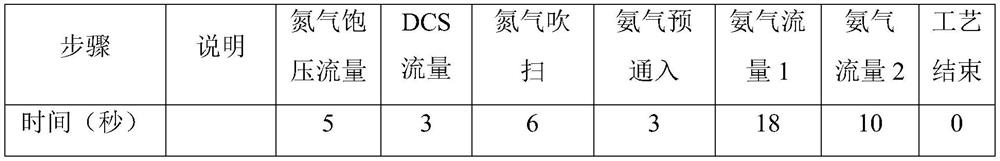

[0049] The thickness of the film depends on the specific number of cycles. At present, each cycle of deposition includes: 1) feeding DCS (dichlorodihydrosilane) gas for the first physical adsorption; 2) purging excess DCS gas sourc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com