Chemical mechanical polishing (CMP) stepwise polishing method

A sub-grinding, chemical-mechanical technology, applied in the field of CMP step-by-step grinding, can solve the problem of large changes in residual film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

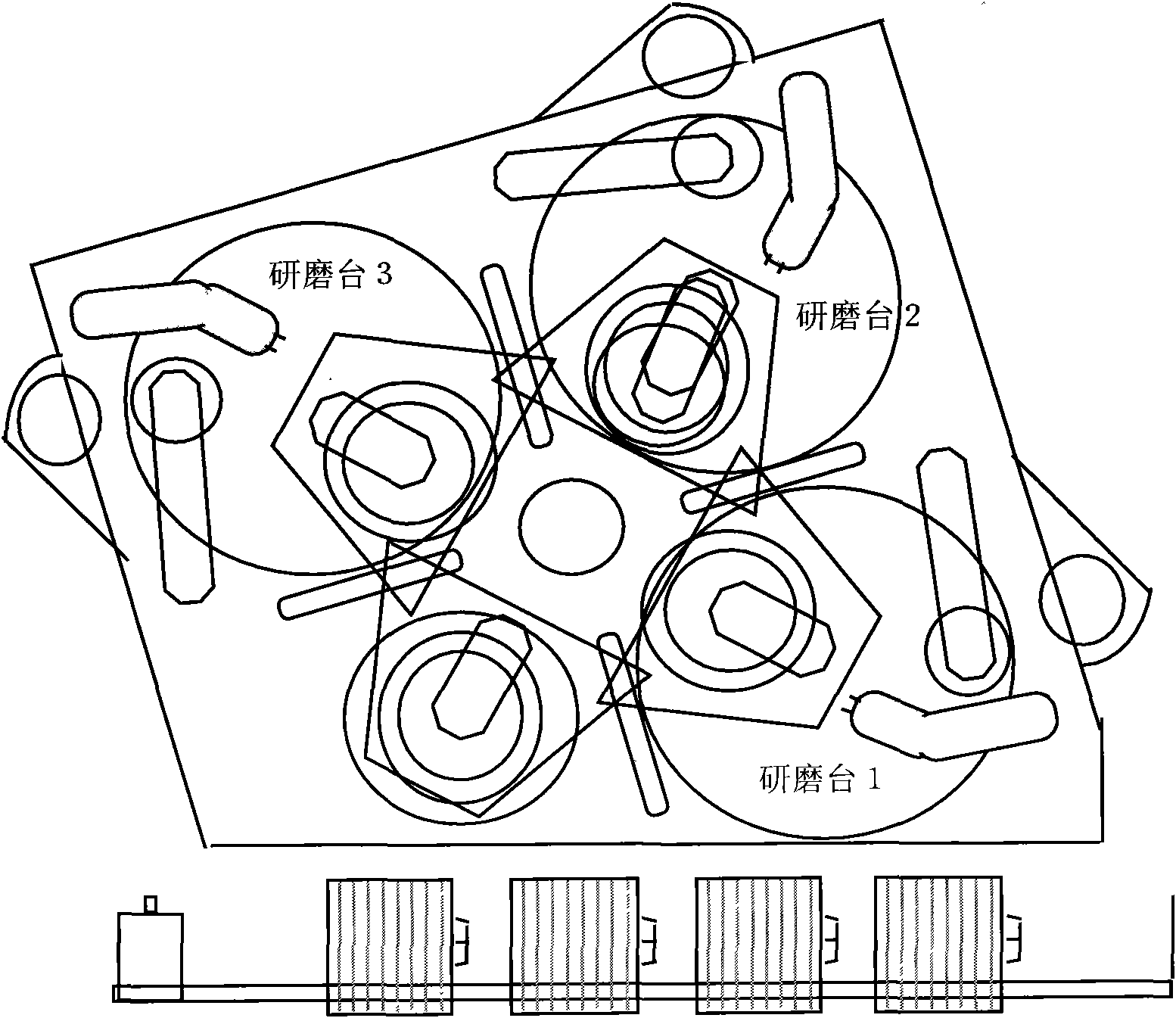

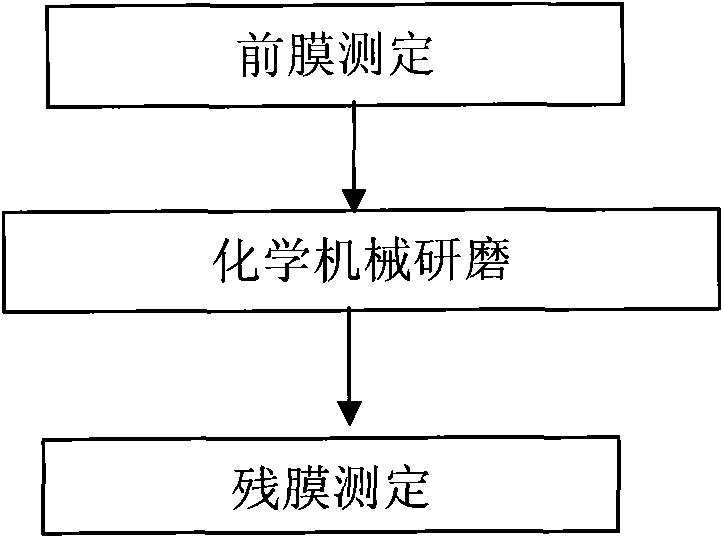

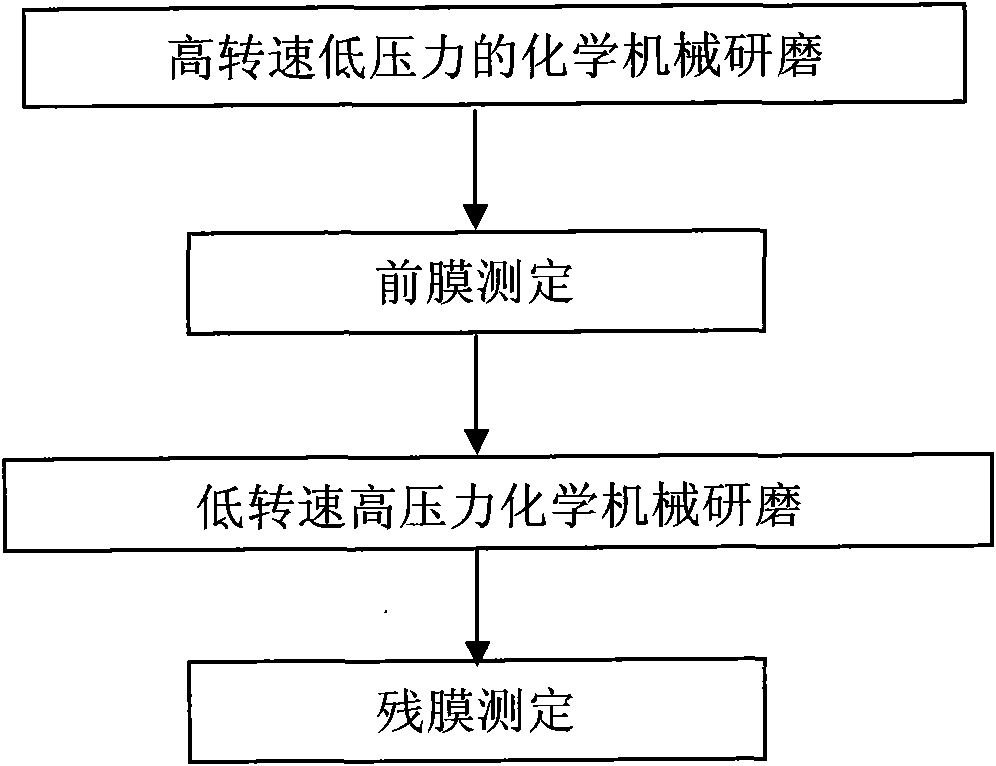

[0022] The present invention reduces the thickness change of the front film by changing the chemical mechanical polishing process (grinding→front film measurement→grinding→residual film measurement), the difference in pattern distribution and the fluctuation of the remaining film thickness caused by the fluctuation of the grinding rate. The CMP analysis of the present invention The method of step grinding mainly includes the following steps:

[0023] The first step: take the product silicon wafer, and use the chemical mechanical grinding conditions of high speed and low pressure to grind the product silicon wafer for the first time, so as to reduce the difference caused by the front film thickness and pattern distribution. Speed setting in this step: 93-112 rpm; pressure: 4-5 pounds per square inch. Grind at an interval of 15 sec, take the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com