Film formation method

A film-forming method and film-forming technology, used in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as changes in film thickness and inability to confirm changes in gas pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

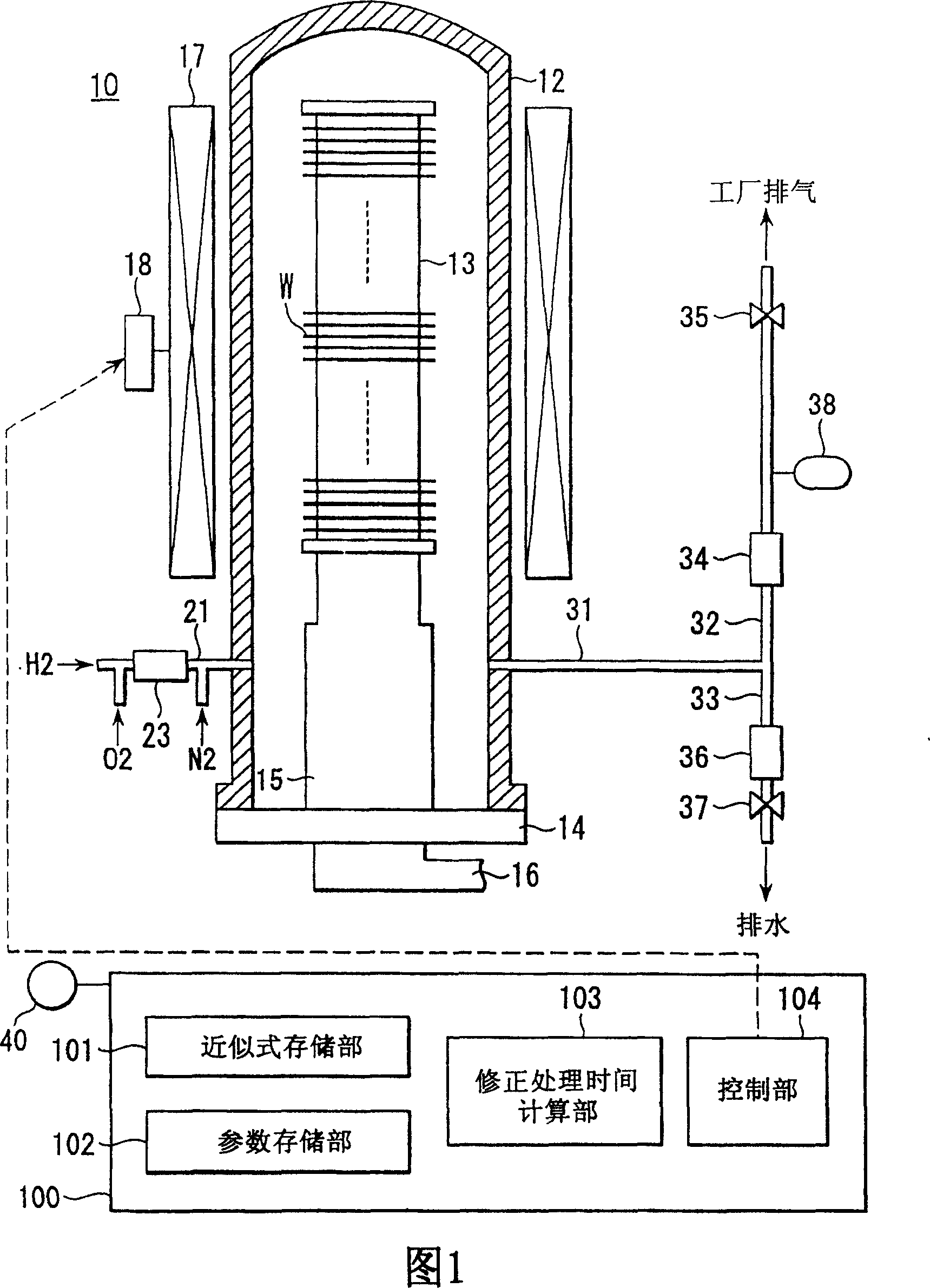

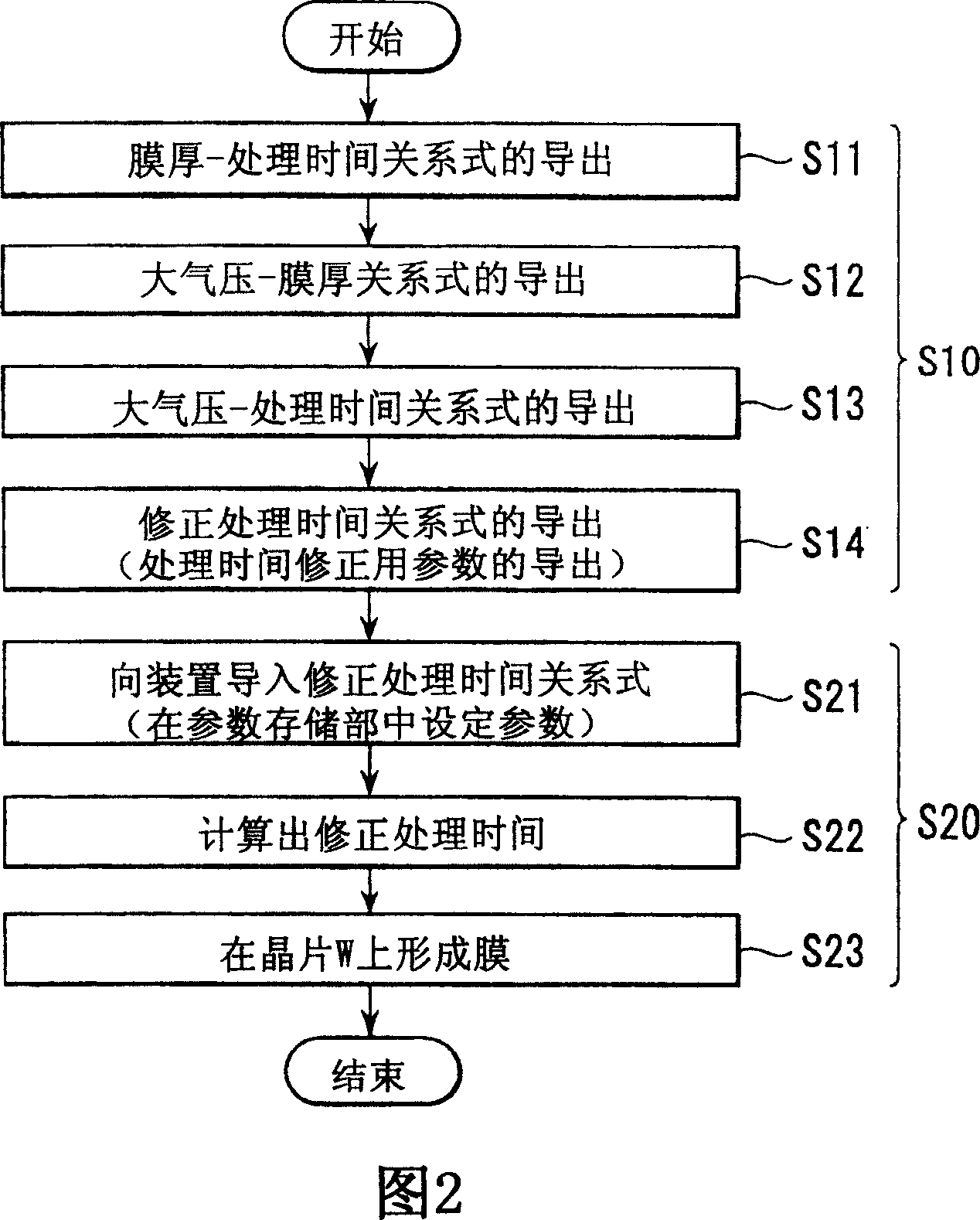

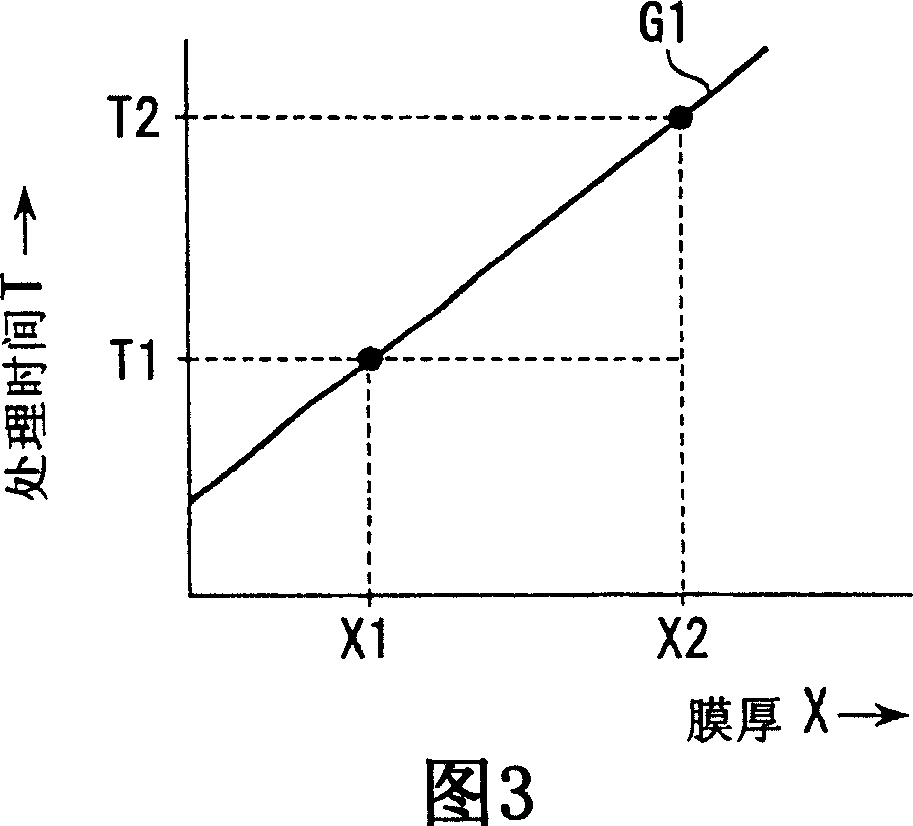

[0019] 1 is a cross-sectional view showing part of a vertical heat treatment apparatus as a film formation apparatus for semiconductor processing according to an embodiment of the present invention. As shown in FIG. 1 , a vertical heat treatment apparatus 10 has a reaction tube 12 made of, for example, quartz and plugged at its upper end. In the reaction tube 12, a plurality of, for example, 150 semiconductor wafers W (product wafers) serving as substrates are placed on the wafer carrier 13 as a holder in a shelf shape at regular intervals up and down in a horizontal state. The wafer carrier 13 is held by the lid body 14 via a thermal insulation cylinder (heat insulator) 15 .

[0020] The lid body 14 is placed on a carrier elevator 16 for carrying the wafer carrier 13 into or out of the reaction tube 12 . When at the upper limit position, the lid body 14 has the function of closing the lower end opening of the processing container constituted by the reaction tube 12 .

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com