Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Reduce dust removal load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

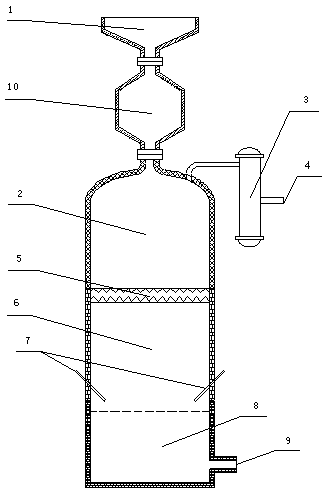

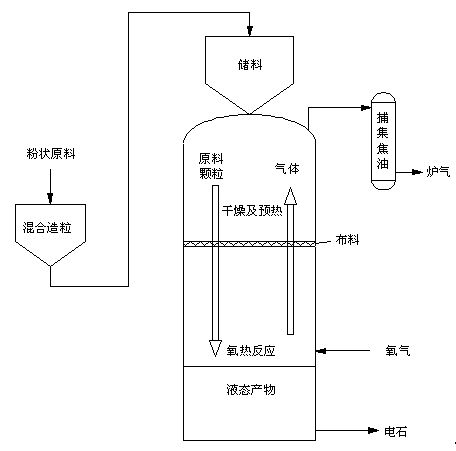

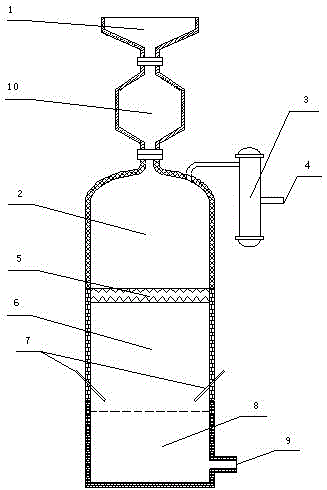

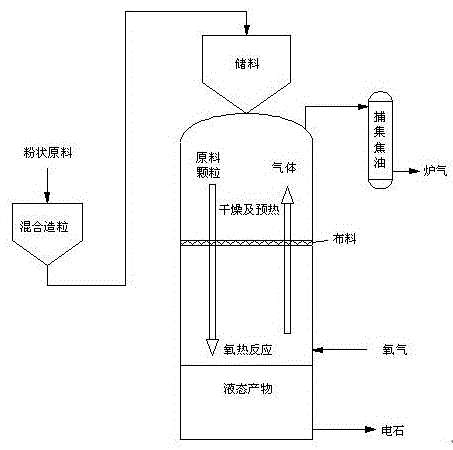

Composite bed reactor and method for combined production of calcium carbide, gas and tar

ActiveCN103272536ATake advantage ofReduce heat lossCalcium carbideSpecial form destructive distillationReaction rateMolten bath

The invention relates to a composite bed reactor and a method for combined production of calcium carbide, gas and tar, and belongs to the field of calcium carbide production. The reactor comprises a hopper, a brake bunker, a moving bed preheating chamber, a tar collector, a gas outlet, a distributing device, an oxygen heat reaction chamber, oxygen spraying burners, a product molten pool and a product outlet, and the hopper is connected with the moving bed preheating chamber by the brake bunker, and the top side surface of the moving bed preheating chamber is provided with the tar collector, and the tar collector is provided with a gas outlet, and the moving bed preheating chamber bottom is provided with a distributing device, and the moving bed preheating chamber is communicated with an oxygen heat reaction chamber by a distributing device, and the oxygen heat reaction chamber bottom is connected with a product molten pool, and the upper portion of the connection between the oxygen heat reaction chamber and the product molten pool is provided with the oxygen spraying burner, and the middle bottom of the product molten pool is provided with a product outlet. The reactor of the invention has the advantages of simple structure and high efficiency, and large scale production is easy to realize, and the raw material is pelleted by powder form carbonaceous raw material and powder form calcium containing raw material, and the contact surface between raw materials is large, the reaction rate is fast, and reactor is convenient for reusing calcium carbide slags.

Owner:BEIJING UNIV OF CHEM TECH

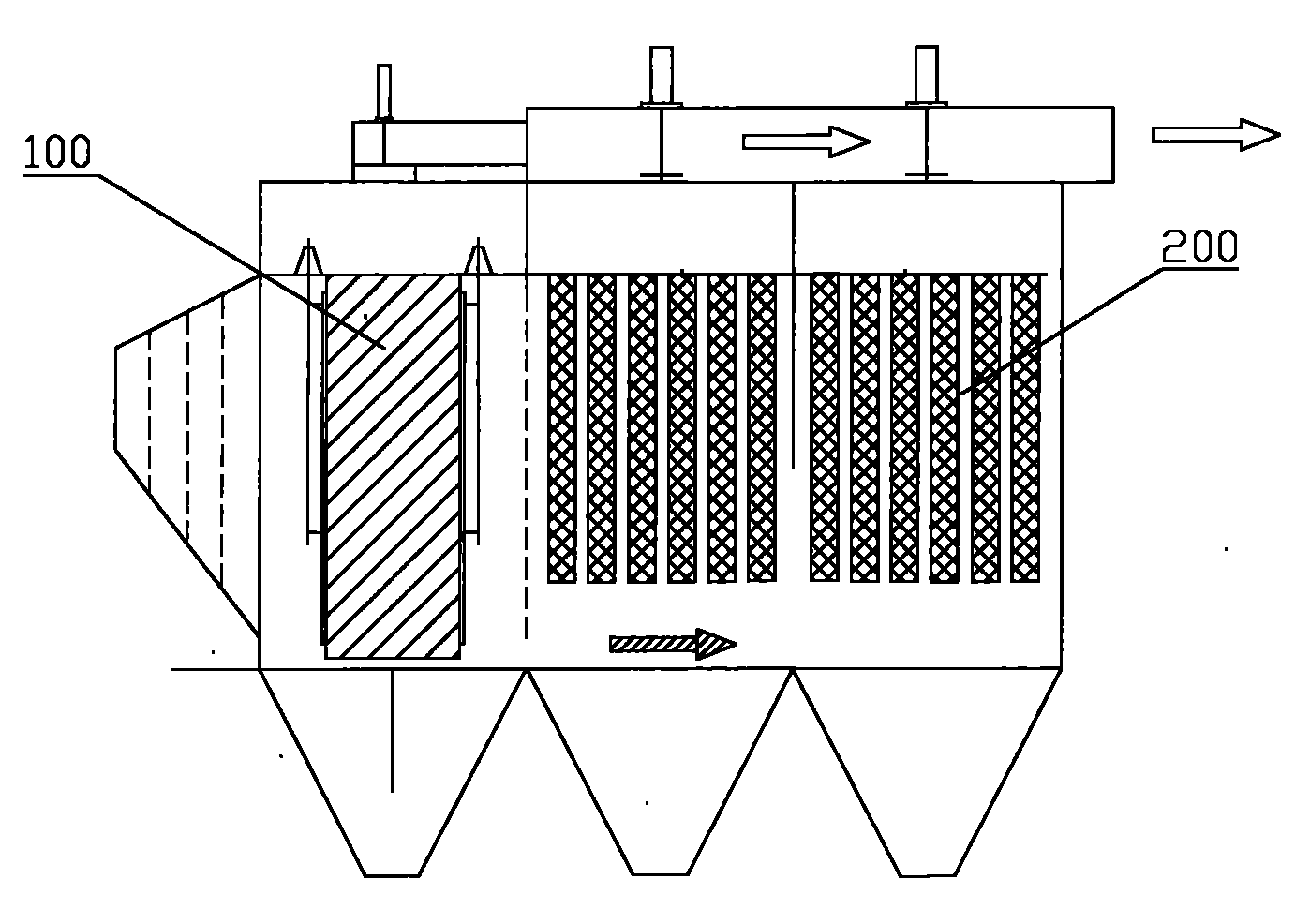

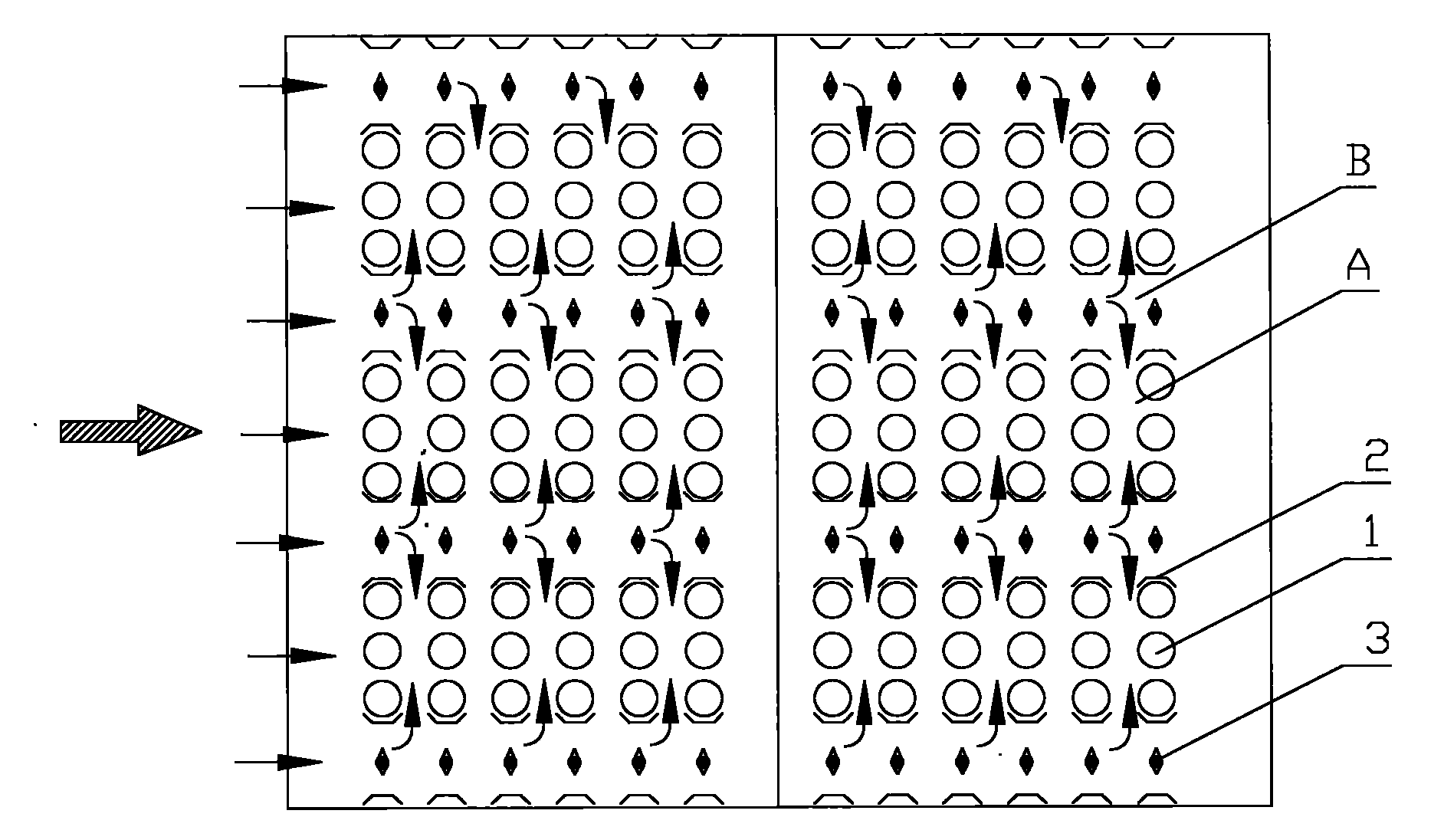

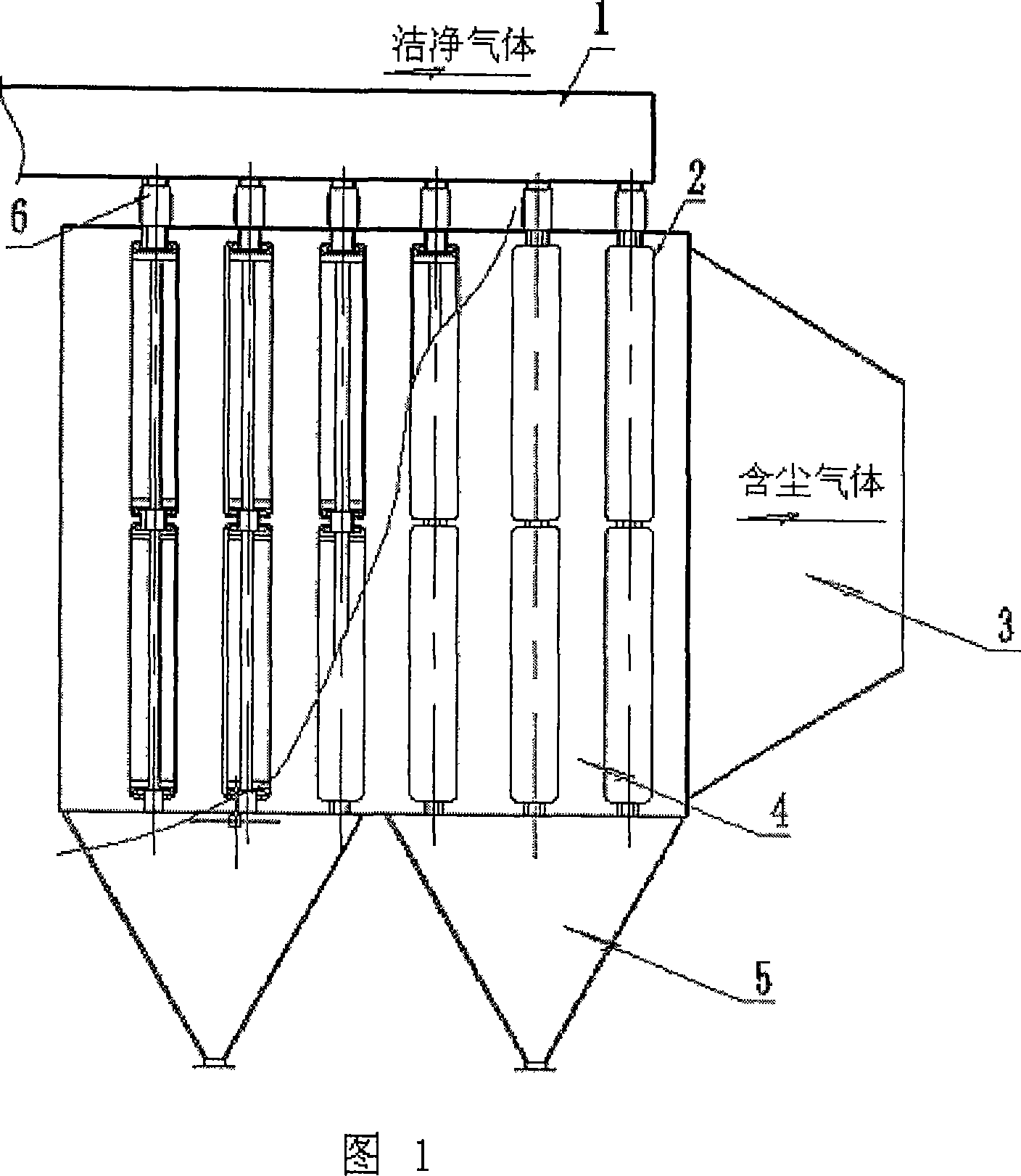

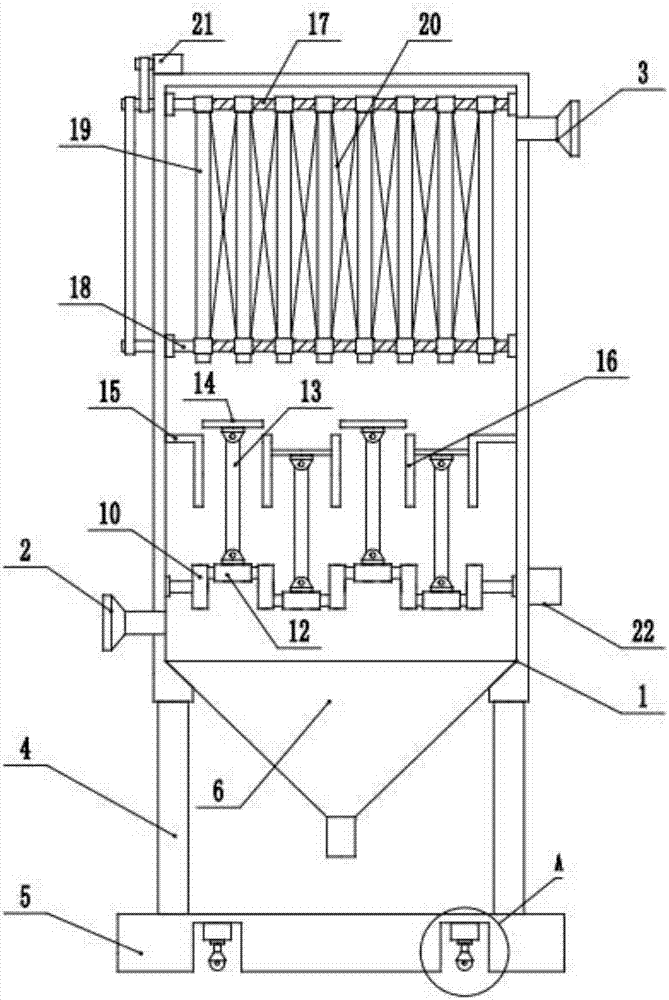

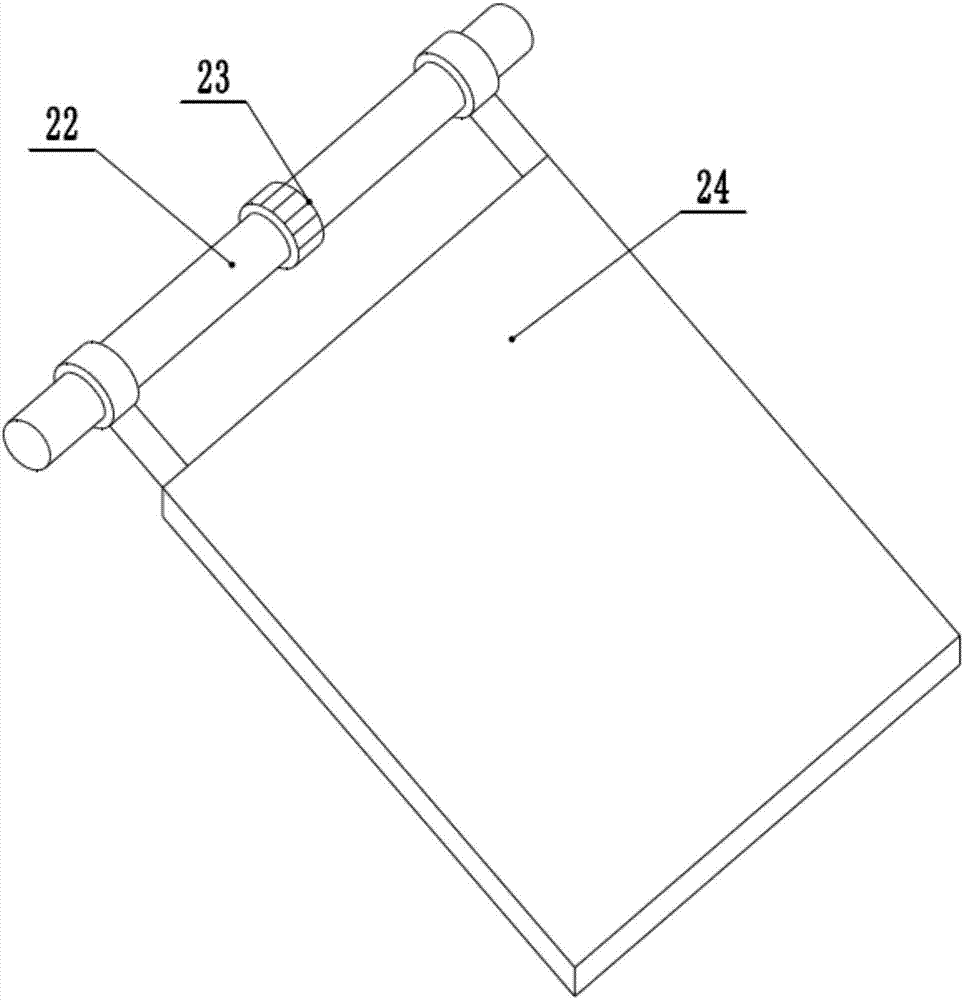

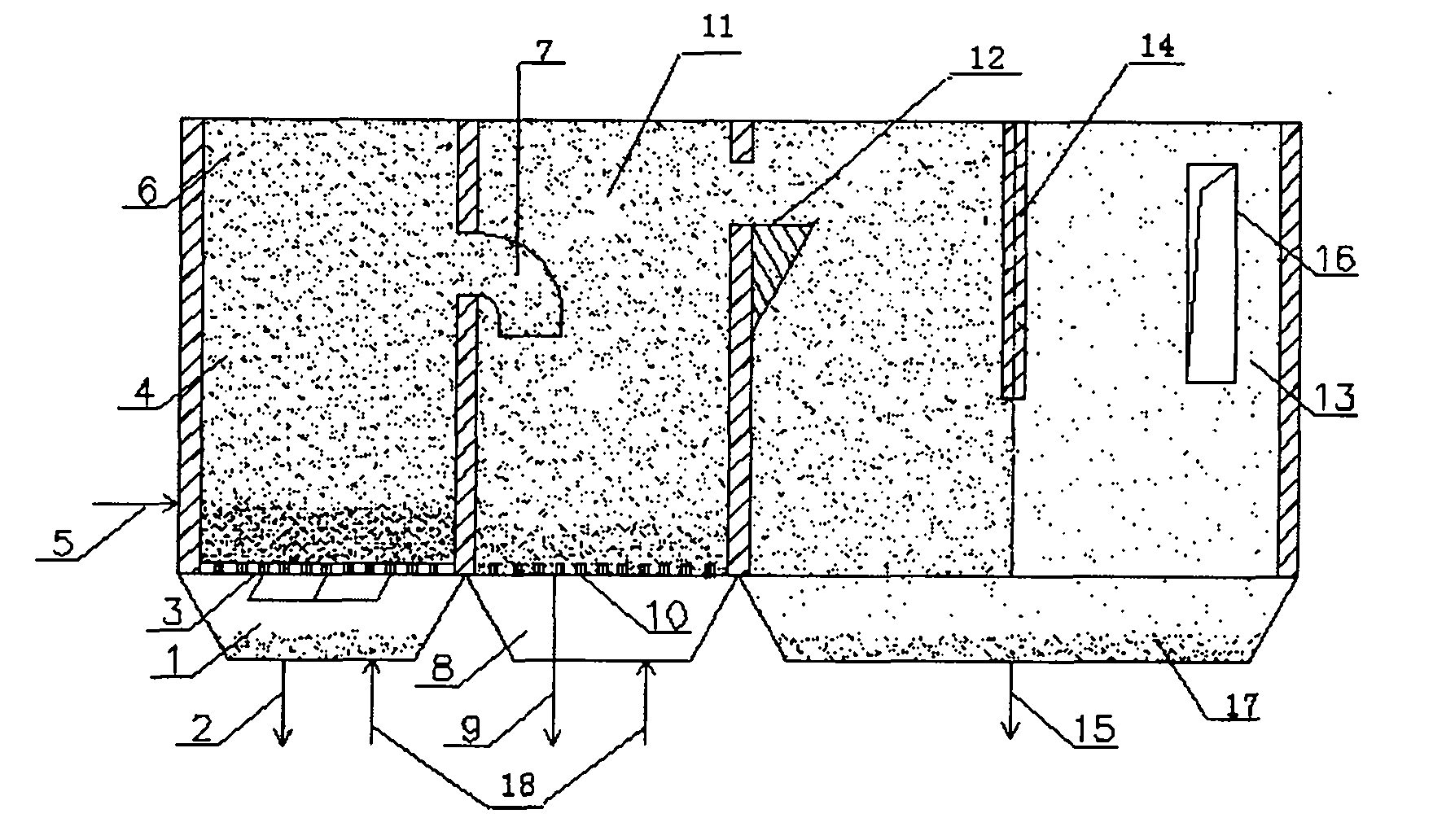

Electrostatic-bag composite dust-collector

ActiveCN101837216ASmall filter resistanceNot easy to loseDispersed particle filtrationFlue gasEngineering

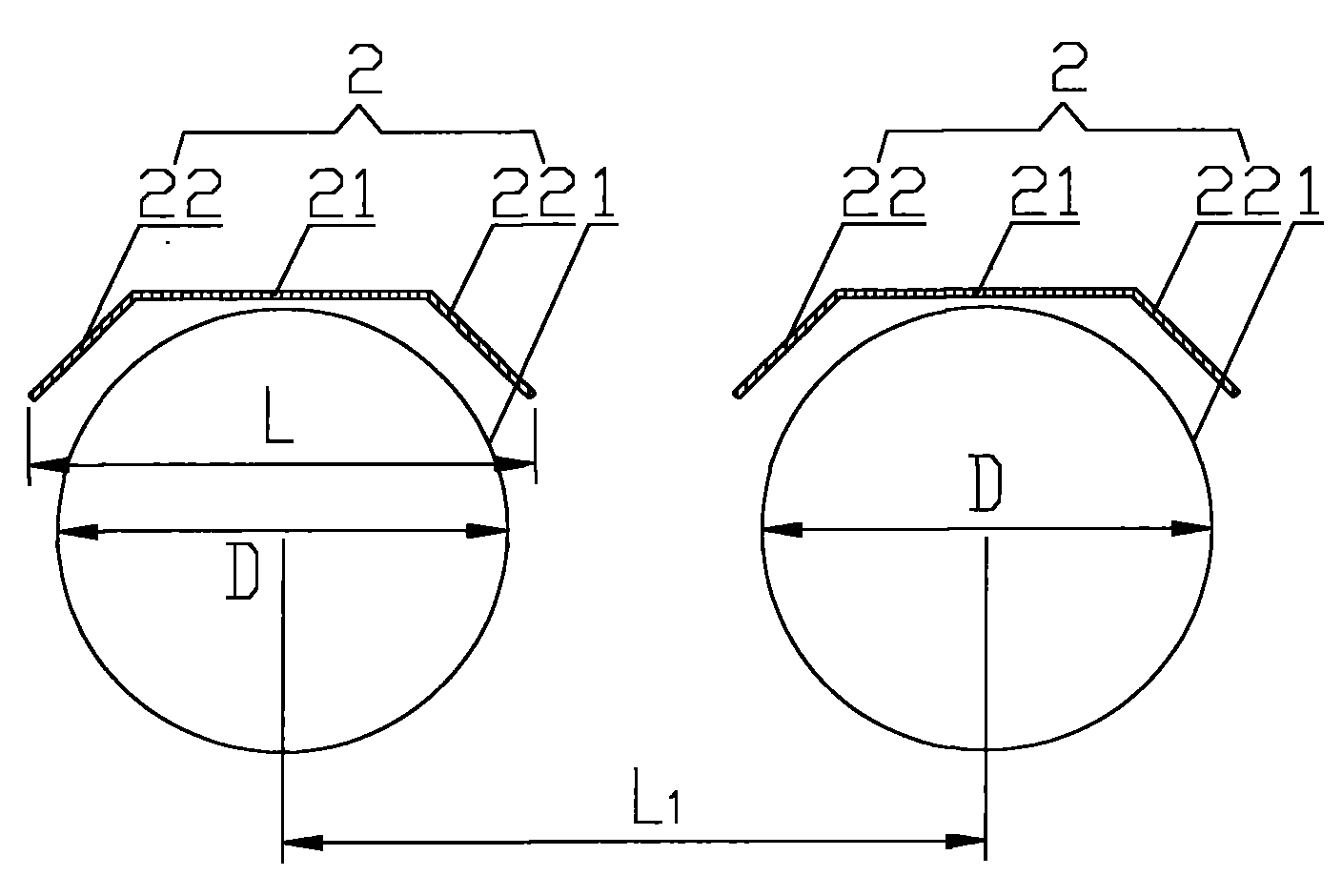

The invention discloses an electrostatic-bag composite dust-collector comprising an electric-bag mixing area, wherein the electrostatic-bag mixing area consists of a plurality of filtering bag rows and a plurality of electric field channels; each filtering bag row and each electric field channel are generally parallel and are arranged at intervals; each filtering bag row is at least provided with a row of filtering bags (1); each electric field channel is at least provided with two anode plates (2); gaps between adjacent anode plates (2) form an airflow passage; flue gas flowing through the electric field channels enters the filtering bag rows through the airflow passage; one anode plate (2) is arranged on the outer side of each filtering bag (1) adjacent to the electric field channel; and the width of the anode plate (2) is more than or equal to the diameter of the filtering bag (1), so that the filtering bags and discharge electrodes of the electric field channels are separated by the anode plates (2). The electrostatic-bag composite dust-collector not only improves the chargeability of dust and the dust collecting efficiency, but also effectively prevents the filtering bags (1) from being adjacent to the discharge electrodes (3) directly, thereby effectively prolonging the service life of the filtering bags (1) and reducing the cost for dust collection.

Owner:FUJIAN LONGKING

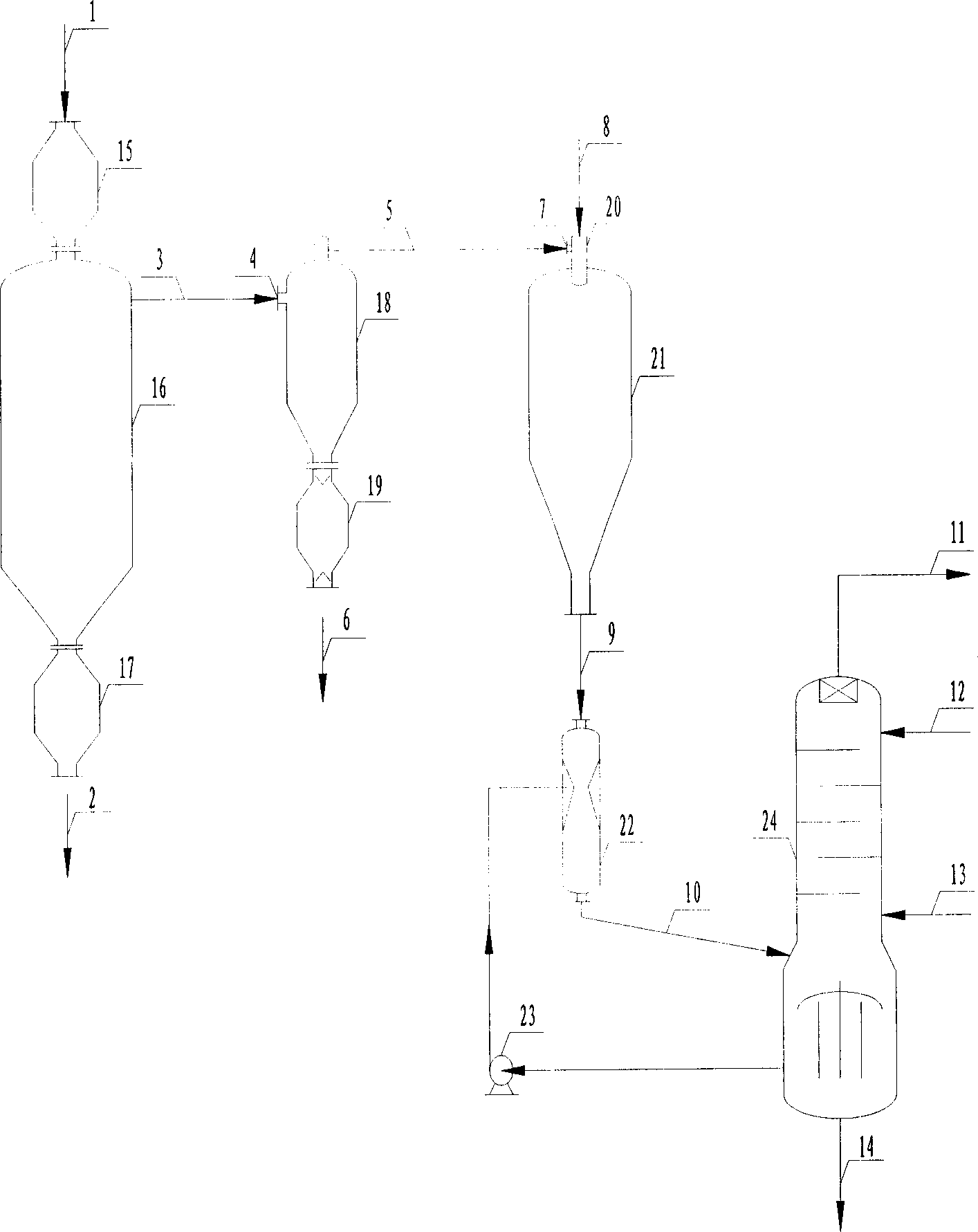

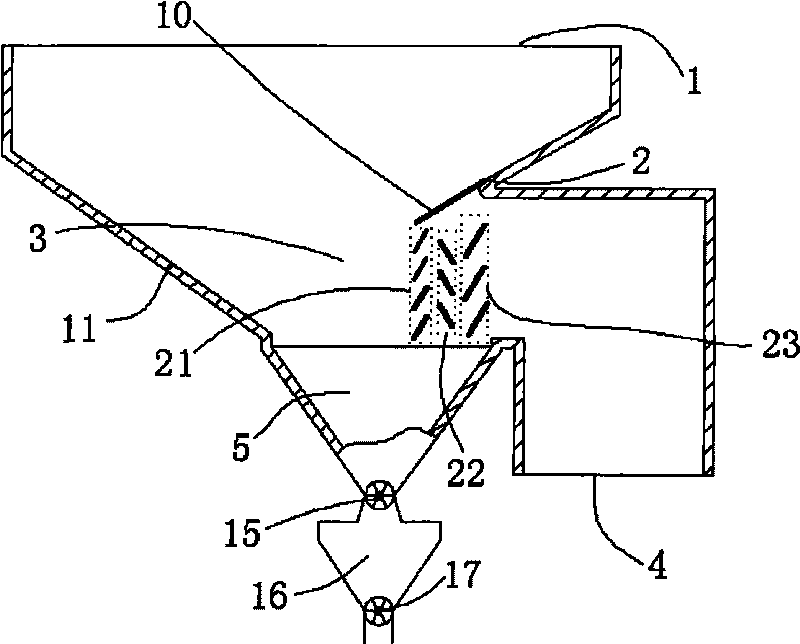

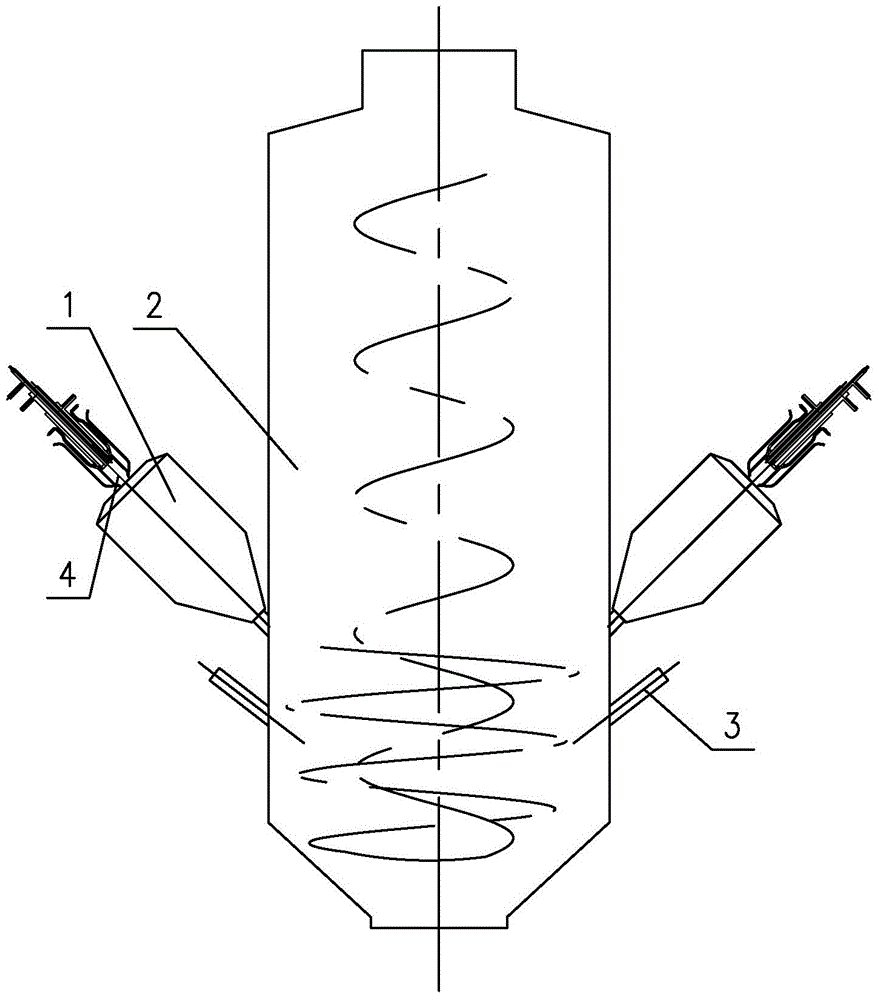

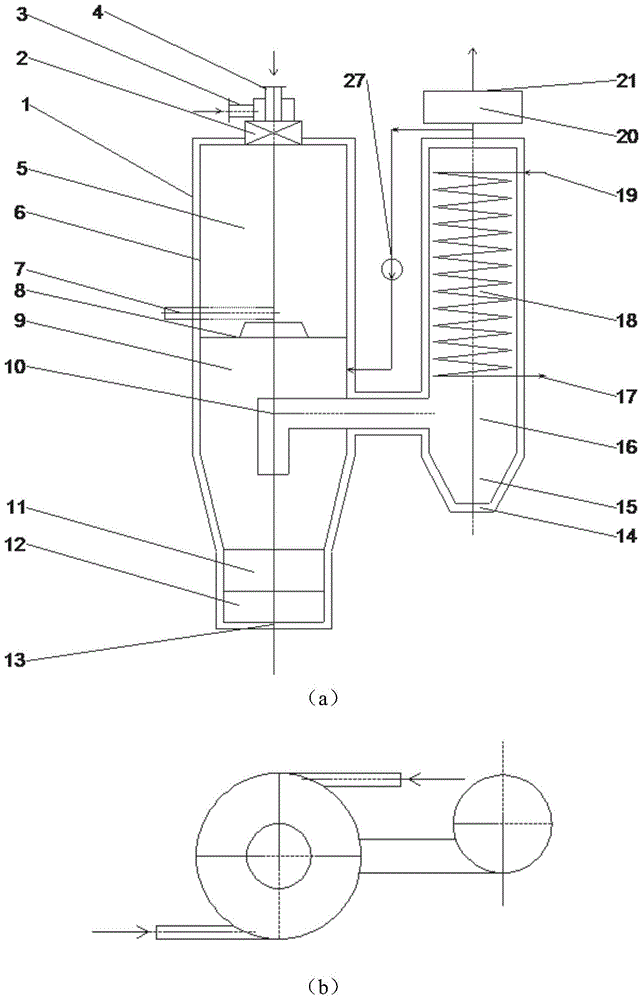

Device and method for removing sulphur dioxide and dioxin from sintering flue gas

InactiveCN102366704AAchieve removalRemove changeDispersed particle separationActivated carbonGas solid

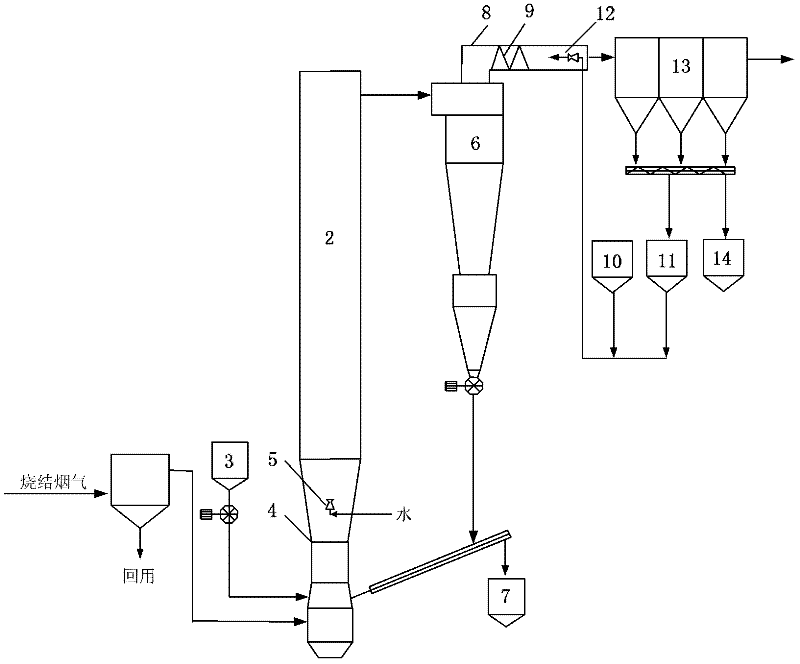

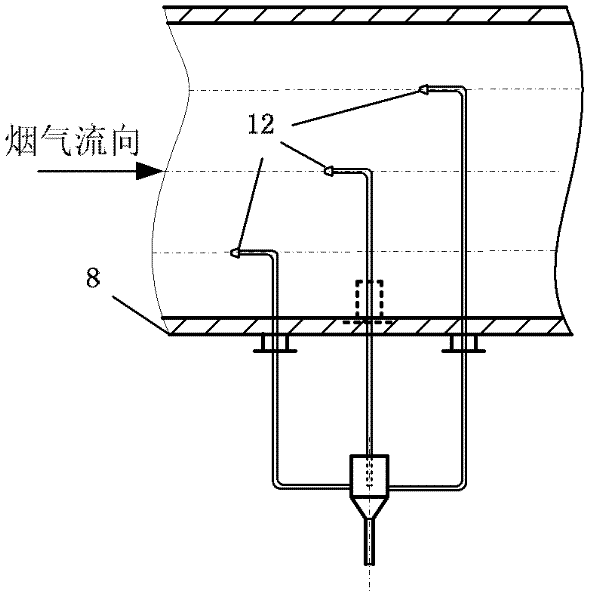

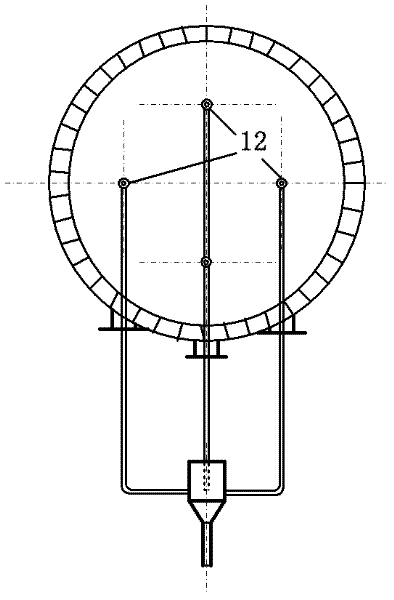

The invention relates to a device and method for removing sulphur dioxide and dioxin from sintering flue gas. The device comprises a circulating fluid bed adsorption tower (2) and a bag-type dust collector (13), wherein a desulphurizer bin (3) and a water spray nozzle are arranged at the bottom of the circulating fluid bed adsorption tower (2); a cyclone separator (6) and a flue duct (8) are sequentially arranged between the top of the circulating fluid bed adsorption tower (2) and the top of the bag-type dust collector (13) along the flowing direction of flue gas; and a plurality of activated carbon spray nozzles (12) are arranged at one end of the flue duct (8) adjacent to the bag-type dust collector (13) in the direction opposite to the flowing direction of the flue gas, and are communicated with an activated carbon bin (10). The device and method for removing sulphur dioxide and dioxin from sintering flue gas, provided by the invention, have the advantages that the sulphur dioxide and the dioxin are separately removed, the influence of the sulphur dioxide on absorption of the dioxin by activated carbon in the flue gas is reduced, and the efficiency of removing the dioxin is increased; and due to the adoption of spiral fins (9) in the flue duct, gas-solid mass transfer of the flue gas and the activated carbon is strengthened, and the efficiency of removing the dioxin from the flue gas can be obviously improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

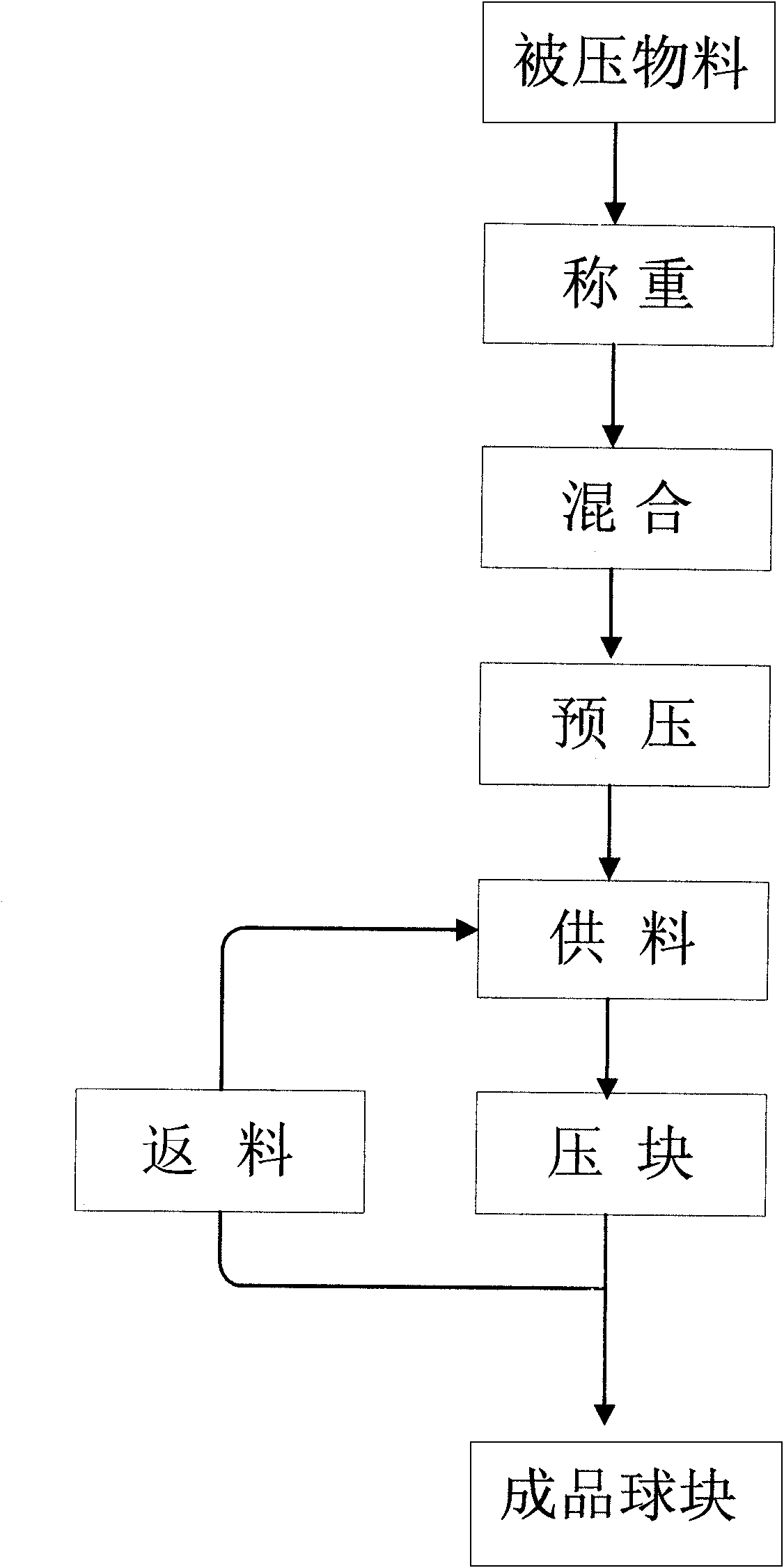

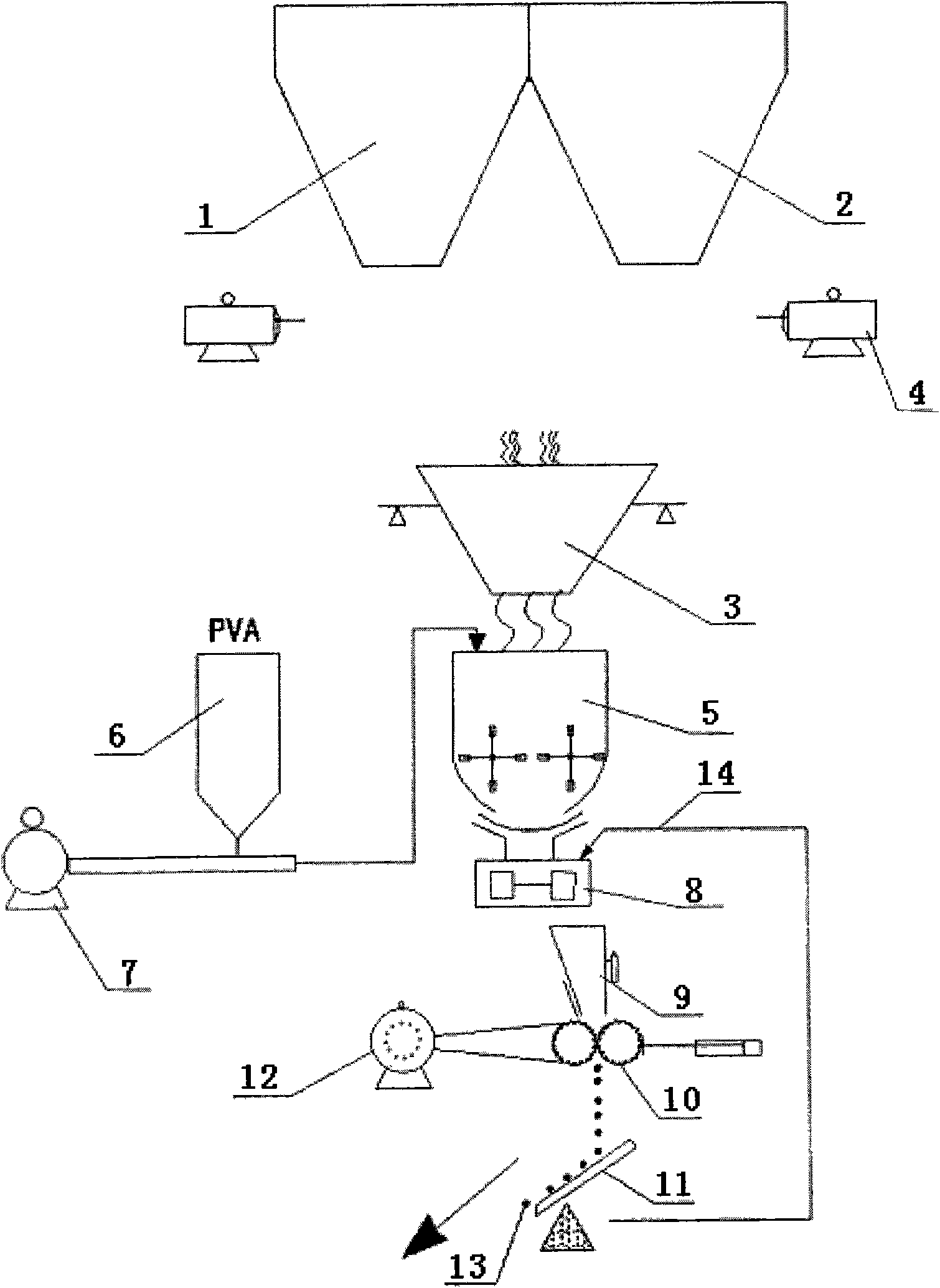

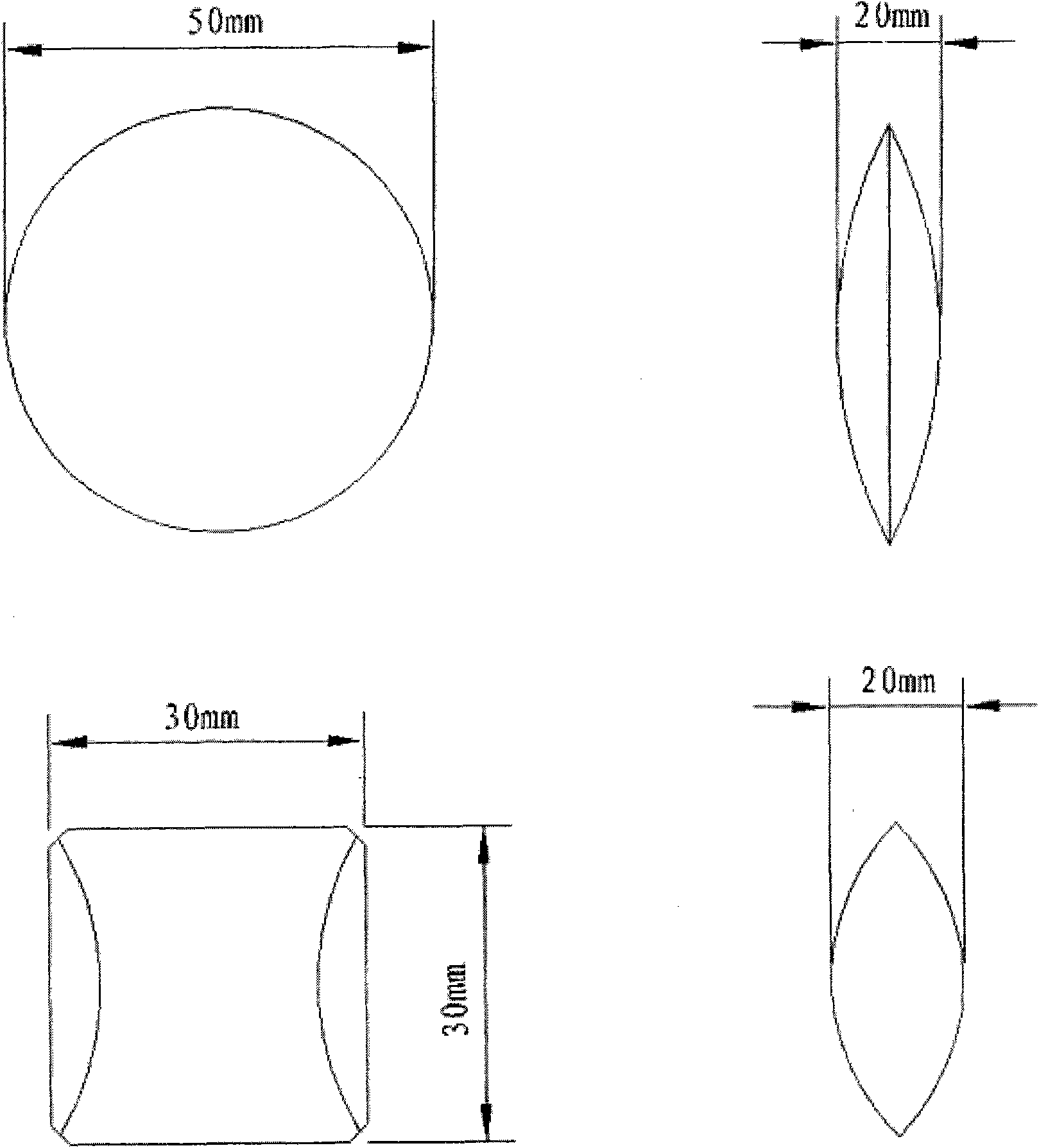

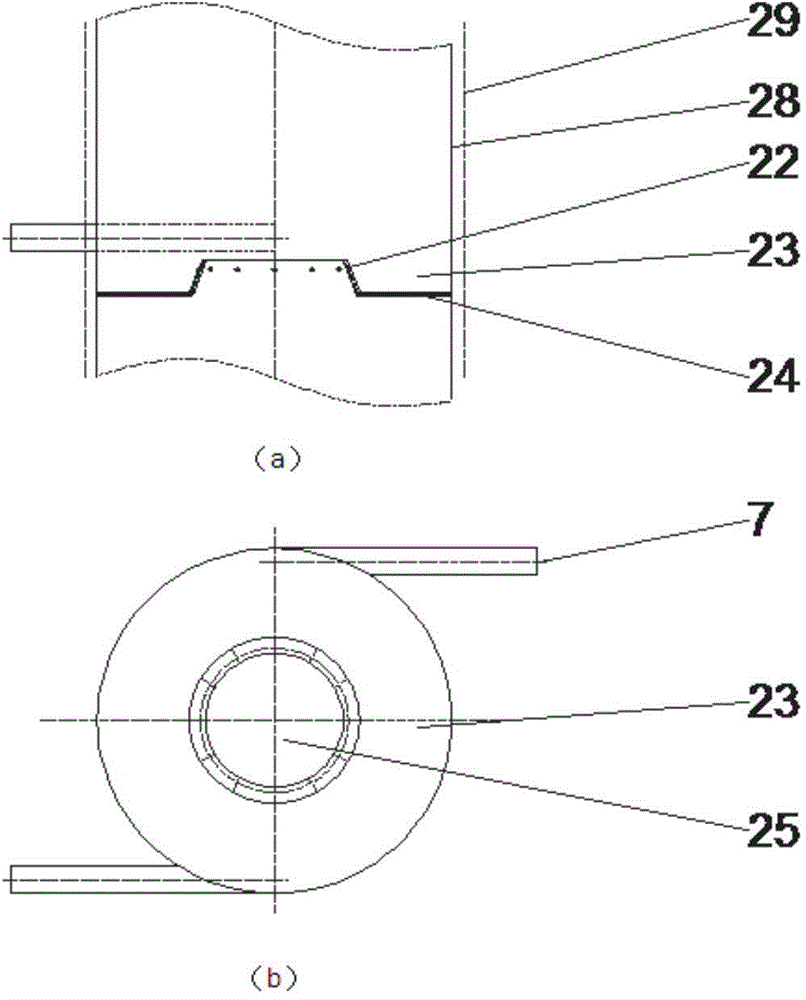

Method for manufacturing high strength green ball block by coal-based direct reduction and device therefor

The invention relates to a method for manufacturing green ball blocks by coal-based direct reduction and a device therefor, which is suitable to be used for a raw material ball pressing section by the coal-based direct reduction in the steel and iron metallurgical industry. The method adopts accurate weight batching, high mixing evenness degree, proper mixture prepressing, suitable feeding, suitable returning charge adding, suitable pressure to a roller, and suitable briquette size, acquires the suitable molding time by frequency control in the required yield, obviously improves the strength of the green ball blocks, reduces the generation of powder materials, improves the material yield and the productivity of a reducing furnace, reduces the flue gas dust removal load of the reducing furnace and the like, and has obvious economic benefits and industrialized popularization value .

Owner:SICHUAN LOMON MINING & METALLURGY

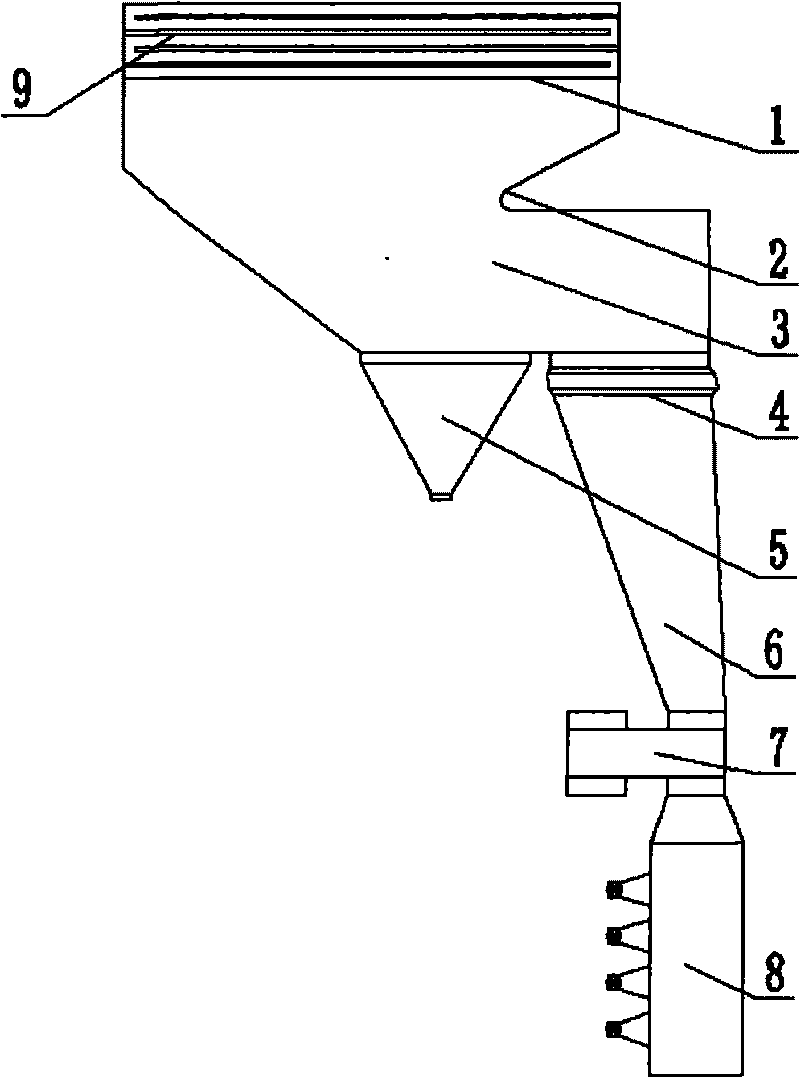

Coal gasifier for slag granulation and coal gas preparation process

ActiveCN104593085AReduce oxygen concentrationReduce the temperatureCombined combustion mitigationGranular/pulverulent flues gasificationCoal waterSlag

The invention discloses a coal gasifier for slag granulation and a coal gas preparation process. The coal gasifier is mainly composed of a pressure-bearing housing, a slag film gasification device, an annular chamber structure slag basin, a quenching chamber, a conduit, a convection cooling section and the like. The process comprises the following steps: with pulverized dry coal or coal water slurry as a raw material, feeding the raw material to a gasification chamber to burn and gasify together with a gasifying agent from a vortex gasification burner; enabling formed liquid slag to collide with the wall surface of the gasification chamber under the vortex action, and flowing from bottom to top under the action of gravity; feeding to the slag basin of the annular chamber structure, carrying out further gasification reaction together with oxygen fed from the upper part of the slag basin, and discharging from a slag discharge hole; feeding coal gas main airflow to the quenching chamber together with liquid drops, cooling to a specific temperature, and then conveying to the convection cooling section to further lower temperature through the conduit; finally removing dust, purifying and then outputting. The liquid slag drops penetrating through the slag basin are cooled to form solid particles and are collected by a dry slag collector; and the heat is recovered by a slag cooler.

Owner:XI AN JIAOTONG UNIV +1

Crushed coal pressure gasifying process for producing synthetic gas

InactiveCN1888028AAdaptive reactivityAdapt to anti-cloggingCombined combustion mitigationFixed-bed gasificationSyngasFixed bed

The crushed coal pressure gasifying process for producing synthetic gas includes pressure gasifying of crushed oil in a fixed bed to produce crude gas, and the subsequent self-heating pure oxygen partial conversion of crude gas to produce synthetic gas. Thus produced synthetic gas has high effective gas (CO+H2) content, low CH4 content, less impurities and other advantages, and is suitable for large scale synthetic gas production.

Owner:太原海力丰科技发展有限公司

Ash remover

ActiveCN101108293AImprove dust removal efficiencyOvercoming the disadvantages of secondary flyingDispersed particle filtrationEngineeringSoot

The invention discloses a dust catcher, which comprises a dust cell, an exhaust column arranged on the dust cell, an air inlet and an ash hopper. At least a filtering screen unit is arranged in the dust cell, which comprises a filtering screen drive device, a sealing component is arranged at the two sides on and down the filtering screen drive device, the filtering screen covers on the drive device and the sealing component and forms a sealing filtering screen unit inner cavity, a soot cleaning device is arranged at a soot cleaning zone close to the filtering screen at one side of the filtering screen unit inner cavity, at least a connection opening which makes the filtering screen unit inner cavity connected with the exhaust column is arranged on the sealing component. The invention can realize continuous exhausting, dedusting and soot cleaning, and overcomes the defects that the existing dust catcher only can dedust fixedly, work and dedust intermittentedly brings increased dedusting load and lower dedusting capability, which has the advantages of high dedusting efficiency, less equipment investment, low running cost and convenient maintenance.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

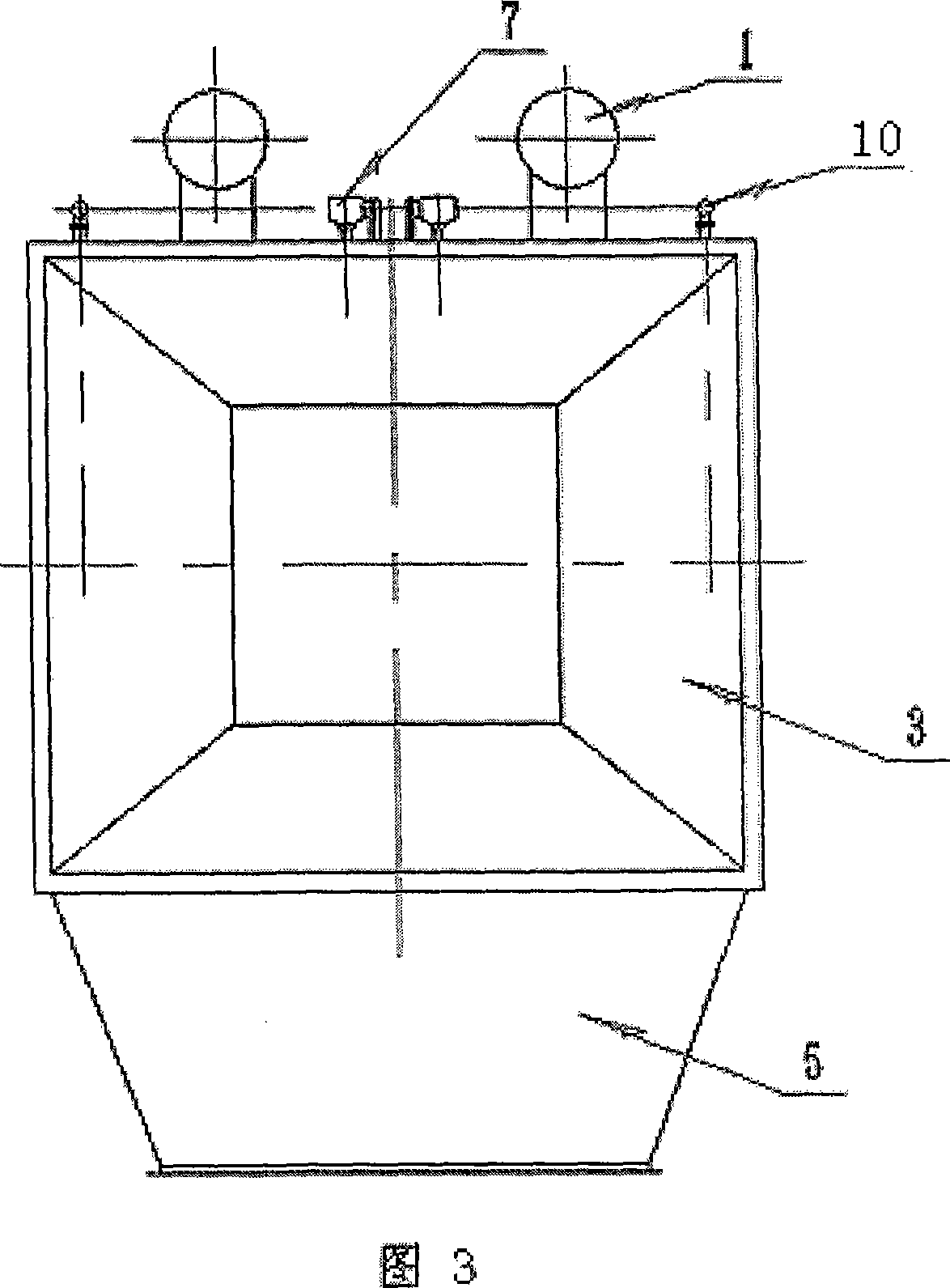

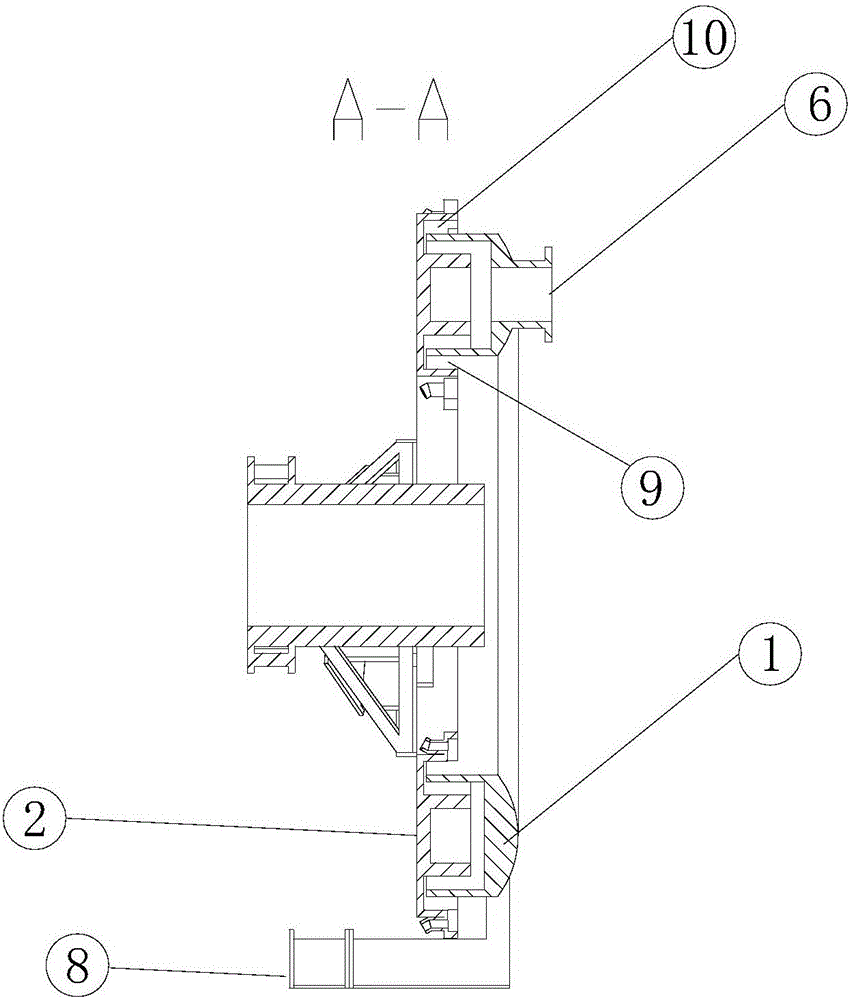

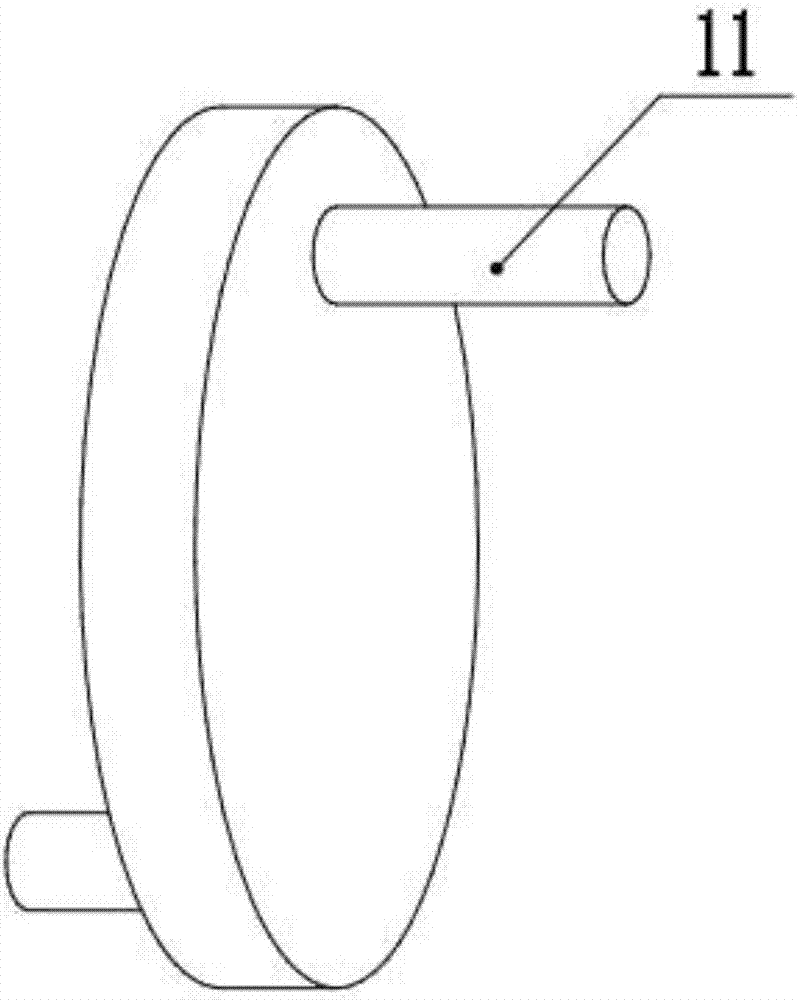

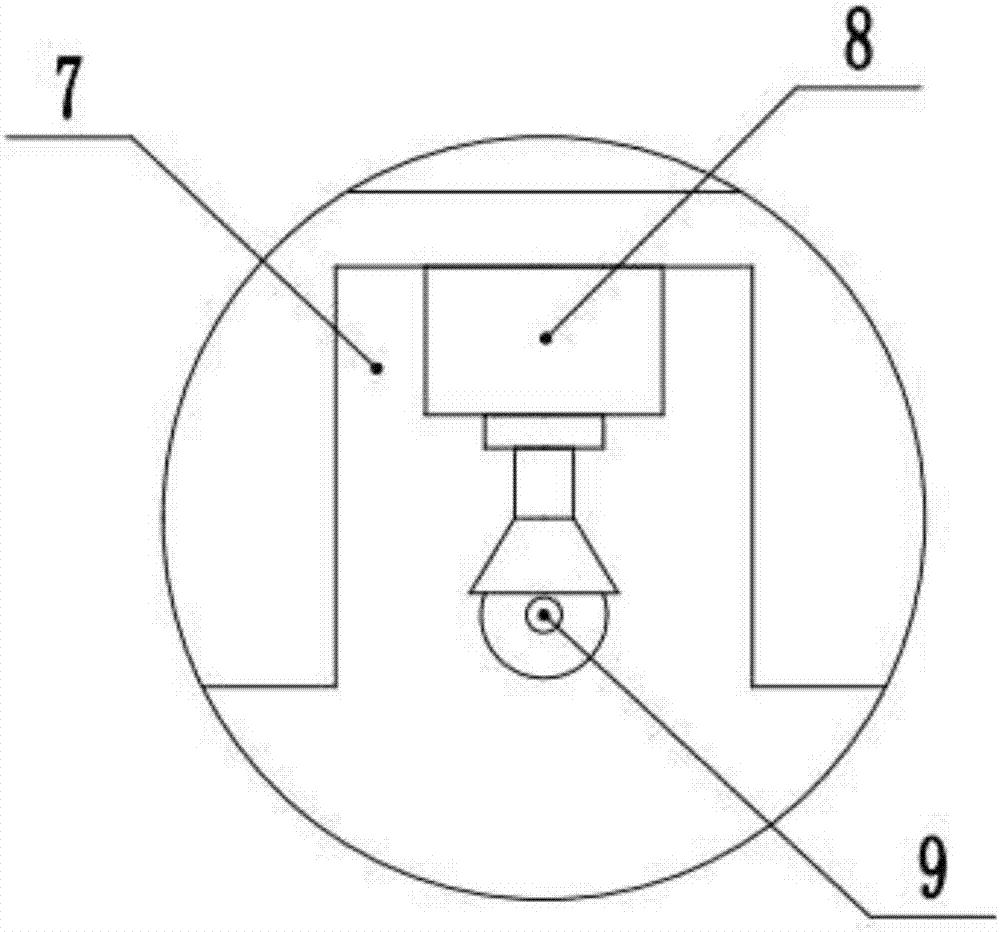

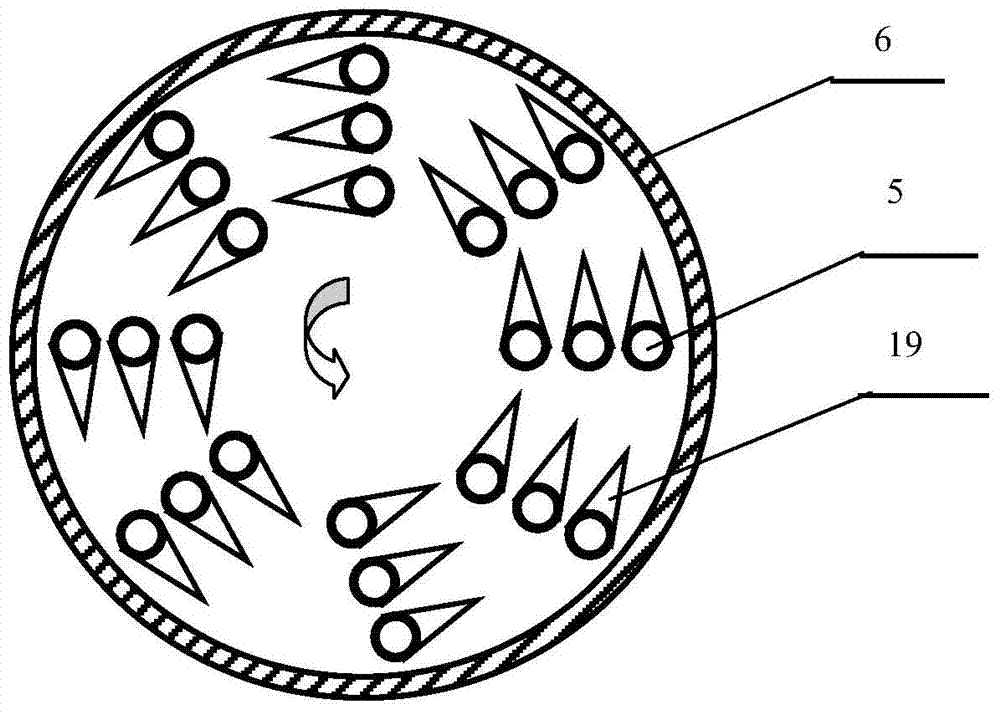

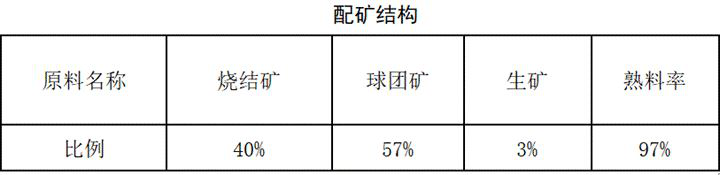

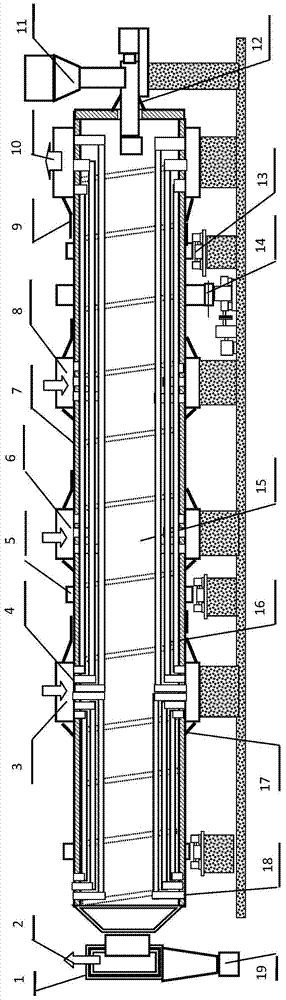

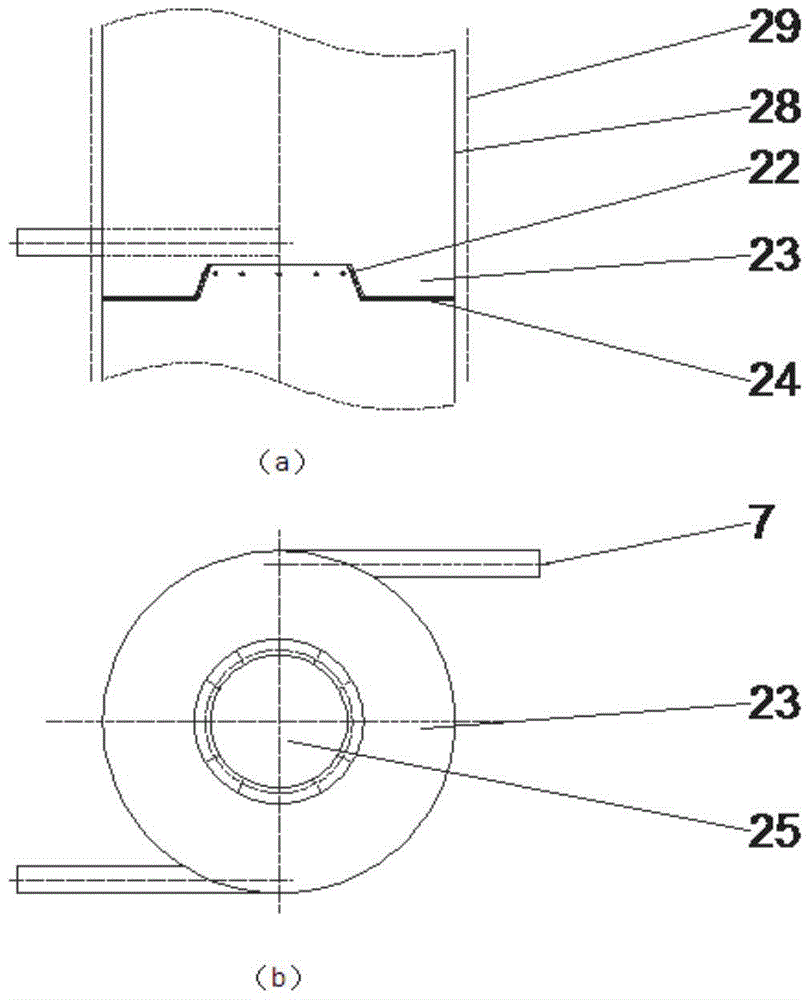

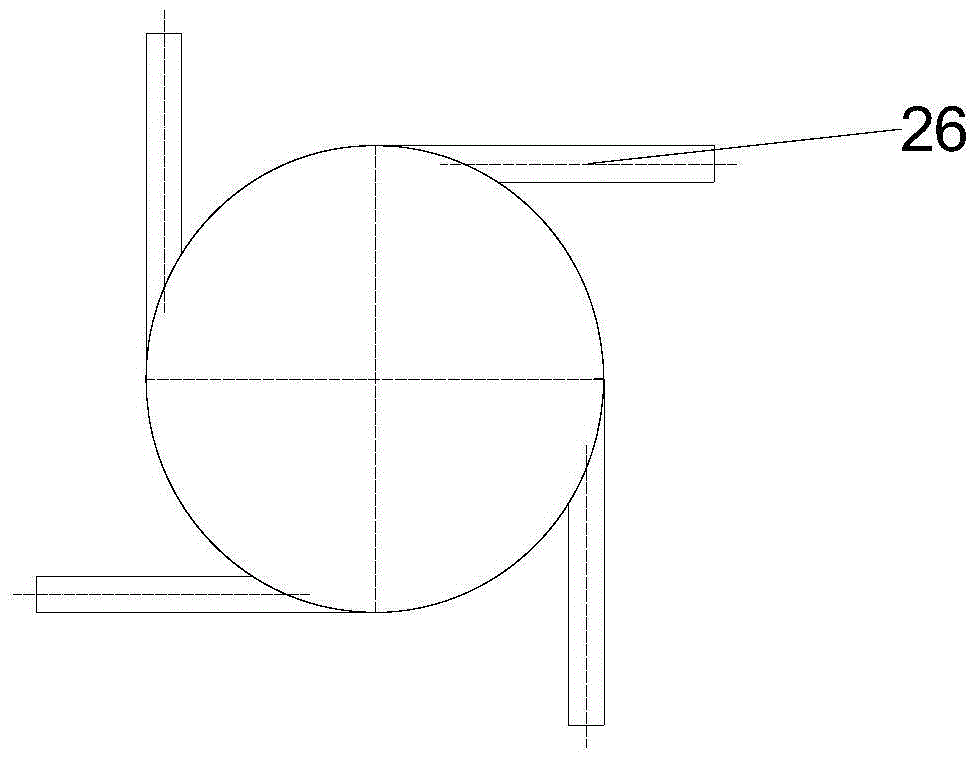

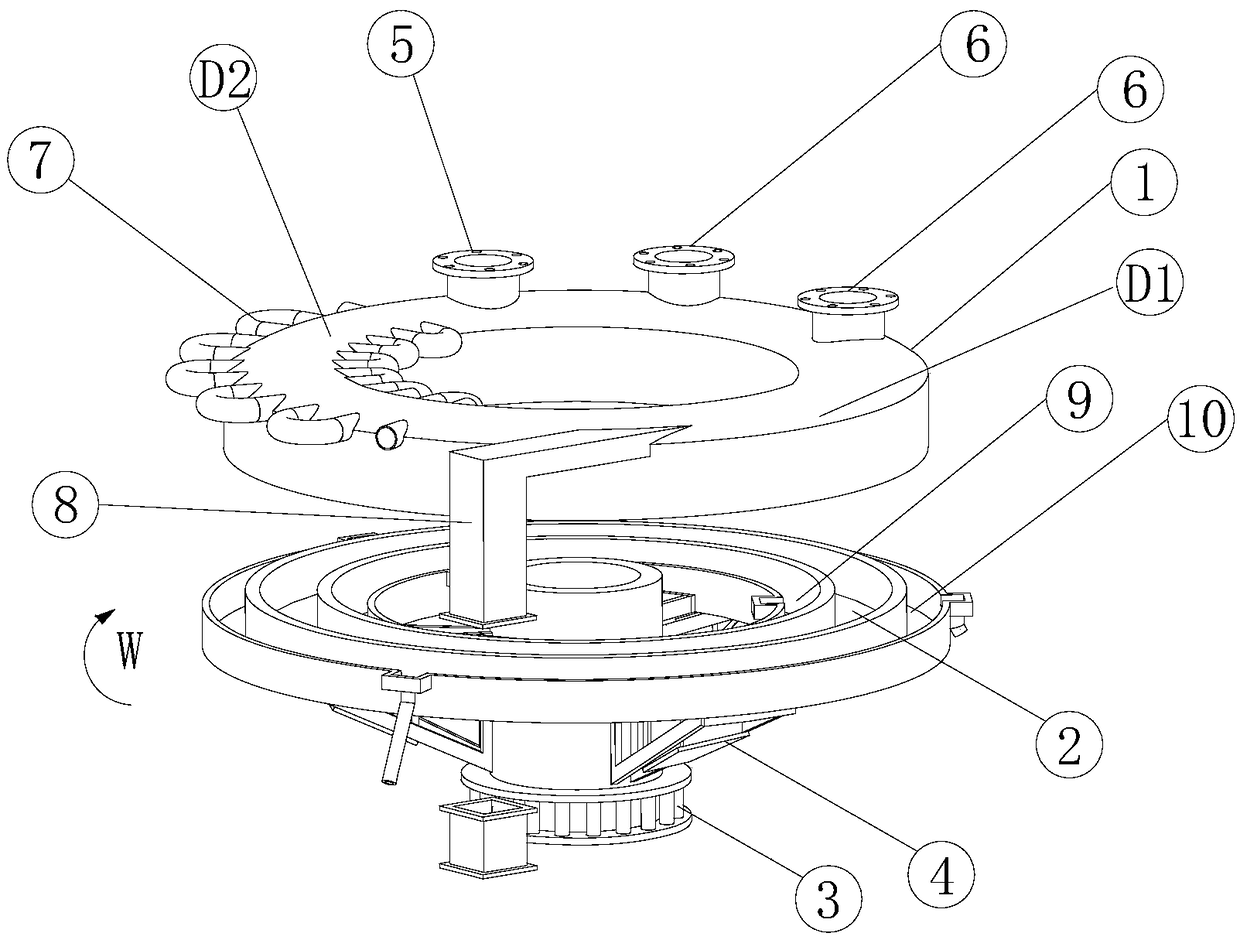

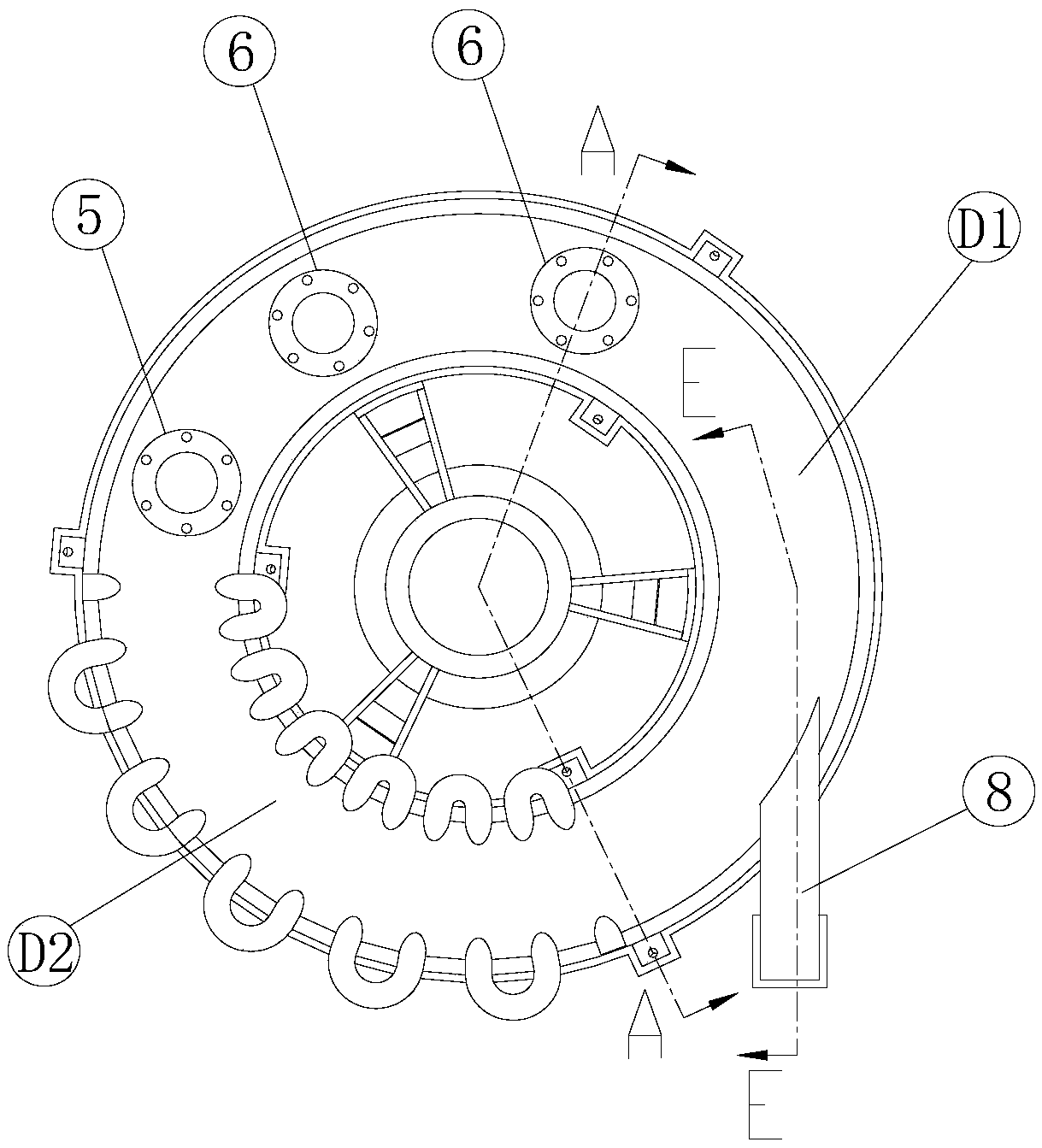

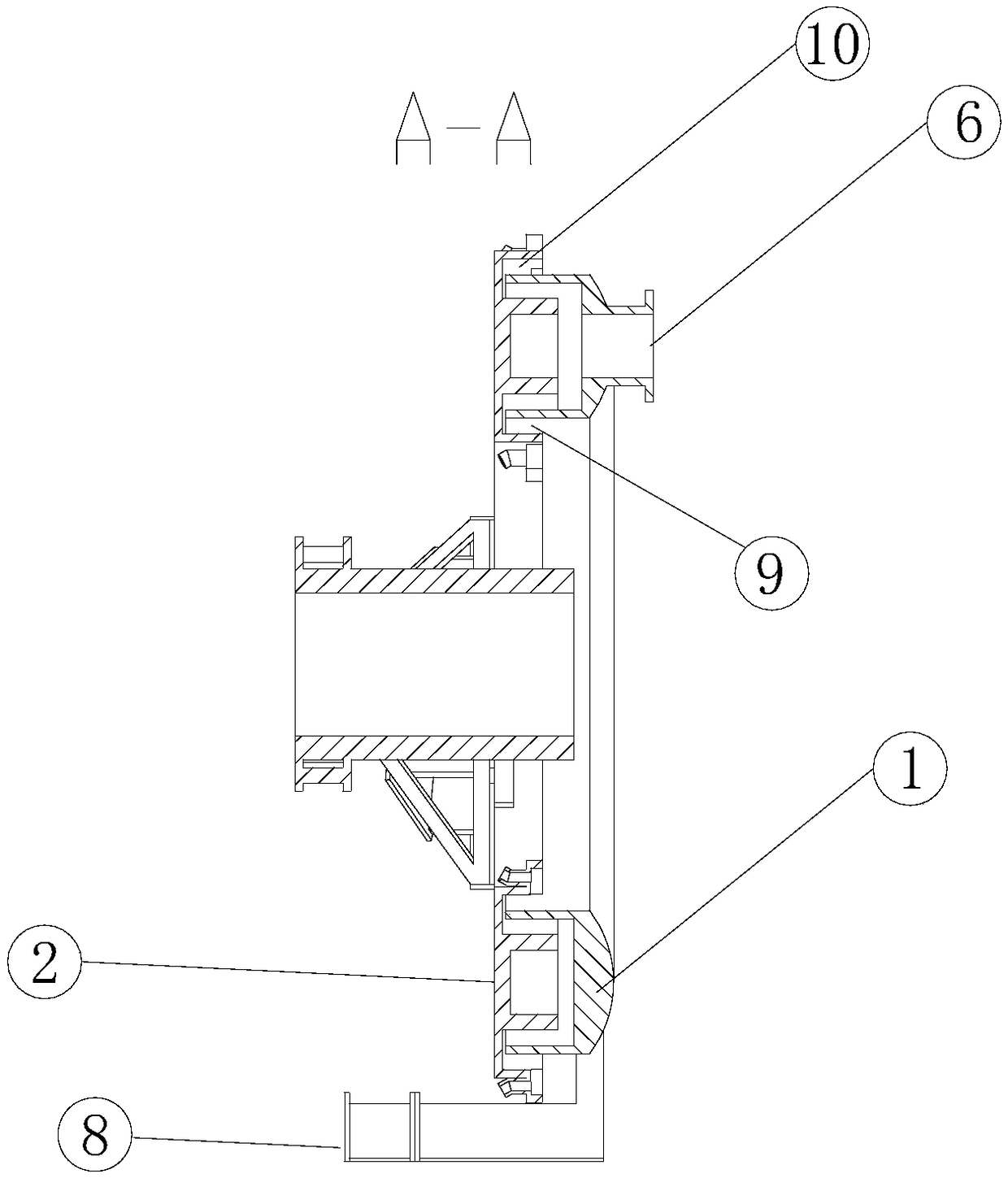

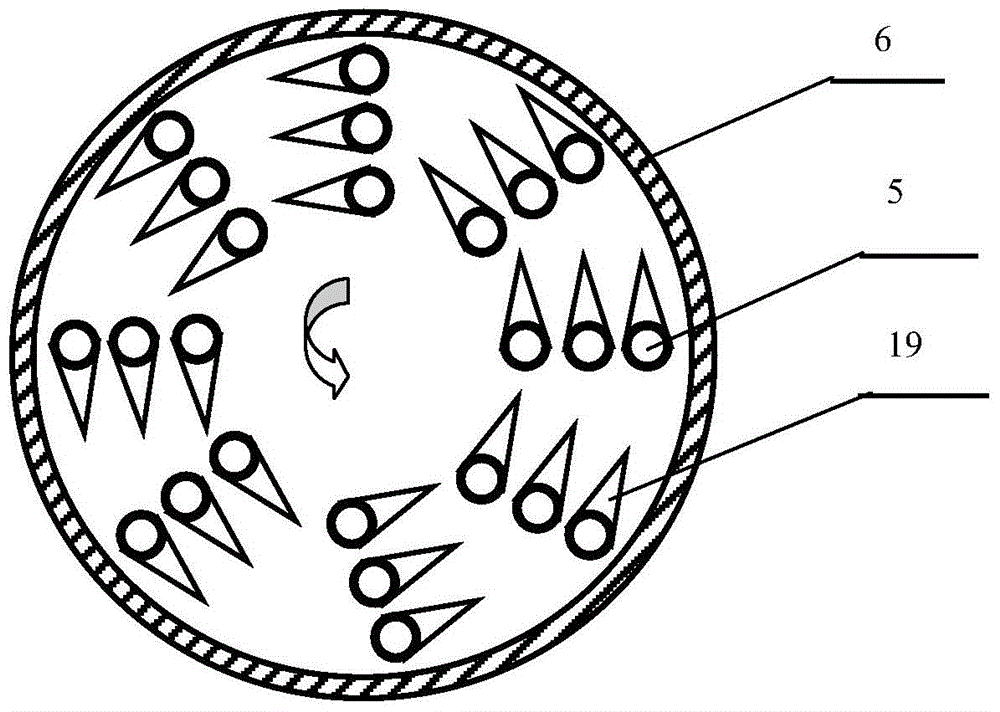

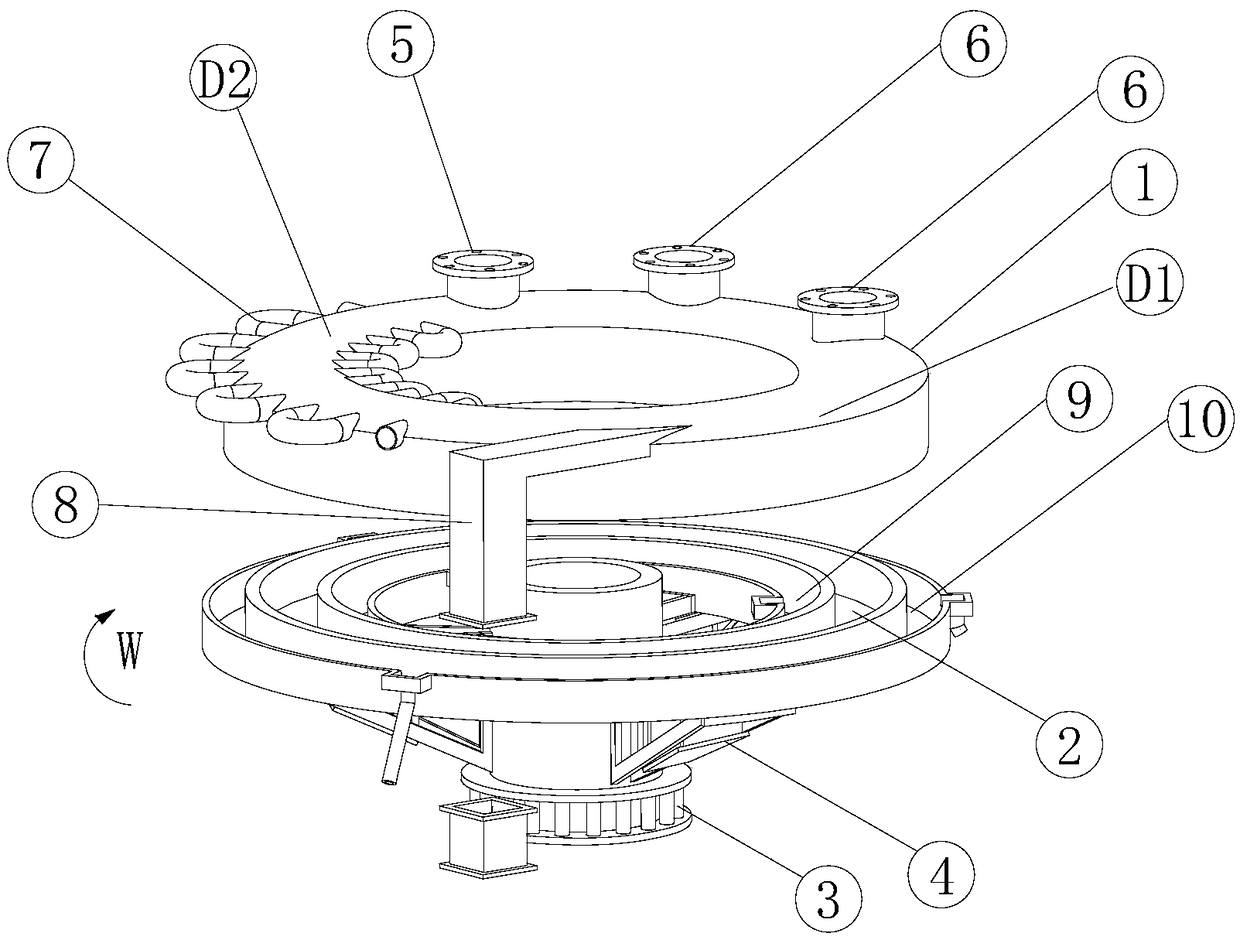

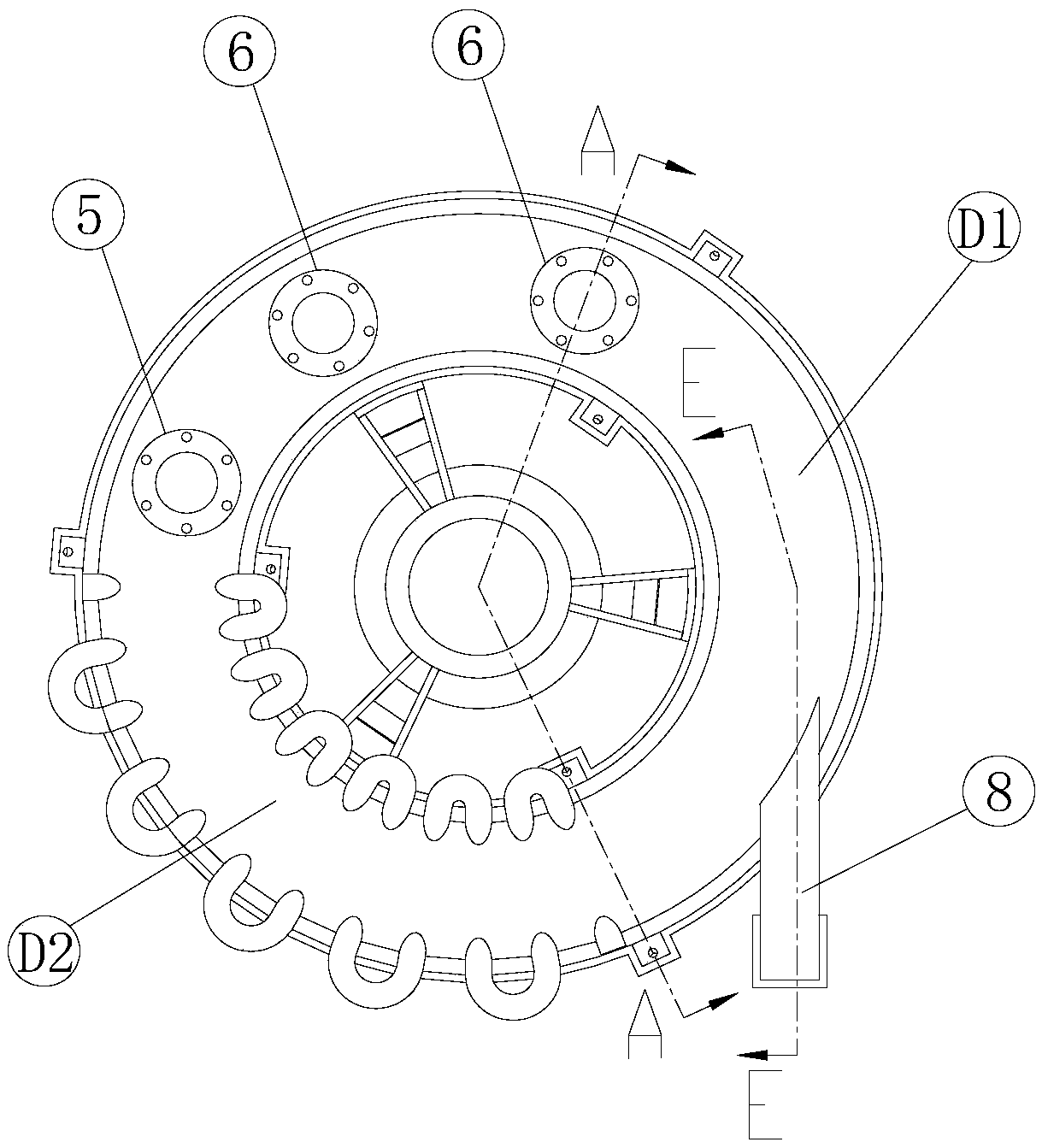

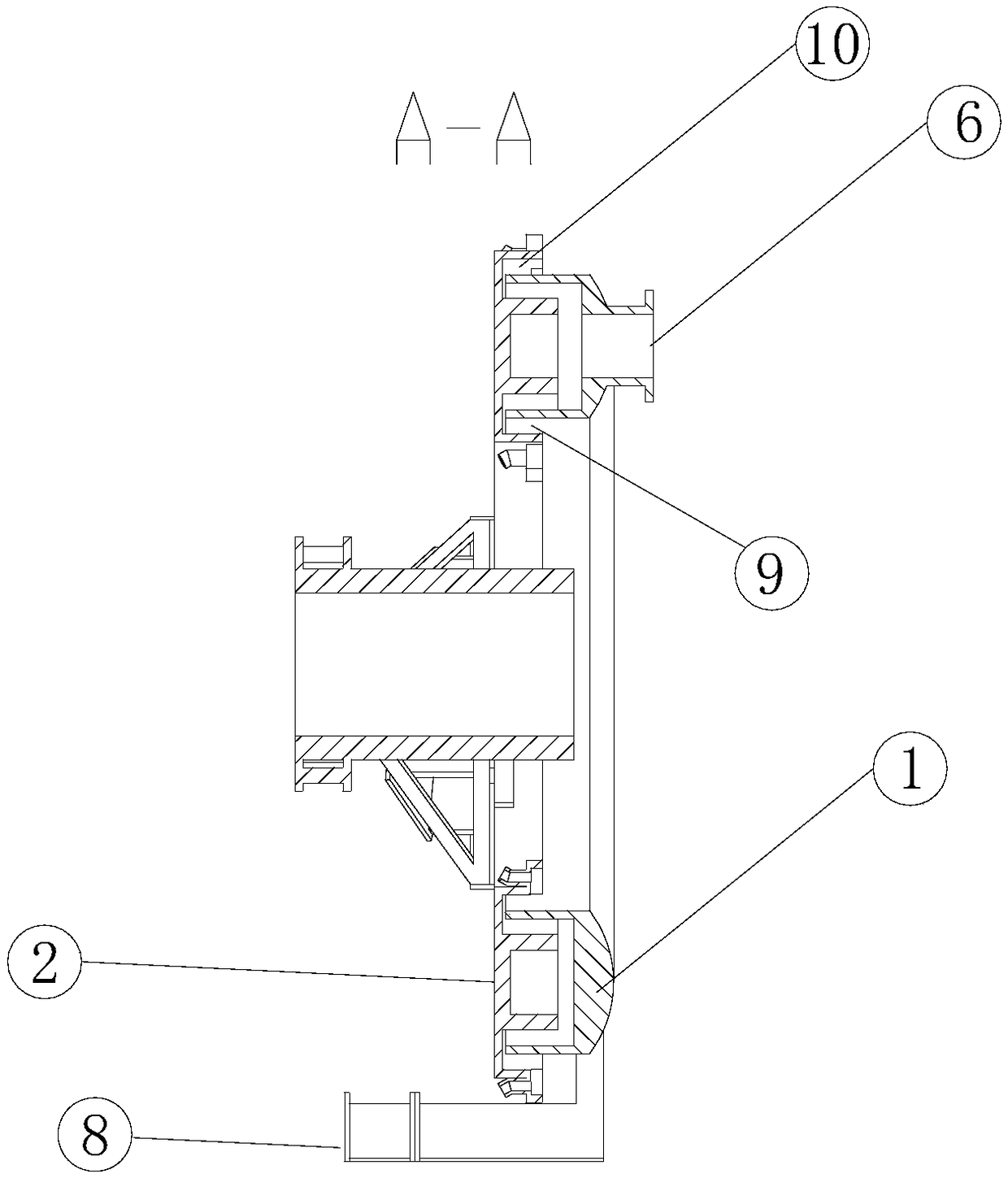

Solid heat carrier pyrolyzer

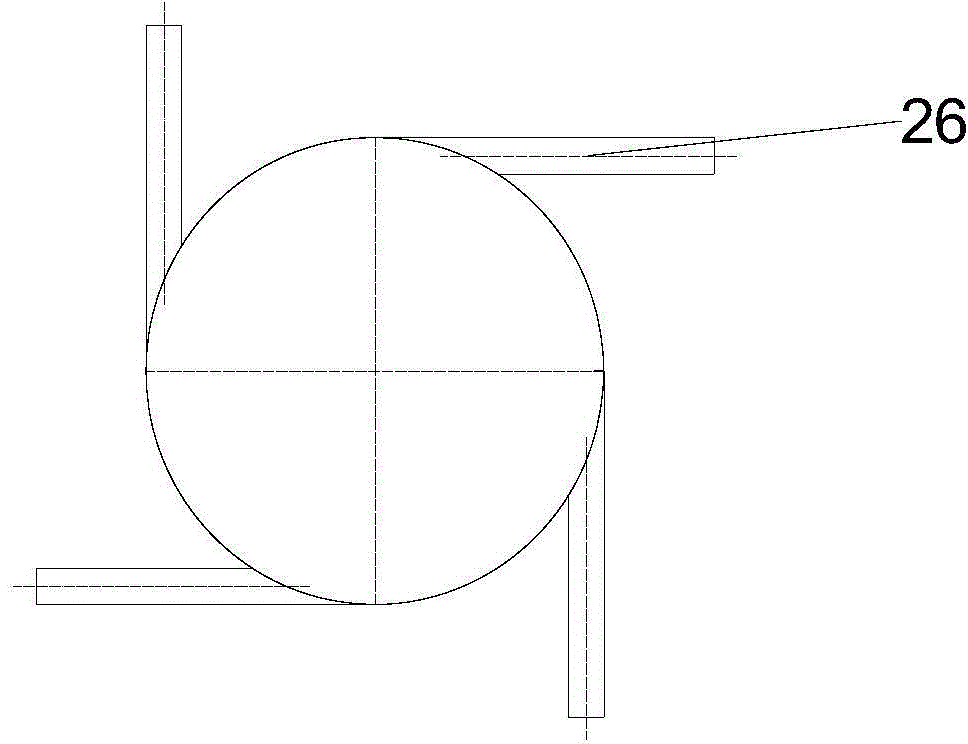

ActiveCN106190206AReduce the overall heightReduce chalkingDirect heating destructive distillationSpecial form destructive distillationHeat carrierPyrolysis

The invention discloses a solid heat carrier pyrolyzer which comprises a top cover (1), a bed (2) and a rotary mechanism. An annular pyrolysis tank is arranged on the top face of the bed, the top cover covers the pyrolysis tank from the upper side, and a feed inlet (5), a pyrolysis gas outlet (6) and a discharge point communicated with the pyrolysis tank are sequentially arranged in the circumferential direction of the sealed annular area, corresponding to the pyrolysis tank, in the top cover in a spaced mode; in the sealed annular area, one side sector ring area between the discharge point and the feed inlet is a pyrolysis area (D1), and the other side sector ring area is a reheating area (D2) provided with heating air pipes (7). Solid heat carriers in the pyrolysis tank rotate along with the bed and are reheated by a heating device, enter the pyrolysis area after being heated, and are mixed with pyrolysis raw materials and pyrolysized, one part of pyrolysis products serve as pyrolysis finished product and are discharged through the discharge point, and the other part of the pyrolysis products circularly flow back to the reheating area. The pyrolyzer is novel and compact in structure and small in occupied space, and integrates pyrolysis, discharging and solid heat carrier heating and circulation functions.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

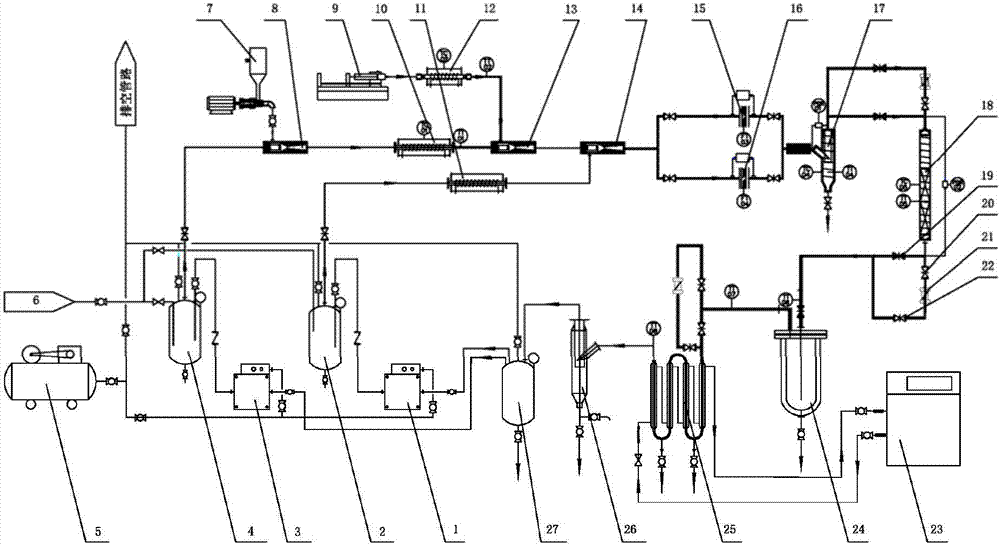

Experimental method and device for step purification of powdered coal pyrolysis high temperature tar containing dusts

InactiveCN106994278AReduce workloadLong working hoursCombination devicesVapor condensationThree levelAir compressor

Provided is an experimental method and a device for step purification of powdered coal pyrolysis high temperature tar containing dusts. The method comprises the steps: adding dust particles into a screw feeder through a hopper; filling solid filter particles into a bed fixing filter; adding pure tar into an injection pump, heating the pure tar to gasification; introducing nitrogen gas from a nitrogen cylinder into an experimental system and into a buffer tank; introducing dusts through the screw feeder, introducing tar gas through the injection pump, after mixing the nitrogen gas introduced through the buffer tank with the dusts to obtain a mixture, and the mixture successively entering into three-level dust removing devices of a cyclone separator, the bed fixing filter, a condensation sedimentation device, cooling and separating purified gas mixture by a cooler and a cyclone hydraulic separator to obtain purified tar, introducing remaining nitrogen gas into a tail gas buffer tank, and pressing the remaining nitrogen gas into a nitrogen buffer tank through a gas booster pump driven by an air compressor to continue to use; and when sampling to measure dust removal efficiency of one level, opening a glass fiber filter membrane sampling apparatus connected with a bypass, and collecting and weighing intercepted dust to calculate the dust removal efficiency. The experimental method and the device for the step purification of the powdered coal pyrolysis high temperature tar containing the dusts are applied to step purification experiment study of high temperature tar gas containing the dusts.

Owner:XI AN JIAOTONG UNIV

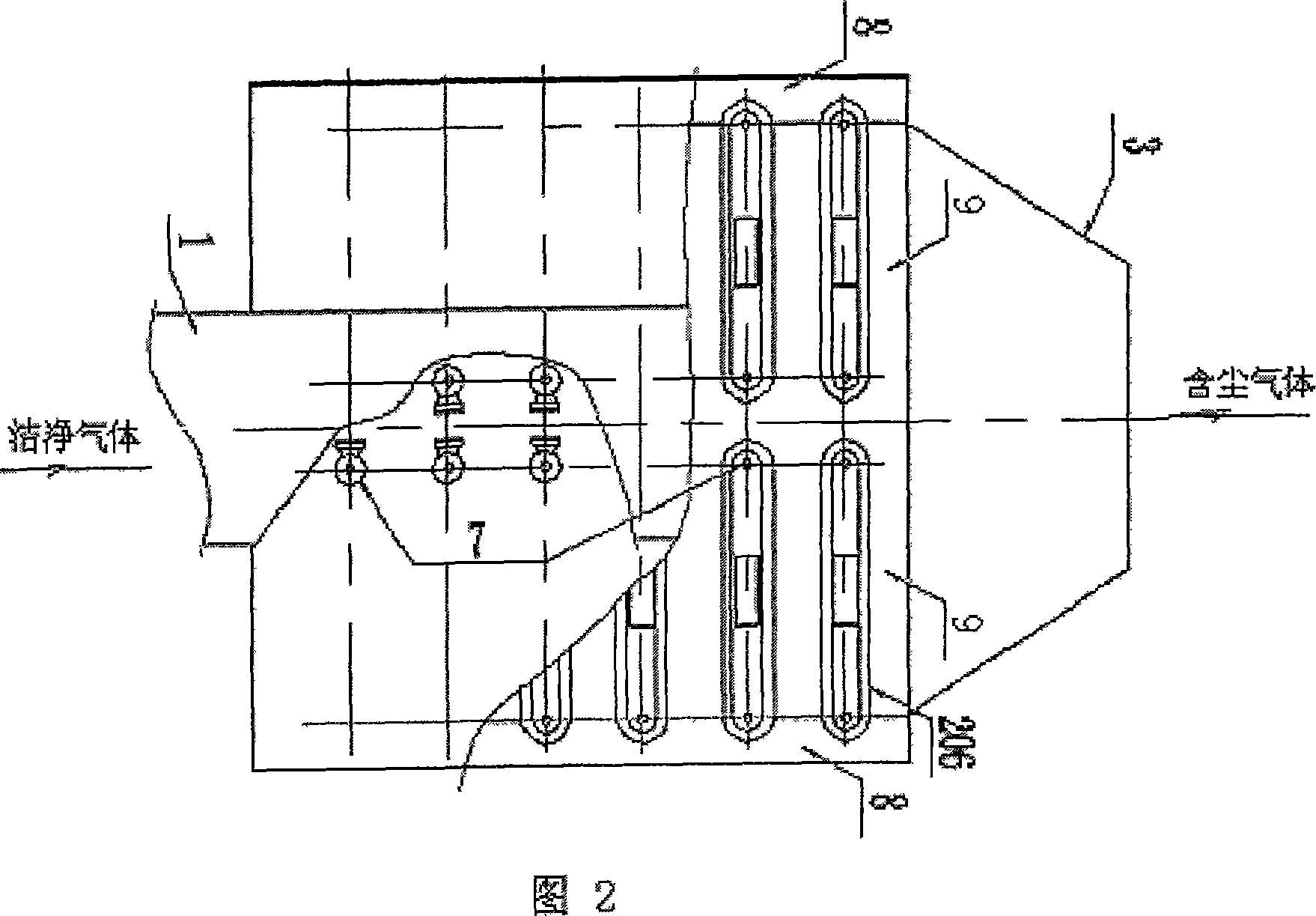

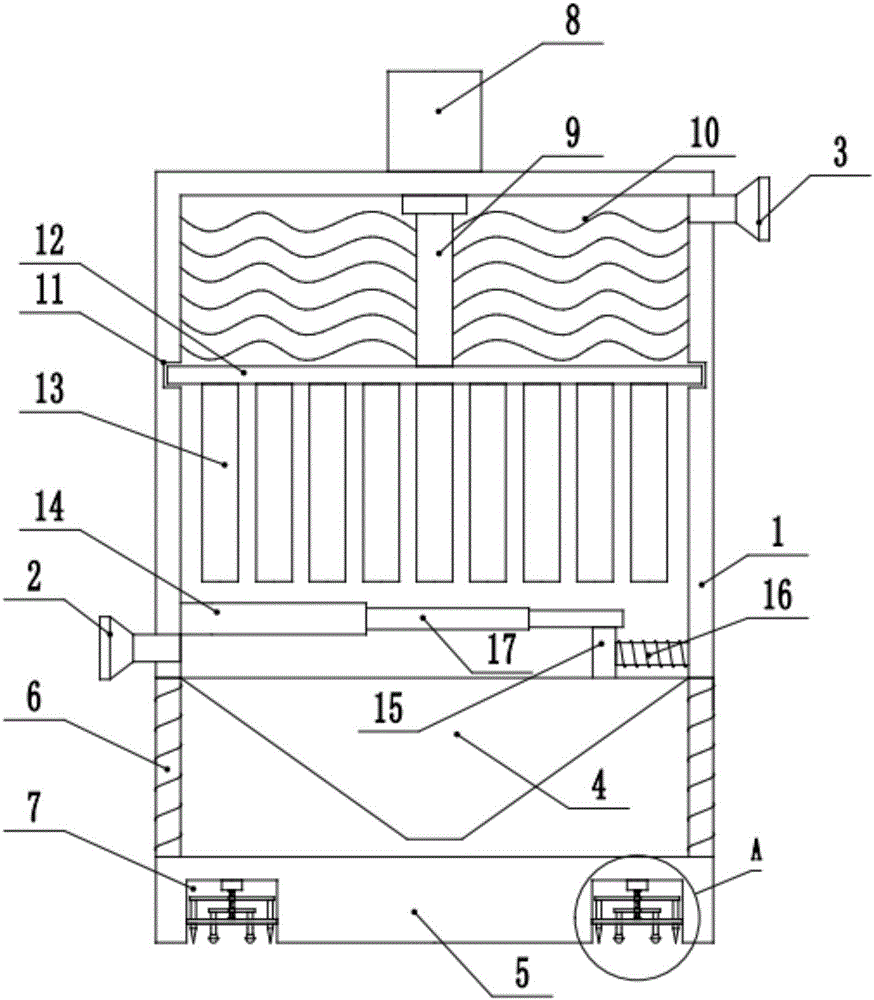

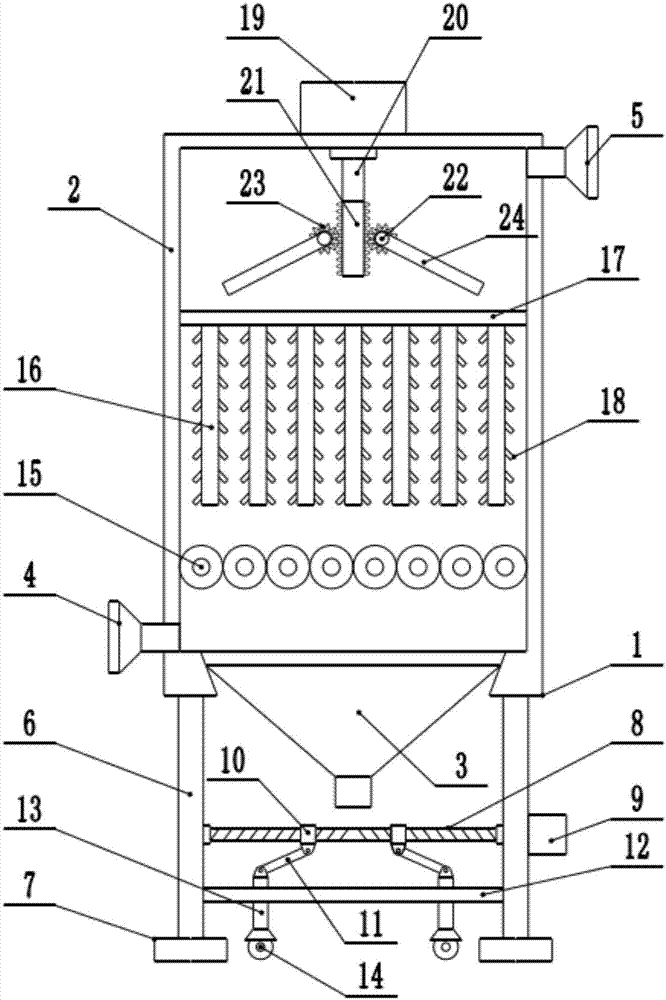

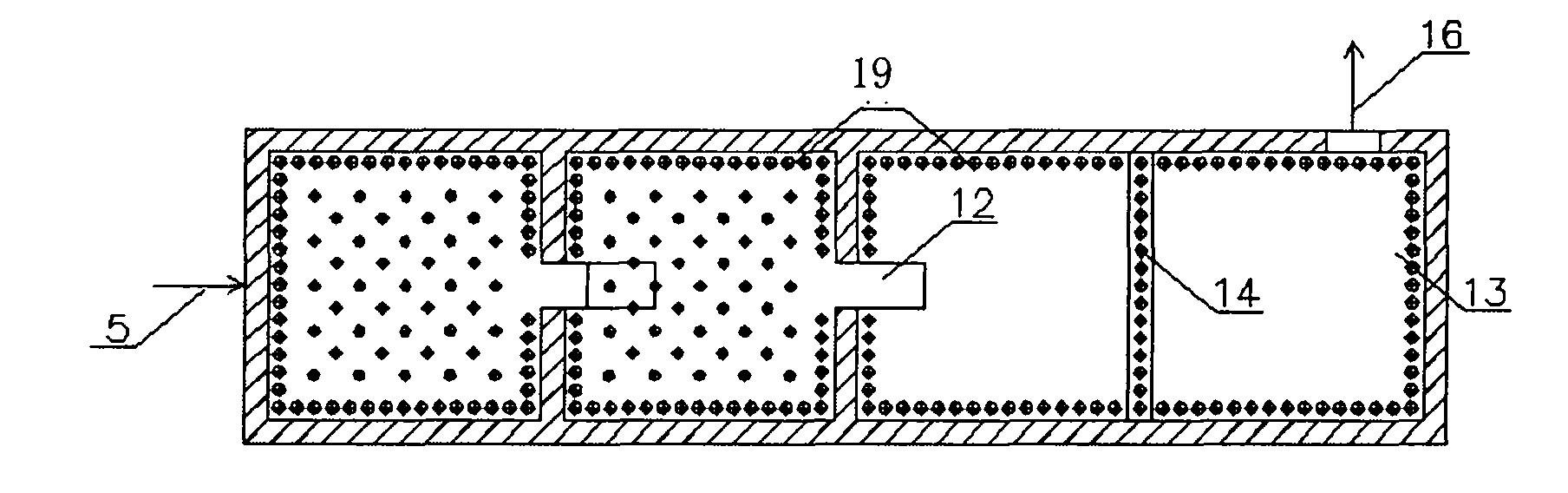

Segmentally-discharging flow-equalizing cloth bag dust-removing device

InactiveCN106943813AReduce dust removal loadImprove dust removal efficiencyDispersed particle filtrationTransportation and packagingFlue gasEngineering

The invention discloses a segmentally-discharging flow-equalizing cloth bag dust-removing device. The segmentally-discharging flow-equalizing cloth bag dust-removing device comprises a device body, wherein the device body mainly consists of a flue gas inlet, a flue gas outlet, a support frame, a base, an ash hopper and a cloth bag assembly; a plurality of runners are arranged at the bottom inside the device body; two side surfaces of the runners are fixedly connected with fixing columns; the fixing columns among the runners are in sleeve connection with casing pipes; the casing pipes are hinged with connecting rods; fixed plates are arranged in the device body; the fixed plates are fixedly connected with a plurality of precipitating barrels; barrier plates are arranged in the precipitating barrels in a sliding way; a first rotating shaft and a second rotating shaft are rotationally connected in the device body; the surfaces of the first rotating shaft and the second rotating shaft are sleeved with moving parts; cloth bag assemblies are fixedly connected among the moving parts. After flue gas enters cloth bags, the dust-removing loads of the cloth bags are lowered, and the dust-removing efficiency of the cloth bags is increased greatly; after the cloth bag assembly is used for a long time, a user can replace the cloth bag assembly periodically and conveniently, so that high dust-removing efficiency of the cloth bag assembly is ensured.

Owner:合肥蔚然花绿化工程有限公司

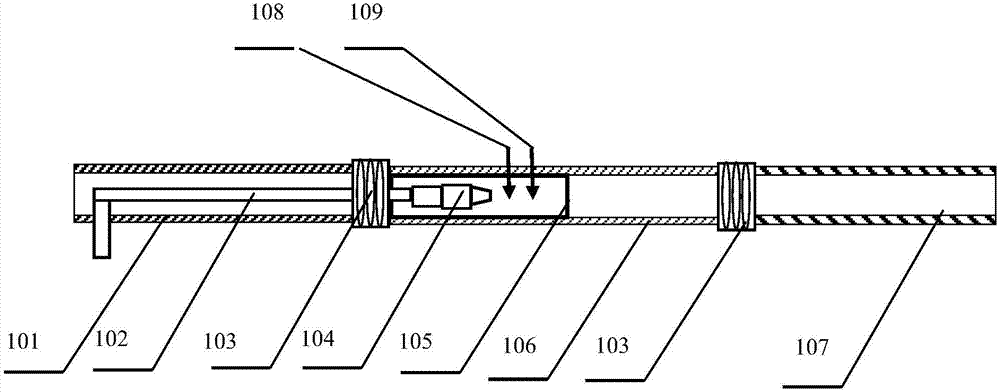

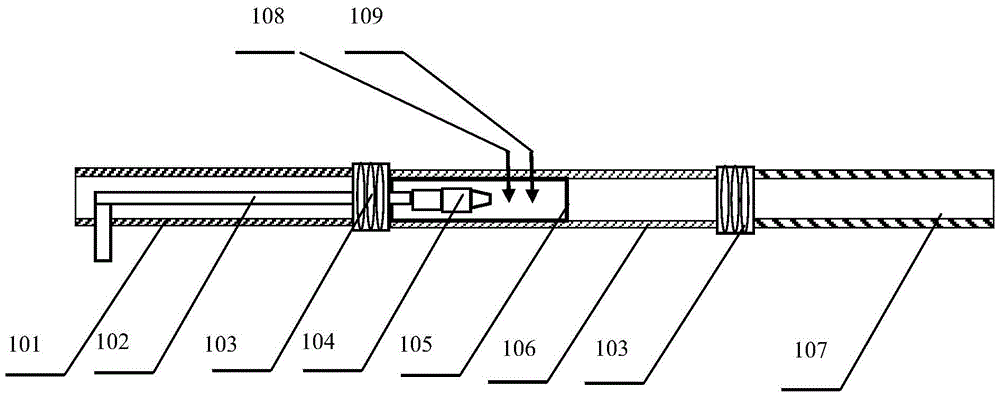

Radiation pyrolytic tube and pulverized coal pyrolytic rotary furnace

InactiveCN104745212AIncrease heat transfer areaIncrease production capacityCoke quenchingEnergy inputRotary furnaceFuel gas

The invention relates to a radiation pyrolytic tube and a pulverized coal pyrolytic rotary furnace. The radiation pyrolytic tube comprises three radiation tubes which are sequentially connected, namely a first radiation tube, a second radiation tube and a third radiation tube, wherein a fuel gas nozzle and an igniter are arranged inside the second radiation tube; the pulverized coal pyrolytic rotary furnace comprises a rotary furnace body, wherein a plurality of radiation pyrolytic tubes are arranged inside the furnace body. By adopting the pulverized coal pyrolytic rotary furnace, the smoke afterheat is utilized for preheating and drying the raw coal and the carbocoal afterheat is utilized for preheating the combustion air and the coal gas; the heat utilization rate is high, the pulverized coal drying, preheating, pyrolysis and carbocoal cooling process are integrally designed and the pyrolytic process is simplified. The rotary furnace provided by the invention is large in heat exchange area, high in pulverized coal processing amount, simple in structure and suitable for million tons of pulverized coal large-scale pyrolytic production.

Owner:CHANGAN UNIV

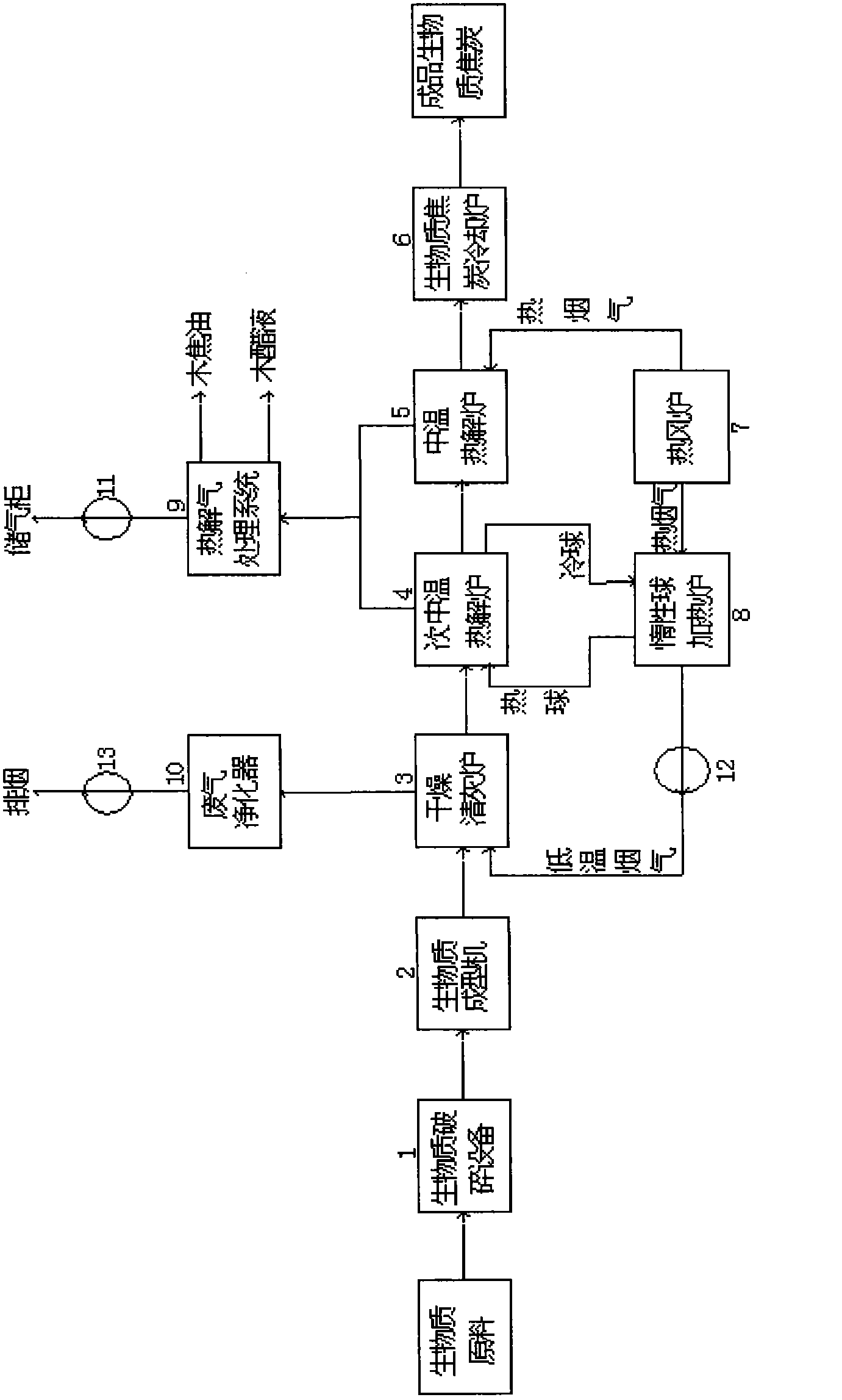

Gas-solid joint biomass partition speed control pyrolysis system and use method thereof

InactiveCN103013542AObvious technical advantagesImprove qualityDirect heating destructive distillationBiofuelsLiquid productEngineering

The invention relates to a gas-solid joint biomass partition speed control pyrolysis system and a use method thereof. The gas-solid joint biomass partition speed control pyrolysis system is mainly characterized in that the process for pyrolyzing by a device includes three stages, wherein the first stage is the drying and deashing stage, and the second stage is the secondary-moderate-temperature pyrolysis stage, and the third stage is the moderate-temperature pyrolysis stage. In the first stage, the low-temperature smoke is taken as the heat carrying medium, and all the waste gas is diffused; in the second stage, the inert solid ball is taken as the heat carrying medium, and the main purpose is to reduce the amount of the smoke entering the pyrolysis gas and avoid the secondary pyrolysis of the tar in the high-temperature region so as to improve the yield of the liquid product; and in the third stage, the high-temperature smoke is taken as the heat carrying medium, and the convection current is adopted to strengthen the medium transfer and the heat transfer in the holes of the biomass. The gas-solid joint biomass partition speed control pyrolysis system in the invention has the comprehensive effects that the quality of the product of pyrolysis is improved greatly, the heat efficiency of the gas-solid joint biomass partition speed control pyrolysis system is improved greatly, the gas treatment equipment is simplified, and the power consumed to treat the gas is reduced greatly.

Owner:河北省隆盛生物质能源开发有限责任公司

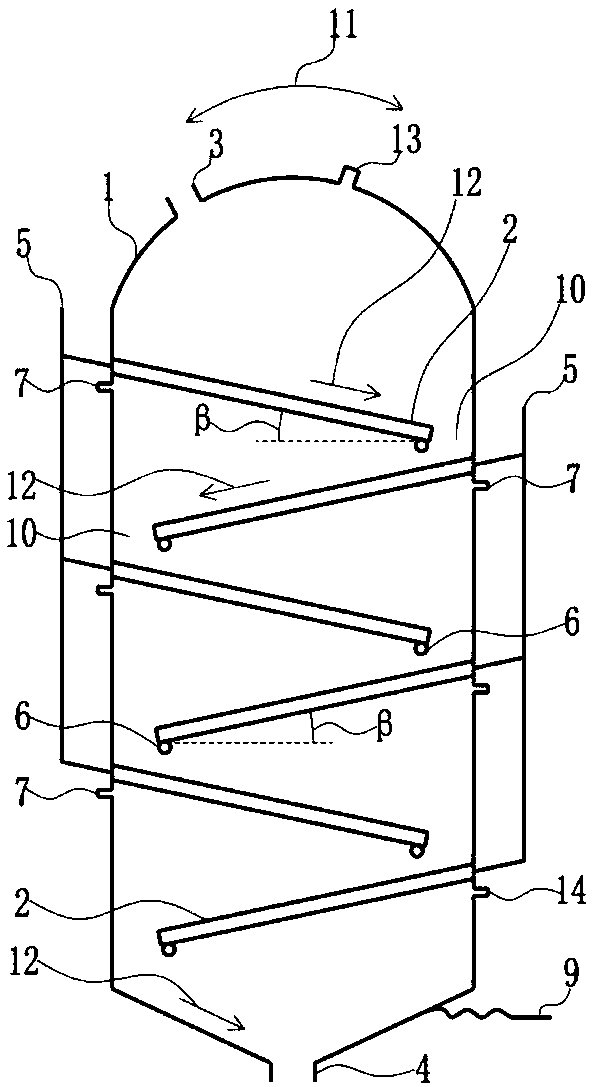

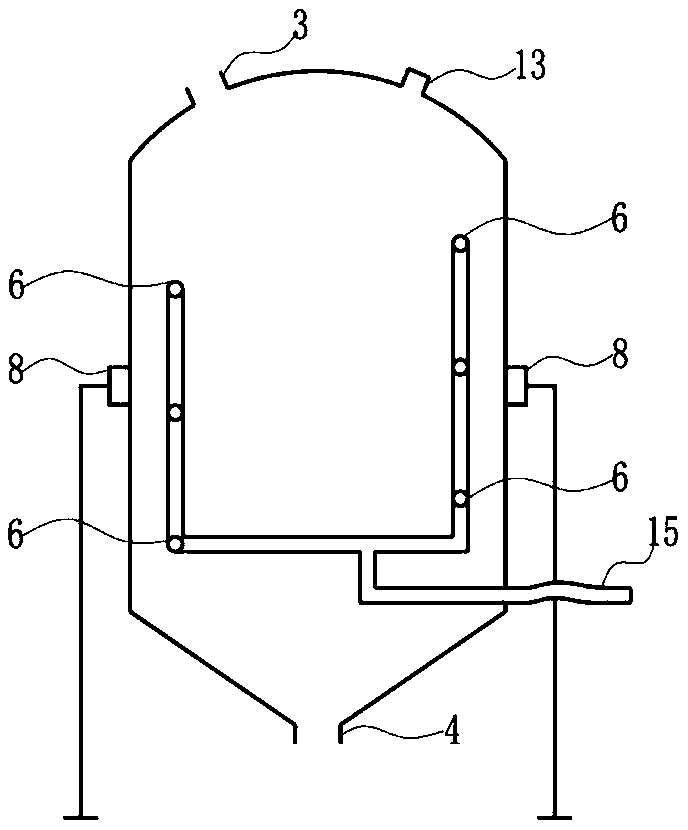

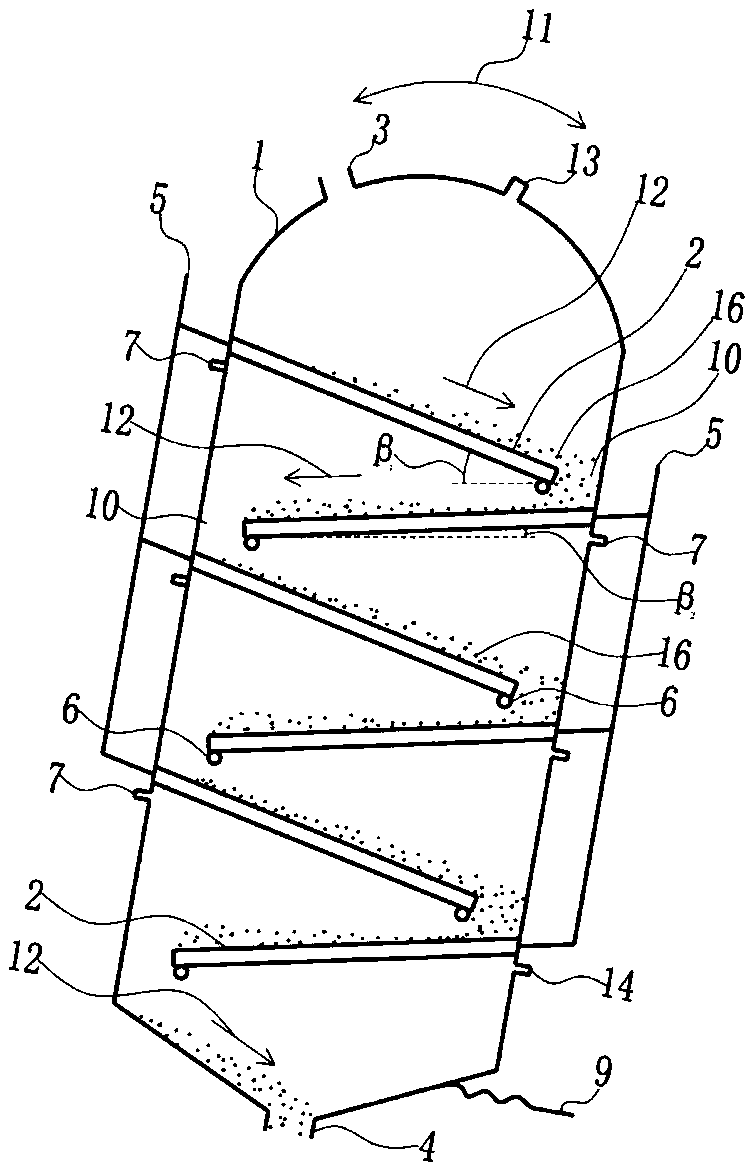

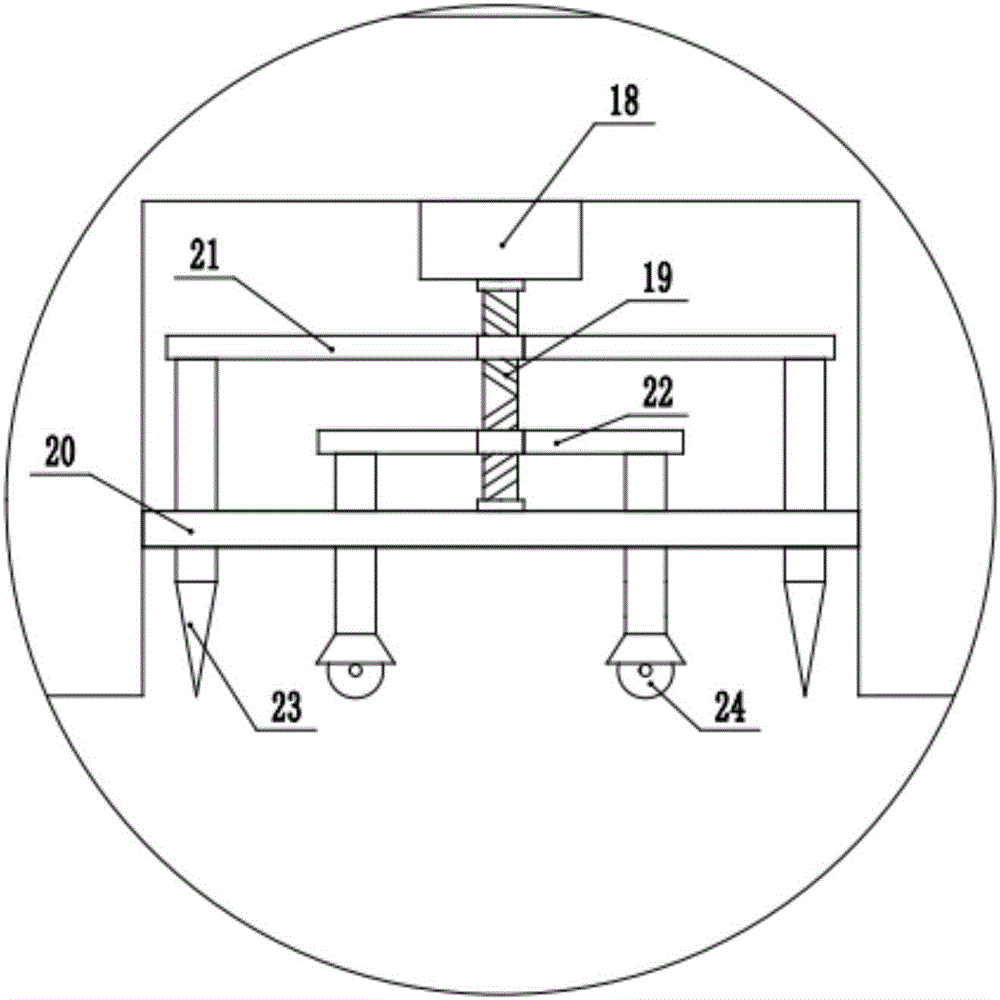

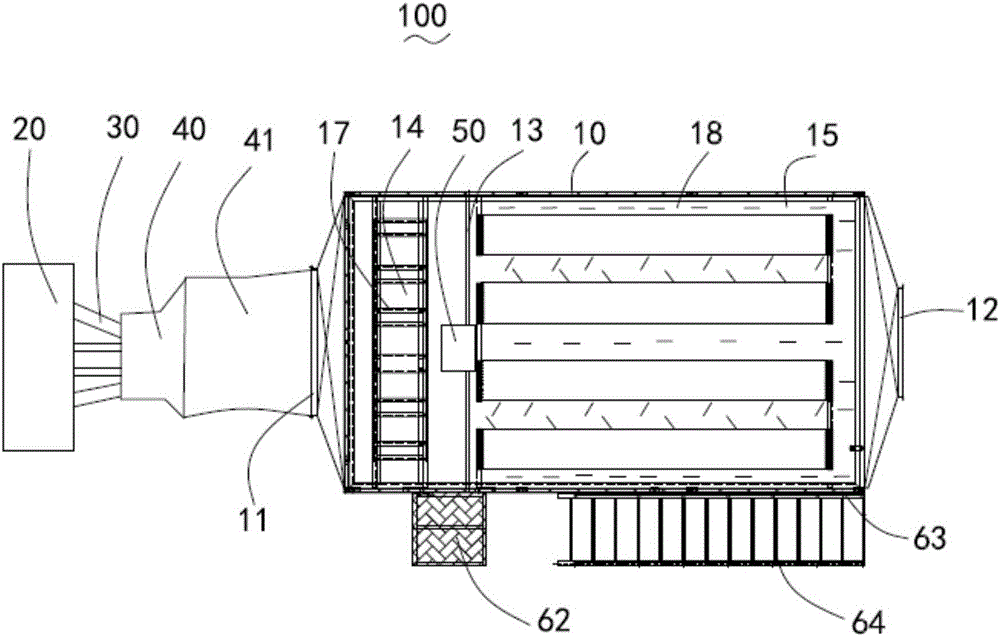

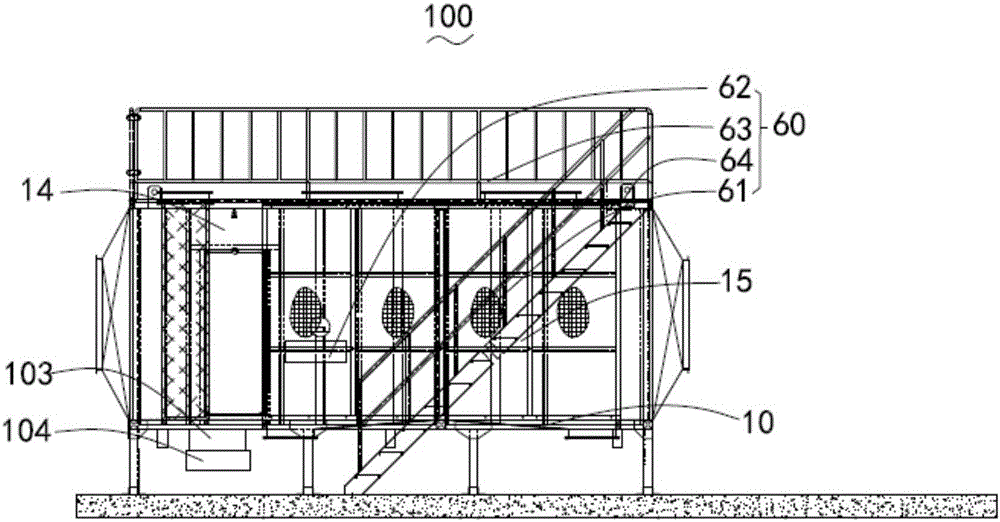

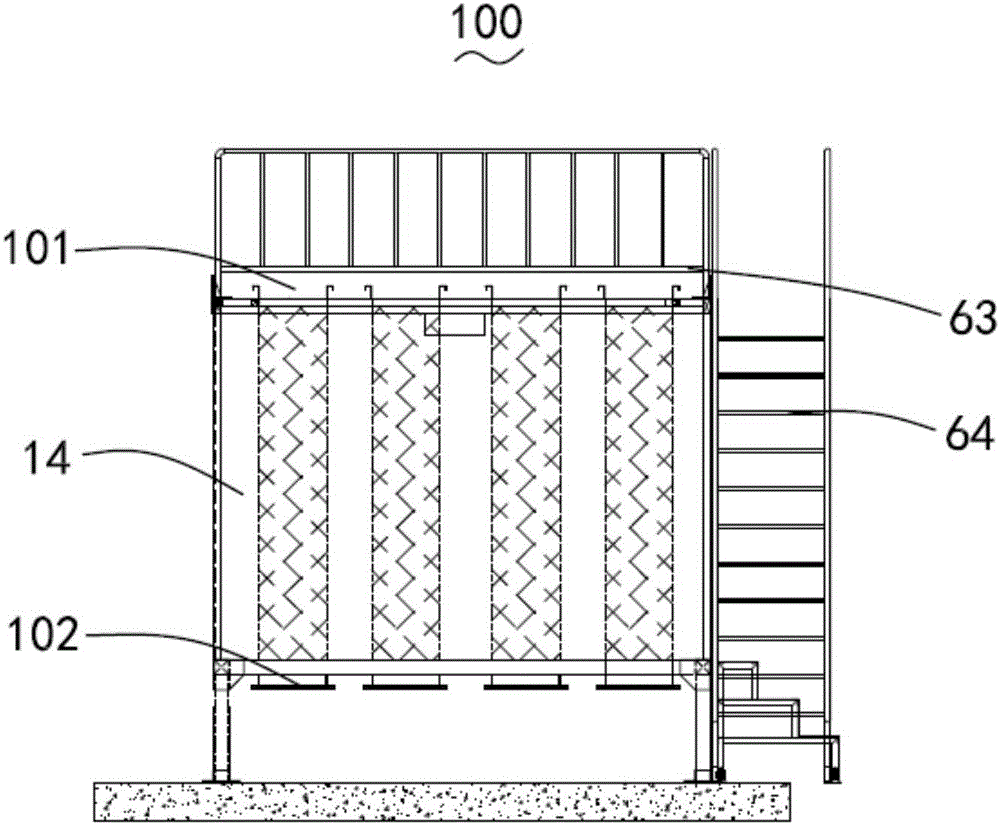

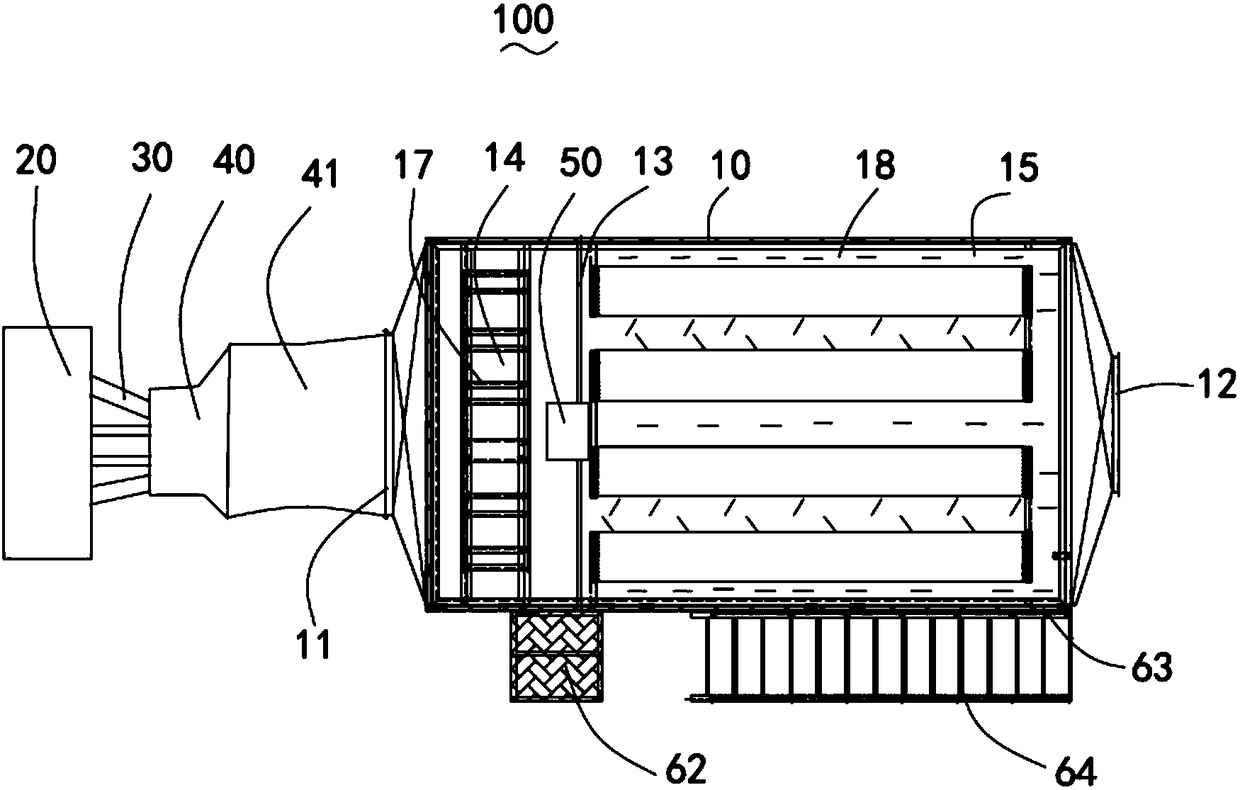

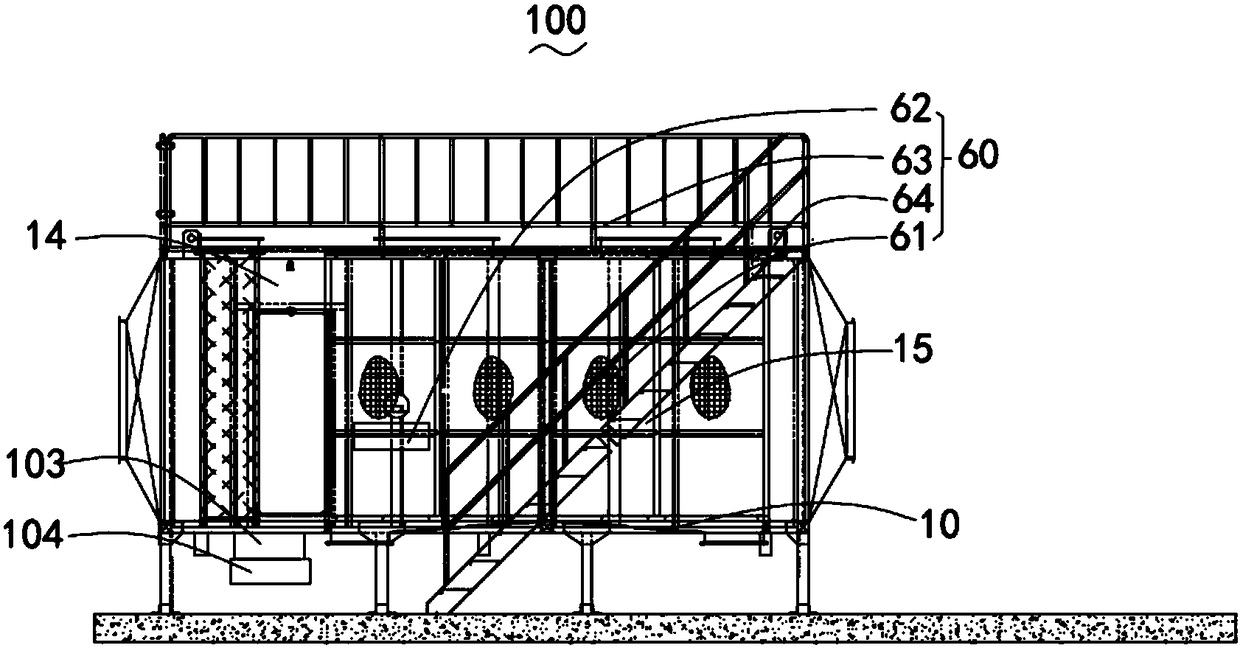

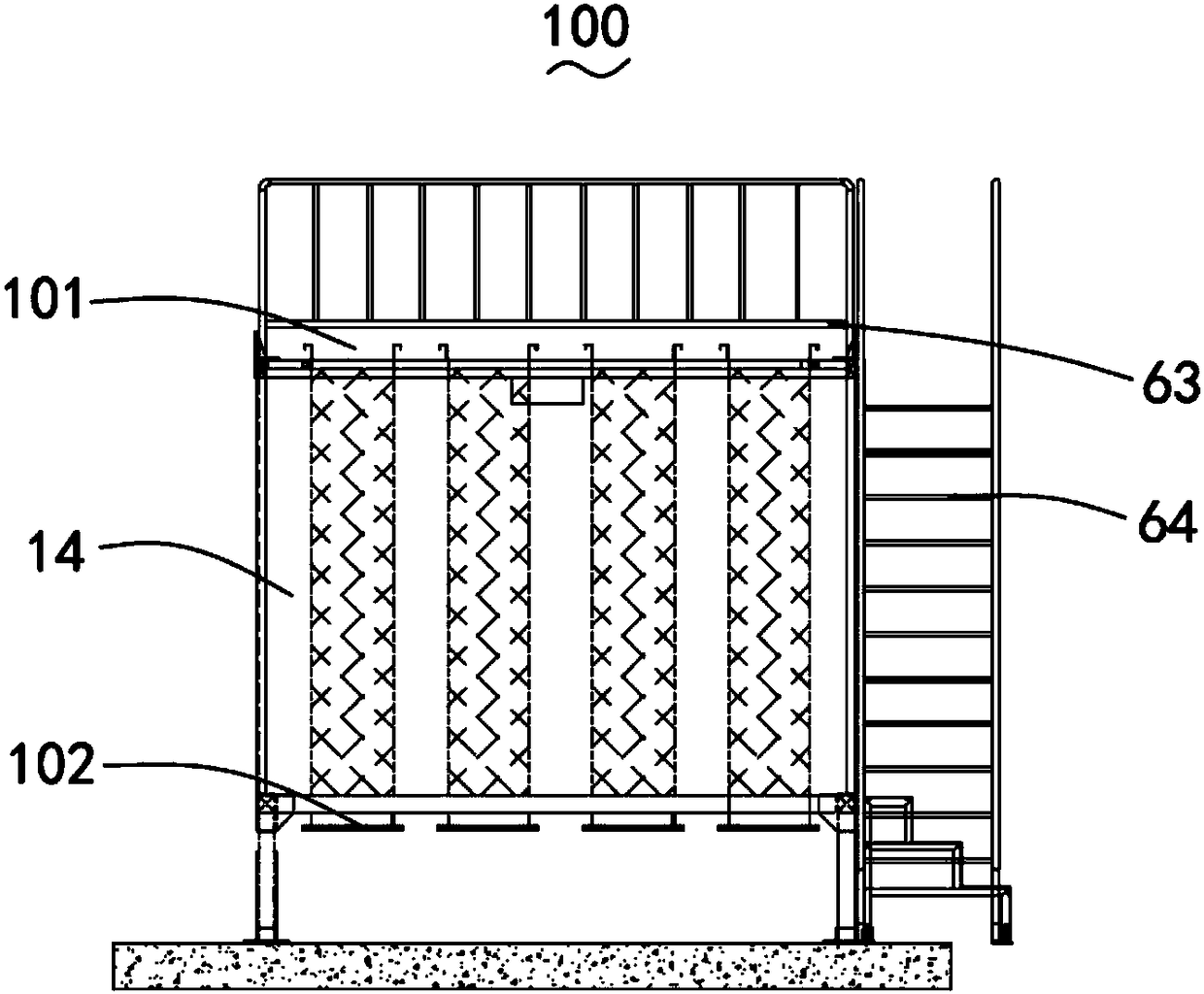

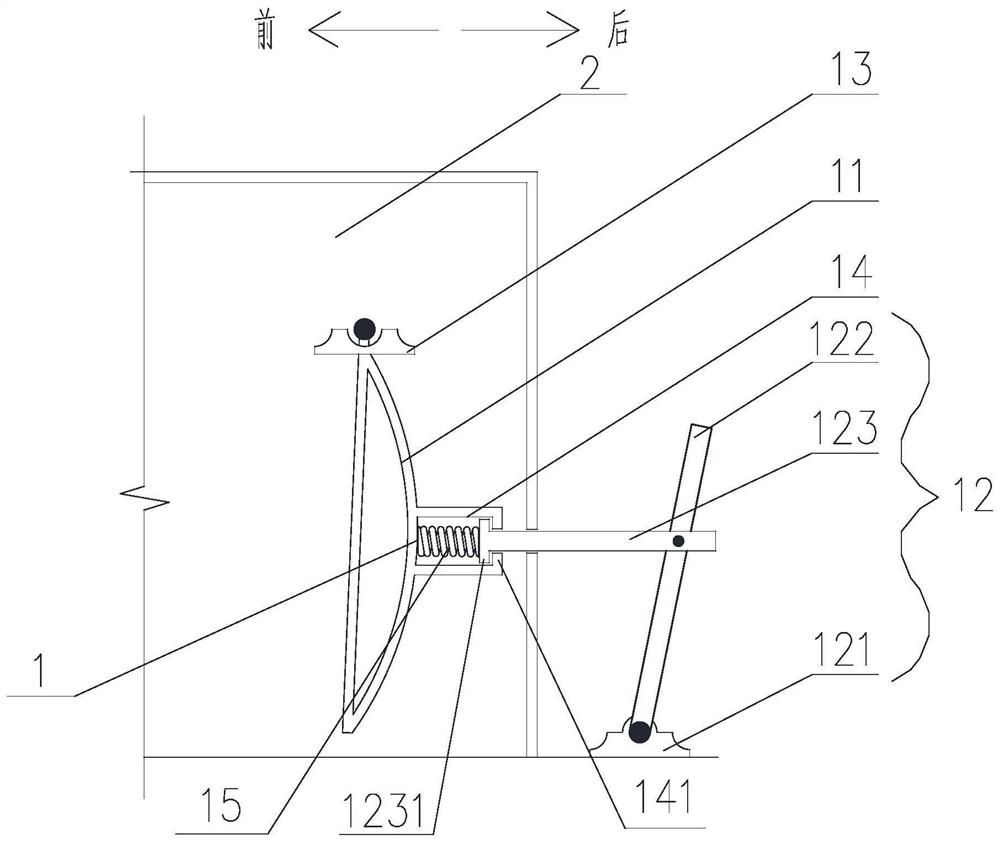

Method and device for drying materials

InactiveCN109595917AKeep dryMove quicklyDrying gas arrangementsDrying solid materialsSlope angleEngineering

The invention relates to a method and device for drying materials. A moving bed drier consisting of heating plates which are alternately sloped in the opposite direction is driven by a swinging mechanism to swing, and the sloping angles of the sloped heating plates are extended, so that the materials are promoted to flow, moving of the materials on the heating plates and material transporting between the heating plates from top to bottom are realized, and high-efficient drying of the materials in the moving bed drier and smooth material moving are achieved; through the adjustment of swinging range and swinging speed, the adjustment of drying capacity is realized, and ordered controllable moving of the materials from top to bottom is simply realized; the control of thickness of feeding layers of the heating plates of the materials and interface updating of materials in layers and heating surfaces are also realized, and smooth moving and smooth discharging of the materials are realized.The method disclosed by the invention has the characteristics of being low in investment cost, low in operation power consumption, low in equipment wear, low in dust removal load, and simple and efficient in device, and a high-efficient low-cost technique and device guarantee are provided for drying of the materials.

Owner:TIANJIN UNIV

Economizer hopper of coal-fired boiler in power plant

InactiveCN101721860AImprove dust collection efficiencyImprove dust collection effectDispersed particle separationAir preheaterSystems design

The invention discloses an economizer hopper of a coal-fired boiler in a power plant. In a reversing chamber of the economizer hopper of the coal-fired boiler, one to five stages of herringbone guide plates are arranged along the horizontal direction, or two to seven stages of T-shaped guide plates are arranged along the vertical direction; the nasal tip of the reversing chamber of the economizer hopper is additionally provided with a guide plate; the outlet of the bottom of a dust hopper is provided with a blocking valve; the outlet of the blocking valve is connected with an ash storage hopper; and the outlet of the ash storage hopper is provided with a blocking valve. The dust collecting efficiency of the economizer hopper is greatly improved; and the ash content of the flue gas entering an air preheater is effectively reduced. The economizer hopper has high operability and obvious effect, can reduce or thoroughly manage ash fouling in the air preheater so as to alleviate or avoid the low-temperature corrosion of the air preheater and reduce the cost of cleaning the ash fouling of the air preheater. The economizer hopper has the advantage of simple process flow, less equipment and easy implementation. The method is applicable to the reform design of the equipment which has been put into operation, and is also applicable to the system design of new equipment.

Owner:BEIJING JIAOTONG UNIV

Cloth bag dust removing device adopting adjustable equipartition dust removal

InactiveCN106807153AAvoid filteringImprove dust removal efficiencyDispersed particle filtrationFlue gasEngineering

The invention discloses an adjustable dedusting device for uniform dust removal, which comprises a device body; the device body is mainly composed of a flue gas inlet, a flue gas outlet, an ash hopper, a base and a cloth bag assembly, and an annular groove is arranged on the inner wall of the device body , a turntable is arranged inside the annular groove, a first motor is fixedly connected to the top of the device body, a rotating shaft is arranged inside the device body, the top of the rotating shaft is connected to the shaft extension end of the first motor, and the other end of the rotating shaft is fixedly connected to the turntable, the base The bottom is provided with a cavity, and the bottom of the cavity is fixedly connected with a connecting plate; the top of the cavity is fixedly connected with a second motor by means of bolts, the bottom of the second motor is connected with a rotating shaft, and the rotating shaft is threadedly connected with a first connecting plate, The bottom of the first connecting plate is fixedly connected with stabilizing teeth, the rotating shaft is threadedly connected with the second connecting plate, and the two ends of the second connecting plate are connected with rollers through fixed rods. The device has strong applicability, high flue gas dust removal efficiency and long service life of the bag.

Owner:合肥智慧殿机械设计有限公司

Purifying device for organic waste gas

ActiveCN105797494AReduce dust removal loadDispersed particle filtrationTransportation and packagingWaste managementActive carbon

The invention discloses a purifying device for organic waste gas. The purifying device comprises a filtering box, a negative pressure fan, a plurality of waste gas branches, a waste gas main pipe, a waste gas guide pipe and an overhauling system, wherein a gas inlet and a gas outlet are formed on the filtering box; one end of each waste gas branch is communicated with the negative pressure fan while the other end of each waste gas branch is communicated with one end of the waste gas main pipe; the other end of the waste gas main pipe is communicated with the gas inlet; a baffle is arranged in the filtering box so as to divide the filtering box into a primary filtering chamber and a secondary filtering chamber; the waste gas guide pipe penetrates through the baffle and is used for communicating the primary filtering chamber with the secondary filtering chamber; a protective screen is arranged on the inner wall of the primary filtering chamber; a primary filter is arranged in a chamber defined by the protective screen; an active carbon filter is arranged in the secondary filtering chamber. The purifying device for organic waste gas provided by the invention has the advantages of good dust removing effect and convenience in maintenance.

Owner:东莞市恒升环保科技有限公司

Hinge ash discharge type high-efficiency bag dust collection device

InactiveCN106975286AImprove dust removal efficiencyEfficient dust removal efficiencyGas treatmentDispersed particle filtrationKeelEngineering

The invention discloses a hinge dust-discharging high-efficiency cloth bag dust removal device, which comprises a device body; the device body is mainly composed of a dust removal shell, an ash hopper, a flue gas inlet, a clean gas outlet and a bag assembly; the dust removal shell The body is fixedly connected with a keel, the bottom of the keel is fixedly connected with a bag assembly, and the side wall of the bag assembly is fixedly connected with a cloth bag strip, and the top of the device body is fixedly connected with a cylinder. It is connected with a moving rod, and the surface of both sides of the moving rod is evenly distributed with locking teeth. The dust removal housing is rotatably connected with a rotating shaft, and the two ends of the rotating shaft are fixedly connected with fan plates, and the rotating shaft is fixedly connected with gears. Tooth fit connection. The device has good stability, is easy to move, has high dust removal efficiency, and has a small bag dust removal load.

Owner:惠安县泉联智能设备技术开发有限公司

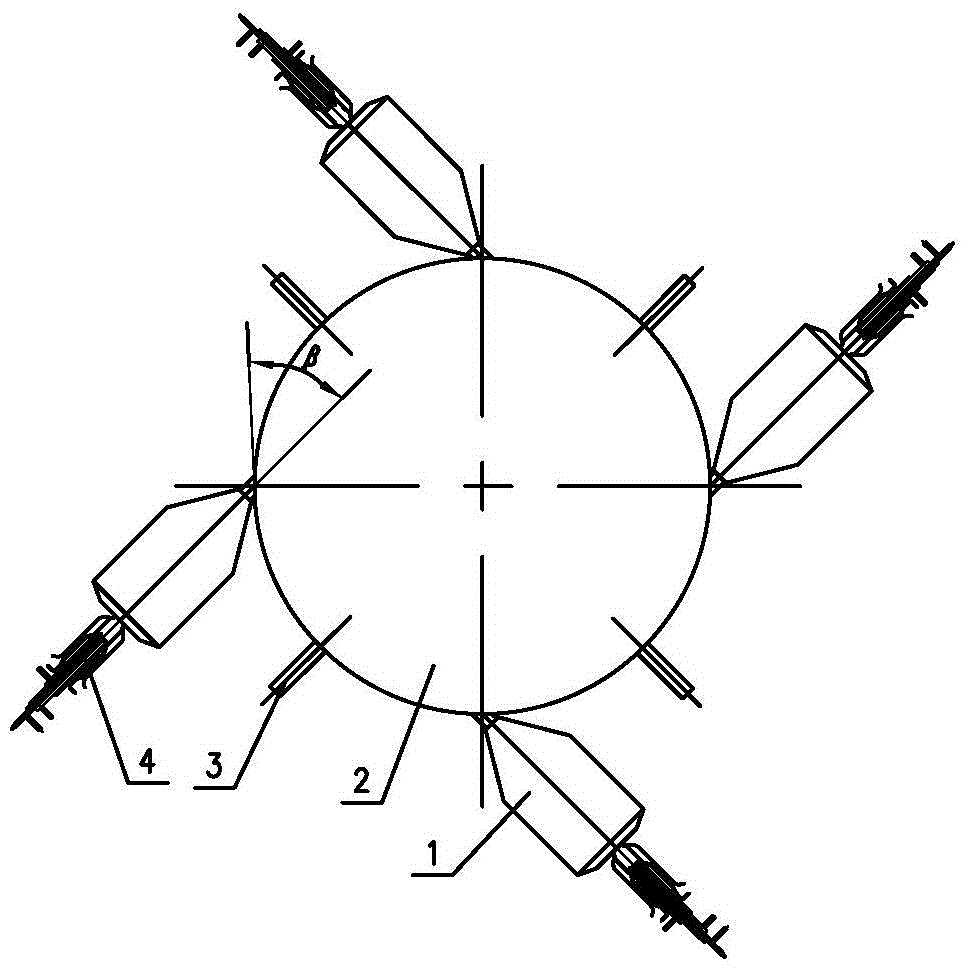

Two-stage type entrained flow gasification furnace

ActiveCN104974796AWork effectively for a long timeReduce volumeGranular/pulverulent flues gasificationSlagEngineering

The present invention discloses a two-stage type entrained flow gasification furnace. In the prior art, under the working condition of dry coal powder entrained flow gasification, the gasification furnace with characteristics of cleaning, long service life, high concern conversion rate and high gasification reaction intensity is required to be developed. The two-stage type entrained flow gasification furnace is characterized in that the outlet of the pre-gasification chamber is obliquely inserted into the main gasification chamber, a ratio of the height from the center of the pre-gasification chamber outlet to the main gasification chamber bottom portion to the diameter of the main gasification chamber is 0.3-2:1, the included angle alpha formed by the axial line of the pre-gasification chamber and the axial line of the main gasification chamber in the vertical cross-section is 30-90 DEG, the included angle beta formed by the axial line of the pre-gasification chamber and the tangent line of the main gasification chamber in the horizontal cross-section is 30-90 DEG, the top portion of the pre-gasification chamber is provided with a coal gasification burner, and the main gasification chamber is provided with a gasification agent spraying nozzle. According to the present invention, the service life of the furnace lining is prolonged, the waste of the fuel due to the falling of the coal powder into the slag pool through the slag discharge port is reduced, and the two-stage type entrained flow gasification furnace is suitable for the occasions using the coal powder to prepare the industrial fuel gas.

Owner:ZHEJIANG ASROAD HIGHWAY CONSTR & MAINTENANCE MACHINERY

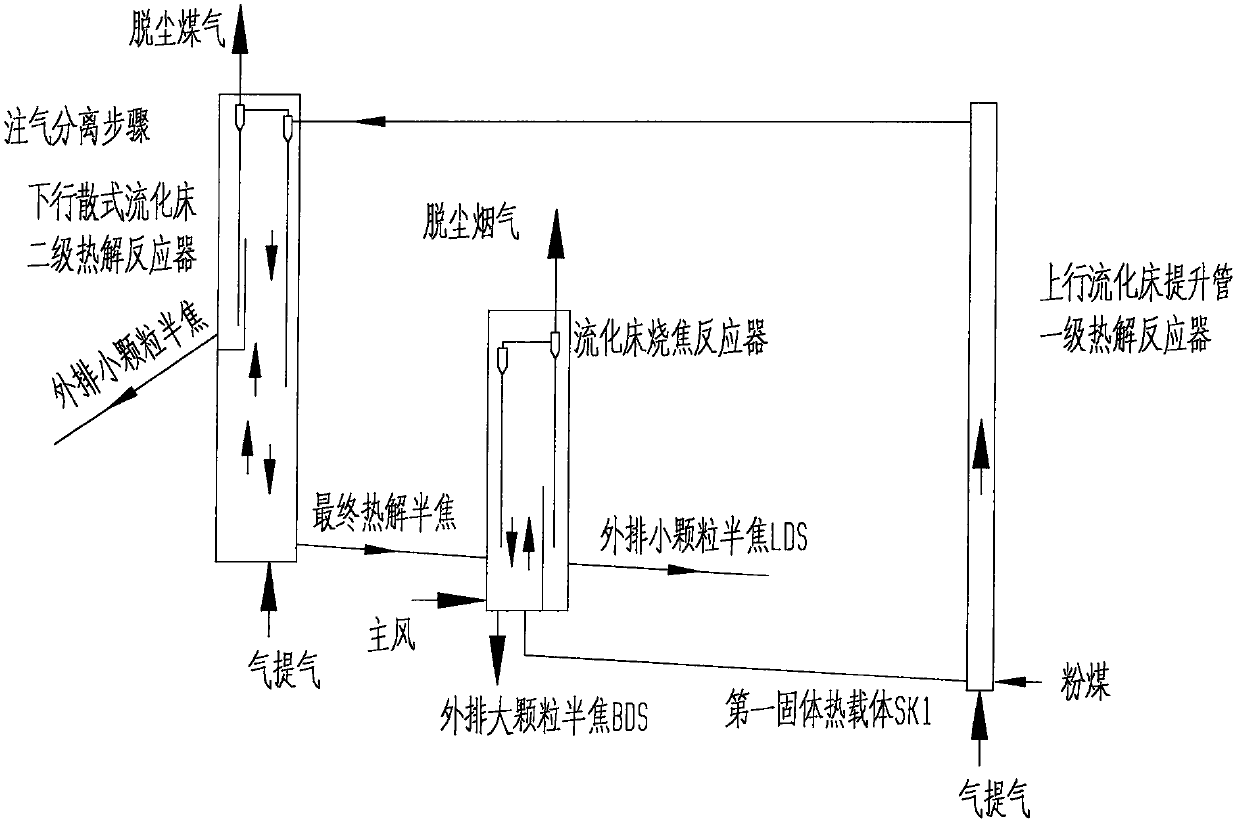

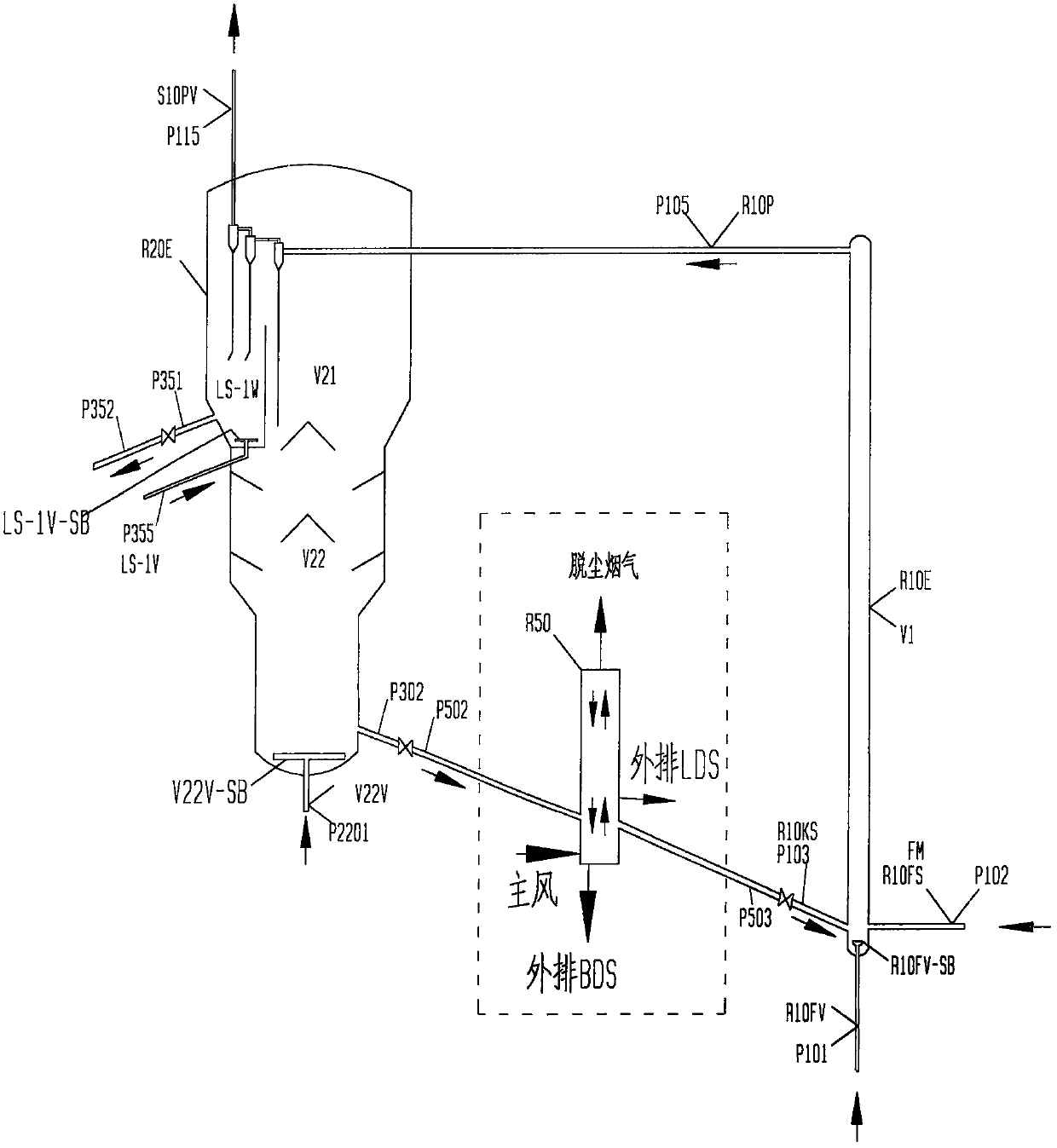

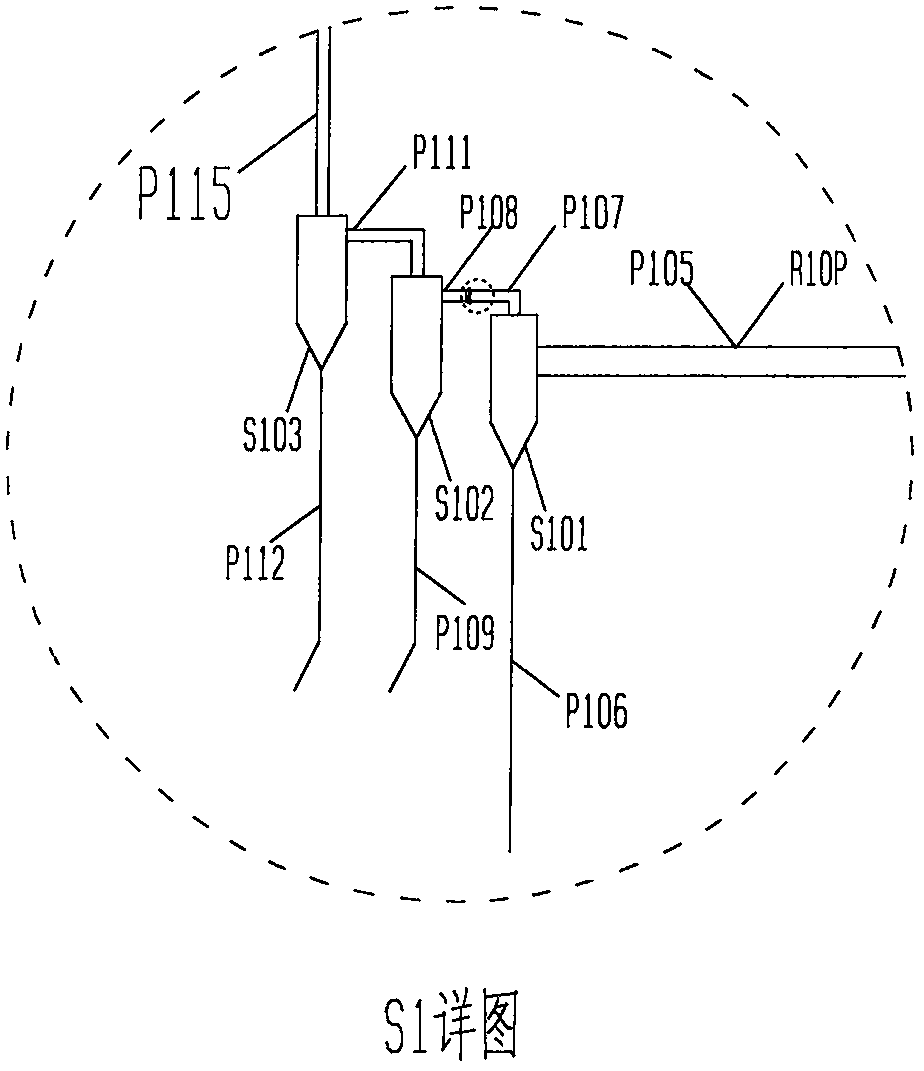

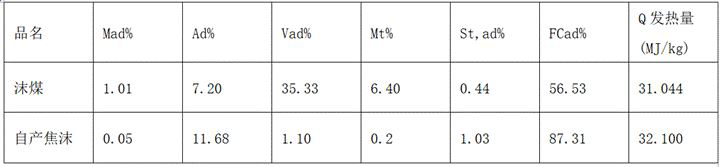

Classified coke discharge method and equipment for carbon hydrogen powder pyrolysis scorching system using solid heat carrier method

InactiveCN108018053AReduce dust removal loadLow solidsSpecial form destructive distillationGas dust removalCoal pyrolysisHeat carrier

A classified coke discharge method and equipment for a carbon hydrogen powder pyrolysis scorching system using solid heat carrier method are disclosed, and are suitable for pulverized coal pyrolysis fluidized bed scorching process, in the carbon hydrogen powder R10FS pyrolysis scorching system UNIT using solid heat carrier R10KS, at least one portion of small particle LS with the particle size less than critical particle size DZ in material EM containing the solid heat carrier is separated at any process position the solid heat carrier R10KS circularly flows to pass through, collected and discharged to reduce the concentration of the small particle LS in the solid heat carrier, the dedusting load of a pyrolysis reaction gas-solid product can be significantly reduced, and the solid contentin pyrolysis tar can be reduced.

Owner:洛阳瑞华新能源技术发展有限公司

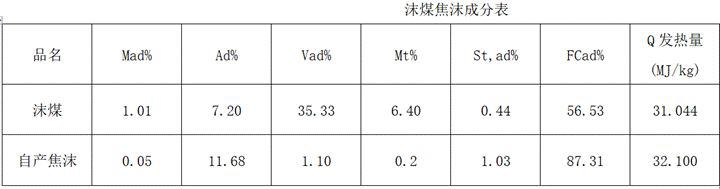

Method for reducing process energy consumption of European smelting furnace

PendingCN114395655AImprove cost competitivenessHigh compressive strengthShaft furnaceCokeComponents of crude oil

The invention discloses a method for reducing process energy consumption of an European smelting furnace, which is characterized in that acid pellets are matched with high-alkalinity sinter, and according to the cost performance and economical efficiency of ore smelting, an ore matching structure suitable for a furnace charge structure of a reduction furnace of the European smelting furnace is obtained as follows: 40% of sinter, 57% of pellets, 3% of raw ore and 97% of clinker rate. Components of the sintered ore are stabilized, the alkalinity of the sintered ore is stabilized to be R = 2.4 times, the content of MgO is 2.4%, and the content of rotary strands is larger than 80%; coal injection is conducted on a vault, the coal injection amount stably reaches about 150 kg / tHM, the material level of the gasification furnace is stabilized, 25 material levels before tapping are stabilized at 50%, 24 material levels after tapping are not smaller than 100%, and low material levels or long-term full material levels are completely eradicated; the coke foam is discharged from a 2500m < 3 > blast furnace, the particle size composition of 5-10mm is 60%, the particle size composition of the slack coal is 5-10mm and is kept above 50%, the moisture of the coke foam is less than 5%, and the moisture of the slack coal is less than 8%; the volatile matter of the slack coal is controlled to be greater than 35%, the gas generation amount is increased, and the fuel consumption is reduced.

Owner:XINJIANG BAYI IRON & STEEL

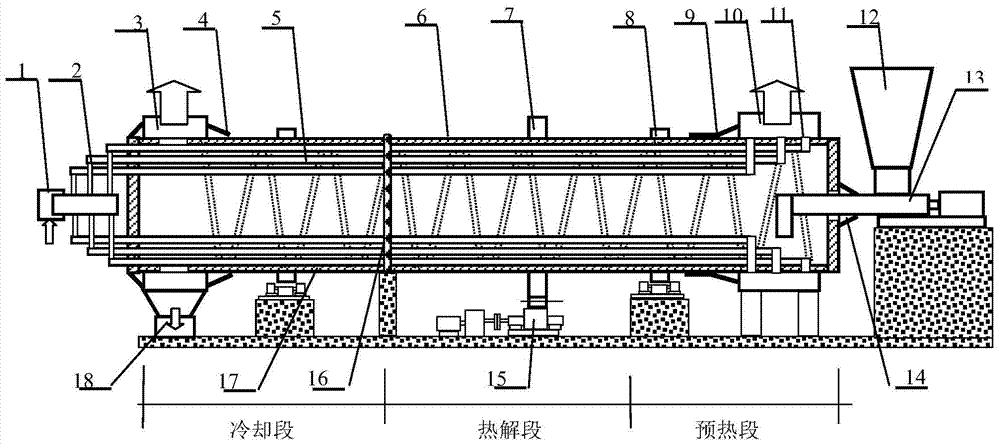

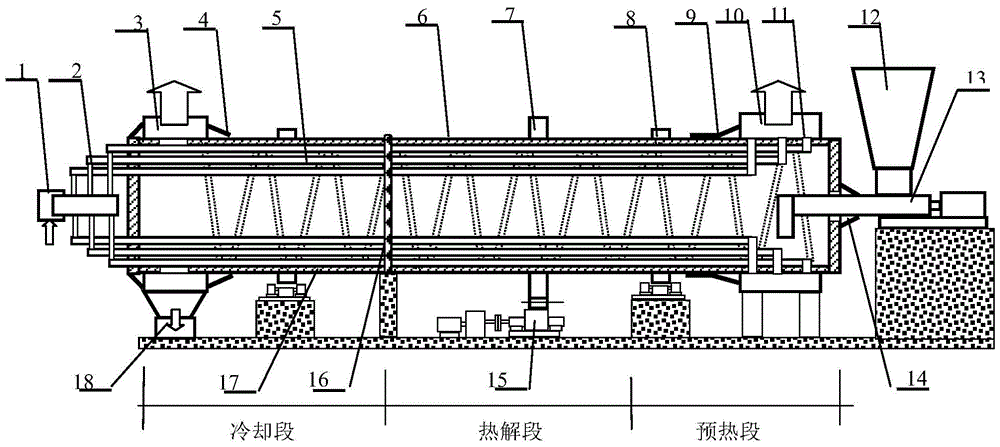

A pulverized coal pyrolysis rotary furnace

InactiveCN104789241BIncrease heat transfer areaIncrease production capacityIndirect heating destructive distillationSpecial form destructive distillationFlue gasEngineering

The invention relates to a pulverized coal pyrolysis rotary furnace. The pulverized coal pyrolysis rotary furnace involved includes a rotary furnace body, and the rotary furnace body is provided with a preheating section, a pyrolysis section and a cooling section; the preheating section and the pyrolysis section are equipped with a plurality of heat exchange tubes, and the The cooling section is equipped with multiple semi-coke cooling heat exchange tubes. At least two hot flue gas inlets are arranged at intervals on the heat exchange tube of the pyrolysis section to facilitate adjustment of the temperature distribution in the furnace length direction. The use of the heat exchange tube greatly increases the heat exchange area. The heat exchange tube rotary furnace of the present invention has a large heat exchange area, a large amount of pulverized coal to be processed, and a simple structure, and is suitable for large-scale pyrolysis production of more than one million tons of pulverized coal.

Owner:CHANGAN UNIV

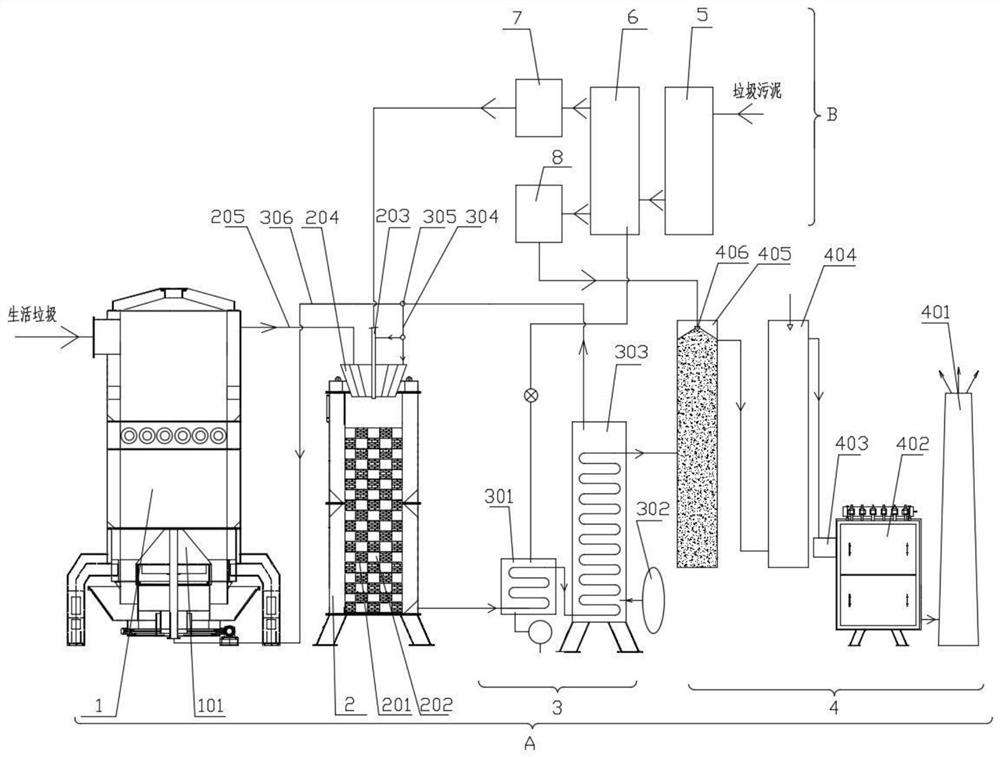

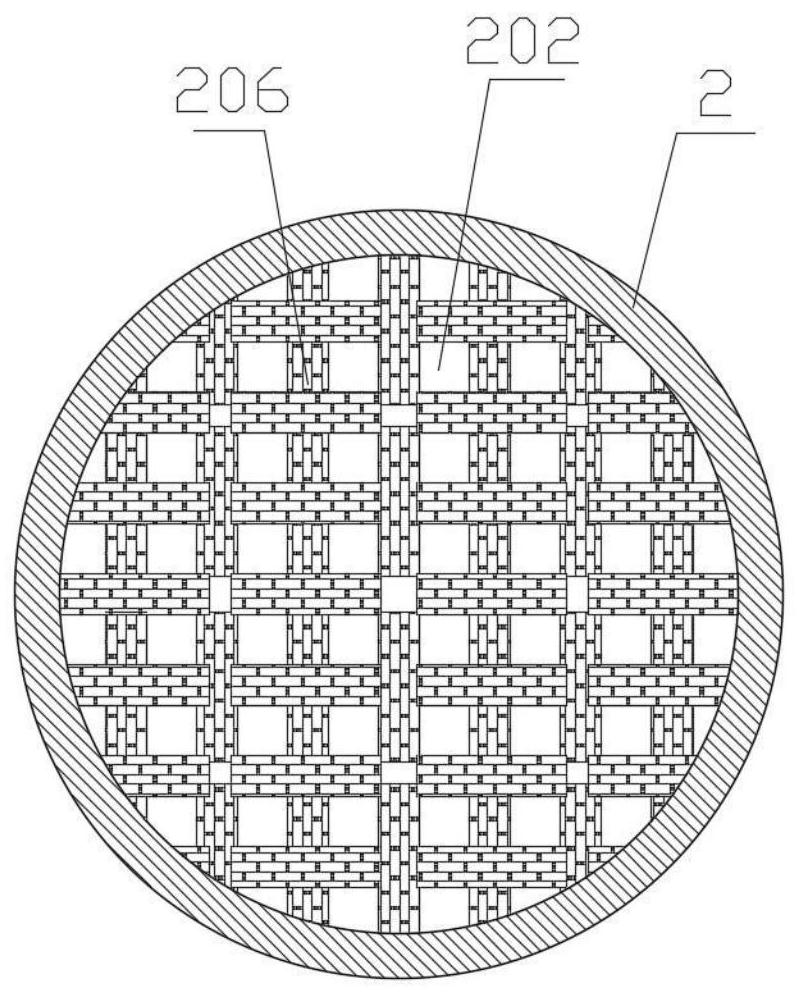

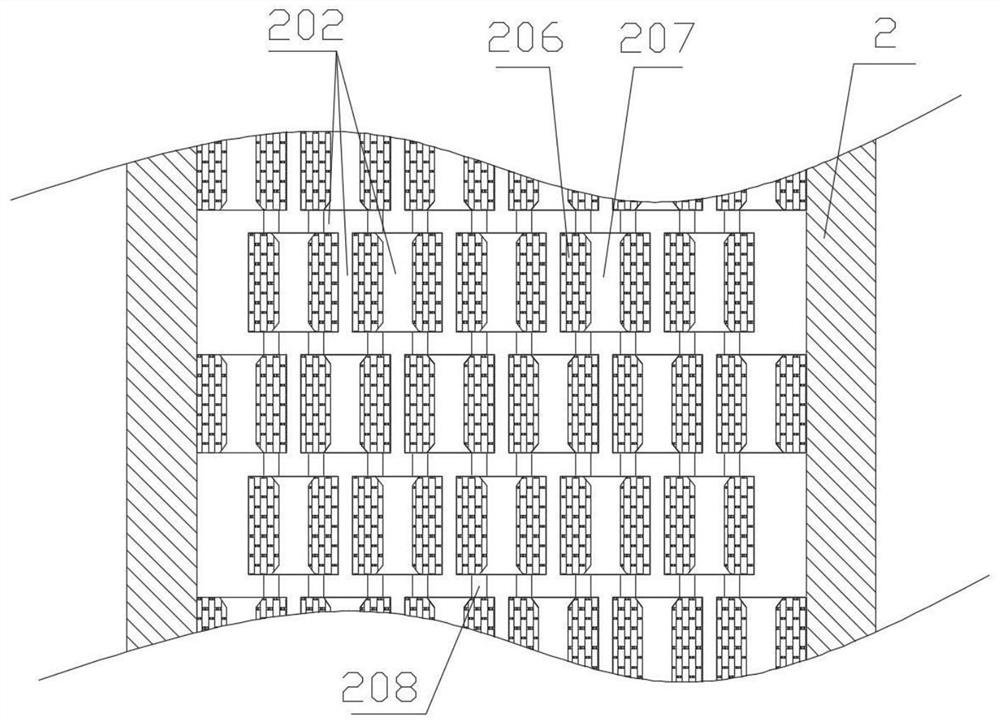

Cooperative treatment method and device for household garbage, municipal sludge and kitchen garbage

ActiveCN112919760AHas deacidification effectTake advantage ofSludge treatment by pyrolysisByproduct vaporizationSludgeSlurry

The invention discloses a household garbage, municipal sludge and kitchen garbage co-processing method and device. The household garbage is fed into a pyrolysis gasification furnace to be combusted and decomposed; municipal sludge and kitchen waste are mixed to form sludge waste, the sludge waste is transferred into an anaerobic fermentation tank for fermentation after being subjected to thermal hydrolysis treatment, and biogas generated in the anaerobic fermentation tank is used as external fuel; and the biogas slurry in the anaerobic fermentation tank is precipitated and filtered, then is introduced into a quench tower in the flue gas purification system in a spray form and is used as desuperheating water, and the flue gas is primarily deacidified in the quench tower through the alkalescence of the desuperheating water. The method not only solves the problem of solid waste garbage treatment and purifies the environment, but also can realize resource waste heat utilization and heat supply, heat supply or power generation, does not discharge waste water such as biogas slurry, and realizes energy cyclic utilization.

Owner:洛阳中科护环工程技术有限公司

A composite bed reactor and method for co-producing calcium carbide, gas and tar

ActiveCN103272536BTake advantage ofReduce heat lossCalcium carbideSpecial form destructive distillationMelting tankReaction rate

The invention relates to a composite bed reactor and a method for combined production of calcium carbide, gas and tar, and belongs to the field of calcium carbide production. The reactor comprises a hopper, a brake bunker, a moving bed preheating chamber, a tar collector, a gas outlet, a distributing device, an oxygen heat reaction chamber, oxygen spraying burners, a product molten pool and a product outlet, and the hopper is connected with the moving bed preheating chamber by the brake bunker, and the top side surface of the moving bed preheating chamber is provided with the tar collector, and the tar collector is provided with a gas outlet, and the moving bed preheating chamber bottom is provided with a distributing device, and the moving bed preheating chamber is communicated with an oxygen heat reaction chamber by a distributing device, and the oxygen heat reaction chamber bottom is connected with a product molten pool, and the upper portion of the connection between the oxygen heat reaction chamber and the product molten pool is provided with the oxygen spraying burner, and the middle bottom of the product molten pool is provided with a product outlet. The reactor of the invention has the advantages of simple structure and high efficiency, and large scale production is easy to realize, and the raw material is pelleted by powder form carbonaceous raw material and powder form calcium containing raw material, and the contact surface between raw materials is large, the reaction rate is fast, and reactor is convenient for reusing calcium carbide slags.

Owner:BEIJING UNIV OF CHEM TECH

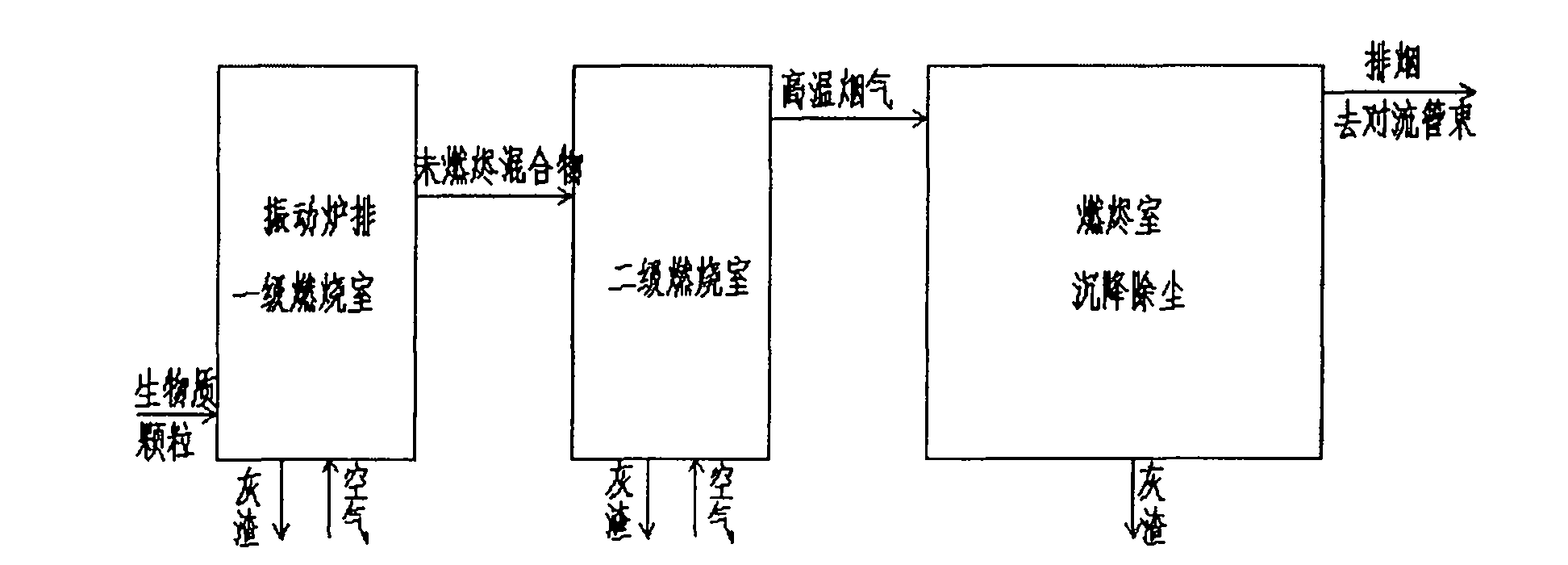

Combustion device for biomass granular fuel

InactiveCN101586805BEasy to assembleRelatively large volumeSolid fuel combustionCombustion apparatusCombustion chamberTop cap

The invention relates to the technical field of clean combustion energy, and relates to a device for efficiently combusting biomass granular fuel. A primary combustion chamber, a secondary combustion chamber and a burnout chamber are arranged in turn to form a communication structure and combined to form a combustion device main body; the bottom of the primary combustion chamber is manufactured with a primary air chamber with a mesa structure, the bottom end of the primary combustion chamber is provided with a periodical ash outlet and a blast pipe respectively, the lower part of the left sideof the primary combustion chamber is provided with a spiral feeding inlet, and the top space of the primary combustion chamber is provided with a top cap cavity; and the upper part of the right sideof the primary combustion chamber is provided with a downward obliquely-bent smoke guide pipe, an outlet of the smoke guide pipe extends to the middle part of the secondary combustion chamber, the topof the right side of the secondary combustion chamber is provided with an inner component in an open mode, the inner component butts the burnout chamber and the secondary combustion chamber in a communication mode, the bottom end of the secondary combustion chamber is provided with a mesa secondary air chamber and a periodical ash outlet pipe, and the bottom of the secondary air chamber is provided with a blast pipe. The combustion device has the advantages of simple structure, full combustion, high efficiency, good dust removing effect, stable and reliable running, and remarkable energy-saving effect.

Owner:QINGDAO UNIV

Organic waste gas purification device

ActiveCN105797494BReduce dust removal loadDispersed particle filtrationTransportation and packagingExhaust fumesEngineering

The invention discloses an organic waste gas purification device. The device includes a filter box, a negative pressure fan, several exhaust gas branch pipes, an exhaust gas main pipe, an exhaust gas duct and a maintenance system. The blower is connected, and the other end is connected with one end of the waste gas main pipe, and the other end of the waste gas main pipe is connected with the air inlet; a baffle is arranged in the filter box, and the filter box is divided into The first-stage filter chamber and the second-stage filter chamber, the waste gas conduit passes through the baffle and communicates with the first-stage filter chamber and the second-stage filter chamber; the inner wall of the first-stage filter chamber is provided with a protective A primary filter is provided in the cavity surrounded by the protective net, and an activated carbon filter is provided in the secondary filter chamber. The organic waste gas purification device of the present invention has the advantages of good dust removal effect and convenient maintenance.

Owner:东莞市恒升环保科技有限公司

A slag granulation coal gasifier and coal gas preparation process

ActiveCN104593085BReduce oxygen concentrationReduce the temperatureCombined combustion mitigationGranular/pulverulent flues gasificationSolid particleMolten slag

The invention discloses a coal gasifier for slag granulation and a coal gas preparation process. The coal gasifier is mainly composed of a pressure-bearing housing, a slag film gasification device, an annular chamber structure slag basin, a quenching chamber, a conduit, a convection cooling section and the like. The process comprises the following steps: with pulverized dry coal or coal water slurry as a raw material, feeding the raw material to a gasification chamber to burn and gasify together with a gasifying agent from a vortex gasification burner; enabling formed liquid slag to collide with the wall surface of the gasification chamber under the vortex action, and flowing from bottom to top under the action of gravity; feeding to the slag basin of the annular chamber structure, carrying out further gasification reaction together with oxygen fed from the upper part of the slag basin, and discharging from a slag discharge hole; feeding coal gas main airflow to the quenching chamber together with liquid drops, cooling to a specific temperature, and then conveying to the convection cooling section to further lower temperature through the conduit; finally removing dust, purifying and then outputting. The liquid slag drops penetrating through the slag basin are cooled to form solid particles and are collected by a dry slag collector; and the heat is recovered by a slag cooler.

Owner:XI AN JIAOTONG UNIV +1

Solid heat carrier pyrolyzer

ActiveCN106190206BReduce the overall heightReduce chalkingDirect heating destructive distillationSpecial form destructive distillationHeat carrierRaw material

The invention discloses a solid heat carrier pyrolyzer which comprises a top cover (1), a bed (2) and a rotary mechanism. An annular pyrolysis tank is arranged on the top face of the bed, the top cover covers the pyrolysis tank from the upper side, and a feed inlet (5), a pyrolysis gas outlet (6) and a discharge point communicated with the pyrolysis tank are sequentially arranged in the circumferential direction of the sealed annular area, corresponding to the pyrolysis tank, in the top cover in a spaced mode; in the sealed annular area, one side sector ring area between the discharge point and the feed inlet is a pyrolysis area (D1), and the other side sector ring area is a reheating area (D2) provided with heating air pipes (7). Solid heat carriers in the pyrolysis tank rotate along with the bed and are reheated by a heating device, enter the pyrolysis area after being heated, and are mixed with pyrolysis raw materials and pyrolysized, one part of pyrolysis products serve as pyrolysis finished product and are discharged through the discharge point, and the other part of the pyrolysis products circularly flow back to the reheating area. The pyrolyzer is novel and compact in structure and small in occupied space, and integrates pyrolysis, discharging and solid heat carrier heating and circulation functions.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

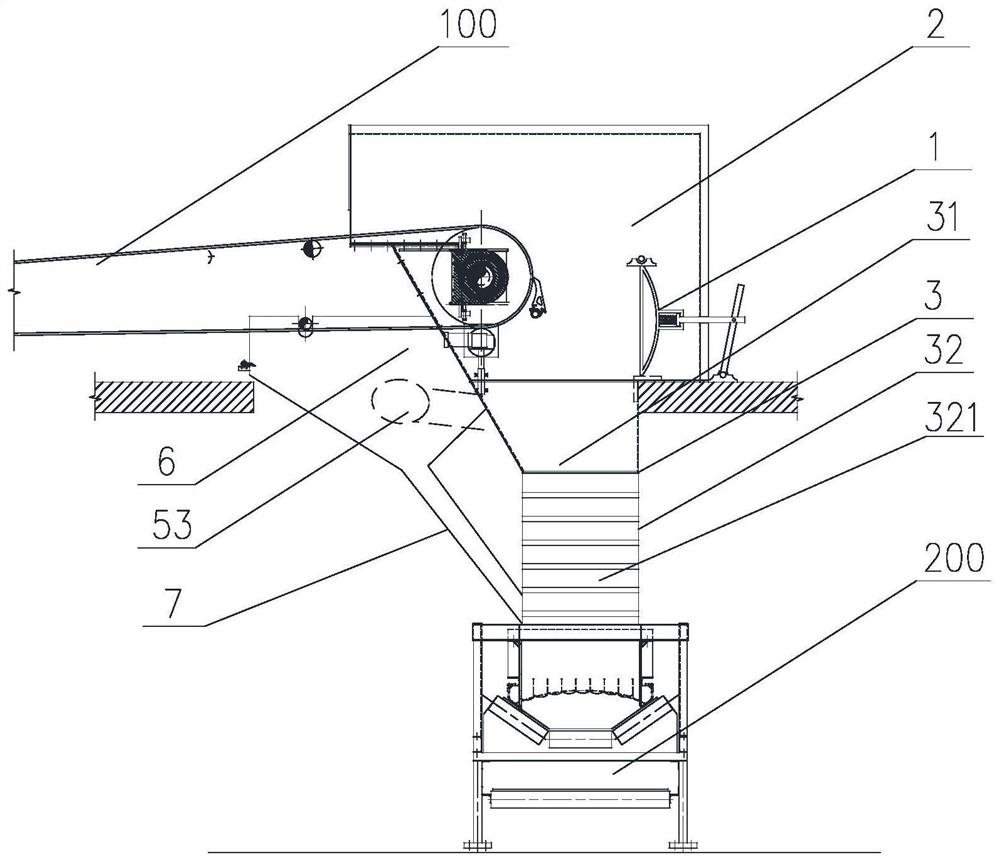

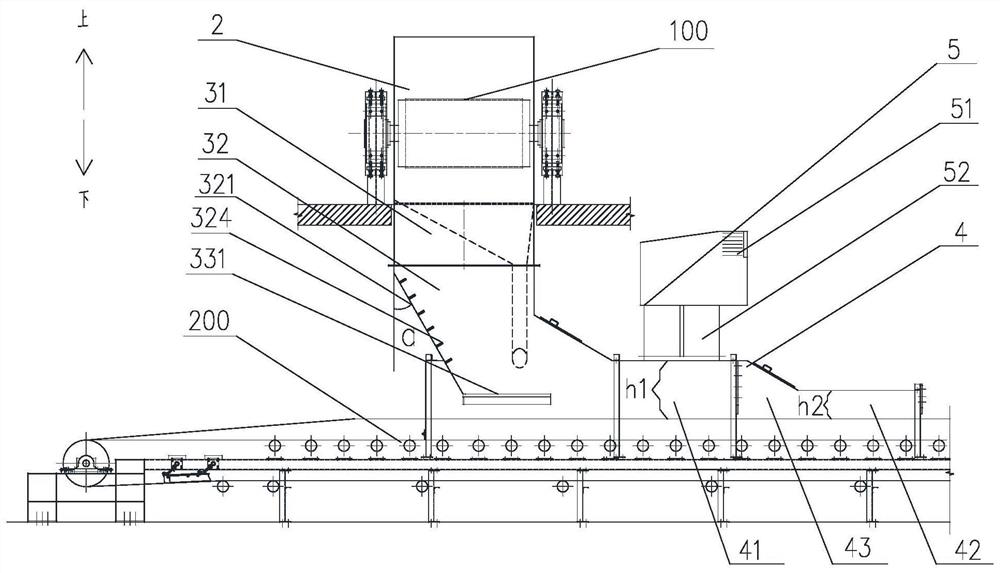

A dust removal device for material conveying system

ActiveCN109607254BReduce spreadGuaranteed dust suppressionLoading/unloadingDust controlEnvironmental engineering

The invention provides a dust suppression device and a dust removal device for a material conveyor. The dust suppression device includes a vertically arranged dust suppression baffle, and the dust suppression baffle is spaced horizontally from the material output end of the material conveyor. Open, the side of the dust suppression baffle facing the material conveyor is the diversion surface, and the diversion surface is concave toward the direction away from the material conveyor, and is a spherical or arc surface; when the material falls from the material conveyor, the material Can hit the diversion surface. The dust suppression device used in the material conveying system of the present invention has better dust suppression effect, and can reduce dust removal and dust suppression costs.

Owner:BAOTOU ENG & RES CORP OF IRON & STEEL IND CHINA METALLURGY CONSTR GROUP BERIS

A radiation pyrolysis tube and a pulverized coal pyrolysis rotary furnace

InactiveCN104745212BIncrease heat transfer areaIncrease production capacityCoke quenchingEnergy inputRotary furnaceCoal pyrolysis

The invention relates to a radiation pyrolytic tube and a pulverized coal pyrolytic rotary furnace. The radiation pyrolytic tube comprises three radiation tubes which are sequentially connected, namely a first radiation tube, a second radiation tube and a third radiation tube, wherein a fuel gas nozzle and an igniter are arranged inside the second radiation tube; the pulverized coal pyrolytic rotary furnace comprises a rotary furnace body, wherein a plurality of radiation pyrolytic tubes are arranged inside the furnace body. By adopting the pulverized coal pyrolytic rotary furnace, the smoke afterheat is utilized for preheating and drying the raw coal and the carbocoal afterheat is utilized for preheating the combustion air and the coal gas; the heat utilization rate is high, the pulverized coal drying, preheating, pyrolysis and carbocoal cooling process are integrally designed and the pyrolytic process is simplified. The rotary furnace provided by the invention is large in heat exchange area, high in pulverized coal processing amount, simple in structure and suitable for million tons of pulverized coal large-scale pyrolytic production.

Owner:CHANGAN UNIV

Solid heat carrier pyrolyzer

ActiveCN106281379BReduce the overall heightReduce chalkingDirect heating destructive distillationSpecial form destructive distillationHeat carrierMixed materials

The invention discloses a solid heat carrier pyrolyzer. The solid heat carrier pyrolyzer comprises a top cover (1), a bed body (2) and a slewing mechanism, wherein a ring-shaped pyrolyzing tank is formed in the top surface of the bed body; the top cover seals and covers the pyrolyzing tank from the top; a feed opening (5), pyrolyzing gas outlets (6) and a discharge point, which communicate with the pyrolyzing tank are sequentially arranged at intervals in the circumferential direction of a capping ring region corresponding to the pyrolyzing tank in the top cover, in the capping ring region, a fan ring region on one side between the discharge point and the feeding opening is a pyrolyzing region (D1), and a fan ring region on the other side is a reheating region (D2) connected to a heating device; and along with the rotation of the bed body, solid heat carriers in the pyrolyzing tank are reheated through the heating device, the heated solid heat carriers enter the pyrolyzing region to be mixed with pyrolyzing raw materials, then mixed materials are pyrolyzed, one part of pyrolyzed products as pyrolyzed finished products are discharged through the discharge point, and the other part of the pyrolyzed products are circulated to return the reheating region. The pyrolyzer is novel and compact in structure and small in land occupation space, and integrates the functions of pyrolyzing, discharging, heating of solid heat carriers, circulating and the like.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com