Method for manufacturing high strength green ball block by coal-based direct reduction and device therefor

A technology for manufacturing equipment and manufacturing methods, which is applied in the field of manufacturing method equipment, can solve problems such as the impossibility of meeting the actual requirements of industrial production, and achieve the effects of flexible methods, strong practicability, and scientific concepts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

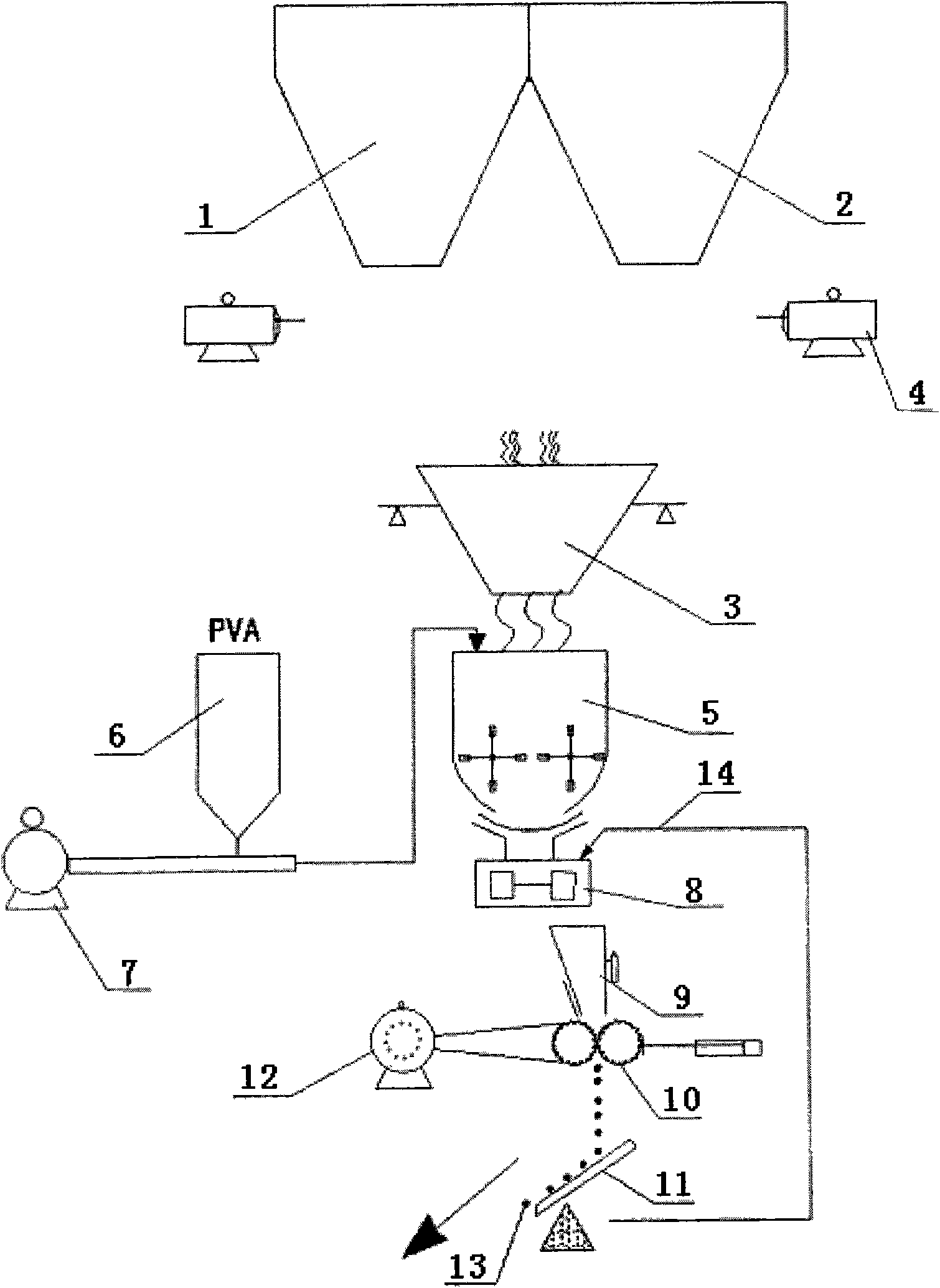

[0018] The preferred implementation of the method for manufacturing high-strength direct reduction green pellets of the present invention will be described in detail below with reference to the accompanying drawings. The technical solution of the present invention is not limited to the specific description of the embodiments.

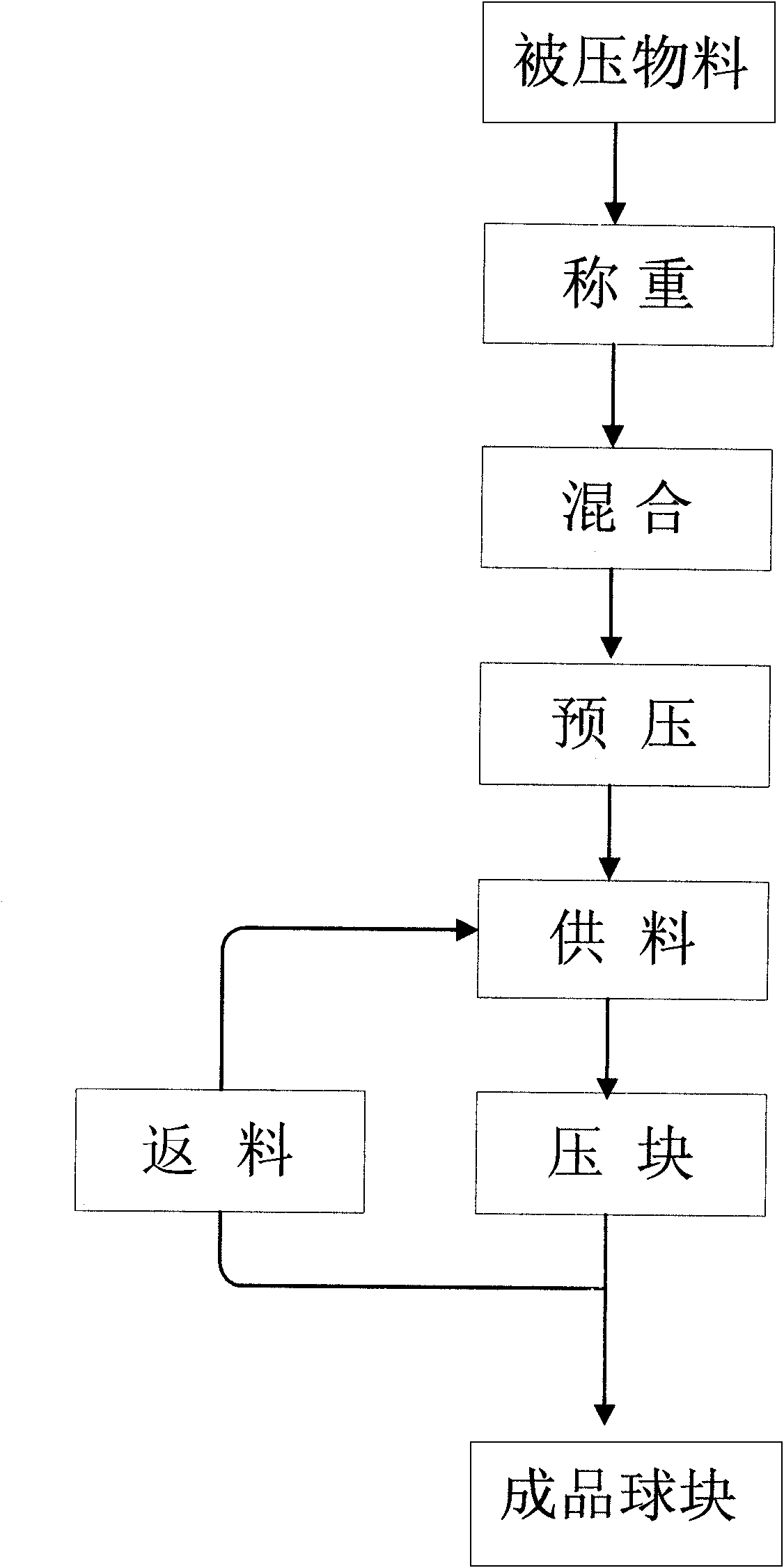

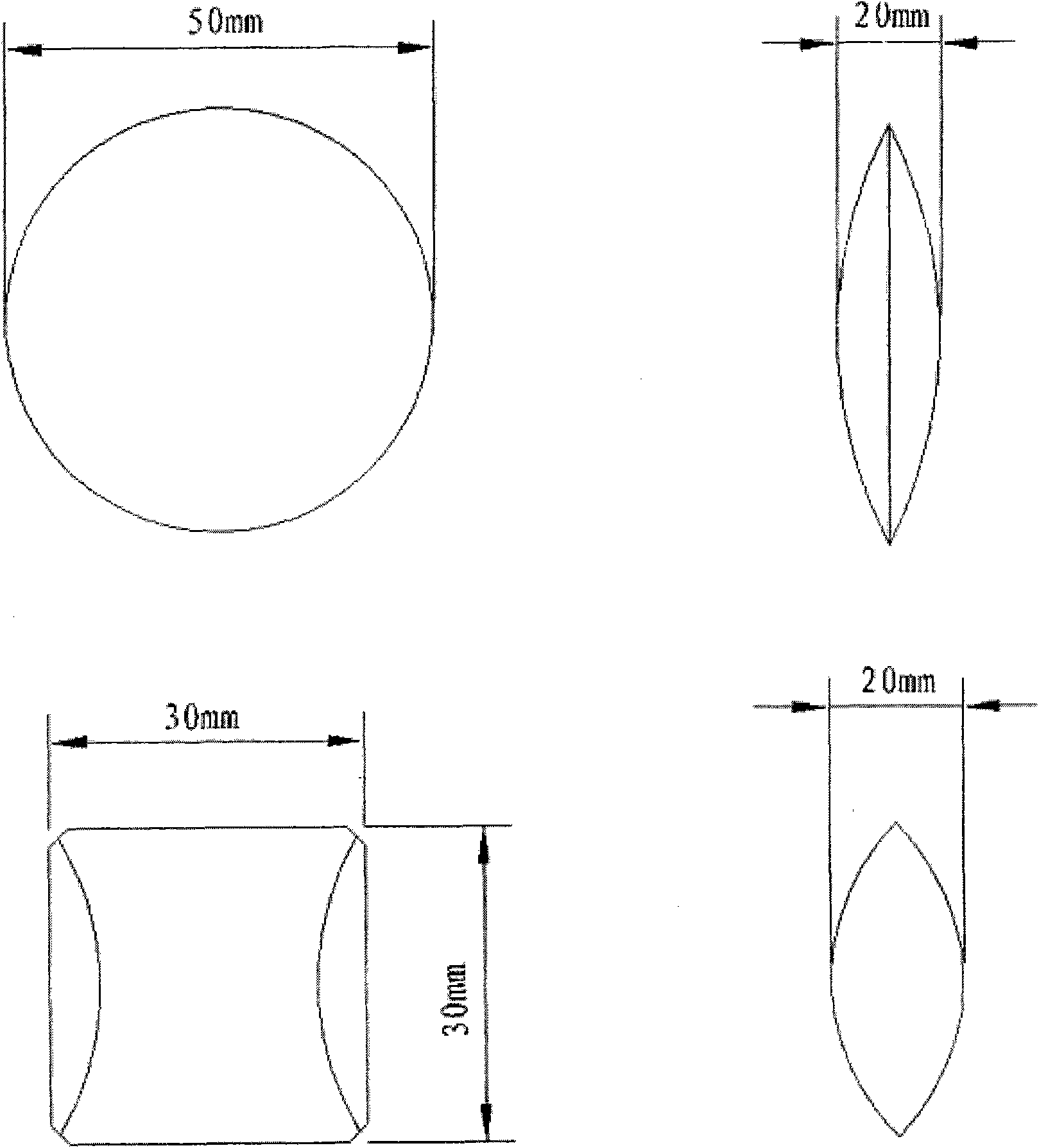

[0019] There are many factors affecting the compacting process, and these factors are often interrelated, mutually promoting and restricting each other. The inventor has carefully studied the relationship between various factors in the influencing factors of the compacting process, and skillfully comprehensively used those factors that affect the compacting process. Agglomerate properties promote each other or affect the same factors. On the basis of successful repeated tests, the present invention provides a high-strength direct reduction green pellet manufacturing method, which mainly includes ① accurate batching and feeding; ② uniform mixing ;③Approp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com