A radiation pyrolysis tube and a pulverized coal pyrolysis rotary furnace

A radiant tube and radiant heat technology, applied in coke ovens, indirect heating carbonization, special carbonization, etc., can solve the problems of small heat transfer area, low thermal efficiency, complex structure, etc., and achieve large heat transfer area and high heat utilization rate , The effect of simplifying the pyrolysis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

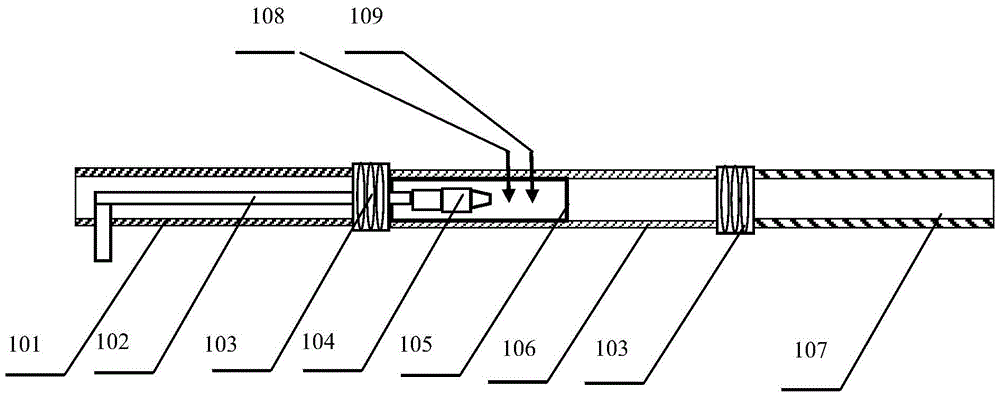

[0030] refer to figure 1 , the radiant pyrolysis tube of this embodiment includes a straight gas radiant tube, along the axial direction, the first radiant tube 101 is a cooling section for cooling semi-coke preheated air and gas, and the second radiant tube 106 is a gas-fired In the heating section, the third radiant tube 107 is used for flue gas cooling, and is used for preheating and drying pulverized coal raw materials to form a preheating section.

[0031] A gas burner, an electronic igniter 108 and a fire detection probe 109 are installed in the second radiant tube 106 . The gas delivery pipe 102 passes through the first radiant pipe 101 and enters the second radiant pipe 106 , and is connected with the gas burner 104 .

[0032] Among them: the preheating section adopts ordinary carbon steel pipe; the heating section adopts high temperature resistant stainless steel pipe (310S material) with silicon carbide lining 105 inside; the cooling section adopts ordinary carbon s...

Embodiment 2

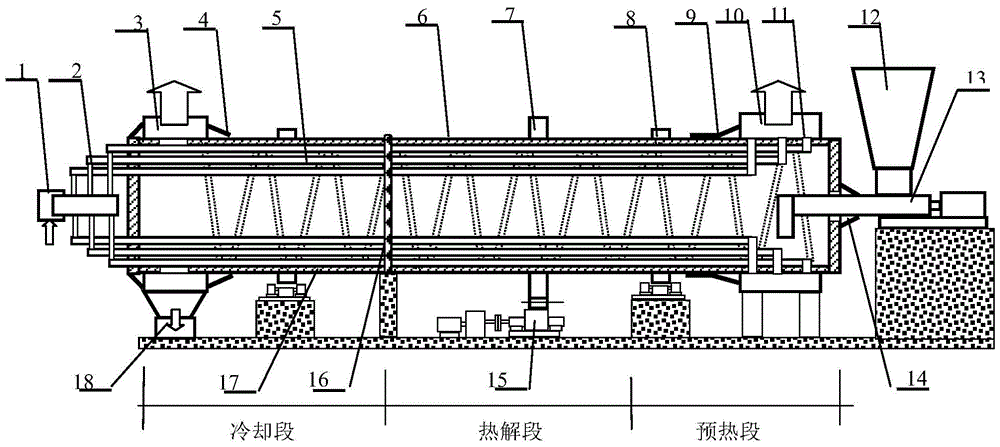

[0034] combine Figure 1-Figure 3 The structure of the rotary furnace device provided in this embodiment includes: raw coal bunker 12, rotary furnace body 6, rotary furnace body 6 is driven by transmission gear 7, wheel belt 8 and main transmission device 15, rotary furnace body 6 is provided with heat Gas outlet 3, flue gas outlet 10, furnace body insulation layer 17 and semi-coke outlet 18, the raw coal is transported into the rotary furnace body 6 through the pulverized coal conveying reamer 13, and the pulverized coal conveying reamer 13 and the rotary furnace body 6 pass through The feed sealing device 14 seals; the hot gas outlet 3 and the rotary furnace body are sealed and connected through the gas dynamic sealing device 4 .

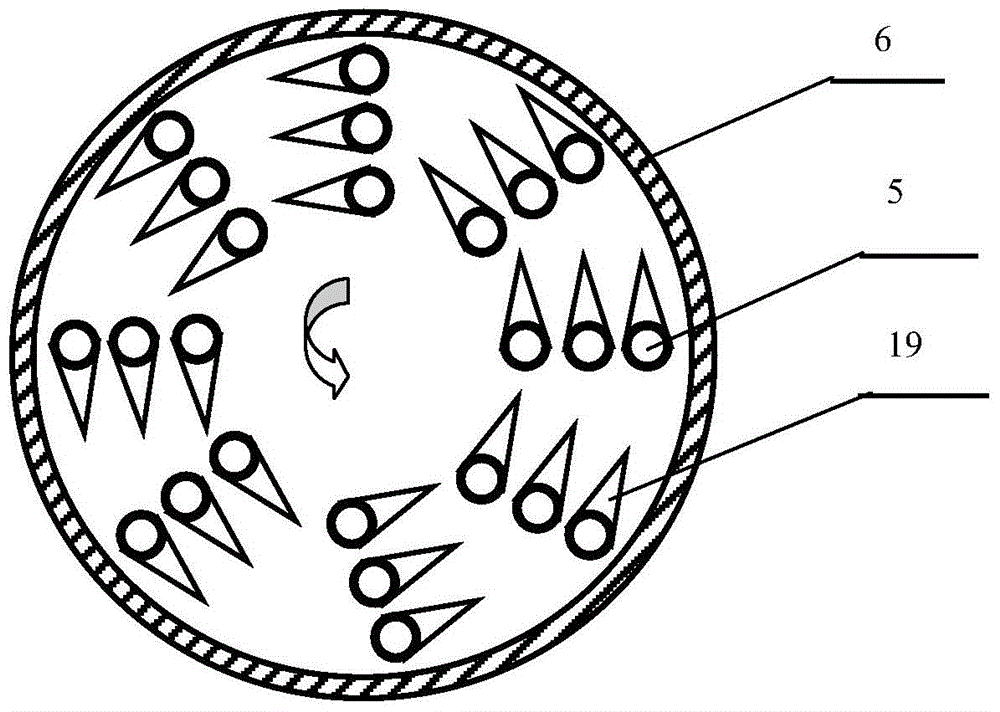

[0035] Radiation pyrolysis tubes 5 are arranged parallel to the axial direction of the rotary furnace body 6, forming an annular radiant tube layer in the radial section of the rotary furnace. Depending on the cross-sectional area of the rotary ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com