Cooperative treatment method and device for household garbage, municipal sludge and kitchen garbage

A technology for domestic waste and municipal sludge, applied in biological sludge treatment, combustion methods, pyrolysis treatment of sludge, etc., can solve problems such as seasons, transportation, environmental conditions, increased waste treatment costs, difficulties in biogas slurry, etc. Achieve the effect of reducing the pressure of deacidification operation, reducing the pressure of sewage treatment, and reducing the input cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

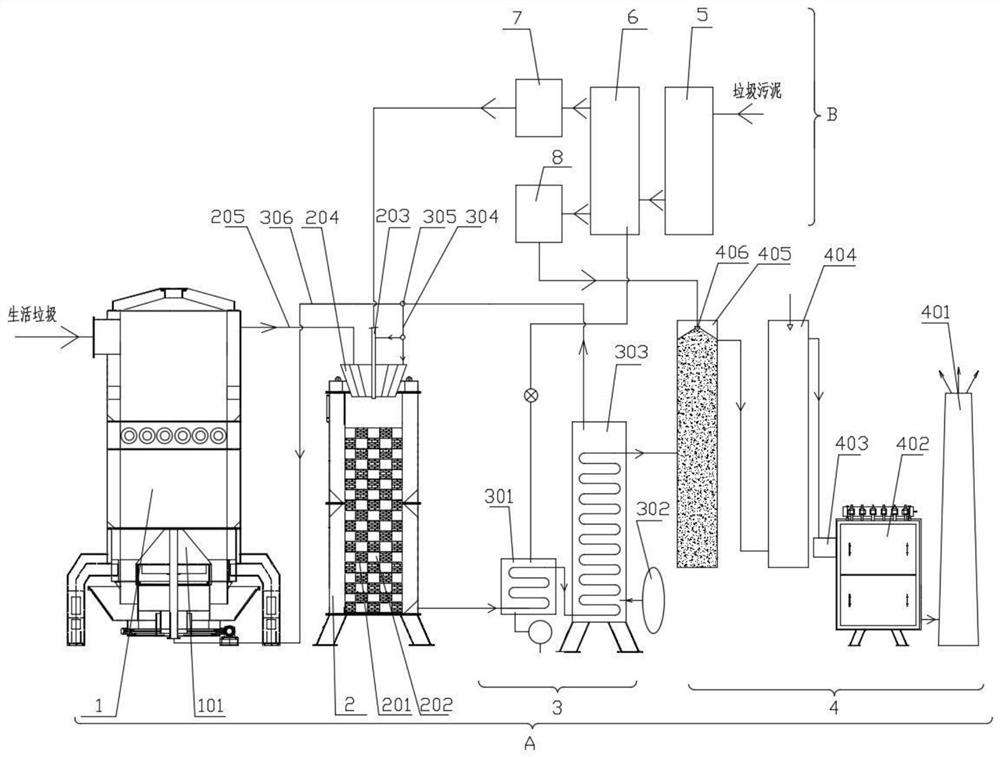

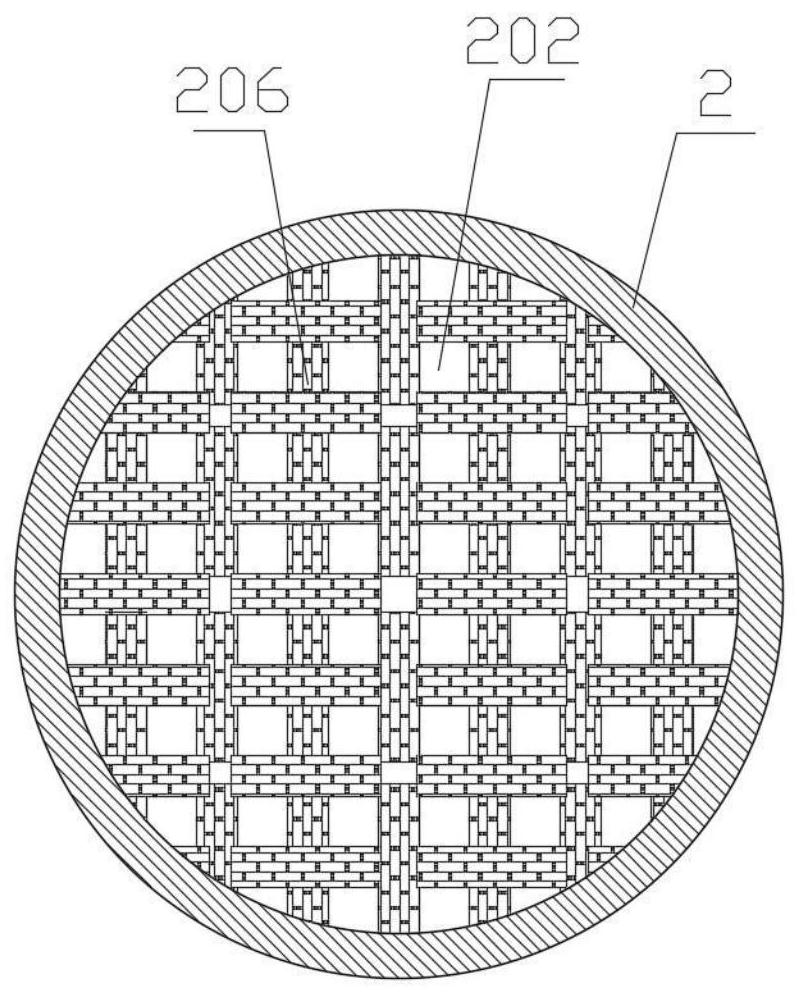

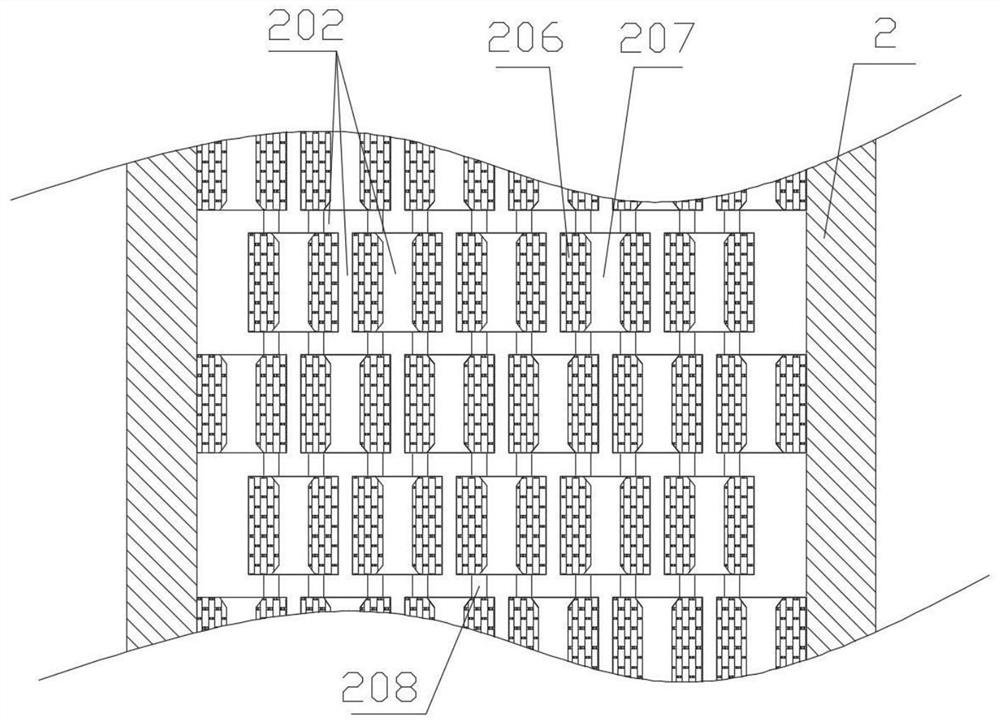

[0028] like figure 1 As shown, a co-processing device for domestic waste, municipal sludge and kitchen waste of the present invention includes incineration equipment A and fermentation equipment B. The incineration equipment A is the same as the conventional domestic waste incineration device, including a pyrolysis gasifier 1, a secondary combustion chamber 2, and a flue gas purification system 4. The flue gas purification system 4 has a quenching tower 405, a semi-dry deacidification tower 404, a cloth bag Dust collector 402 and chimney 401. The domestic waste is burned in the pyrolysis gasifier 1 to produce synthesis gas, and the synthesis gas is fully burned in the second combustion chamber 2 to release heat, decompose dioxins and generate flue gas, which passes through the quench tower 405, semi- The dry deacidification tower 404 and the bag filter 402 are discharged through the chimney 401 after reaching the standard. In the quenching tower 405, the temperature of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com