Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about How to "Realize online recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

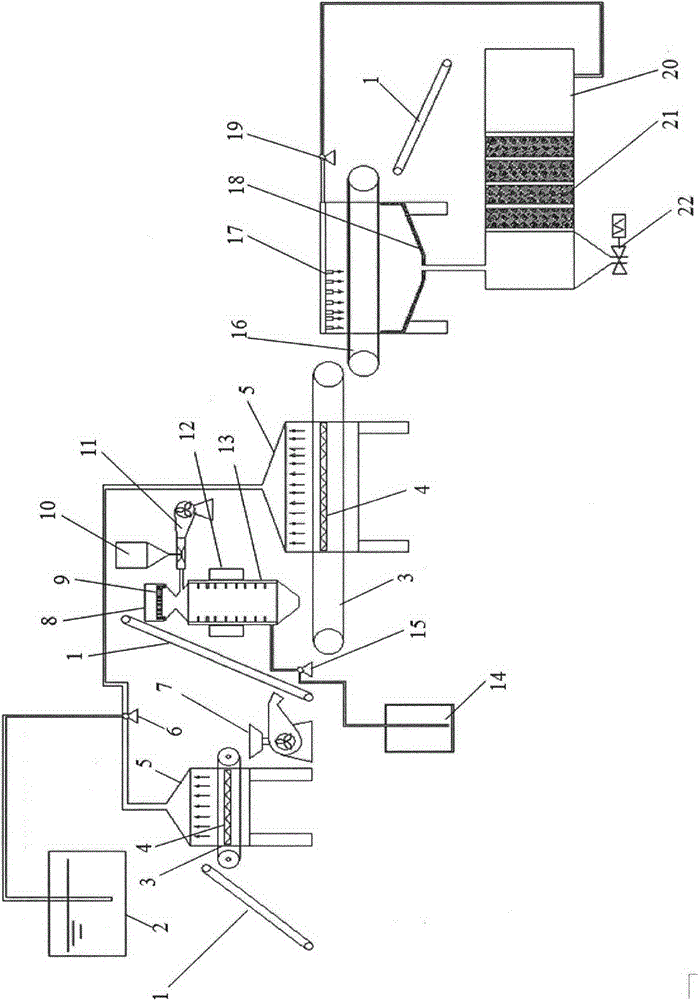

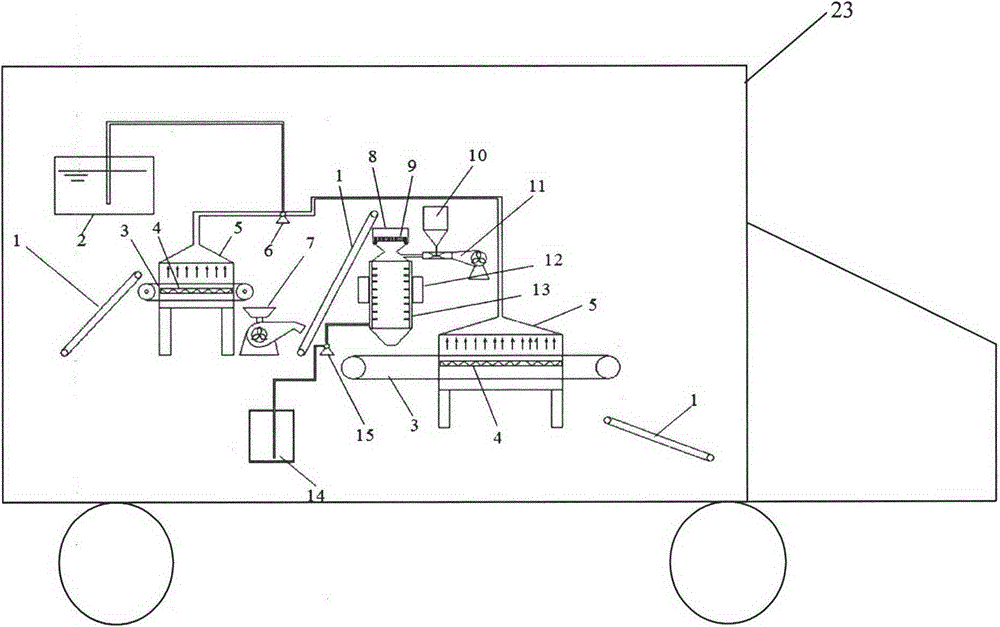

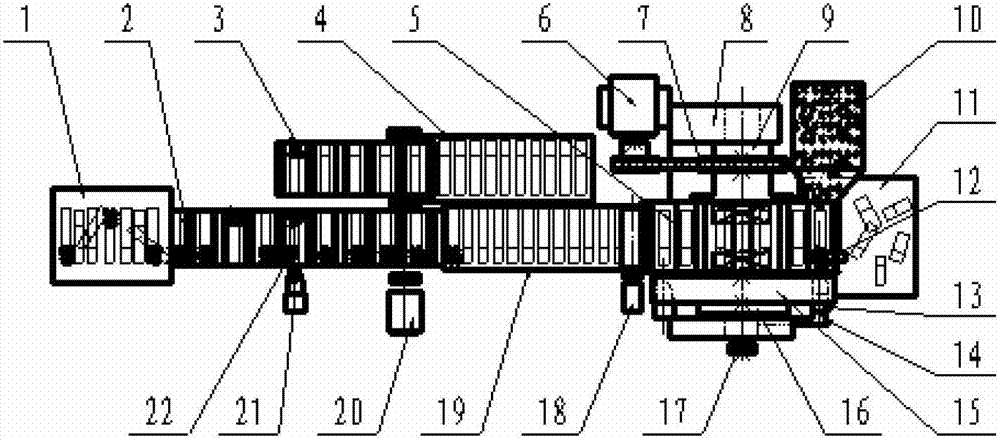

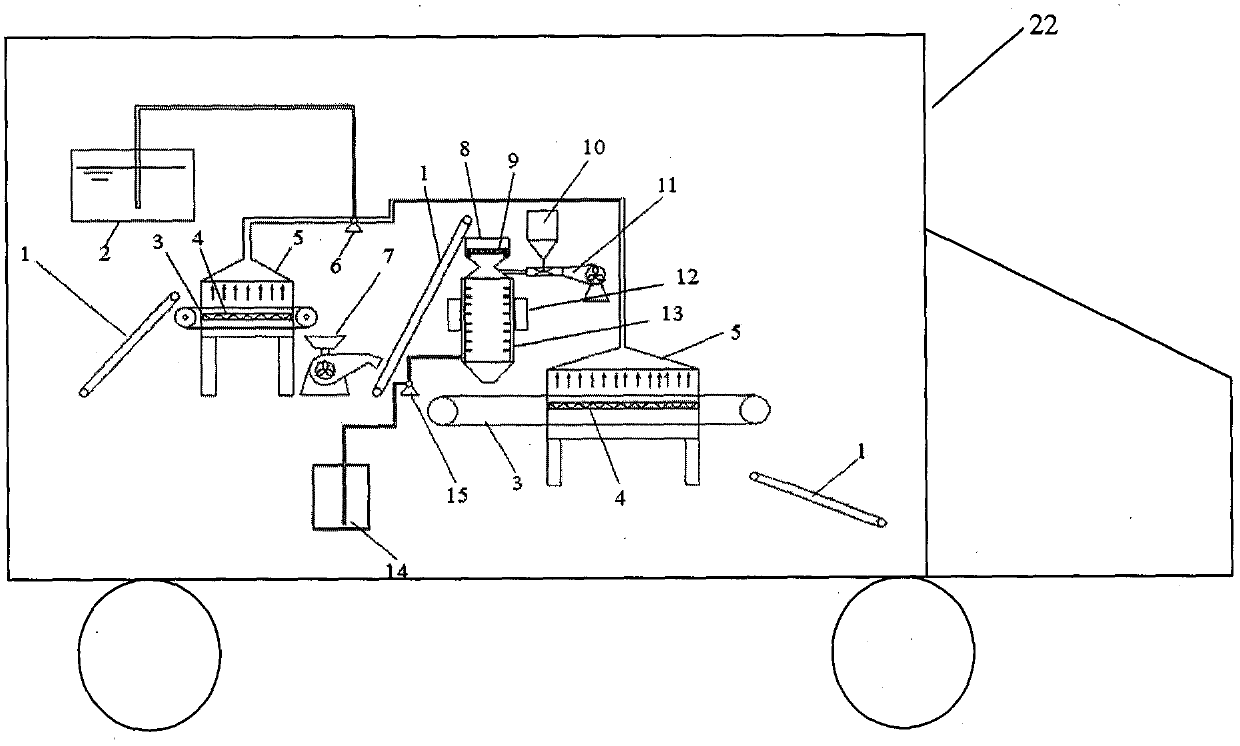

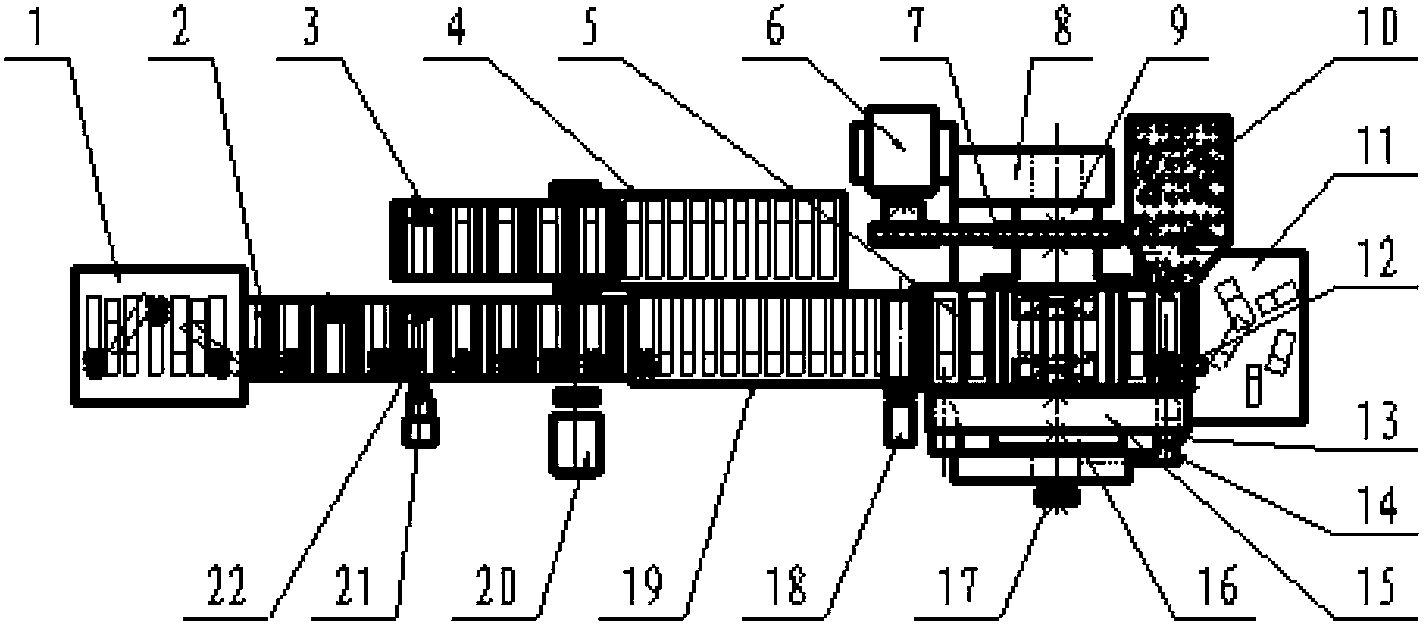

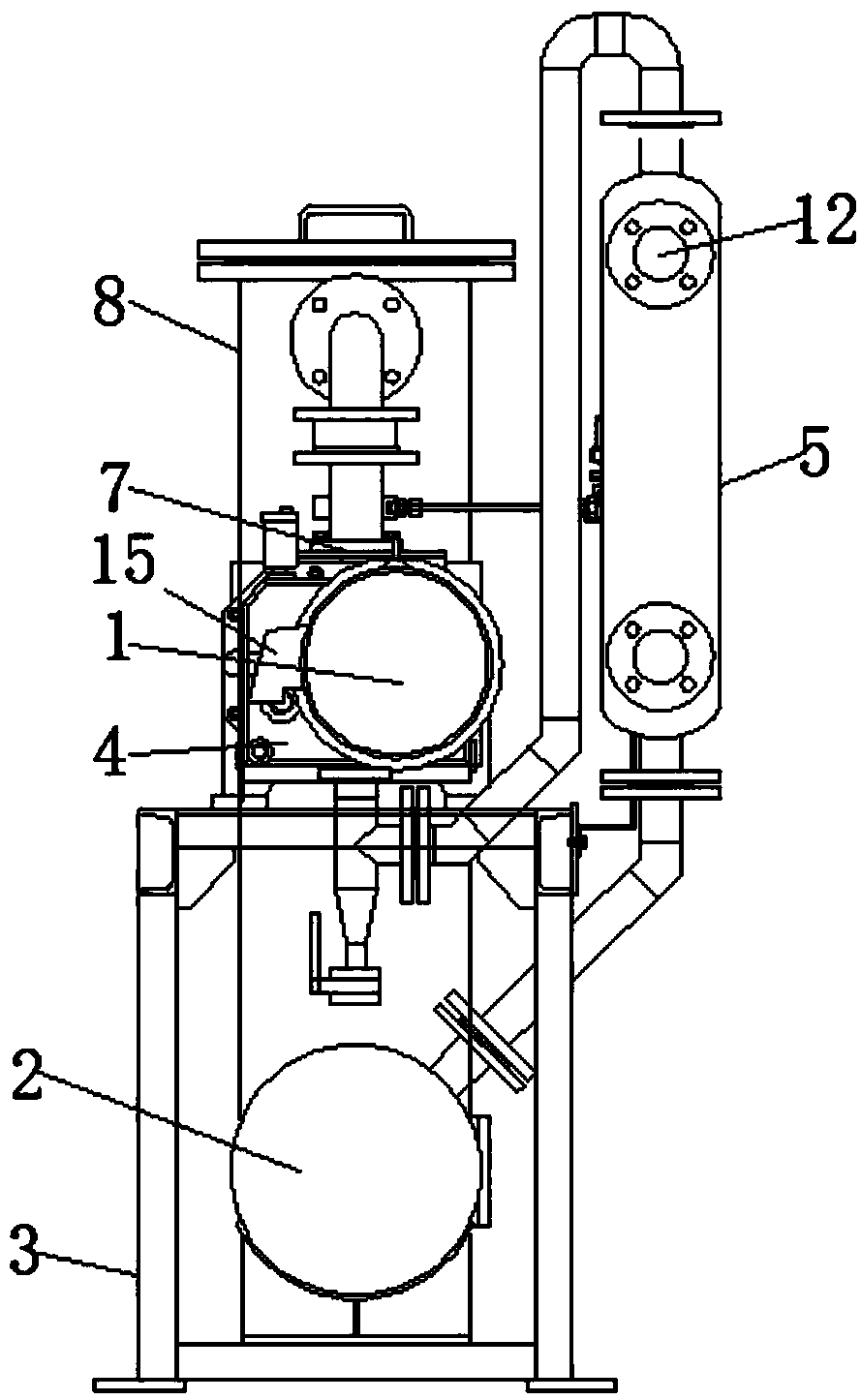

Integrated and comprehensive soil in-place position-changing combined remedying equipment

ActiveCN105013806AAchieving Heterotopic Continuous Joint RepairImprove repair efficiencyContaminated soil reclamationEnvironmental resistancePeristaltic pump

The invention discloses integrated and comprehensive soil in-place position-changing combined remedying equipment, and belongs to the technical field of soil remedying. The equipment mainly comprises feeding and discharging machines, heating baking channels, conveying belts, a vacuum pump, a smashing device, a mixer, a solid chemical adding tank, a Venturi conveying pump, an ultrasonic atomizer, a peristaltic pump, a liquid chemical storage tank, a drip washing device, an activated carbon adsorption purification tank, a mud discharging electromagnetic valve and an absorbent storage tank. The modularized design is adopted for the whole set of remedying equipment, flexible matching and combining can be performed according to different types of polluted soil to be remedied, and therefore the cost is lowered. The whole set of equipment can be installed on a trailer to achieve moving operation. The equipment has the multiple remedying functions of thermal desorption treatment, chemical oxidation / restoration, chemical drip washing and others, can achieve in-place position-changing combined remedying on soil containing organic pollutants and heavy metal combined pollution, and is high in remedying efficiency, wide in range, free of harmful gas emissions, safe and environmentally friendly.

Owner:南京康地环保科技有限公司

Novel process for recycling acid and base from viscose sodium sulfate waste liquid by using a bipolar membrane electrodialysis method

InactiveCN103341320AExtended service lifeImprove yield and qualitySemi-permeable membranesPolypropyleneActivated carbon

The invention discloses a novel process for recycling acid and base from viscose sodium sulfate waste liquid by using a bipolar membrane electrodialysis method. The novel process is characterized by sequentially comprising the following steps of crystallizing, regulating pH, carrying out primary prefiltration, oxidizing reducing substances by utilizing O3, carrying out secondary prefiltration, removing organic matters by utilizing activated carbon, removing zinc ions by utilizing ion exchange resin, carrying out filtering and refined filtration by utilizing pp (polypropylene) micropores, and preparing and concentrating the acid and the base. According to the novel process, the recycling rates of the acid and the base in the viscose waste liquid are improved, the damage of a bipolar membrane caused by impurities of the waste liquid is reduced, the service life of the bipolar membrane is prolonged, and the smooth operation of bipolar membrane electrodialysis and subsequent processes can be guaranteed.

Owner:宜宾海翔化工有限责任公司 +2

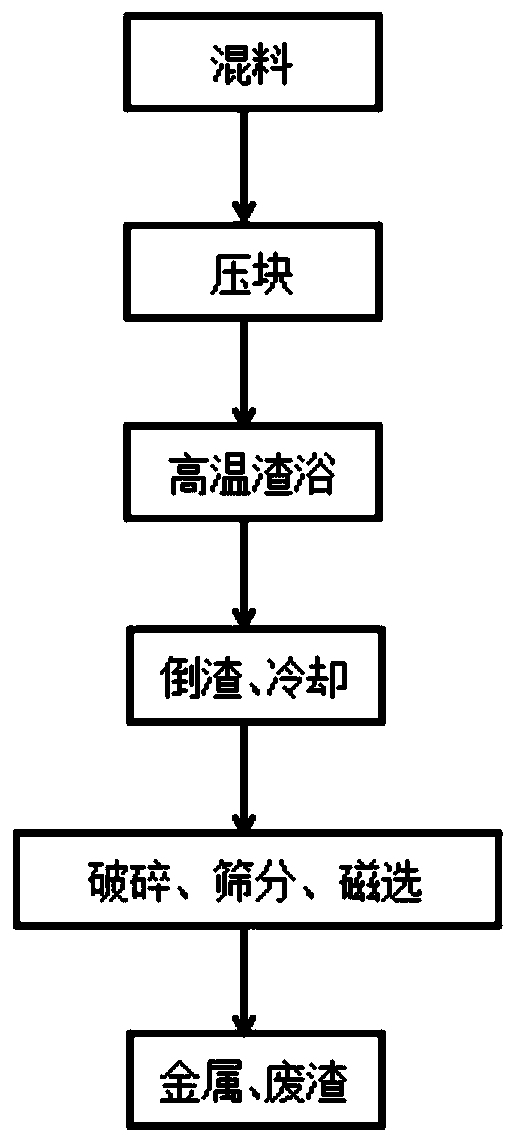

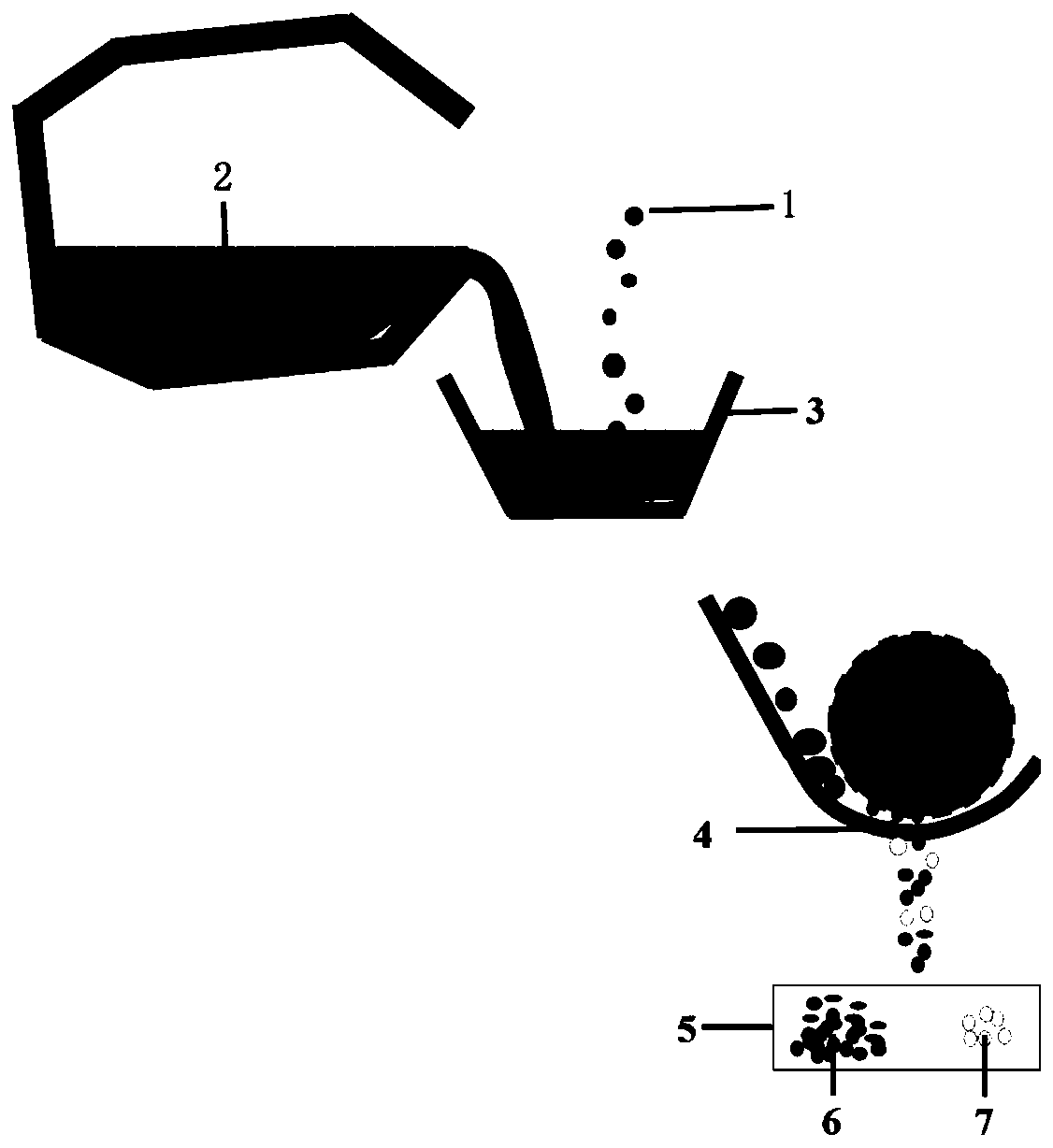

Method for treating Cr-containing pickling sludge in slag bath

InactiveCN109943726AComplete restoration and detoxificationRealize online recyclingProcess efficiency improvementSteelmakingSludge

The invention discloses a method for treating Cr-containing pickling sludge in a slag bath. The method comprises the following steps: 1, adding a reducing agent and lime into the Cr-containing pickling sludge, and fully mixing; 2, pressing the mixed materials into balls by a ball pressing machine, and drying the balls; 3, throwing the dried sludge balls into high-temperature metallurgical slag forreaction; and 4, and after cooling the molten slag, crushing, screening, performing magnetic separation to separate and recover metal particles. Under the process condition of the method, the high-temperature metallurgical slag is utilized to fully reduce and detoxify the Cr-containing pickling sludge by fixing most of sulfur elements in slag phase, secondary discharge is avoided in the process,valuable metal elements such as Cr / Fe are fully reduced to the metal phase, and the valuable metal elements are separated and recovered through the magnetic separation. The method is simple to operate, and can be operated in an original steelmaking process with no secondary discharge, so that on-line recycling and source emission reduction of the Cr-containing pickling sludge are achieved.

Owner:UNIV OF SCI & TECH BEIJING

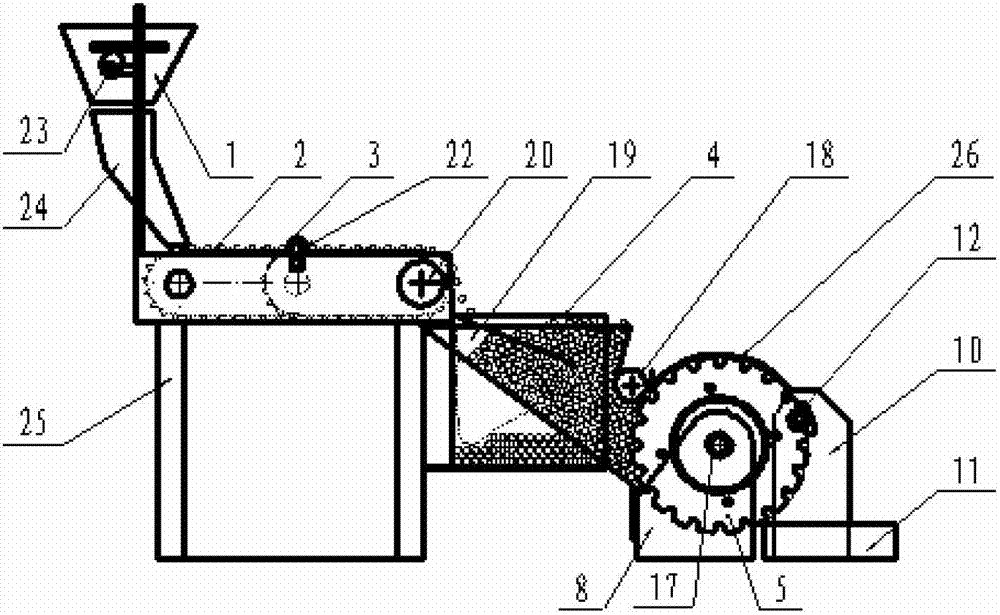

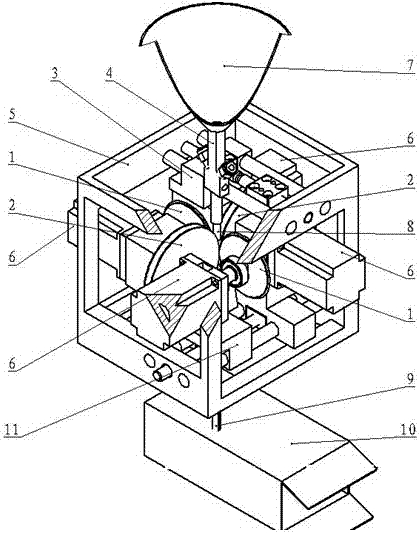

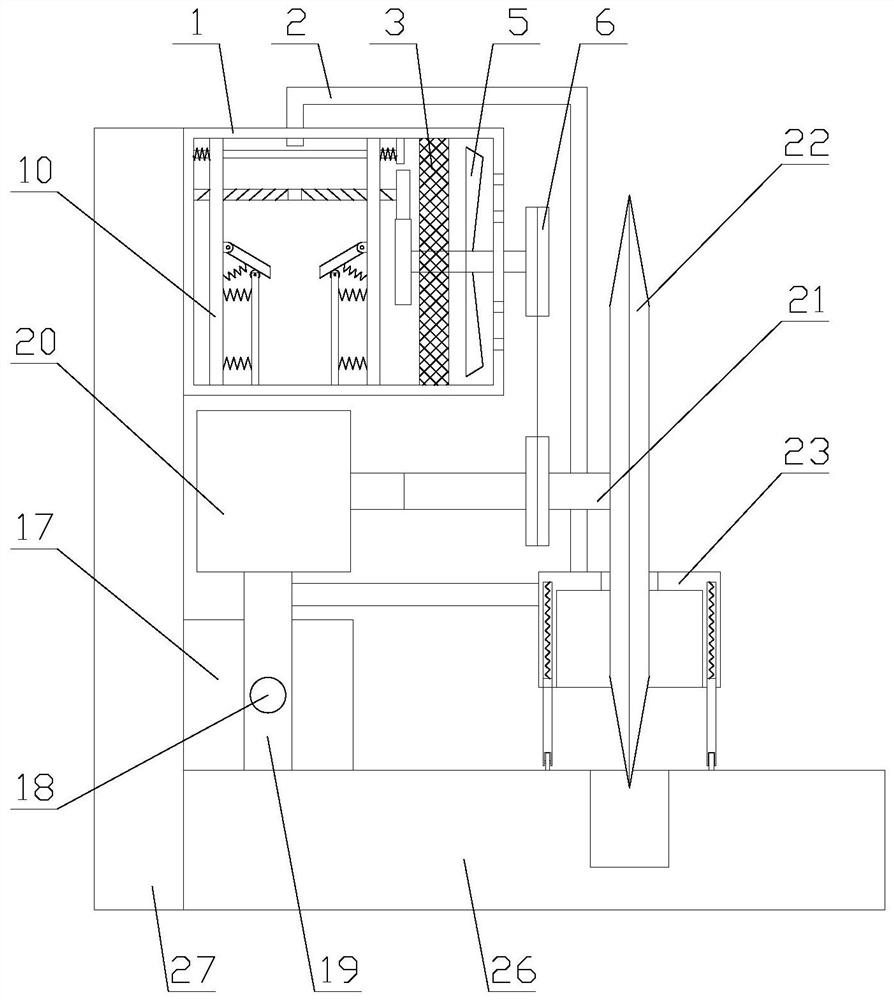

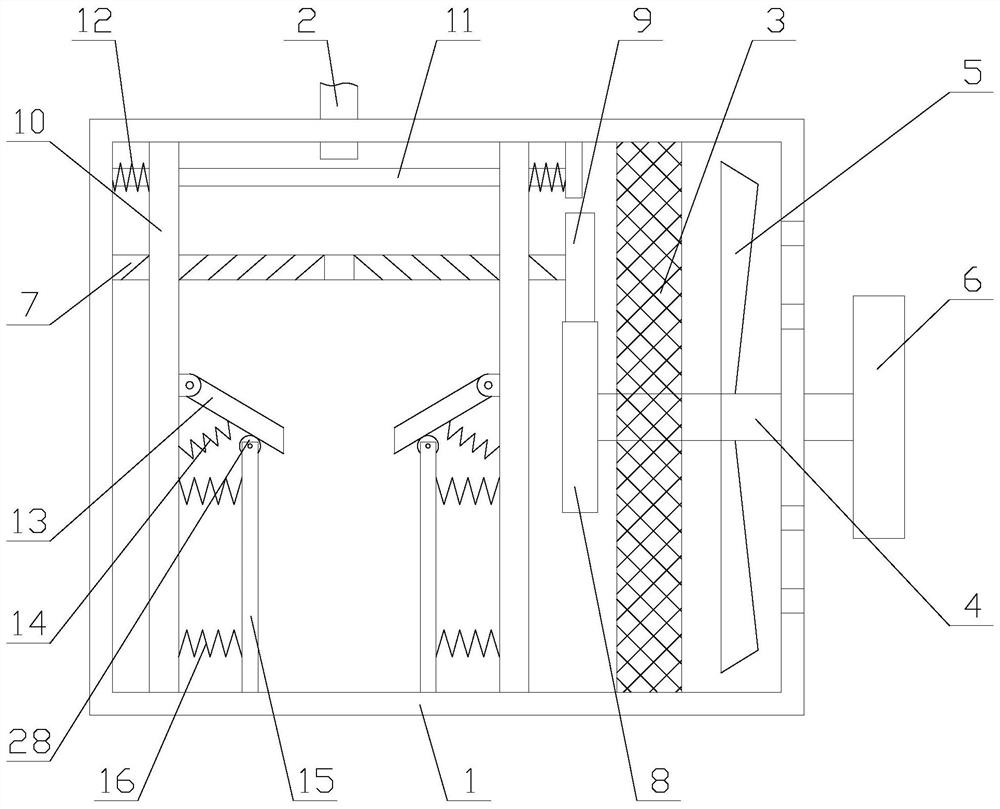

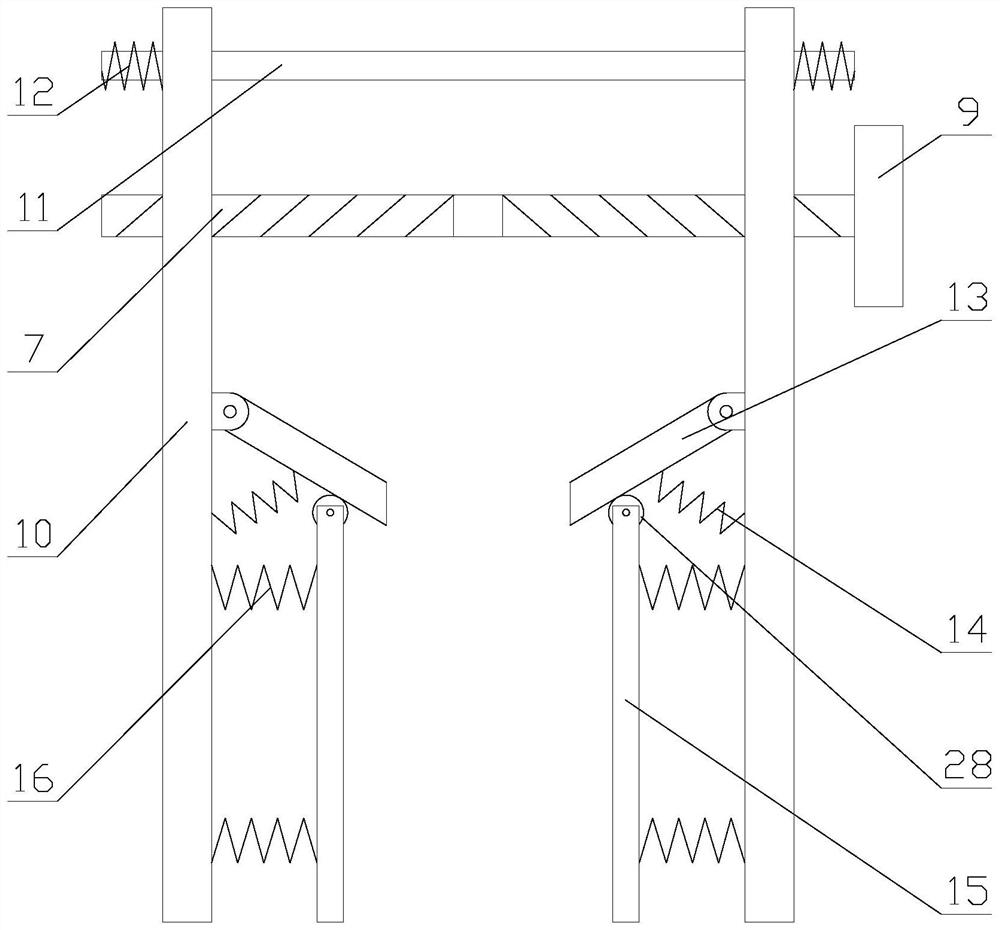

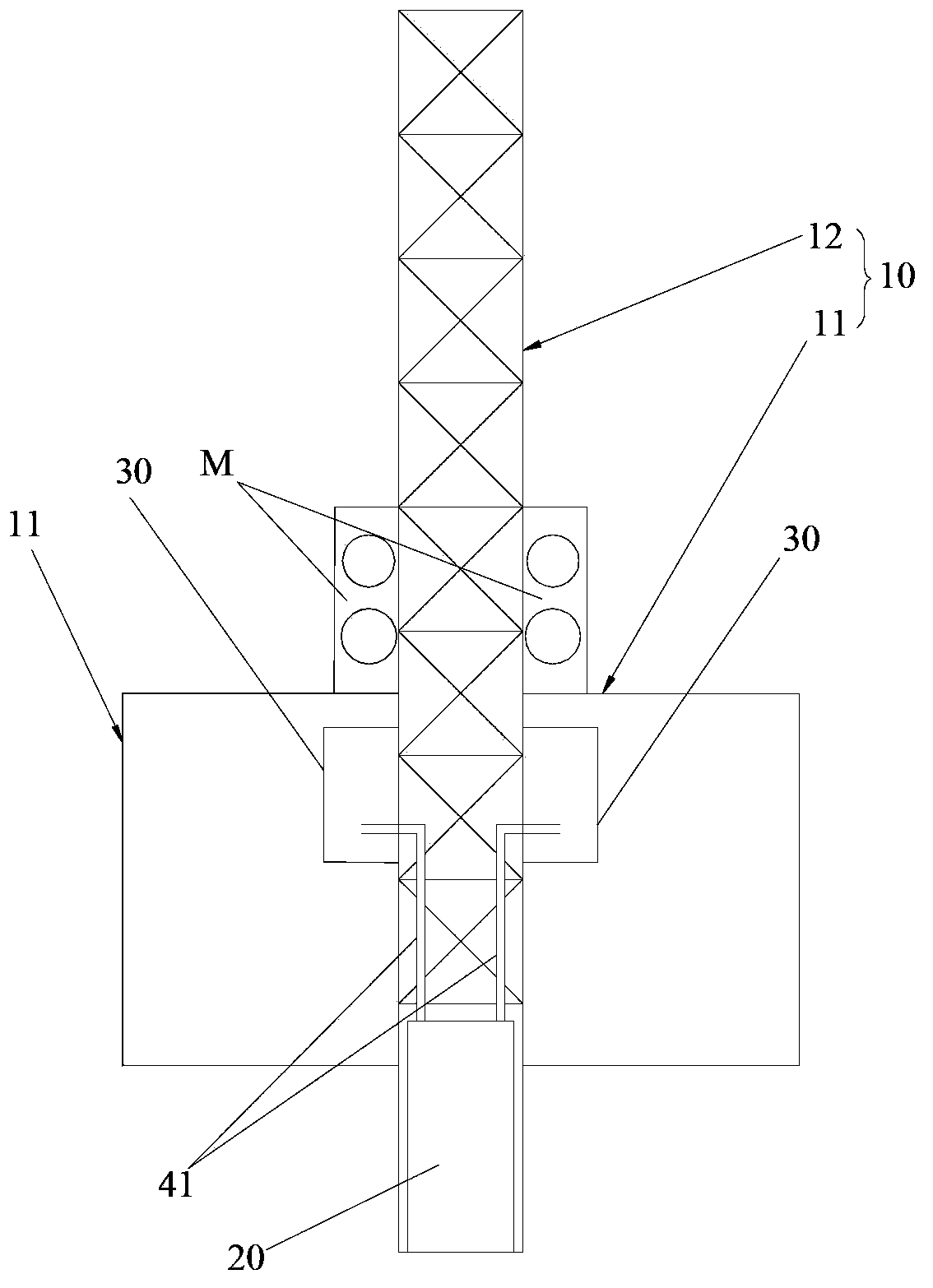

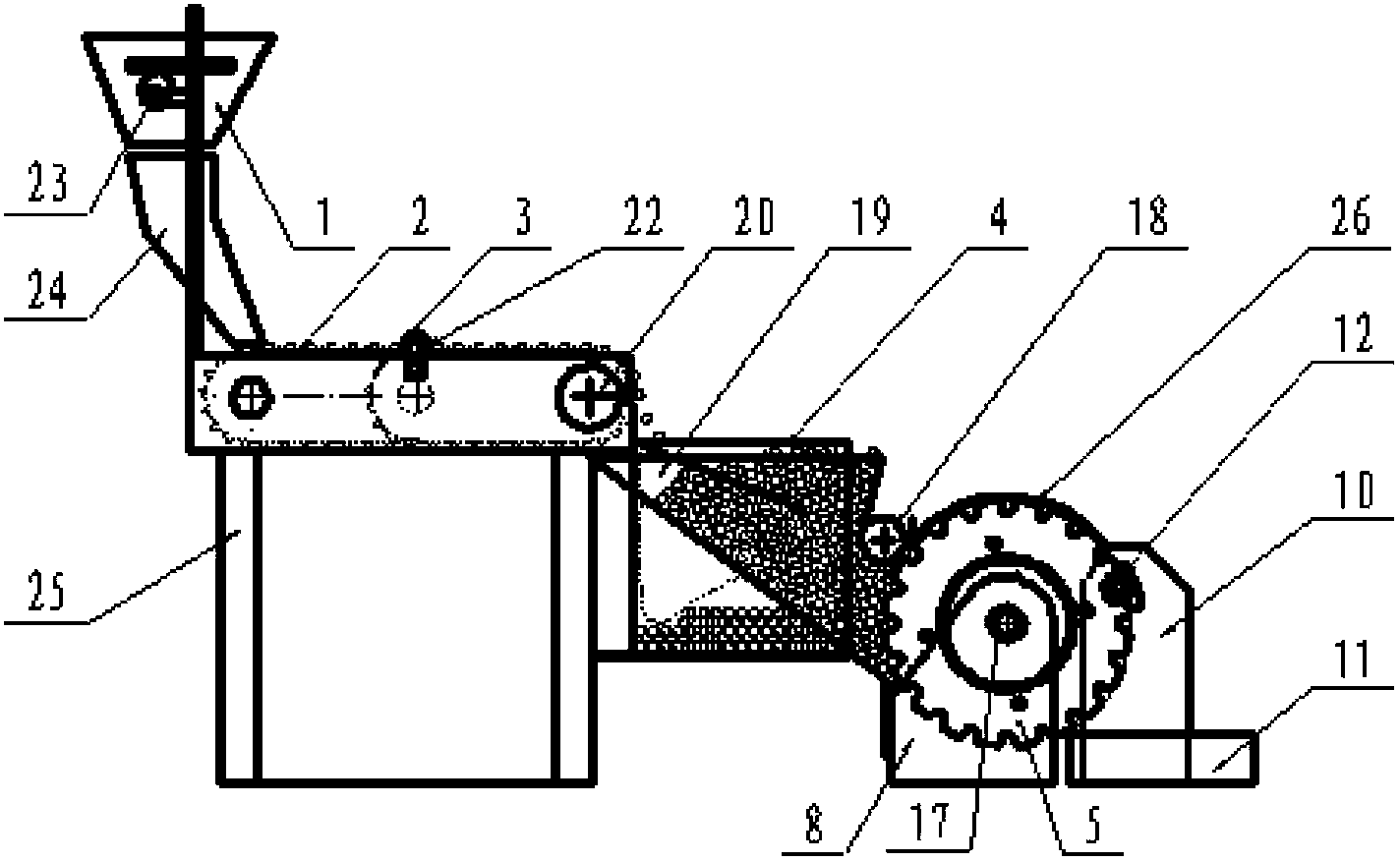

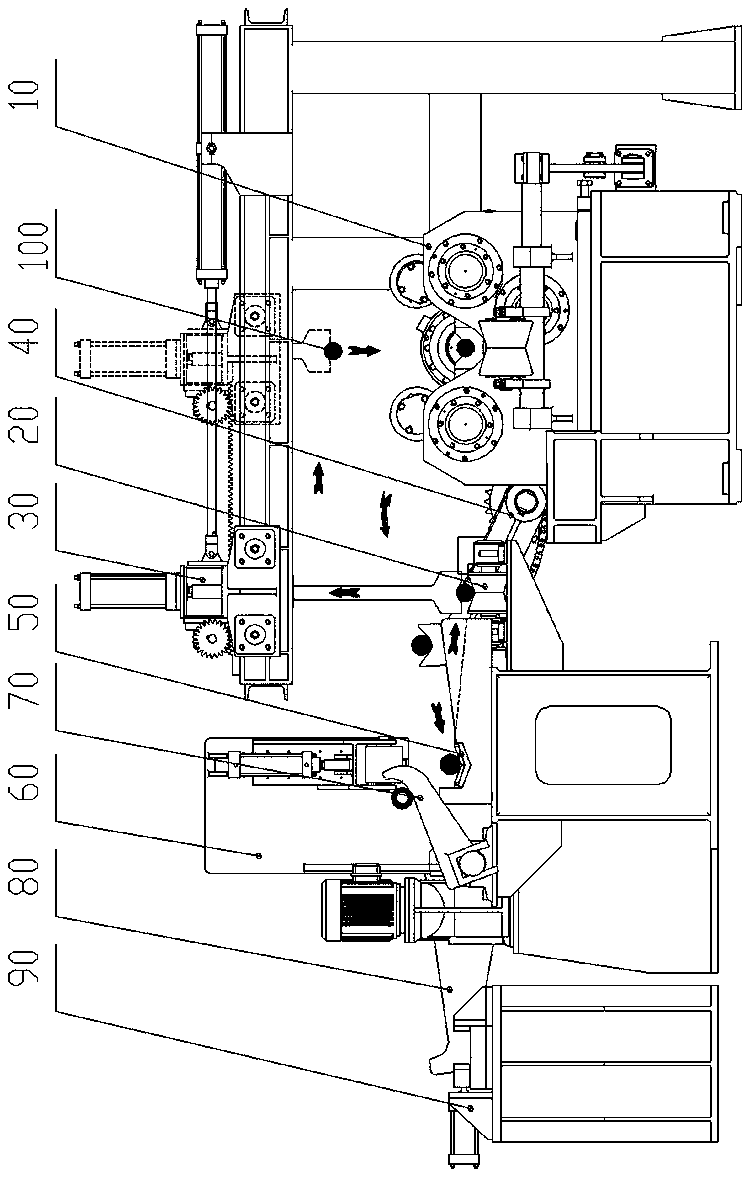

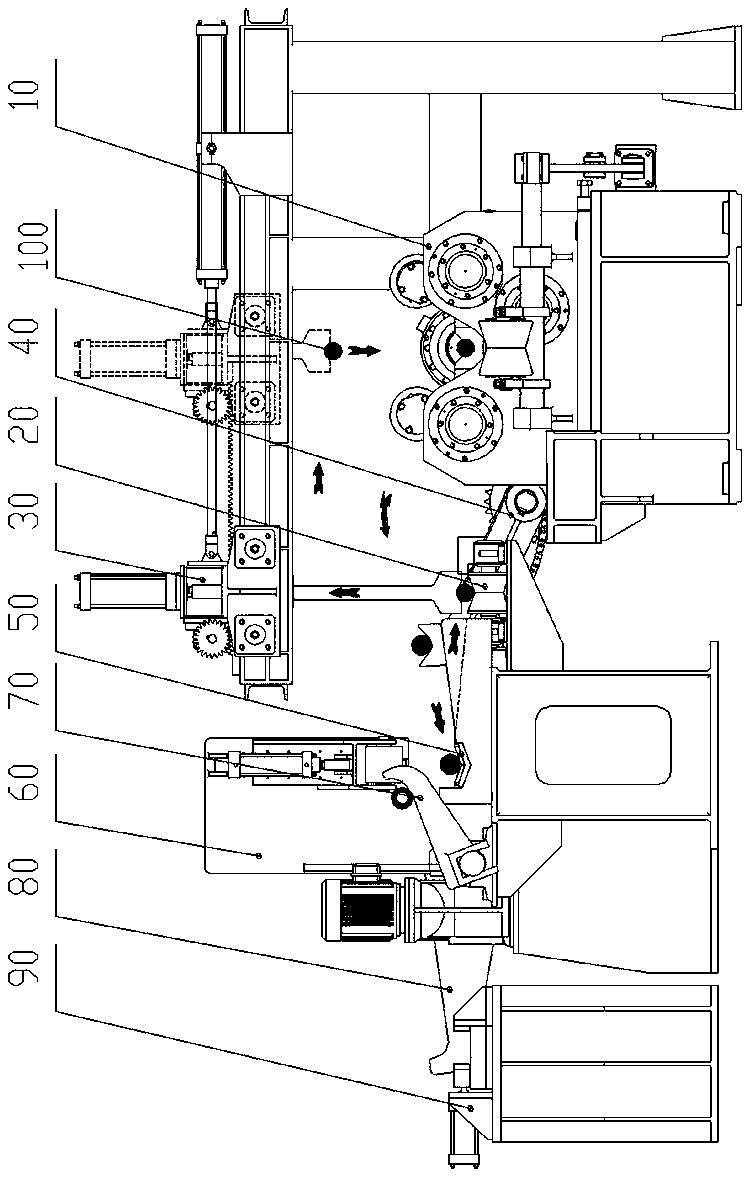

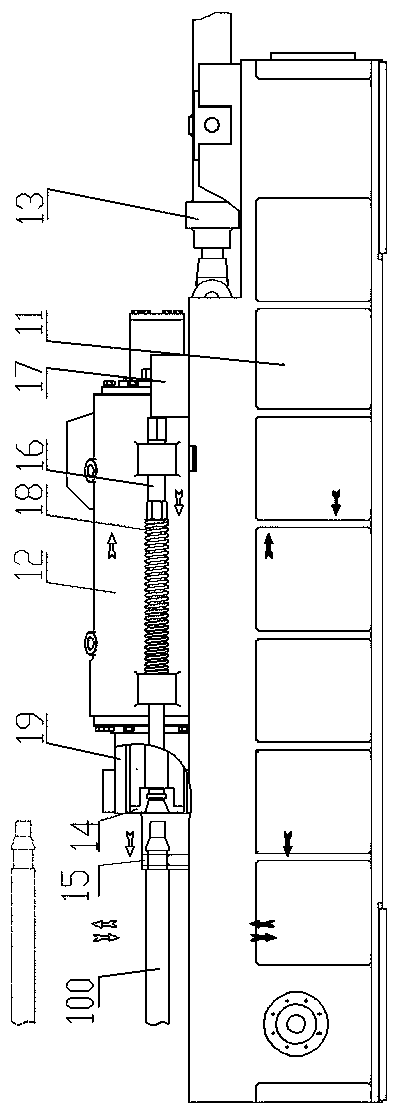

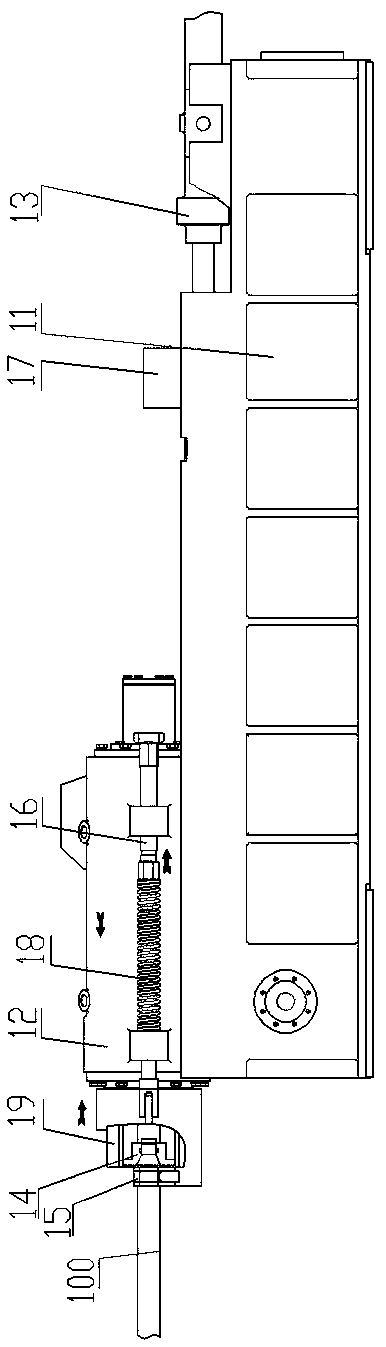

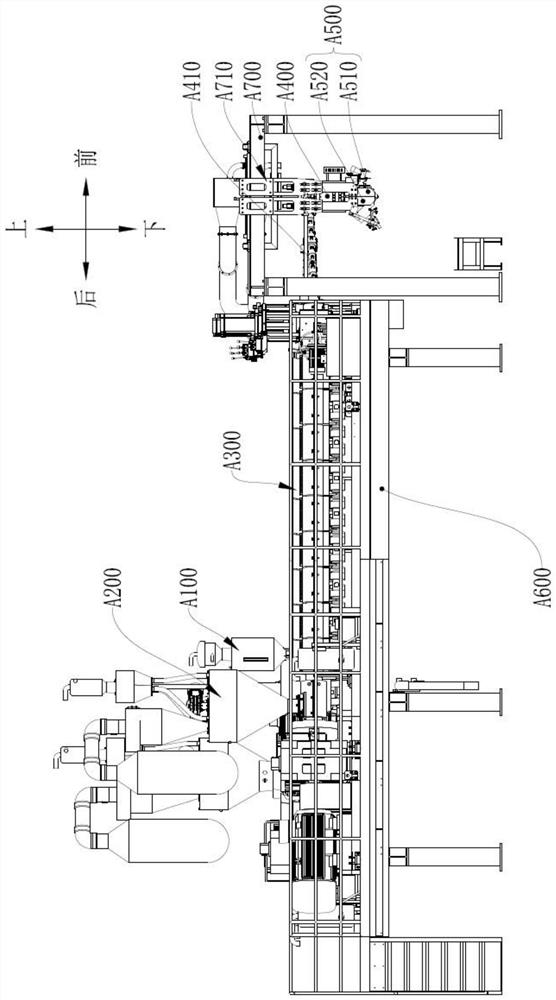

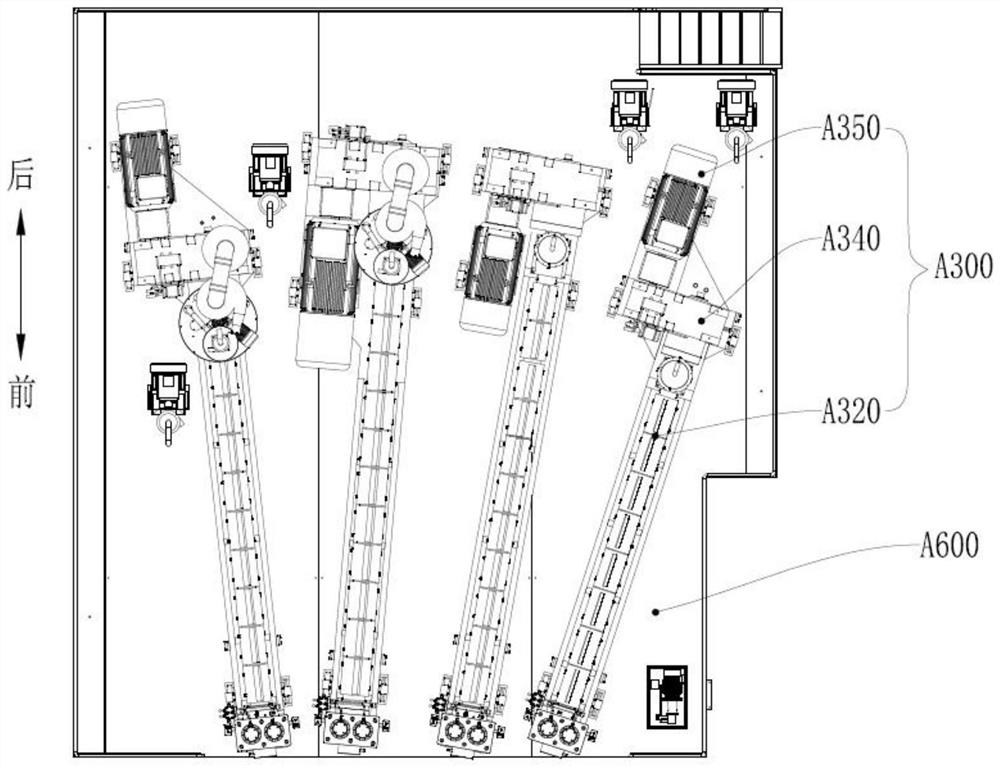

Imperfect cigarette collating and tobacco shred recycling integrated equipment

The invention discloses imperfect cigarette collating and tobacco shred recycling integrated equipment which is special equipment of a cigarette making machine. Difficult technical problems in aspects of continuously recycling and treating serviceable tobacco shreds of imperfect cigarettes in an online manner and directly utilizing the serviceable tobacco shreds are solved by the imperfect cigarette collating and tobacco shred recycling integrated equipment. The technical scheme includes that the imperfect cigarette collating and tobacco shred recycling integrated equipment comprises a vibratory charging bin (1), a cigarette collating device, a supply bin (19), a gear (5) with teeth, a pressing piece (12), a retractable blowing nozzle (13), a tobacco shred collecting hopper (10) and a waste collecting hopper (11). The imperfect cigarette collating and tobacco shred recycling integrated equipment has the advantages that the integrated equipment can be directly used for recycling and treating imperfect cigarettes in an online manner, paper tubes, filter tips and tobacco shreds are perfectly separated from one another and are respectively recycled and treated, and an effect is excellent.

Owner:KUNMING LEIEN SCI & TECH

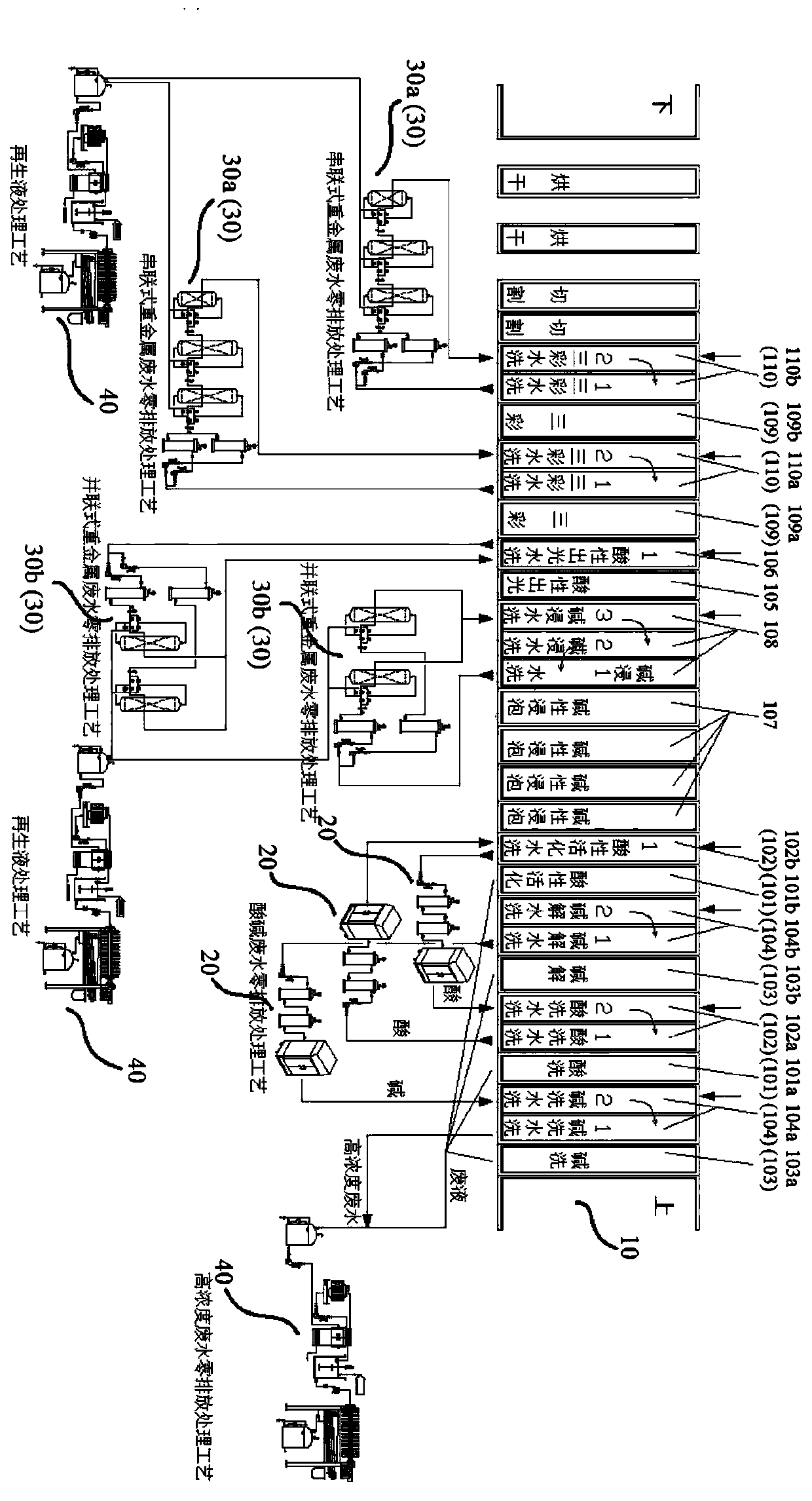

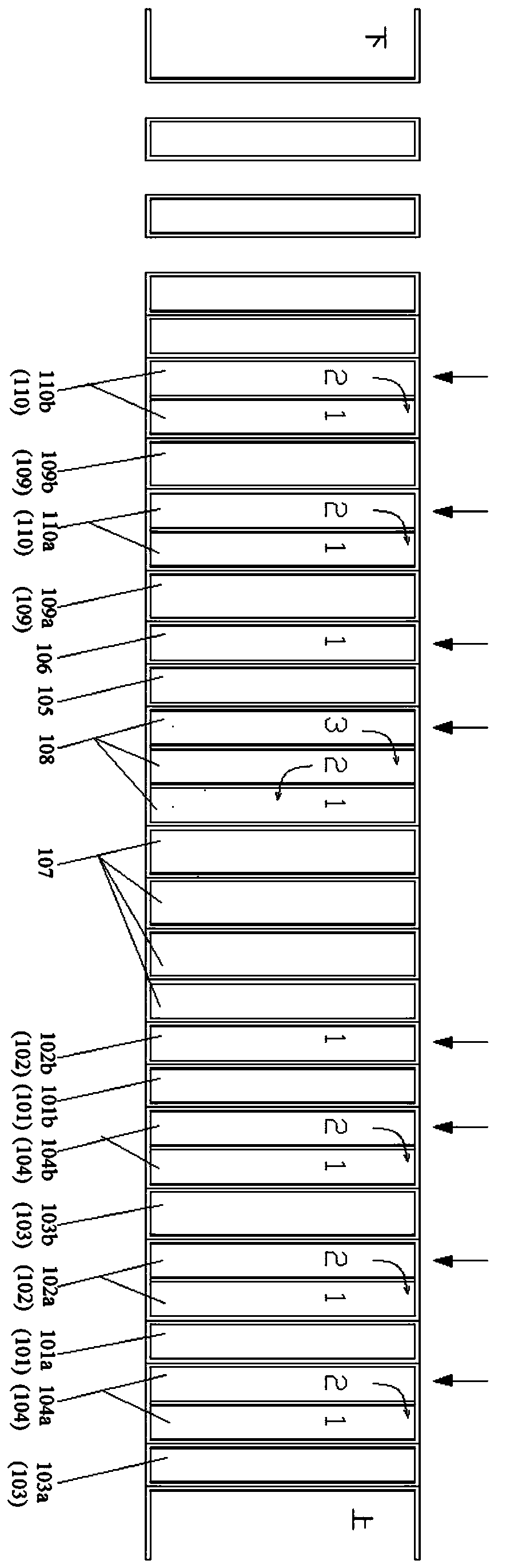

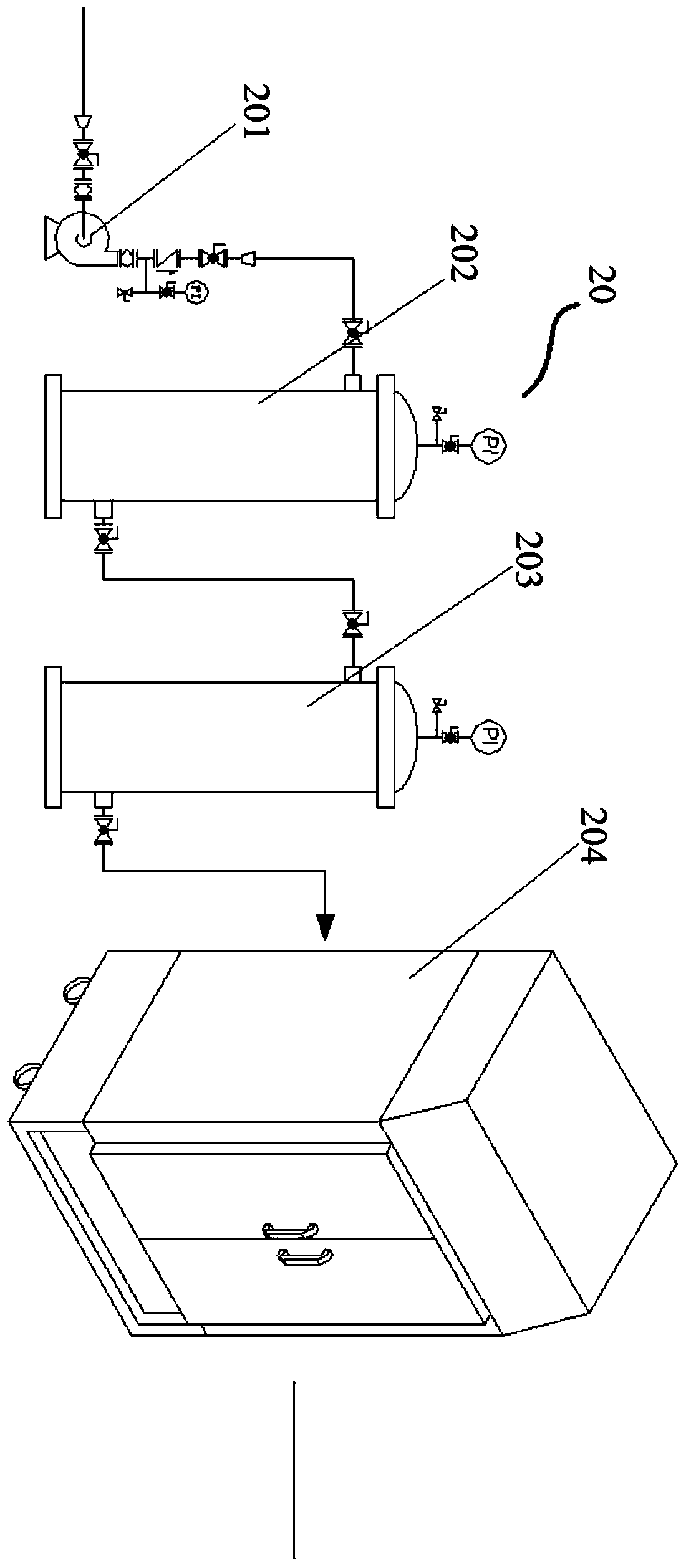

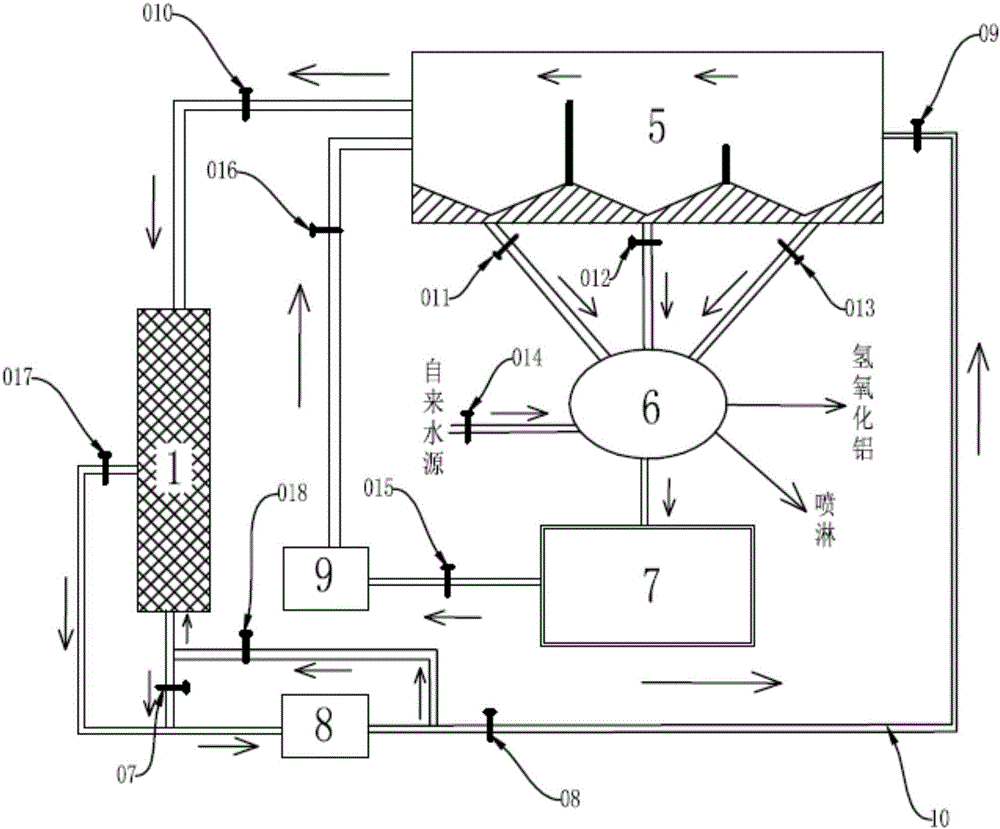

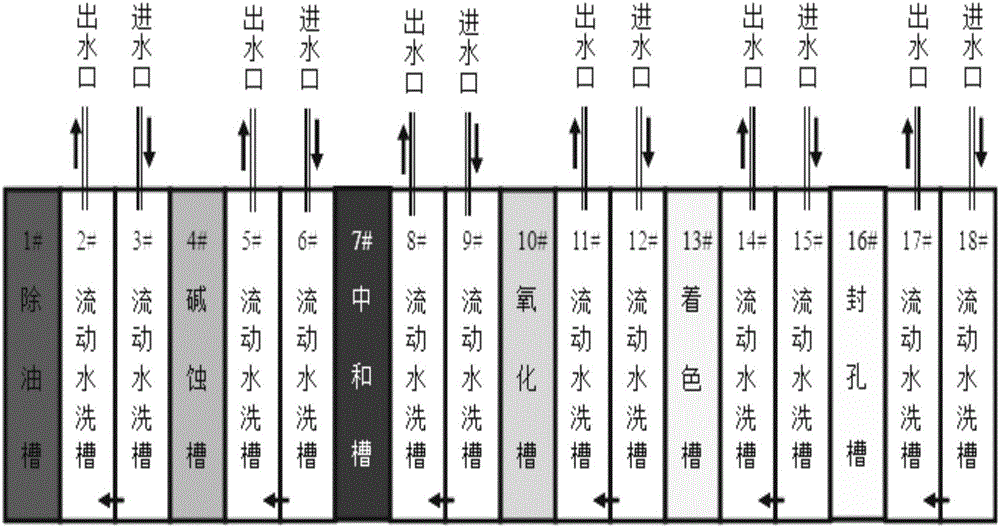

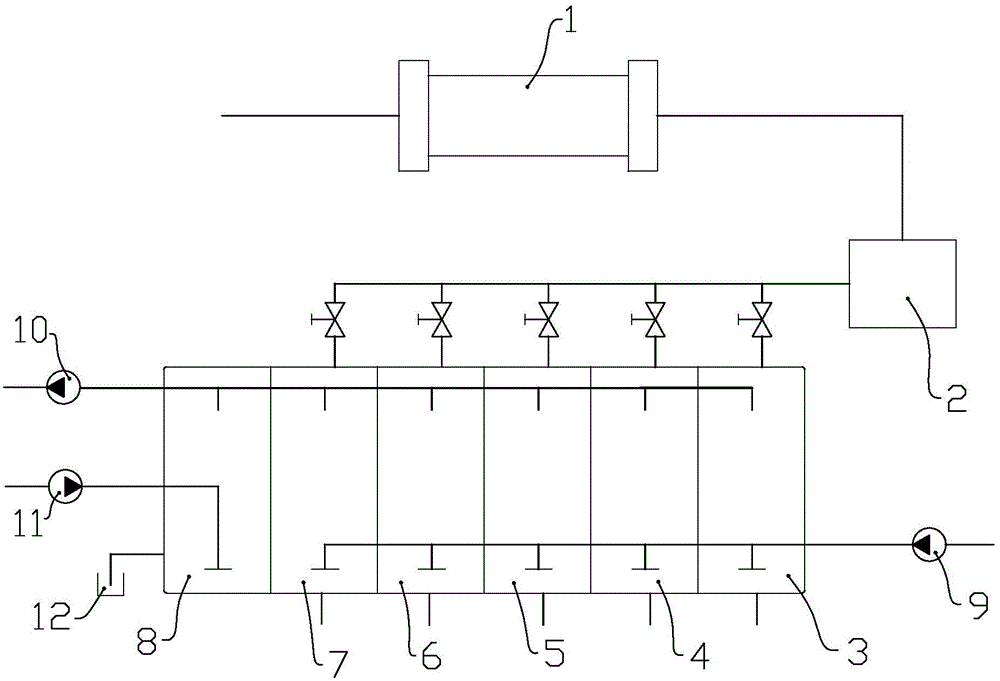

Zero-discharge recycling treatment process for wastewater and waste liquid on surface chemical treatment process line

ActiveCN111533315AEmission reductionRealize online recyclingFatty/oily/floating substances removal devicesTreatment involving filtrationHazardous substanceWastewater

The invention discloses an online wastewater recycling zero-emission treatment process for various water systems of a surface chemical equipment line. The process mainly comprises an acid-base wastewater zero-discharge treatment process, a heavy metal wastewater zero-discharge treatment process, a regenerated liquid treatment process and a high-concentration wastewater zero-discharge treatment process. The process is based on the types and contents of harmful substances in waste water and waste liquid generated in each process stage. The process comprises the following steps: treating waste water and waste liquid generated in each stage of a manufacturing process by adopting different treatment processes, treating acidic or alkaline waste water and waste liquid in the manufacturing processby utilizing an acid-base waste water zero-discharge treatment process to realize online recycling of the acidic or alkaline waste water and waste liquid, and treating by utilizing a high-concentration waste water zero-discharge treatment process to realize zero emission; the heavy metal wastewater zero-discharge treatment process is used for treating wastewater and waste liquid containing heavymetal components to realize on-line recycling of the wastewater and the waste liquid, and the discharge amount of the wastewater and the waste liquid is greatly reduced after the wastewater and the waste liquid are treated by the regenerated liquid treatment process.

Owner:昆山水立净环保节能科技有限公司

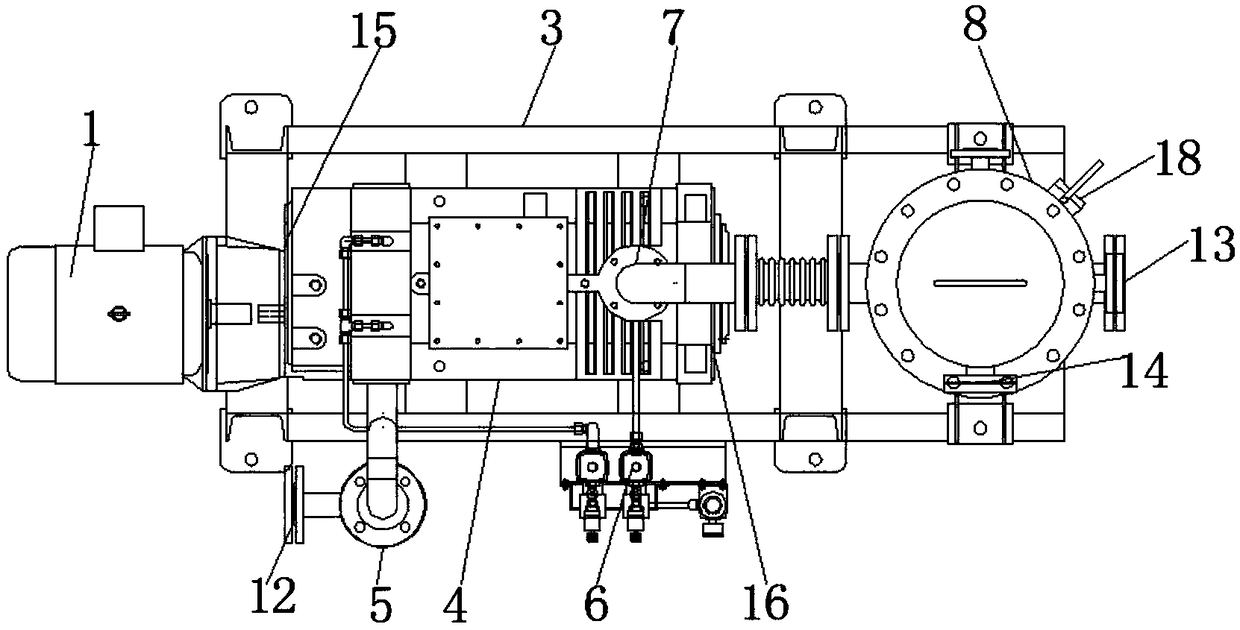

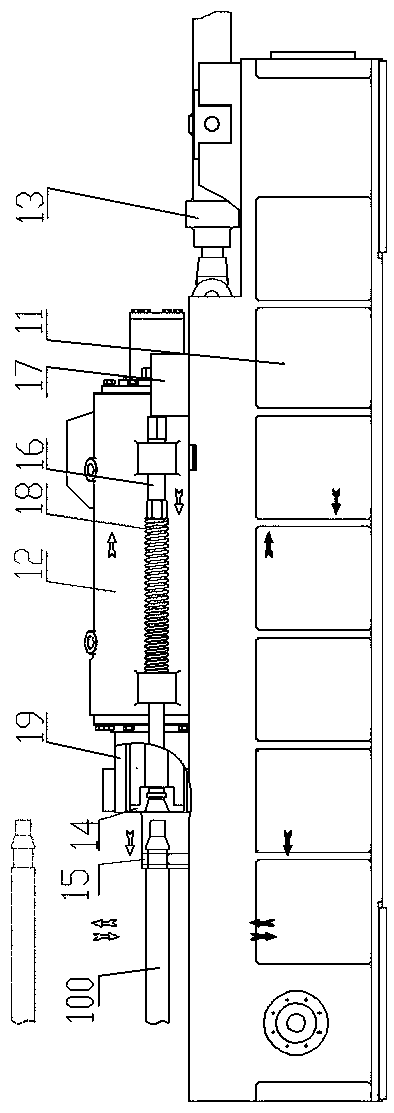

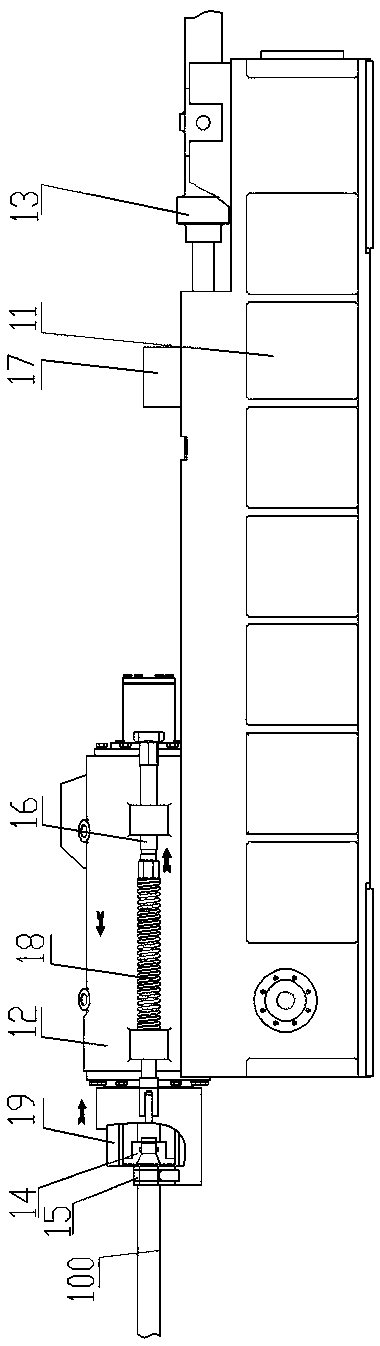

Defective cigarette cutting and recycling tobacco shreds equipment

ActiveCN105495679BCleanliness is unaffectedSimple structureCigarette manufactureProduction lineDrive motor

The invention discloses equipment for recycling tobacco shreds through sectioning processing conducted on defective cigarettes and solves the technical problem of online recycling processing for direct application of the defective cigarettes, wherein the equipment is special auxiliary equipment for cigarette production. According to the technical scheme, a defective cigarette collecting and conveying device (7) is arranged at the top of a master support (5), a cigarette air pressure conveying device (4) is connected below the defective cigarette collecting and conveying device (7), a bicircular cutting knife (1) and a bicircular clamping roller (2) are arranged at an outlet in a corresponding mode, the rear end of the bicircular cutting knife (1) and the rear end of the bicircular clamping roller (2) are each independently linked with a driving motor (6), a bicircular cutting knife center distance position adjusting device (3) is installed in the middle of the master support, a bicircular clamping roller center distance position adjusting device (11) is installed at the bottom of the master support, and a vibrating and separating stock bin (10) are connected to the lower portion of the master support. The equipment can be used for directly processing the defective cigarettes on the production line, the recycled tobacco shreds are utilized directly, efficiency is high, the yield is high, and the cigarettes of different specifications can be processed in a self-adaptation mode.

Owner:KUNMING LEIEN SCI & TECH

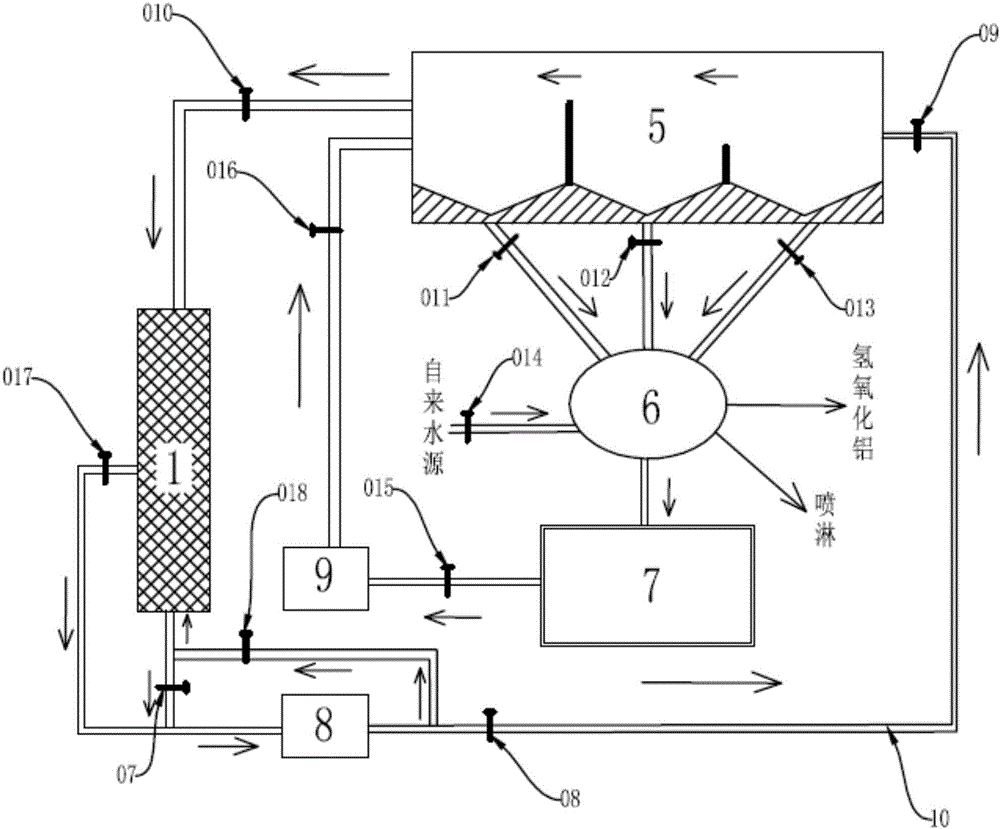

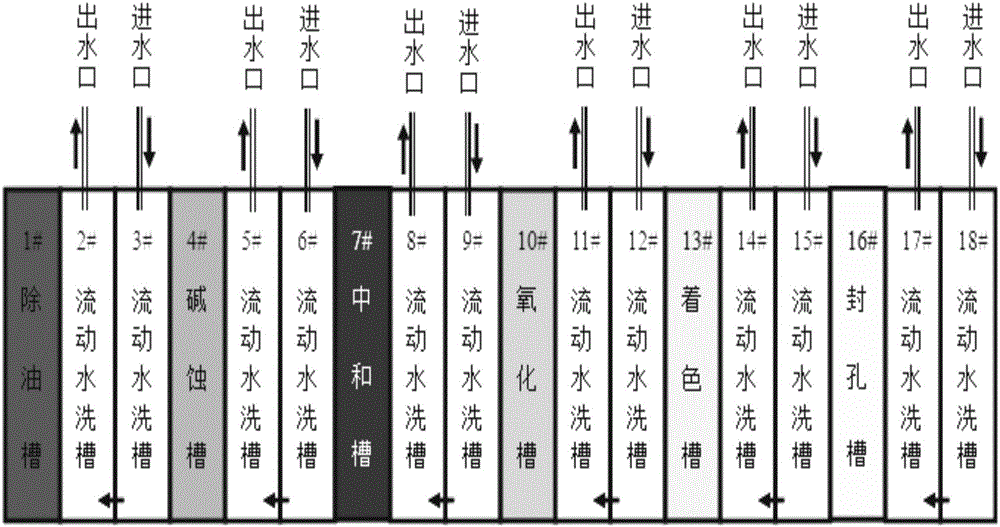

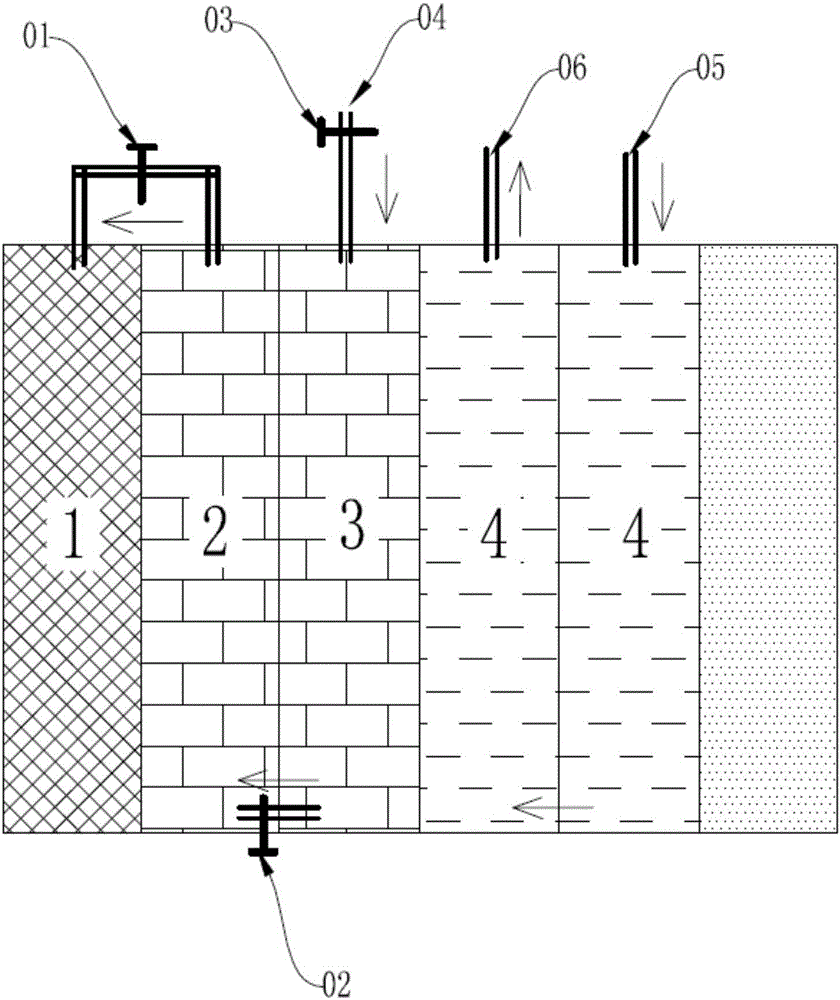

Aluminum pretreatment alkaline three-in-one, alkaline liquor regeneration and aluminum hydroxide online recycling process

ActiveCN106757268AFull recoveryReduce processing costsSurface reaction electrolytic coatingWater savingSlag

The invention provides an aluminum pretreatment alkaline three-in-one, alkaline liquor regeneration and aluminum hydroxide online recycling process. A medicament recycling system and two flowing washing tanks are included. The medicament recycling system comprises an alkaline three-in-one grinding tank and a non-flowing washing tank sub system; the a non-flowing washing tank sub system is arranged to be in reverse series-connection with the alkaline three-in-one grinding tank through a first valve; the non-flowing washing tank sub system comprises a first non-flowing washing tank body and a second non-flowing washing tank body which are arranged to be in reverse series-connection with each other, and the start end of the second non-flowing washing tank body is furthermore provided with a water supplementing opening and a third valve in the water flowing direction; and the two flowing washing tanks are arranged to be in reverse series-connection, the start end is provided with a water inlet in the water flowing direction, and a water outlet in the final end is connected with the water supplementing opening of the second non-flowing washing tank body. The aluminum pretreatment alkaline three-in-one, alkaline liquor regeneration and aluminum hydroxide online recycling process proposed by the invention has the advantages that zero discharging of waste water is achieved, waste slag is reduced, chemical consumption is low, water is saved, blocking caused by scaling is avoided, and online recycling of alkaline liquor and aluminum hydroxide is achieved.

Owner:FOSHAN SANSHUI XIONGYING INNOVATION CENT FOR ALUMINUM SURFACE TECH

Alkaline three-in-one grinding process capable of integrating pretreatment of aluminum with on-line recycle of aluminum hydroxide

ActiveCN106367791AFull recoveryReduce processing costsSurface reaction electrolytic coatingAluminium hydroxideEngineering

The invention discloses an alkaline three-in-one grinding process capable of integrating pretreatment of aluminum with on-line recycle of aluminum hydroxide. The process comprises a medicament recycling system and two flowing water washing tanks, wherein the medicament recycling system comprise an alkaline three-in-one grinding tank and a stagnant water washing tank subsystem which are connected in series oppositely; the liquid in the alkaline three-in-one grinding tank is alkaline liquid and contains sodium nitrate of which the concentration is 40g / L to 80g / L; the ratio of the concentration of sodium nitrate to the concentration of free alkali is equal to 1; the stagnant water washing tank subsystem comprises a first stagnant water washing tank and a second stagnant water washing tank which are connected in series oppositely; the start end, along the water flowing direction, of the second stagnant water washing tank is also provided with a water replenishing hole and a third valve; the two flowing water washing tanks are connected in series oppositely. The alkaline three-in-one grinding process capable of integrating pretreatment of aluminum with on-line recycle of aluminum hydroxide, disclosed by the invention, has the characteristics that the aluminum alloy surface quality is improved, a grinded surface is uniform and smooth, grains are grinded completely, few industrial waste residues are generated, medicament consumption is low, scale formation and blocking are prevented, on-line recycle of the alkaline liquid and the aluminum hydroxide is realized and the like.

Owner:FOSHAN SANSHUI XIONGYING INNOVATION CENT FOR ALUMINUM SURFACE TECH

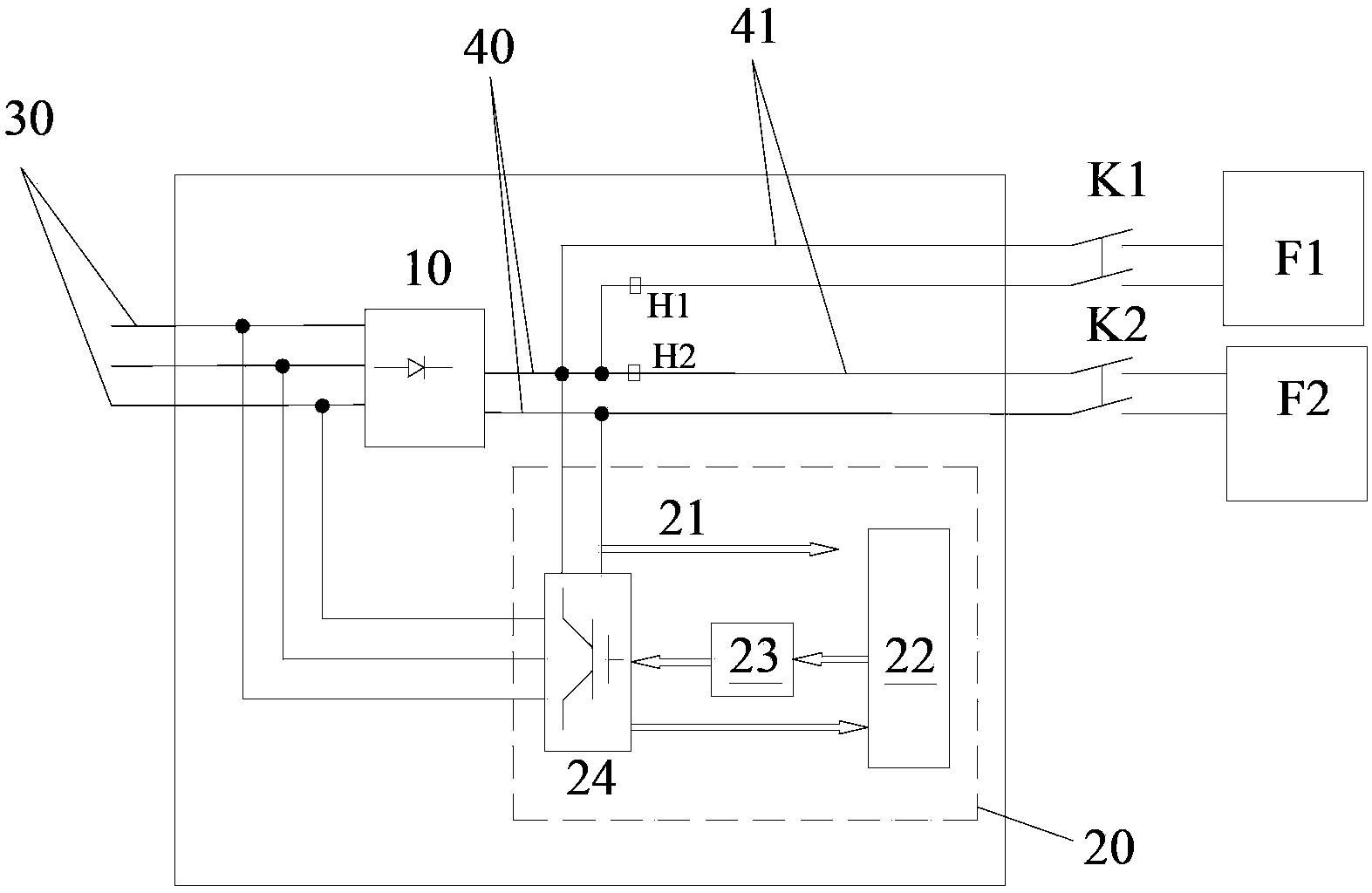

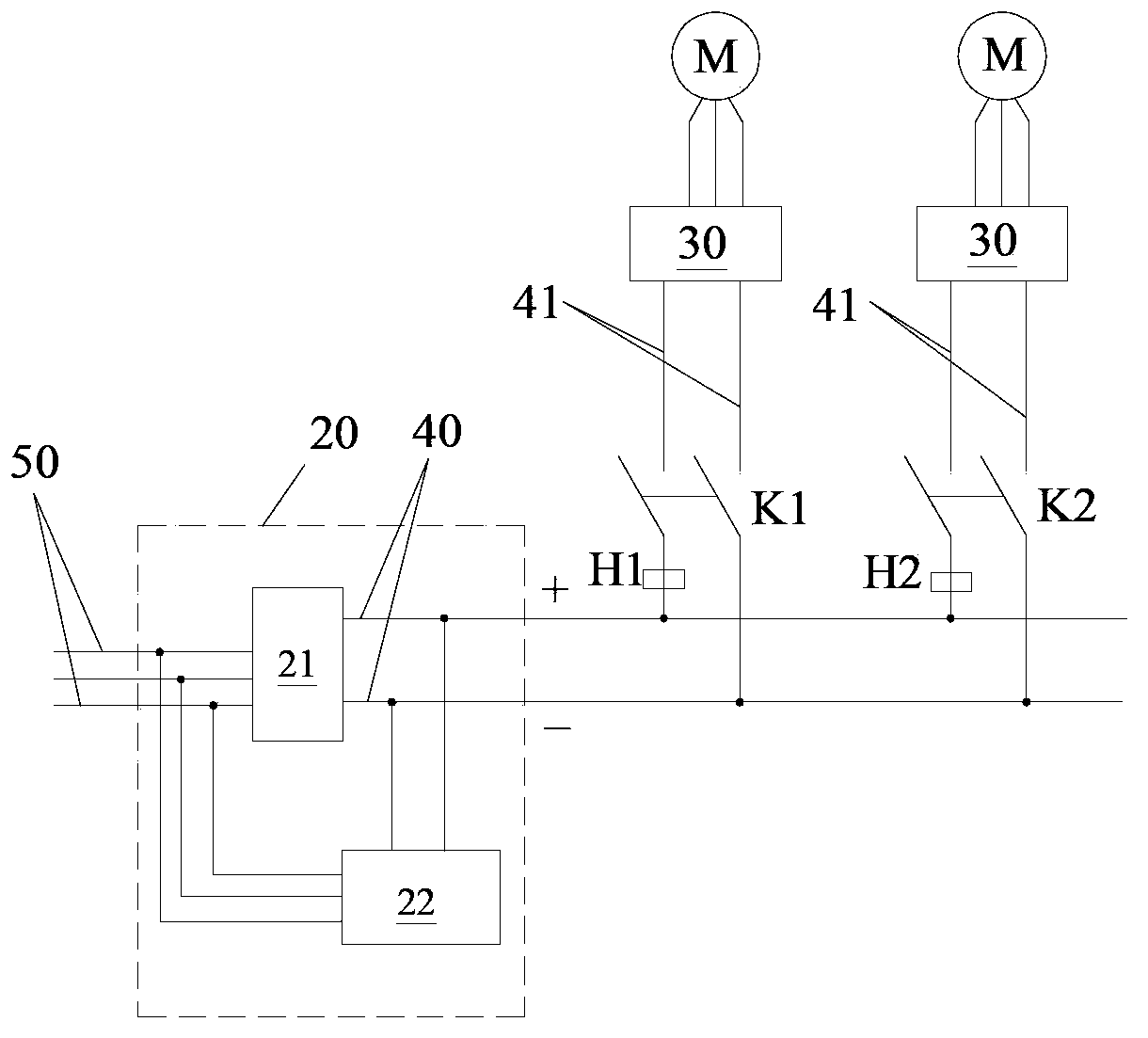

Rectified feedback circuit

ActiveCN103368206AImprove energy efficiencyGuaranteed stabilitySingle network parallel feeding arrangementsEnergy feedbackSpeed control system

The invention discloses a rectified feedback circuit used for a variable-frequency speed control system. The rectified feedback circuit comprises a rectifying circuit and an energy feedback circuit. The rectifying circuit is used for converting an alternating current of an input power grid into a direct current and outputting the direct current to a direct current bus supplying electricity to the variable-frequency speed control system. The energy feedback circuit is used for feeding redundant electric energy on the direct current bus back to the input power grid. According to the rectified feedback circuit, the direct current bus on the output side of the rectifying circuit is connected with the input power grid on the input side of the rectifying circuit through the energy feedback circuit, regeneration energy produced when the variable-frequency speed control system with the electricity supplied by the direct current bus is under the condition of passive operation is fed back to the input power grid through the energy feedback circuit, accordingly, the regeneration energy is recycled on line, the energy-saving efficiency of the whole system is improved, and the stability of direct current supplying voltage of the variable-frequency speed control system is guaranteed.

Owner:湖南建科鼎智能科技有限公司

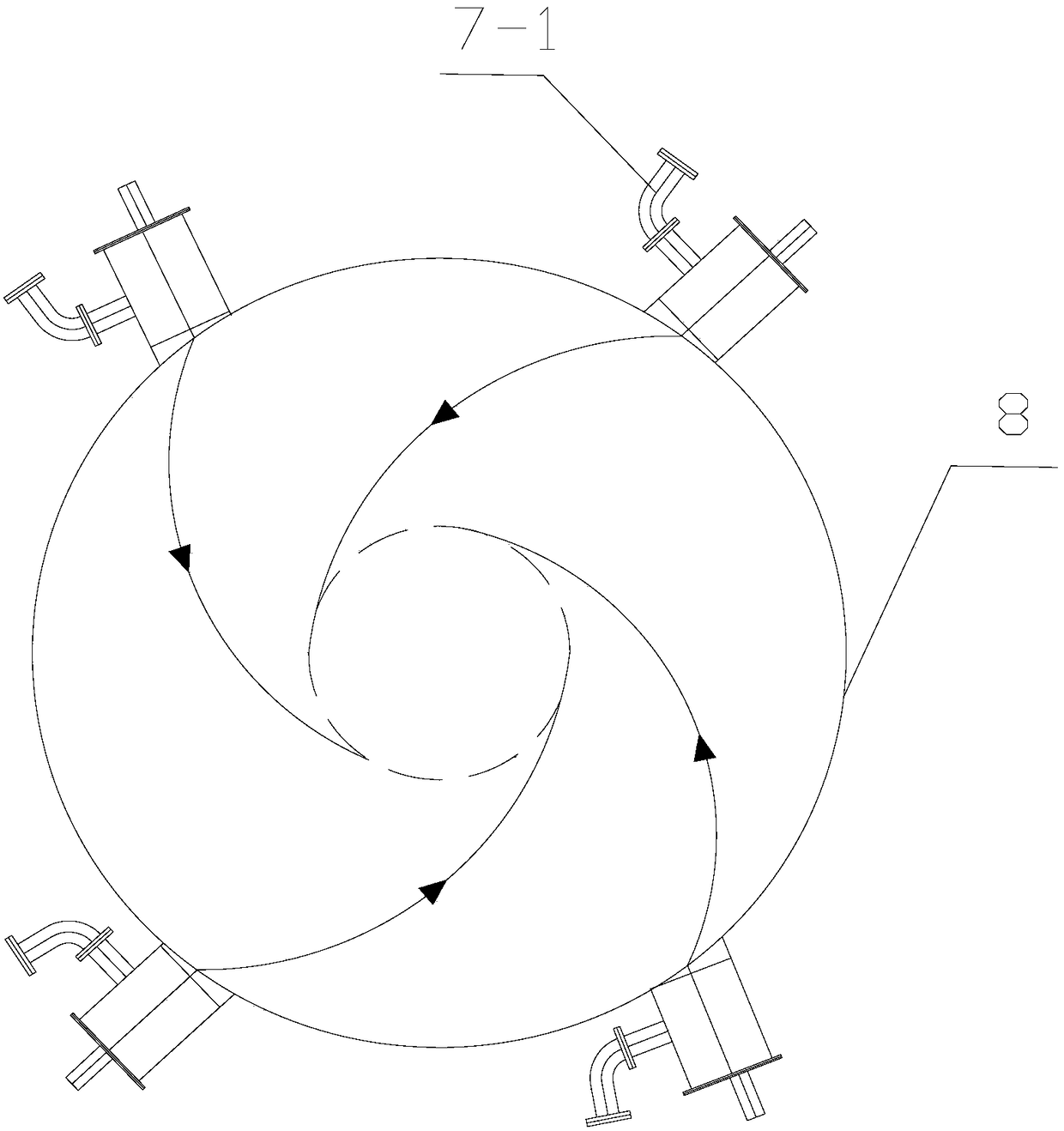

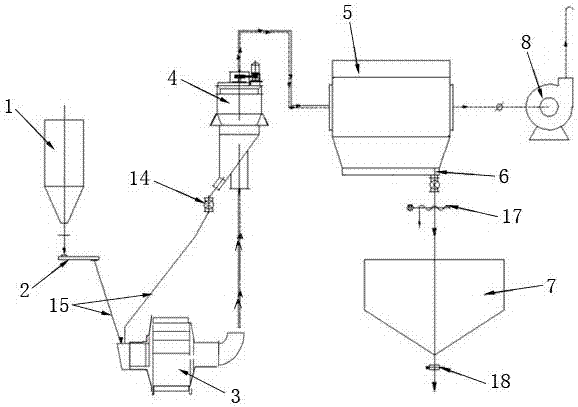

Method and device for treating organic waste gas with on-line circulation regeneration

ActiveCN105944503BIncrease the range of motionExtended stayDispersed particle separationCycloneDesorption

An online cyclic regeneration organic waste gas treatment method and device. The device comprises a cyclone tower (8), a liquid storage tank (4), a settling tank (10), a biological desorption chamber (5), and a storage chamber (9) disposed at one side of the biological desorption chamber (5). The bottom of the cyclone tower (8) is connected with the settling tank (10) by means of a pipeline; a centrifugal pump is disposed at the bottom of the settling tank (10), and adsorbent particle pellets (5-1) having a micropore structure in the settling tank are delivered to the biological desorption chamber (5) by the centrifugal pump; a plurality of cyclone atomizing nozzles (7) arranged in circle of contact is distributed at the circumferential wall of the lower side of the cyclone tower (8) at intervals; an organic absorbent solution, desorbed adsorbent particle pellets (5-1), and organic waste gas are ejected into the cyclone tower (8) by the cyclone atomizing nozzles (7) in a manner of circle of contact and are sufficiently mixed, and flow and spirally rise along the circumferential direction of the inner wall of the cyclone tower (8). The device integrates an adsorption-recycling method, an absorption method, and a biological method into a new device, thus overcoming the defect of conventional purification, achieving online cyclic regeneration of an adsorbent, improving purification efficiency, reducing operating costs, and resolving the problem of low regeneration efficiency of the adsorbent.

Owner:SOUTH CHINA UNIV OF TECH

Hydrocarbon cleaning method and device for preventing copper oxidization

ActiveCN107354475ASolve the greenSolve the blackeningCleaning using liquidsHydrogenMegasonic cleaning

The invention relates to a hydrocarbon cleaning method and device for preventing copper oxidization. According to the hydrocarbon cleaning method for preventing copper oxidization, a cleaning way that a three-layer square basket is compatible with a three-layer rotary drum is adopted, and degassed hydrocarbon ultrasonic cleaning A, degassed hydrocarbon ultrasonic cleaning B, vacuum hydrocarbon ultrasonic cleaning, copper tarnish prevention treatment, vacuum vapor treatment and vacuum drying are sequentially conducted on a copper-containing workpiece. The hydrocarbon cleaning device comprises a degassed ultrasonic cleaning tank A, a degassed ultrasonic cleaning tank B, a vacuum ultrasonic cleaning tank, a protective agent tank, a vacuum vapor cleaning and drying tank, the three-layer square basket and the three-layer rotary drum. By adoption of the hydrocarbon cleaning method for preventing copper oxidization, blanking oil stains on the surface of a part can be effectively removed, and yellow points / yellow spots are avoided after cleaning; and meanwhile, the requirement for cleaning and protecting flat sheet type parts and angled parts can be met, and the one-time checked qualification rate of the cleaned parts is 97%-98%.

Owner:厦门金越电器有限公司

Wood cutting device for furniture manufacturing

InactiveCN113524354ARealize online recyclingSave energyProfiling/shaping machinesBark-zones/chip/dust/waste removalProcess engineeringWood cutting

The invention relates to a wood cutting device for furniture manufacturing. The wood cutting device for furniture manufacturing comprises a support, a cutting mechanism and a recycling mechanism, the cutting mechanism is arranged on the support, the recycling mechanism comprises a recycling assembly and a compressing assembly, the recycling assembly comprises a recycling unit and an absorbing unit, the compressing assembly comprises a rotating unit, a moving unit, a limiting unit and a compressing unit, and the cutting mechanism comprises a cutting assembly and a traveling assembly. According to the wood cutting device for furniture manufacturing, wood cutting is achieved through the cutting mechanism, wood chips are compressed and recycled through the recycling mechanism, operation of the cutting mechanism and the recycling mechanism is achieved through one output end, energy is saved, linkage is adopted, on-line recycling of wood chips is achieved, meanwhile, linkage is of a pure mechanical structure, the stability of the device is improved, the service life of the device is prolonged, on-line compression of the wood chips is achieved through linkage of the recycling mechanism, efficiency is improved, the recycling space is saved, and practicability is improved.

Owner:广州其成家具有限公司

Method for recovering acid and base from viscose fiber sodium sulfate waste liquid by use of bipolar membrane electrodialysis method

ActiveCN103361769AExtended service lifeHigh yieldSemi-permeable membranesArtificial filament recoveryLiquid wasteFiltration

The invention discloses a method for recovering an acid and a base from a viscose fiber sodium sulfate waste liquid by use of a bipolar membrane electrodialysis method. The method successively includes the following steps: crystallization, regulation of pH, first prefiltration, oxidation of reducing substances by O3, secondary prefiltration, removal of organic matters by activated carbon, removal of zinc ions by ion exchange resin, fine filtration by pp microporous filtration, and preparation and concentration of the acid and base. Through use of the method, regeneration recovery rate of the acid and base in the viscose fiber waste liquid can be improved, bipolar membrane damage caused by impurities of the waste liquid can be reduced, the service life of the bipolar membrane can be improved, and the method can ensure that bipolar membrane electrodialysis and subsequent processes are carried out smoothly.

Owner:宜宾海翔化工有限责任公司 +2

Novel method for recovering acid and base from viscose fiber sodium sulfate waste liquid by use of bipolar membrane electrodialysis method

ActiveCN103361770AAvoid damageExtended service lifeSemi-permeable membranesArtificial filament recoveryLiquid wasteActivated carbon

The invention discloses a novel method for recovering an acid and a base from a viscose fiber sodium sulfate waste liquid by use of a bipolar membrane electrodialysis method. The novel method is characterized by successively including the following steps: crystallization, regulation of pH, first prefiltration, oxidation of reducing substances by O3, secondary prefiltration, removal of organic matters by activated carbon, removal of zinc ions by ion exchange resin, fine filtration by pp microporous filtration, and preparation and concentration of the acids and bases. Through use of the novel method, the regeneration recovery rate of the acid and base in the viscose fiber waste liquid can be improved, bipolar membrane damage caused by impurities of the waste liquid can be reduced, the service life of the bipolar membrane can be improved, and the novel method can ensure that bipolar membrane electrodialysis and subsequent processes are carried out smoothly.

Owner:宜宾海翔化工有限责任公司 +2

Viscose sodium sulfate waste liquor acid and alkali recycling technology by virtue of bipolar membrane electrodialysis method

ActiveCN103343403AExtended service lifeImprove yield and qualitySemi-permeable membranesArtificial filament recoveryChemistryActivated carbon

The invention discloses a viscose sodium sulfate waste liquor acid and alkali recycling technology by virtue of a bipolar membrane electrodialysis method. The technology is characterized by sequentially comprising the following steps of: crystallizing, pH regulating, first primary filtering, oxidizing reducing substances with O3, secondary primary filtering, removing organic matters with activated carbon, removing zinc ions with ion exchange resin, refined filtering by a propene polymer (pp) millipore filter, and acid and alkali producing and concentrating. By virtue of the technology, the regenerating and recycling rates of acid and alkali in viscose sodium sulfate waste liquor are improved, the damage of waste liquor impurities to a bipolar membrane is alleviated, the service life of the bipolar membrane is prolonged, and the bipolar membrane electrodialysis and subsequent processes can be successfully carried out.

Owner:宜宾海翔化工有限责任公司 +2

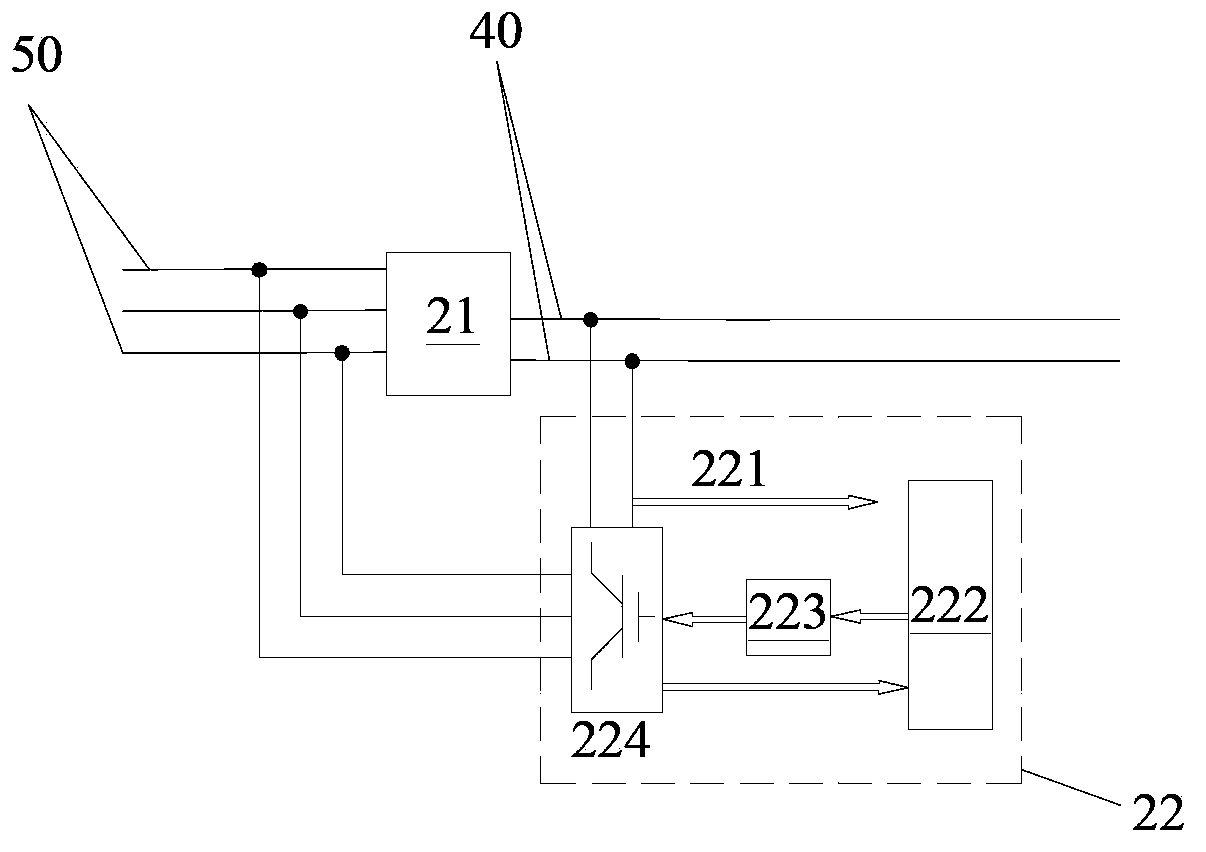

Energy-saving control system

InactiveCN103350935AGuaranteed stabilityRealize online recyclingSingle network parallel feeding arrangementsElevatorsControl systemPower grid

The invention discloses an energy-saving control system. The energy-saving control system comprises an energy-saving control unit and a varying frequency driving unit. The energy-saving control unit comprises a rectifying circuit and an energy feedback circuit, wherein the rectifying circuit is used for converting alternating current of an input power grid into direct current and outputting the direct current to a direct current bus. The varying frequency driving unit is used for converting the direct current on the direct current bus into alternating current with adjustable frequency and voltage to drive a motor to work. The energy feedback circuit is located between the direct current bus and the input power grid, and is used for feeding regenerated energy on the direct current bus back to the input power grid in the descending or braking process of a lift. According to the energy-saving control system, the alternating current of the input power grid is converted into the direct current at the direct current bus side by means of the rectifying circuit, a direct current bus located at the output side of the rectifying circuit is connected with the input power grid at the input side of the rectifying circuit through the energy feedback circuit, so that the regenerated energy on the direct current bus is fed back to the input power grid through the energy feedback circuit, and therefore one-line recycling of regenerated energy is realized.

Owner:HUNAN CCBT CONSTR MACHINERY

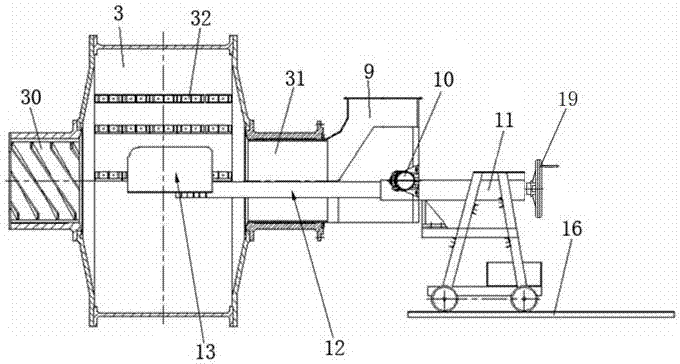

Aluminum oxide crust block air-swept autogenous mill capable of recycling aluminum slag online

PendingCN107321476ARealize online recyclingAvoid the pitfalls of prolonged downtimeProcess efficiency improvementGrain treatmentsSlagEngineering

The invention provides an aluminum oxide crust block air-swept autogenous mill capable of recycling aluminum slag online. A feeding end hollow shaft and a discharging end hollow shaft are arranged at the two ends of the autogenous mill correspondingly. The discharging end hollow shaft is provided with a discharging air duct. The discharging air duct is provided with an opening device with the air tightness. One side of the discharging air duct of the autogenous mill is provided with a recycling trolley which can move back and forth in the axial direction of the autogenous mill. The recycling trolley is provided with a material receiving rod corresponding to the opening device. A material receiving hopper is arranged at the end, adjacent to the discharging air duct, of the material receiving rod. By setting the length of the material receiving rod, the recycling trolley can drive the material receiving rod to enter the opened opening device, the material receiving hopper is made to stretch into the autogenous mill, and the aluminum slag in the rotating autogenous mill can fall into the material receiving hopper. According to the aluminum oxide crust block air-swept autogenous mill capable of recycling the aluminum slag online, the aluminum slag can be recycled online, the defect that long-time shutdown is caused due to manual recycling of the aluminum slag is overcome, and the efficiency is improved.

Owner:河南助拓电气科技股份有限公司

A method for preparing acid-base from viscose fiber sodium sulfate waste liquid by bipolar membrane electrodialysis

ActiveCN103388198BElectrodialysis went wellAvoid damageSemi-permeable membranesArtificial filament recoveryLiquid wasteFiltration

The invention discloses a method for preparing acid base from waste liquid of viscose sodium sulphate by a bipolar membrane electrodialysis method, which comprises the following steps of performing crystallization, pH adjustment, primary pre-filtration, O3 oxidation of reducing substances, secondary pre-filtration, organism removal by active carbon, zinc ion removal by ion exchange resin and pp micro-porous filtration and refined filtration on the waste liquid of viscose sodium sulphate in which a sodium sulphate concentration is 5-20%; then, feeding a product into a sodium sulphate runner of a bipolar membrane electrodialysis membrane device; and feeding demineralized water serving as absorption liquid into an acid runner and a base runner of the bipolar membrane electrodialysis membrane device respectively to obtain a sulphuric acid solution and a sodium hydroxide solution, wherein the working pressure of the bipolar membrane electrodialysis membrane device is 0.03-0.08MPa. The method disclosed by the invention improves the regeneration recovery rate of acid and base in the waste liquid of viscose, reduces the damage of a bipolar membrane caused by impurities of the waste liquid, prolongs the service life of the bipolar membrane, and guarantees the electrodialysis of the bipolar membrane as well as the smooth operation of follow-up processes.

Owner:宜宾海翔化工有限责任公司 +4

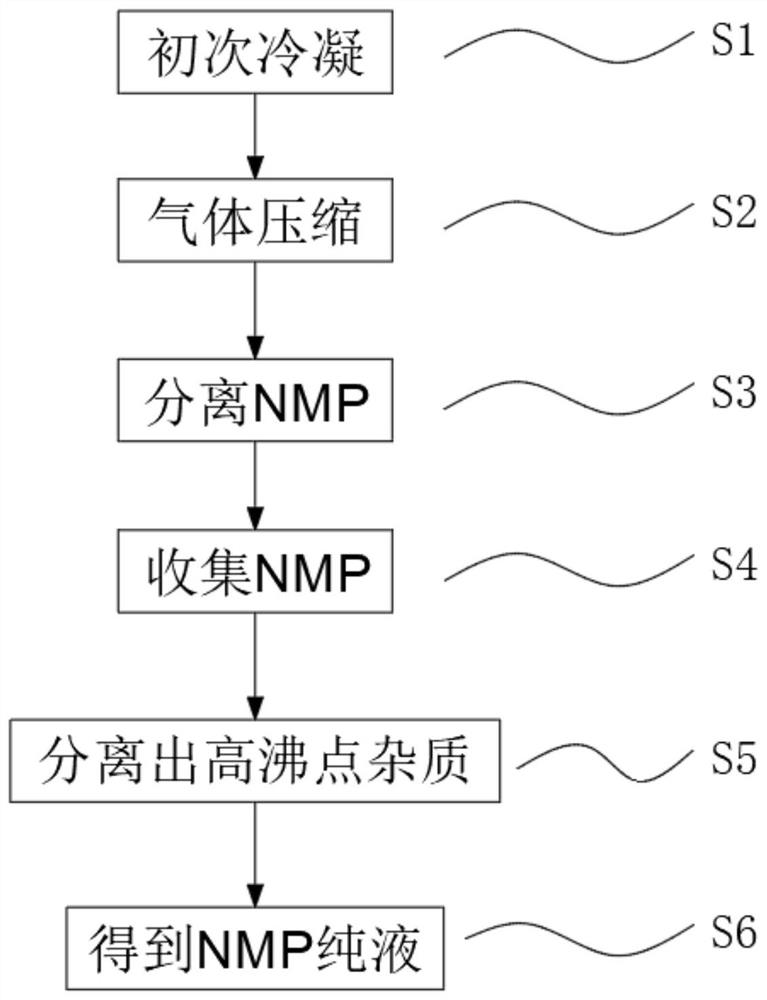

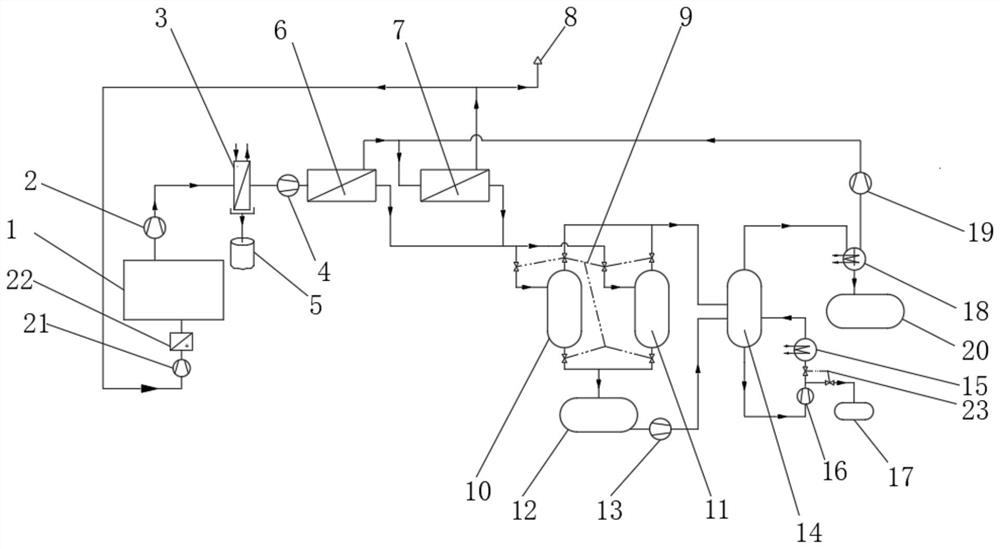

Method and system for purifying NMP in coating process of lithium ion battery

ActiveCN113788776ARealize online recyclingReduce energy consumptionOrganic chemistryDispersed particle separationThermodynamicsLiquid storage tank

The invention discloses a method and a system for purifying NMP in coating process of a lithium ion battery, and belongs to the field of NMP purification. The NMP purification method comprises the following steps: S1, primary condensation, S2, gas compression, S3, NMP separation, S4, NMP collection, S5, high boiling point impurity separation, and S6, NMP pure liquid obtaining. The NMP purification system comprises a pre-cooling surface air cooler, a first NMP liquid storage tank, a compressor, a separation assembly, a pressure buffer assembly, a negative pressure flash tank, a vacuum pump, a vacuum condenser and an NMP pure liquid tank, the pre-cooling surface air cooler is connected with the compressor and the first NMP liquid storage tank, the compressor is connected with the separation assembly, the separation assembly is connected with the pressure buffer assembly, the pressure buffer assembly is connected with the negative pressure flash tank, the negative pressure flash tank is connected with the vacuum pump, and the vacuum condenser is connected between the vacuum pump and the negative pressure flash tank. According to the invention, the system structure can be simplified, recovery and purification are facilitated, then butt joint with production is facilitated, effective recycling of NMP is realized, and the cost is reduced.

Owner:深圳市德尼环境技术有限公司

An integrated and comprehensive soil in situ joint restoration equipment

ActiveCN105013806BAchieving Heterotopic Continuous Joint RepairImprove repair efficiencyContaminated soil reclamationPeristaltic pumpSolenoid valve

Owner:南京康地环保科技有限公司

Novel viscose sodium sulfate waste liquor acid and alkali recycling method by virtue of bipolar membrane electrodialysis method

ActiveCN103343400AExtended service lifeHigh yieldSemi-permeable membranesArtificial filament recoveryActivated carbonZinc ion

The invention discloses a novel viscose sodium sulfate waste liquor acid and alkali recycling method by virtue of a bipolar membrane electrodialysis method. The method is characterized by sequentially comprising the following steps of: crystallizing, pH regulating, first primary filtering, oxidizing reducing substances with O3, secondary primary filtering, removing organic matters with activated carbon, removing zinc ions with ion exchange resin, refined filtering with a propene polymer (pp) millipore filter, and acid and alkali producing and concentrating. By virtue of the method, the regenerating and recycling rates of acid and alkali in viscose sodium sulfate waste liquor are improved, the damage of waste liquor impurities to a bipolar membrane is alleviated, the service life of the bipolar membrane is prolonged, and the bipolar membrane electrodialysis and subsequent processes can be successfully carried out.

Owner:宜宾海翔化工有限责任公司 +2

Imperfect cigarette collating and tobacco shred recycling integrated equipment

The invention discloses imperfect cigarette collating and tobacco shred recycling integrated equipment which is special equipment of a cigarette making machine. Difficult technical problems in aspects of continuously recycling and treating serviceable tobacco shreds of imperfect cigarettes in an online manner and directly utilizing the serviceable tobacco shreds are solved by the imperfect cigarette collating and tobacco shred recycling integrated equipment. The technical scheme includes that the imperfect cigarette collating and tobacco shred recycling integrated equipment comprises a vibratory charging bin (1), a cigarette collating device, a supply bin (19), a gear (5) with teeth, a pressing piece (12), a retractable blowing nozzle (13), a tobacco shred collecting hopper (10) and a waste collecting hopper (11). The imperfect cigarette collating and tobacco shred recycling integrated equipment has the advantages that the integrated equipment can be directly used for recycling and treating imperfect cigarettes in an online manner, paper tubes, filter tips and tobacco shreds are perfectly separated from one another and are respectively recycled and treated, and an effect is excellent.

Owner:KUNMING LEIEN SCI & TECH

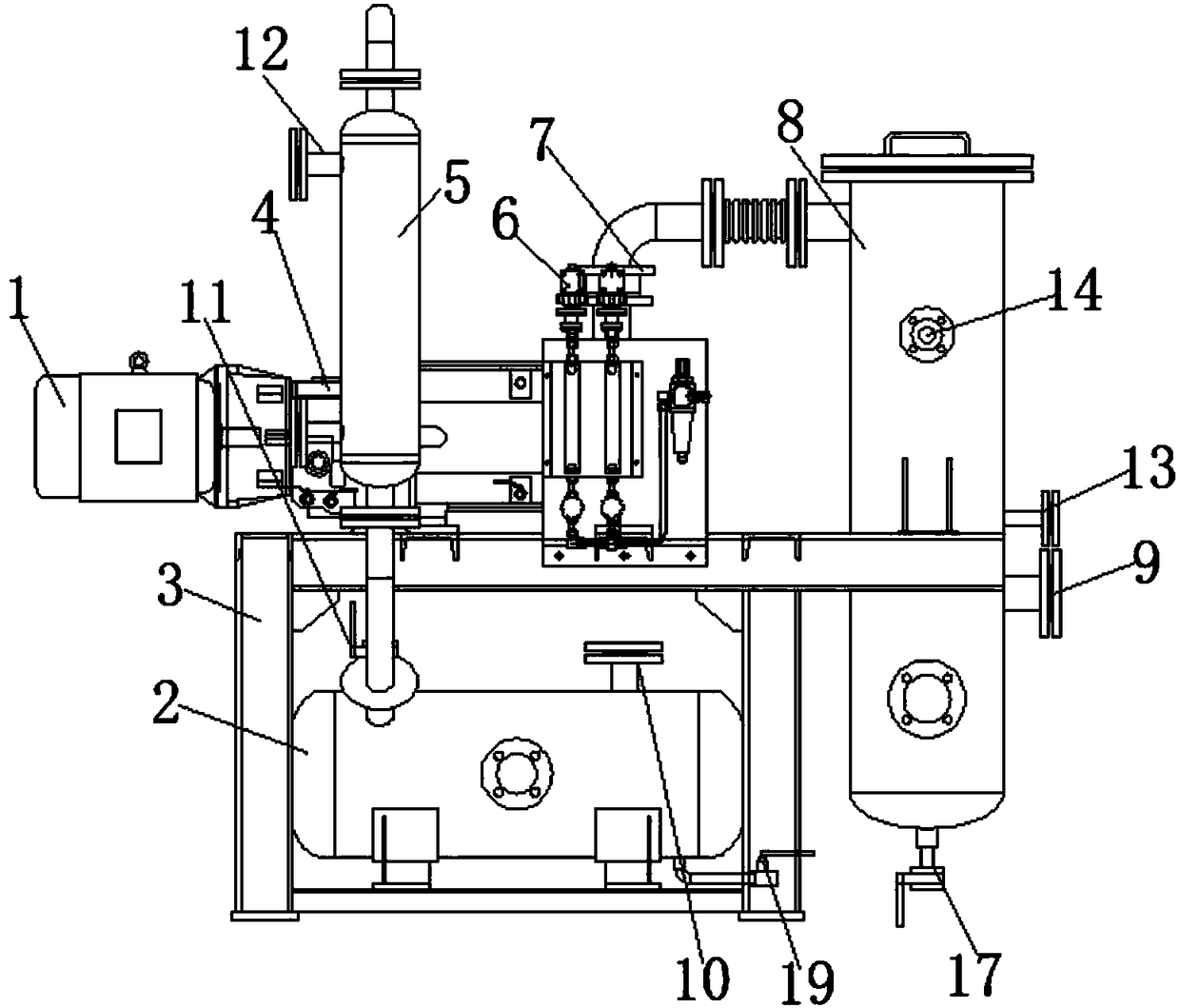

Dry type vacuum unit for solvent recycling

PendingCN108591056ACompact structureEasy to installRotary piston pumpsRotary piston liquid enginesSolventCheck valve

The invention relates to the technical field of solvents, in particular to a dry type vacuum unit for solvent recycling. The dry type vacuum unit comprises a rack, the bottom of the rack is horizontally provided with a recycling tank, the top of the rack is provided with a screw vacuum pump, the two ends of the screw vacuum pump are provided with a vacuum pump cooling water inlet and a vacuum pumpcooling water outlet correspondingly, and the end, close to the vacuum pump cooling water inlet, of the screw vacuum pump is connected with an electromotor. An air suction opening of the screw vacuumpump is connected with a filter through a pipe, the filter is vertically and fixedly installed at one end of the rack, and the filter communicates with the interior of the screw vacuum pump. The pipebetween the filter and the screw vacuum pump is provided with an inlet check valve. The dry type vacuum unit is of integrated design and is compact in structure, convenient to install and capable ofrealizing condensation, filtering, condensed liquid online recycling and discharging of sucked air; and meanwhile, contamination of a solvent is effectively reduced, consumption of the solvent is lowered, and the economic benefits of pharmaceutical enterprises are increased.

Owner:山东博科真空科技有限公司

Automatic circulating equipment and method for perforating machine core rods

ActiveCN107716555ARealize online recyclingReduce long-distance round-trip timeMandrel separation arrangementsMandrelsShortest distanceEngineering

The invention discloses automatic circulating equipment for perforating machine core rods. The automatic circulating equipment comprises a perforating machine is used for driving the corresponding core rod to penetrate a pipe material and further comprises a return roller way, a first material delivering mechanism, a second material delivering mechanism, a rod breaking-away roller way, a rod breaking-away device, a third material delivering mechanism and a fourth material delivering mechanism, wherein the return roller way is used for carrying the to-be-used core rod; the first material delivering mechanism is used for delivering the core rod on the return roller way into the perforating machine; the second material delivering mechanism is used for delivering the pipe material provided with the corresponding core rod in a penetrated manner to the rod breaking-away roller way; the rod breaking-away roller way is used for carrying the pipe material provided with the corresponding core rod in a penetrated manner; the rod breaking-away device is used for breaking the pipe material on the rod breaking-away roller way away from the core rod which is arranged in the pipe material in a penetrating manner; the third material delivering mechanism is used for delivering the pipe material on the rod breaking-away roller way to the next procedure; and the fourth material delivering mechanism is used for delivering the core rod on the rod breaking-away roller way to the return roller way. By means of the automatic circulating equipment, online cyclic use of the three core rods can be achieved at the same time; after perforating is completed, a trolley body only needs to retreat for a short distance, the head of the corresponding core rod extends out of the outer edge of a machine main body, and perforating of the next time can be conducted; and the long-distance round-trip time of the trolley body is shortened.

Owner:常州常宝精特钢管有限公司

Method for recovering acid and alkali from viscose sodium sulfate waste liquor through bipolar membrane electrodialysis way

ActiveCN103343401BAvoid damageExtended service lifeSemi-permeable membranesArtificial filament recoveryActivated carbonHydrogen

The invention discloses a method for recovering acid and alkali from viscose sodium sulfate waste liquor through a bipolar membrane electrodialysis way. The method is characterized by sequentially comprising the following steps of: crystallizing; adjusting pH (Potential of Hydrogen); initially filtering at the first time; oxidizing reducing substances through O3; initially filtering at the second time; removing organic substances through activated carbon; removing zinc ions through ion exchange resin; filtering and performing refined filtration through pp micropores; preparing acid and alkali; and concentrating. By adopting the method, the regenerative recovery rate of the acid and alkali in the viscose sodium sulfate waste liquor is increased, the damage of impurities in the waste liquor on a bipolar membrane is reduced, so that the service life of the bipolar membrane is prolonged, and the bipolar membrane electrodialysis and the subsequent processes can be able to be carried out smoothly.

Owner:宜宾海翔化工有限责任公司 +2

Online concentration device of post-column component of chromatographic column and control process

ActiveCN104399271ARealize online recyclingAvoid pollutionDistillation regulation/controlSolenoid valveSolvent

The invention discloses an online concentration device of a post-column component of a chromatographic column and a control process. An inner cavity of a concentration pot is divided into a plurality of abreast concentration cavities, and a condensation pot is fixedly arranged at the tail end of the concentration pot; an inlet of a detector flow cell is communicated with the chromatographic column, and an outlet of the detector flow cell is communicated to the upper ends of all the concentration cavities of the concentration pot; solenoid valves are arranged on branches of all the concentration cavities, and discharge openings are respectively formed in the lower ends of all the concentration cavities; a heat medium pump is communicated to the lower ends of all the concentration cavities, a negative pressure pump is communicated to the upper ends of all the concentration cavities and the cavity of condensation pot, and a cold medium pump is communicated to the lower end of the inner cavity of the condensation pot; an exhausting opening of the condensation pot is communicated with a regenerative solvent tank. Through the use of the device, the online concentration of post-chromatographic column liquid and the online recovery of chemical solvent can be realized, so that not only is the concentration efficiency improved, but also the device is free from the limitation of the stock of the post-chromatographic column liquid in concentration, the whole process is performed in a sealed environment, and the device is suitable for extracting a concentrated solution of an object easy to oxidize and deteriorate; generated impurities are recycled, and pollution to the environment is avoided.

Owner:LIAOCHENG WANHE IND MFR

An automatic circulation device and method for perforated mandrel rod

ActiveCN107716555BRealize online recyclingReduce long-distance round-trip timeMandrel separation arrangementsMandrelsStructural engineeringPipe

The invention discloses automatic circulating equipment for perforating machine core rods. The automatic circulating equipment comprises a perforating machine is used for driving the corresponding core rod to penetrate a pipe material and further comprises a return roller way, a first material delivering mechanism, a second material delivering mechanism, a rod breaking-away roller way, a rod breaking-away device, a third material delivering mechanism and a fourth material delivering mechanism, wherein the return roller way is used for carrying the to-be-used core rod; the first material delivering mechanism is used for delivering the core rod on the return roller way into the perforating machine; the second material delivering mechanism is used for delivering the pipe material provided with the corresponding core rod in a penetrated manner to the rod breaking-away roller way; the rod breaking-away roller way is used for carrying the pipe material provided with the corresponding core rod in a penetrated manner; the rod breaking-away device is used for breaking the pipe material on the rod breaking-away roller way away from the core rod which is arranged in the pipe material in a penetrating manner; the third material delivering mechanism is used for delivering the pipe material on the rod breaking-away roller way to the next procedure; and the fourth material delivering mechanism is used for delivering the core rod on the rod breaking-away roller way to the return roller way. By means of the automatic circulating equipment, online cyclic use of the three core rods can be achieved at the same time; after perforating is completed, a trolley body only needs to retreat for a short distance, the head of the corresponding core rod extends out of the outer edge of a machine main body, and perforating of the next time can be conducted; and the long-distance round-trip time of the trolley body is shortened.

Owner:常州常宝精特钢管有限公司

Regeneration method of electroless nickel plating waste solution

ActiveCN110965051BHigh selectivityNo lossLiquid/solution decomposition chemical coatingElectroless nickelProcess engineering

The invention discloses a regeneration method of electroless nickel plating waste liquid. Firstly, a phosphorous removal agent with 2 to 6 times the phosphorus content in the waste liquid is added to the waste liquid, and then sulfuric acid is added to adjust the pH value of the waste liquid to 2.5 to 2.5. 4.5. The clear liquid is obtained after filtration, crystallized at a temperature of -2°C to -10°C, and can be regenerated after filtration and crystallization. The process operation method of the present invention is simple, has no special requirements for equipment, and can be applied to actual production In the process, online recycling can be realized to achieve the effect of continuous production without tank down, so that the chemical nickel plating raw materials can be fully utilized, the discharge of hazardous wastes can be reduced, and the cost of chemical nickel plating can be reduced.

Owner:南通湛清环保科技有限公司

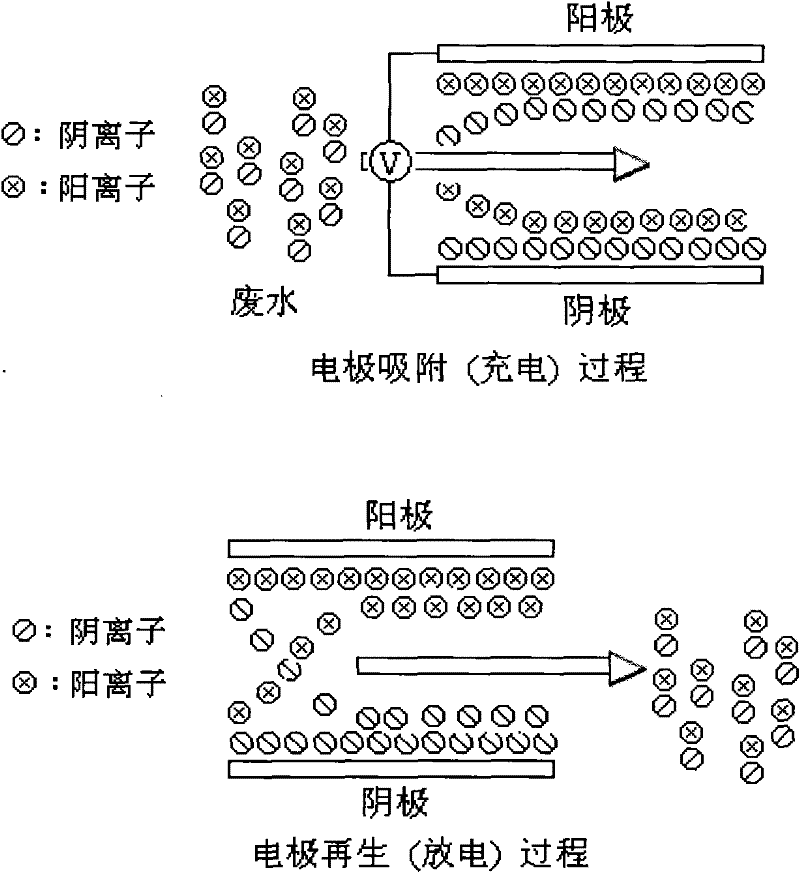

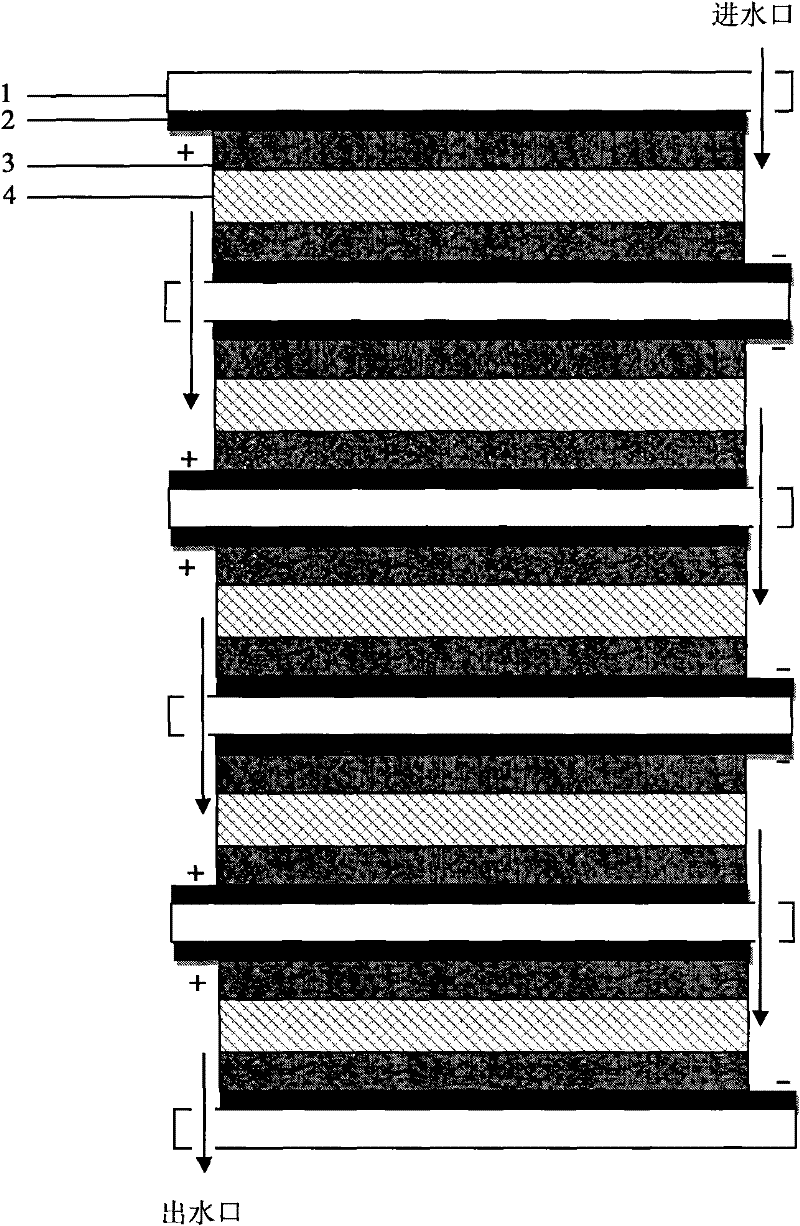

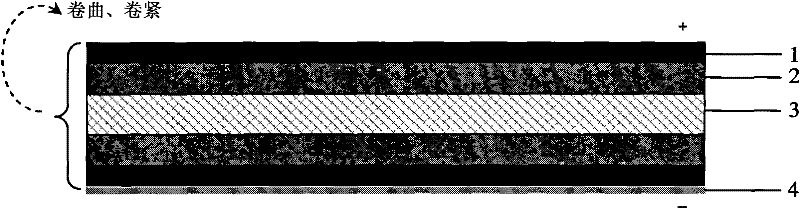

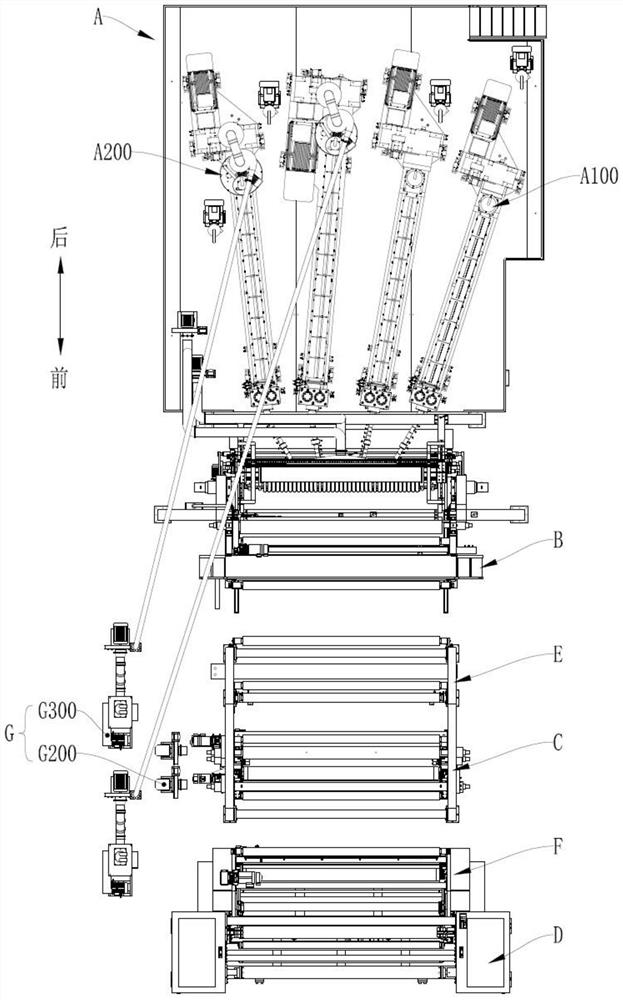

System for purifying and recycling electroplating/chemical plating wastewater on line

ActiveCN101891286BOptimize application parametersLess waste waterDispersed particle separationWaste water treatment from metallurgical processIonChemical plating

The invention belongs to the technical field of water treatment, and relates to a system for purifying and recycling electroplating / chemical plating wastewater on line. The system comprises a washing device positioned on an electroplating / chemical plating production line, wherein a purifying device is arranged in the washing device and is a capacitive deionization device; the capacitive deionization device comprises at least one electrode pair consisting of ion electroadsorption electrodes, collector electrodes and an insulating layer; two ion electroadsorption electrode layers covers the outer layer of the insulating layer in the electrode pair, and then two collector electrode layers covers the outer layer of the ion electroadsorption electrode layers; and one side of the insulating layer is an anode, and the other side of the insulating layer is a cathode. By combining the characteristics of the electroplating / chemical plating wastewater and the specific conditions of the process flow, a wastewater treatment and recovery system which is suitable to be practically applied to the field is arranged, so that various application parameters are optimized, and the wastewater amount isobviously reduced; meanwhile, the quality of plated parts is ensured and water resources are effectively saved; and in addition, the on-line recovery of waste materials is realized and resources are effectively utilized.

Owner:TANTZ ENVIRONMENTAL TECH

Multi-layer co-extrusion centrifugal casting film production line

ActiveCN112477185AReduce the frequency of downtime for maintenanceReduce manufacturing costPlastic recyclingThin membraneEngineering

The invention discloses a multi-layer co-extrusion centrifugal casting film production line, and relates to the technical field of film production. According to the multi-layer co-extrusion centrifugal casting film production line, a first edge cutting mechanism is arranged between a flow casting mechanism and a corona mechanism, so that the two side edges of the cooled and formed film are cut, and the problem that a rubber layer in the corona mechanism is damaged due to large thickness of the two side edges of the just formed film is solved, so as to reduce the frequency of shutdown maintenance of the corona mechanism. A second edge cutting mechanism is arranged between the corona mechanism and a winding mechanism to cut the two side edges of the thin film coming out of the corona mechanism so as to produce the thin film with the actually needed width. A rim charge recovery device recovers rim charges cut by the first edge cutting mechanism and the second edge cutting mechanism, the rim charges are crushed and then put into an inner layer discharging mechanism, so that the rim charges produced by subsequent processing are used as part of raw materials of the inner layer of the film, online rim charge recovery is realized, the rim charges are recycled, and the production cost is reduced.

Owner:GUANGDONG SHICHENG PLASTIC MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com