Alkaline three-in-one grinding process capable of integrating pretreatment of aluminum with on-line recycle of aluminum hydroxide

An aluminum hydroxide, three-in-one technology, applied in electrolytic coatings, surface reaction electrolytic coatings, coatings, etc., can solve the problems of wasting aluminum resources, increasing the pressure of fluorine-containing and ammonia nitrogen-containing wastewater, and paying environmental protection costs. The effect of aluminum scale clogging, elimination of fluorine-containing components, and reduction of treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

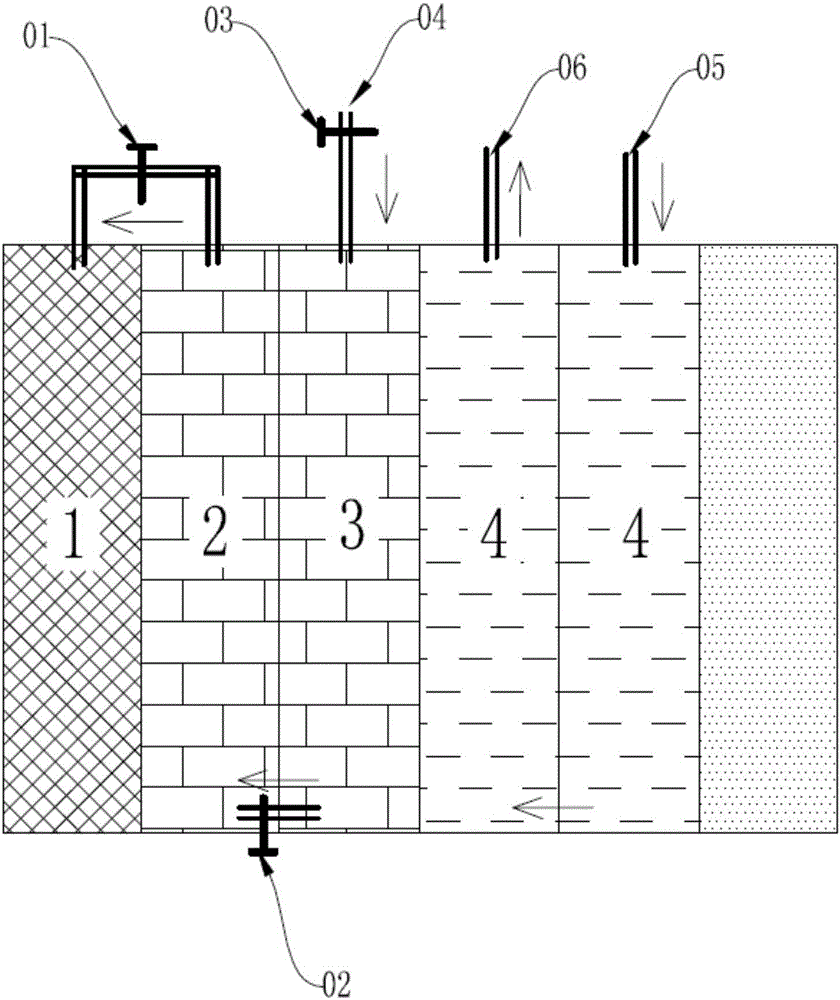

[0129] Embodiment 1 (sand surface material)

[0130] The aluminum material directly enters the alkaline three-in-one frosting tank 1, S=1, mixed agent (sodium nitrate / sodium hydroxide) 40g / L, reacts for 10 minutes, 60-70°C, drips for 1 minute; passes through the first non-flowing Washing tank 2 is cleaned for 1.5 minutes, dripping for 1 minute, and the second non-flowing washing tank 3 is cleaned for 1 minute, dripping for 1 minute; enter two flowing washing tanks, wash for 1 minute, trickle for 1 minute, and complete the pre-oxidation treatment.

Embodiment 2

[0131] Embodiment 2 (sand surface material)

[0132]The aluminum material directly enters the alkaline three-in-one frosting tank 1, S=1, mixed agent (sodium nitrate / sodium hydroxide) 60g / L, reacts for 10 minutes, 60-70°C, drips for 1 minute; passes through the first non-flowing Washing tank 2 is cleaned for 1.5 minutes, dripping for 1 minute, and the second non-flowing washing tank 3 is cleaned for 1 minute, trickling for 1 minute; enter two flowing washing tanks, wash for 1 minute and trickle for 1 minute respectively, and complete the pre-oxidation treatment.

Embodiment 3

[0133] Embodiment 3 (sand surface material)

[0134] The aluminum material directly enters the alkaline three-in-one frosting tank 1, S=1, mixed agent (sodium nitrate / sodium hydroxide) 80g / L, reacts for 10 minutes, 60-70°C, drips for 1 minute; passes through the first non-flowing Washing tank 2 is cleaned for 1.5 minutes, dripping for 1 minute, and the second non-flowing washing tank 3 is cleaned for 1 minute, trickling for 1 minute; enter two flowing washing tanks, wash for 1 minute and trickle for 1 minute respectively, and complete the pre-oxidation treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com