Method for treating Cr-containing pickling sludge in slag bath

A treatment method and a technology for pickling sludge, applied in the field of metallurgical engineering, can solve the problems of Cr-containing pickling sludge pollution, difficult recovery of heavy metals, etc., and achieve the effects of source emission reduction, simple operation, and online recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

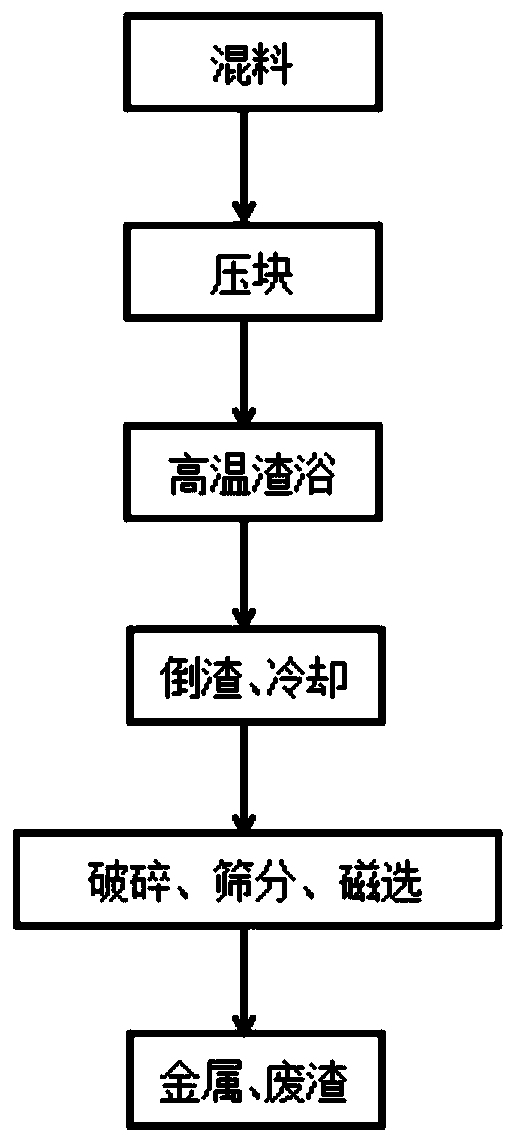

[0030] (1) Add reductant graphite powder and lime in chromium-containing pickling sludge and fully mix, wherein the mass percent of graphite powder, lime and pickling sludge is 22%: 7%: 71%;

[0031] (2) The mixed material is briquetted with a briquetting machine, dried at 110° C. for 5 hours, and prepared into Cr-containing acid-washed sludge pellets required for slag bath treatment;

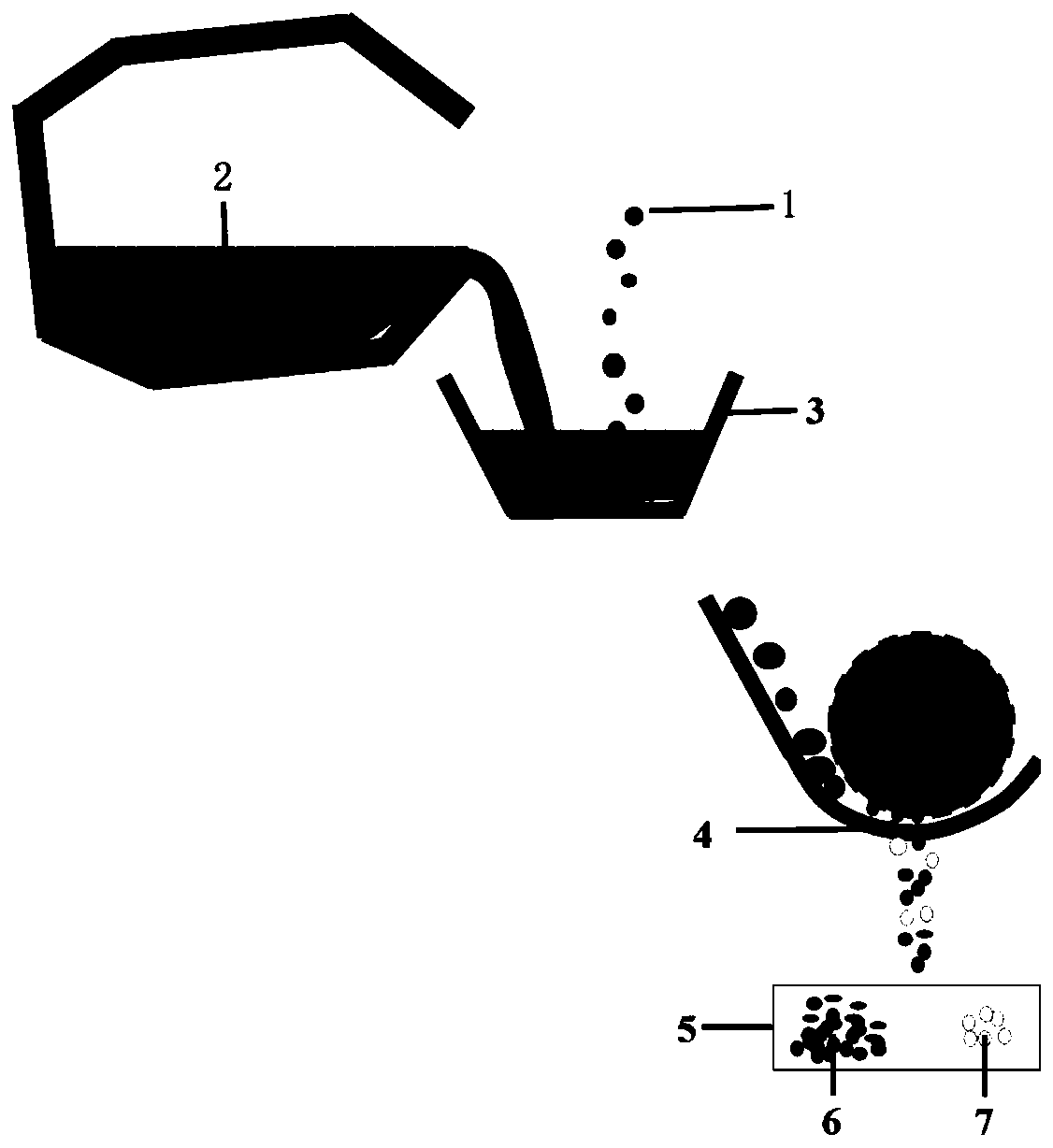

[0032] (3) Take the AOD slag and mix it uniformly according to the mass ratio of molten slag, carbonaceous reducing agent and ferrosilicon powder at 98.9%: 0.85%: 0.25%, heat and melt at 1550°C, and keep it warm for 20 minutes to ensure a constant temperature. Throw the dried sludge pellets in (2) into the AOD slag for a slag bath reaction at 1550° C., the reaction time is 15 minutes, wherein the mass ratio of the sludge pellets to the AOD slag is 3%;

[0033] (4) After the slag is cooled, it is crushed, screened, and magnetically separated to separate metal particles.

Embodiment 2

[0035] (1) Add reductant graphite powder, additive and lime in chromium-containing pickling sludge and fully mix, wherein the mass percent of graphite powder, lime and pickling sludge is 18%: 8%: 74%;

[0036] (2) The mixed material is pressed into balls with a ball press machine, and dried at 120° C. for 3 hours to prepare Cr-containing acid-washed sludge pellets required for slag bath treatment;

[0037] (3) Take the AOD slag and heat and melt it at 1550°C, and keep it warm for 20 minutes to ensure a constant temperature. Throw the dried sludge pellets in (2) into the AOD slag and carry out the slag bath reaction at 1550°C. The reaction time is 20 Minutes, wherein the mass ratio of sludge pellets to AOD slag is 5%;

[0038] (4) After the slag is cooled, it is crushed, screened, and magnetically separated to separate the metal particles. image 3 It is the separated residue and metal particles.

Embodiment 3

[0040] (1) Add reductant graphite powder and lime in chromium-containing pickling sludge and fully mix, wherein the mass percent of graphite powder, lime and pickling sludge is 16%: 7%: 77%;

[0041] (2) Pressing the mixed materials with a briquetting machine and drying at 130° C. for 7 hours to prepare Cr-containing acid-washed sludge pellets required for slag bath treatment;

[0042] (3) Take converter slag and heat and melt it at 1600°C, keep it warm for 30 minutes to ensure a constant temperature, throw the dried sludge pellets in (2) into converter slag and carry out slag bath reaction at 1600°C, the reaction time is 15 minutes, wherein the mass ratio of sludge pellets to converter slag is 10%;

[0043] (4) After the slag is cooled, it is crushed, screened, and magnetically separated to separate metal particles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com