Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Optimal operating parameters" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

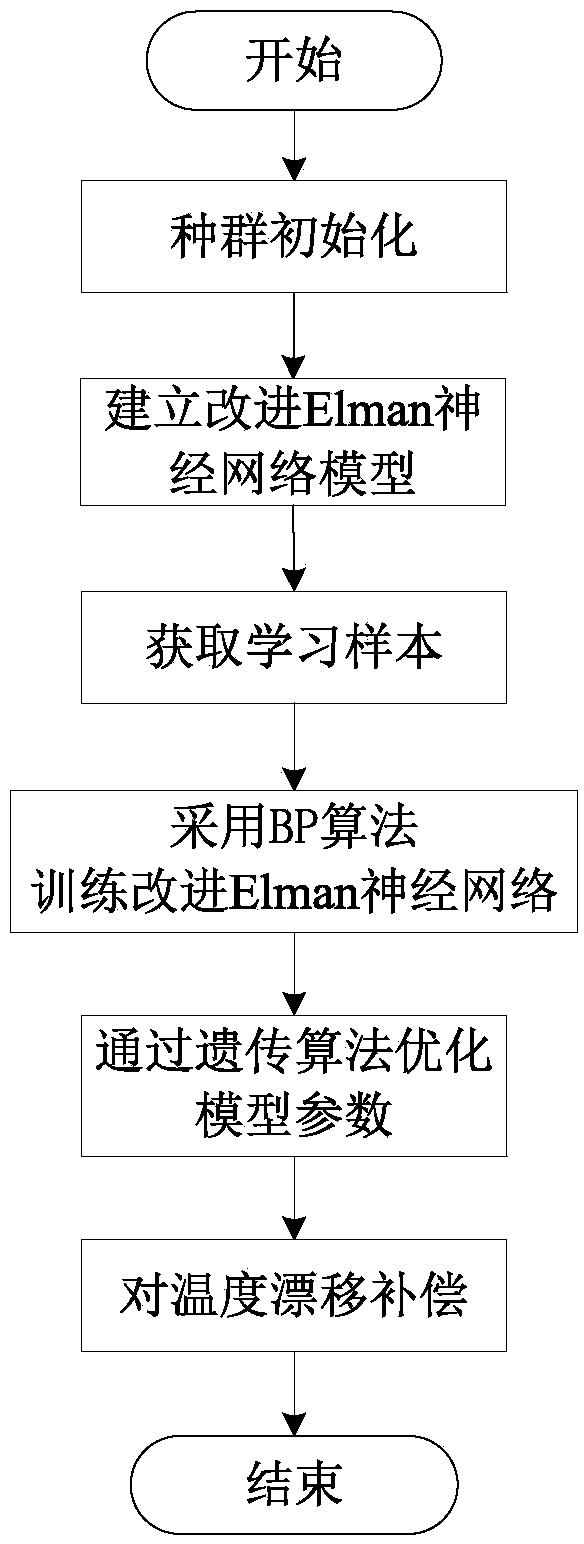

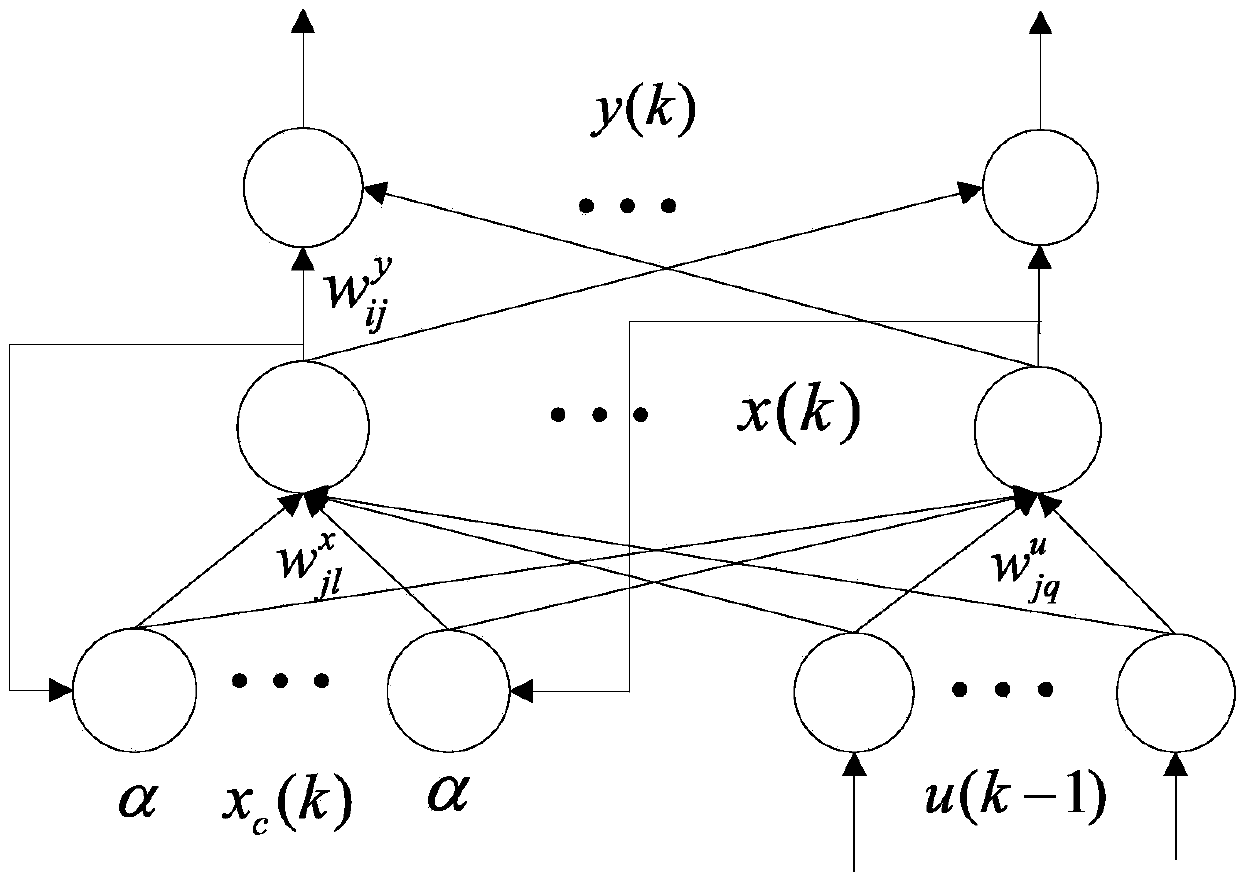

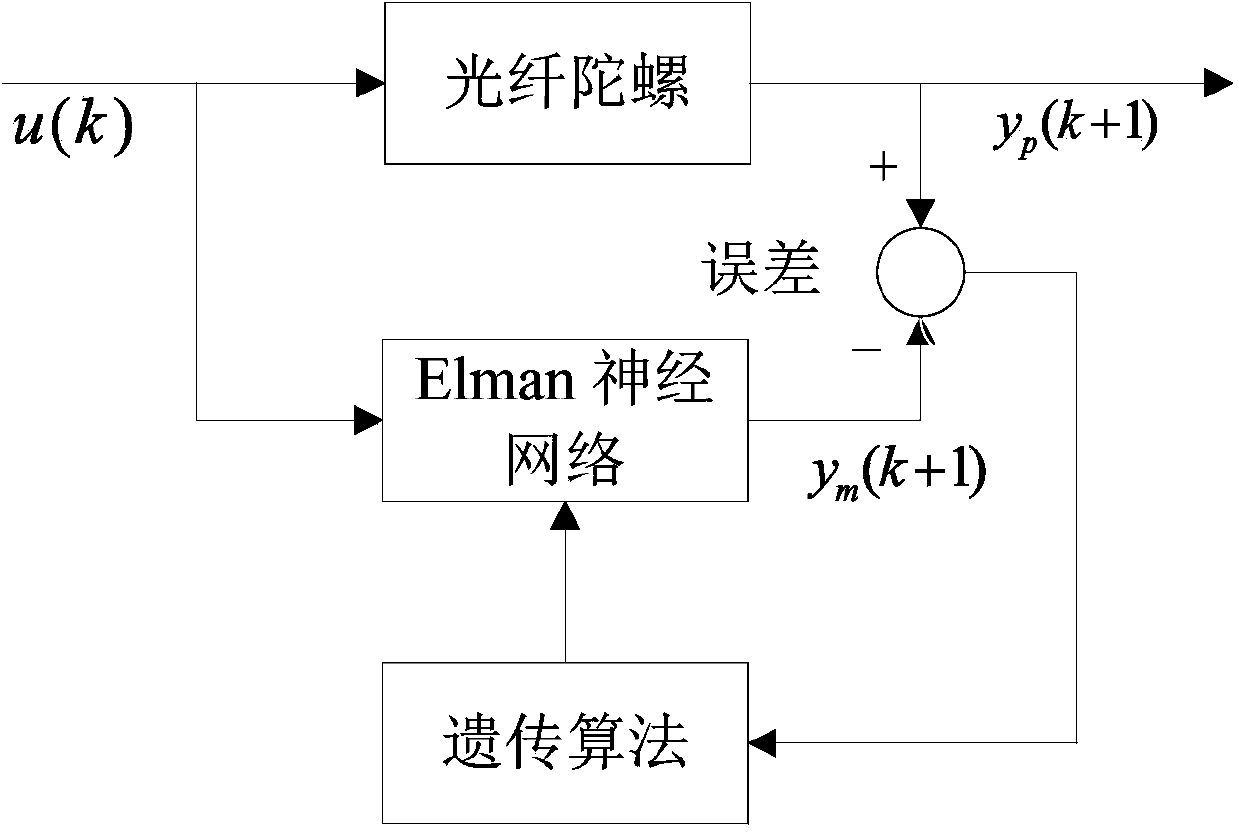

Fiber optic gyroscope temperature drift modeling method by optimizing dynamic recurrent neural network through genetic algorithm

ActiveCN103593538AWith dynamic memorySimplify the scaleBiological neural network modelsSagnac effect gyrometersFiberGyroscope

The invention discloses a fiber optic gyroscope temperature drift modeling method by optimizing a dynamic recurrent neural network through a genetic algorithm. The fiber optic gyroscope temperature drift modeling method by optimizing the dynamic recurrent neural network through the genetic algorithm comprises the following steps of (1) initializing network parameters, and establishing an improved Elman neural network model; (2) obtaining a training and testing sample; (3) training an improved Elman neural network, and optimizing model parameters through the genetic algorithm; (4) outputting forecasts of an fiber optic gyroscope, and compensating errors. The output of the fiber optic gyroscope processed through a denoising algorithm is trained by introducing the improved Elman neural model with self-feedback connection weight, constant iterative optimization is carried out on the model parameters through the genetic algorithm, and the optimal model is obtained according to the magnitude of the errors of the model under different parameters. According to the fiber optic gyroscope temperature drift modeling method by optimizing the dynamic recurrent neural network through the genetic algorithm, the complexity of the algorithm is taken into consideration, the accuracy of the fiber optic gyroscope temperature drift model is improved, the application of the fiber optic gyroscope temperature drift model in engineering is expanded, and certain practical significance is achieved.

Owner:SOUTHEAST UNIV

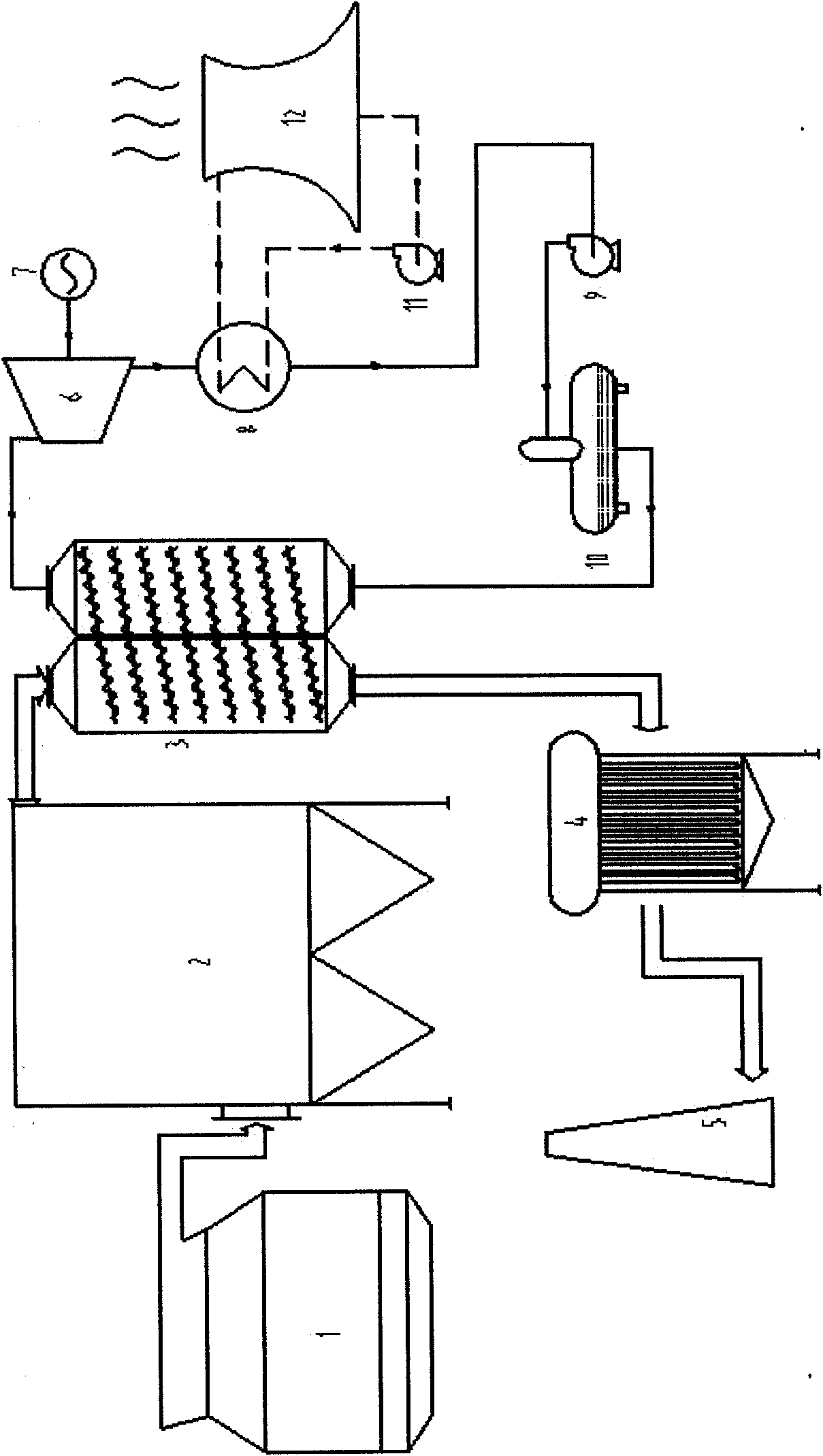

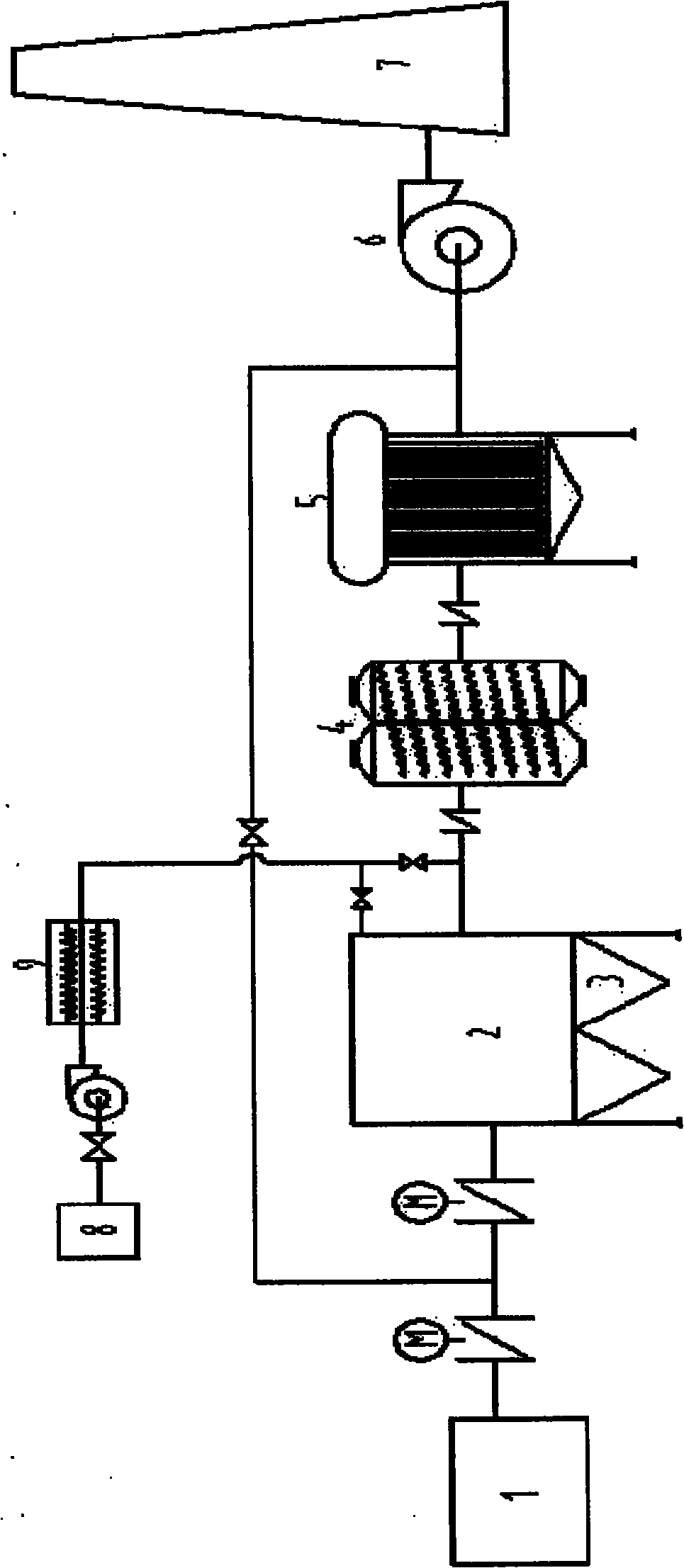

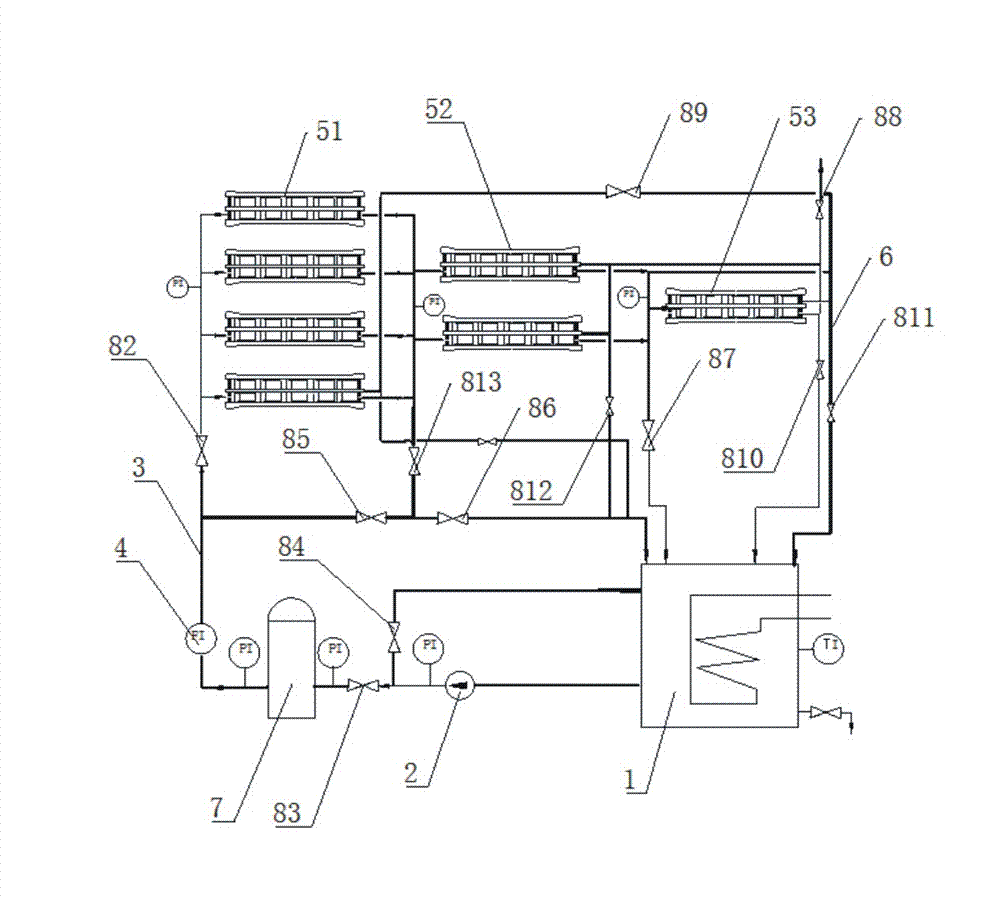

Integrated waste heat generating and heating system and process flow thereof

InactiveCN101852555AAvoid paralysisLow running costValve arrangementsDispersed particle filtrationFiberHeat conducting

The invention discloses a waste heat generating equipment system and a waste heat generating process. The system comprises a ceramic fiber dust collector (2), a rapid heat conducting heat-pipe waste heat boiler (3), a rapid heat conducting heating device (4), a steam replenishing and condensing steam turbine (6), a condenser (8), a condensing water pump (9) and a vacuum deaerator (10), wherein ceramic fiber dust collector (2) is arranged at a waste heat outlet end; the rapid heat conducting heat-pipe waste heat boiler (3) bears a steam preparing device for power generation; the rapid heat conducting heating device (4) is arranged on the smoke inlet of a boiler; medium and high-pressure main steam generated by a rapid heat conducting heat-pipe waste heat boiler is mixed and enters the steam replenishing and condensing steam turbine (6) through a pipeline; low-pressure steam enters the steam replenishing and condensing steam turbine (6) through a steam replenishing pipeline; waste steam on the tail part of the steam turbine enters the condenser (8); condensed water enters the vacuum deaerator (10) through the condensing water pump (9) and a pipeline; water from which oxygen is removed in the deaerator enters the heat-pipe waste heat boiler (3) through a water supply pump of the boiler; and low-temperature smoke discharged from the back end of the boiler is delivered into the rapid heat conducting heating device (4). The waste heat utilization ratio of the integrated system is enhanced by over 60 percent on average, so unit energy consumption of an enterprise is greatly lowered, the problem of unstable running of the system due to dust blocking of the boiler and wearing of a heat exchange tube in a medium and low temperature waste heat generating system is solved and comprehensive generating efficiency is enhanced by over 30 percent.

Owner:童裳慧

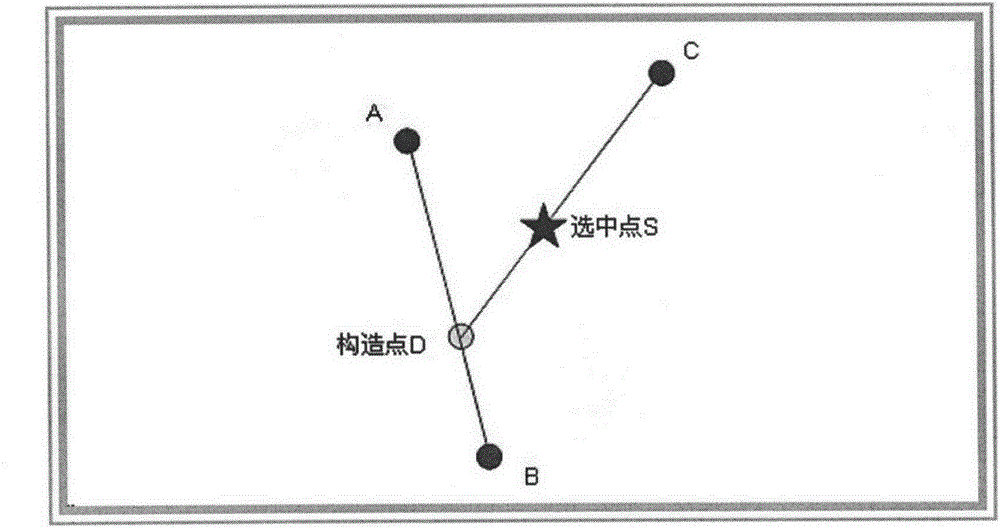

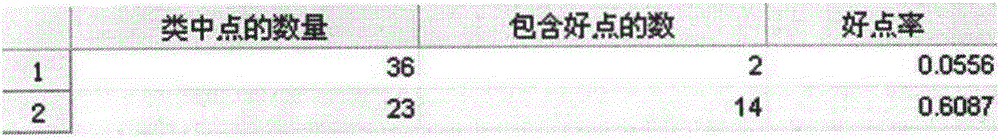

Method for optimizing multi-objective parameters based on fuzzy analysis and visualization technology

InactiveCN102722103AGuaranteed maximum retentionReliable optimal point setAdaptive controlOperating pointData set

The invention relates to a method for optimizing multi-objective parameters based on a fuzzy analysis and visualization technology, which provides an effective measure for processing, analysis, optimization and prediction of parameter data in an industrial process. The method comprises the following steps of: classifying the data by an evolution algorithm and the conventional fuzzy C average clustering hybrid algorithm to select an optimized data set; improving the conventional non-linear mapping evaluation function, introducing a distance error weight and a differentiation factor to ensure that a dimension reduction error of a distance between the farthest point and the nearest point in the data set is smallest to the greatest extent, concentrating the dimension reduction error on secondary information, procedurally solving by a fastest reduction method, and finally reducing high-dimensional spatial data to a two-dimensional plane; and finally, performing axis mapping on multi-dimensional data along each dimension, drawing contour lines, observing influences and optimization potentials of all the parameters on operating points to provide abundant intuitive information for people, repeatedly selecting the points, performing inverse mapping, and reducing to an actual operation space to fulfill the aim of parameter optimization.

Owner:镇江雅迅软件有限责任公司

New treatment method of threonine mother liquid

ActiveCN103723894AWell mixedReduce usageOrganic compound preparationMultistage water/sewage treatmentBacterial agentChemistry

The invention relates to a new treatment method of threonine mother liquid. The method comprises a step of adding an alcohol substance into a threonine mother liquid solution obtained in an extraction process of threonine mother liquid so as to reduce the solubility and separate out threonine, and a compound microbial bacterial agent is added into other impurities to reach the emission standard. The method provided by the invention has the advantages of low production cost, high threonine extraction yield and little wastewater discharge, is economical and environment-friendly and has a broad application prospect.

Owner:HULUNBEIER NORTHEAST FUFENG BIOTECHNOLOGIES CO LTD

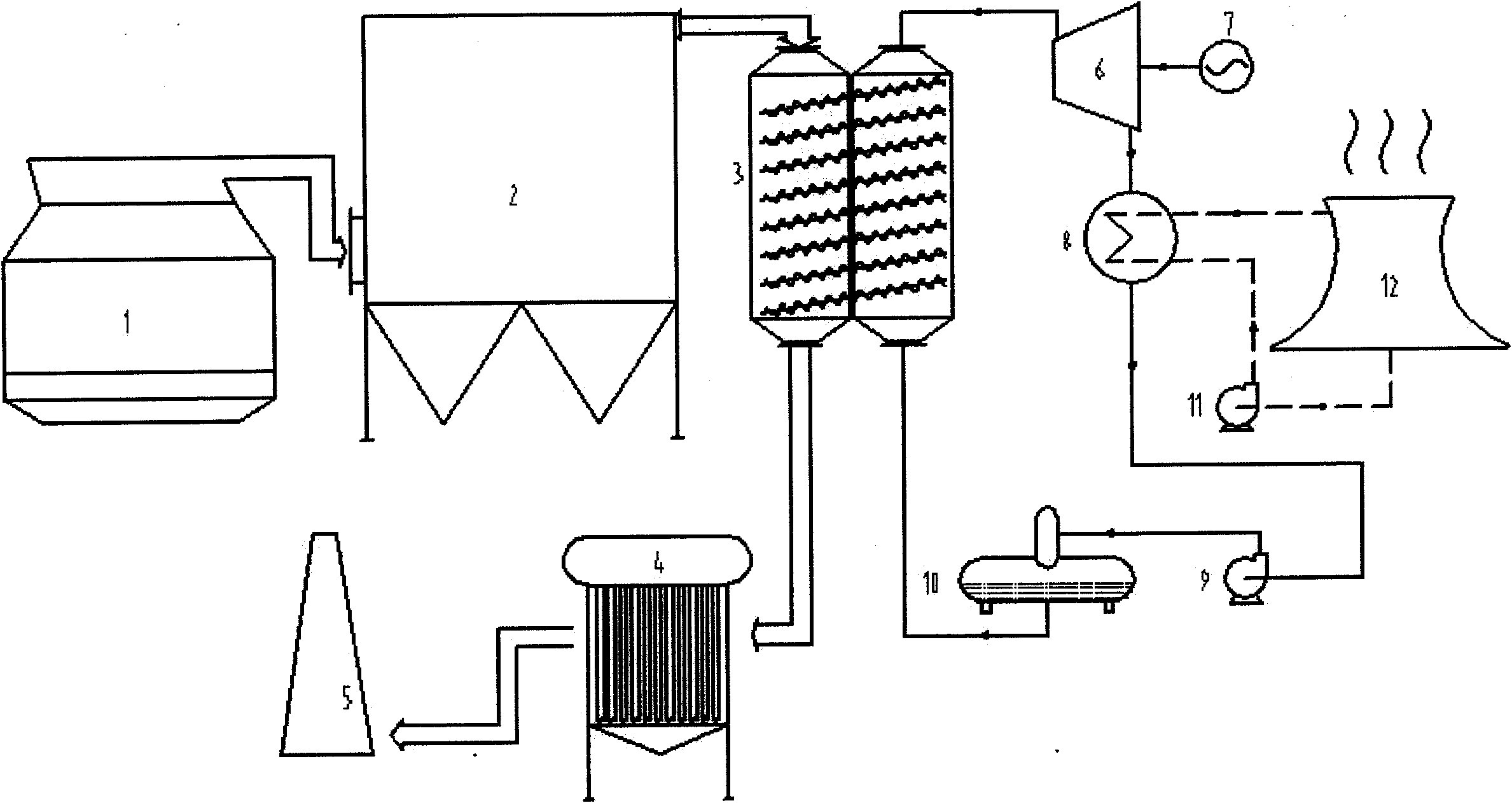

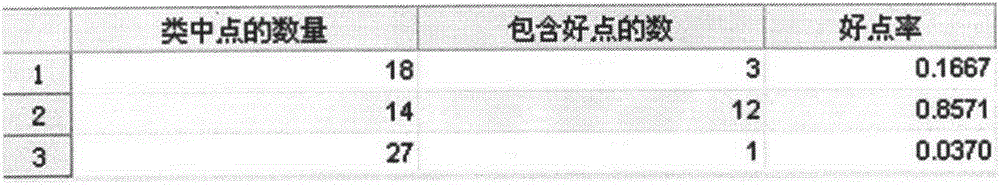

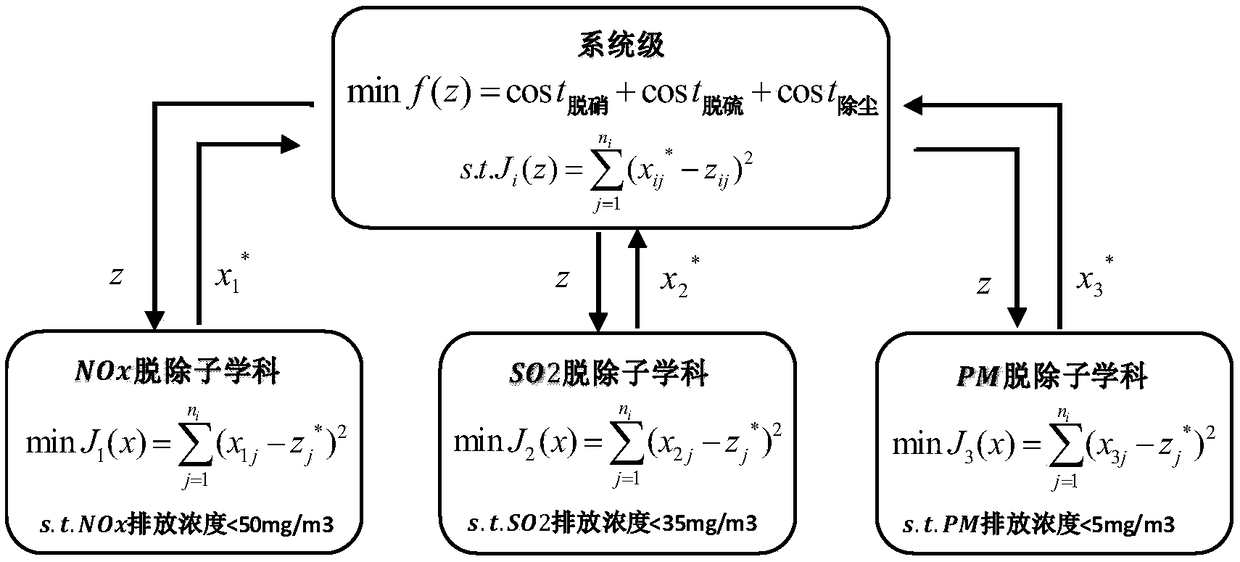

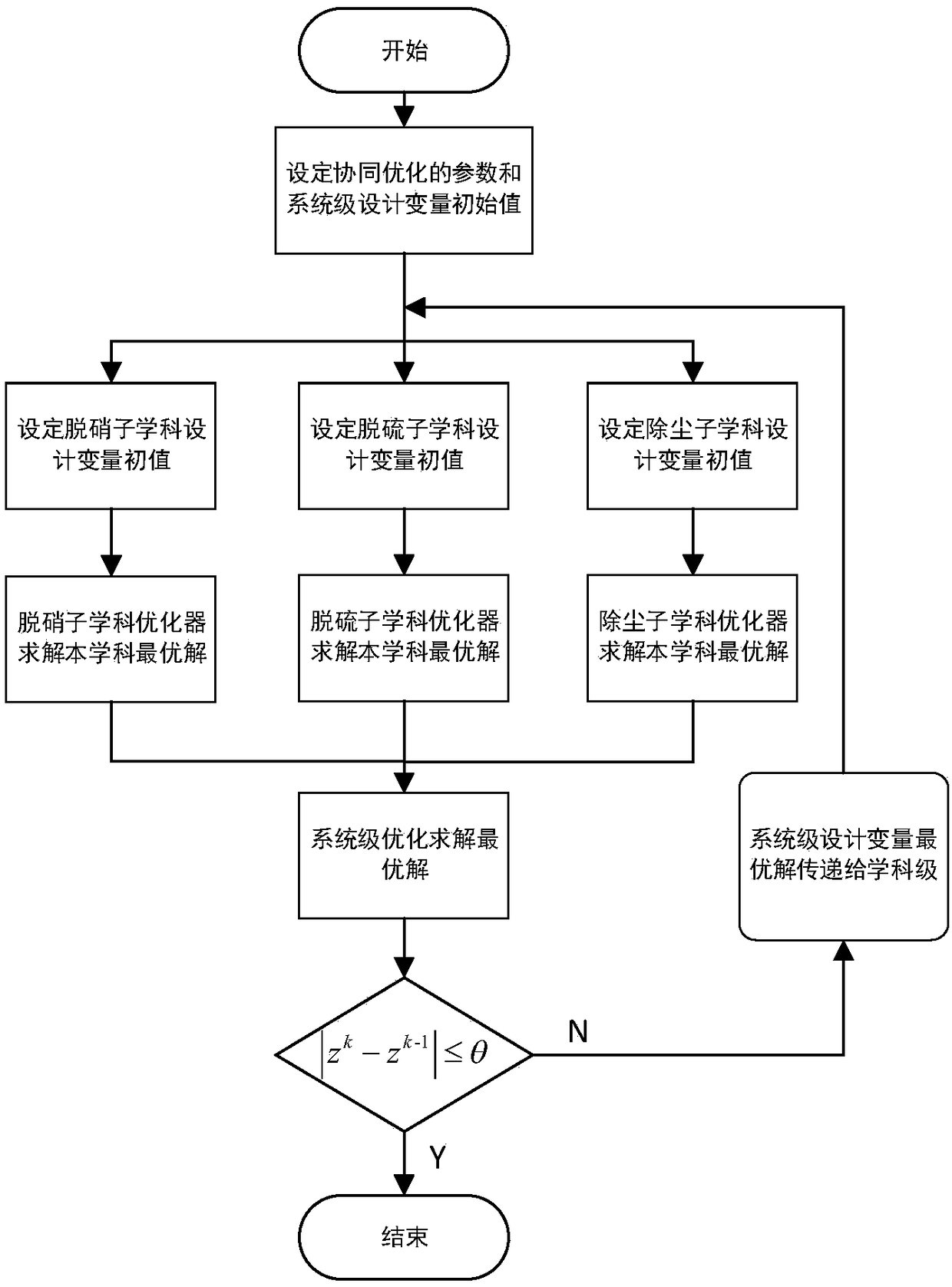

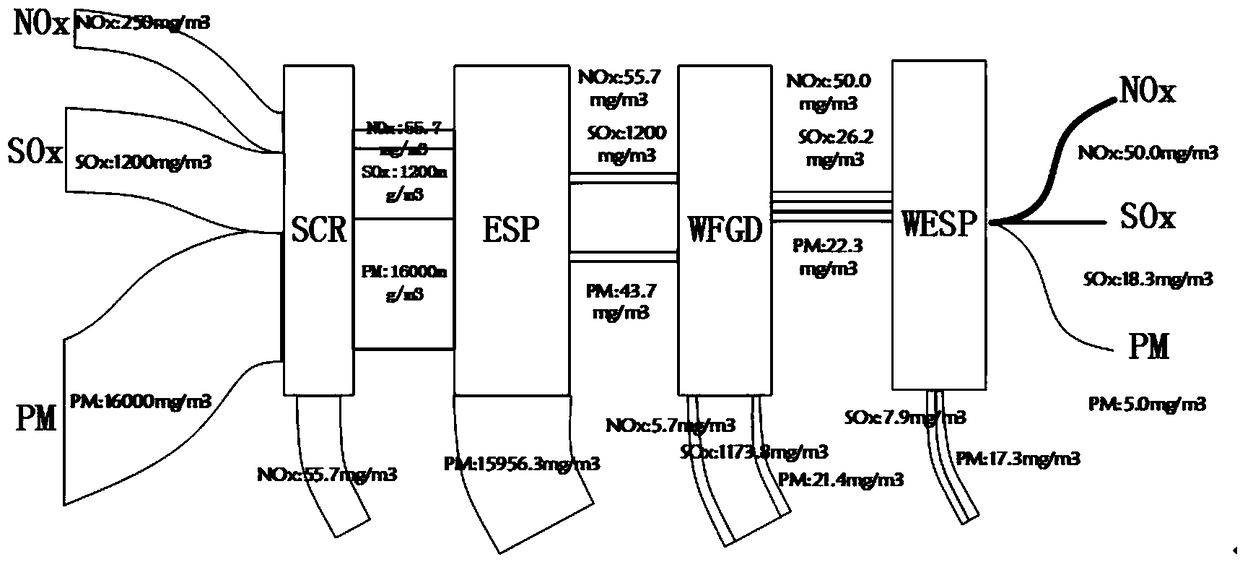

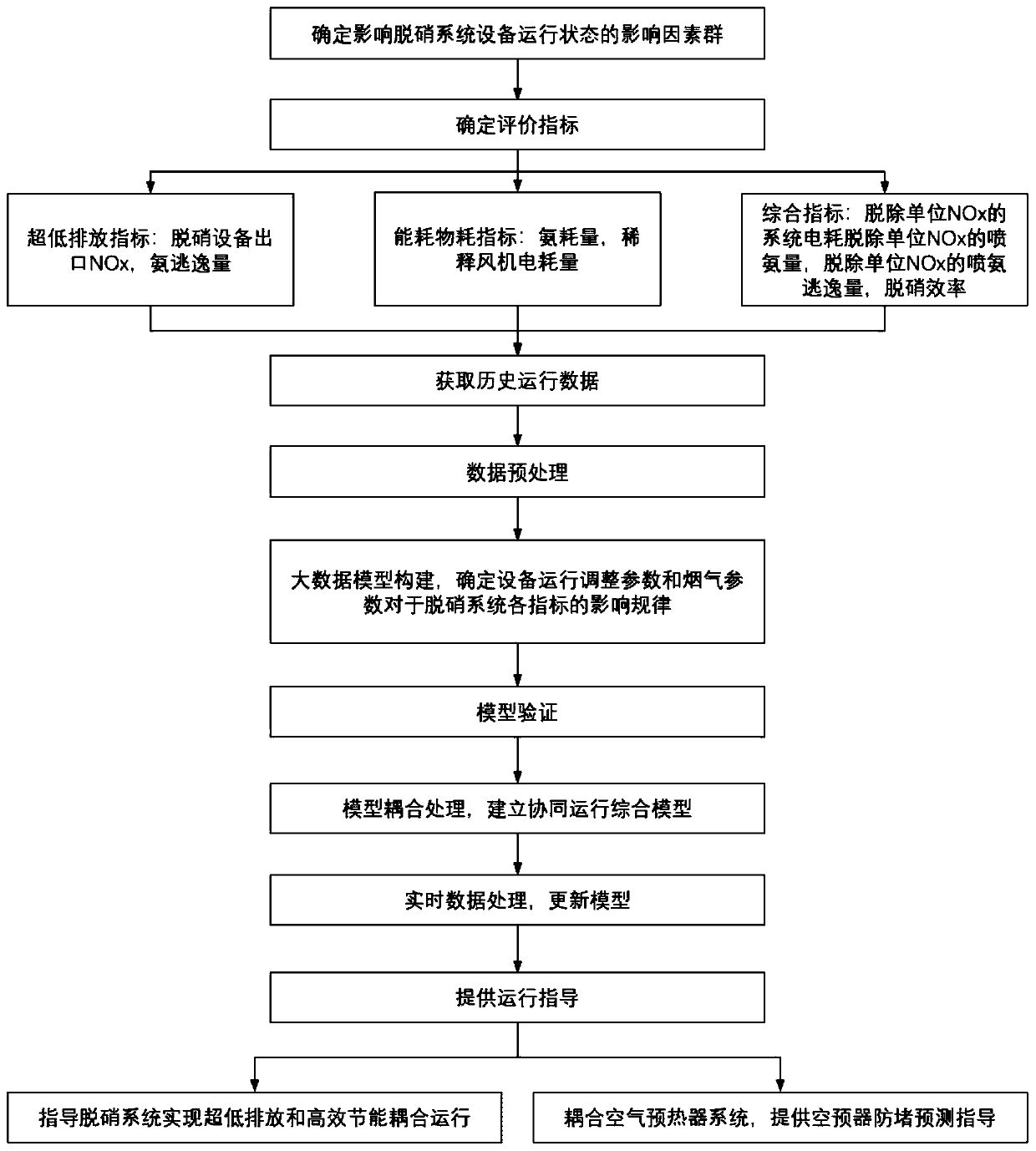

A low-cost collaborative removal modeling and optimization method for pollutants in a coal-fired power plant

ActiveCN109034457ALow running costOptimal operating parametersGas treatmentDispersed particle separationPollutantProcess engineering

A low-cost collaborative removal modeling and optimization method for pollutants in a coal-fired power plant includes collecting operation parameters and related variable of each pollutant removal device, analyzing energy consumption and / or income generated in each pollutant removal process, and establishing operation cost models of denitrification, desulfurization and dust removal; establishing acollaborative model of pollutant removal, which includes three sub-disciplinary models and one system model. The three sub-disciplinary models are a denitrification sub-disciplinary model, a desulfurization sub-disciplinary model and a dust removal sub-disciplinary model. The objective function of the system-level model is to minimize the sum of the costs of denitrification, desulfurization and dust removal, and the objective function of each sub-discipline level is added to the system-level objective function as a penalty term. A dynamic penalty function collaborative optimization algorithmis adopted to optimize the pollutant collaborative removal model, and the operation parameters of each device that make the system operation cost lowest under the condition of meeting the emission standard are solved.

Owner:HANGZHOU DIANZI UNIV

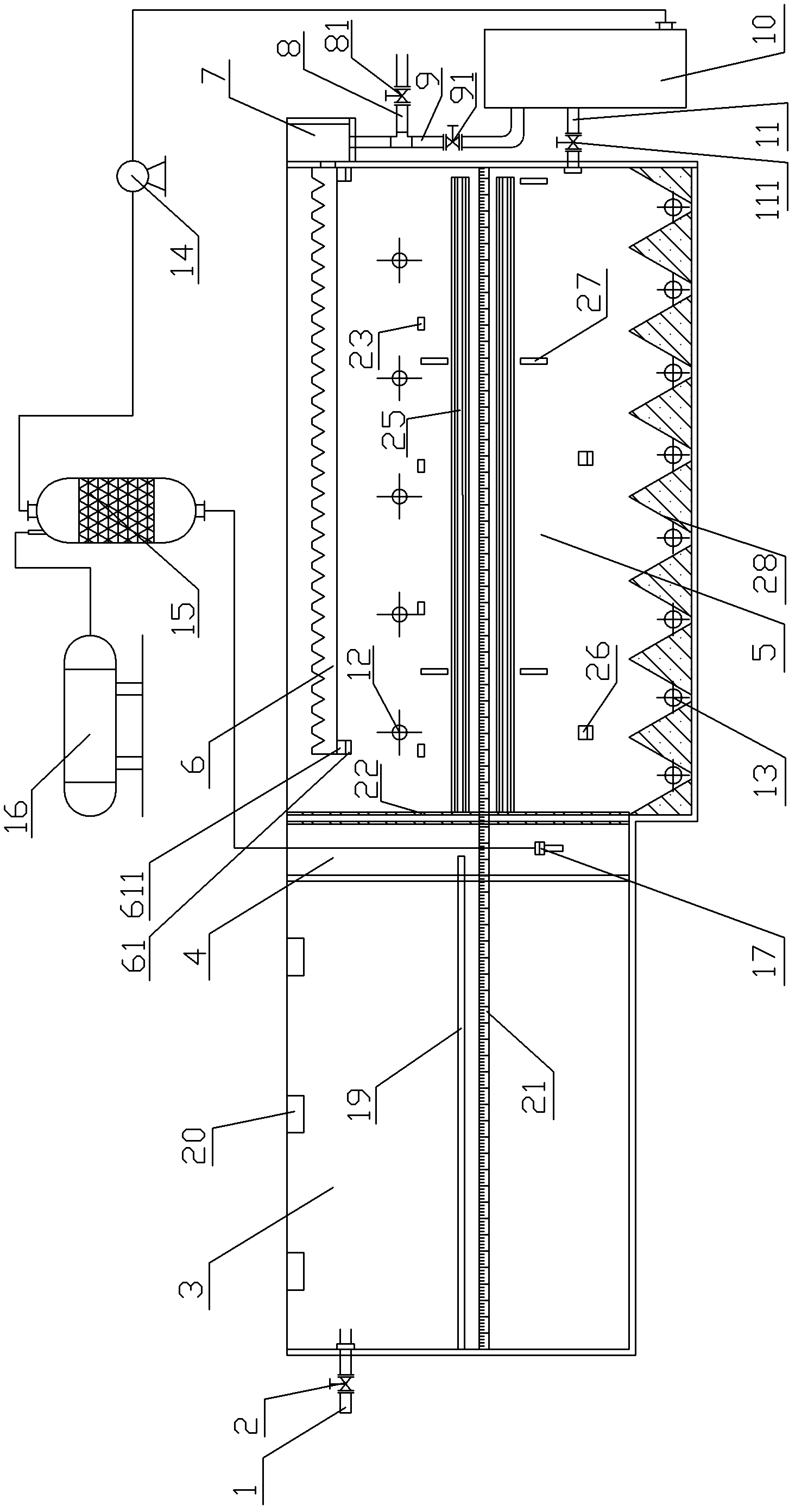

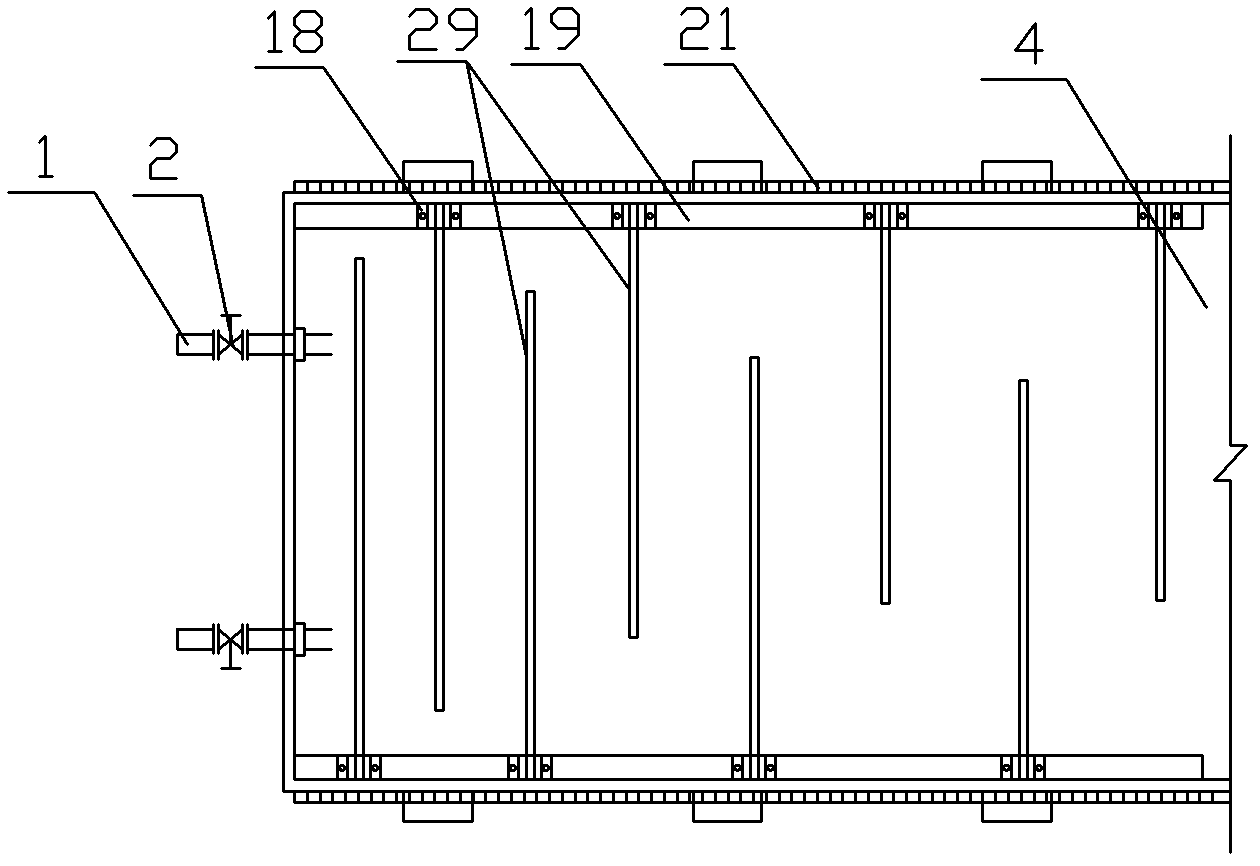

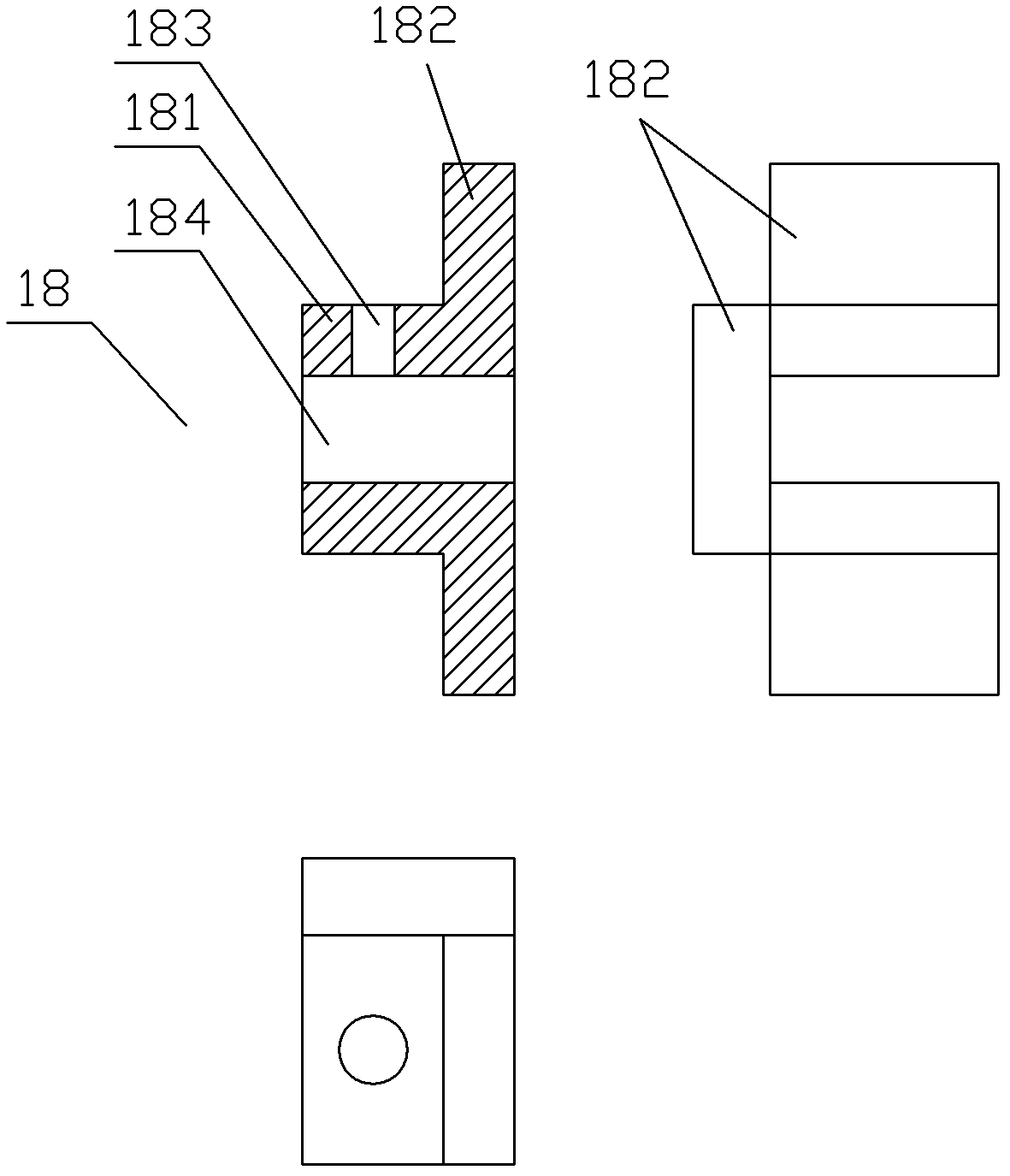

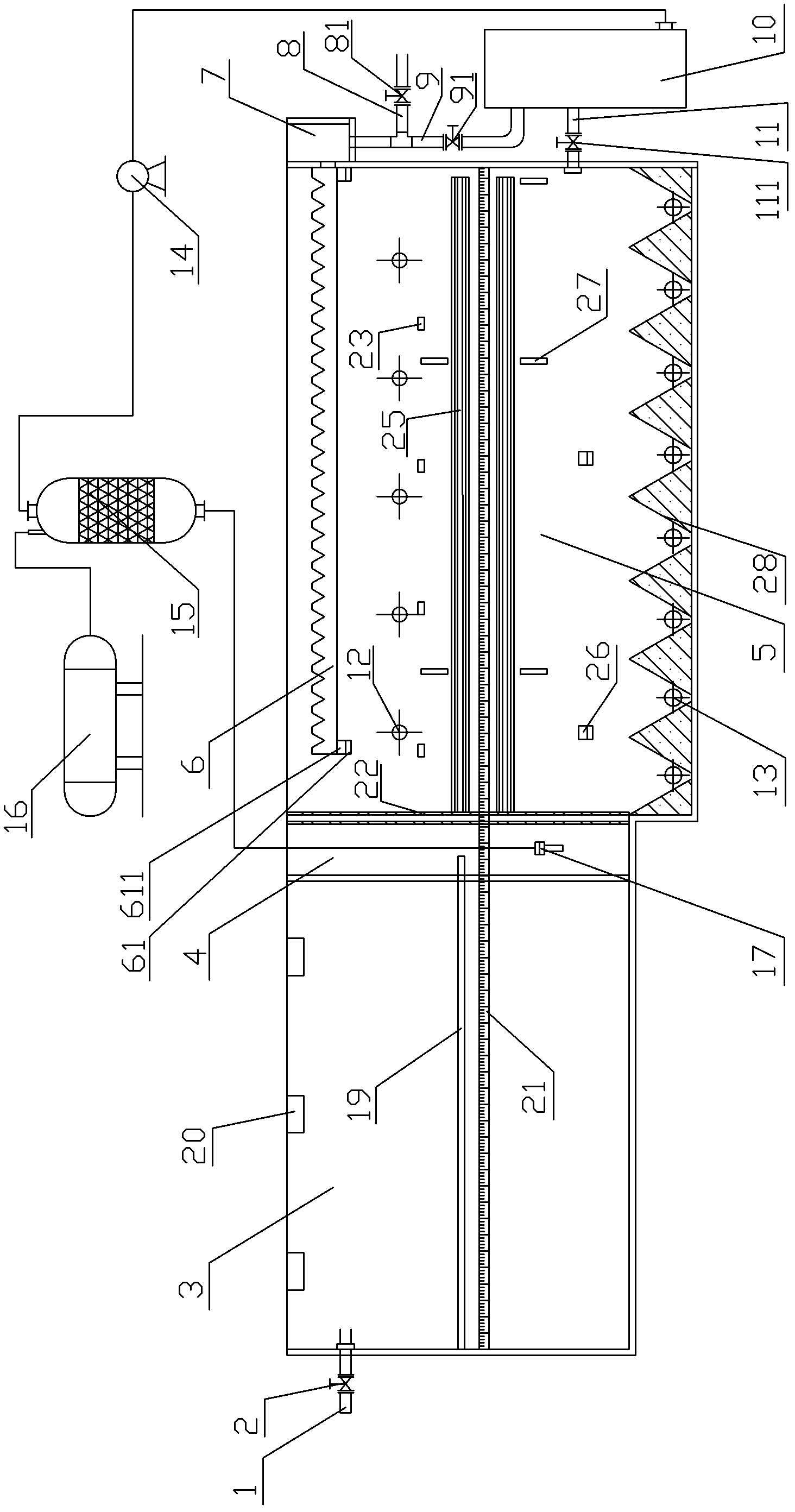

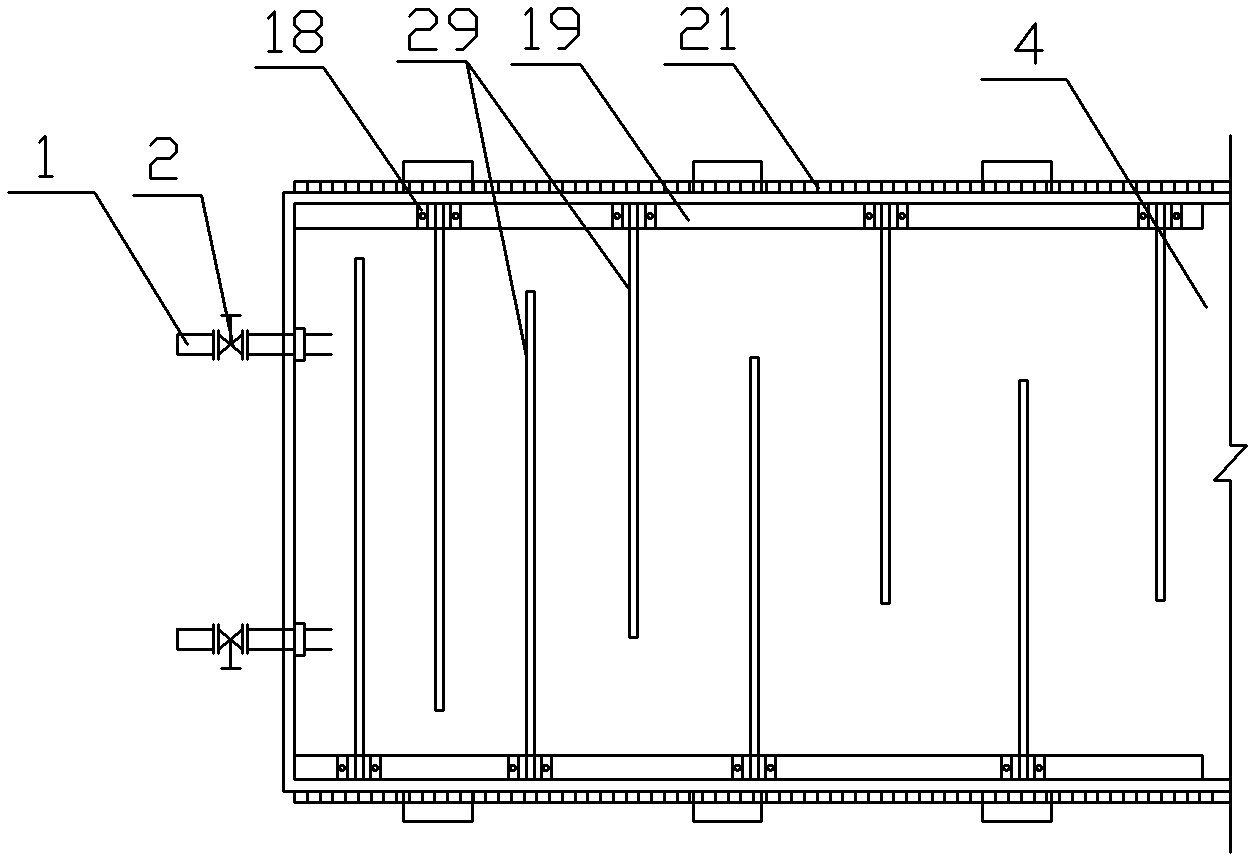

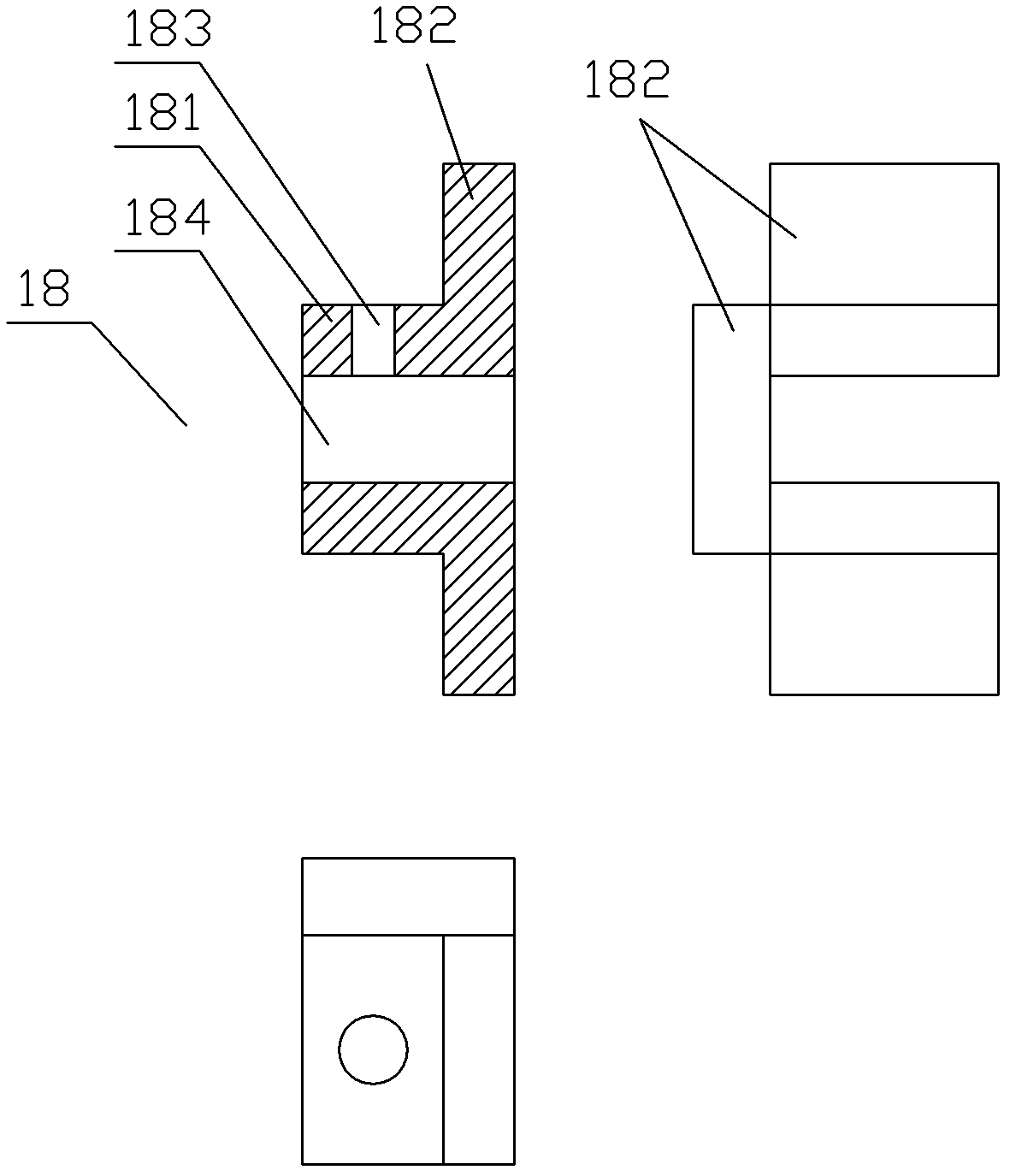

Multifunctional flocculation and oscillation experiment device

InactiveCN102583829AReduce manufacturing costSmall footprintMultistage water/sewage treatmentFlocculationWater quality

The invention relates to a multifunctional flocculation and oscillation experiment device, which aims at performing multiple water purification process experiments on a same experiment device. The multifunctional flocculation and oscillation experiment device mainly comprises a flocculation tank, a gas contact tank, an oscillation tank, a water tank, a water pump, a gas dissolution tank, an air compressor and a plurality of accessories. According to the technological requirements of the experiments, one of the following flocculation tanks including a reciprocating clapboard flocculation tank,a folded-plate and flat-plate combined flocculation tank and a mechanical flocculation tank is combined with one of the following oscillation tanks including an upward-flow sloping-plate oscillation tank, a downward-flow sloping-plate oscillation tank, an upward-flow sloping-plate sedimentation tank, a downward-flow sloping-plate sedimentation tank and a downward-flow floatation tank to form the experiment device needed by the different experiments. According to the invention, spaces among clapboards in the flocculation tank can be changed freely, an included angle between each sloping plate in the oscillation tank and the horizontal plane ranges from 20 degrees to 160 degrees, and horizontal spaces among the sloping plates can be changed freely, thereby guaranteeing the obtaining of optimum operating parameters in the experiments, greatly decreasing a space occupied by the experiment device, and reducing the manufacturing cost of the experiment device.

Owner:王志勇 +1

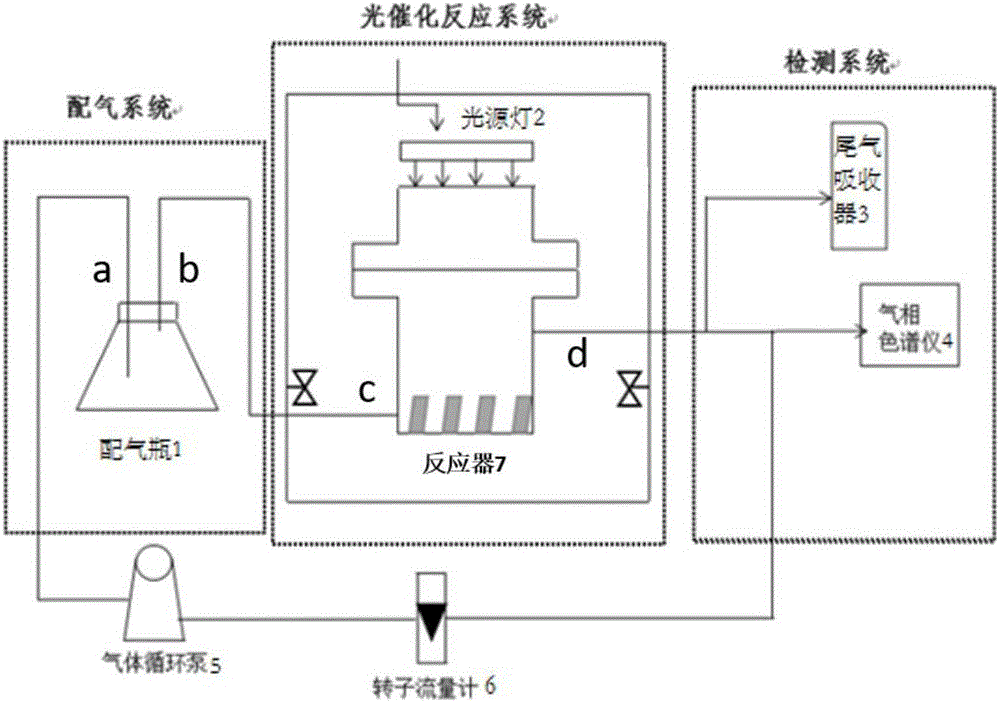

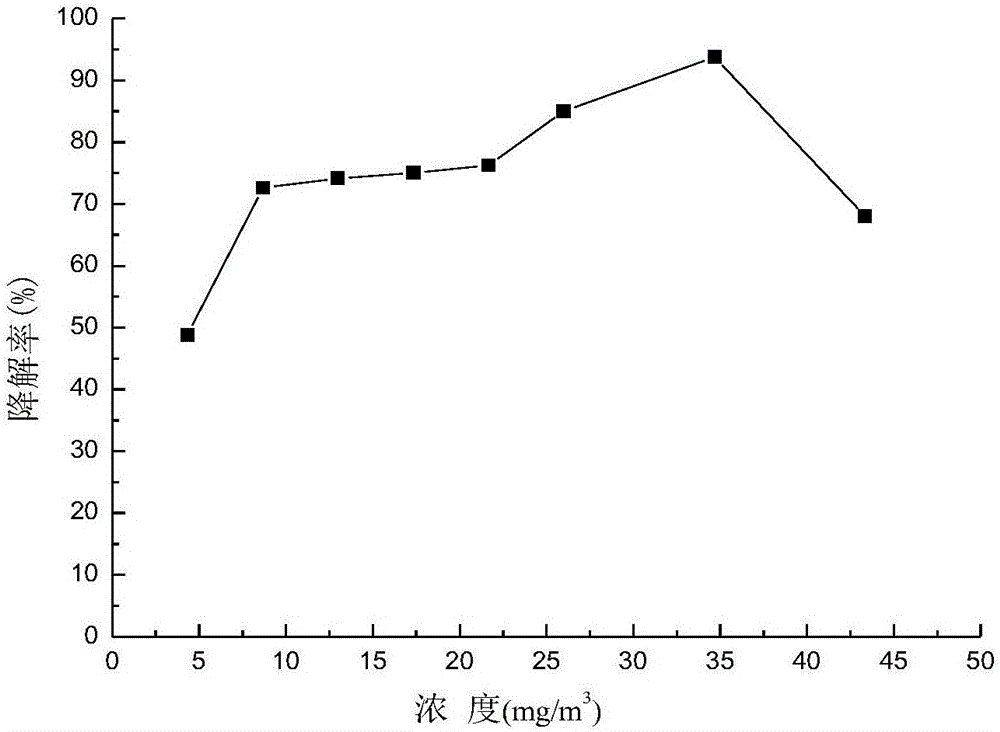

Device and method for removing volatile organic compounds in air by photocatalysis

InactiveCN106422765AOptimal operating parametersImprove utilization efficiencyGas treatmentDispersed particle separationPhotocatalytic reactionGas cylinder

The invention discloses a device and a method for removing volatile organic compounds in air by photocatalysis. The air inlet a of an air distribution bottle is communicated with the air outlet pipe of a reactor through an air circulation pump and a rotor flowmeter in sequence; the air outlet b of the air distribution bottle is communicated with the bottom of the reactor of a photocatalysis reaction device; TiO2 photocatalyst loaded on a titanium sheet is evenly tiled on the bottom of the reactor; the top of the reactor is provided with an illuminant light by being vertical to the bottom of the reactor; the air outlet d of the reactor is communicated with a gas chromatograph after being subjected to sampling by the air outlet pipe of the reactor; the position, which is near the air outlet d, of the air outlet pipe of the reactor is connected with a tail gas absorber through a branch air outlet pipe. The photocatalyst is tiled, an ultraviolet lamp light source vertically irradiates the catalyst, light utilization efficiency is improved, and the device has the advantages of simple structure, convenience in control, energy saving and low operation cost. Toluene photocatalytic degradation efficiency reaches 93.72%, and volatile organic compound (VOCs) pollutants in the air can be effectively removed.

Owner:QINGDAO AGRI UNIV

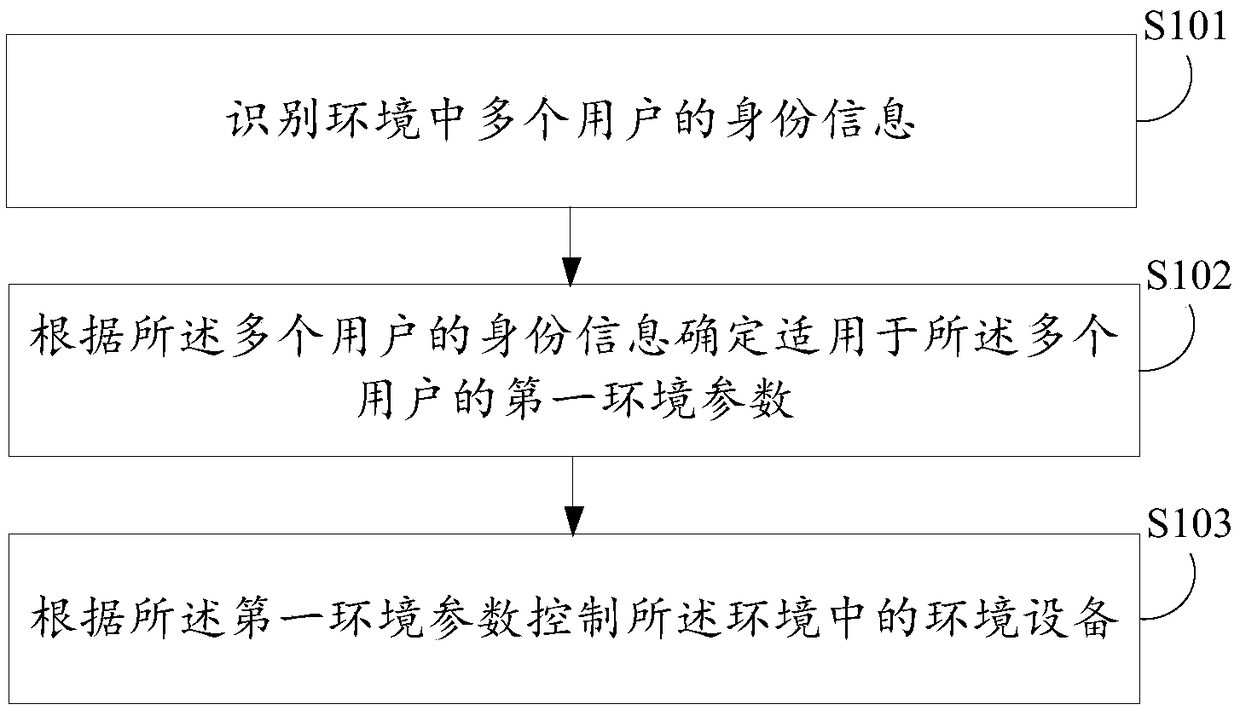

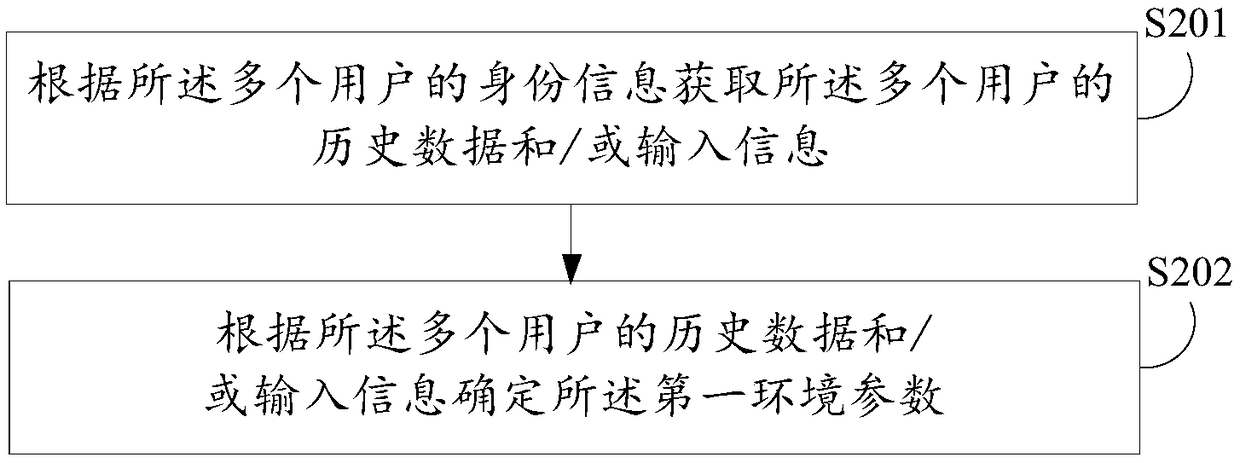

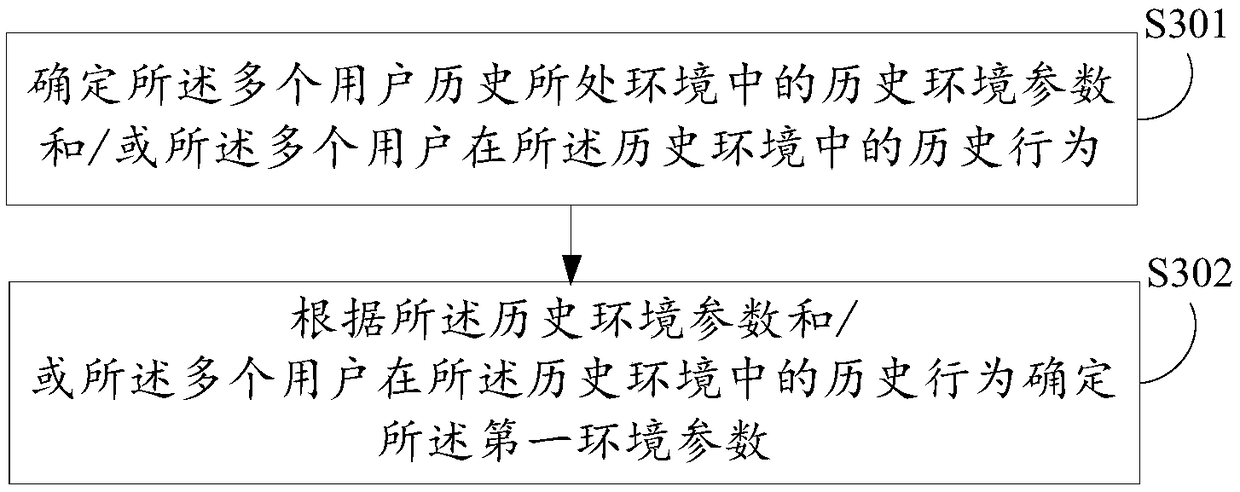

Control method and device of environmental equipment, electronic equipment and storage medium

PendingCN108758962AOptimal operating parametersMechanical apparatusLighting and heating apparatusComputer scienceElectronic equipment

The embodiment of the invention discloses a control method and device of environmental equipment, electronic equipment and a storage medium. The control method comprises the steps that the identity information of a plurality of users in the environment is identified; first environment parameters applicable to the multiple users are determined based on the identity information of the multiple users; and the environmental equipment in the environment is controlled according to the first environmental parameters. In multi-person space, the obtained personal identity information can automaticallymatch comfort data, so as to obtain the best operating parameters of the equipment in the environment which enables each person to feel comfortable. The control method is not only applicable to a certain multi-person space, but also can control the environmental parameters according to historical data when a region changes.

Owner:BEIJING HECHUANG SANZEN ENERGY TECH RPORATION

Environment-friendly technology for cleanly producing sodium glutamate

The invention relates to an environment-friendly technology for cleanly producing sodium glutamate. The environment-friendly technology comprises the following steps of: simultaneously adding liquid ammonia and sodium carbonate into sodium glutamate fermentation liquor for reaction, and thereby obtaining coarse fermentation liquor; filtering by micromembrane, and collecting degerming liquid and mycoprotein; adopting the mycoprotein to prepare probiotics, pumping the degerming liquid into a bleaching tank to perform decoloration process, and concentrating and crystallizing to obtain sodium glutamate coarse crystal; then refining and processing waste water; the technology is economical and environment-friendly, and has wide application prospects.

Owner:内蒙古阜丰生物科技有限公司

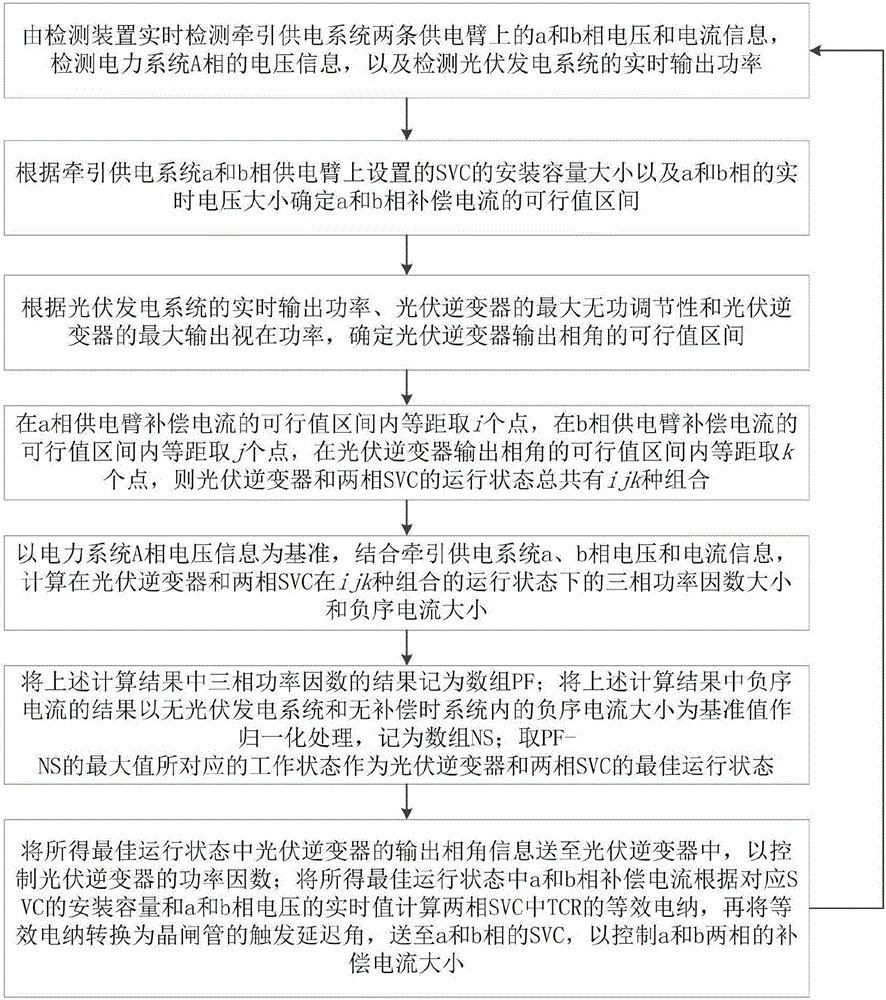

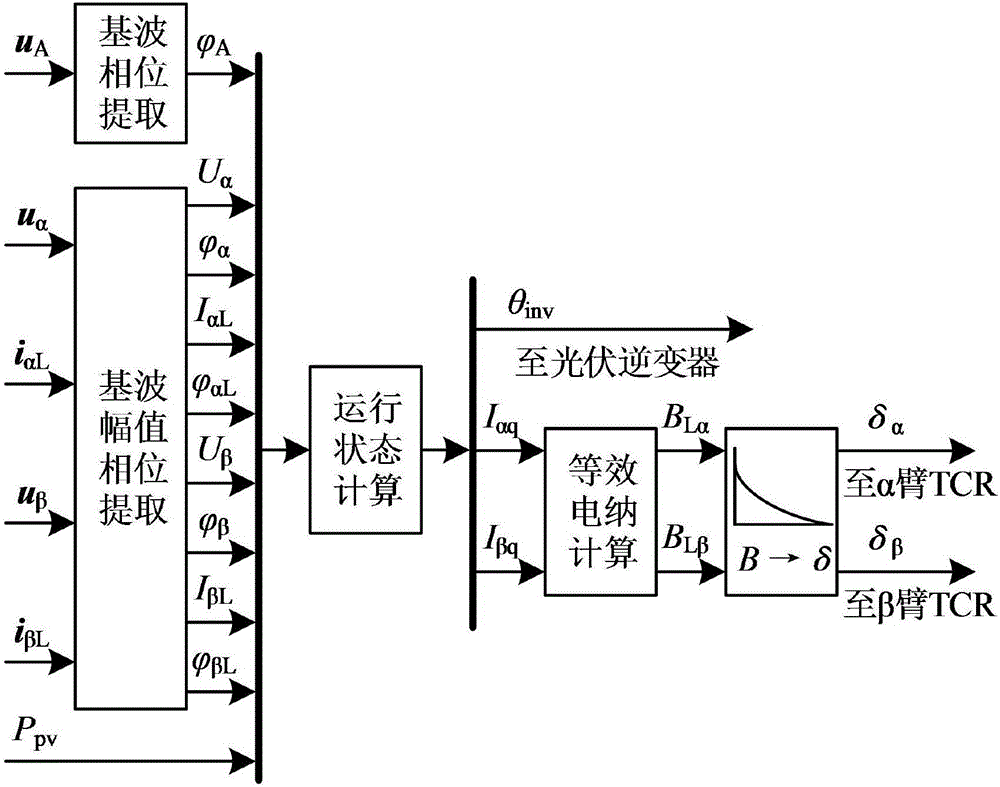

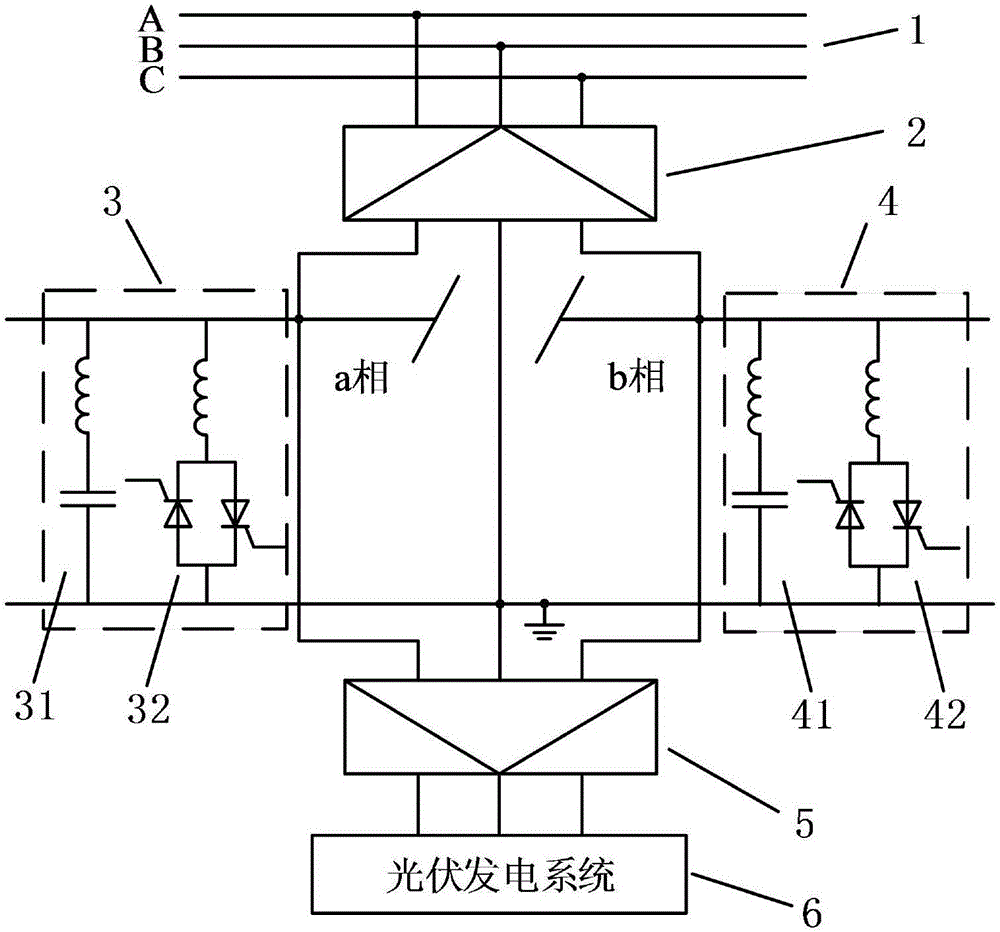

Photovoltaic inverter two-phase SVC optimization control method in tractive power supply system

ActiveCN106451559AImprove power factorSmall negative sequence currentFlexible AC transmissionPower supply linesPower qualityPower flow

The invention discloses a photovoltaic inverter two-phase SVC optimization control method in a tractive power supply system. The system is capable of monitoring the voltage of a phase A of a power system, the voltage and current of phase a and b supply arms of the tractive power supply system and the output power of a photovoltaic power station in real time. The method comprises the following steps: acquiring a phase of the phase of the phase A voltage of the power system through a fundamental current amplitude and phase extraction module, simultaneously inputting the amplitude of the voltage and current and the phase information of phase a and b supply arms as well as the output power of the photovoltaic power station, calculating to obtain the optimal operating parameters of the photovoltaic inverter two-phase SVC under the condition. According to the control method provided by the invention, the power factor added into the tractive power supply system of a photovoltaic power generation system is as high as possible, and the negative-sequence current added into the tractive power supply system of the photovoltaic power generation system is as low as possible, so that the electric energy quality of the system is improved, and the system power supply is safe and reliable.

Owner:SOUTHWEST JIAOTONG UNIV

Multifunctional flocculation and oscillation experiment device

InactiveCN102583829BReduce manufacturing costSmall footprintMultistage water/sewage treatmentFlocculationWater quality

The invention relates to a multifunctional flocculation and oscillation experiment device, which aims at performing multiple water purification process experiments on a same experiment device. The multifunctional flocculation and oscillation experiment device mainly comprises a flocculation tank, a gas contact tank, an oscillation tank, a water tank, a water pump, a gas dissolution tank, an air compressor and a plurality of accessories. According to the technological requirements of the experiments, one of the following flocculation tanks including a reciprocating clapboard flocculation tank,a folded-plate and flat-plate combined flocculation tank and a mechanical flocculation tank is combined with one of the following oscillation tanks including an upward-flow sloping-plate oscillation tank, a downward-flow sloping-plate oscillation tank, an upward-flow sloping-plate sedimentation tank, a downward-flow sloping-plate sedimentation tank and a downward-flow floatation tank to form the experiment device needed by the different experiments. According to the invention, spaces among clapboards in the flocculation tank can be changed freely, an included angle between each sloping plate in the oscillation tank and the horizontal plane ranges from 20 degrees to 160 degrees, and horizontal spaces among the sloping plates can be changed freely, thereby guaranteeing the obtaining of optimum operating parameters in the experiments, greatly decreasing a space occupied by the experiment device, and reducing the manufacturing cost of the experiment device.

Owner:王志勇 +1

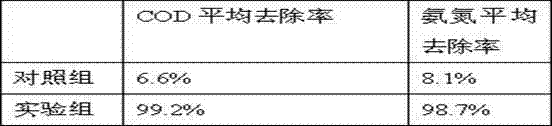

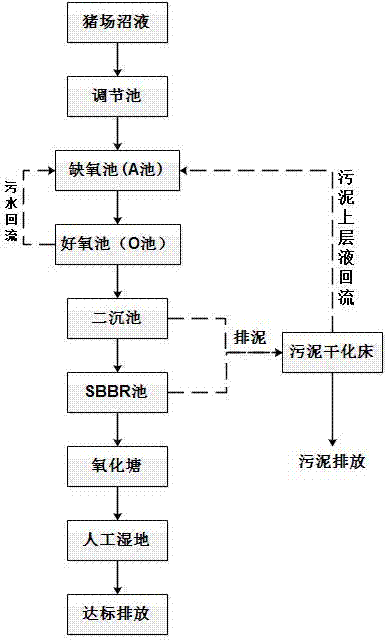

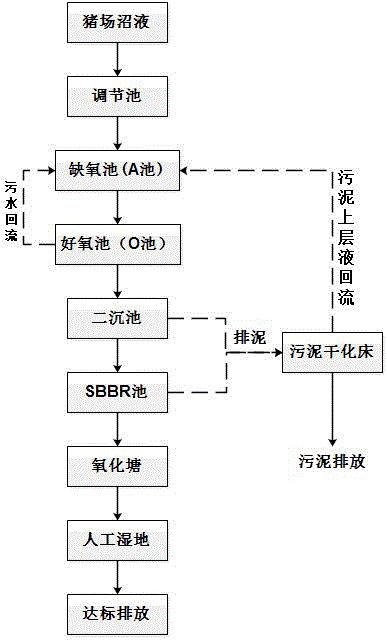

A/O-SBBR-oxidation pond-constructed wetland treatment piggery methane fluid system

InactiveCN106865890ALow costImprove biodegradabilityWaste water treatment from animal husbandryTreatment involving filtrationConstructed wetlandTherapeutic effect

The invention relates to an A / O-SBBR-oxidation pond-constructed wetland treatment piggery methane fluid system. An adjusting pond, an anoxia pond, an aerobic pond and a secondary sedimentation pond are sequentially arranged before a sequencing batch biofilm reactor (SBBR), an oxidization pond and a three-stage constructed wetland comprising canna indica, reed, typha orientalis, cane shoots and other aquatic plant are sequentially constructed behind the SBBR; the system has a stable treatment effect, and is strong in anti-impact load capacity, simple to operate, and low in running cost. The operating mode and time parameters of the SBBR are as follows: water inflow lasts for 1h, aeration lasts for 3.5h, anoxia environment lasts for 2h, aeration lasts for 3.5h, sedimentation lasts for 1h, and drainage lasts for 1h. The effluent index of the piggery methane fluid meets the requirement of pollution discharge standard of livestock and poultry industry (GB 18596-2001) after being treated by the combination technology.

Owner:NANCHANG UNIV

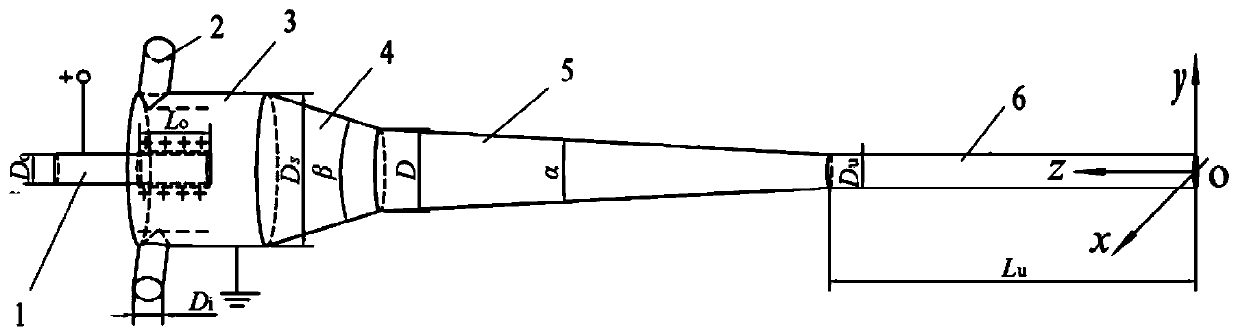

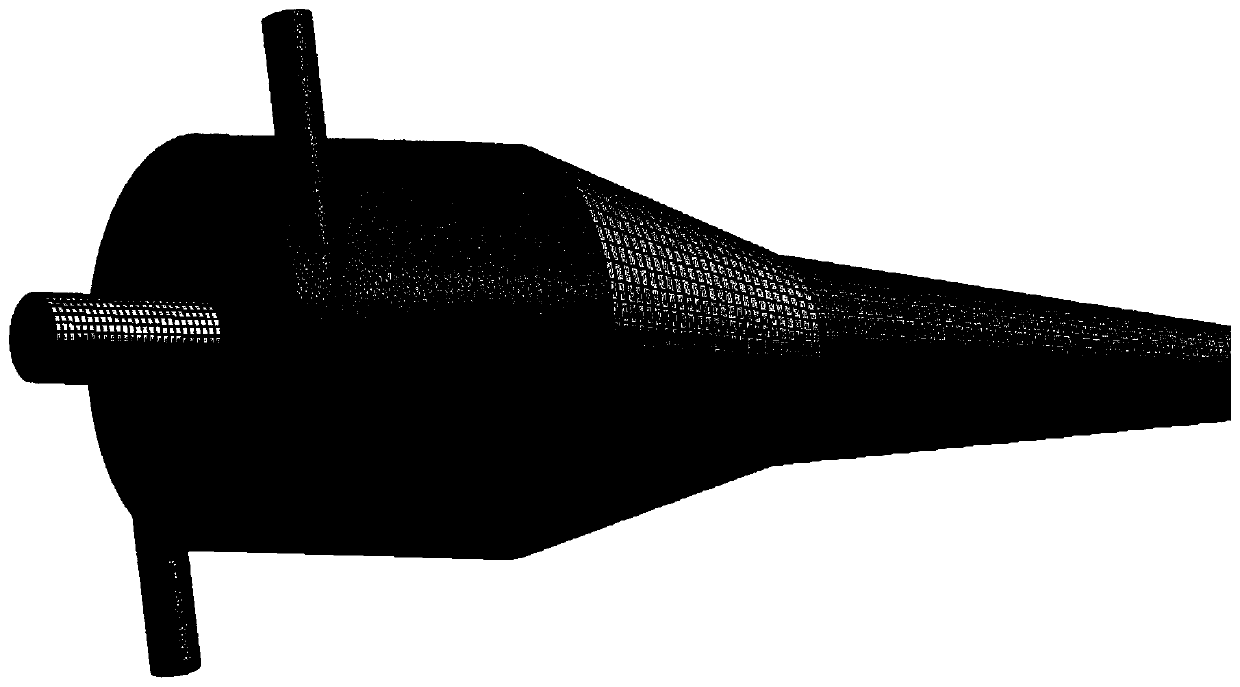

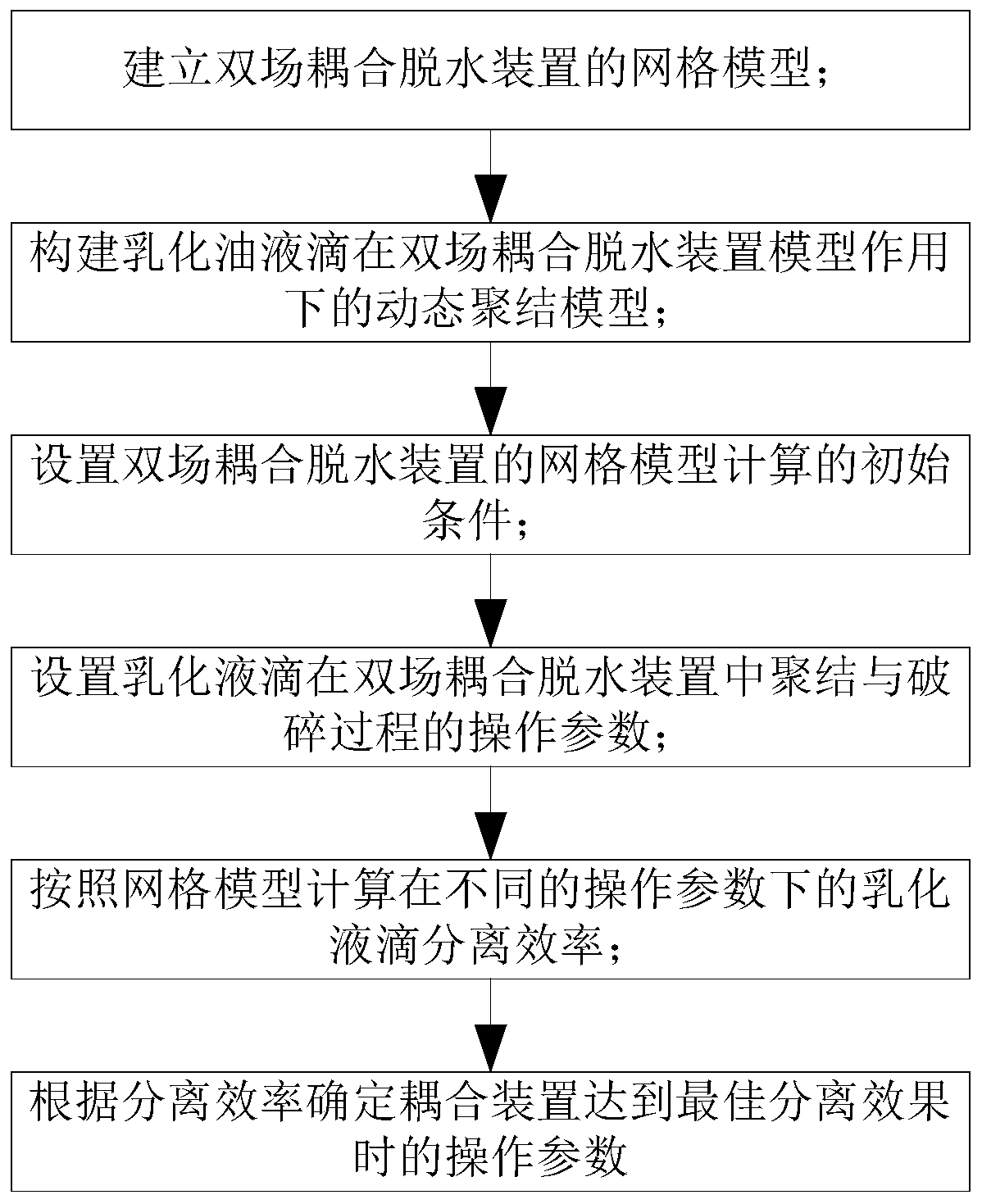

Method for determining optimal operation parameter of double-field coupling dewatering device

ActiveCN109903820AOptimal operating parametersDewatering/demulsification with mechanical meansDewatering/demulsification with electric/magnetic meansPopulation balance equationEngineering

The invention discloses a method for determining an optimal operation parameter of a double-field coupling dewatering device. The effects of an eddy flow centrifugal field and a high-voltage electricfield are integrally considered. A calculating hydrodynamics method is utilized. A flow field control equation, an electric field control equation and a population balance equation are combined for constructing a dynamic coalescence model of emulsified oil liquid drops in a double-field coupling reinforcing function. The population balance equation is used for simulating the coalescence and fragmentation process of the emulsified oil liquid drops in the device, thereby calculating the liquid drop dimension distribution, average particle size and separating efficiency on the condition of different operation parameters, and determining the operation parameter when the coupling device realizes an optimal separating effect.

Owner:CHONGQING TECH & BUSINESS UNIV

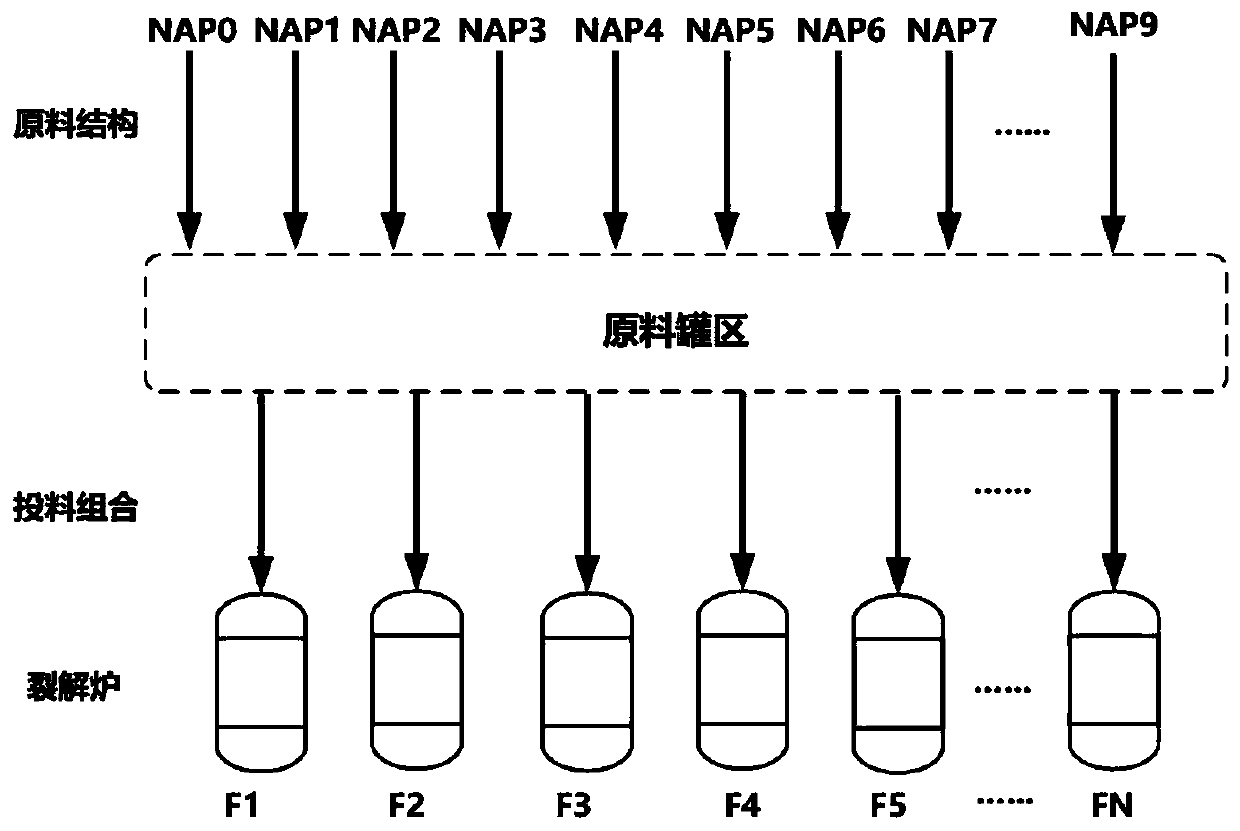

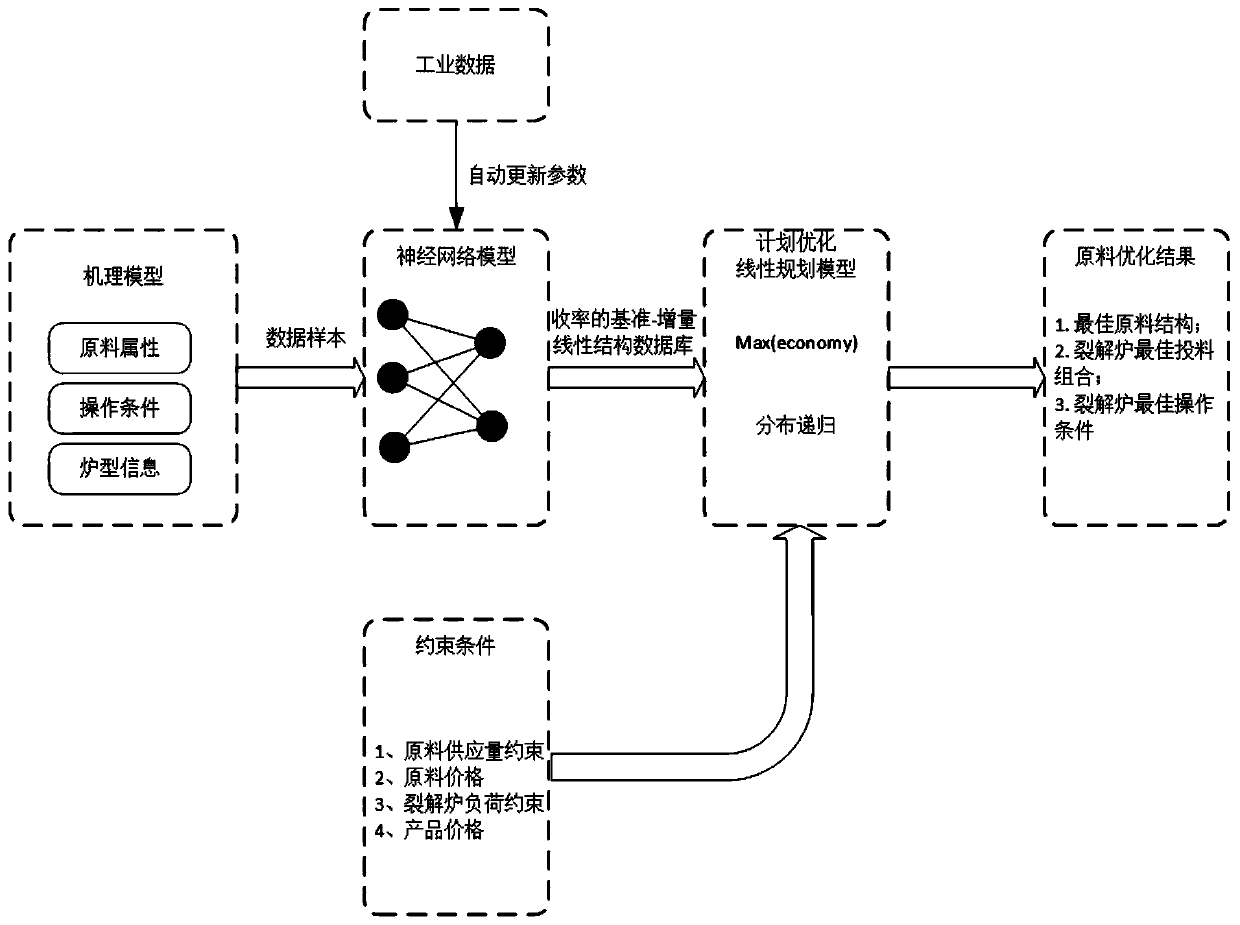

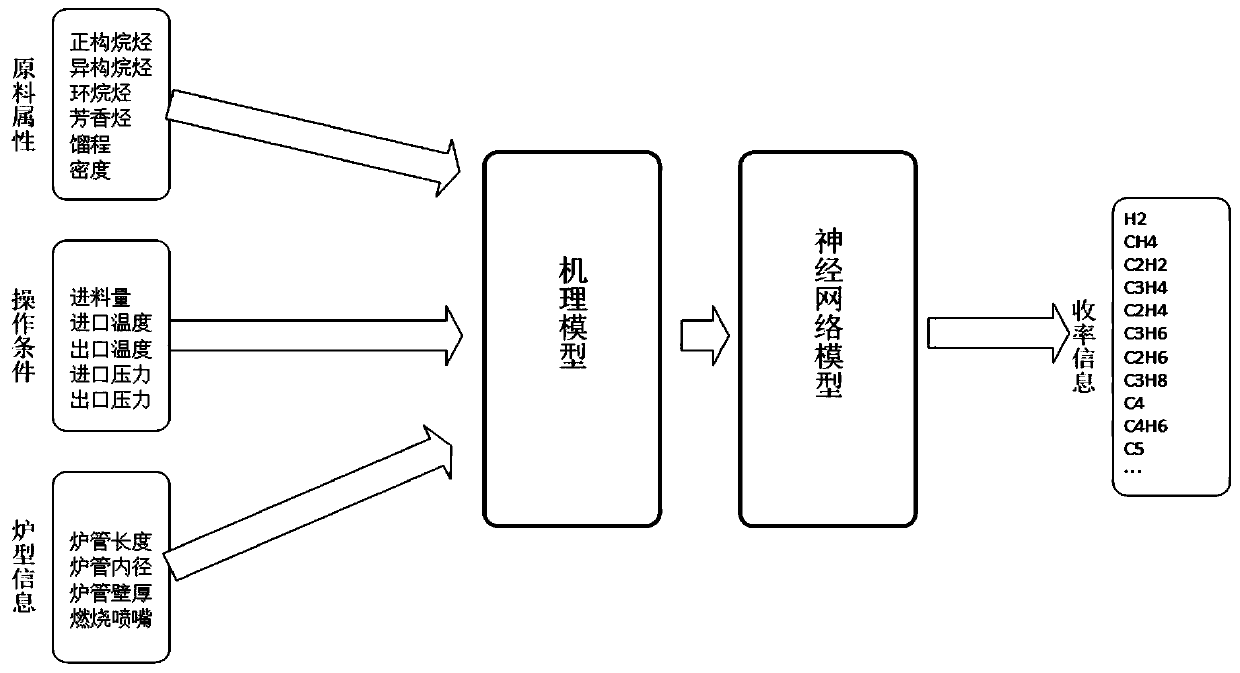

Ethylene production raw material optimization method based on hybrid modeling

PendingCN111461406AImprove economic efficiencyAccurate planning and productionForecastingDesign optimisation/simulationNon lineariteIndustrial engineering

The invention relates to an ethylene raw material optimization method based on a mechanism and data hybrid modeling and linear programming technology, which utilizes a large-scale linear programming method to carry out ethylene raw material selection optimization in a constraint range of a whole plant so as to maximize profits of the whole plant. The method comprises the following steps: firstly,establishing a mechanism model for an ethylene cracking furnace, simulating and generating massive data samples based on the mechanism model, constructing a neural network data model, and establishinga hybrid model for predicting the cracking product yield; secondly, aiming at the nonlinear relation that the yield of the cracking product changes along with the raw material attributes and the process parameters, adopting a multi-section linear processing mode, and constructing a reference-increment database between the yield and the raw material attribute key parameters and between the yield and the key process parameters through a mixed model; and writing the reference-increment multi-segment linear structure database of the yield into a plan optimization linear programming model in combination with other constraint information, and solving the model in a distribution recursion mode to obtain a raw material selection optimization result. In order to ensure the accuracy of a yield reference-increment structure and the prediction precision of a linear programming model, the hybrid model can automatically correct model parameters and quickly update a yield reference-increment multi-segment linear structure database. The method provided by the invention can provide a quantitative basis for raw material purchasing and planned production scheduling of ethylene enterprises, so that the economic benefits and the raw material utilization rate of the enterprises are improved.

Owner:EAST CHINA UNIV OF SCI & TECH

Simulation processing system for volatile organic compounds

PendingCN109529529AReduce commissioning costsOptimal operating parametersGas treatmentDispersed particle separationDesorptionProduct gas

The invention relates to a simulation processing system for volatile organic compounds. The processing system is used for evaluating the adsorption and regeneration performance of an adsorption material under the condition of simulating the actual engineering condition. The processing system comprises a gaseous VOCs (volatile organic compounds) generating device, a carrier gas introducing pipeline, a mixing device, an adsorption tower and a circulating fan, and further comprises a first concentration detector, a second concentration detector and a gas heating device, wherein the adsorption tower is provided with an air inlet and an air outlet. The processing system has a first use state and a second use state, namely adsorption treatment and desorption treatment are integrated; and when the adsorption material reaches a saturation adsorption state in the first use mode, the system can be immediately switched to the second use state and can perform simulation processing on different operating conditions (flow velocity, humidity and temperature), various kinds of waste gas treatment engineering conditions can be simulated to the largest extent, and therefore an optimal operation parameter is obtained, and the debugging cost of an enterprise in the practical engineering process is lowered.

Owner:JIANGSU SUJING GROUP

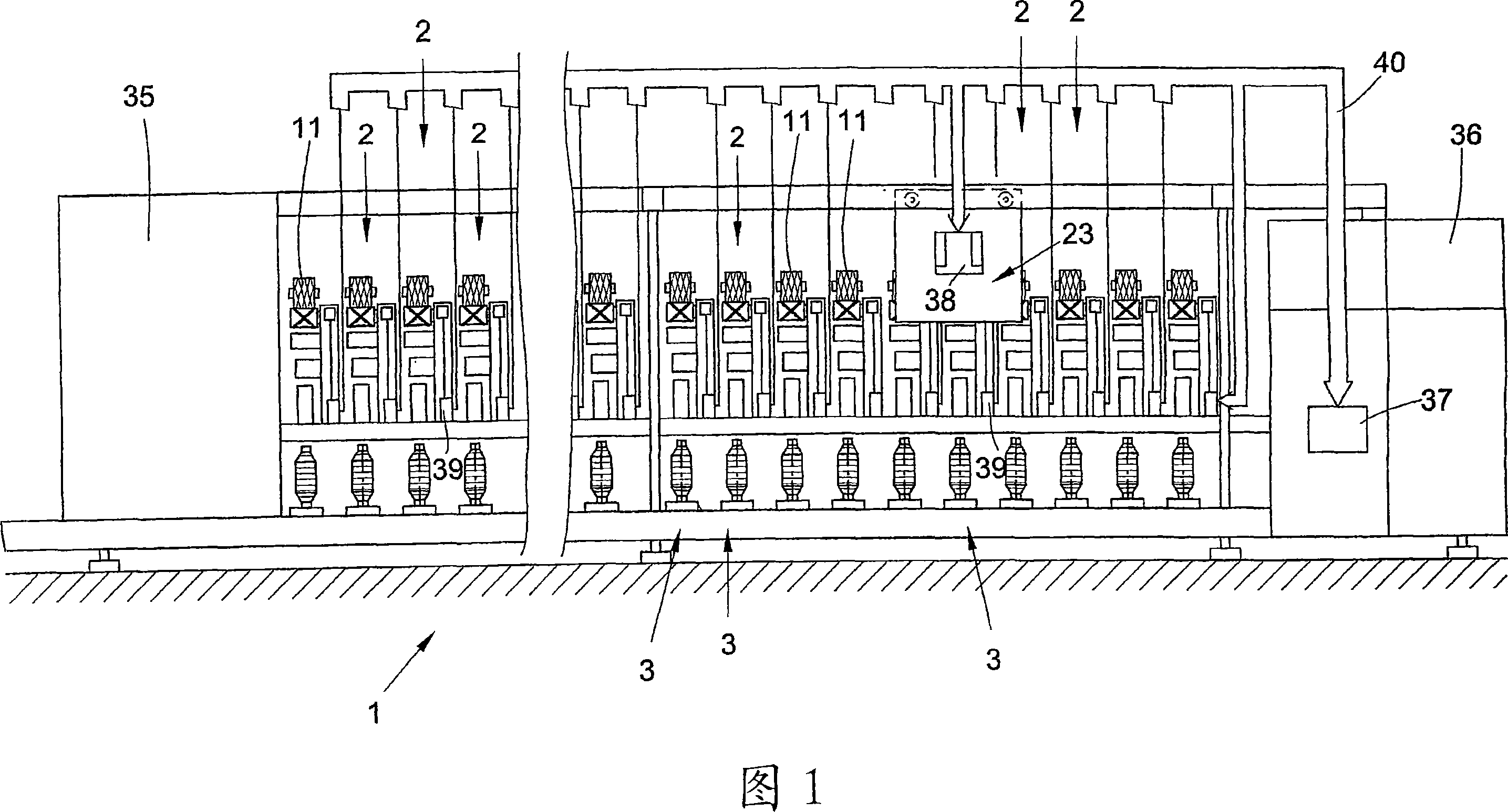

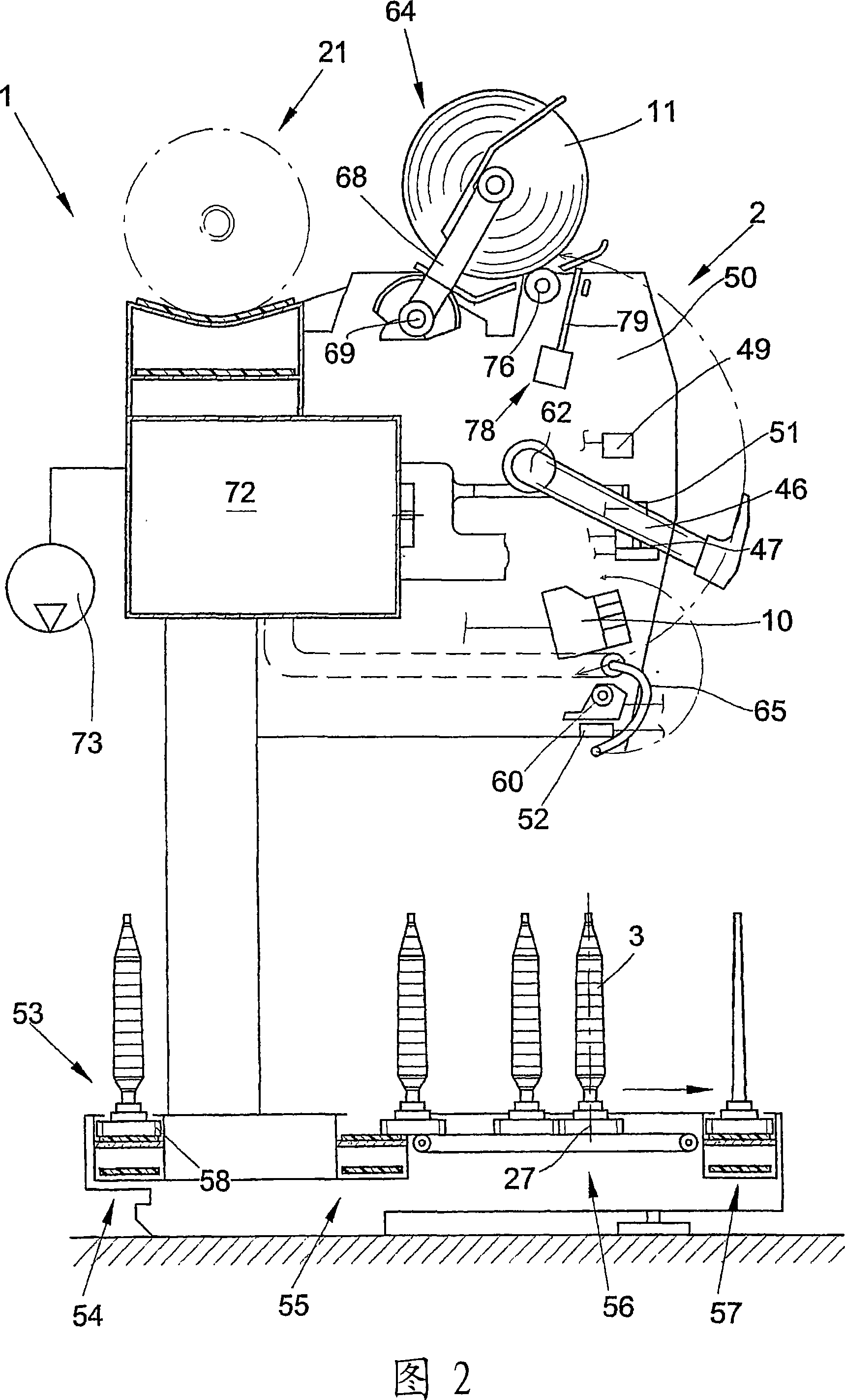

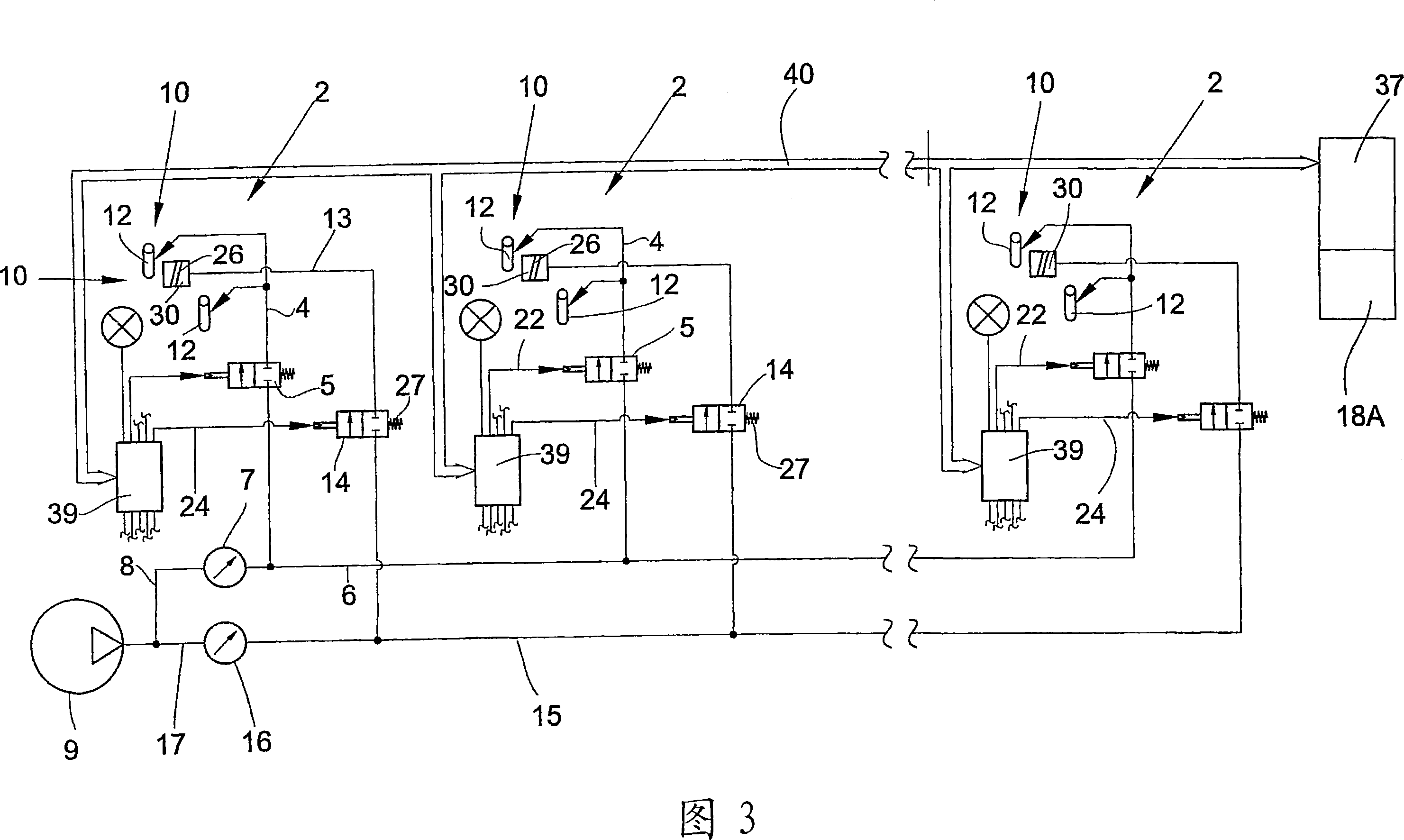

Method and device for optimising operating parameters on an operating point of a textile machine producing cross-wound spools

InactiveCN101010247AImprove work resultsOptimal operating parametersFilament handlingYarnOperating point

The invention relates to a method and a device for optimising operating parameters of a textile machine (1) comprising a plurality of operating points (2) and producing cross-wound spools (11). According to the invention, before beginning a new thread part, first, the base operating parameters on at least one of the operating points of the textile machine (1) are changed; checkable characteristics of the thus produced cross-wound spool (11) or the thread, affecting the selection of the operating parameters, are compared with textile physical or optical patterns, the patterns respectively containing a nominal pattern and a defective pattern deviating from the nominal pattern; and the control device determines corrected values for the operating parameters following confirmation of a match with a defective pattern.

Owner:SAURER GERMANY GMBH & CO KG

New fermentation technology of sodium glutamate

ActiveCN104211610APromote degradationHigh activityOrganic compound preparationAmino-carboxyl compound preparationFiltrationFermentation

The invention relates to a new fermentation technology of sodium glutamate. The technology includes following steps: adding liquid ammonia and sodium carbonate to a fermented solution of sodium glutamate at the same time for carrying out a reaction with a molar ratio of the liquid ammonia to the sodium carbonate being 2:1 to obtain a fermenting solution which contains a crude product of the sodium glutamate and is 6.9-7.1 in pH value; performing micro-membrane filtration, wherein hole diameters of the micro membrane are 0.04-0.06 [mu]m; performing centrifugation at 2000 r / min for 3-5 min; collecting a microorganism-removed solution and a precipitated bacterial protein; pumping the microorganism-removed solution to a decoloring pot for carring out a decoloration treatment; adding powdery activated carbon accounting for 1.5% of the mass of the microorganism-removed solution to the decoloring pot; controlling the temperature in the decoloring pot within 45-50 DEG C; performing concentration after the decoloration treatment being carried out for 30 min, wherein concentration parameters are described as follows: a temperature is 60-70 DEG C and a vacuum degree is -0.1 kpa; performing one-step crystallization to obtain a crude crystal of sodium glutamate; and performing purification and treating wastewater. The technology is economical and environmental protective and has a wide application prospect.

Owner:XINJIANG FUFENG BIOTECH

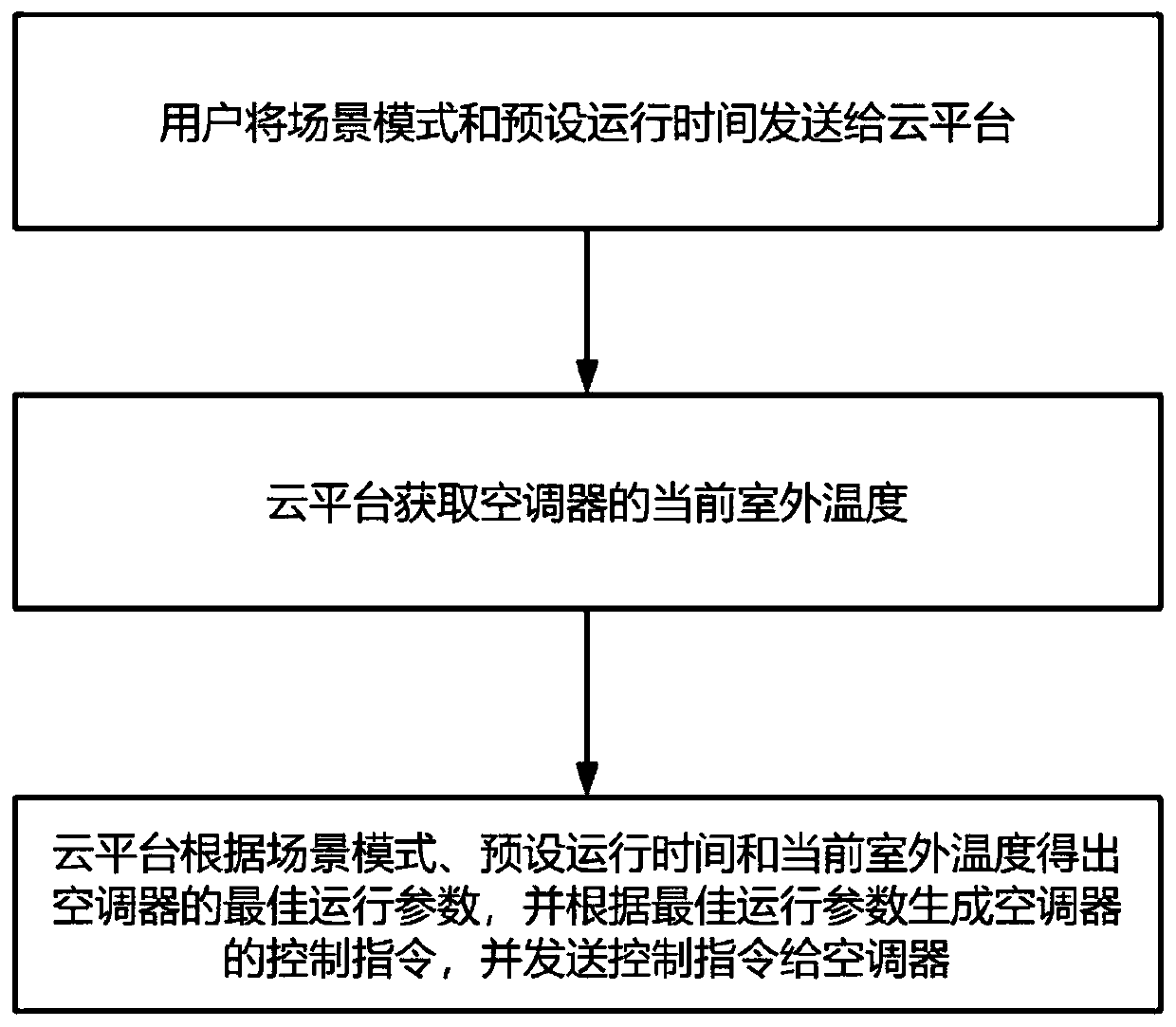

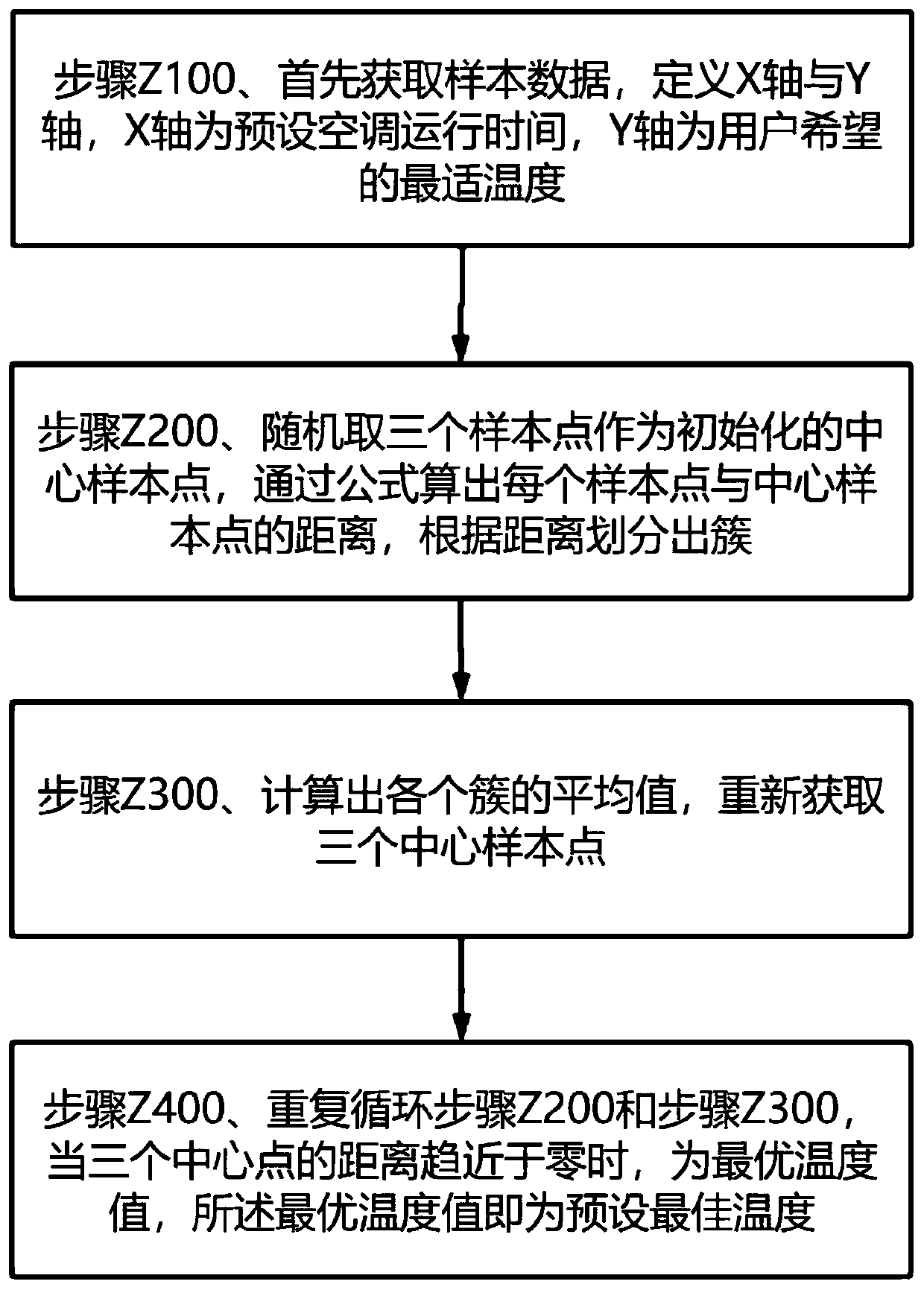

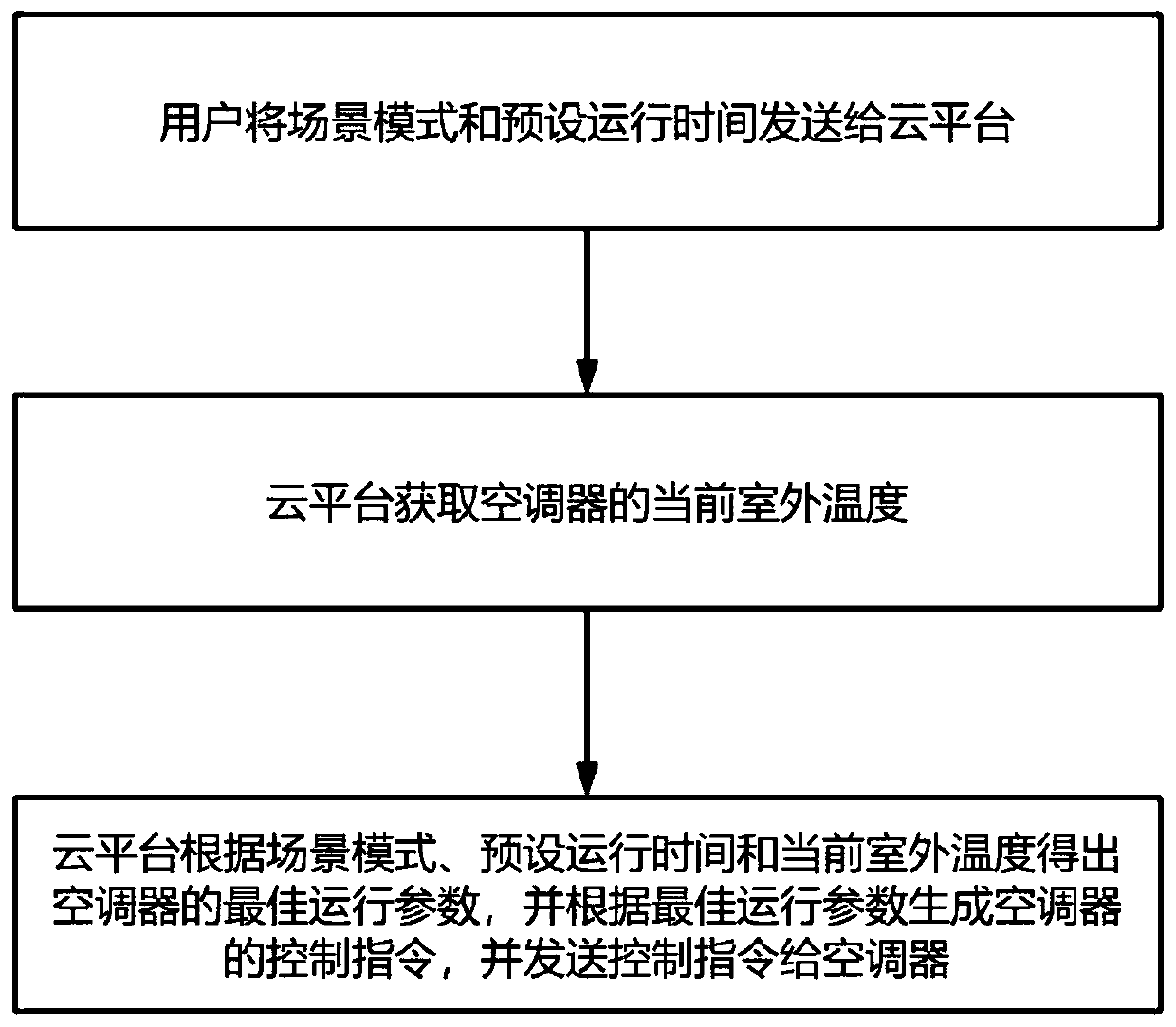

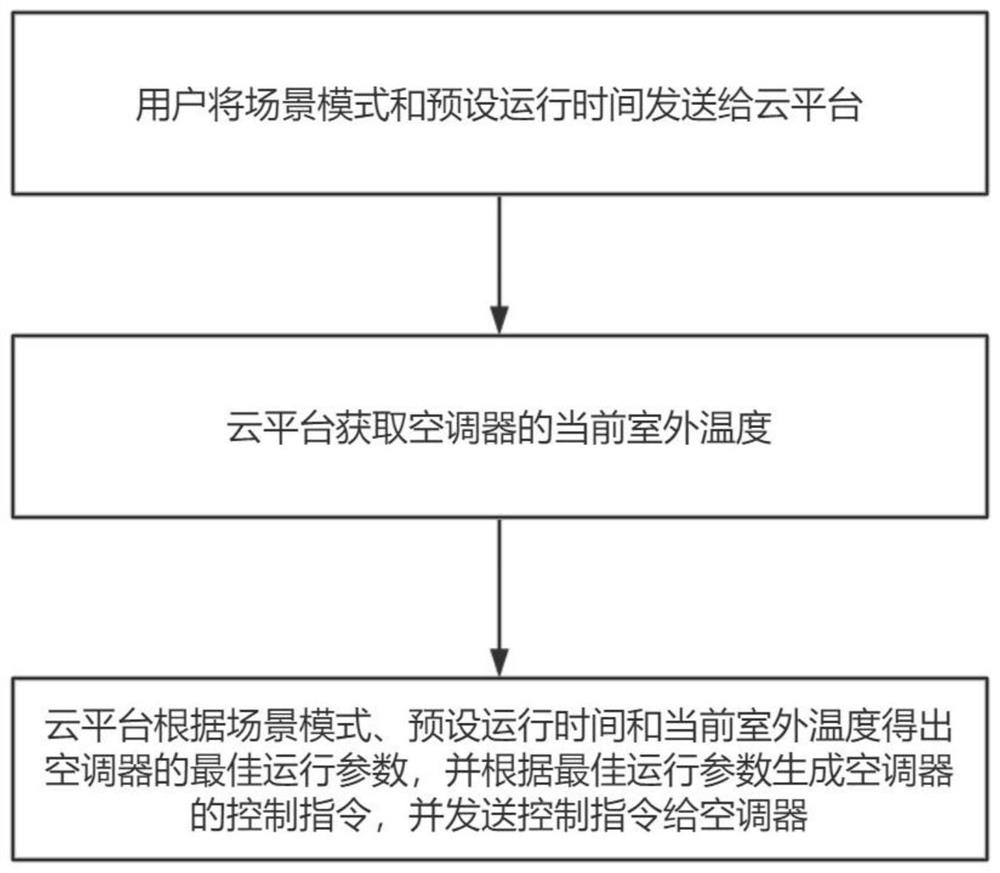

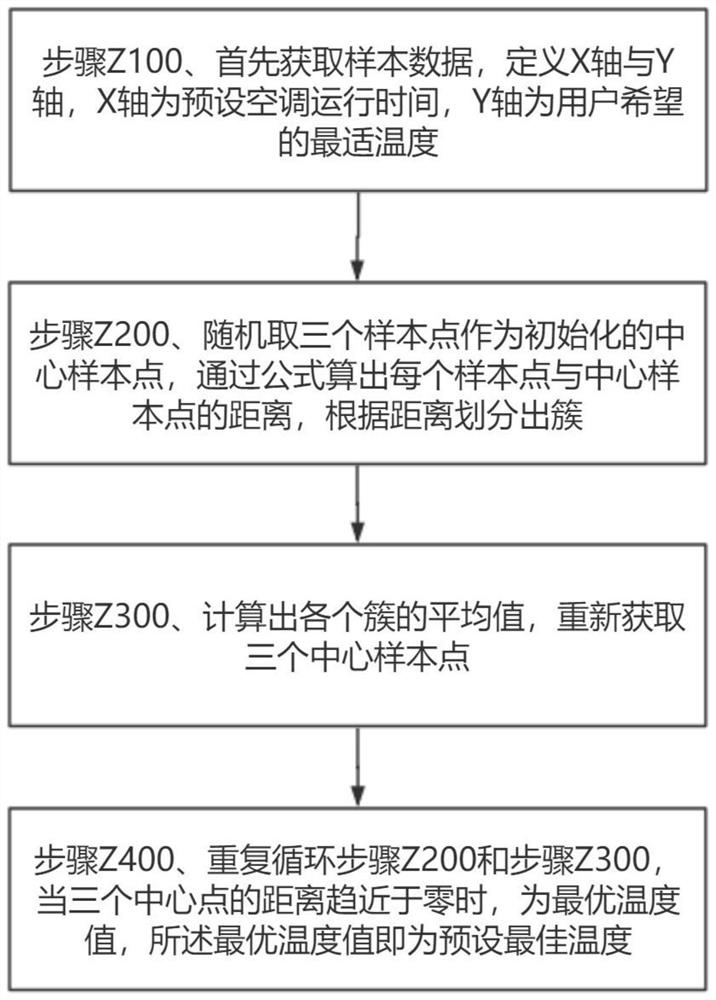

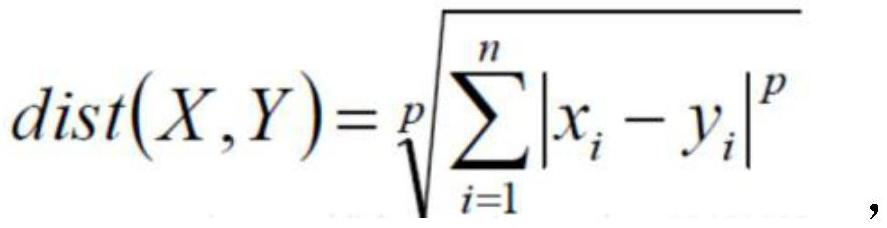

Control method and control device of air conditioner

ActiveCN111156664AIn line with the real situationMeet individual needsMechanical apparatusSpace heating and ventilation safety systemsPersonalizationControl engineering

The invention provides a control method of an air conditioner. The control method comprises the steps that a cloud platform obtains a scene mode input by a user and preset running time; the cloud platform obtains the current outdoor temperature of the air conditioner; the cloud platform obtains optimal operation parameters of the air conditioner according to the scene mode, the preset operation time and the current outdoor temperature, generates a control instruction of the air conditioner according to the optimal operation parameters and sends the control instruction to the air conditioner; and according to the control method, the manual parameter setting time of the user can be saved, misoperation is reduced, personalized requirements of different users can be met, the control efficiencyand the control accuracy are high, and the user experience is improved.

Owner:NINGBO AUX ELECTRIC +1

A/O-SBBR-oxidation pond-artificial wetland treatment pig farm biogas slurry technology

InactiveCN106830543ALow costImprove biodegradabilityTreatment using aerobic processesWaste based fuelPig farmsConstructed wetland

The invention discloses an A / O-SBBR-oxidation pond-artificial wetland treatment pig farm biogas slurry technology. Pig farm biogas slurry sequentially passes through a regulating tank, an anoxia tank / aerobiotic tank (A / 0), a secondary sedimentation tank, a sequencing batch type membrane bioreactor (SBBR), an oxidation pond and artificial wetland and finally reaches the standard to be discharged. The technological treatment effect is stable, the shock resistance load capacity is high, operation is easy, and the operating cost is low. According to the SBBR running mode and time parameters, water flows in for 1 h, aeration is performed for 3.5 h, anoxia is performed for 2 h, aeration is performed for 3.5 h, precipitation is performed for 1 h, and drainage is performed for 1 h. All indexes of the outflow pig farm biogas slurry treated through the combination technology conform to the discharge standard of pollutants for livestock and poultry breeding (GB 18596-2001).

Owner:NANCHANG UNIV

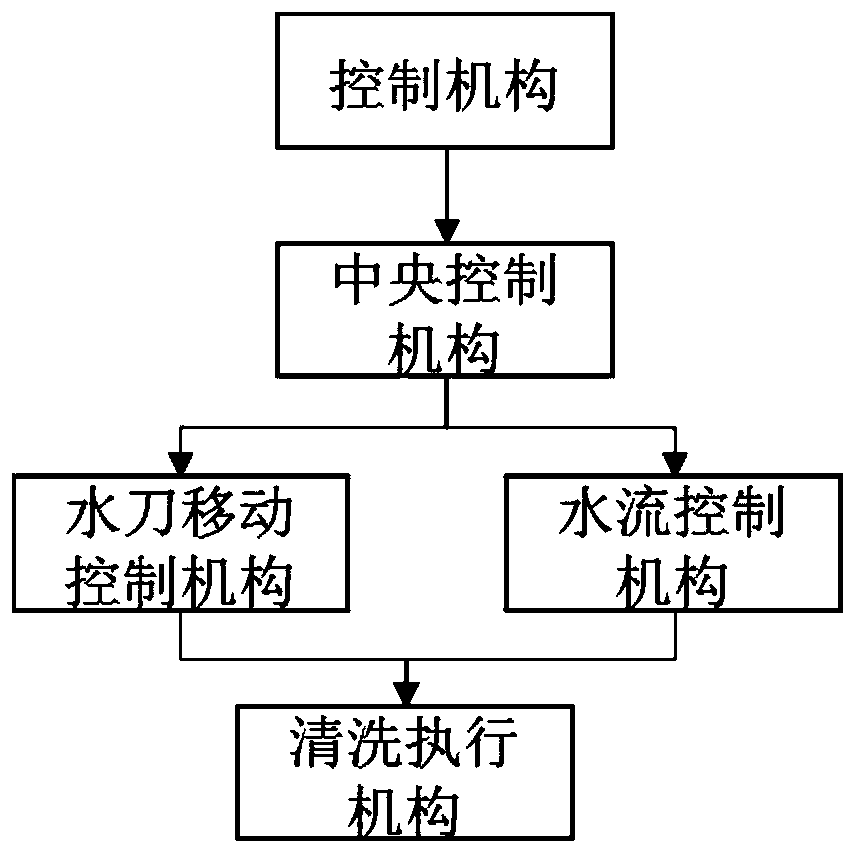

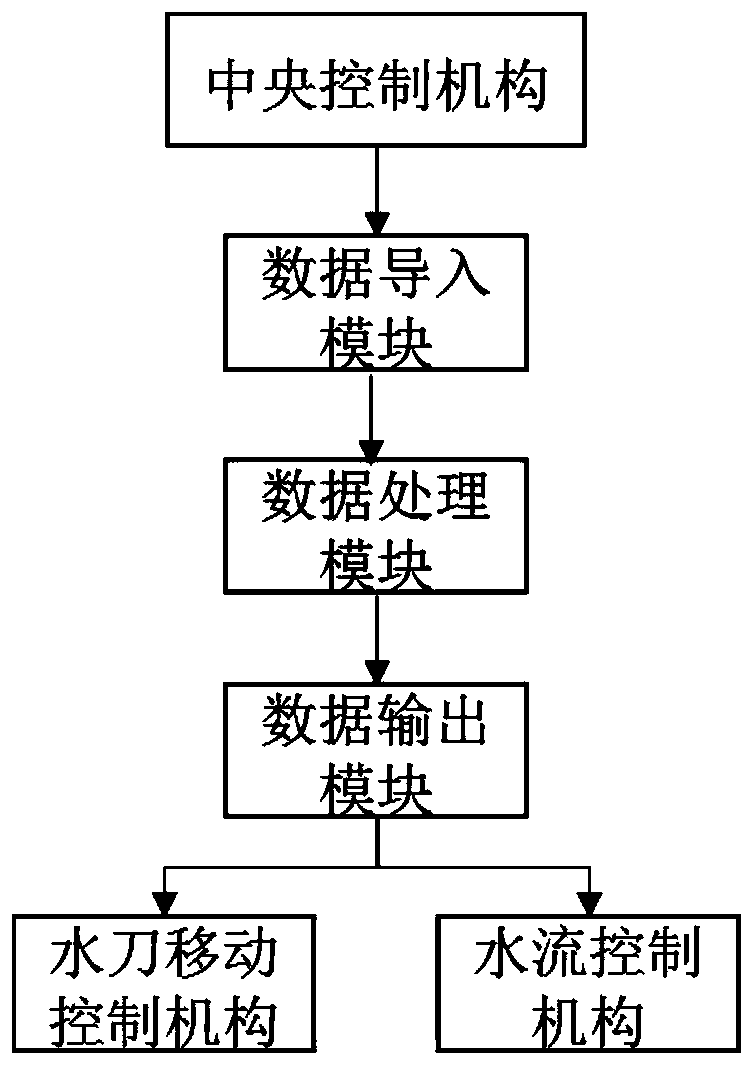

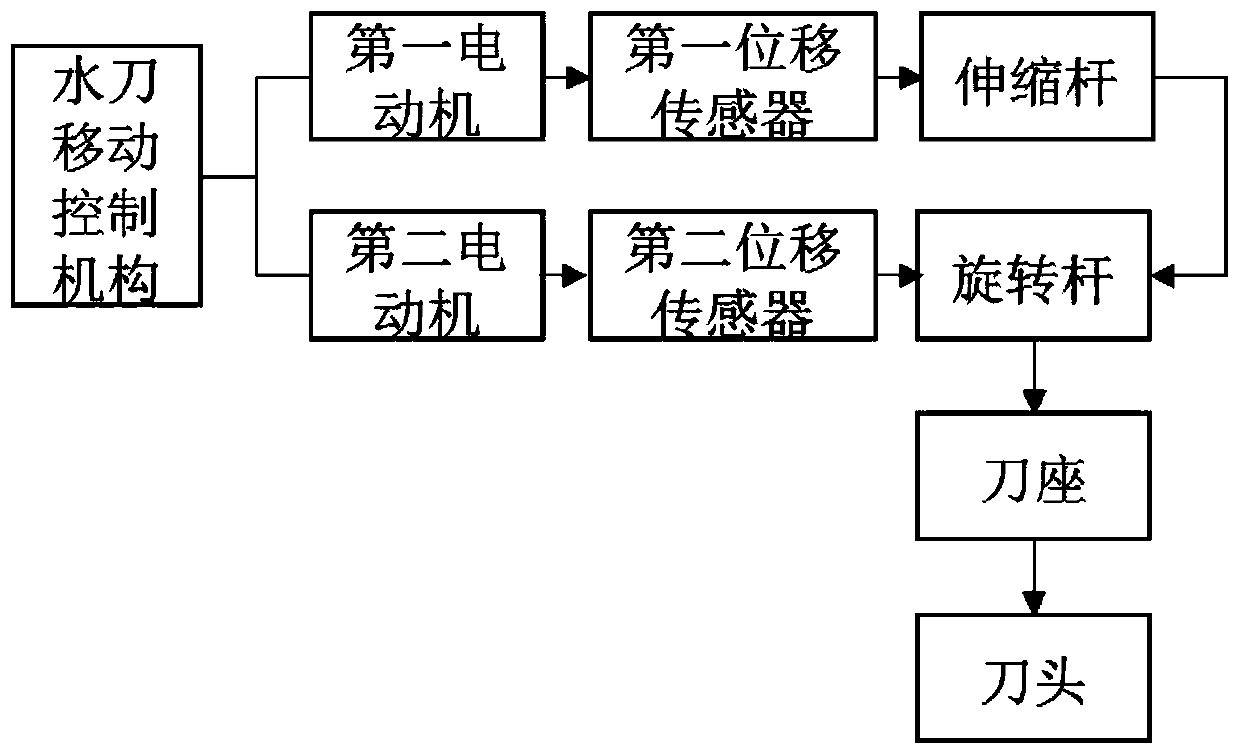

Water jet cleaning system and cleaning method of converter vaporization cooling flue

ActiveCN111424132AFully automatic cleaningAvoid damageHollow article cleaningManufacturing convertersTool bitThermodynamics

The invention provides a water jet cleaning system and a cleaning method of a converter vaporization cooling flue. The water jet cleaning system comprises a control mechanism and a cleaning executionmechanism, wherein the cleaning execution mechanism comprises a cutter head and a cutter holder. A central control mechanism, a water jet moving control mechanism and a water flow control mechanism are added on the basis of an existing water jet cleaning technology; the central control mechanism designs an optimal operation parameter of the cleaning execution mechanism according to the converter vaporization cooling flue; the water jet moving control mechanism monitors displacement of a water jet by a displacement sensor so as to control telescopic and rotating motion of the water jet; and thewater flow control mechanism monitors jet pressure of the water jet by a pressure sensor so as to control water flow of the water jet. The water jet cleaning system can realize comprehensive and harmless automatic cleaning on the inner wall of the converter vaporization cooling flue and can prevent damage to the flue caused by too high pressure of the water flow.

Owner:武汉市赟巨科技有限公司

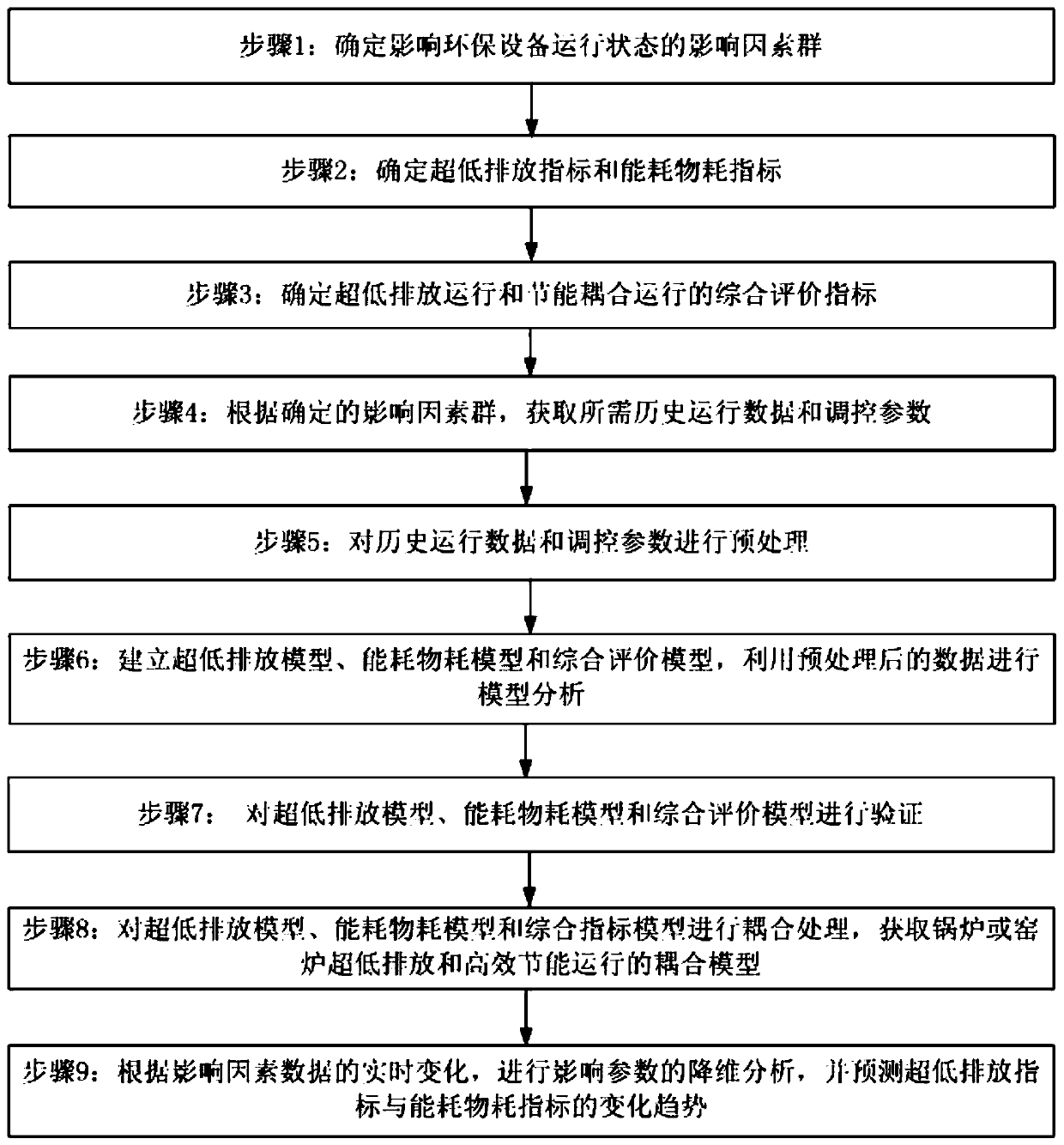

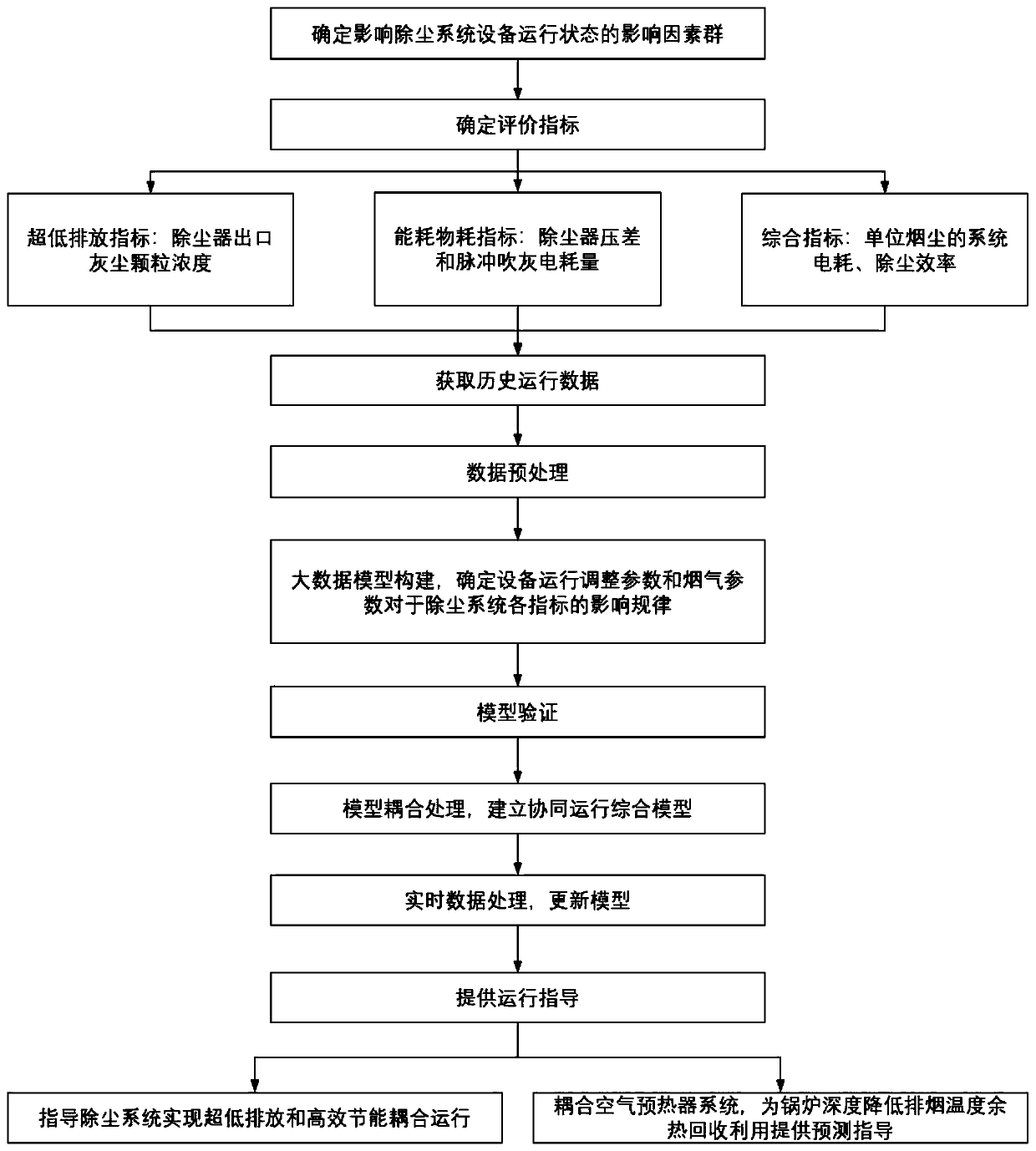

Method and system for ultra-low emission and efficient energy-saving coupling operation of boiler or kiln

PendingCN111242469ADouble benefitReduce material consumption and energy consumptionResourcesMaterial consumptionProcess engineering

The invention discloses a method and system for ultralow emission and efficient energy-saving coupling operation of a boiler or a kiln. The method comprises the following steps: determining an influence factor group influencing the operation state of environment-friendly equipment; determining an ultralow emission index and an energy and material consumption index; determining comprehensive evaluation indexes of ultra-low emission operation and energy-saving coupling operation; acquiring required historical operation data and regulation and control parameters according to the determined influence factor group; preprocessing the historical operation data and the regulation and control parameters; establishing an ultralow emission model, an energy consumption and material consumption model and a comprehensive evaluation model, and performing model analysis by utilizing the preprocessed data; verifying the ultralow emission model, the energy consumption and material consumption model andthe comprehensive evaluation model; carrying out coupling processing to obtain a coupling model of ultralow emission and efficient energy-saving operation of the boiler or the kiln; carrying out dimension reduction analysis of the influence parameters, and predicting the change trend of the ultralow emission index and the energy consumption index. According to the method and system, the low-energy-consumption and material-consumption operation of the environment-friendly equipment under the ultralow emission index is realized.

Owner:JINAN DANENG POWER TECH

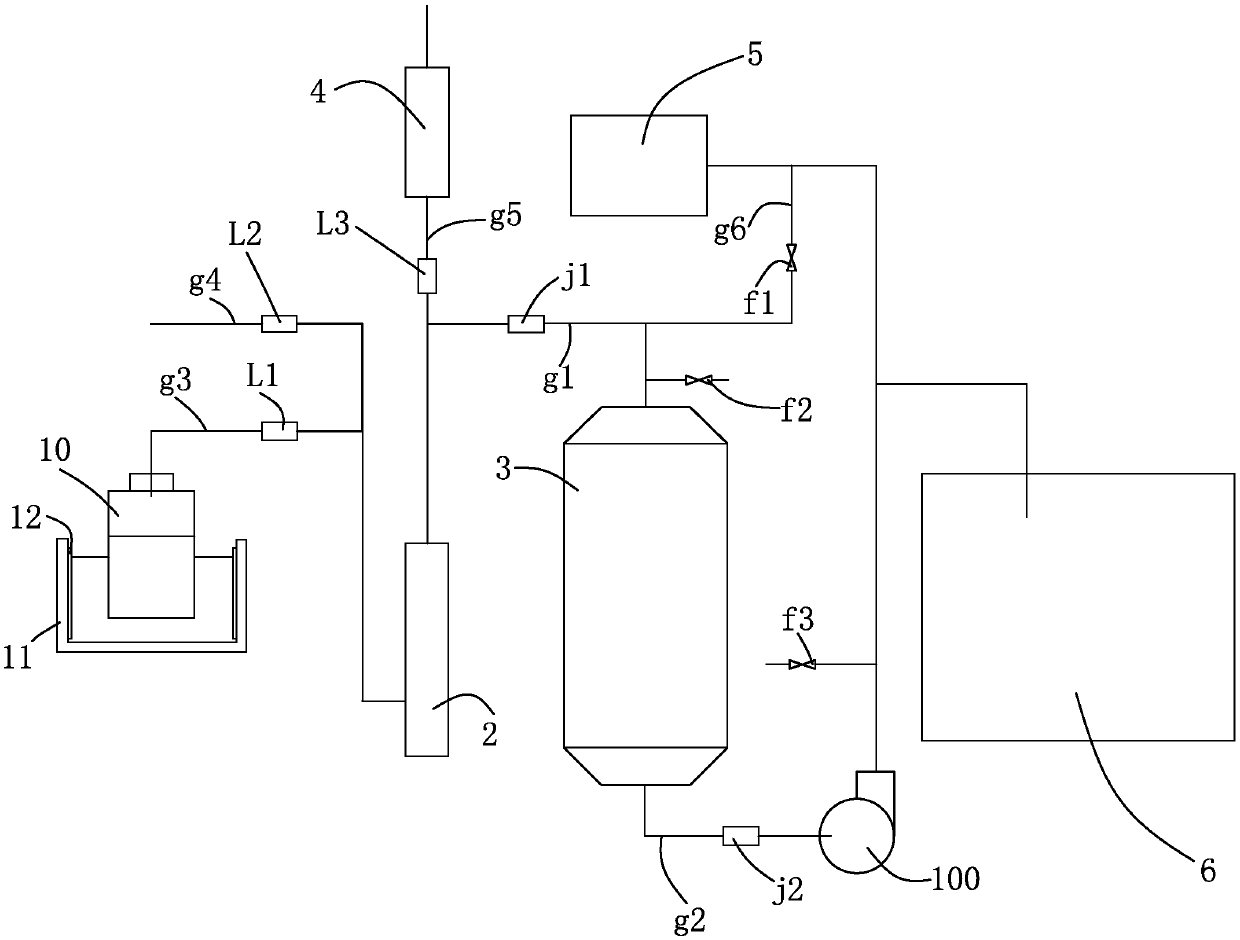

Dynamic simulation experiment platform for reverse osmosis scale inhibitors

InactiveCN104764856ASolve the problem of complex and easily damaged membrane elementsRealize dynamic simulationMaterial analysisReverse osmosisProduced water

The invention discloses a dynamic simulation experiment platform for reverse osmosis scale inhibitors, and is used for solving the problems that selected reverse osmosis scale inhibitor products are complicated and membrane elements are easy to damage in the prior art. The dynamic simulation experiment platform comprises a water tank, wherein the water tank is connected with a water pump, a reverse osmosis scale inhibitor dosing tank and membrane pressure containers in sequence through water pipes; the experiment platform is of a one-stage three-section structure; each membrane pressure container at each section is communicated with a drain pipe which is used for draining concentrated water and produced water; valves are arranged on the drain pipes; the drain pipes are all communicated with the water tank. The dynamic simulation experiment platform for the reverse osmosis scale inhibitors can dynamically evaluate the property of the reverse osmosis scale inhibitors so as to prevent the undesirable effects of reverse osmosis membrane scaling, oxidation and the like caused by direct use of unqualified reverse osmosis scale inhibitors which are not verified.

Owner:陕西安得科技实业有限公司

New fermentation technology of sodium glutamate

The invention relates to a new fermentation technology of sodium glutamate. The technology includes following steps: adding liquid ammonia and sodium hydroxide to a fermented solution of sodium glutamate at the same time for carrying out a reaction with a molar ratio of the liquid ammonia to the sodium hydroxide being 2:1 to obtain a fermenting solution which contains a crude product of the sodium glutamate and is 6.9-7.1 in pH value; performing micro-membrane filtration, wherein hole diameters of the micro membrane are 0.04-0.06 [mu]m; performing centrifugation at 2000 r / min for 3-5 min; collecting a microorganism-removed solution and a precipitated bacterial protein; pumping the microorganism-removed solution to a decoloring pot for carring out a decoloration treatment; adding powdery activated carbon accounting for 1.5% of the mass of the microorganism-removed solution to the decoloring pot; controlling the temperature in the decoloring pot within 45-50 DEG C; performing concentration after the decoloration treatment being carried out for 30 min, wherein concentration parameters are described as follows: a temperature is 60-70 DEG C and a vacuum degree is -0.1 kpa; performing one-step crystallization to obtain a crude crystal of sodium glutamate; and performing purification and treating wastewater. The technology is economical and environmental protective and has a wide application prospect.

Owner:XINJIANG FUFENG BIOTECH

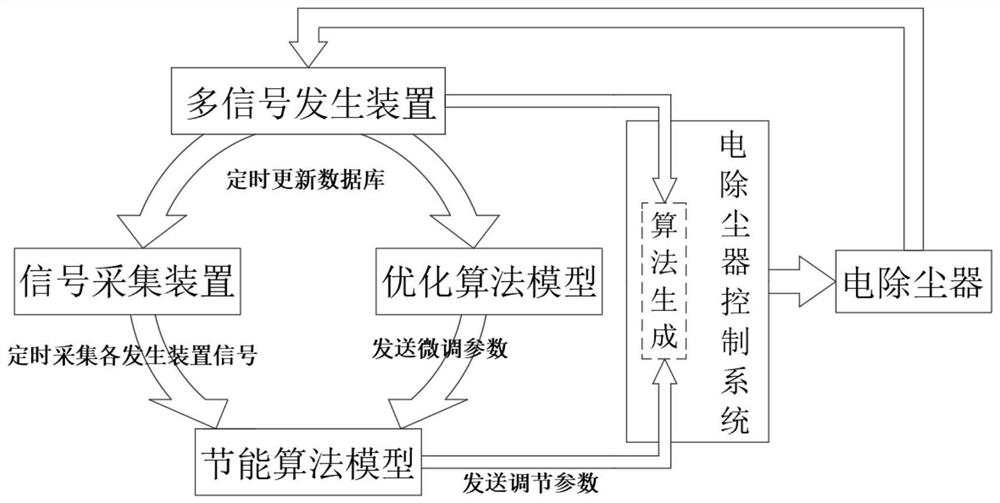

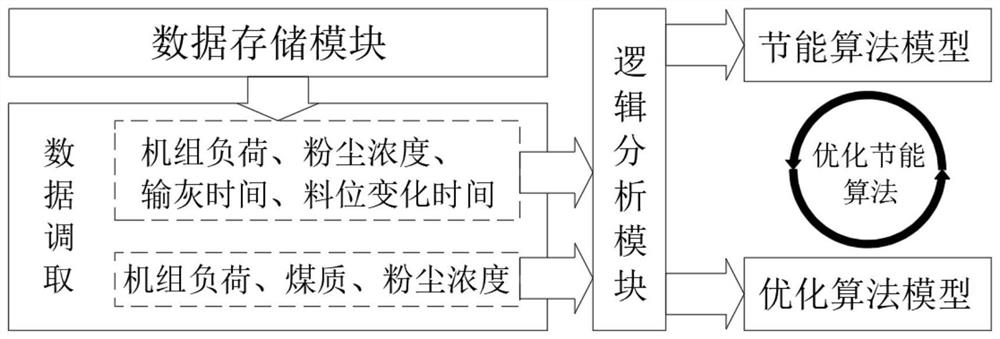

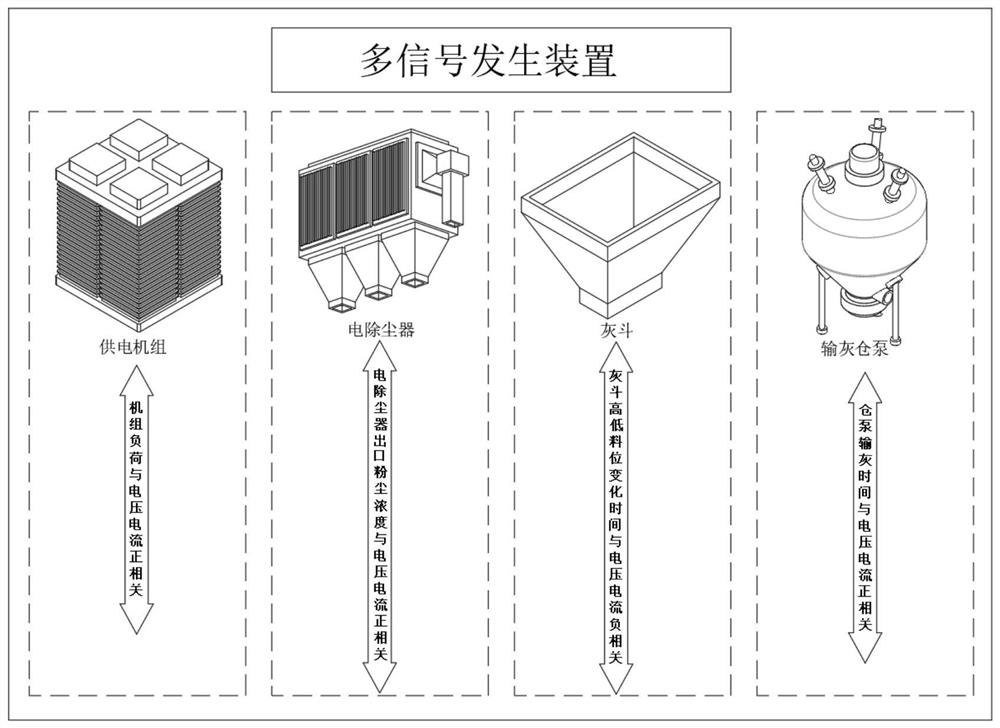

Multi-signal optimization energy-saving electric precipitation control method

PendingCN113976323AImprove dust removal efficiencyOptimal operating parametersDesign optimisation/simulationSpecial data processing applicationsDust controlLogical analysis

The invention discloses a multi-signal optimization energy-saving electric precipitation control method, and relates to the technical field of energy conservation and environmental protection, the multi-signal optimization energy-saving electric precipitation control method comprises an electric precipitator control system, and the electric precipitator control system comprises an optimization algorithm system based on an electric precipitation control system. The optimization algorithm system comprises a signal acquisition device, a data storage module and a logic analysis module. According to the method, the unit load, the dust concentration of a powder outlet, the dust conveying time of a bin pump and the high-low material level change time of a dust hopper are combined and analyzed to obtain the dust removal efficiency of the electric dust remover with known airflow parameters and dust radiuses under different limit line board intervals, and the optimal dust removal efficiency is found through comparison so as to obtain the optimal operation parameters; and by combining and analyzing unit load, dust concentration of a powder outlet and coal quality parameters and substituting voltage and current when a signal peak value occurs, energy consumption changes of a front system and a rear system are obtained, an optimization strategy of an energy-saving model is obtained, and power consumption of system operation is reduced to the maximum extent.

Owner:HUANENG QUFU THERMAL POWER CO LTD

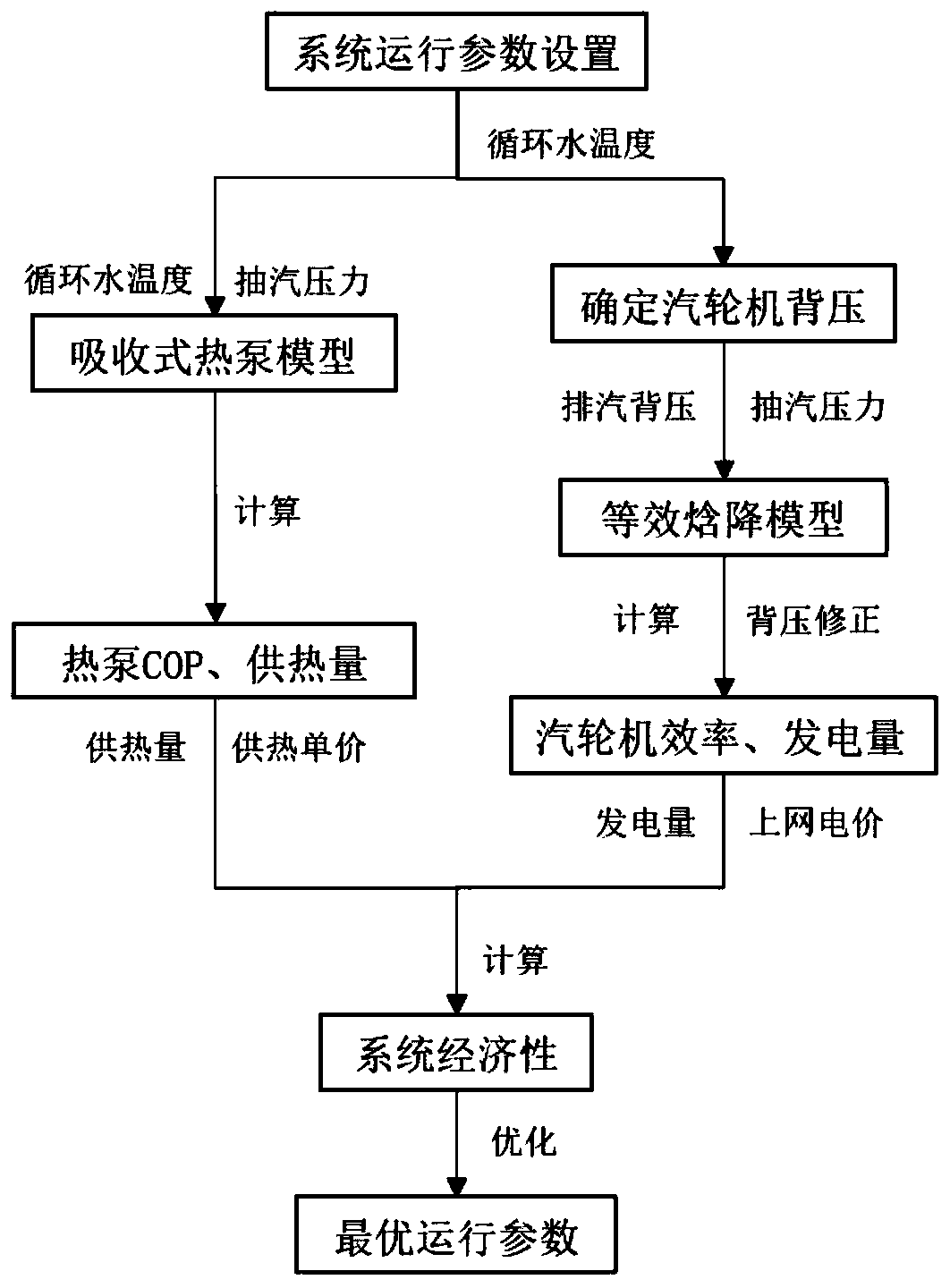

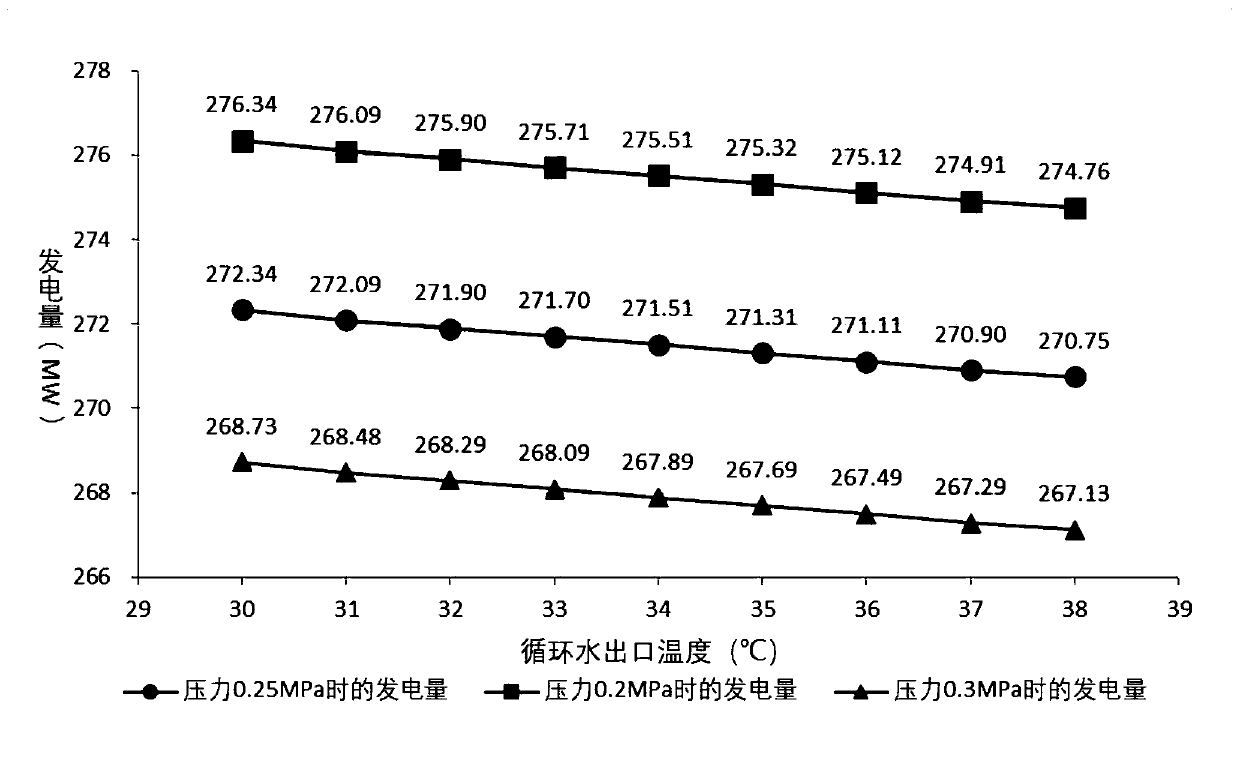

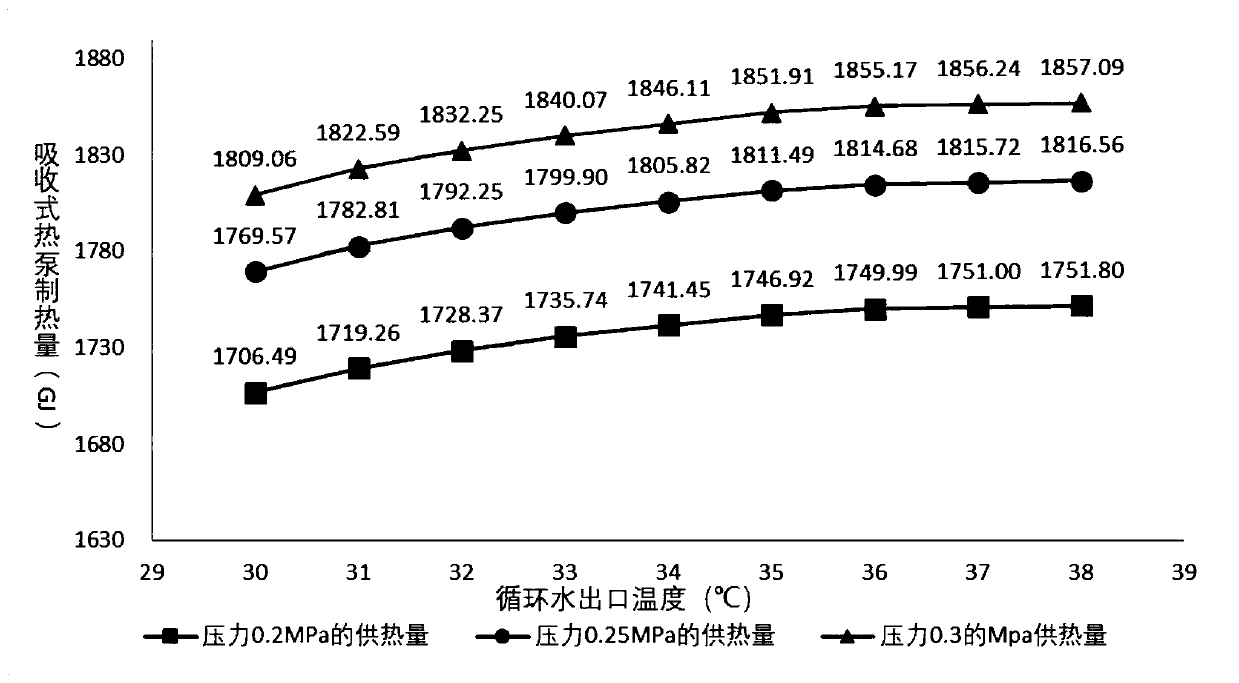

Heat supply optimization method for coupling absorption heat pump of thermal power plant

ActiveCN111256204AOptimal operating parametersImprove economyLighting and heating apparatusSpace heating and ventilation detailsLithium bromideAbsorption heat pump

The invention provides a heat supply optimization method for a coupling absorption heat pump of a thermal power plant. The method comprises the following steps of 1, establishing an equivalent enthalpy drop model according to data and operation conditions of a steam turbine in the thermal power plant, determining corresponding steam exhaust back pressure of the steam turbine according to differentcirculating water temperatures by the model, and calculating the heat supply of the coupling absorption heat pump based on the steam extraction pressure and the steam exhaust back pressure, and calculating turbine efficiency and generating capacity; 2, establishing a thermal power plant cold end optimization model according to the characteristics of the steam turbine, and correcting the efficiency and the generating capacity of the steam turbine; 3, establishing an absorption heat pump model according to the property of the absorption lithium bromide heat pump, and calculating COP and heat supply after the absorption heat pump is coupled with the heat supply of the thermal power plant; and 4, setting different operating parameters (circulating water temperature and steam extraction pressure) according to the absorption heat pump waste heat recovery heat supply system, performing joint calculation through the models in the steps 1-3, and calculating the operating economy of the systemaccording to the local on-grid electricity price and the heat supply price to obtain the optimal operating parameters.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

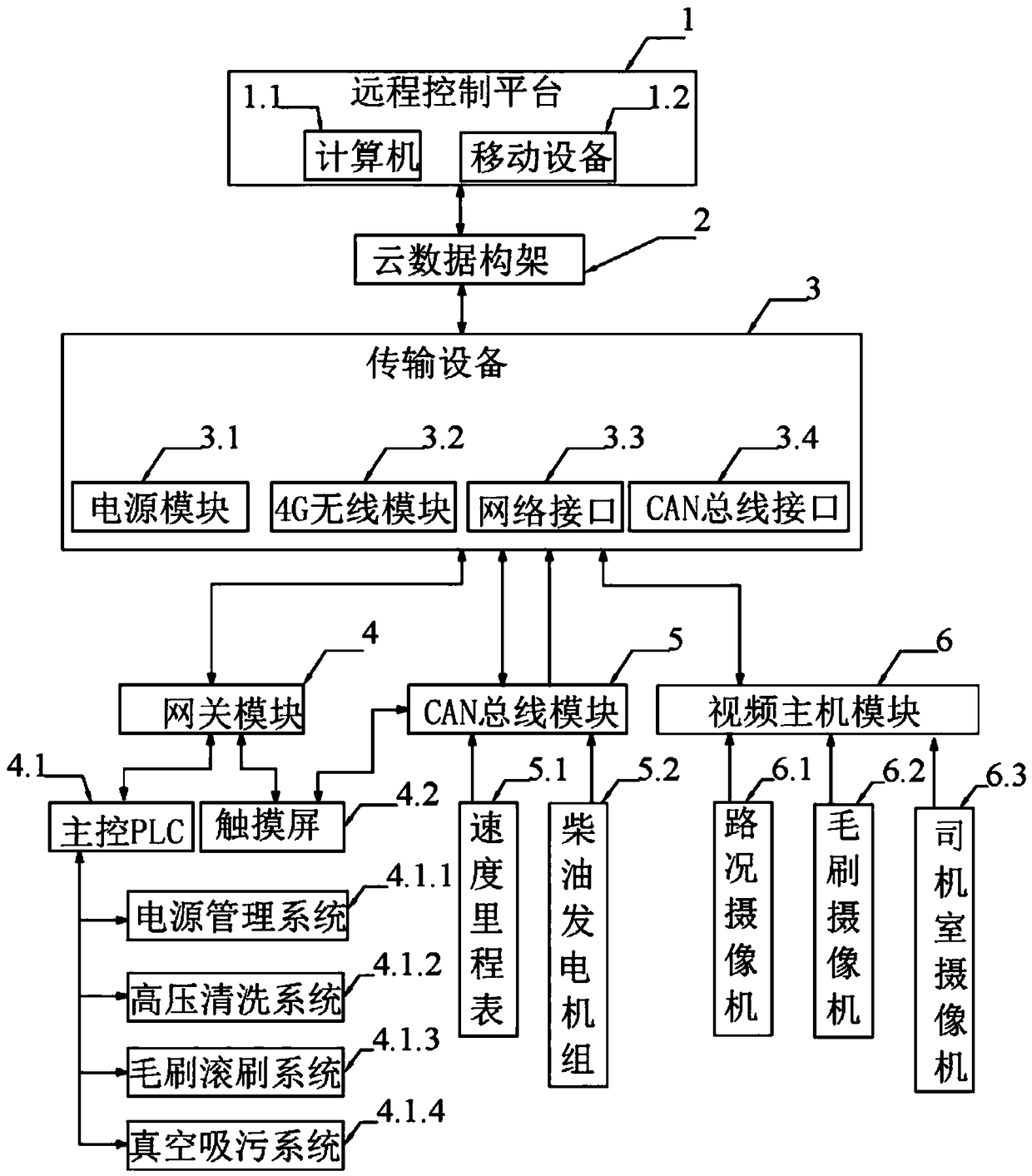

Remote monitoring method and a system for a tunnel dust cleaning vehicle

ActiveCN109267522AAchieving RecoveryLow failure rateRoad cleaningAutomotive engineeringThrough transmission

The invention discloses a remote monitoring method and a remote monitoring system of a tunnel dust cleaning vehicle. When the tunnel dust cleaning vehicle is operating, the dust cleaning operation data, the operation speed data and the operation image information of the tunnel dust cleaning vehicle are obtained and are uploaded to a remote control platform through a transmission device and a clouddata structure in turn. The remote control platform receives the operation data, the operation speed data and the operation image information of the tunnel dust cleaning vehicle, and analyzes the operation image information. The remote control platform calculates the optimal operation speed data according to the analyzed operation image information, the operation speed data and the skylight time.In case of failure of the tunnel cleaning vehicle, the best cleaning data is calculated according to the analyzed image information. And is transmitted to the tunnel dust cleaning vehicle through thecloud data structure and transmission equipment; the tunnel dust collection and cleaning vehicle receives the optimum operation speed and the optimum dust collection and cleaning operation data, andoperates according to the data.

Owner:CRRC SHANDONG CO LTD

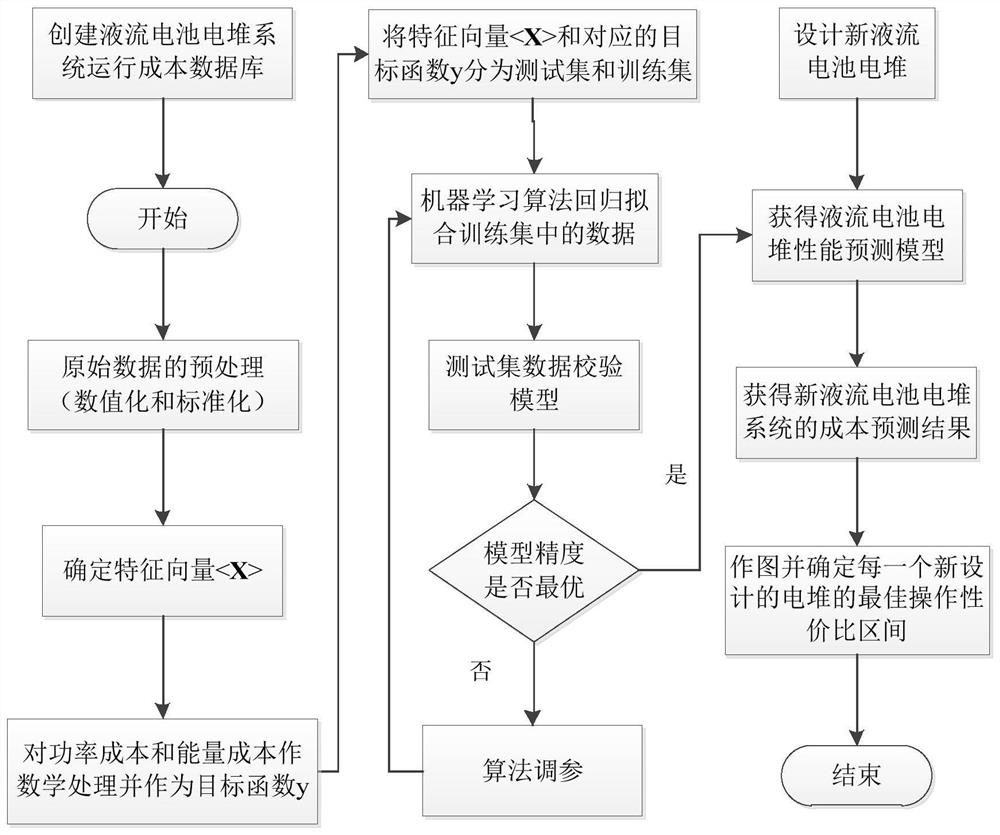

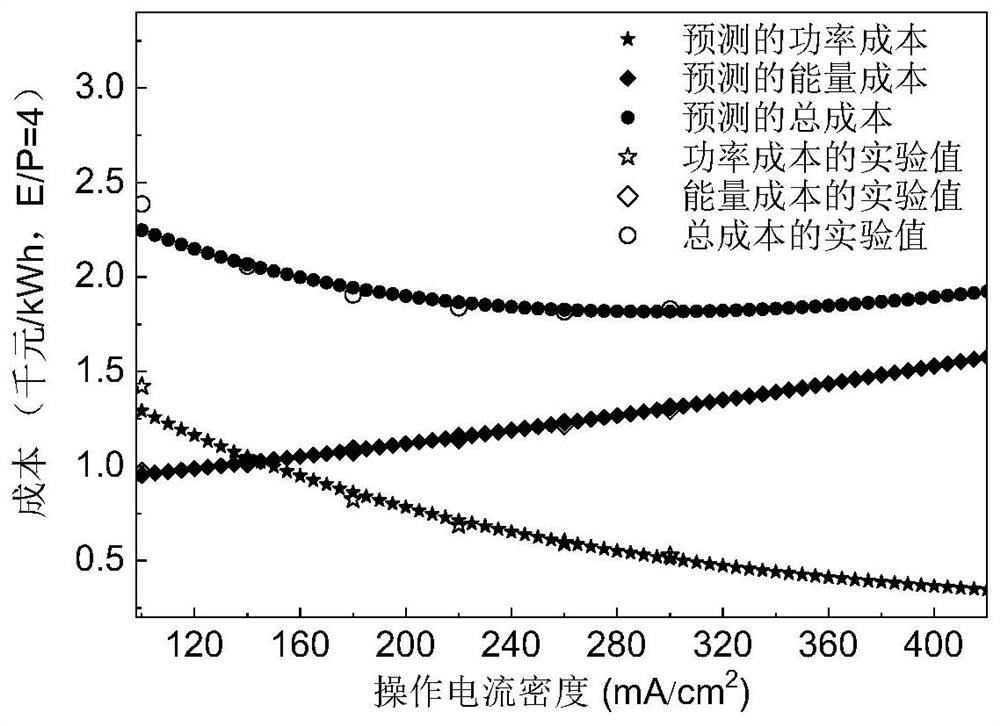

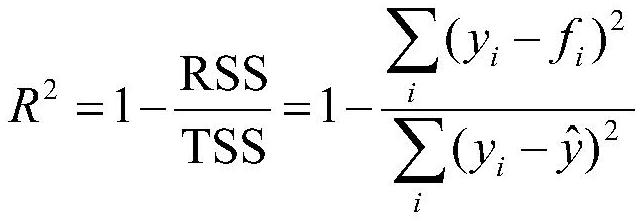

Flow battery stack optimal operation condition prediction method based on machine learning

PendingCN114094150AGuide operating conditionsOptimal operating parametersKernel methodsFuel cellsElectrochemical energy storageEnergy cost

The invention belongs to the field of large-scale electrochemical energy storage, and particularly relates to a flow battery stack optimal operation condition prediction method based on machine learning. The method comprises the following steps: establishing a database; carrying out numeralization and standardization processing on the type variable parameters in the database; forming a multi-dimensional feature vector <X> by using the parameter variables, respectively taking the power cost and the energy cost of the electric pile as target functions y, and randomly cclassifying the multi-dimensional feature vector < X > and the target functions y into a training set and a test set; training a galvanic pile performance prediction model by using the parameter data in the training set; evaluating the trained flow battery galvanic pile performance prediction model by using parameter data in the test set, and constructing a cost prediction model; and predicting the materials and the cost variable parameters in the database by using the cost prediction model, and calculating the total system operation cost. According to the method, the optimal operation cost performance interval and the optimal operation parameters of each researched and developed flow battery stack can be determined through a small number of tests.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

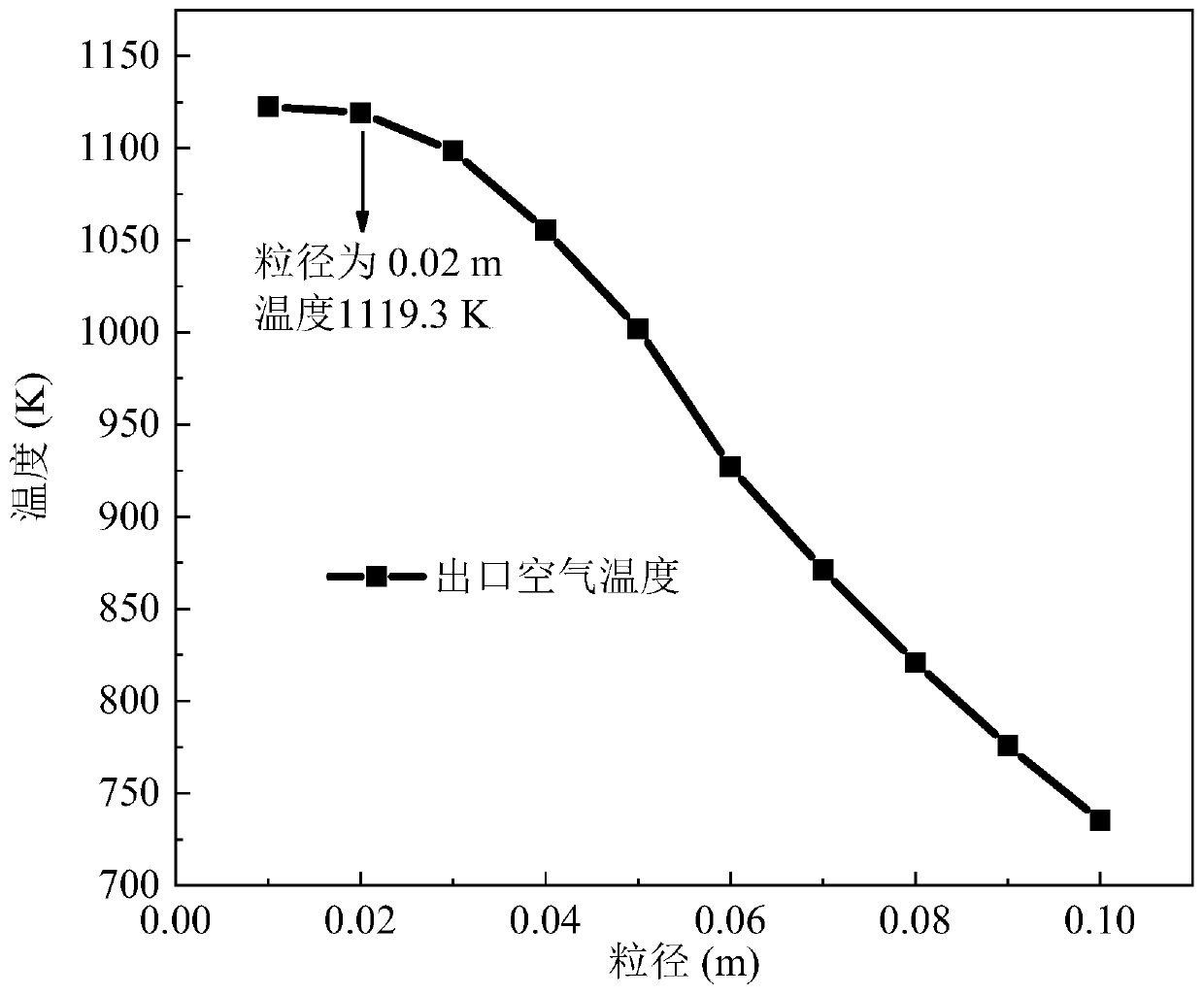

A CFD technology-based simulation analysis method for sensible heat recovery of high-temperature activated fly ash

ActiveCN109885947AStrong operabilityReduce labor costsSpecial data processing applicationsCost (economic)Pulverised fuel ash

The invention provides a CFD technology-based high-temperature activated fly ash sensible heat recovery simulation analysis method. The method comprises the following steps: S1, establishing a simplified sensible heat recovery packed bed model; performing CFD numerical simulation on the sensible heat recovery packed bed model; and S2, performing initial setting on the simplified sensible heat recovery packed bed model, performing calculation according to the initial setting to obtain air temperature distribution at different moments in the sensible heat recovery packed bed model and the temperature condition of hot air at a bed outlet, and setting different operation conditions to perform regular adjustment on the sensible heat recovery process. The CFD-based simulation analysis method forthe sensible heat recovery process of the high-temperature activated fly ash, provided by the invention, has the advantages that the operability is high, the fitting degree with actual working conditions is very high, the labor cost can be reduced, the economic cost of experimental equipment is further reduced, and potential safety hazards caused in an experimental operation process are also eliminated.

Owner:CHONGQING UNIV

A kind of environment-friendly process of cleanly producing sodium glutamate

The invention relates to an environmentally friendly process for cleanly producing sodium glutamate, which includes the following steps: simultaneously adding liquid ammonia and sodium carbonate to glutamic acid fermentation liquid for reaction to obtain crude fermentation liquid; filtering through micromembrane, collecting and sterilizing liquid, and bacterial protein; bacterial protein is used to prepare probiotics, the sterilizing liquid is pumped into a decolorization tank for decolorization, and concentrated and crystallized to obtain crude sodium glutamate crystals; then the wastewater is refined and treated. The process of the present invention is economical and environmentally friendly. It has broad application prospects.

Owner:内蒙古阜丰生物科技有限公司

Air conditioner control method and control device

ActiveCN111156664BReduce misuseAutomatically adjust the running stateMechanical apparatusSpace heating and ventilation safety systemsPersonalizationControl engineering

The present invention provides an air conditioner control method, comprising: the cloud platform obtains the scene mode and the preset running time input by the user; the cloud platform obtains the current outdoor temperature of the air conditioner; temperature to obtain the best operating parameters of the air conditioner, and generate control instructions for the air conditioner according to the best operating parameters, and send the control instructions to the air conditioner; the control method can save the user's time for manually setting parameters and reduce misoperations. In addition, it can meet the individual needs of different users, has high control efficiency and control accuracy, and improves user experience.

Owner:NINGBO AUX ELECTRIC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com