Ethylene production raw material optimization method based on hybrid modeling

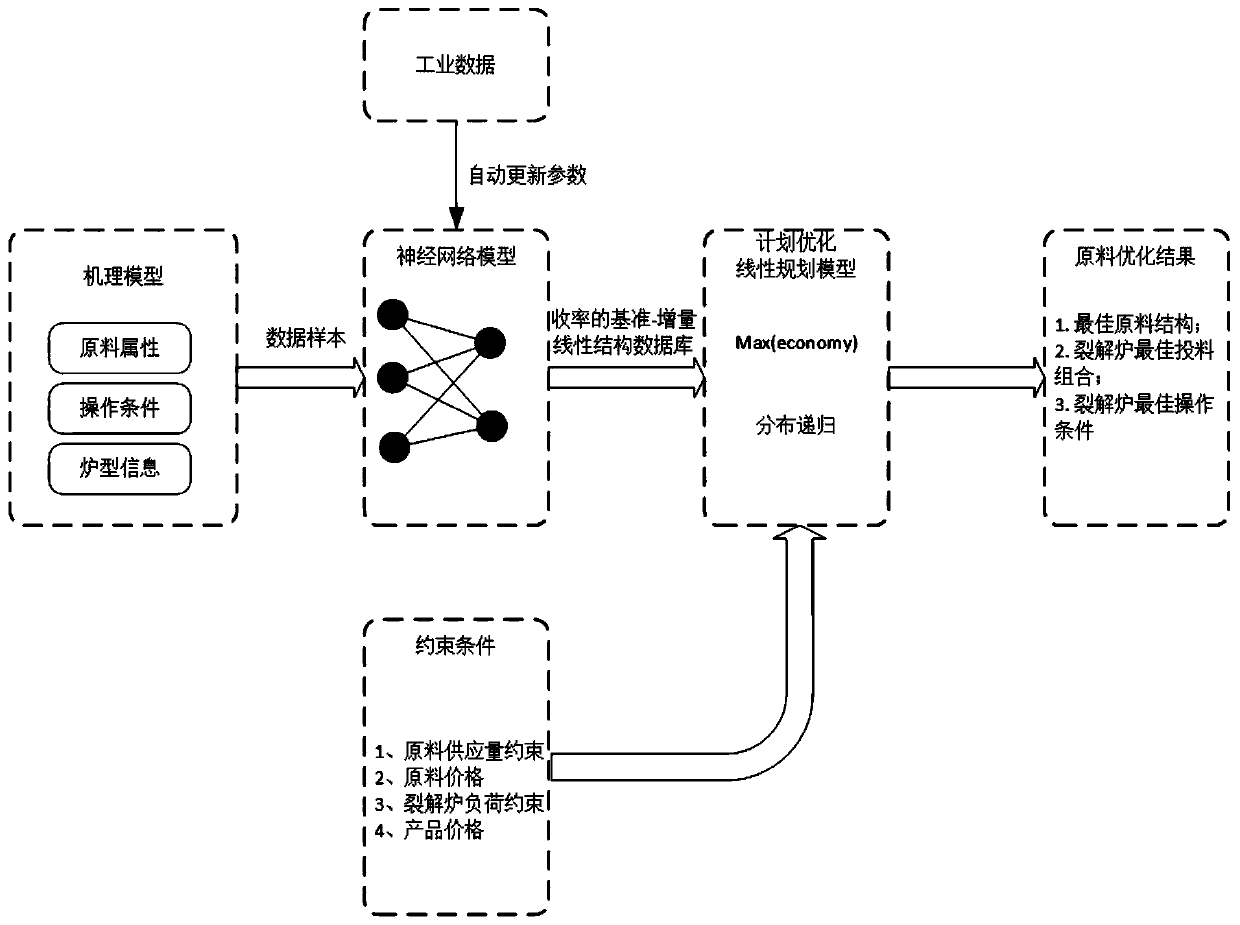

An ethylene and raw material technology, which is applied in the field of ethylene raw material optimization based on hybrid modeling and linear programming, can solve problems such as low computational efficiency, time-consuming, and cumbersome optimization process, and achieve the effect of improving economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0162] In order to make the technical solutions and advantages of the present invention more obvious, some technical contents in the specific examples of the present invention will be illustrated below.

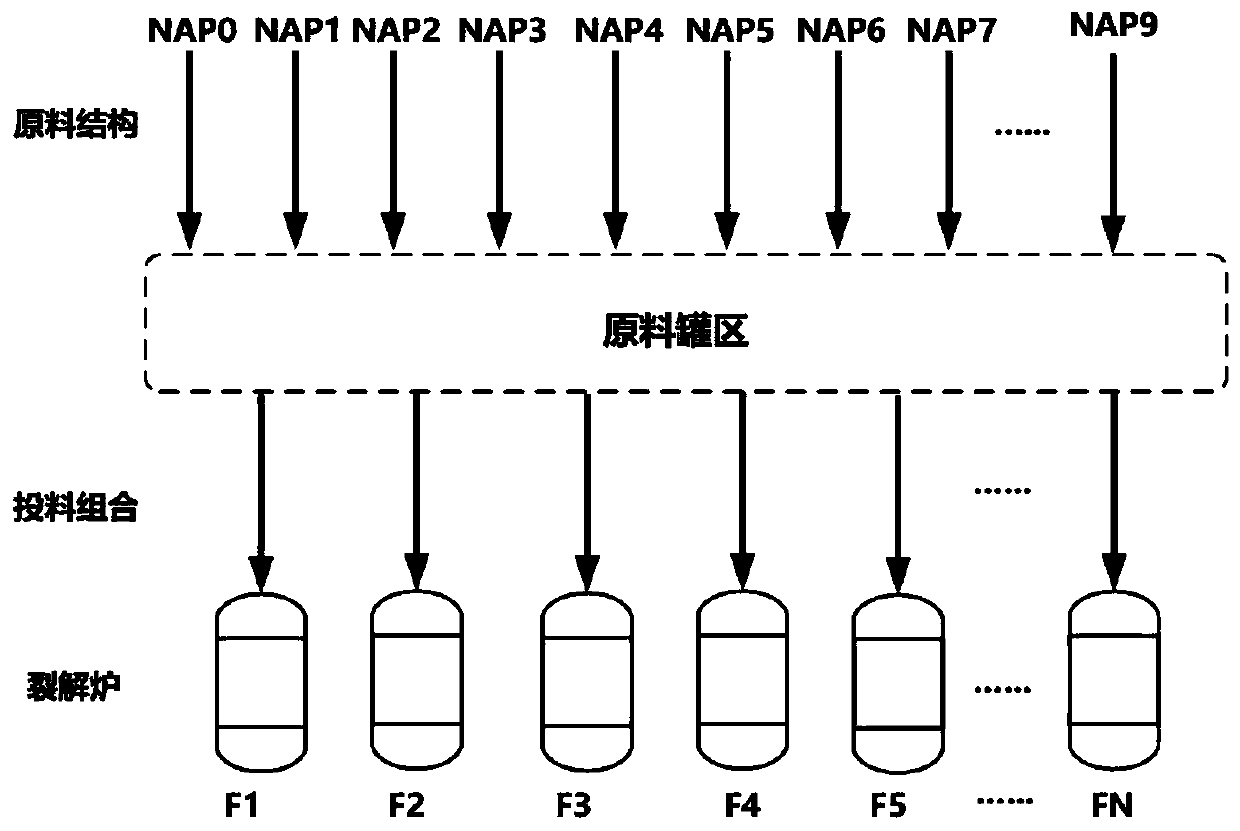

[0163] There are 33 raw material streams available for cracking in an ethylene production enterprise, and the names and codes of raw materials are shown in Table 4.

[0164] Table 4 Name of the raw material stream of an ethylene plant

[0165]

[0166]

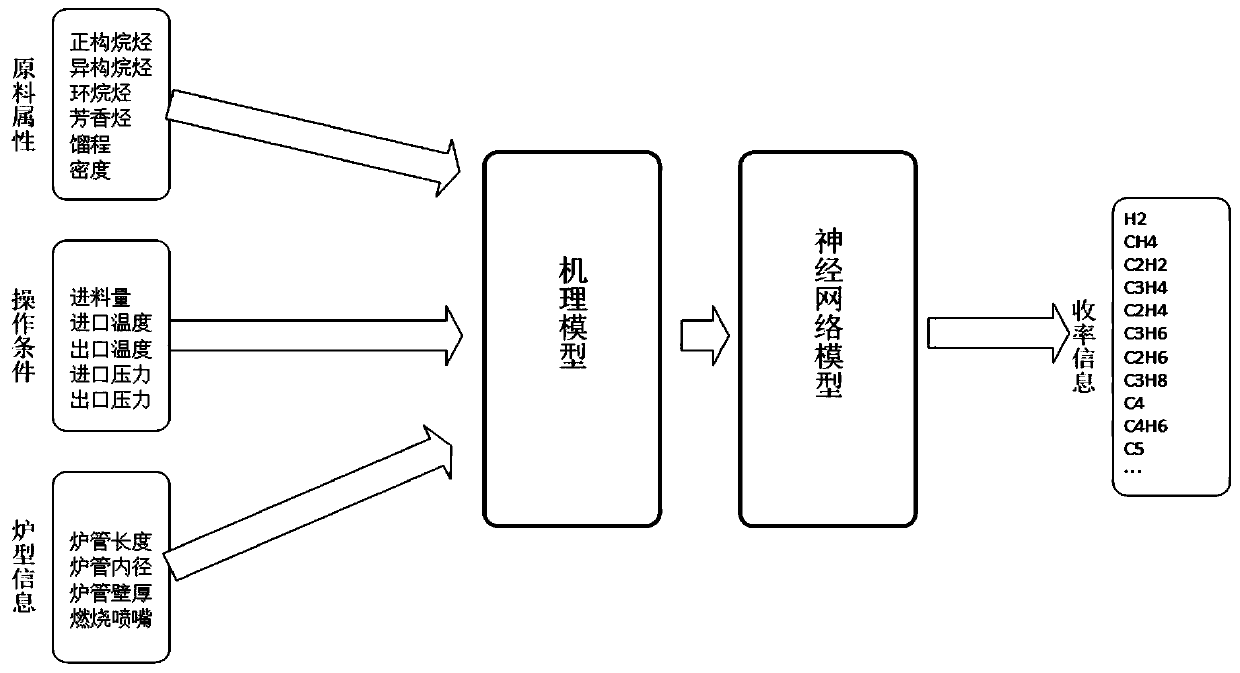

[0167] After averaging the properties of the raw materials, the neural network predicts the yield, changes the components of the raw materials for multiple predictions, and then constructs the benchmark-increment data structure according to the data. data.

[0168] Table 5 A certain type of ethylene cracking furnace naphtha benchmark-incremental linear structure database

[0169]

[0170]

[0171]The baseline-incremental linear structure database and plant-wide constraints including raw material prices, minimum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com