Strip metal auto-screening and integrated feeding device

A feeding device and automatic screening technology, which is applied in the direction of transportation and packaging, conveyor objects, conveyors, etc., can solve the problems of insufficient automation, reduce the number of manual feeding, have a high degree of automation, and save labor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

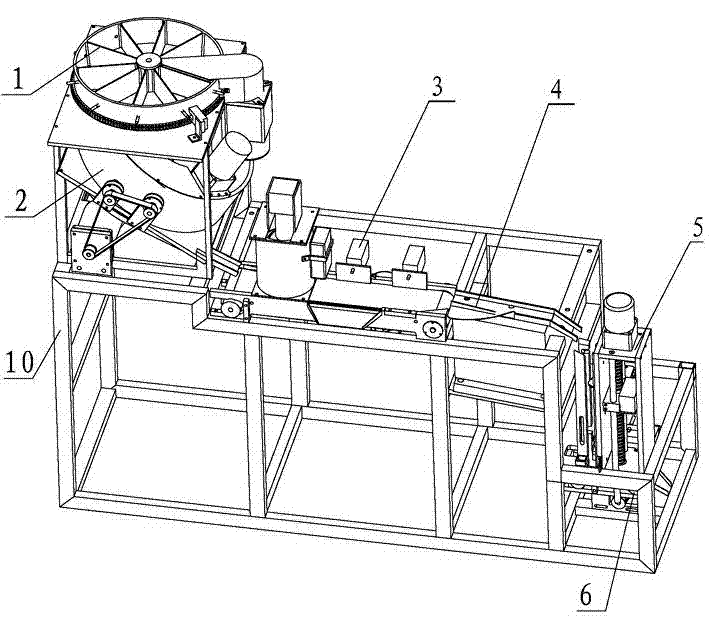

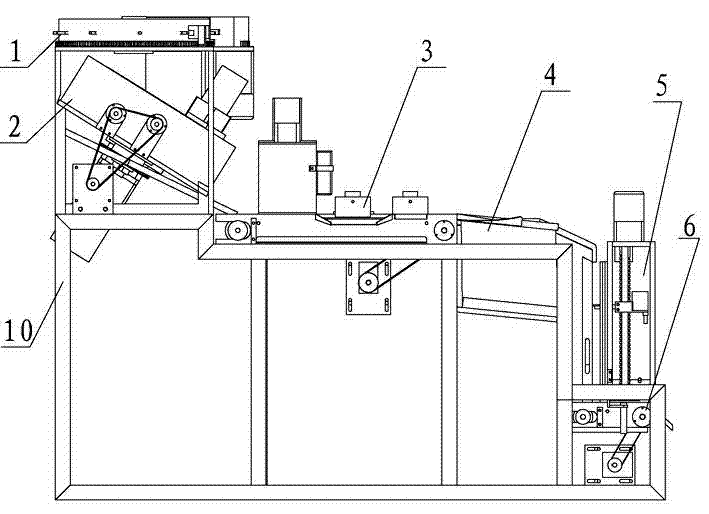

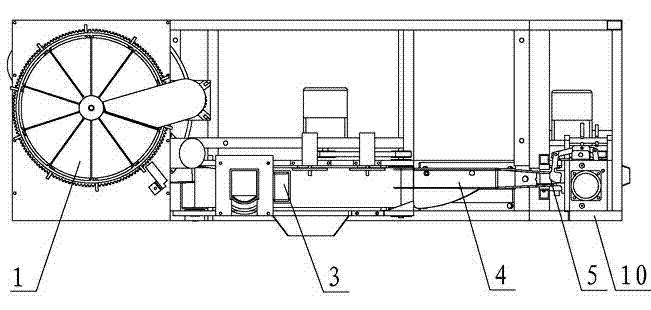

[0048] Such as figure 1 , 2 , 3 and 4, a strip metal automatic screening and integrated feeding device is used for automatic screening and feeding of key blanks in the key production process, including a frame 10. According to the flow sequence, the frame 10 is sequentially provided with a grid blanking device 1 , a turntable blanking device 2 , a screening device 3 , an overturning device 4 , an integration device 5 , and a feeding device 6 .

[0049] Described lattice unloading device 1 is positioned at an end of frame, as Figure 5 As shown, there is a horizontal mounting plate 11, and a vertical fixed shaft is fixed in the center of the mounting plate 11. The upper part of the fixed shaft is movably connected to a horizontal turntable 12 through a bearing. The distributed partitions are divided into uniform fan-shaped storage compartments 13, and a ring of gear teeth 14 surrounds the side wall of the turntable 12.

[0050] There is a fan-shaped blanking opening A15 on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com