Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "More heat energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

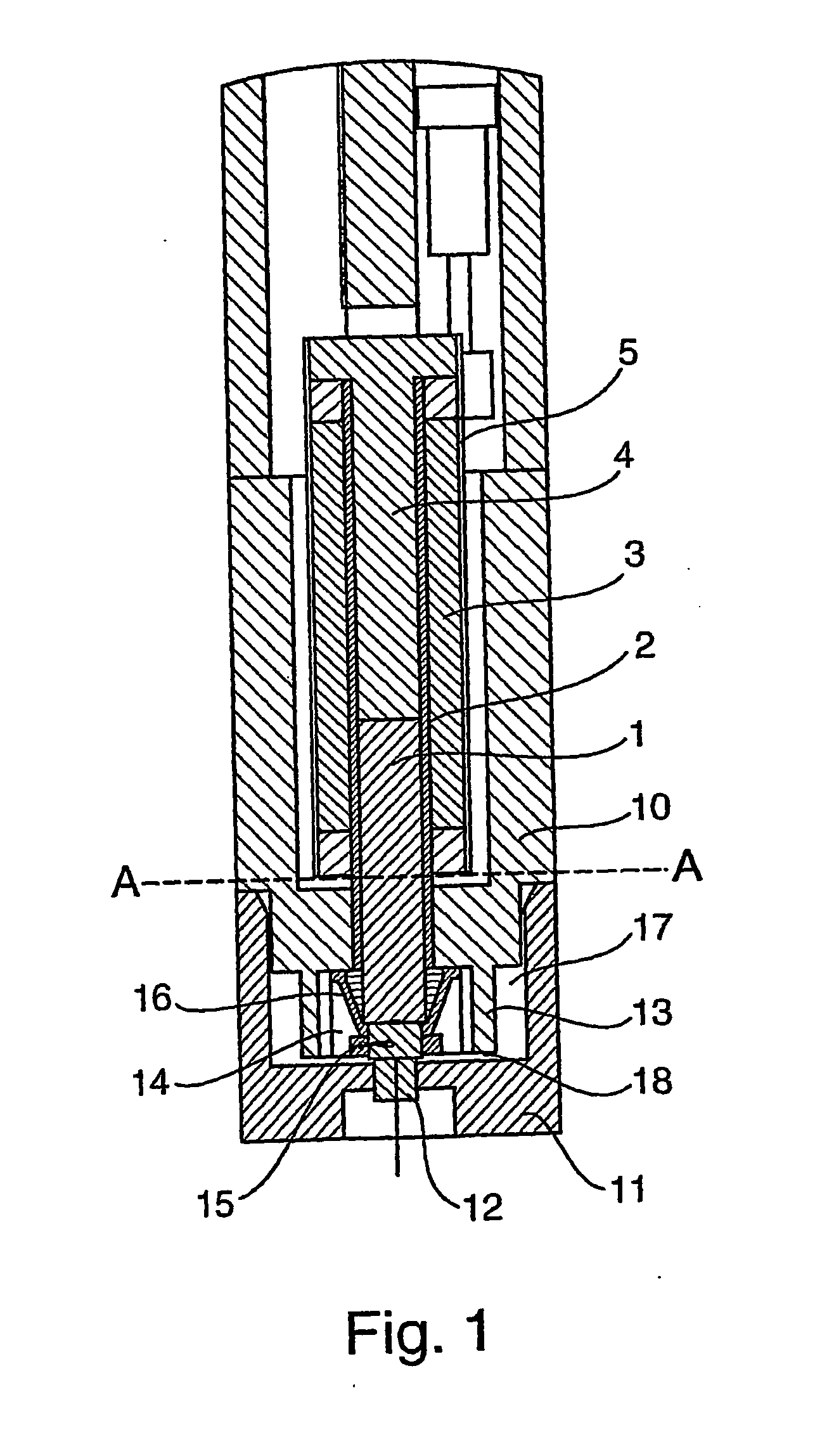

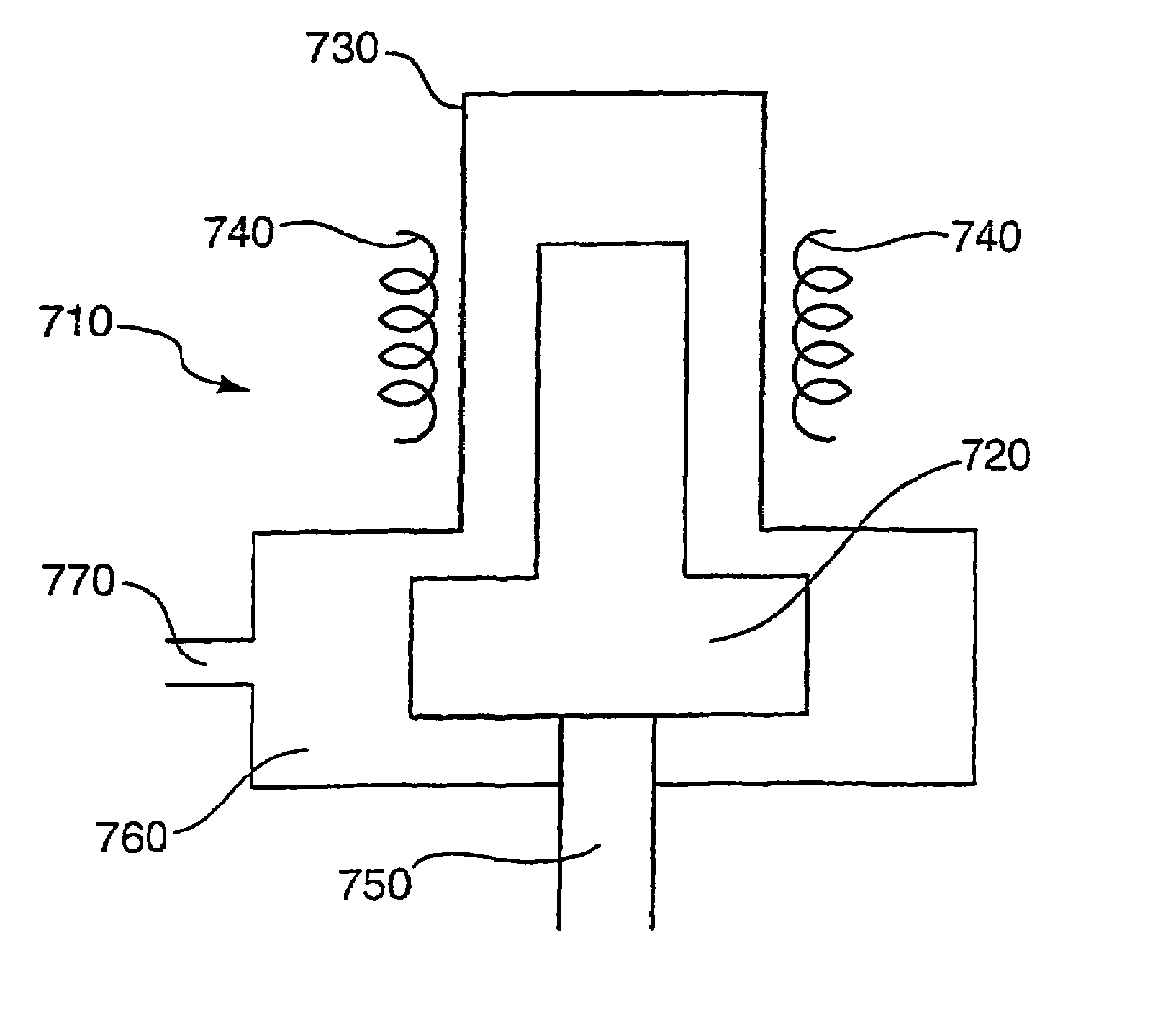

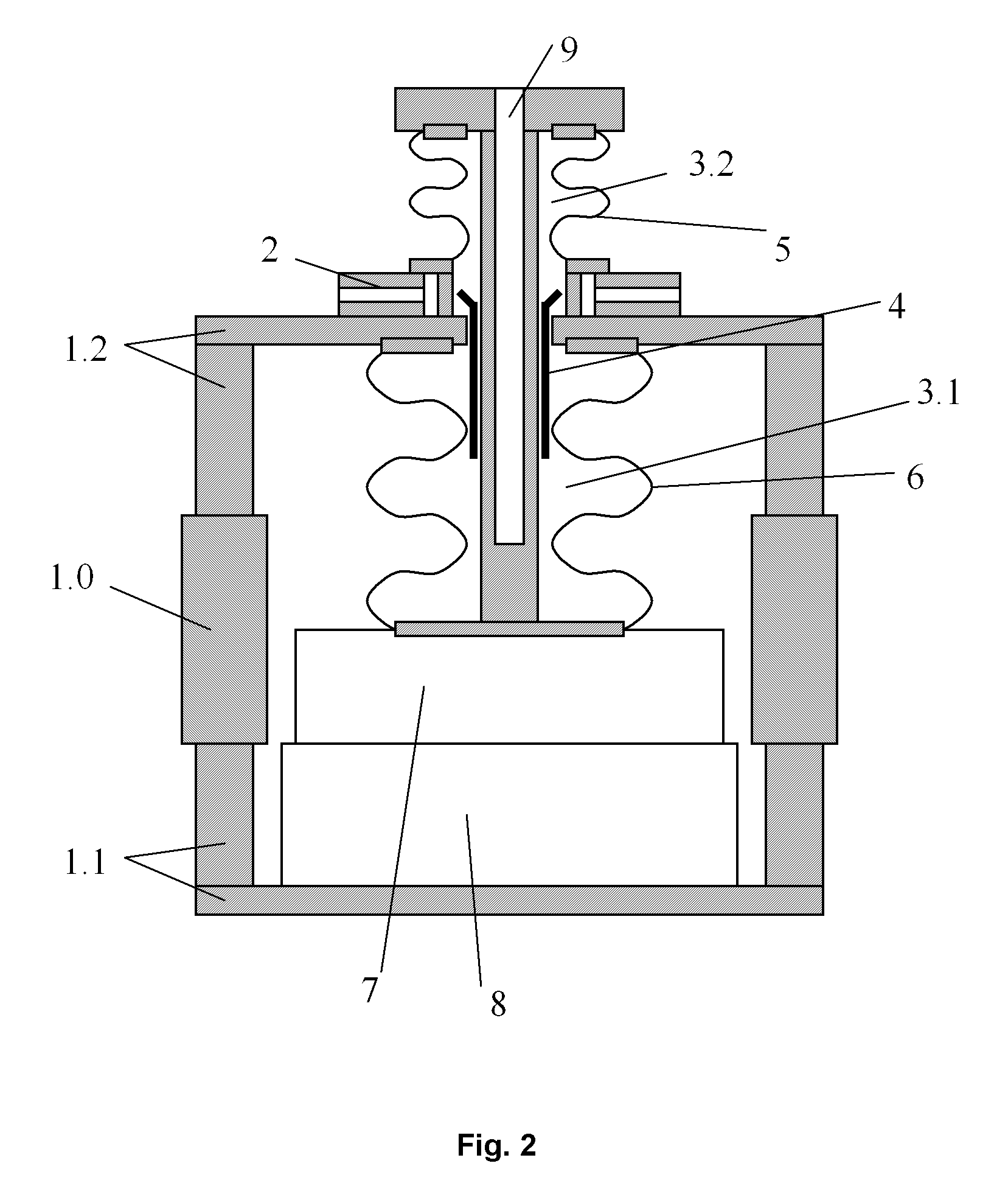

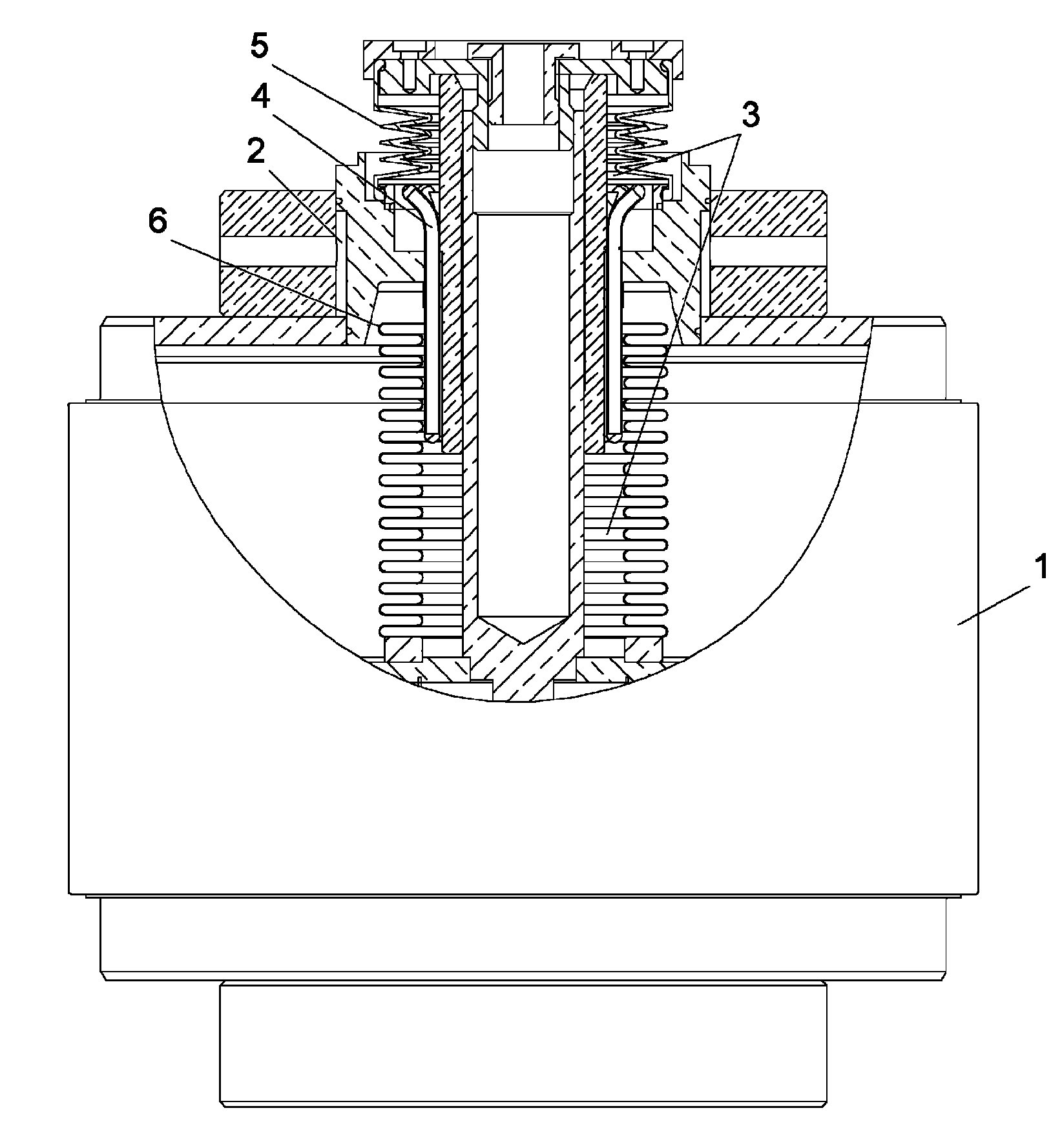

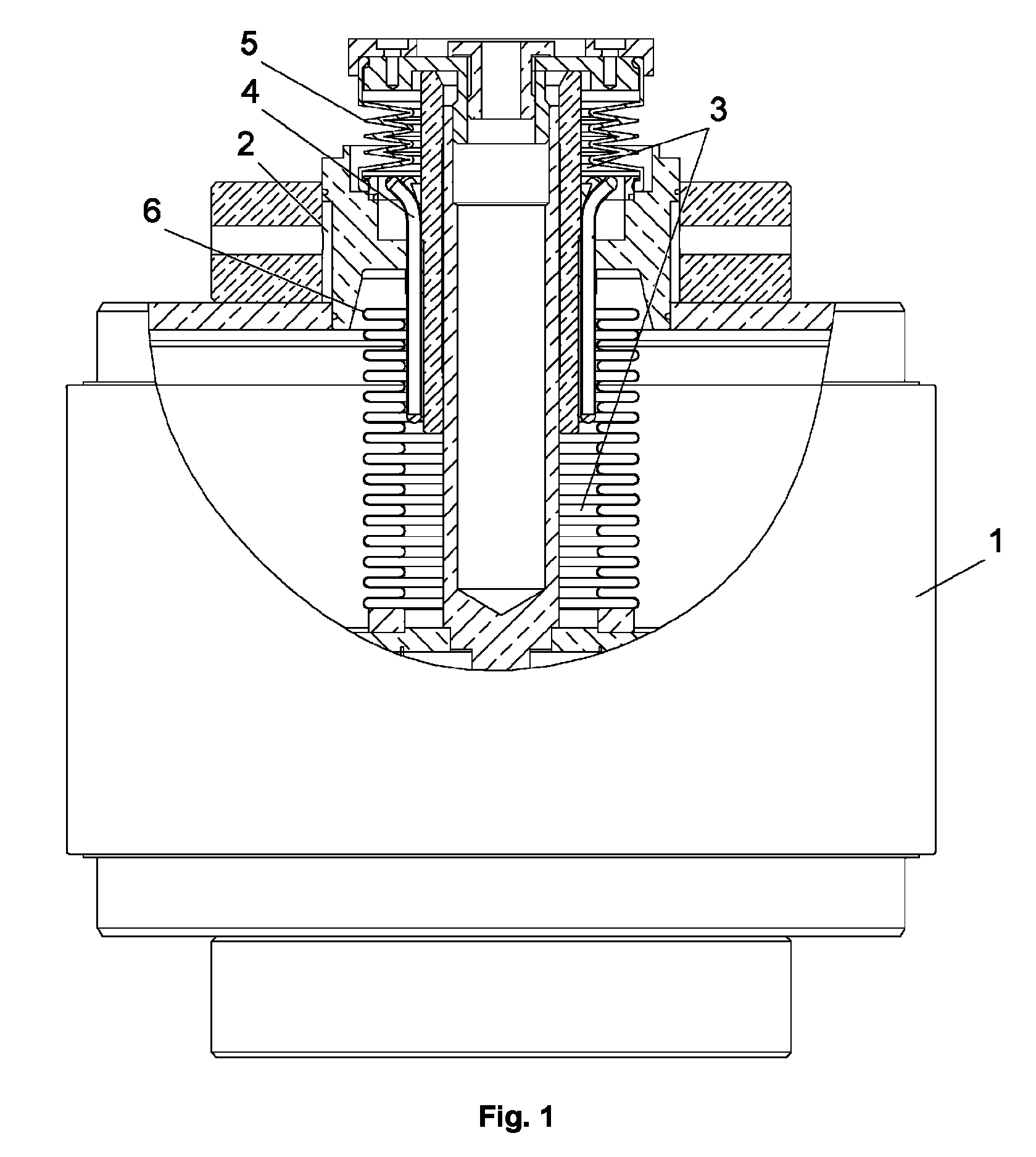

Solenoid valve

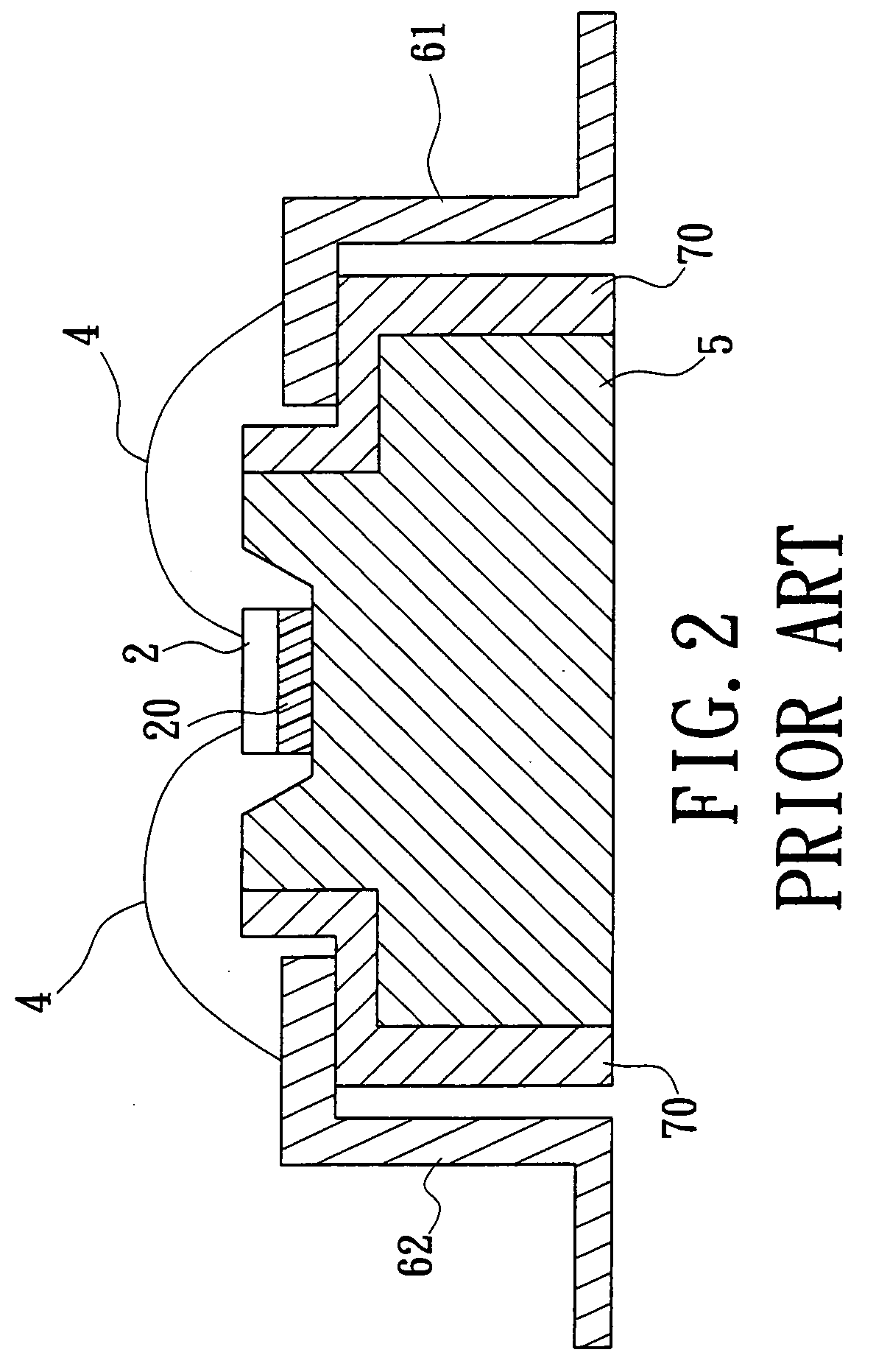

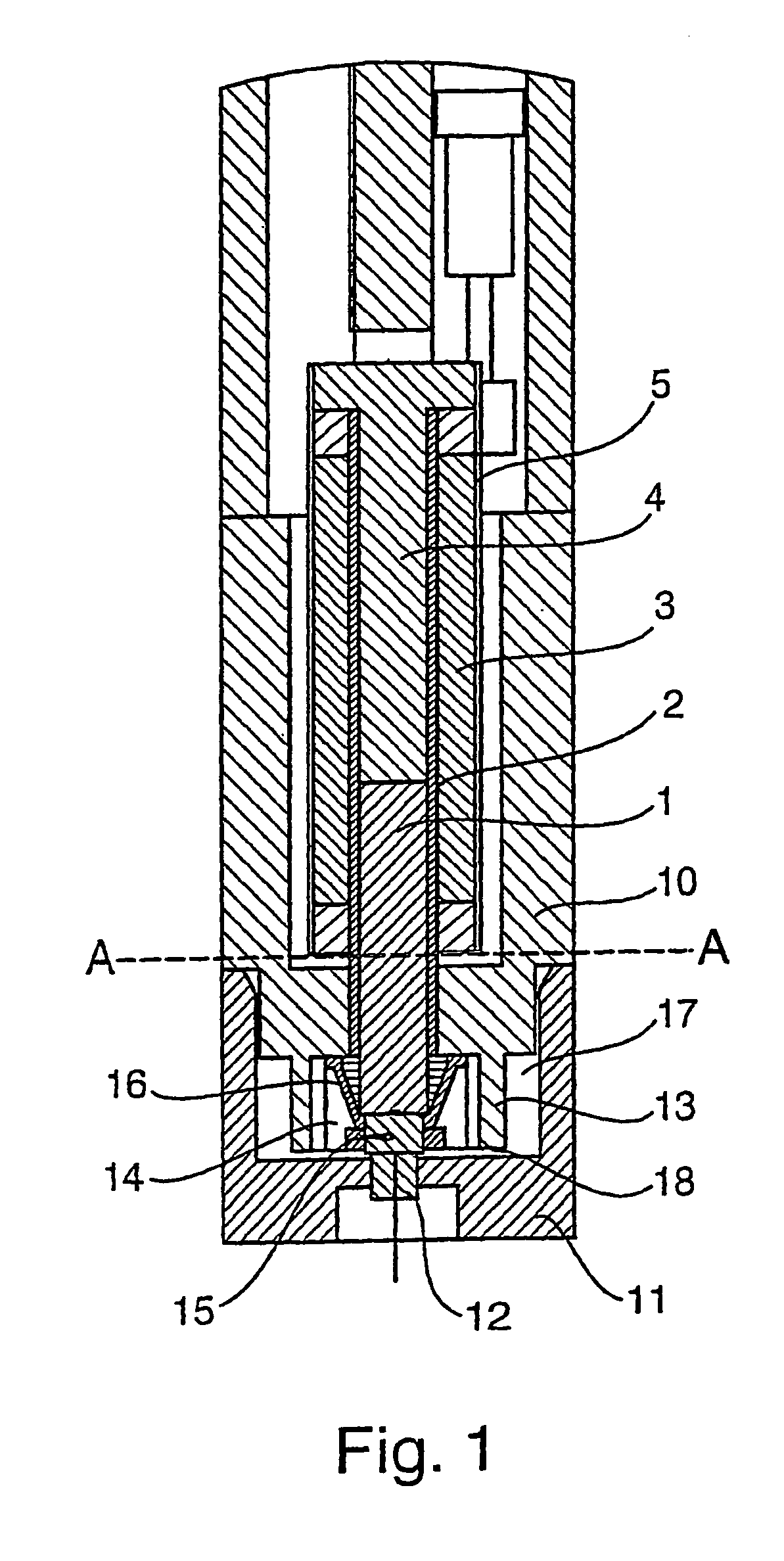

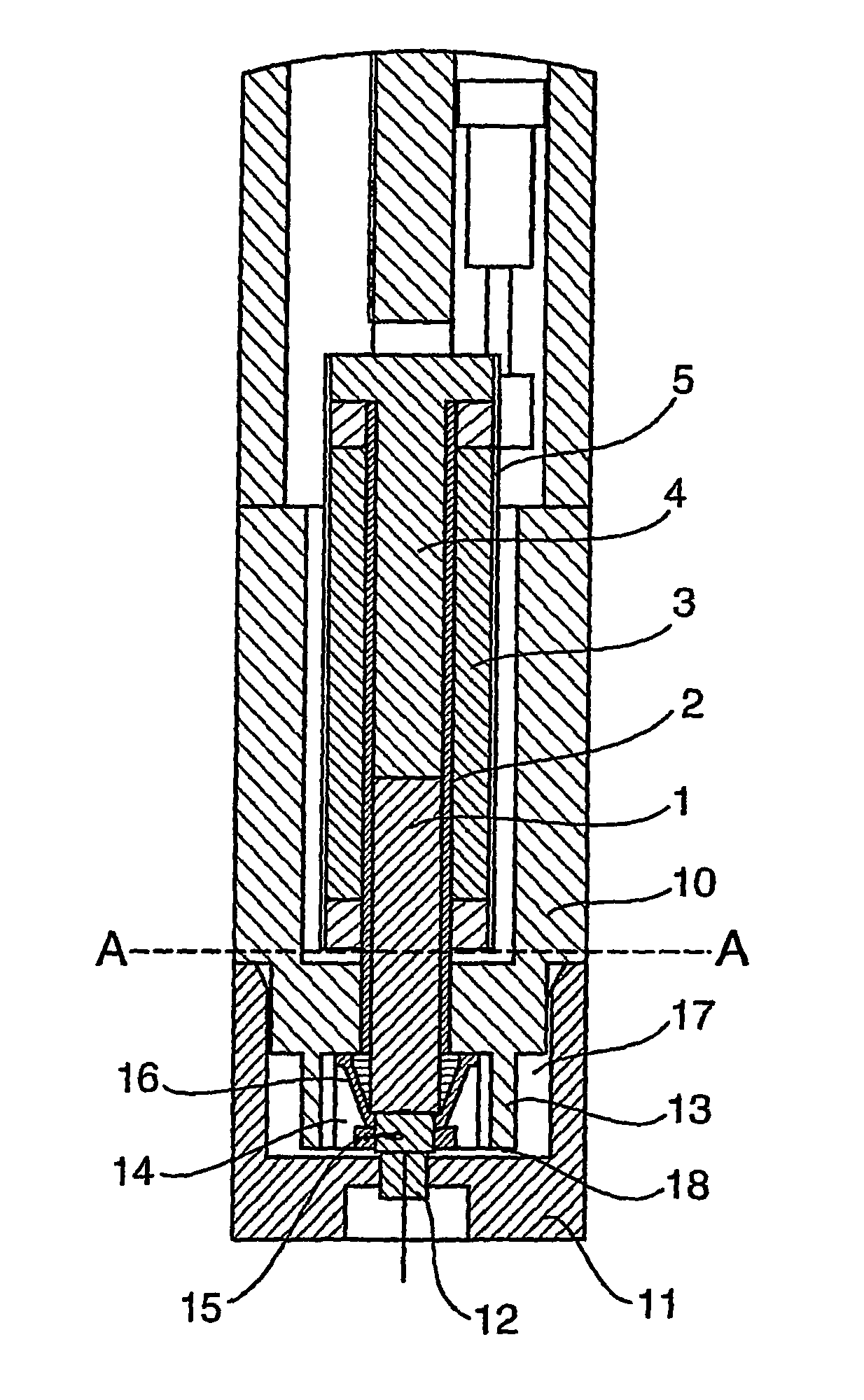

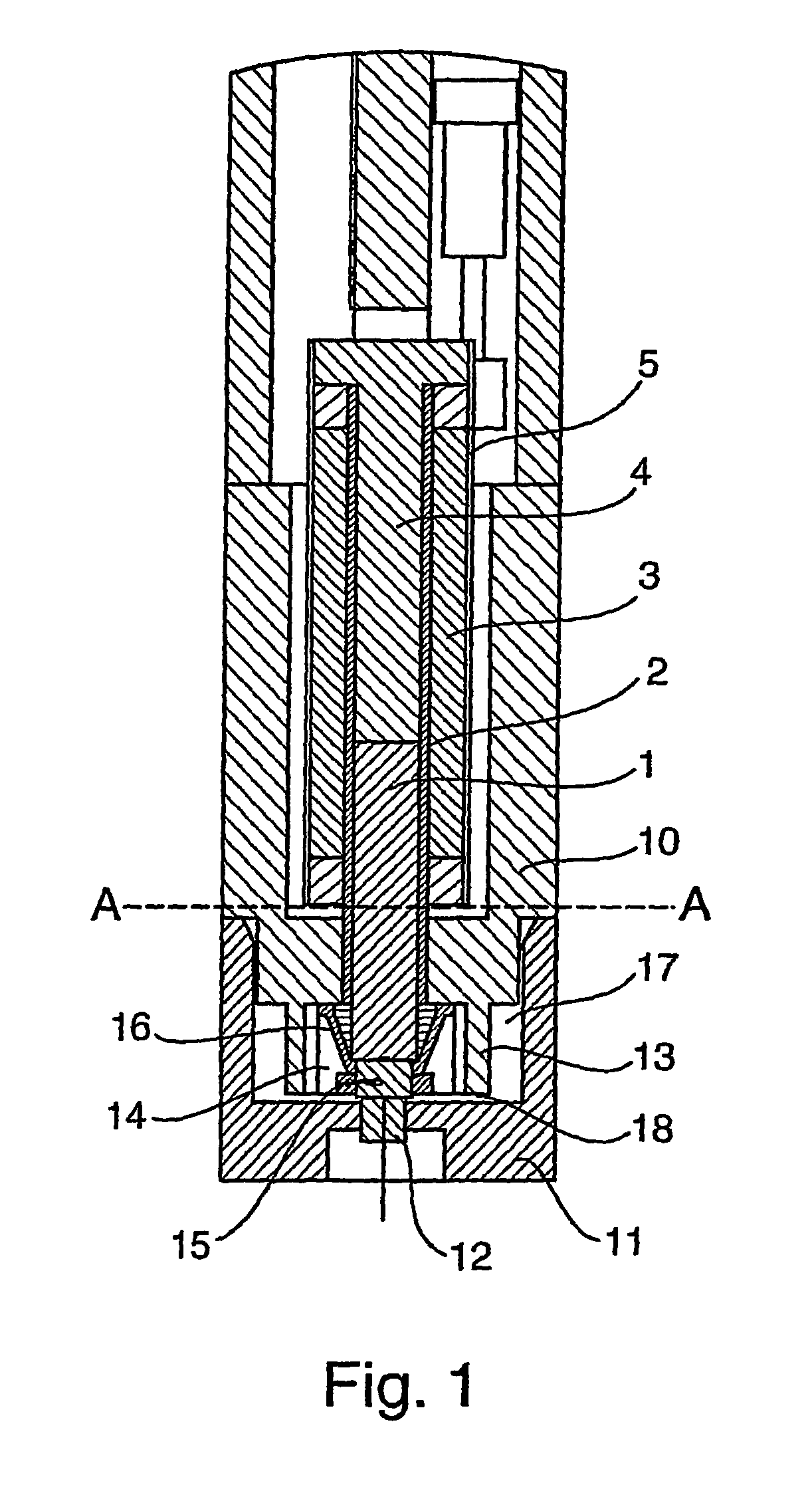

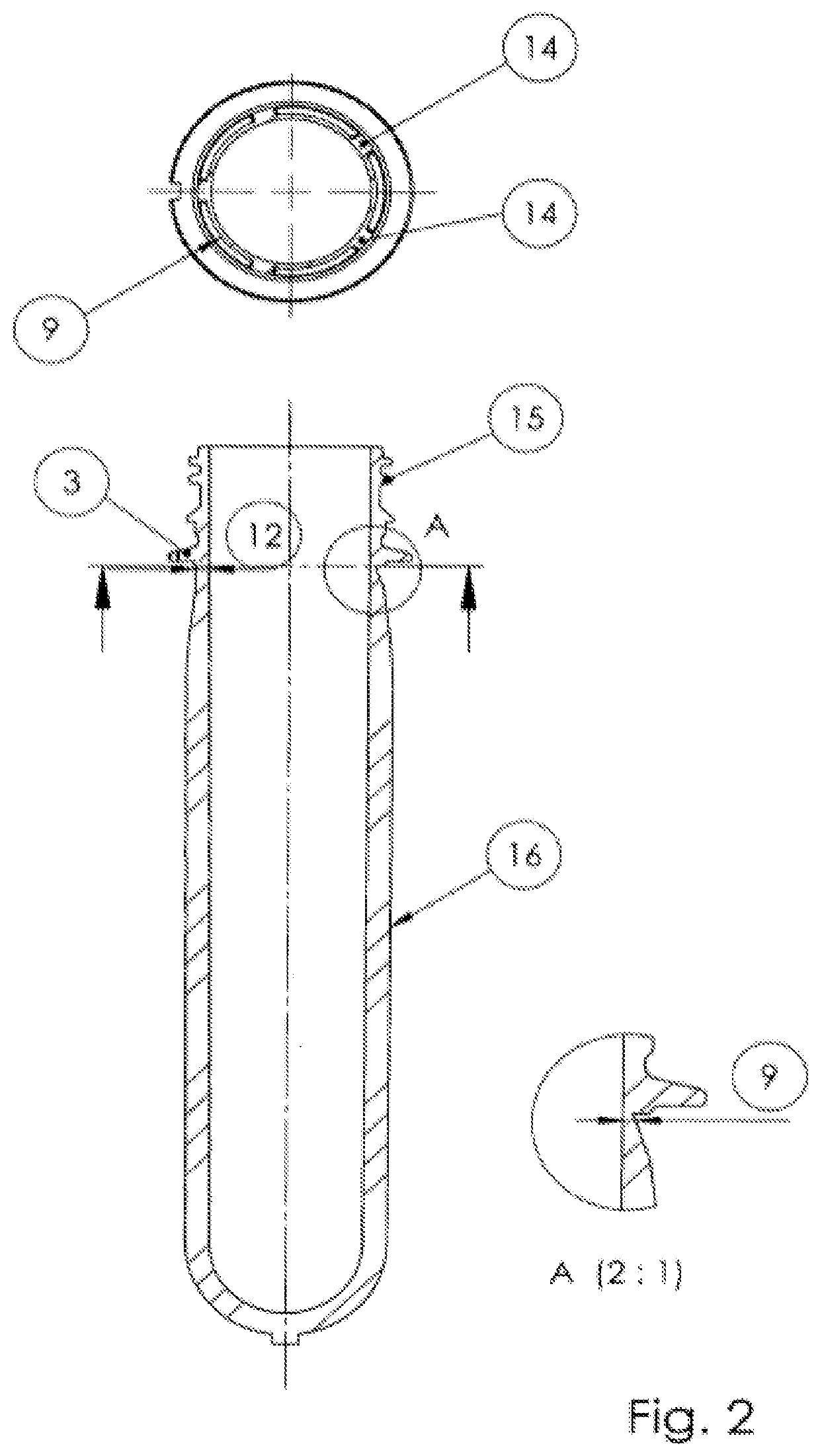

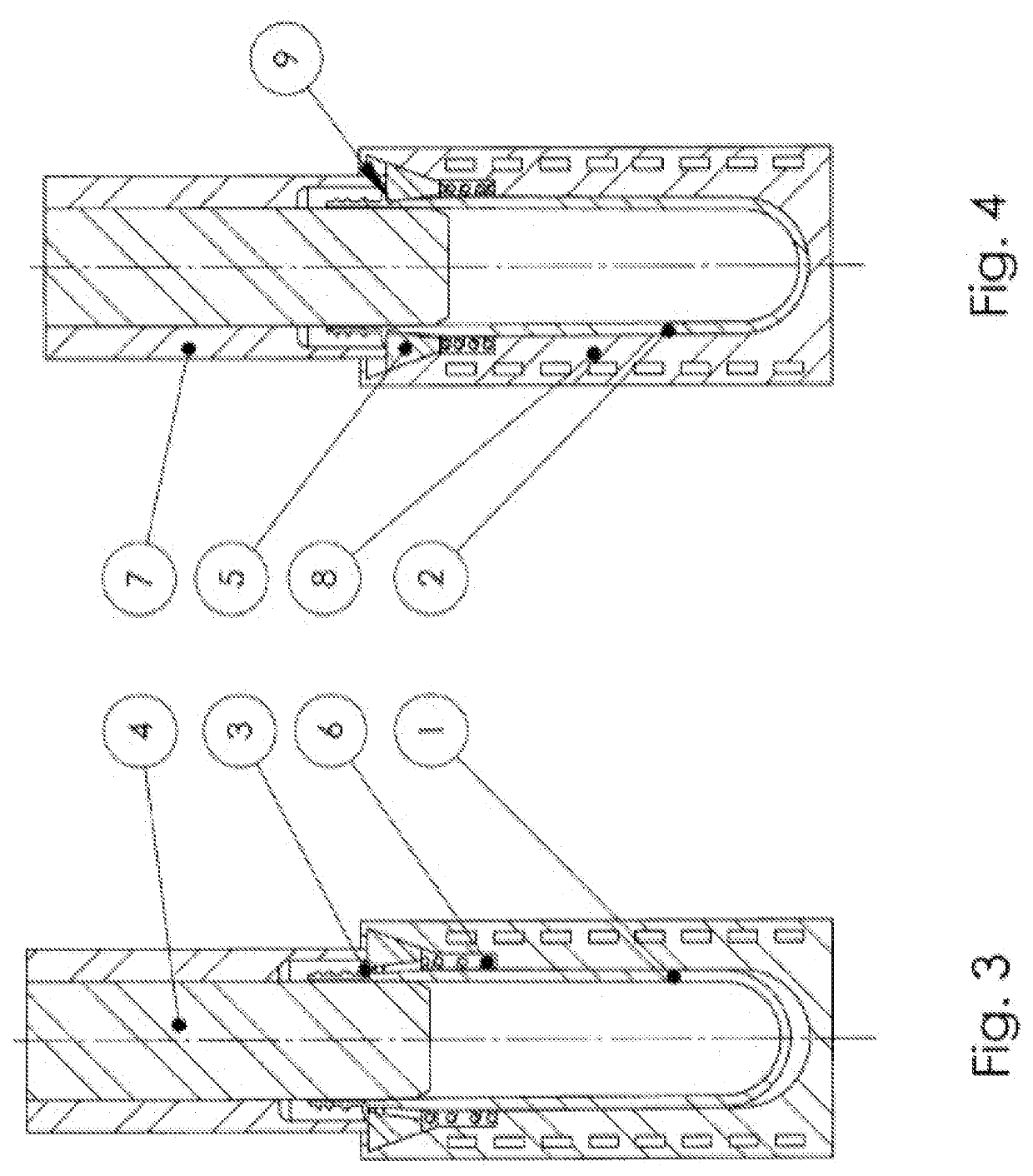

InactiveUS20050231553A1Reduce intensityQuality improvementInking apparatusOperating means/releasing devices for valvesSolenoid valveInk printer

A solenoid valve making use of certain materials which is capable of operation at high frequencies and which can be made as a compact unit. The plunger (1) is made from a material having a saturation flux density greater than 1.4 Tesla preferably more than 1.6 Tesla, a coercivity at less than 0.25 ampere per centimeter and a relative magnetic permeability in excess of 10.000; and the nozzle bore leading from the valve head chamber (14) to the nozzle orifice (12) has a length to diameter ratio of less than 8:1 preferably between 2:1 to 4:1 and the nozzle orifice (12) has a diameter substantially the same as that of the nozzle bore. The invention also relates to method for operating a drop on demand ink jet printer incorporating such a valve.

Owner:WILLETT INT

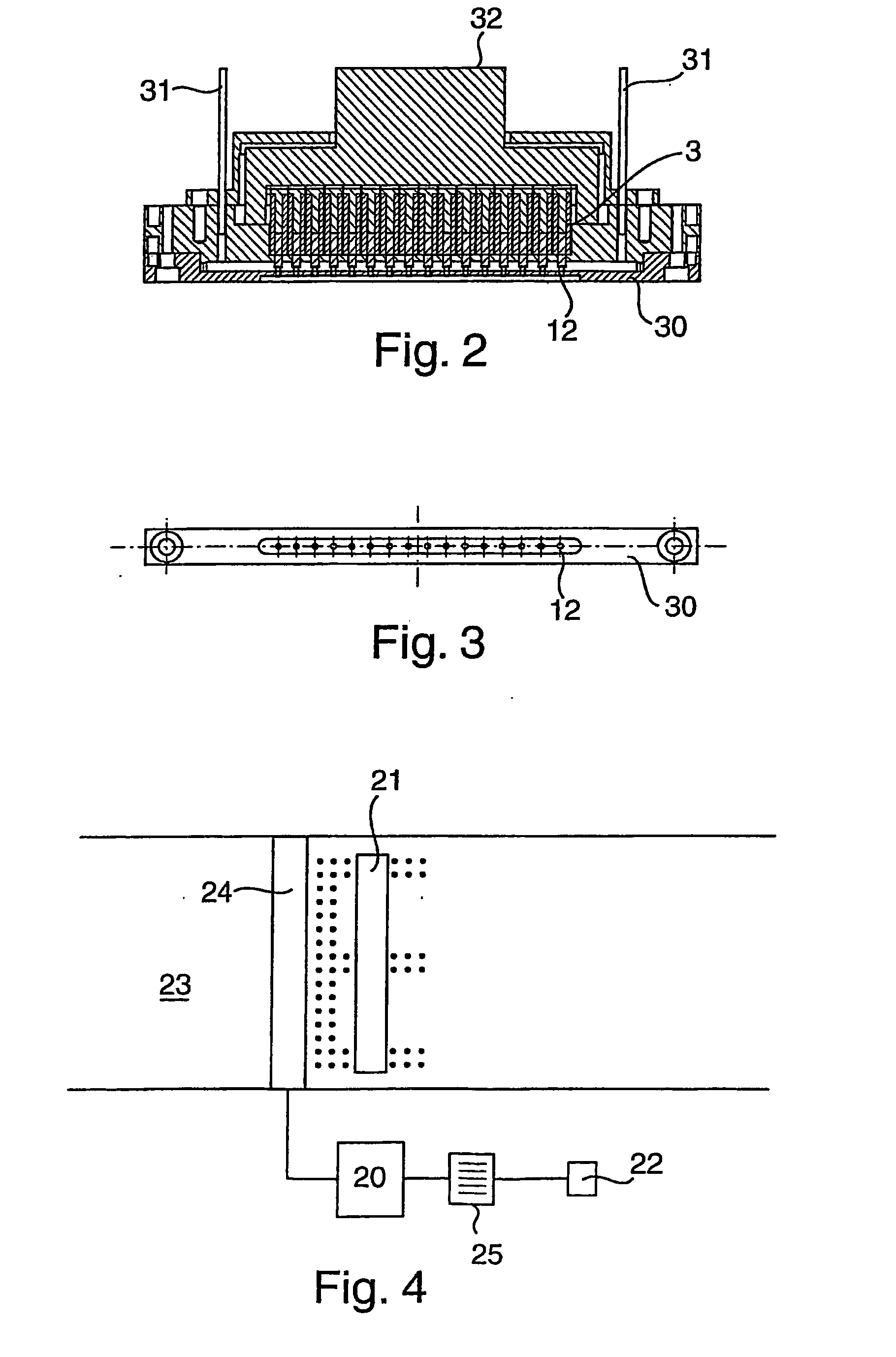

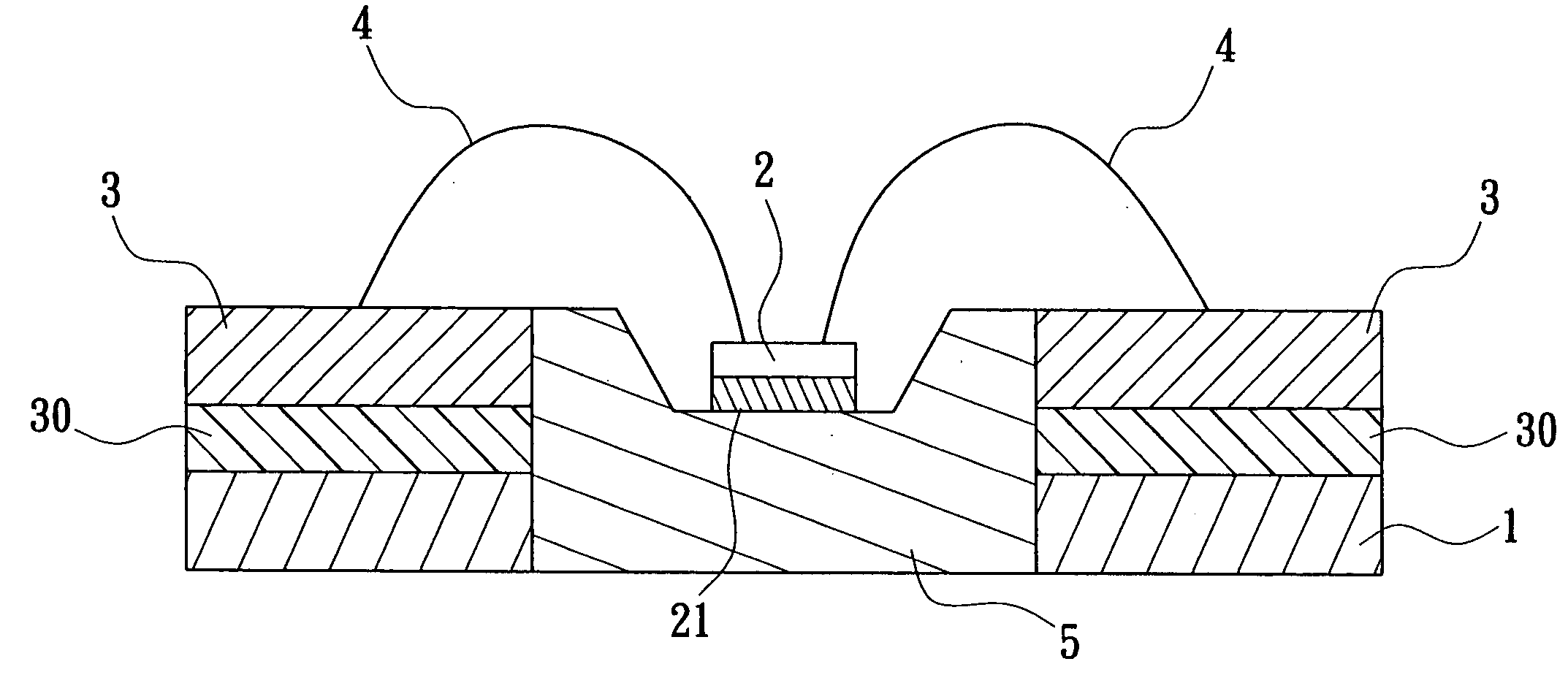

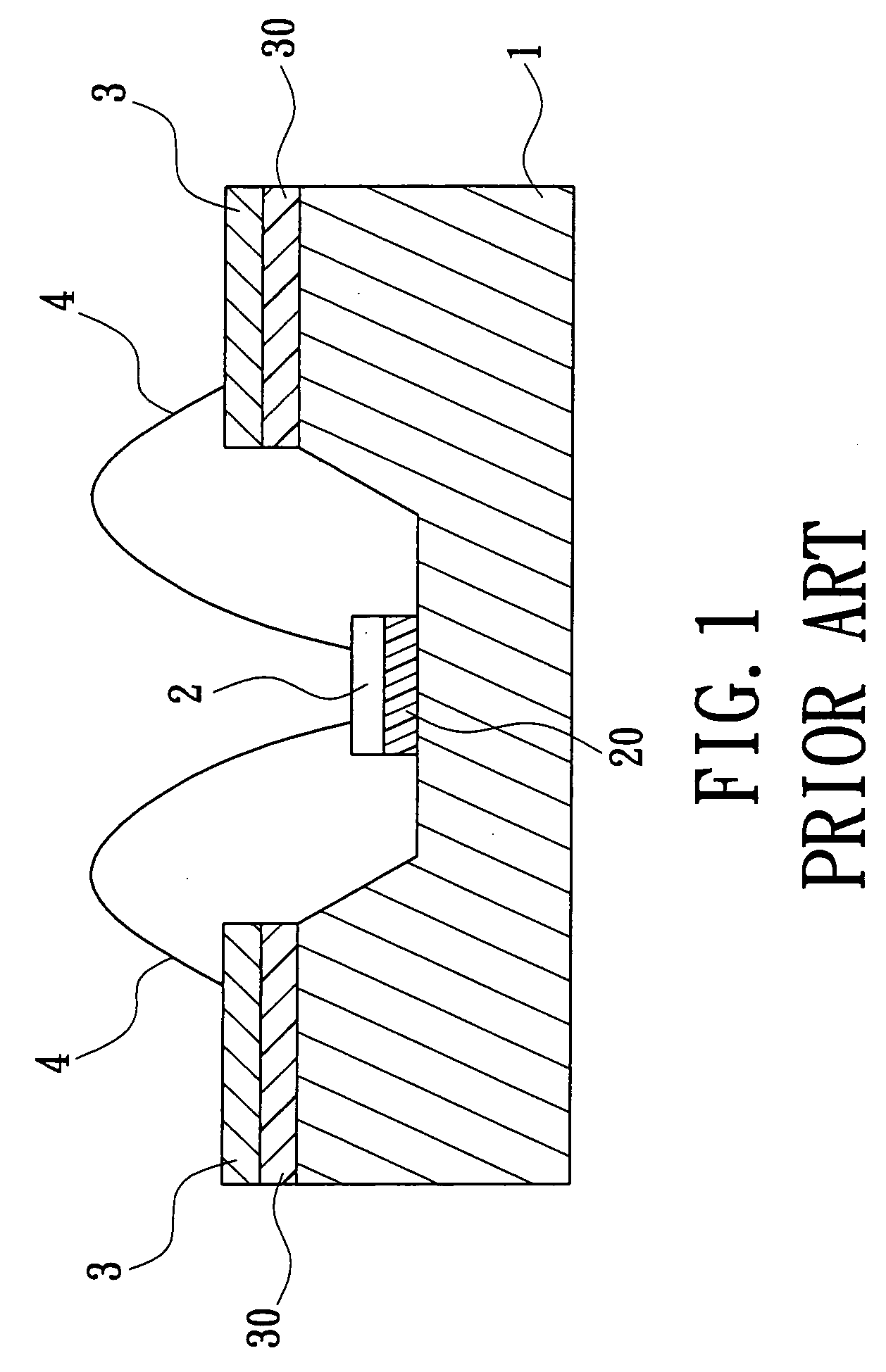

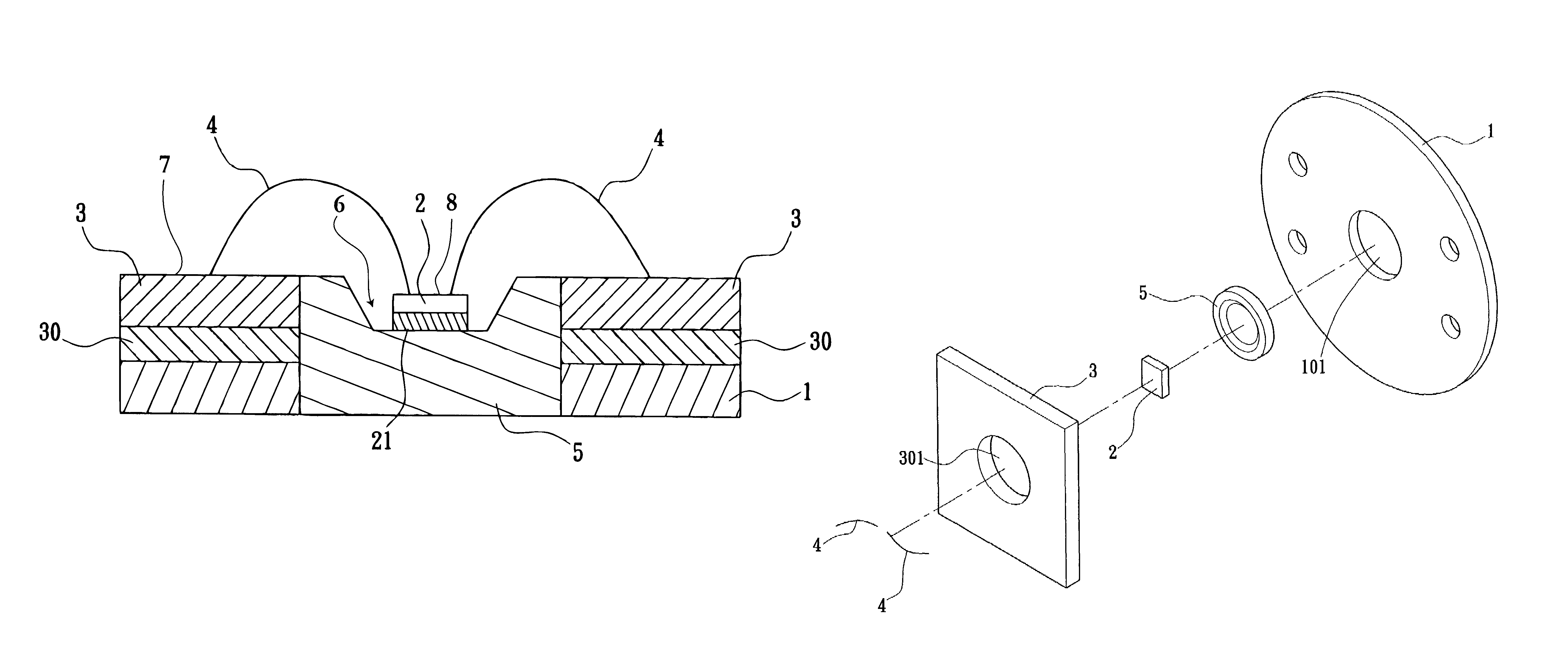

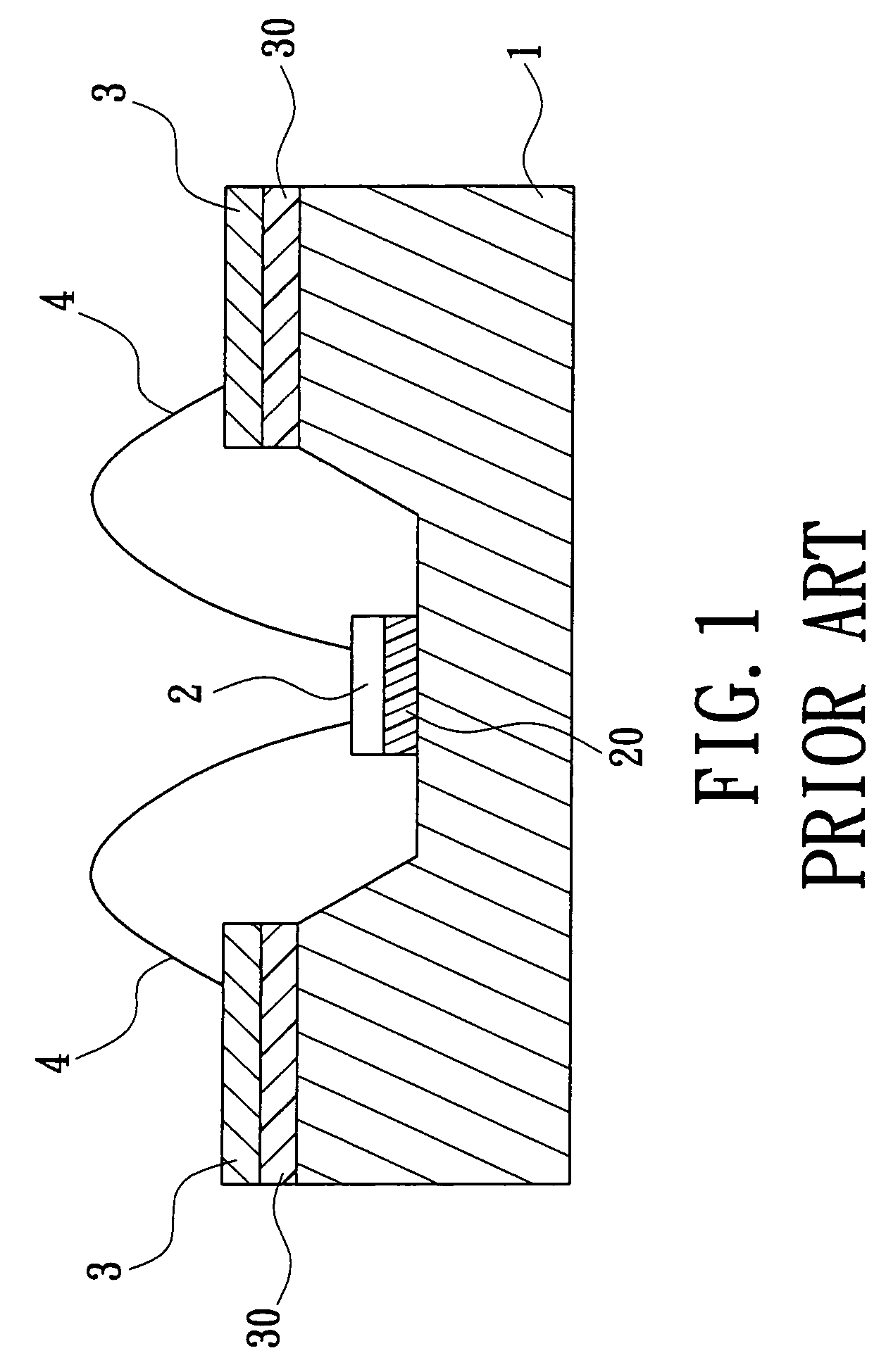

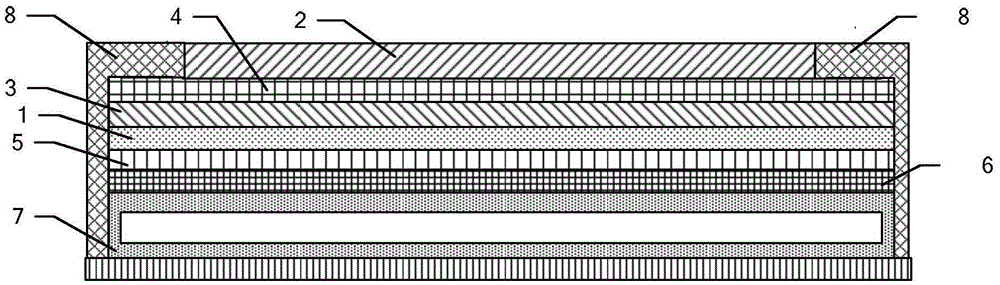

Light emitting module and process thereof

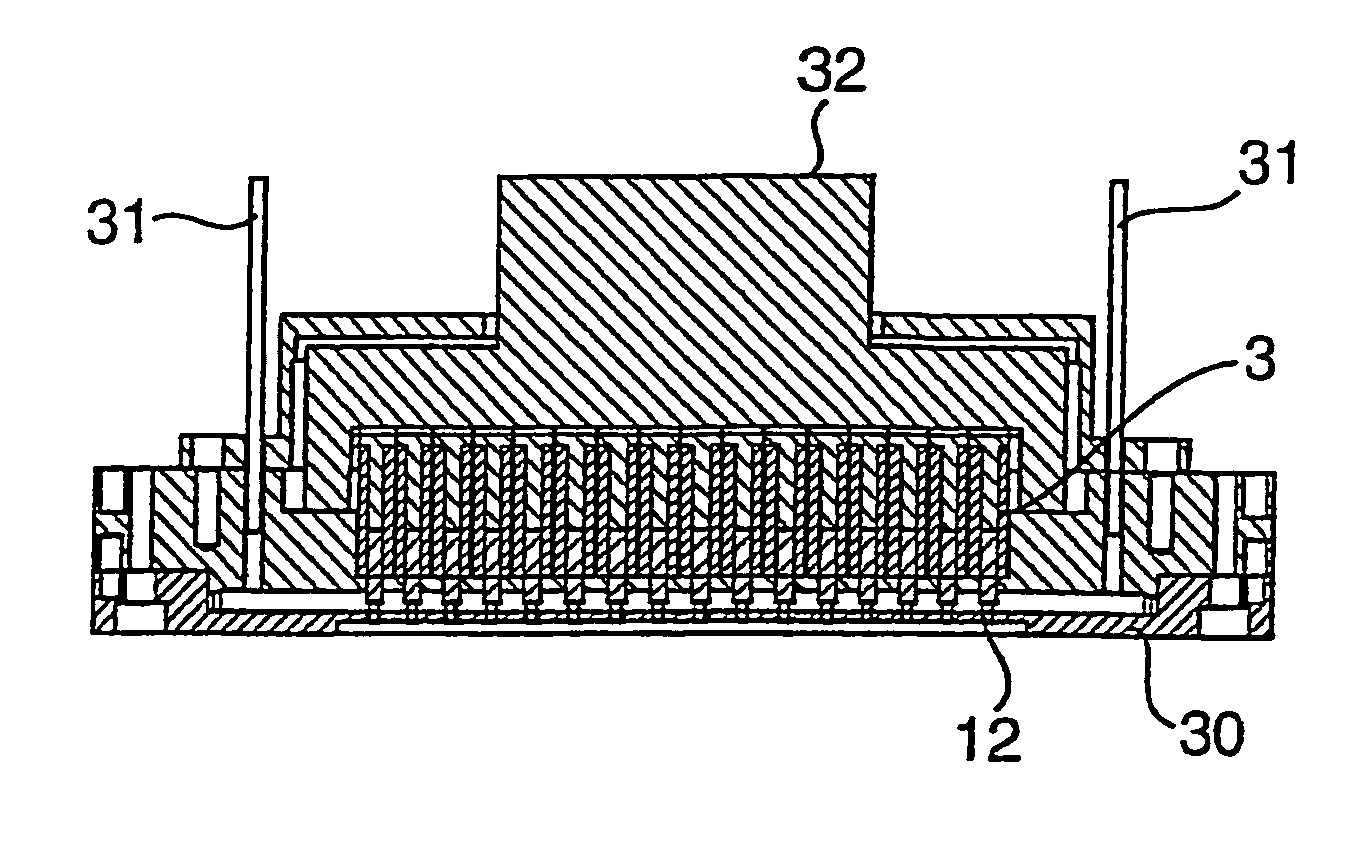

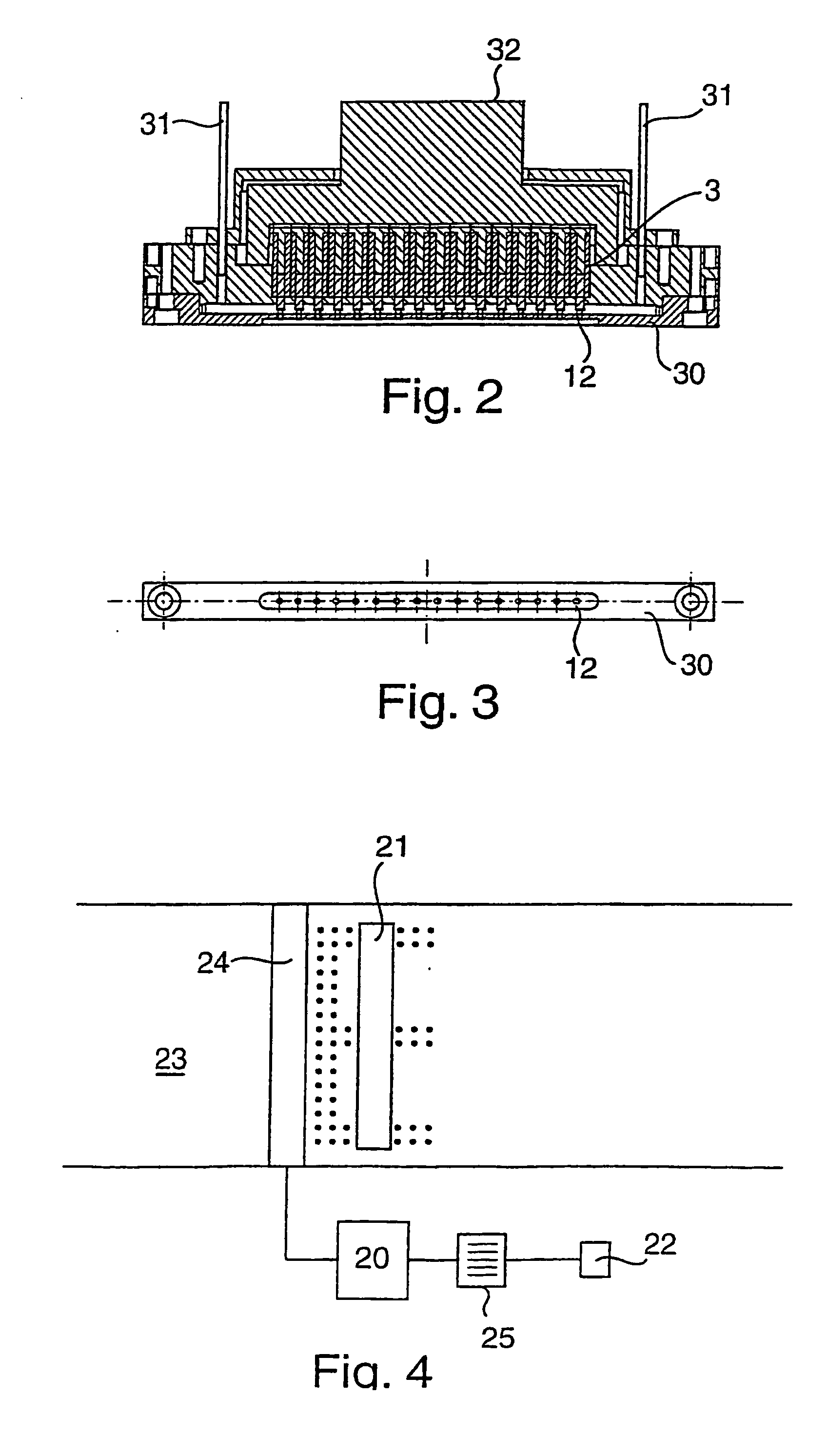

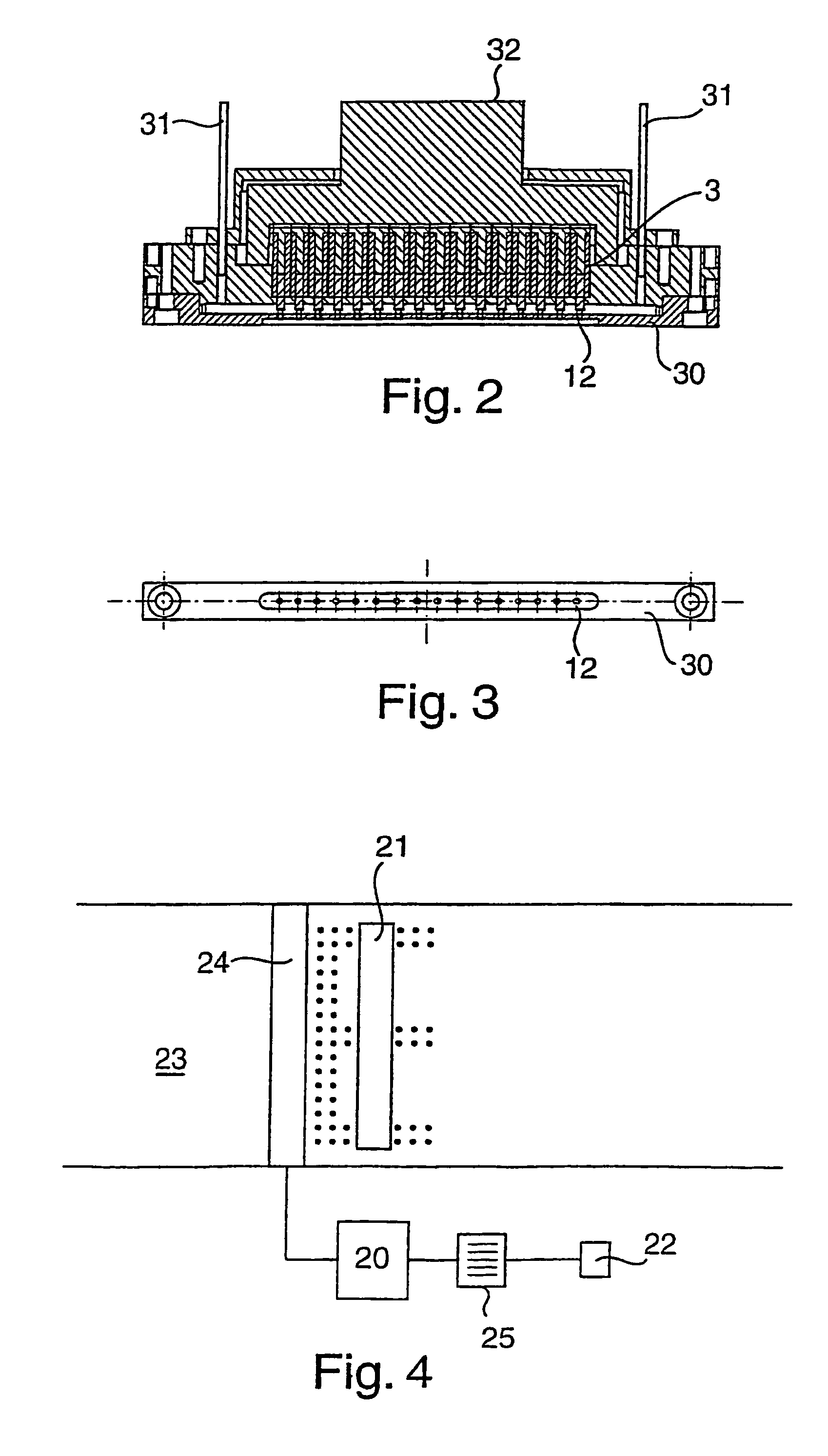

InactiveUS20070170563A1More heat energyReduce the temperatureSemiconductor/solid-state device detailsLighting heating/cooling arrangementsEngineeringSoldering

A light emitting module includes a metal substrate, a bearing base, at least one LED, a printed circuit board, and at least one conductive wire. A first perforation is formed on the metal substrate and the bearing base is embedded into the first perforation of the metal substrate. According to an eutectic soldering method, the LED(s) is / are adhered on the bearing base by a compound metal. A second perforation is formed on the printed circuit board to expose the LED(s) which is / are adhered on the bearing base and further allows the printed circuit board to stick on the metal substrate. The conductive wires are used to connect electrically the LED(s) with the printed circuit board.

Owner:CHEN CHIEN CHUNG

Device and method of operation

InactiveUS20060098060A1Uniform colorHigh viscosityInking apparatusOperating means/releasing devices for valvesSolenoid valveComputer printing

The invention relates to a solenoid valve made using certain materials which is capable of operation at high frequencies and which can be made as a compact unit. The invention also relates to method for operating a drop on demand ink jet printer incorporating such a valve.

Owner:WILLETT INT

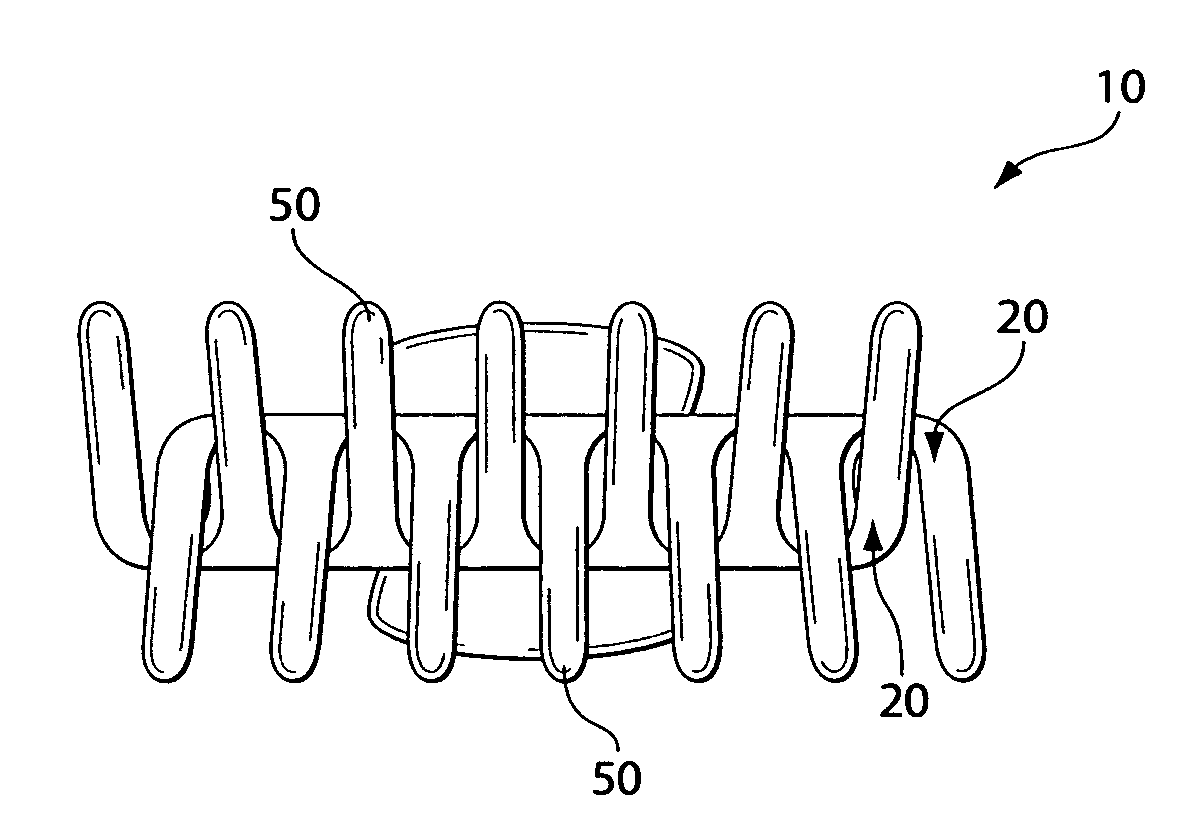

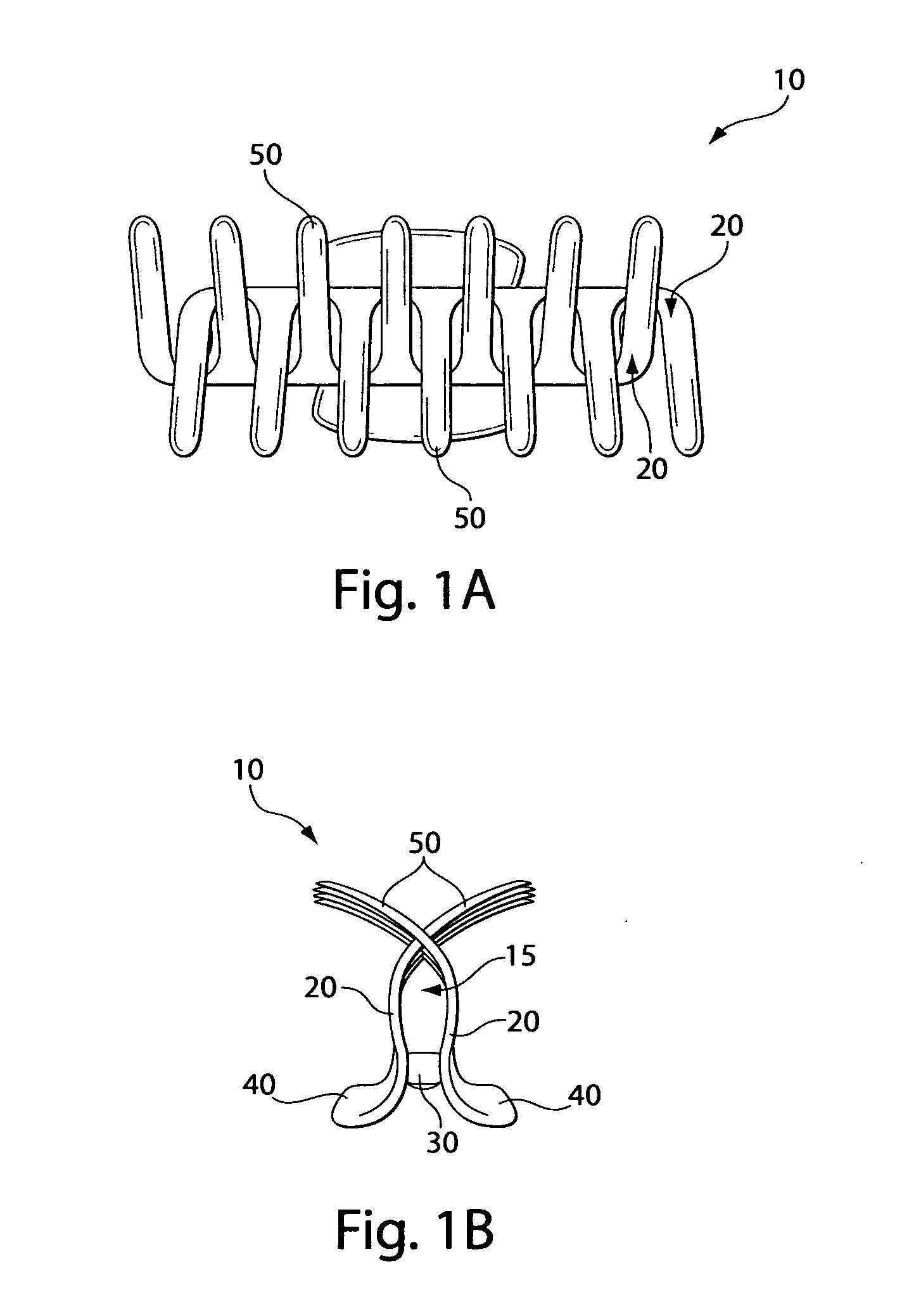

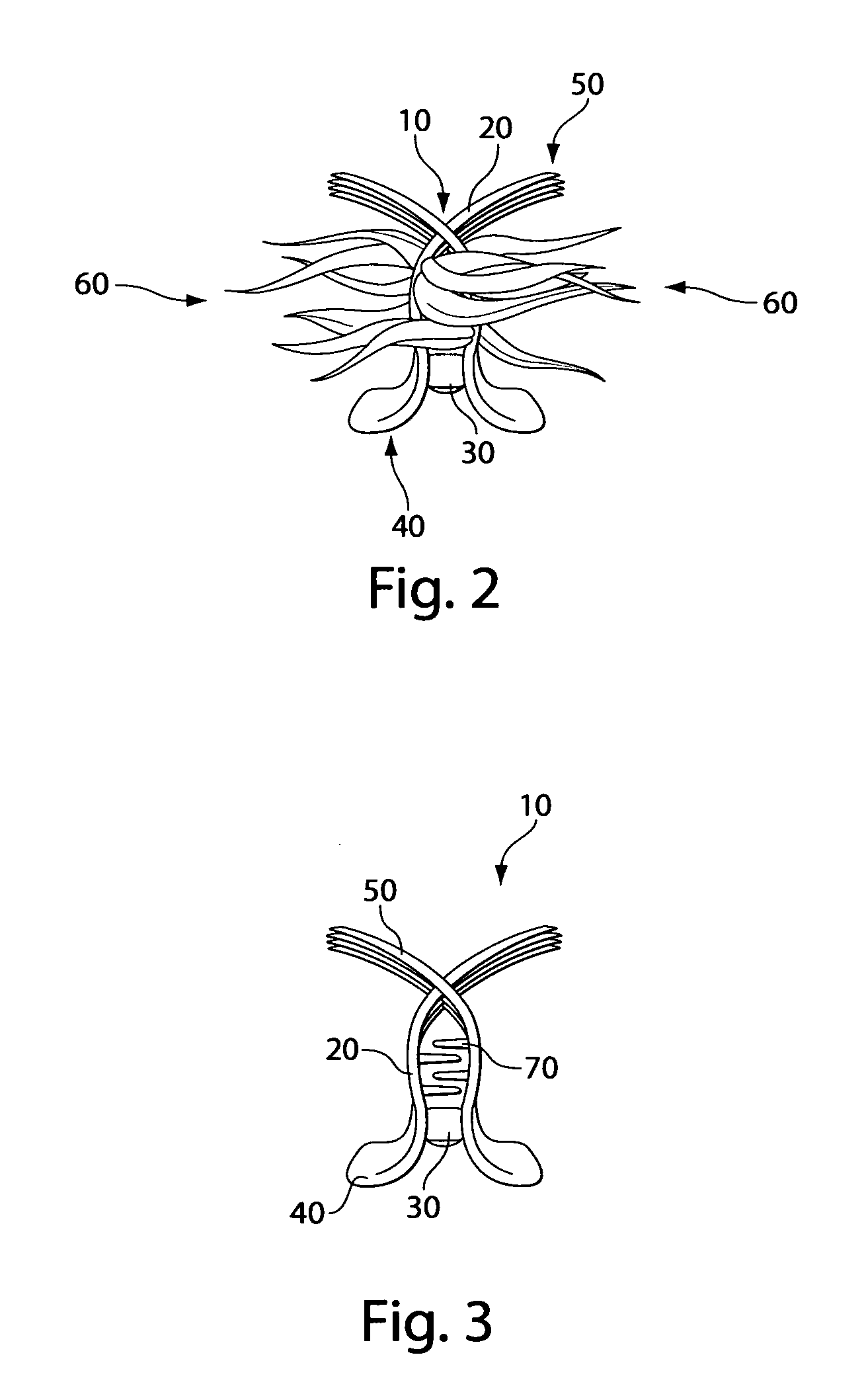

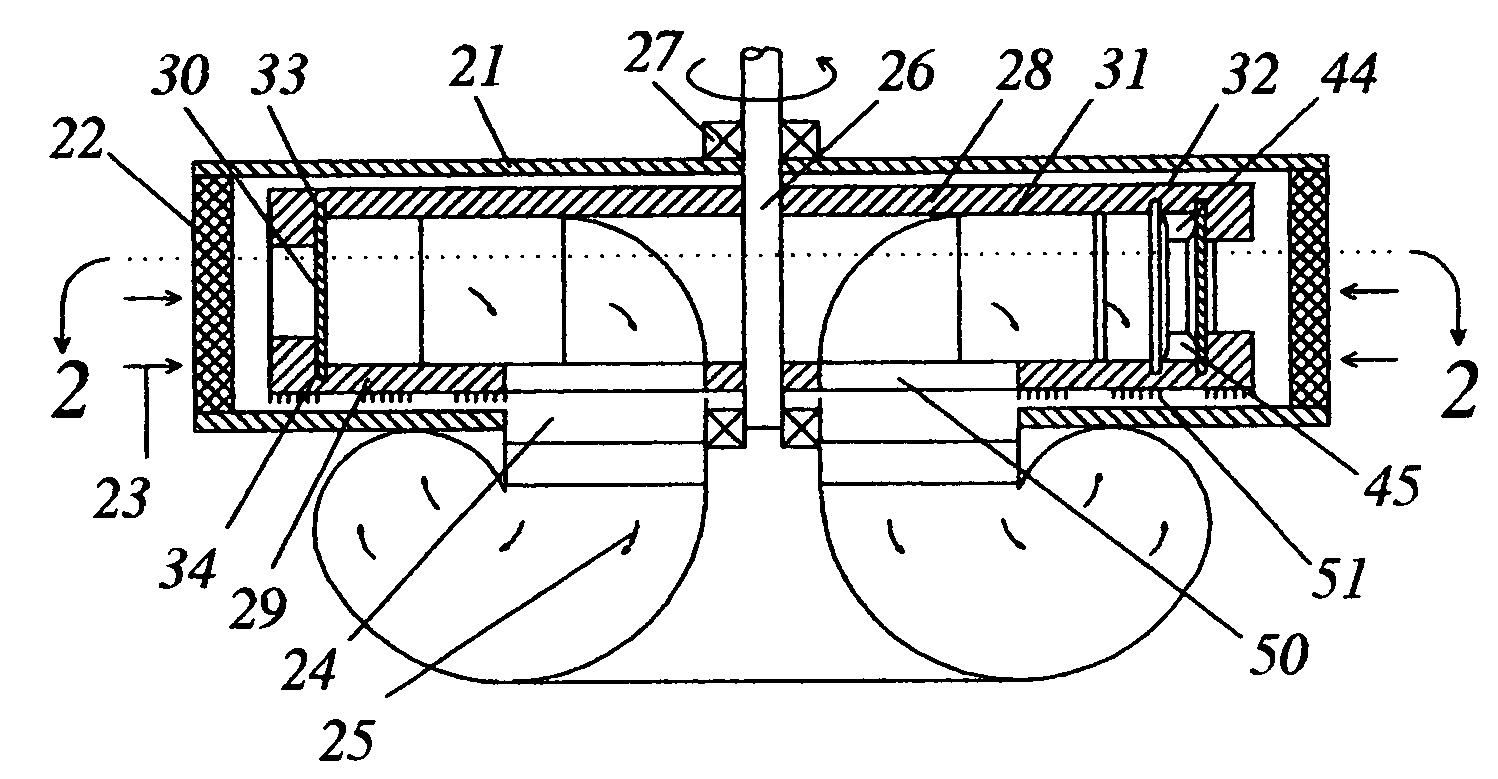

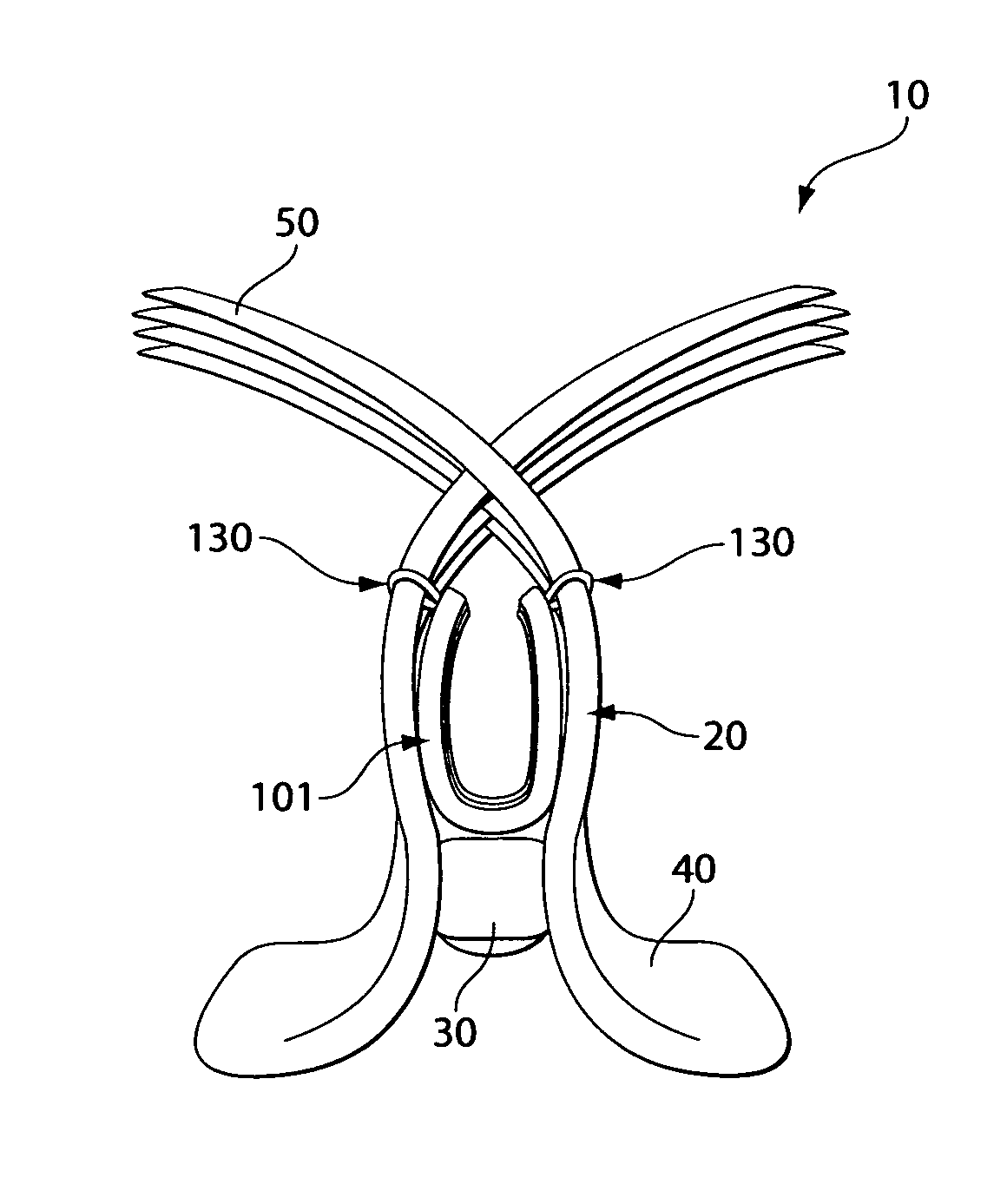

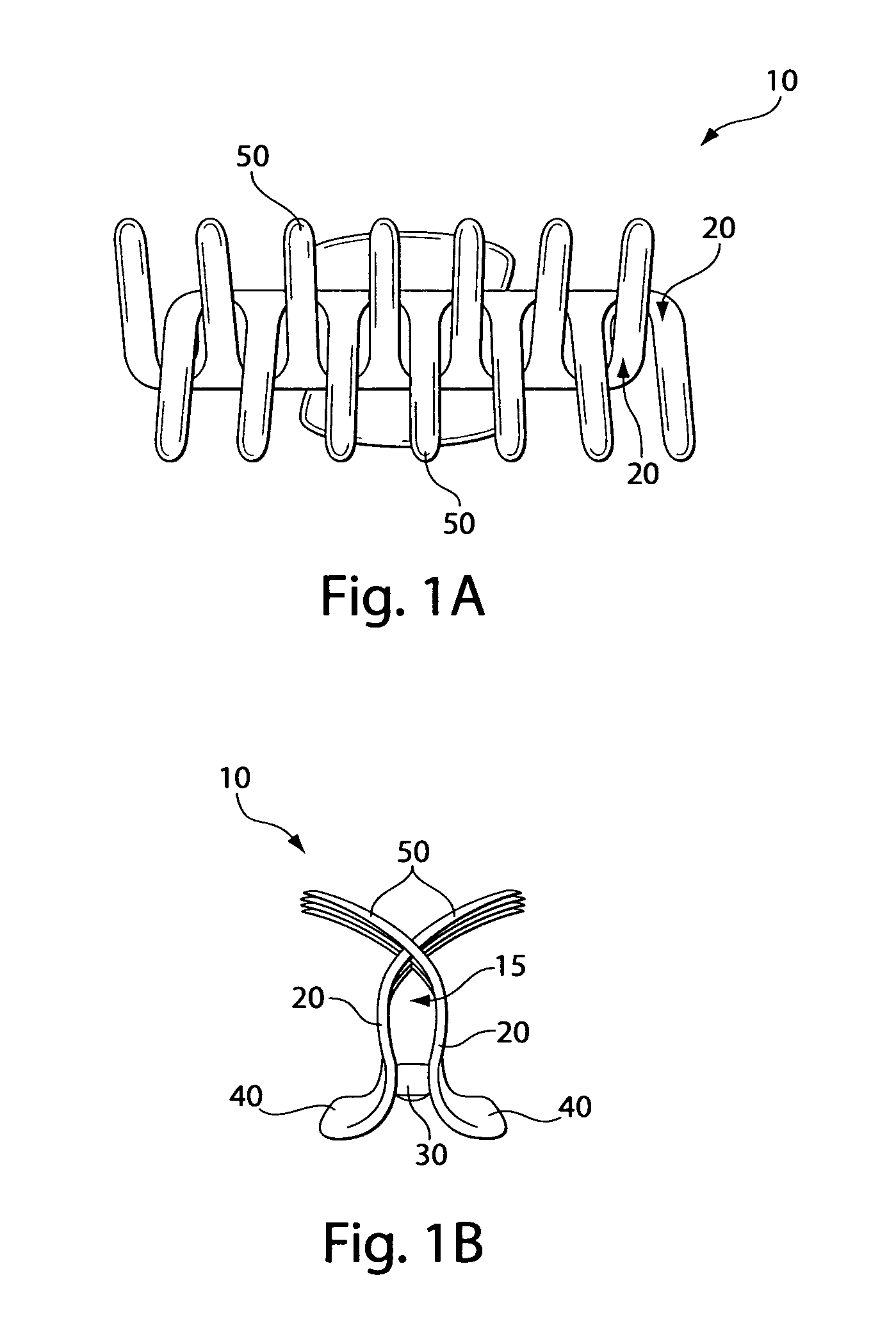

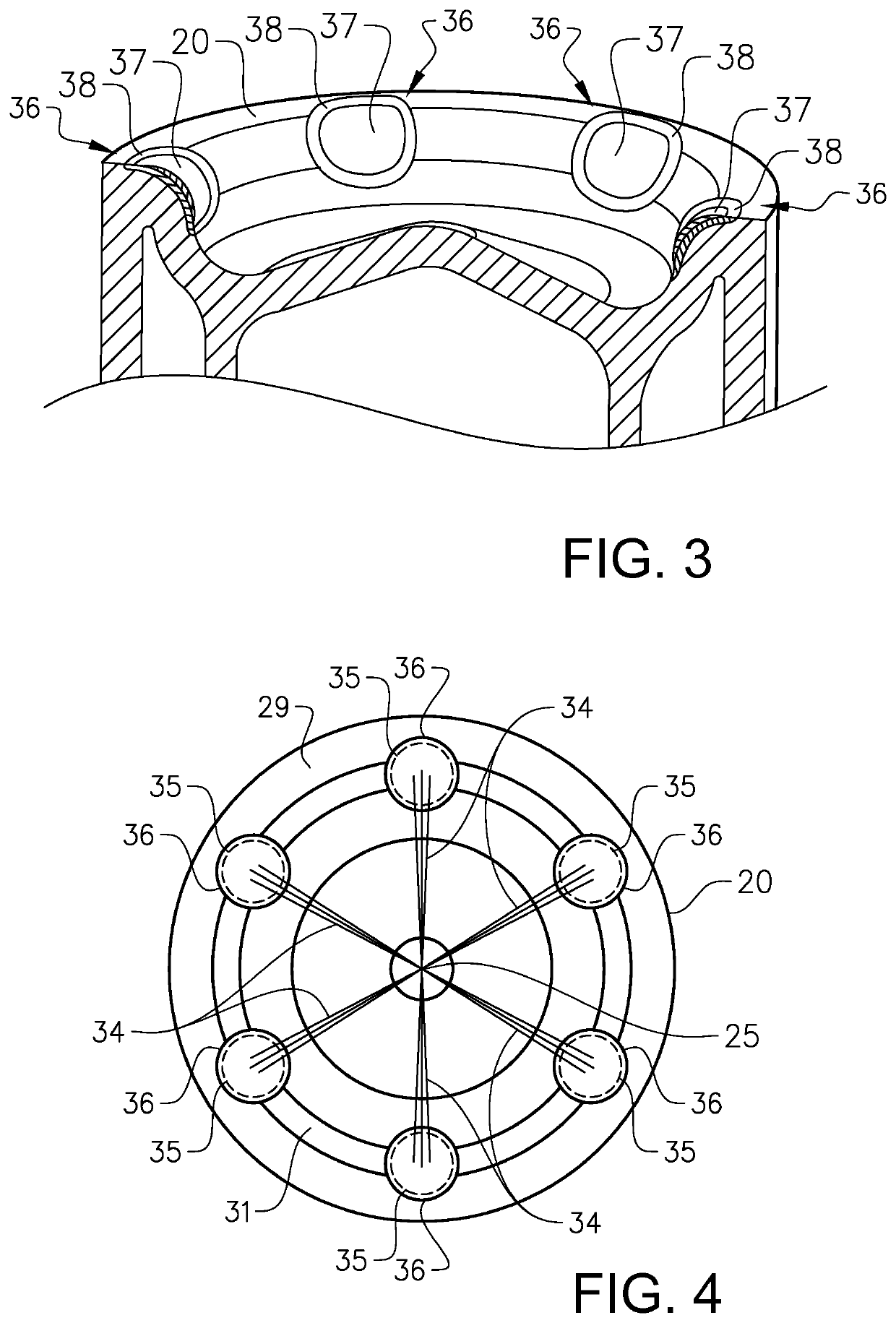

Heated hair styling clip for rapid setting of informal hair styles

InactiveUS20090223533A1Quick SetupEasy to operateCurling-ironsCurling-tongsElectrical resistance and conductanceMicrowave oven

A heated hairstyling clip, optionally with heat-transfer accessories, is provided for rapid informal (“scrunch”-type) hair styling. (To “scrunch” is to crumple, crush or squeeze something tightly together; for example, a handful of hair.) In one embodiment the clip is a pair of concave jaws, optionally with interlocking fingers, held together by a spring mechanism. The hair is set and secured within the heated hairstyling clip, optionally with accessories supplying additional heat, and the clip is then allowed to cool before being removed. The clip is heated by a device, which may be a microwave oven, a conventional oven, a heated bath, or a resistive heating element. Heating of the clip may be supplemented or replaced by a heatable clip liner, held between the clip and the hair being treated, or a heatable clip pad supplying heat to the clip and the hair, or a reservoir within the clip, or a styling element in contact with the hair. The heated clip can be used for the purpose of creating natural looking scrunched styles, tousled body, informal waves or curls, or similar configuration or formation of hair.

Owner:DALEY TINA

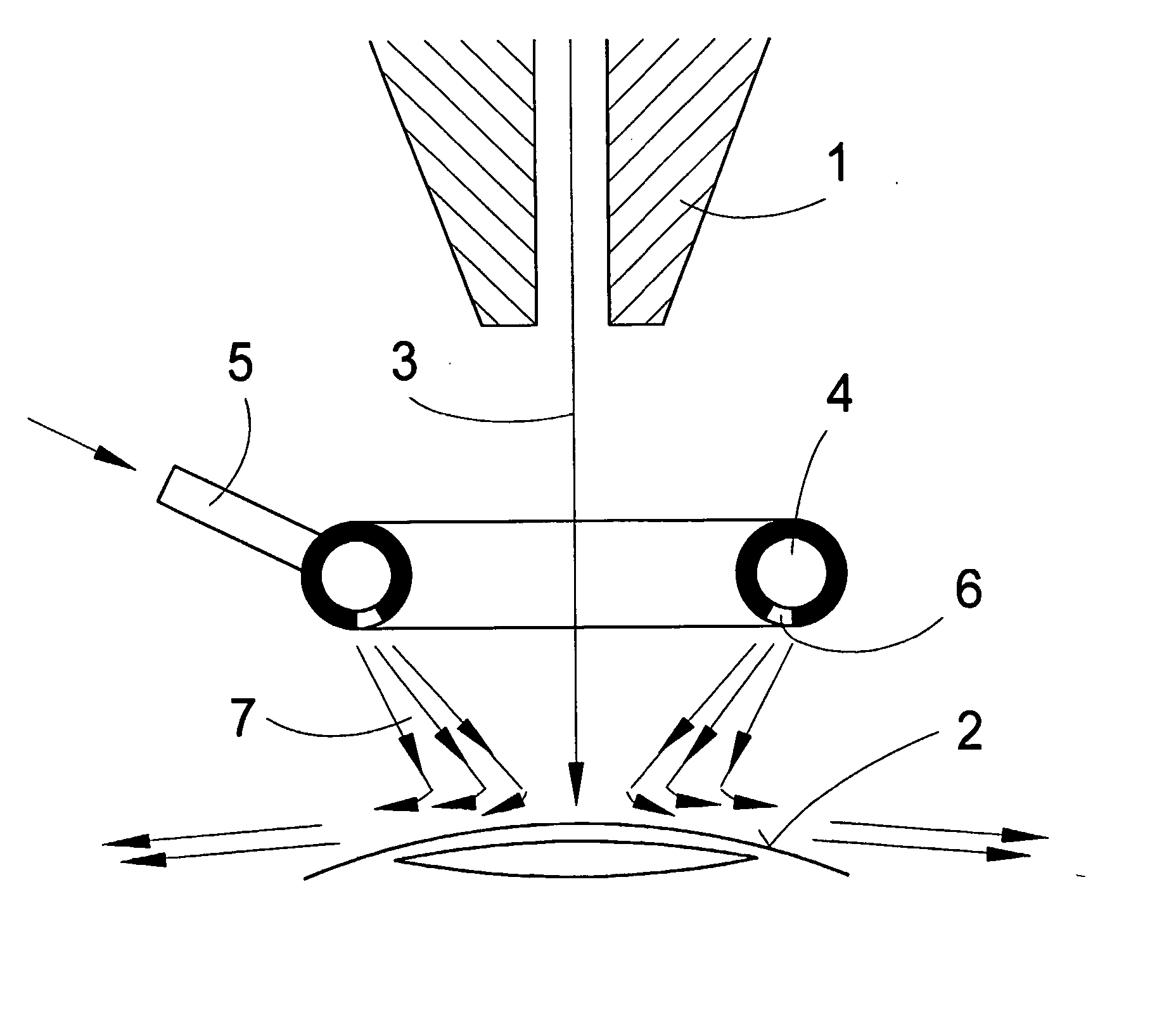

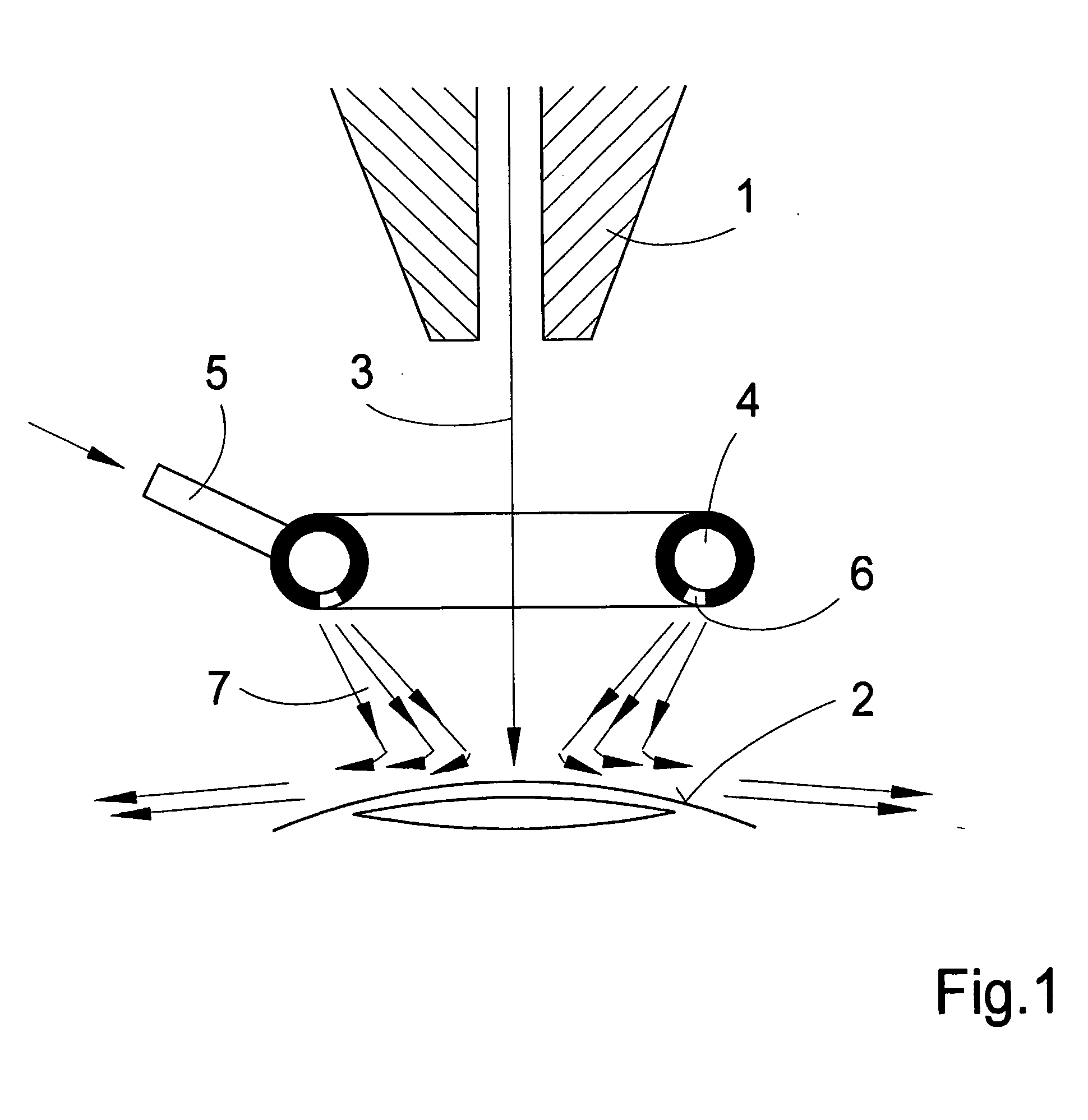

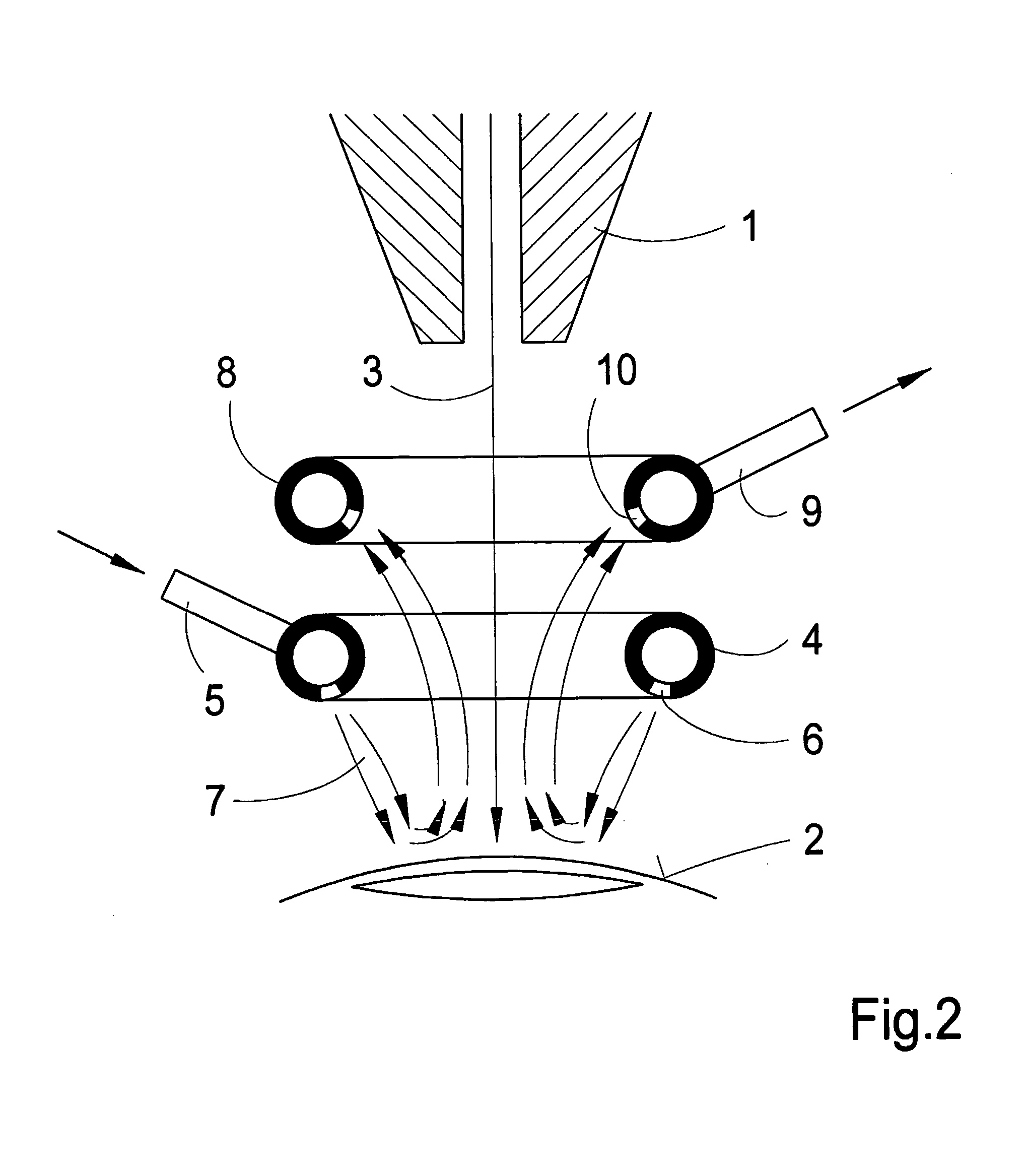

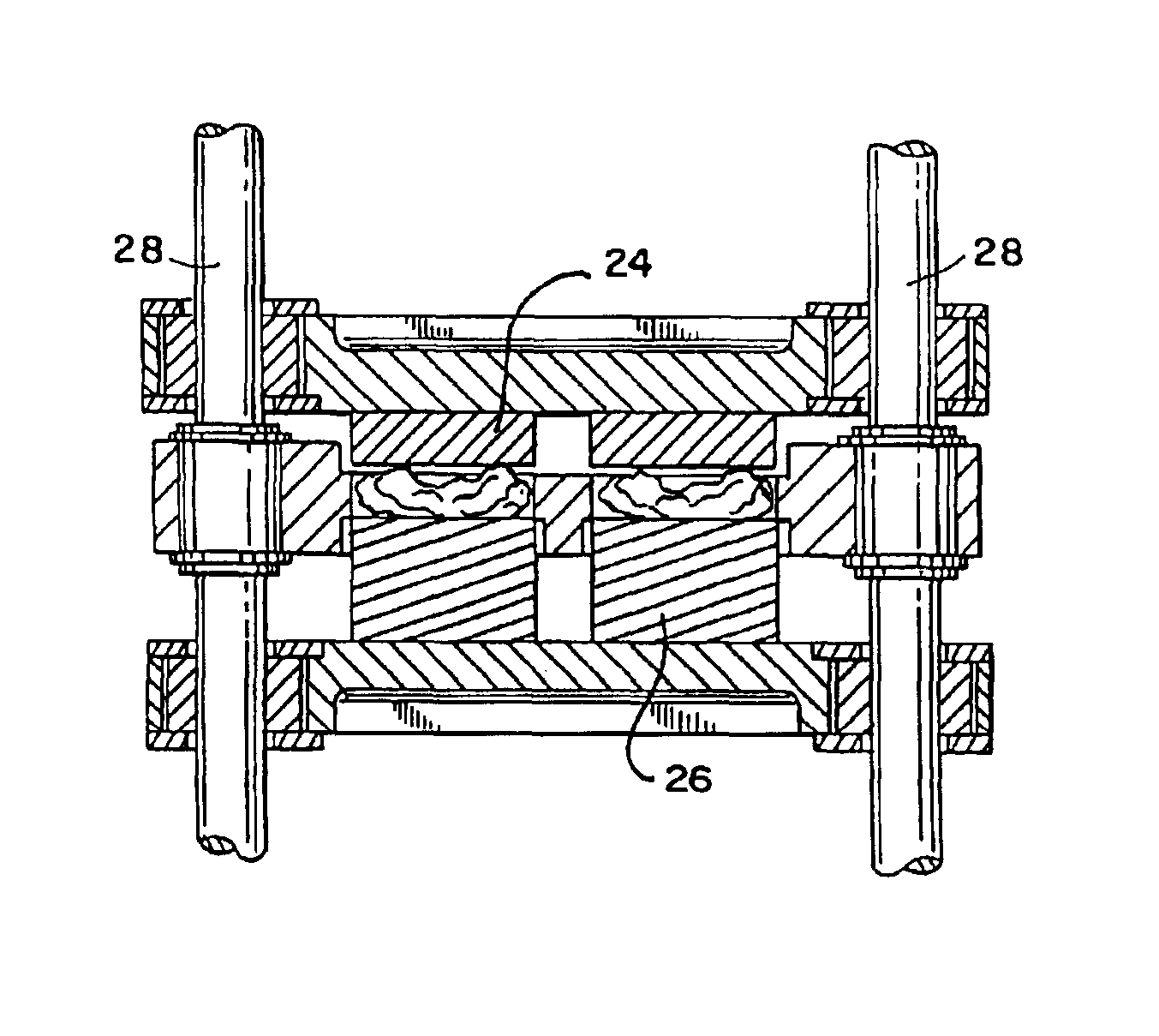

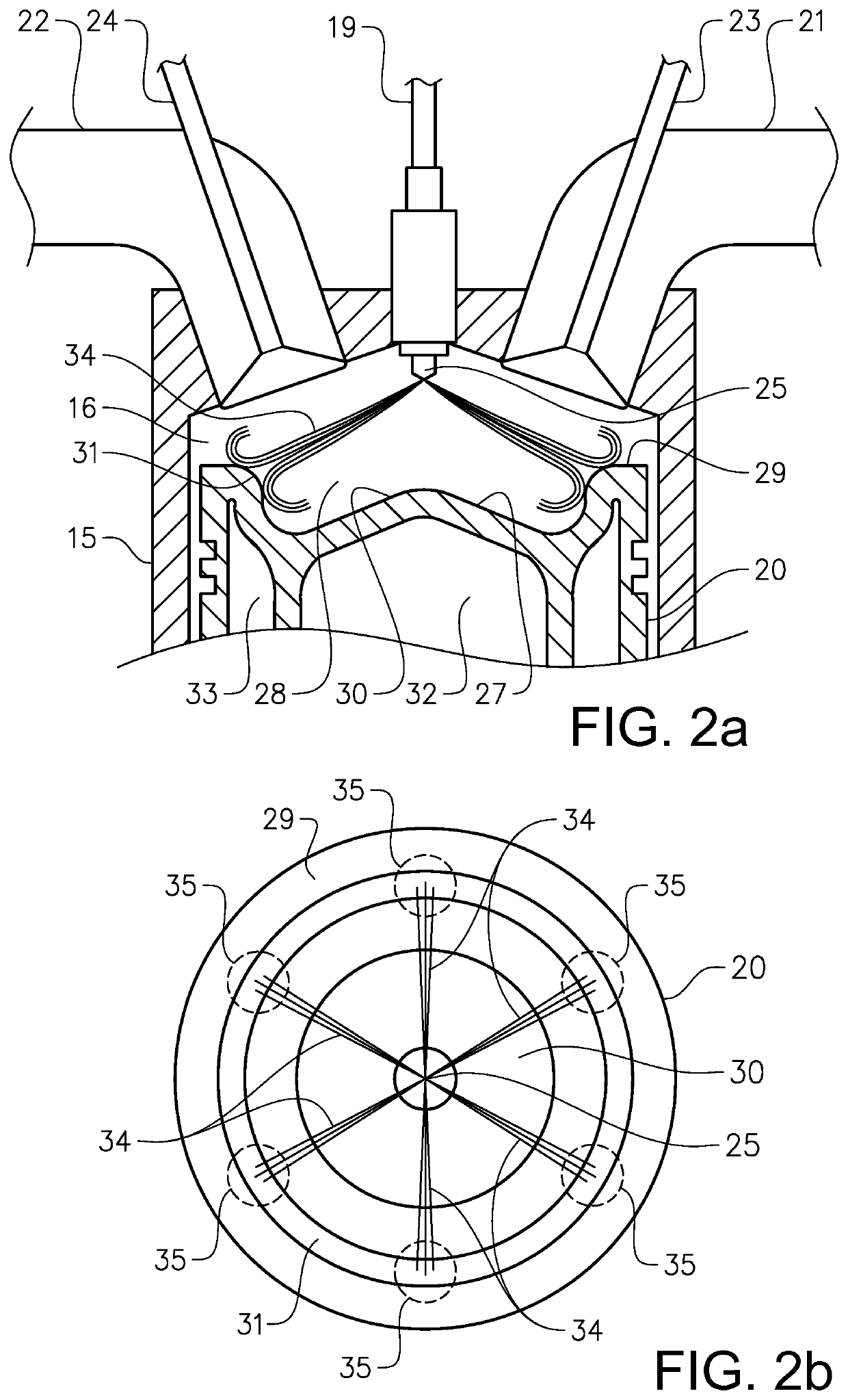

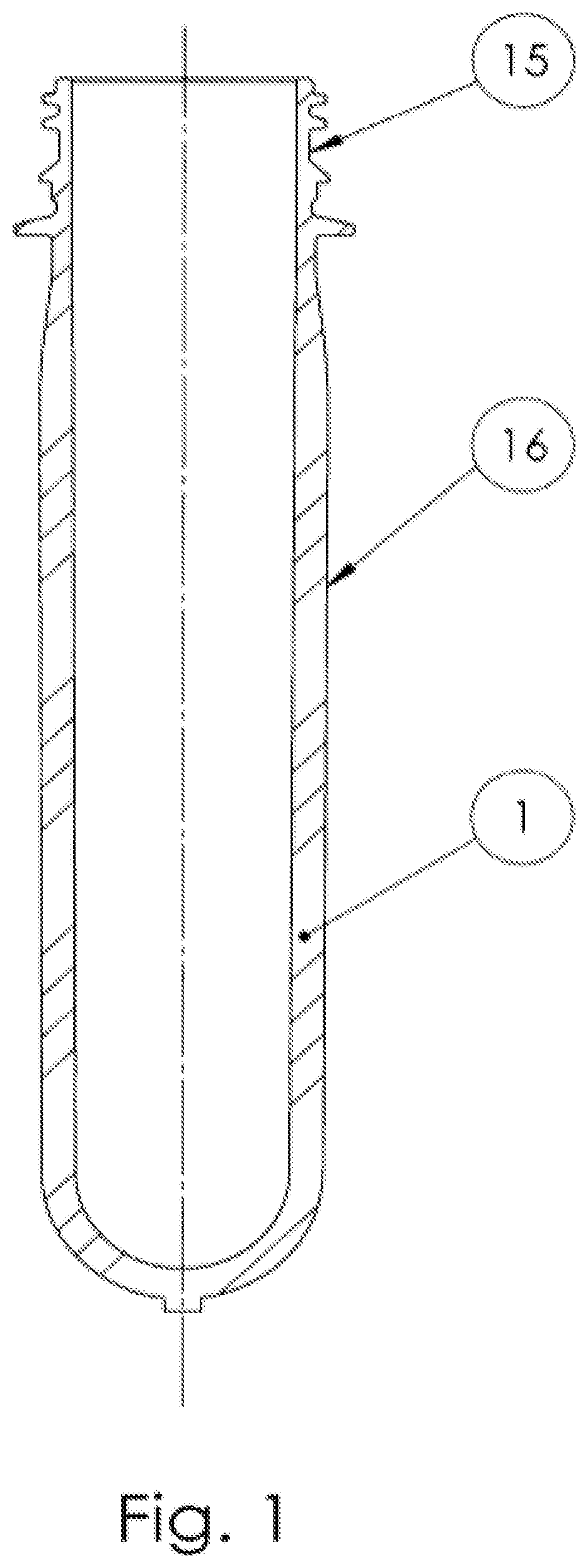

Method and system for the removal of material

InactiveUS20040236392A1More heat energyIncrease humidityLaser surgeryTherapeutic coolingProduct gasEngineering

The invention relates to a method and to a corresponding system for removing material using laser radiation. The aim of the invention is to keep the laser beam cross-section free from contaminations and to ensure constant climatic ambience conditions at the site of removal during the removal process. The inventive method and system is characterized in that the temperature and / or the humidity at the site of removal is maintained substantially constant by means of a gas that is allowed to flow across the site of removal in a predetermined direction. In different embodiments of the invention the gas has constant or varying temperatures, humidities and flow speeds during the removal process. The inventive system for carrying out the method is characterized by a tubular channel (1) through whose end a laser beam (3) is incident on the surface of an object (2) and removes material. A warm air current (7) having a defined humidity is emitted from outlet openings (6) of a flow channel (4) that is linked with a conveyor means via a connecting sleeve (5) and is directed onto the site of removal.

Owner:CARL ZEISS MEDITEC AG

Light emitting module and process thereof

InactiveUS7494250B2More heat energyReduce the temperatureSemiconductor/solid-state device detailsLighting heating/cooling arrangementsEngineeringSoldering

A light emitting module includes a metal substrate, a bearing base, at least one LED, a printed circuit board, and at least one conductive wire. A first perforation is formed on the metal substrate and the bearing base is embedded into the first perforation of the metal substrate. According to an eutectic soldering method, the LED(s) is / are adhered on the bearing base by a compound metal. A second perforation is formed on the printed circuit board to expose the LED(s) which is / are adhered on the bearing base and further allows the printed circuit board to stick on the metal substrate. The conductive wires are used to connect electrically the LED(s) with the printed circuit board.

Owner:CHEN CHIEN CHUNG

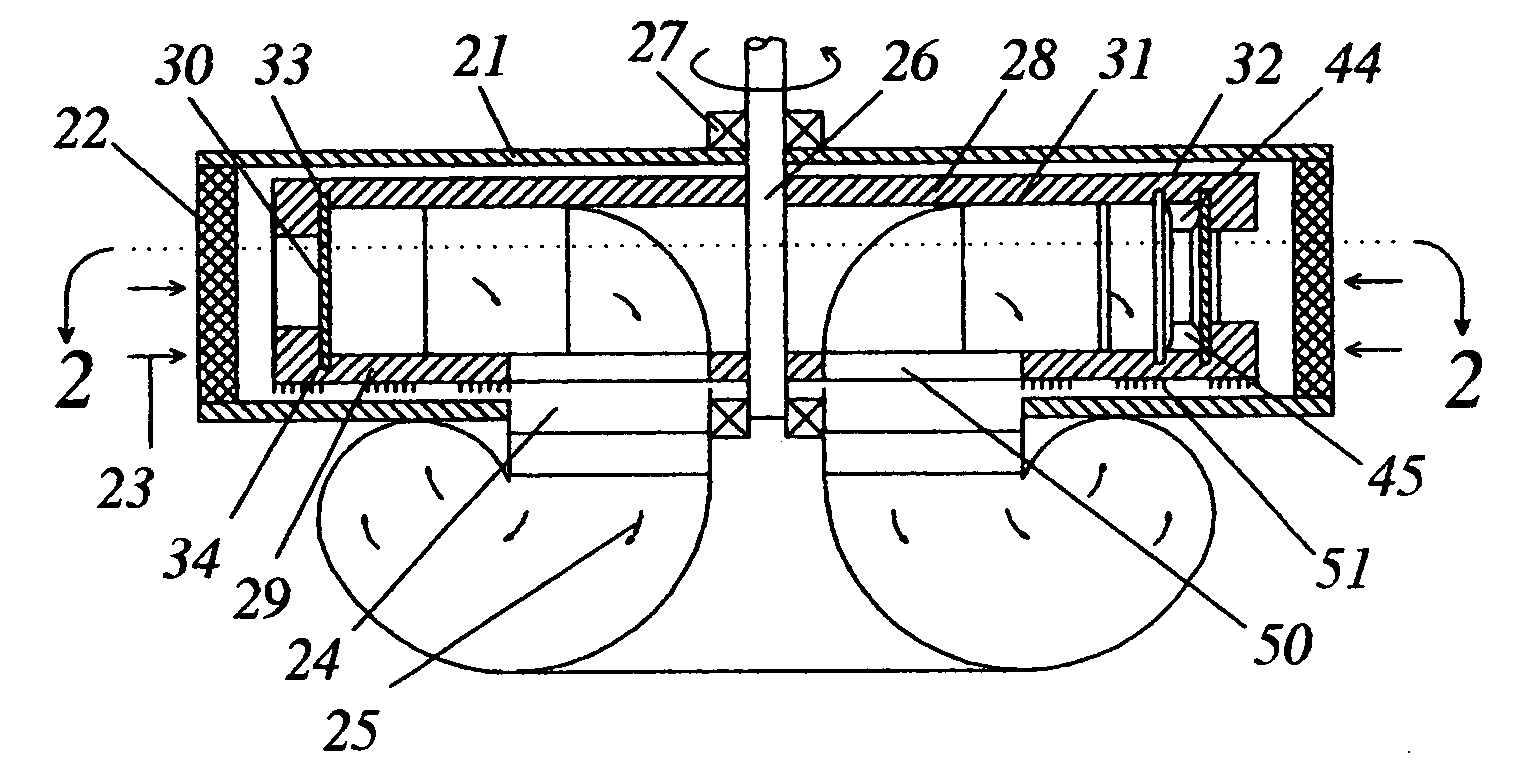

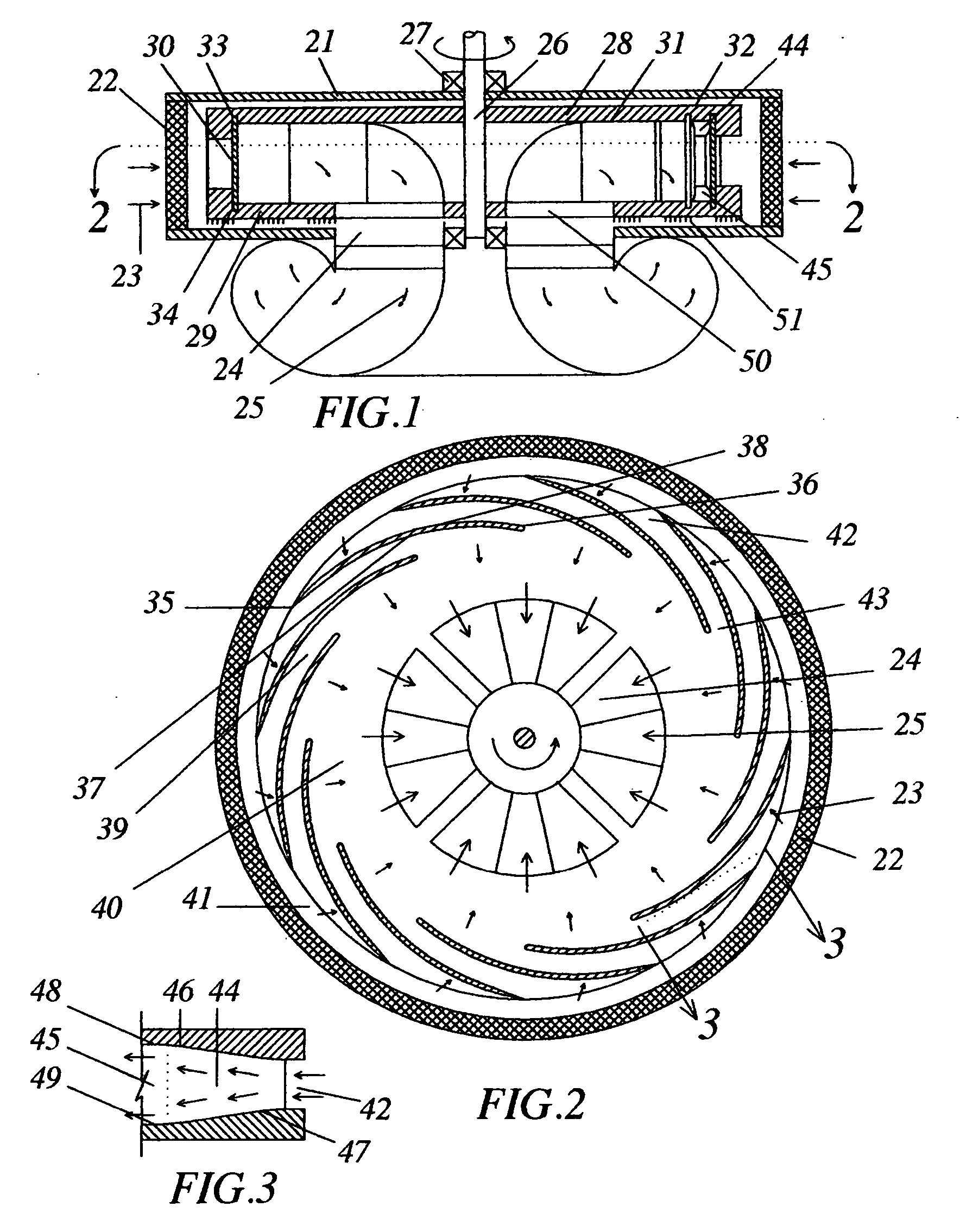

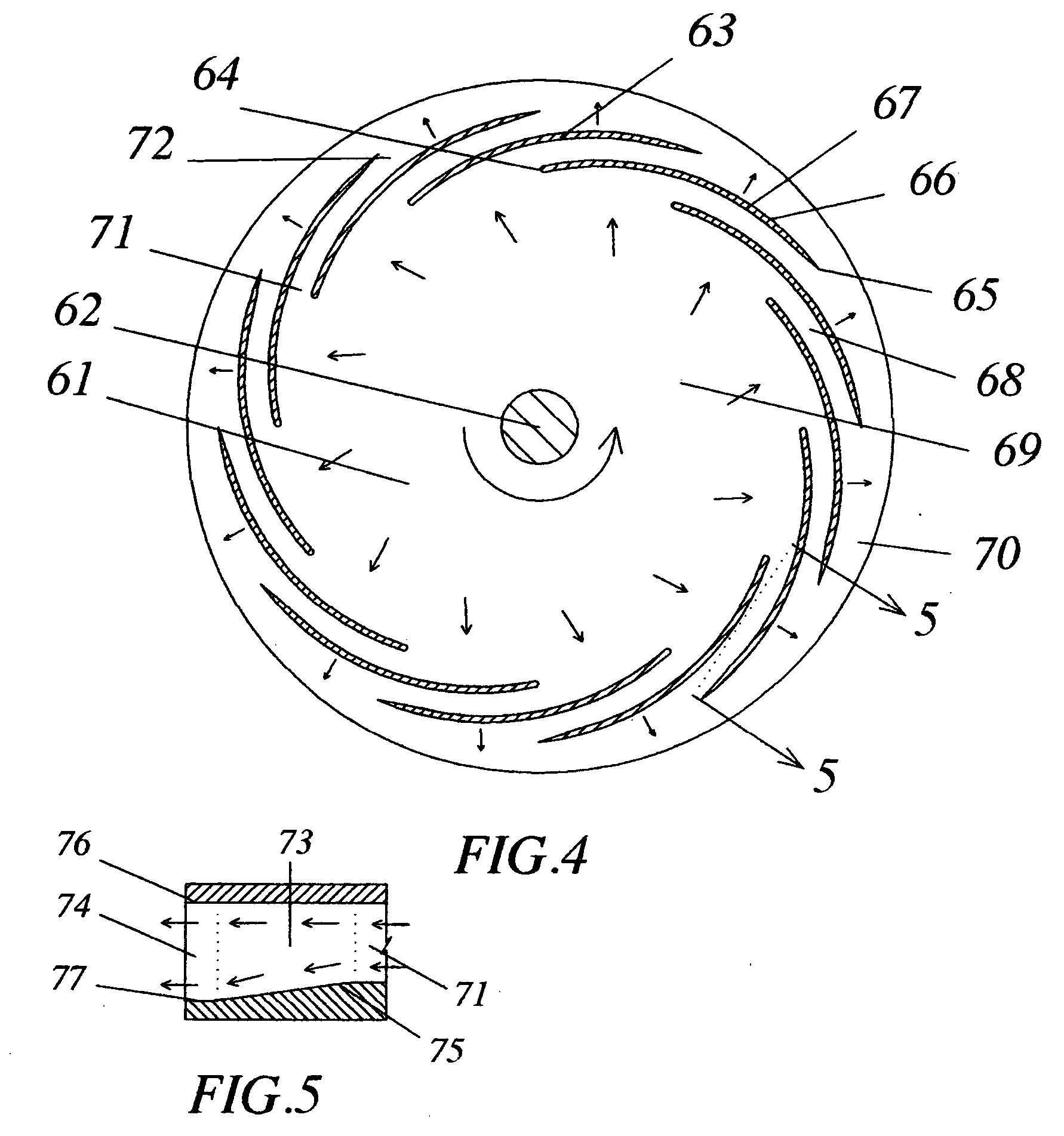

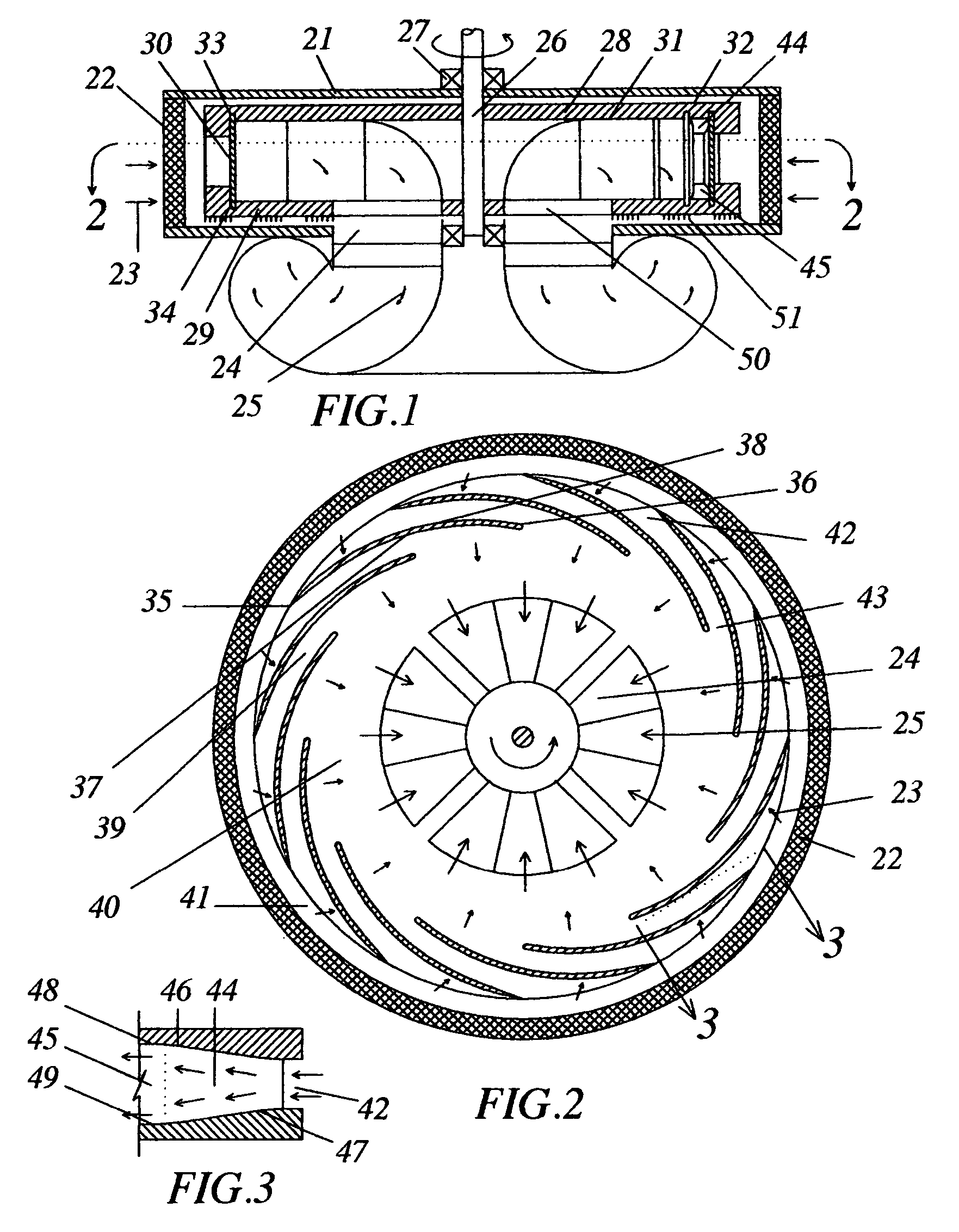

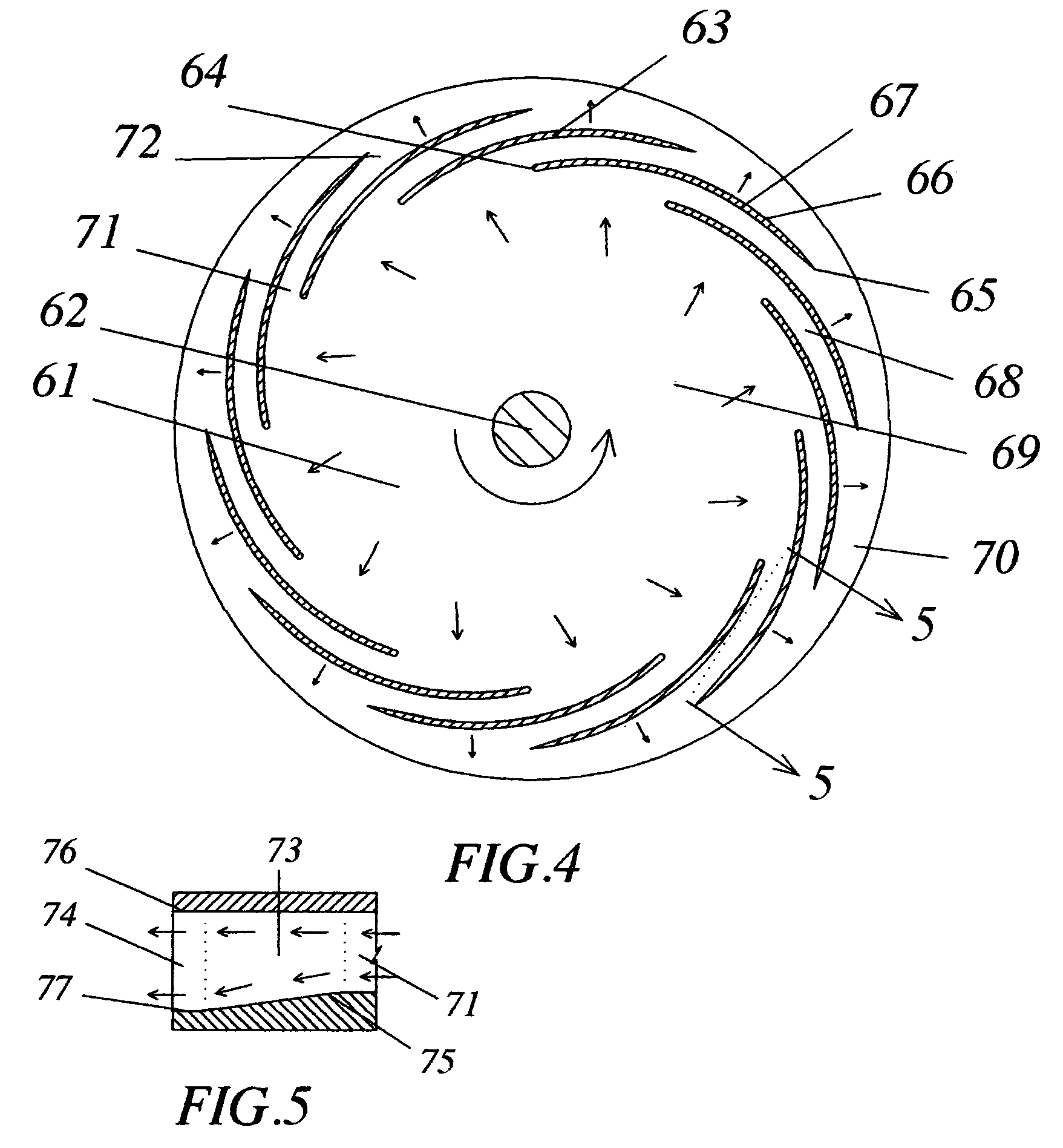

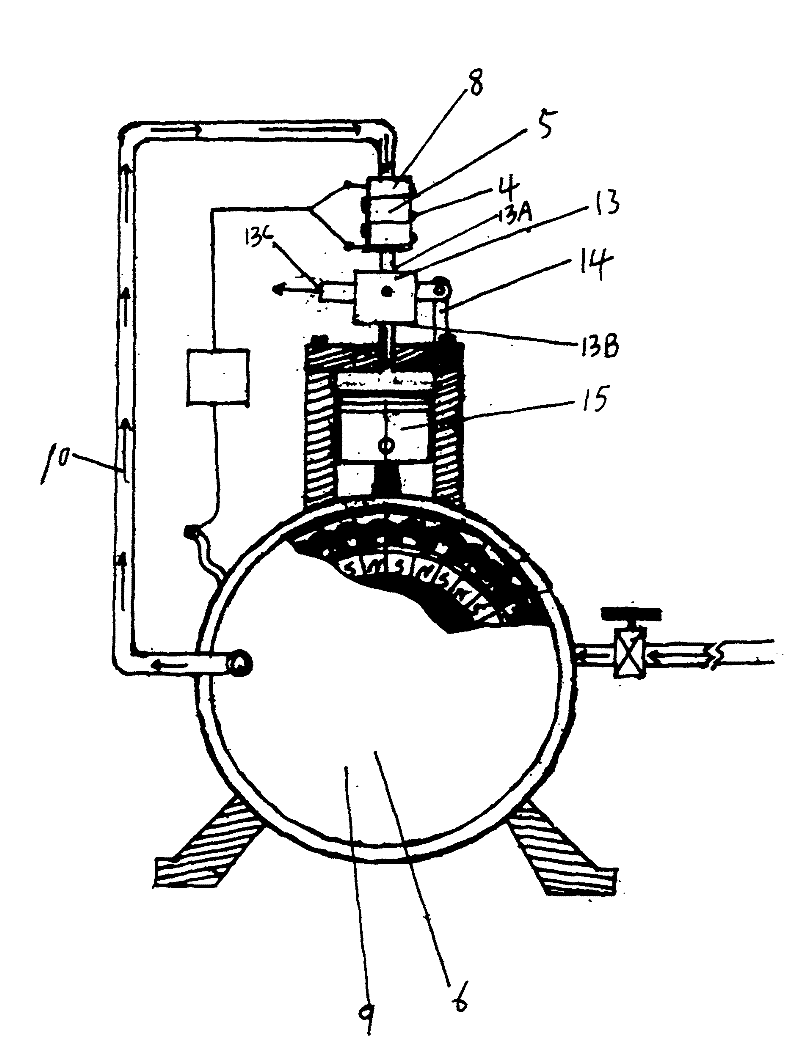

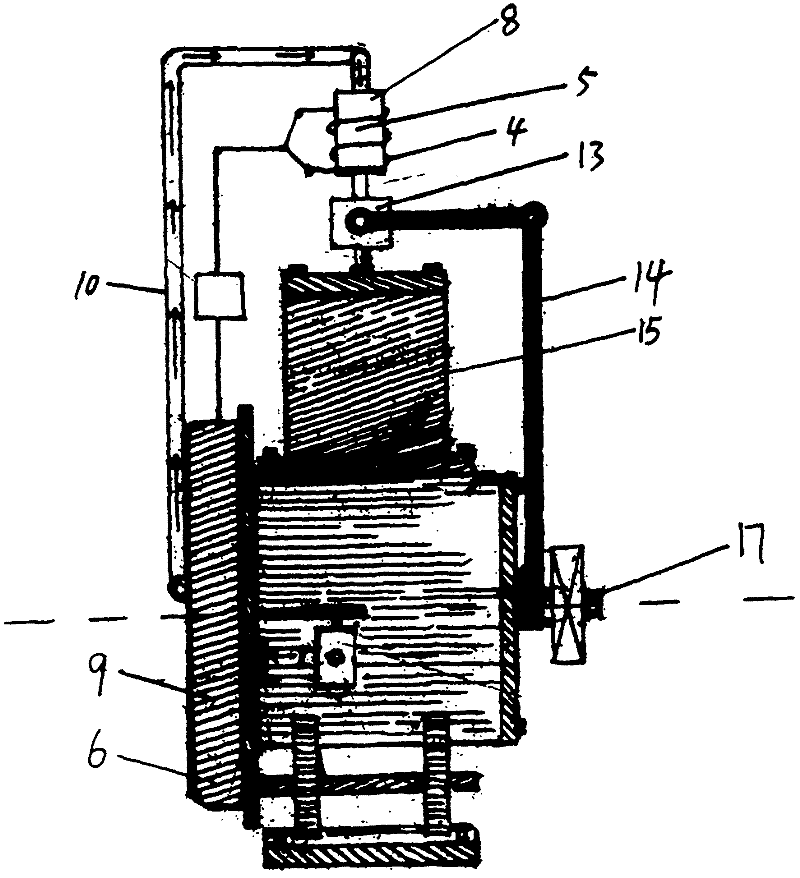

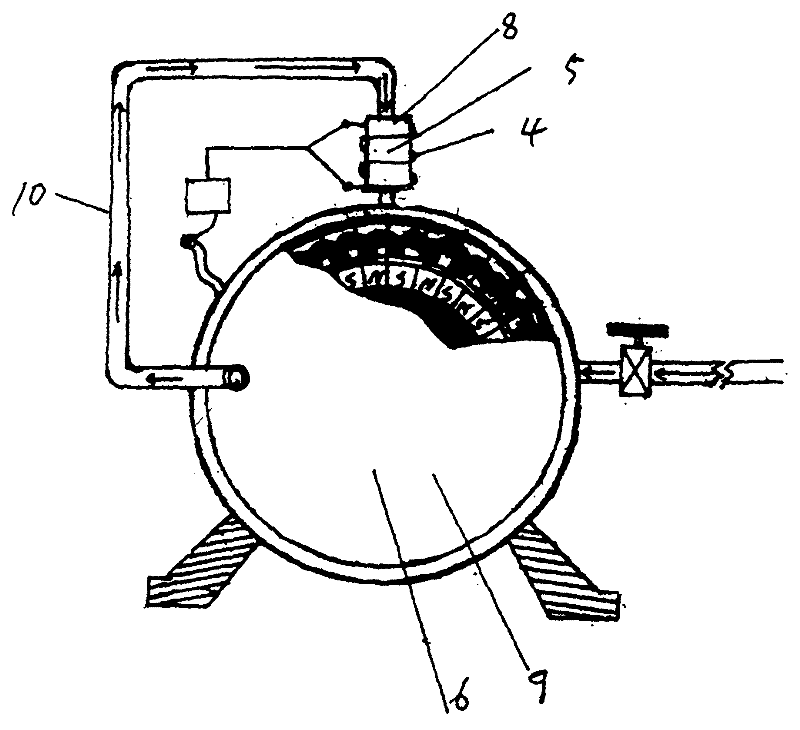

Rotary ram compressor

InactiveUS20060198730A1Decrease riseEasy to operateWind motor controlPump componentsEngineeringTurbine

A rotary ram compressor for use in gas turbine engines and the like, having a plurality of vanes attached to discs, with the opposing parts of each two adjacent vanes and the opposing parts of the disks' surfaces confined between the opposing parts of the surfaces of the two adjacent vanes defining a channel in-between. Each channel is formed of two successive freely communicating portions: a first diverging inlet portion; and a second constant cross-sectional area outlet portion. In operation, gases are rammed into the first diverging inlet portion of the channel and are gradually displaced to the second constant cross-sectional area outlet portion of the channel, while being diverged, resulting into a rise in the static pressure energy of the gases, followed by smoothening of the stream of flow of the pressurized gases within the second constant cross-sectional area outlet portion of the channel.

Owner:RRC SGTE TECH

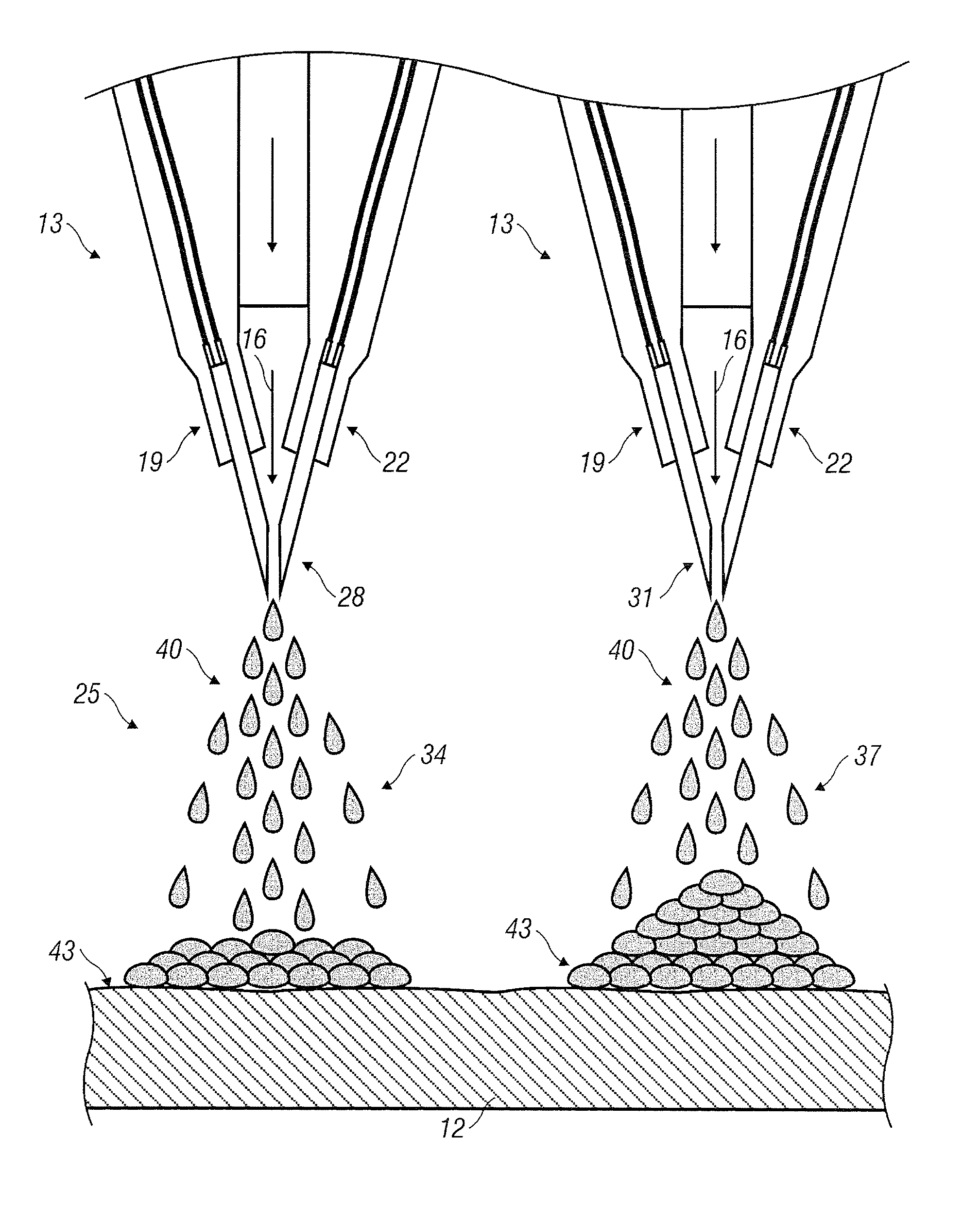

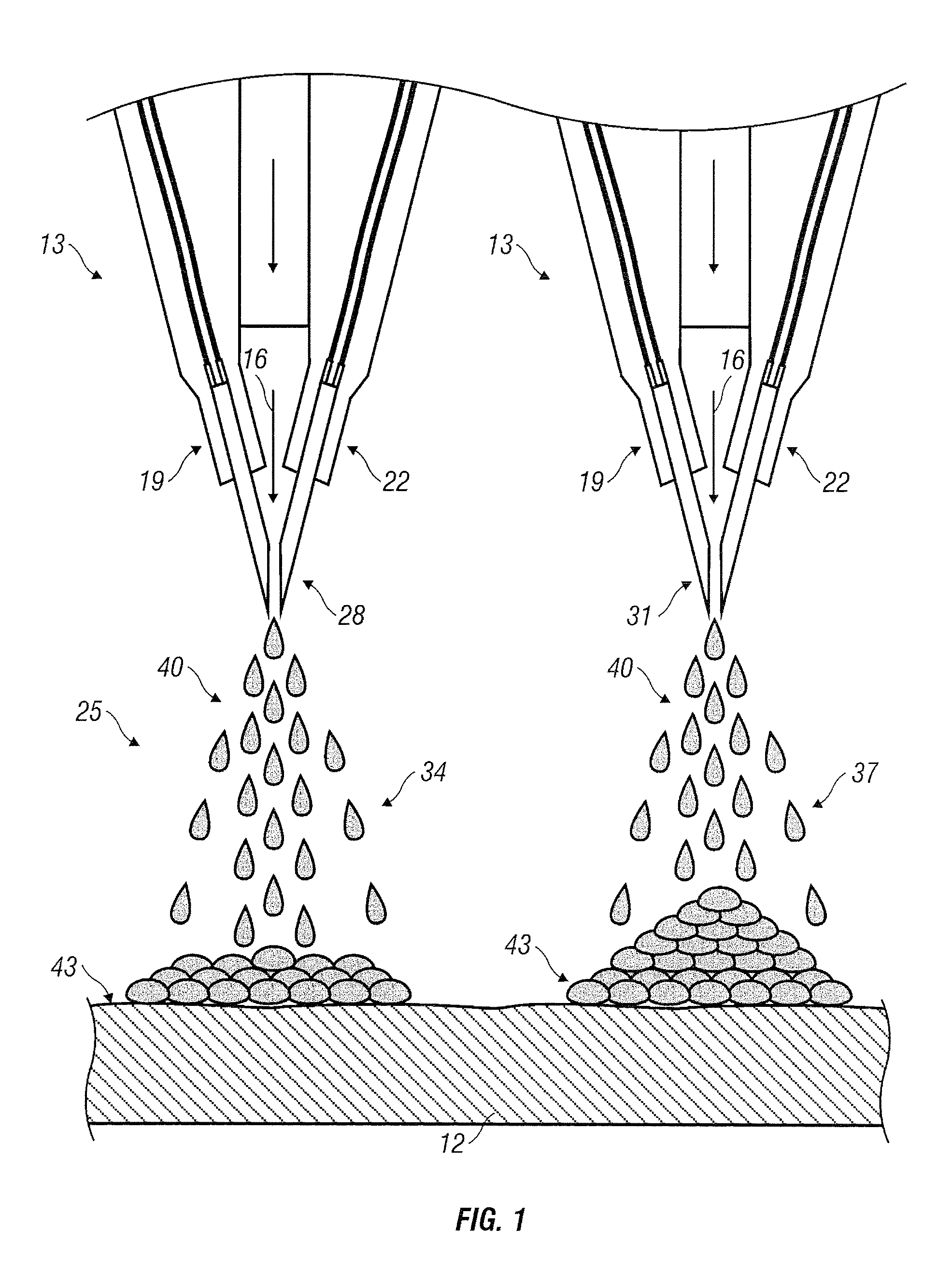

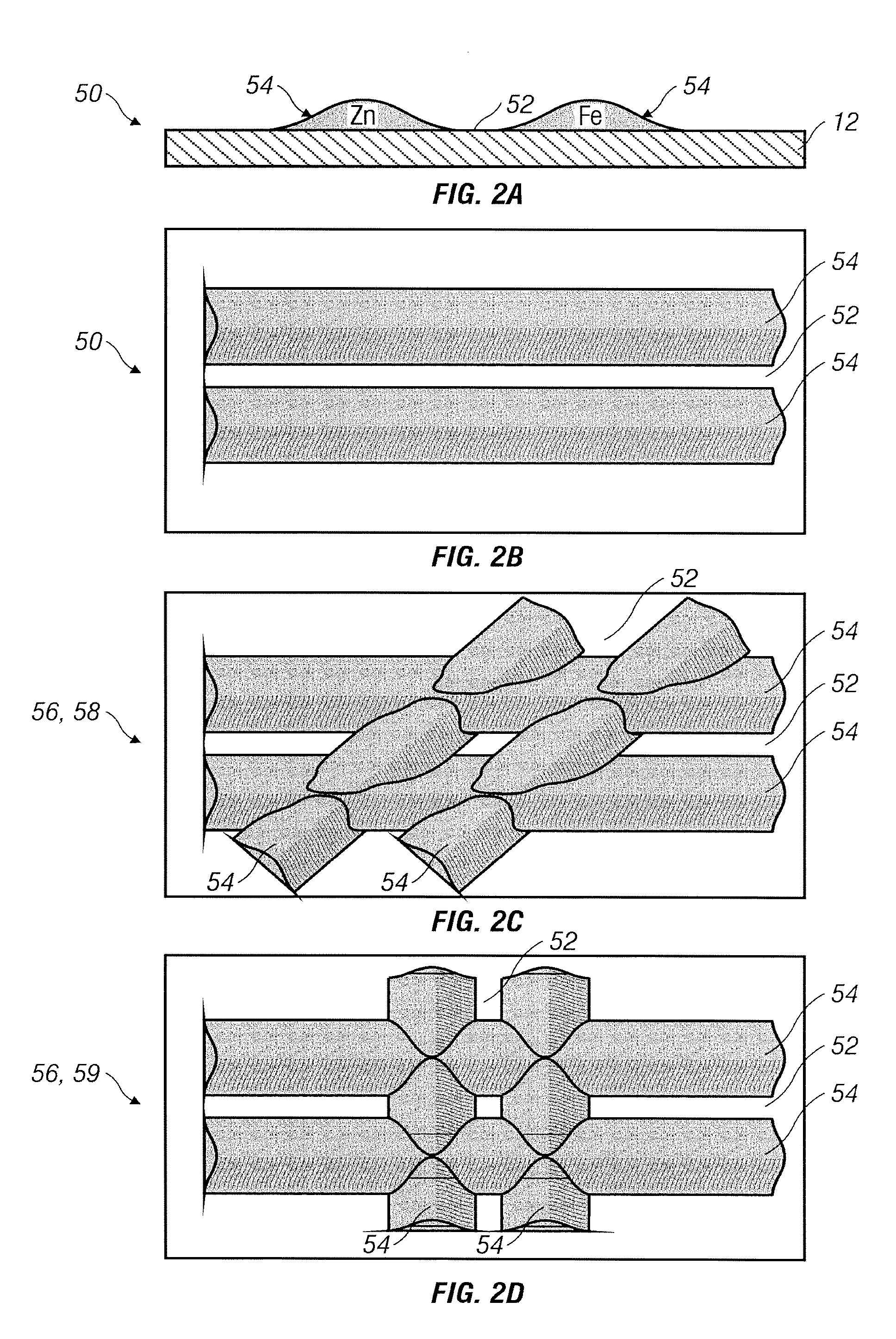

Spray-formed articles made of pseudo-alloy and method for making the same

InactiveUS20050284599A1More heat energyShaping toolsAdditive manufacturing apparatusElement compositionSpray forming

Method and arrangement for spray forming an article. The method includes spraying a plurality of metal streams upon a low-heat resistant model and thereby forming a spray formed article. Each of the plurality of metal streams is composed of moltenized droplets, and as between the plurality of metal streams, each is composed of different constituent elements. In the spray form process, conditions of the metal streams are controlled, particularly around the time that the droplets land, to prevent adverse affects such as melting or burning the master model. The spray conditions are controlled in such a manner that the individual metal droplets forming the metal streams remain substantially segregate. The segregated state is maintained through out solidification so that the resulting spray formed article is composed at least partially of psuedo-alloy.

Owner:FORD GLOBAL TECH LLC

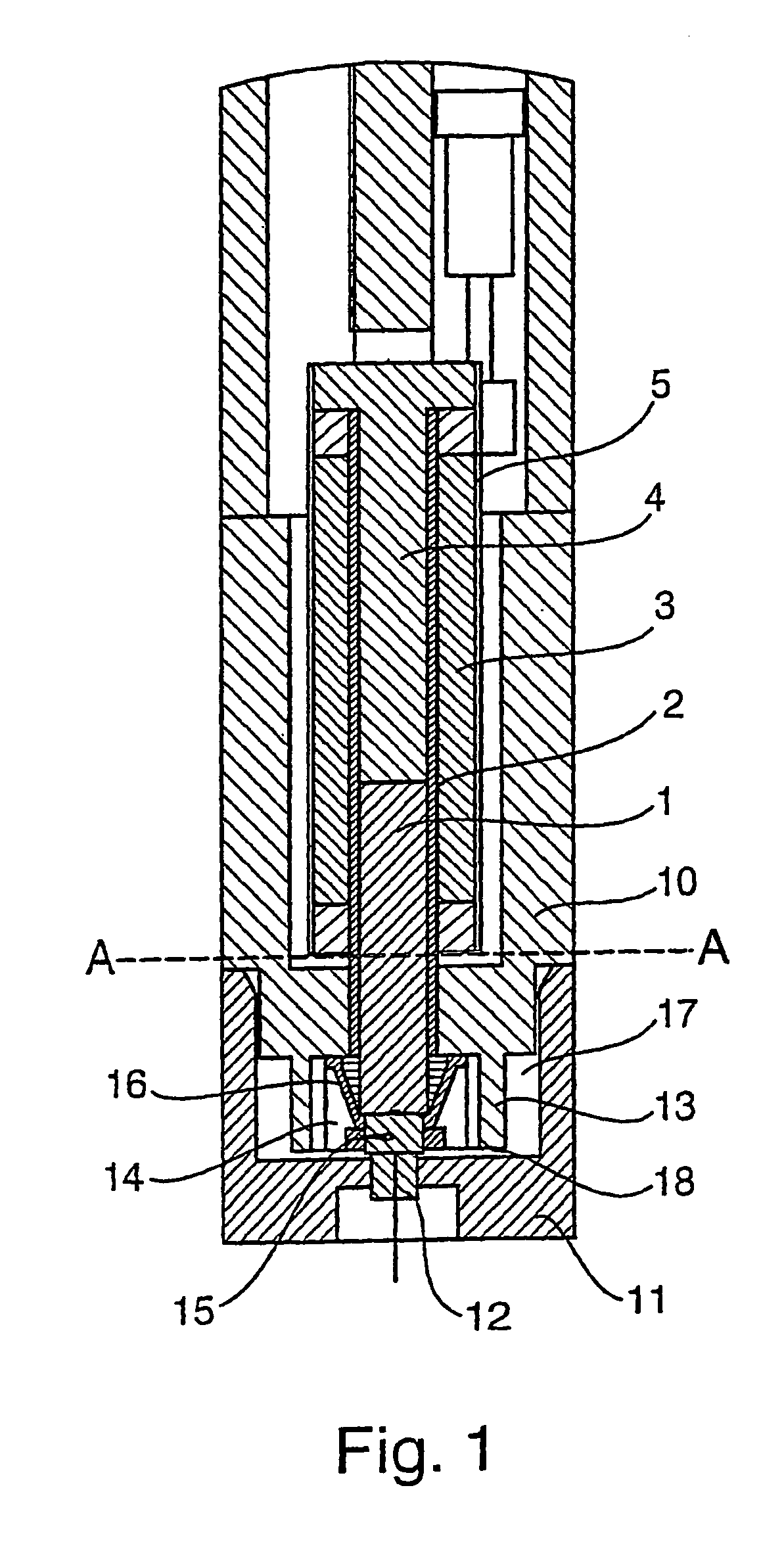

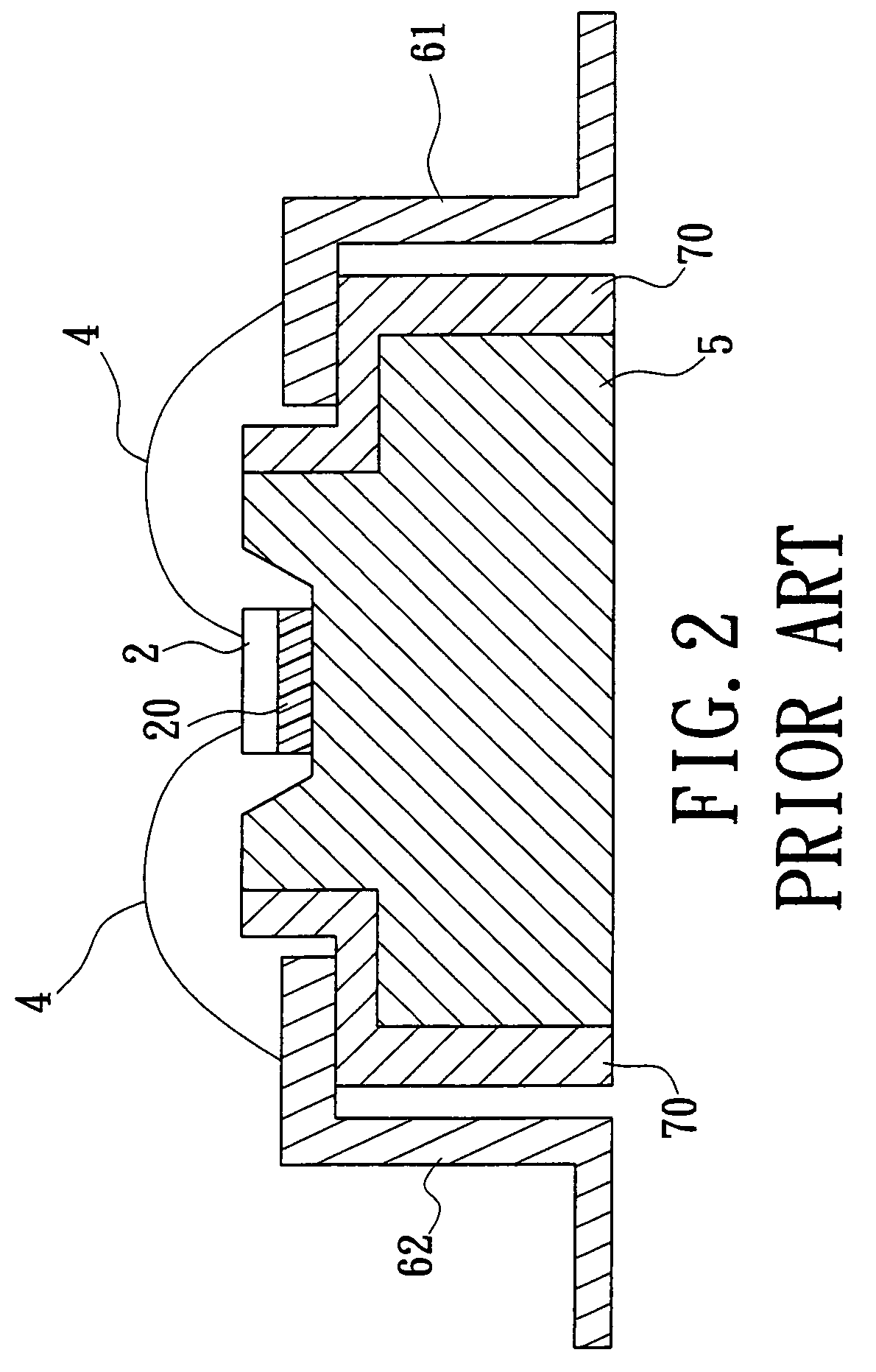

Solenoid valve for a drop on demand ink jet printer

InactiveUS7571986B2Aid rapid rise and fallMore heat energyInking apparatusOperating means/releasing devices for valvesSolenoid valveEngineering

The invention relates to a solenoid valve made using certain materials which is capable of operation at high frequencies and which can be made as a compact unit. The invention also relates to method for operating a drop on demand ink jet printer incorporating such a valve.

Owner:WILLETT INT

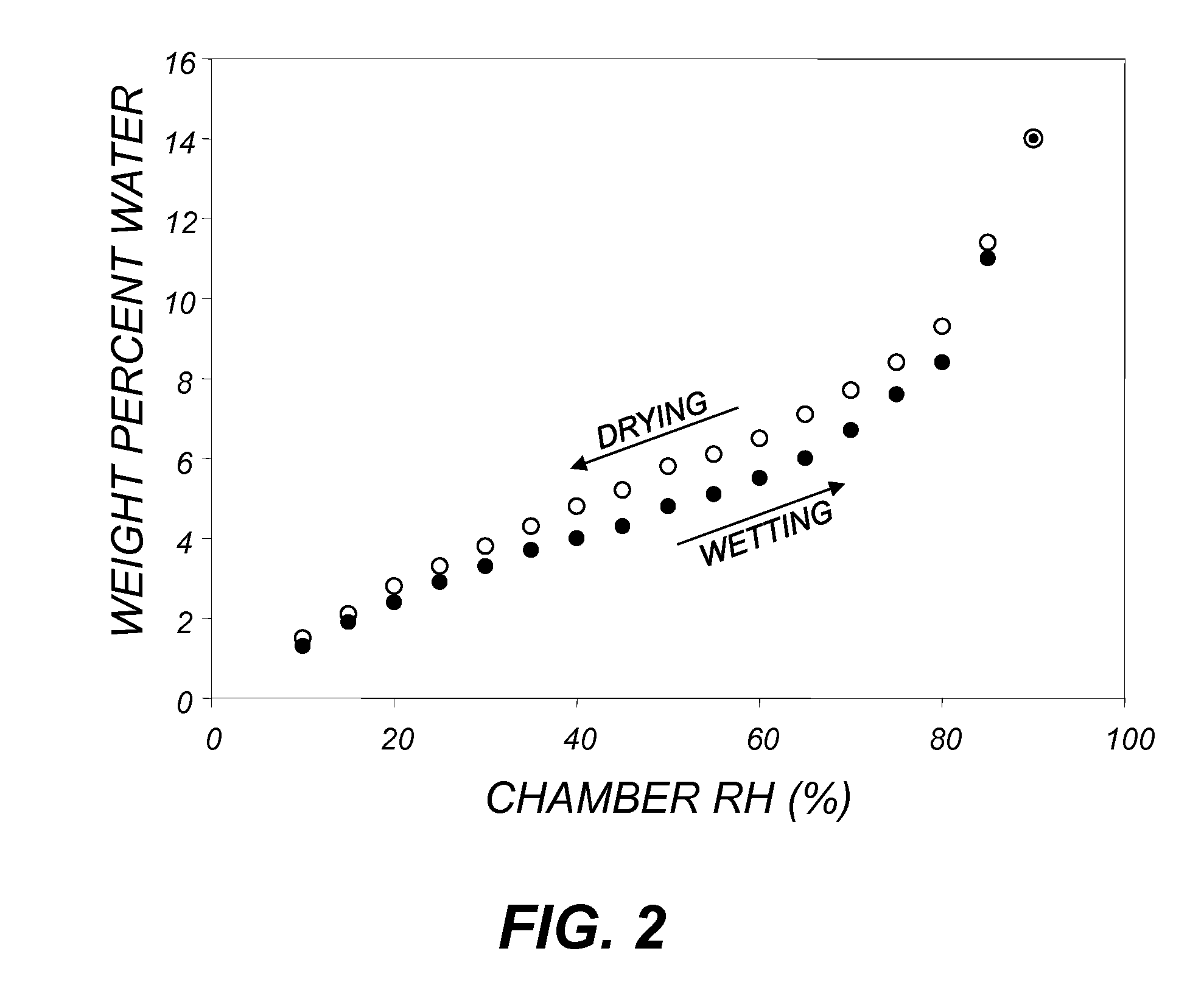

Method for making a puffed food starch product

InactiveUS6929813B2Reduce pressurePromote puffingBakery productsFood shapingFood productsFOOD STARCH

The present invention provides a method of making a puffed food starch material product. A food starch material capable of volumetric expansion in three dimensions is placed into a puffing chamber. Expansion of the food starch material includes constraining expansion of the food starch material in at least a first dimension while permitting unconstrained expansion of the food starch material in a second dimension to produce a unitary, puffed food starch material product with at least one surface having a wavy contour.In a method of making a puffed food starch material product of the present invention, a puffing chamber is provided having inner surfaces and a chamber volume. A bulk amount of the food starch material is placed into the puffing chamber. The bulk amount of food starch material is caused to volumetrically expand. The expanding food starch material is constrained in its expansion in at least a first dimension, while permitting expansion of the bulk amount in at least a second dimension.

Owner:THE QUAKER OATS CO

Rotary ram compressor

InactiveUS7390162B2Decrease riseEasy to operateWind motor controlPump componentsEngineeringProduct gas

A rotary ram compressor for use in gas turbine engines and the like, having a plurality of vanes attached to discs, with the opposing parts of each two adjacent vanes and the opposing parts of the disks' surfaces confined between the opposing parts of the surfaces of the two adjacent vanes defining a channel in-between. Each channel is formed of two successive freely communicating portions: a first diverging inlet portion; and a second constant cross-sectional area outlet portion. In operation, gases are rammed into the first diverging inlet portion of the channel and are gradually displaced to the second constant cross-sectional area outlet portion of the channel, while being diverged, resulting into a rise in the static pressure energy of the gases, followed by smoothening of the stream of flow of the pressurized gases within the second constant cross-sectional area outlet portion of the channel.

Owner:RRC SGTE TECH

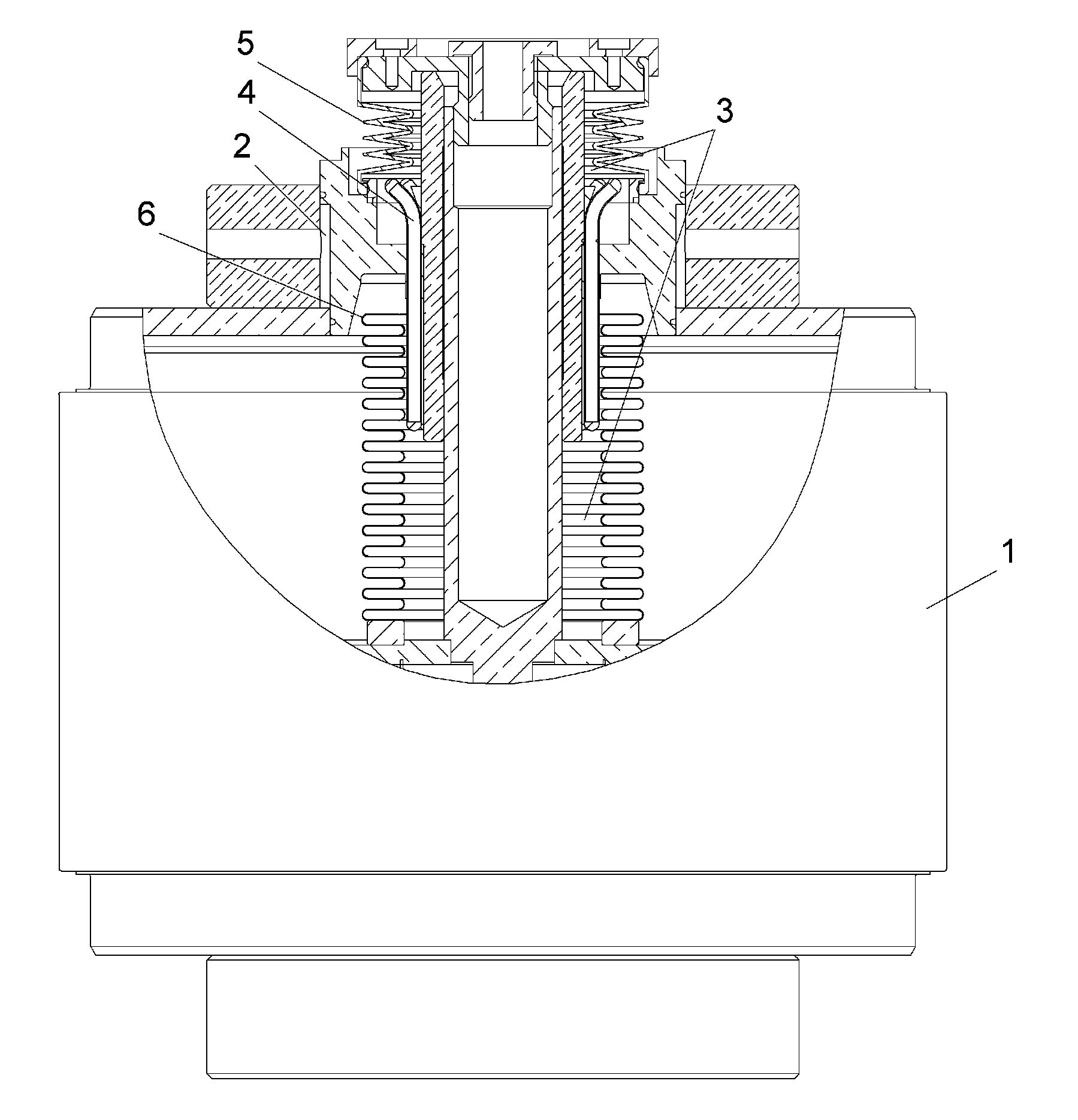

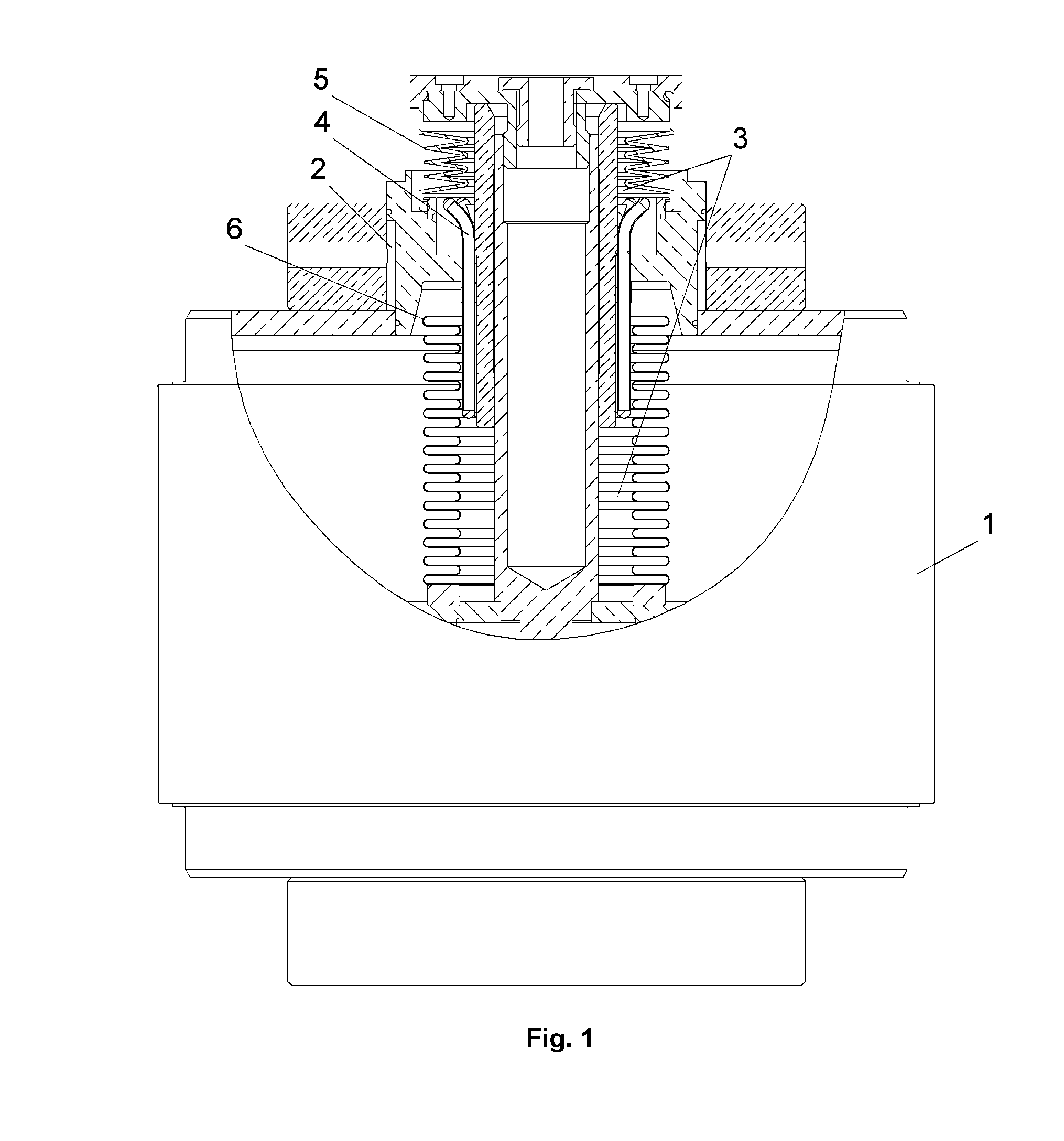

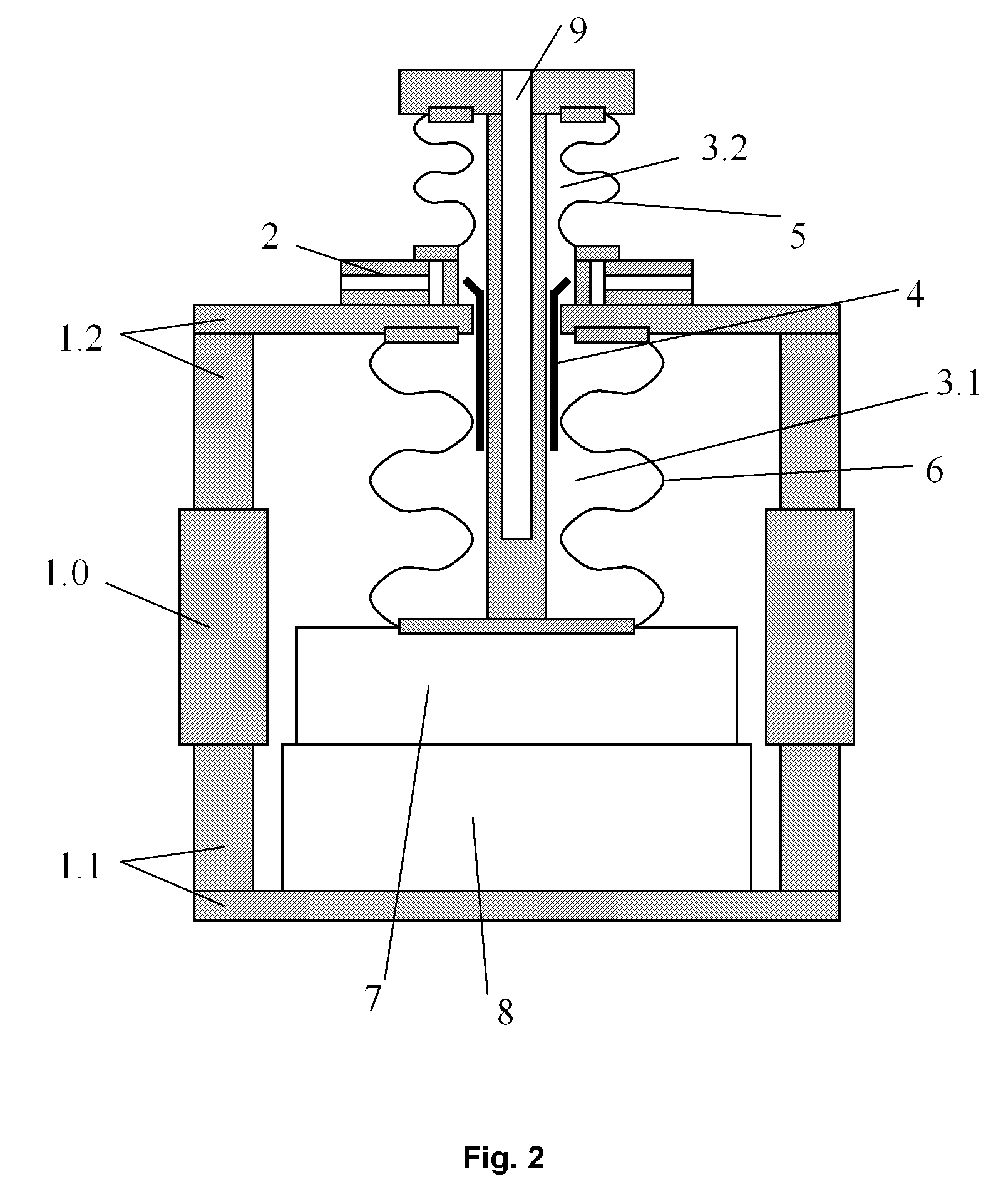

Cooling system for a variable vacuum capacitor

ActiveUS20100193160A1Improve heat absorptionGood energy dissipationMechanically variable capacitor detailsIndirect heat exchangersEngineeringCapacitor

In a cooling system for a variable vacuum capacitor, a liquid is arranged inside a cooling reservoir, a first part of the reservoir is designed to absorb heat energy from first bellows of the variable vacuum capacitor, the first bellows being responsible for transporting electrical energy to a second electrode of the variable vacuum capacitor, a second part of the reservoir is designed to dissipate heat energy towards a cooling circuit, and heat pipes are arranged between the first part of the reservoir and the second part of the reservoir.

Owner:COMET HOLDING

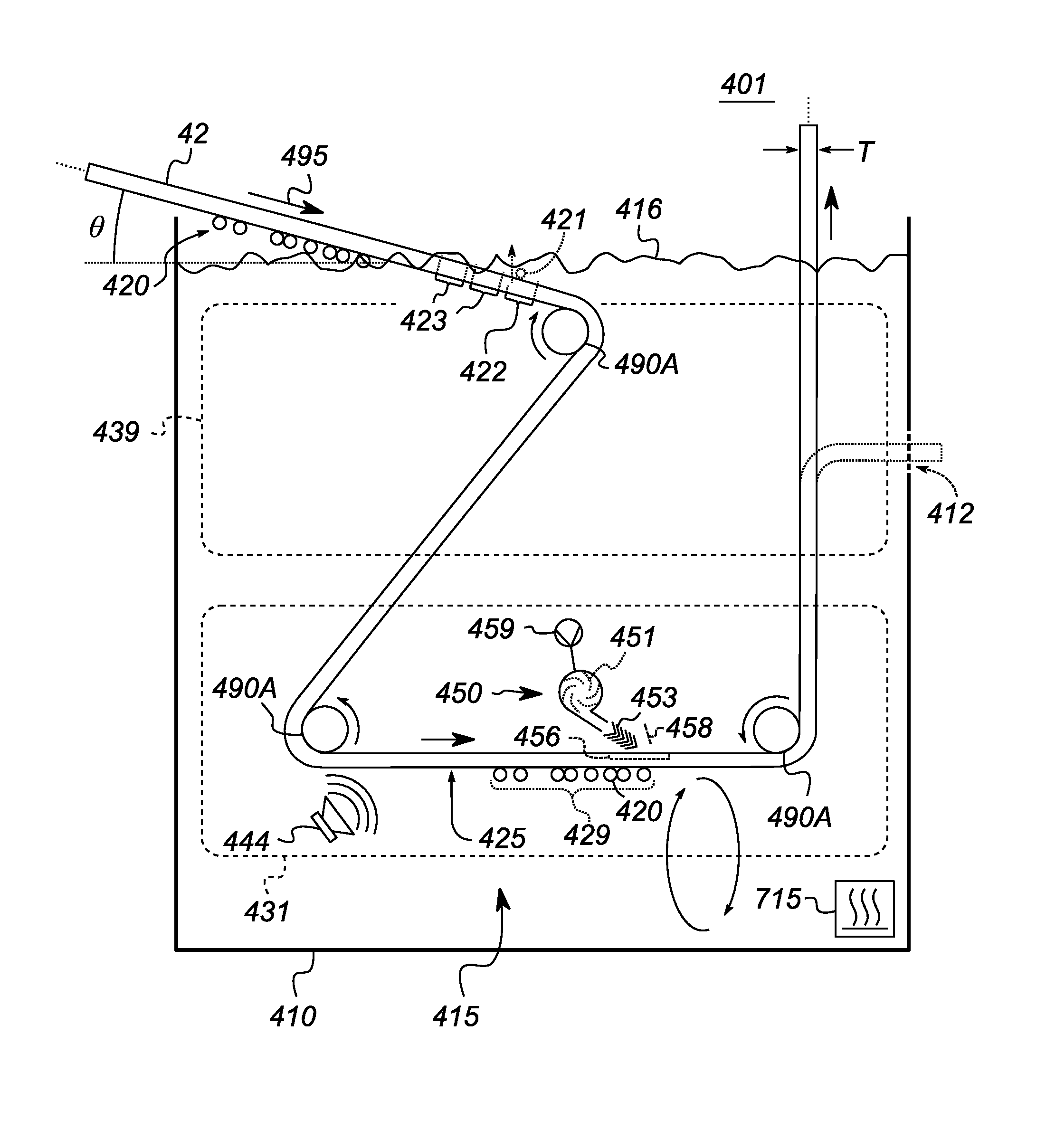

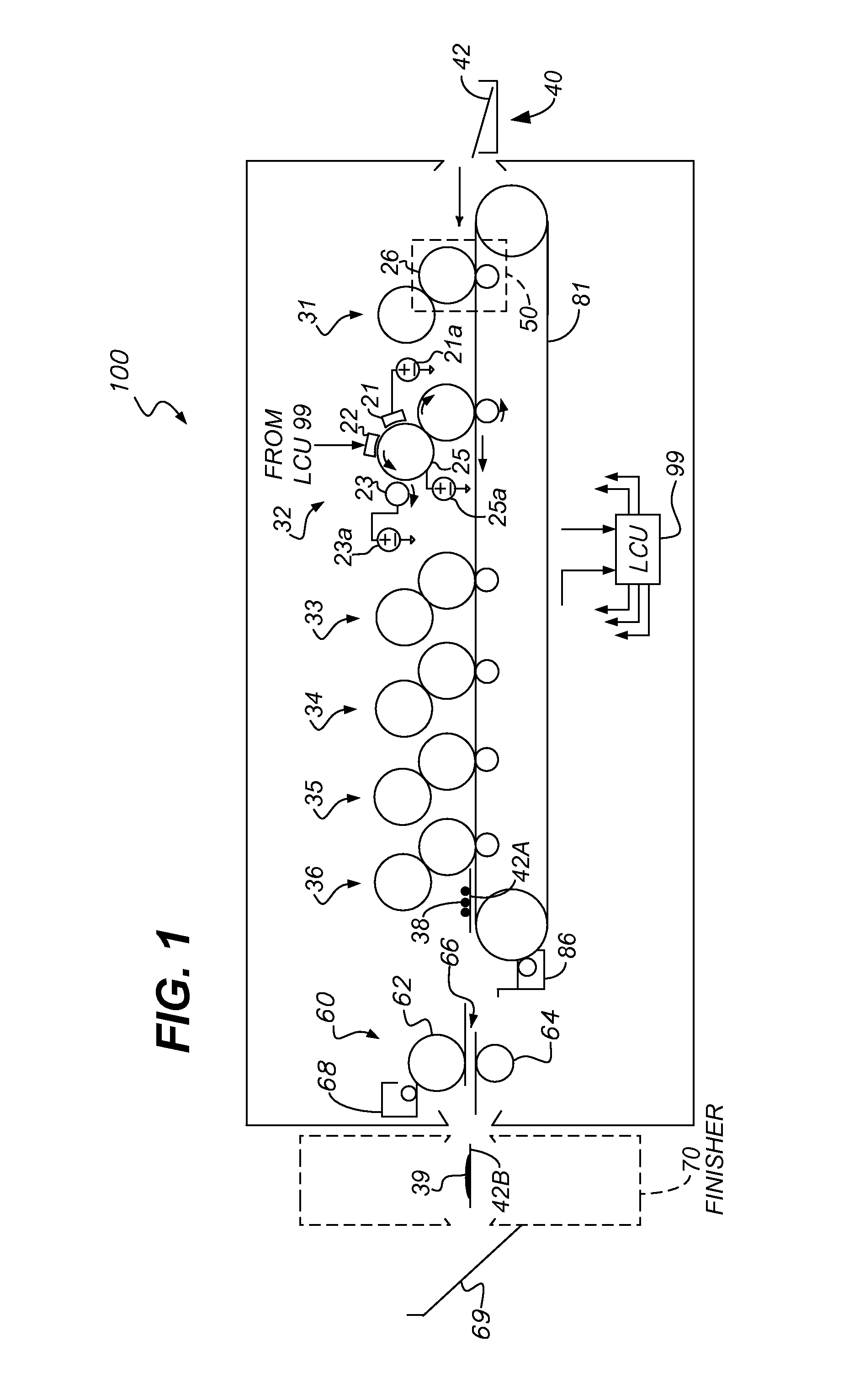

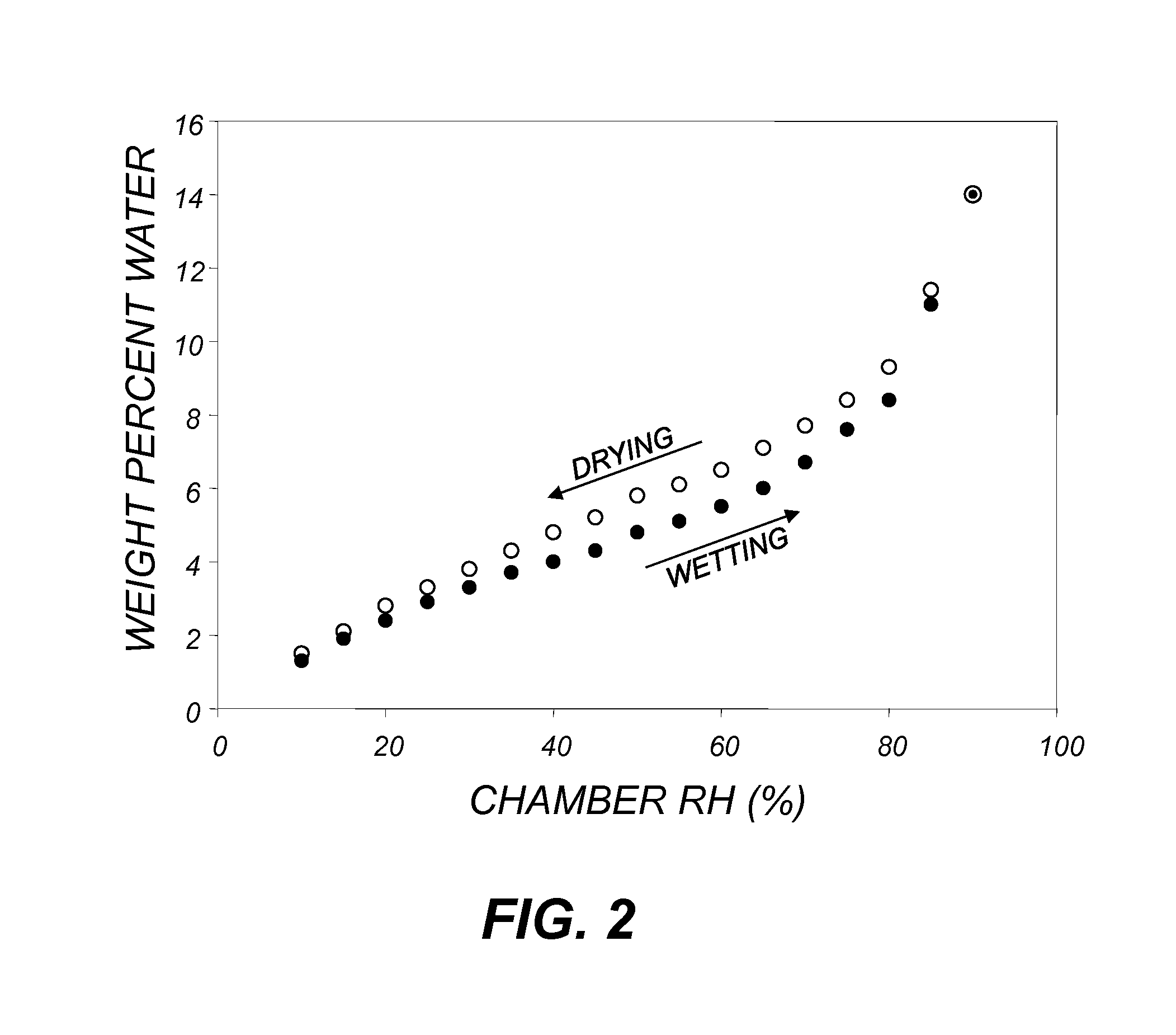

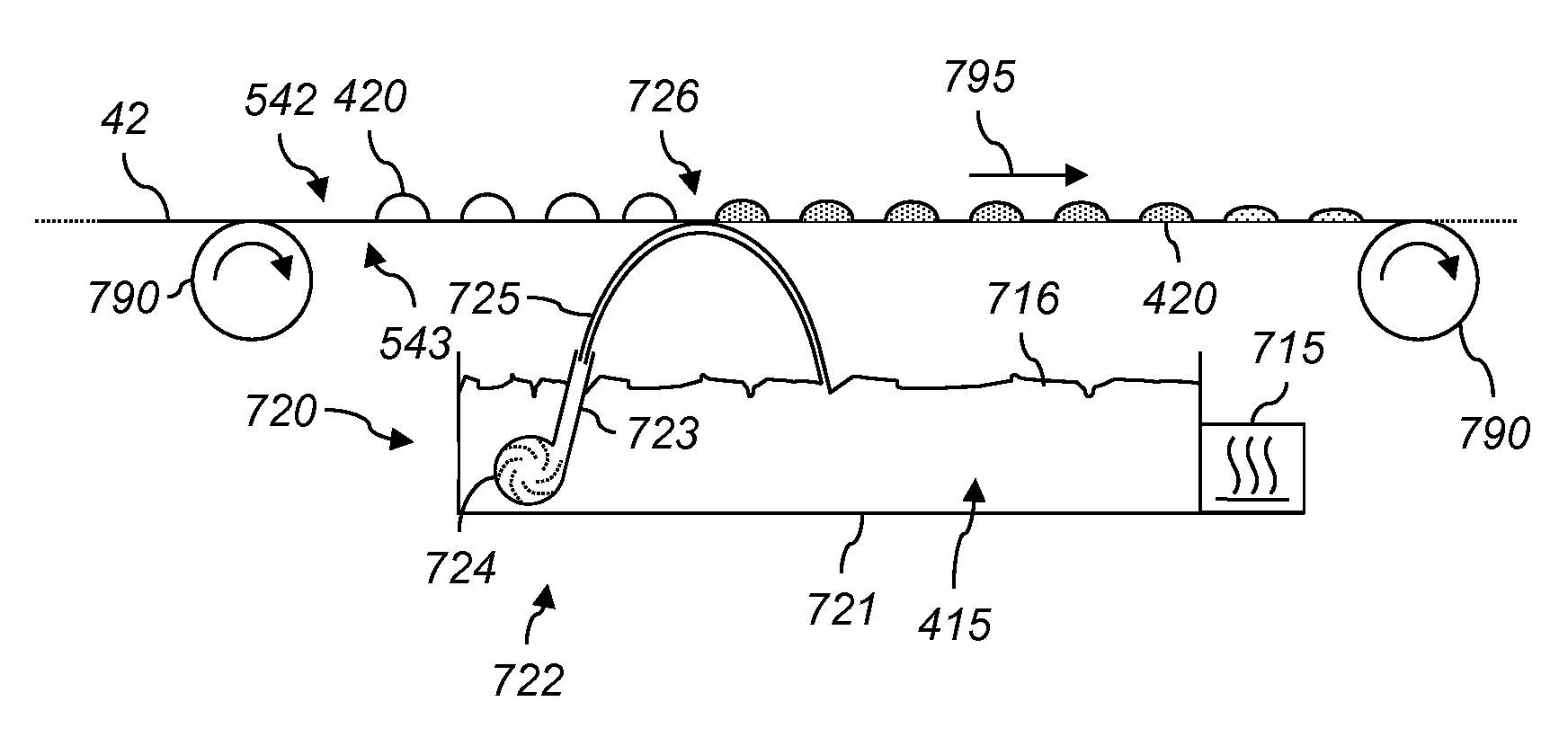

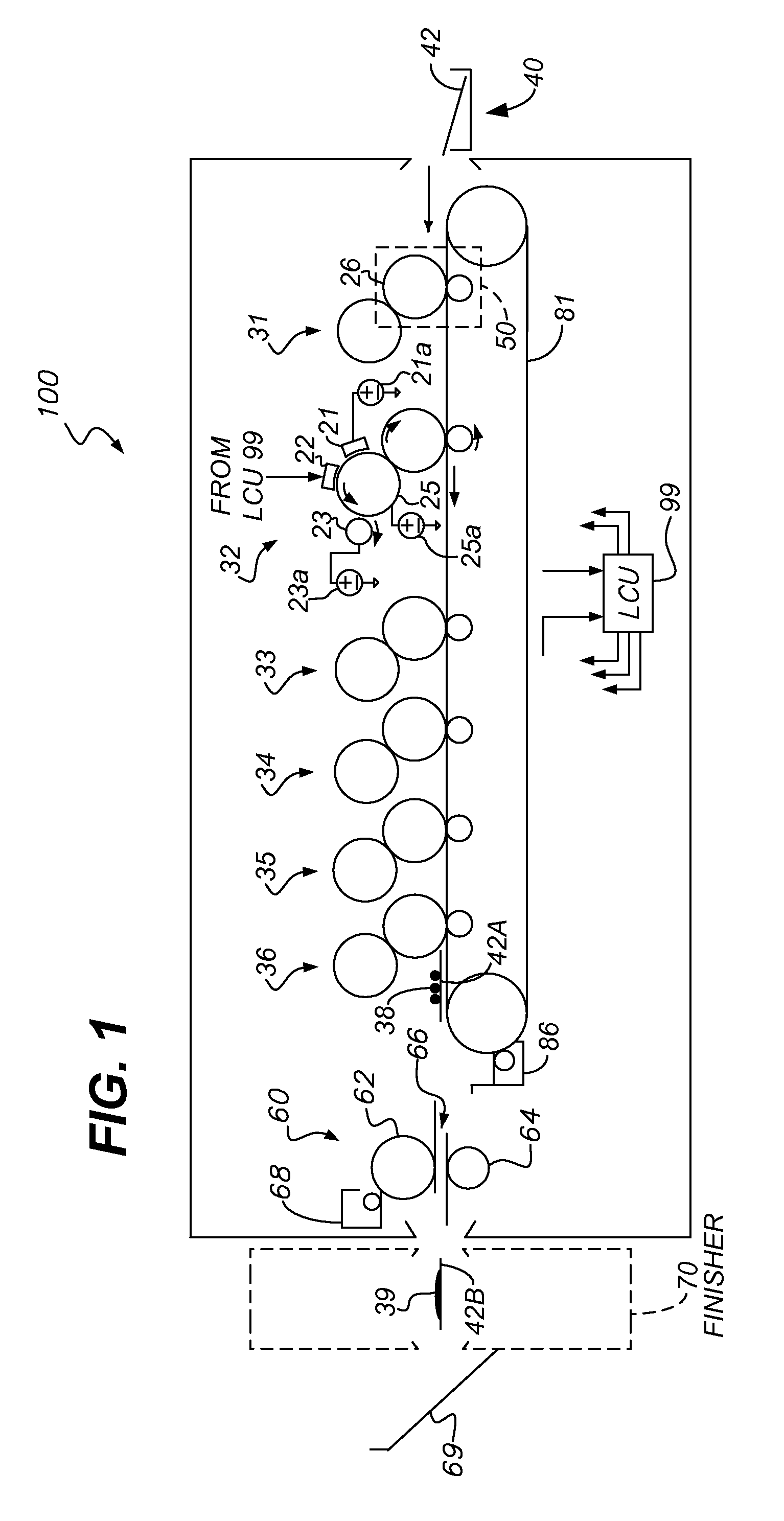

Toner fixer transporting medium through heating liquid

InactiveUS8818252B2Effectively fixedReduce probabilityElectrographic process apparatusVitrificationTransport system

A toner fixing system fixes toner onto a receiver medium. A reservoir contains a heating liquid. A liquid-heating system warms the heating liquid in the reservoir to a temperature greater than a toner glass transition temperature. A media-transport system transports the receiver medium along a transport path which passes through the reservoir. The receiver medium is submerged in the warmed heating liquid, so heat is transferred from the warmed heating liquid to the toner. The temperature of the toner is raised to a level above the toner glass transition temperature.

Owner:EASTMAN KODAK CO

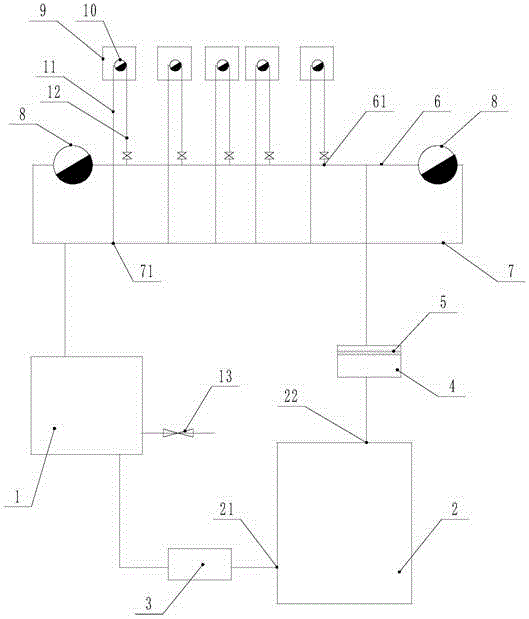

Steam ironing heat energy utilization system and heat energy utilization method thereof

InactiveCN104790193AReduce lossIncrease profitHand ironTextiles and paperElectricityWater storage tank

The invention discloses a steam ironing heat energy utilization system which comprises an electric heating boiler, a main steam pipe, a main liquid return pipe and a plurality of ironing devices. The main steam pipe is connected with a steam outlet and provided with a plurality of steam division ports, and each steam division port is connected with a steam supply pipe. The main liquid return pipe is provided with a plurality of liquid return ports, each liquid return port is connected with a water return pipe, each water return pipe and the corresponding steam supply pipe are connected with a water return port and a steam inlet of one ironing device respectively, and the main steam pipe is connected with the main liquid return pipe through an outer drain valve. The main liquid return pipe is communicated with a water storage tank, and the water storage tank is connected with a water injection port of the electric heating boiler. Through the heat energy utilization system, the utilization rate of heat energy is greatly increased, electricity consumption is reduced, energy is saved, and the operating environment for workers is improved.

Owner:ZHANGJIAGANG GELAIMEI CLOTHING

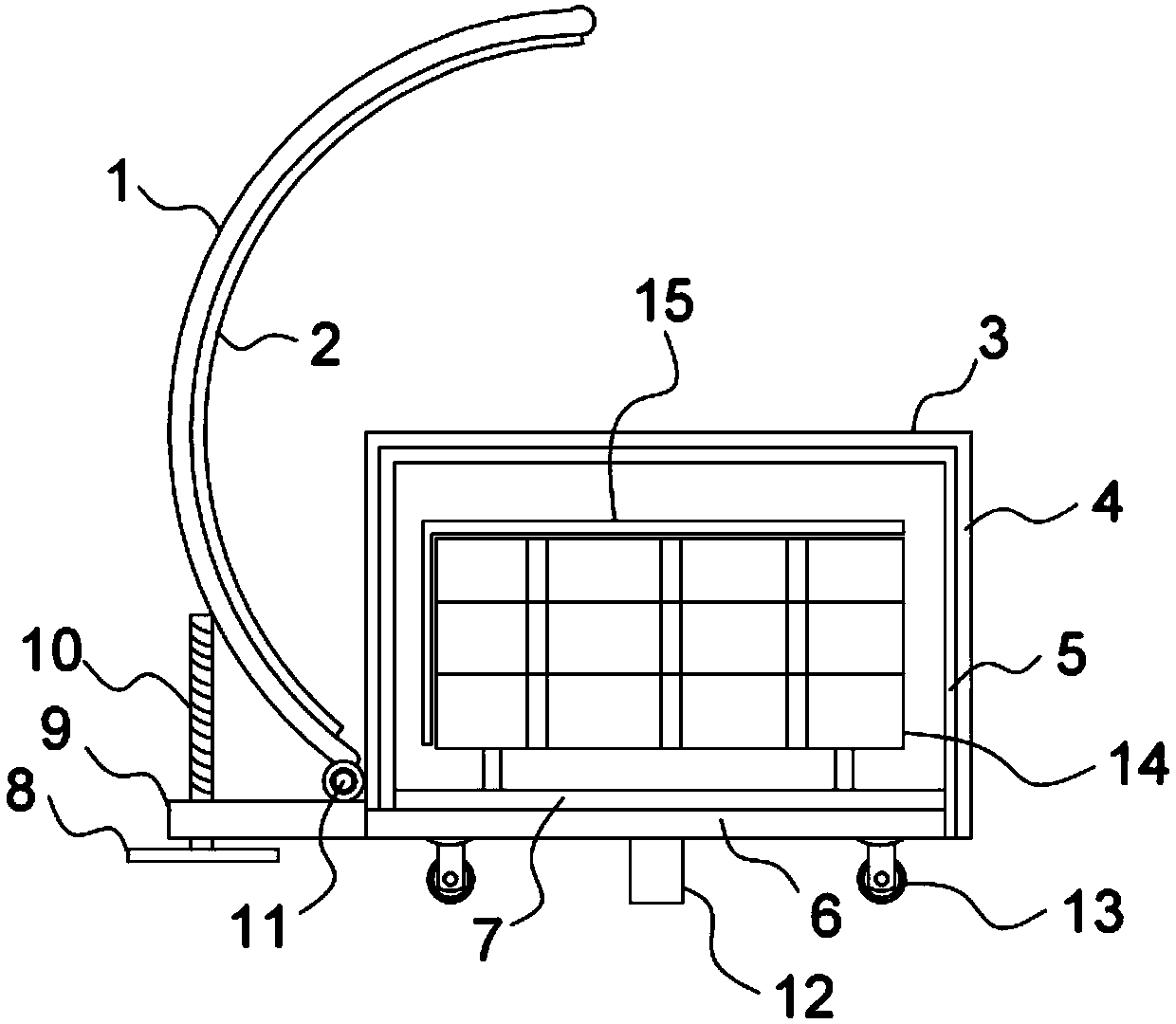

Wood drying device utilizing photo-thermal energy

InactiveCN107763968AReceive moreMuch lightDrying solid materials with heatDrying chambers/containersThermal energyVehicle frame

The invention discloses a wood drying device utilizing photo-thermal energy. The wood drying device comprises a transparent glass room, an arc-shaped supporting frame, a threaded rod and a wood frame;the transparent glass room is fixedly arranged on a vehicle frame; an arc-shaped mirror surface is fixedly connected to one side of the arc-shaped supporting frame; the top of the wood frame is fixedly connected with a sun shield; and the side surface of the transparent glass room is provided with a transparent glass door. According to the wood drying device, the arc-shaped mirror surface structure and the threaded rod adjusting structure are arranged so that the light can be better adjusted, and more light and heat energy can be received by the transparent glass room; through the arrangementof a vacuum layer and a greenhouse gas layer, and after the short wave of solar radiation is converted into heat energy, the long wave of the heat energy can be prevented from radiating outwards, sothat the heat can be well stored, and drying can be facilitated; the sun shield is arranged so that the wood can be prevented from directly receiving the light, and the light energy can be fully absorbed to transformed into heat; and the device is simple in structure, easy to realize, capable of fully utilizing the solar energy for achieving the drying function, is environment-friendly and energy-saving, and is worthy of popularization and use.

Owner:WUXI ZHIGURUITUO TECH SERVICE CO LTD

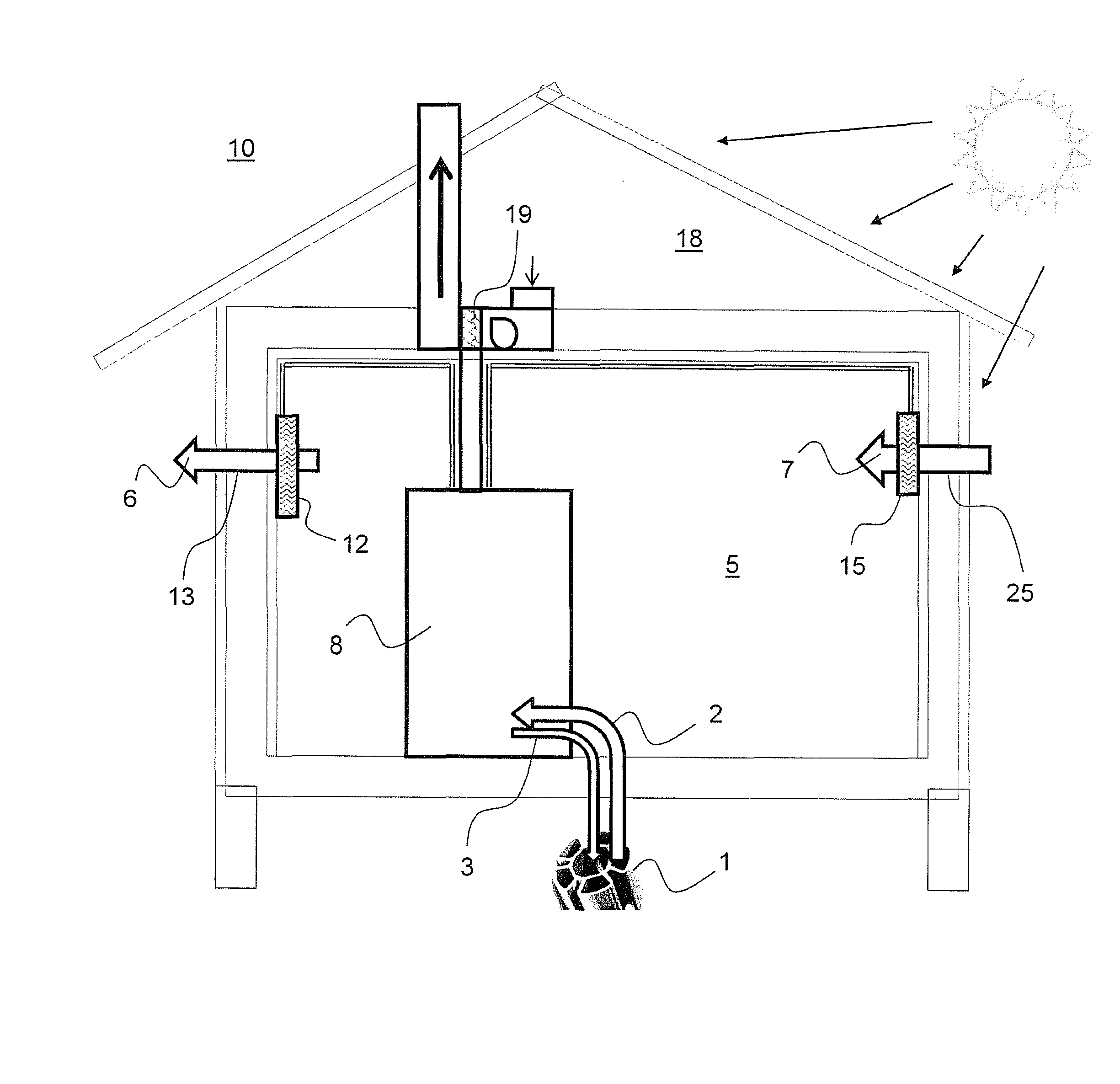

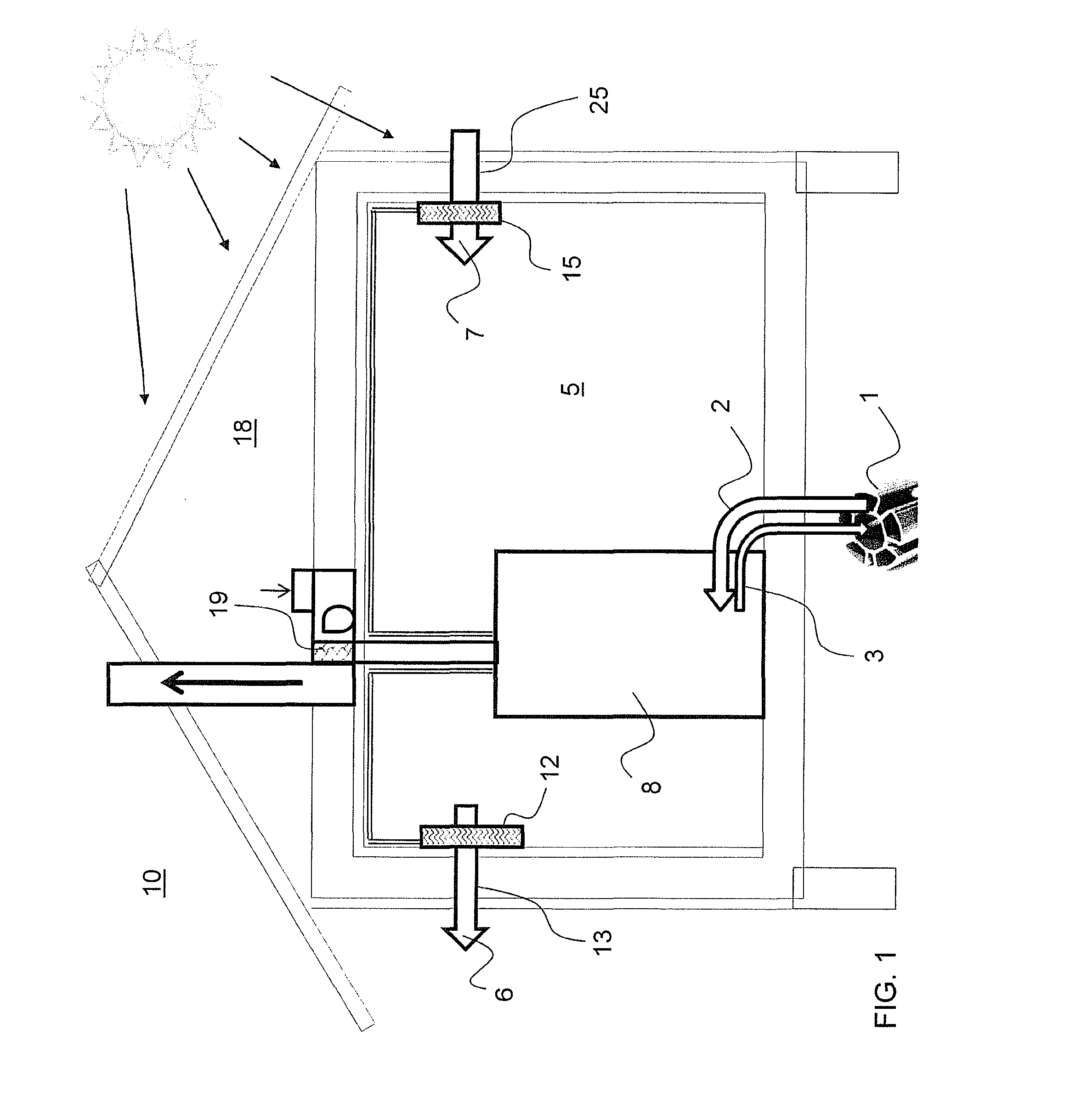

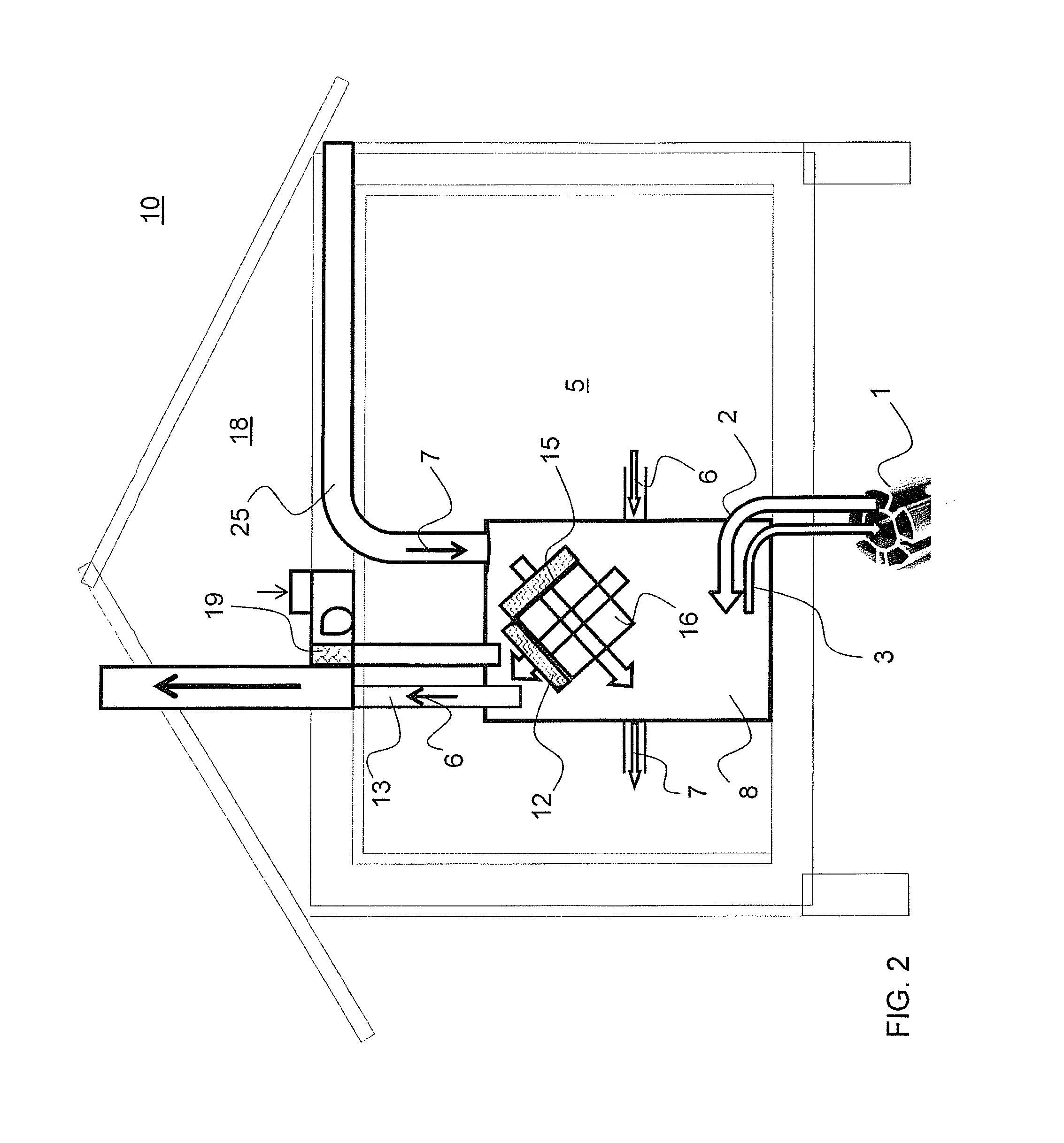

Method and arrangement for using low-energy source for controlling air temperature in room space

InactiveUS20130000882A1Reduce consumptionDecrease inside air humidityEnergy recovery in ventilation and heatingCentral heating with accumulated heatEngineeringIndoor air temperature

The present invention relates to a method and arrangement for using a low-energy source for controlling the air temperature in a room space (5). In the invention, the ratio of the desired inside air temperature in the room space (5) to the outside air (10) temperature is compared. Furthermore the temperature of a heat transfer liquid coming from an extraction circuit (1) is determined. On the basis of these detected temperature levels, heat energy of the heat transfer liquid is regulated, if necessary, after which the heat transfer liquid is channelled to a supply air radiator (15) controlling the temperature of air (7) to be supplied to the room space (5) in order to control this air temperature. At the end of the circulation, the heat transfer liquid is channelled via a return circuit (3) of means back to the extraction circuit (1).

Owner:INS TSTO EJPAN

Cooling system for a variable vacuum capacitor

ActiveUS8139359B2Improve high pressure performanceMore heat energyMechanically variable capacitor detailsFixed capacitor detailsCapacitorHeat pipe

In a cooling system for a variable vacuum capacitor, a liquid is arranged inside a cooling reservoir, a first part of the reservoir is designed to absorb heat energy from first bellows of the variable vacuum capacitor, the first bellows being responsible for transporting electrical energy to a second electrode of the variable vacuum capacitor, a second part of the reservoir is designed to dissipate heat energy towards a cooling circuit, and heat pipes are arranged between the first part of the reservoir and the second part of the reservoir.

Owner:COMET HOLDING

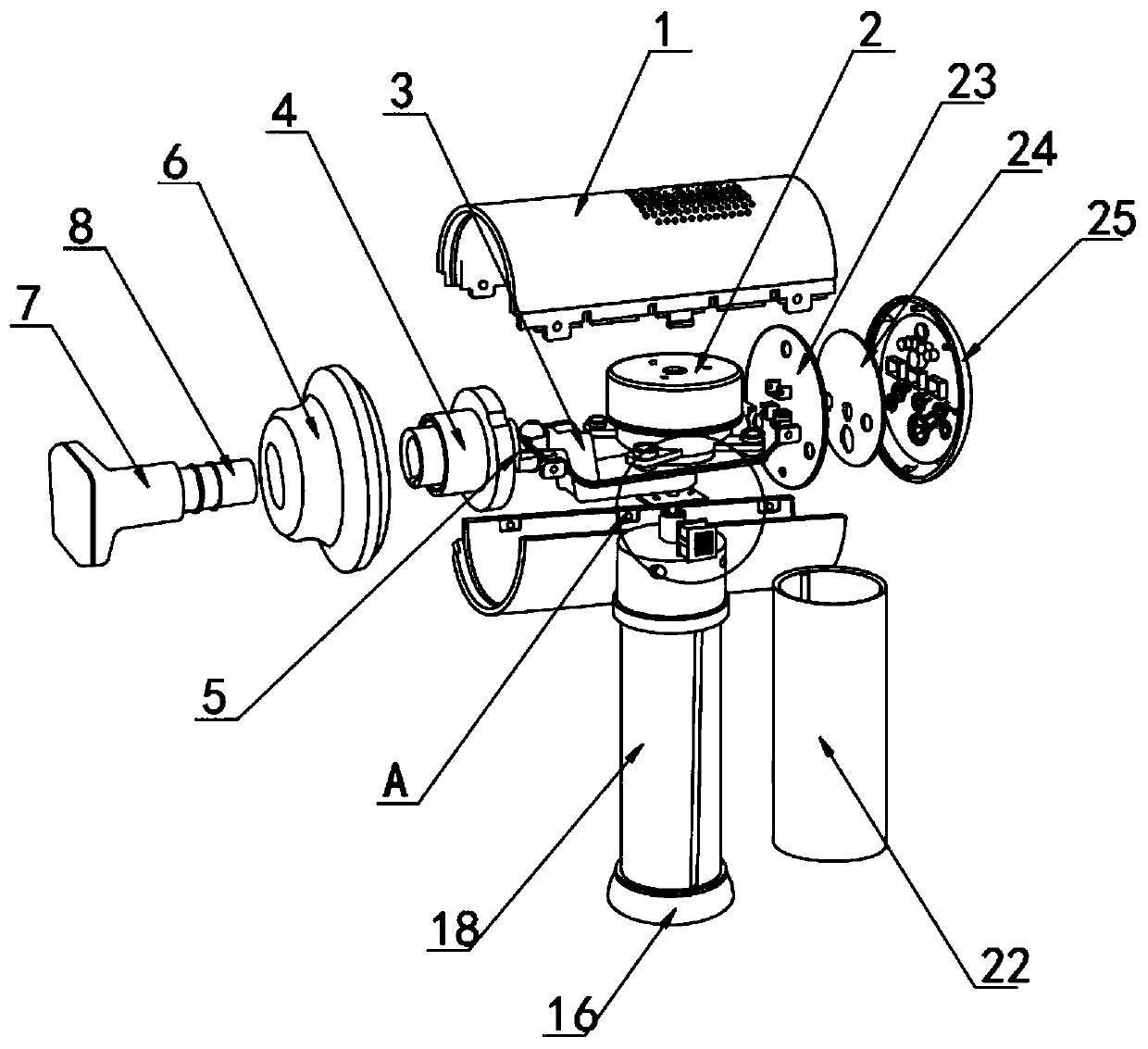

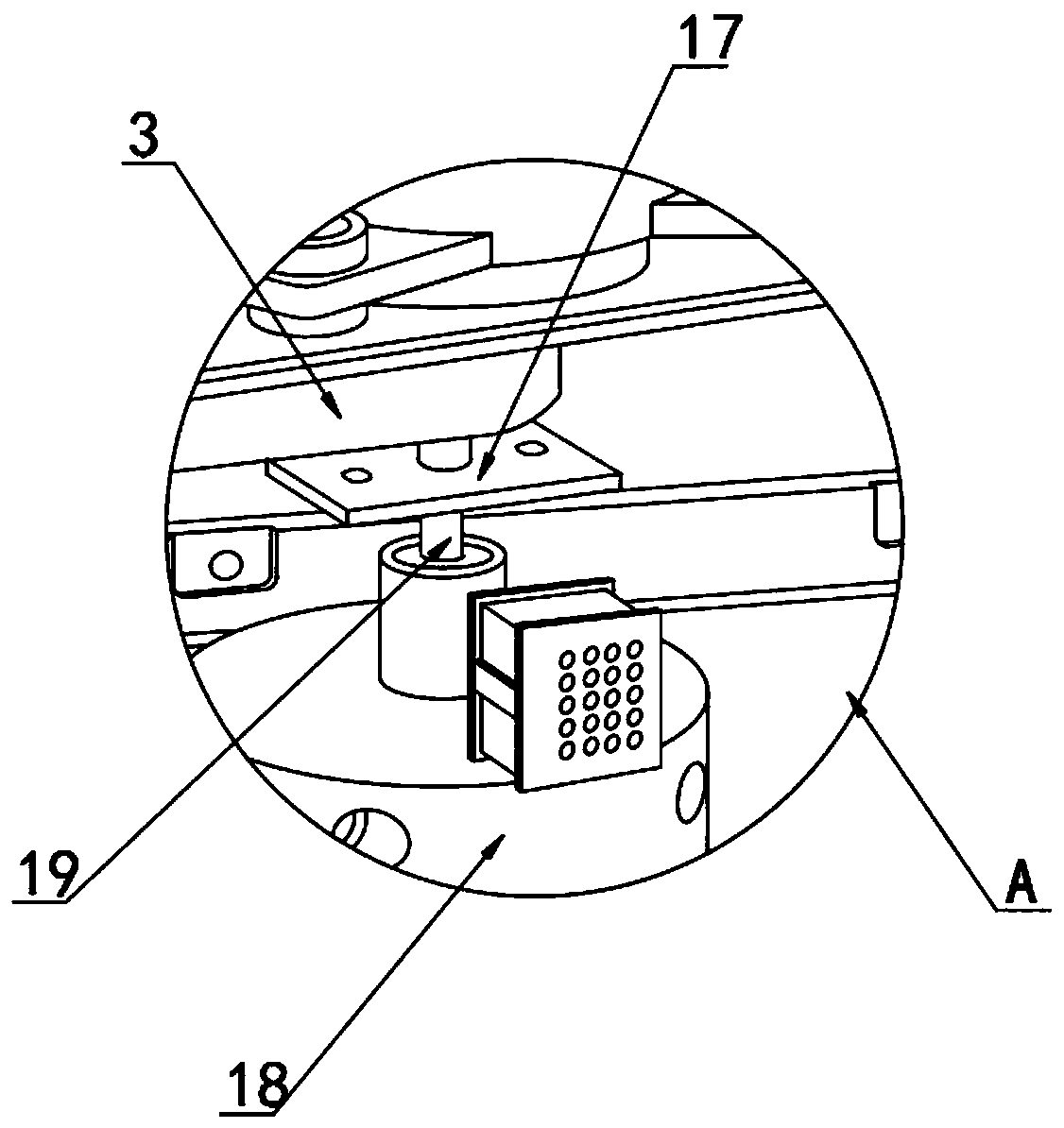

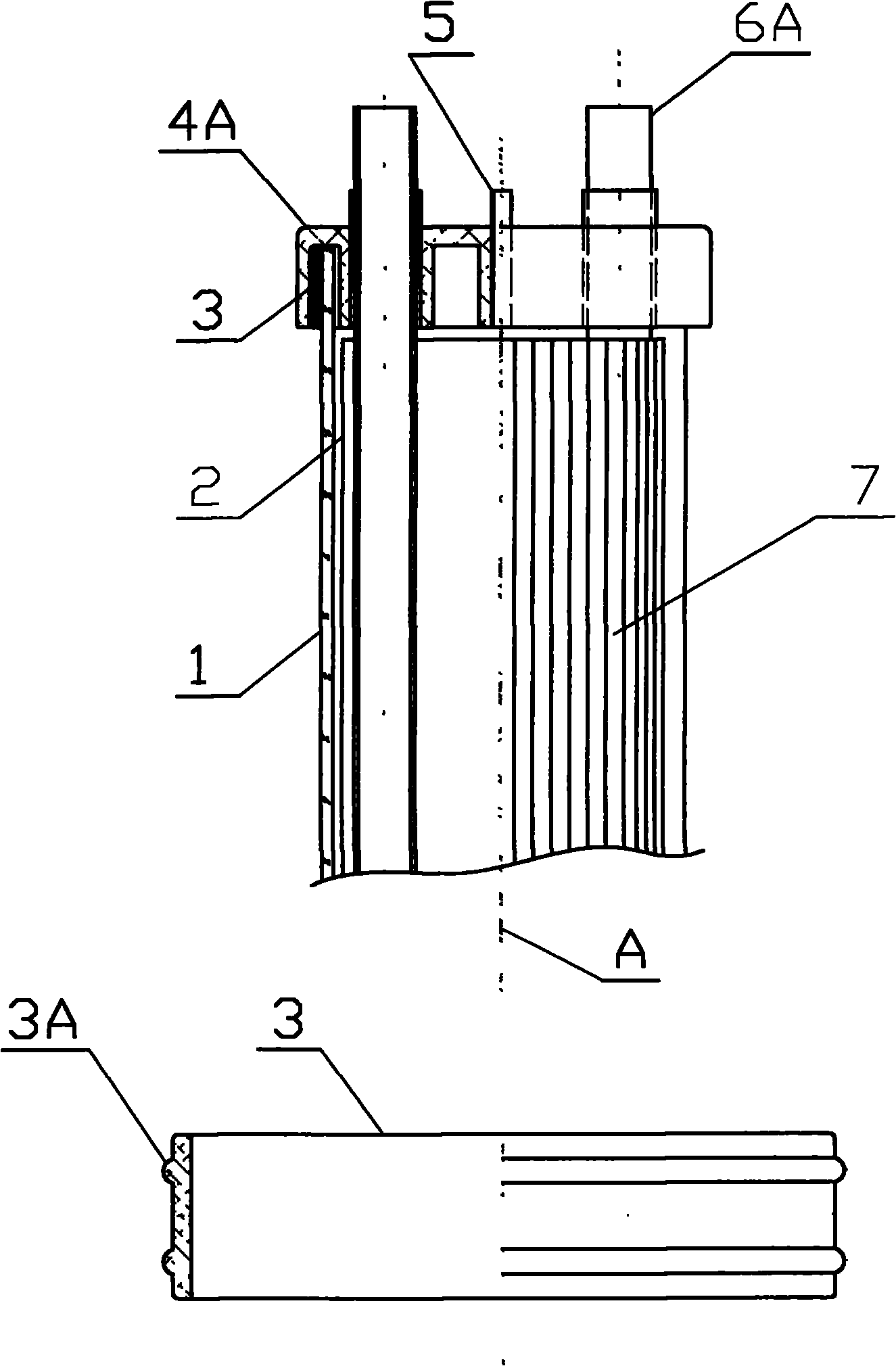

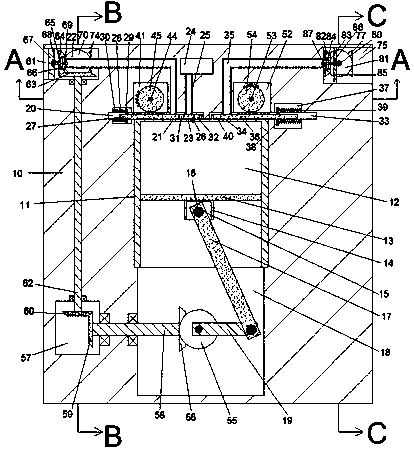

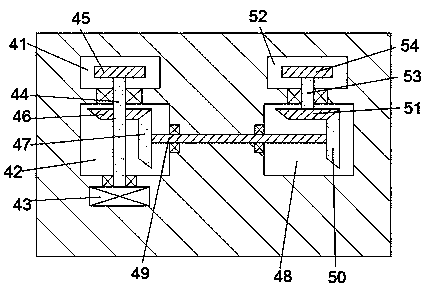

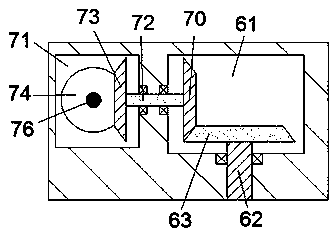

Reciprocating impact type stone needle electronic heating electric physiotherapy instrument

PendingCN110812178AMore heat energyFar-infrared energyUltrasound therapyVibration massageBrushless motorsEngineering

The embodiment of the invention discloses a reciprocating impact type stone needle electronic heating electric physiotherapy instrument, in particular to the technical field of stone needle physiotherapy. The reciprocating impact type stone needle electronic heating electric physiotherapy instrument comprises a machine body housing, wherein a brushless motor is fixedly arranged in the machine bodyhousing, and a connecting rod is fixedly arranged at the output end of the brushless motor; a metal sleeve ring is arranged on one side of the brushless motor, one end of the connecting rod is hingedto the metal sleeve ring, and power transmission connecting contacts are fixedly arranged at one end of the inner part of the metal sleeve ring; a machine body front housing sleeve is fixedly arranged at one end of the machine body housing; and the metal sleeve ring is movably connected with the machine body front housing sleeve. An electrical heating device is used for heating and warming a stone needle massaging head, so that stone needles can release heat for a long time; and the brushless motor drives the connecting rod, so that automatic mechanical massaging can be conveniently realizedby the stone needle physiotherapy head. The reciprocating impact type stone needle electronic heating electric physiotherapy instrument is convenient to operate, the heat released by the stone needlesis sufficient, flexible physiotherapy can be performed on any parts of bodies, and the physiotherapy effect is improved.

Owner:即刻(中国)有限公司

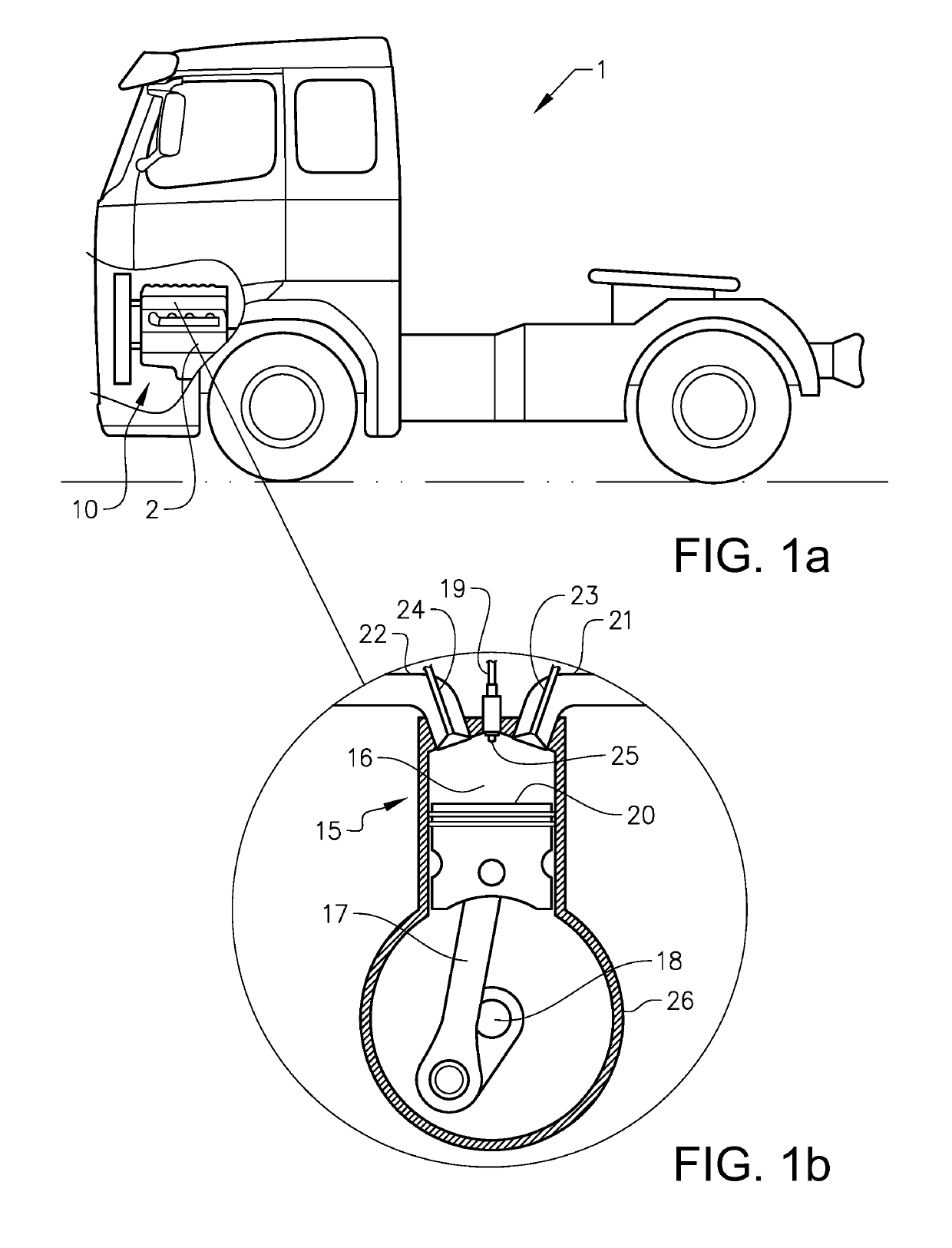

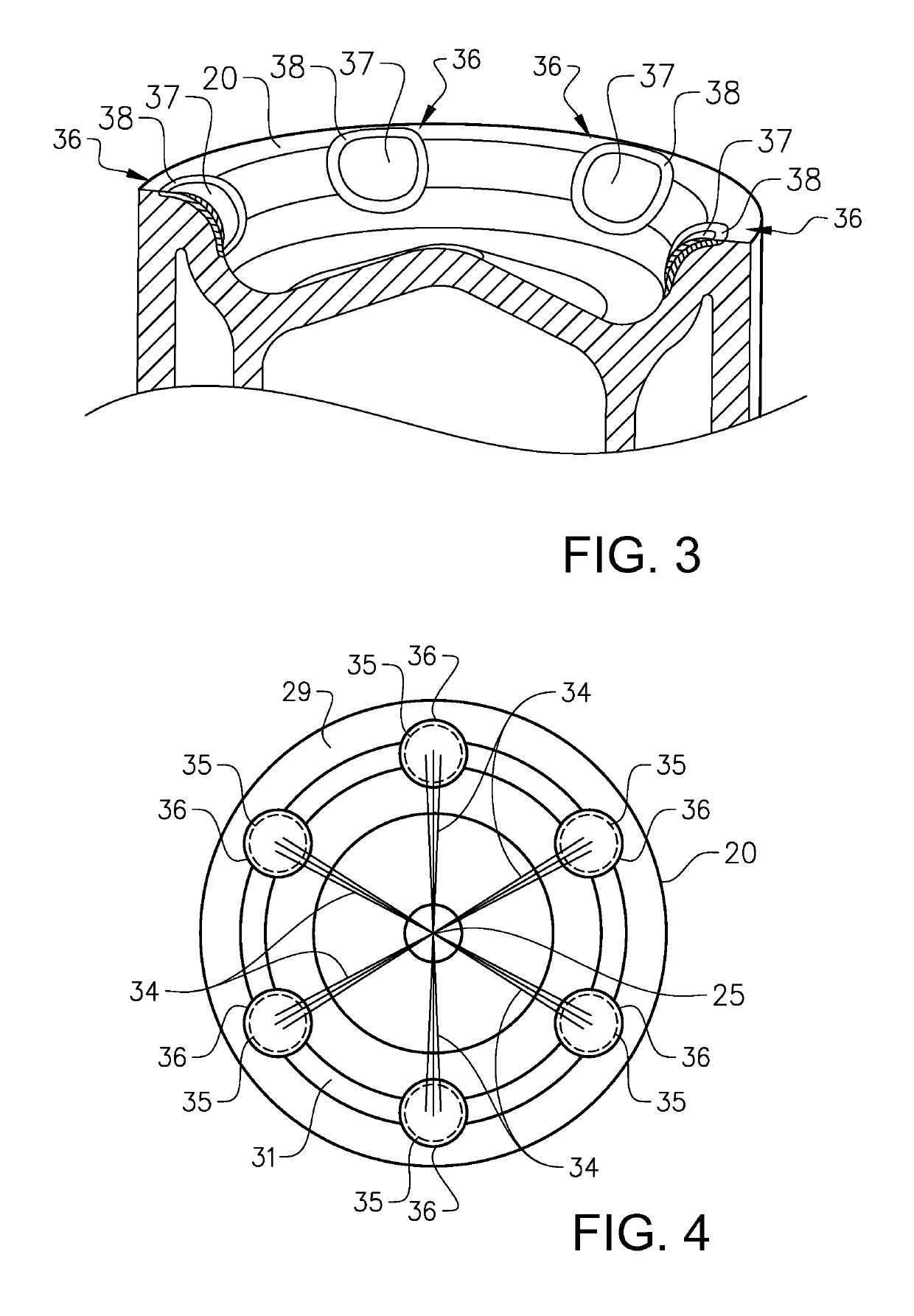

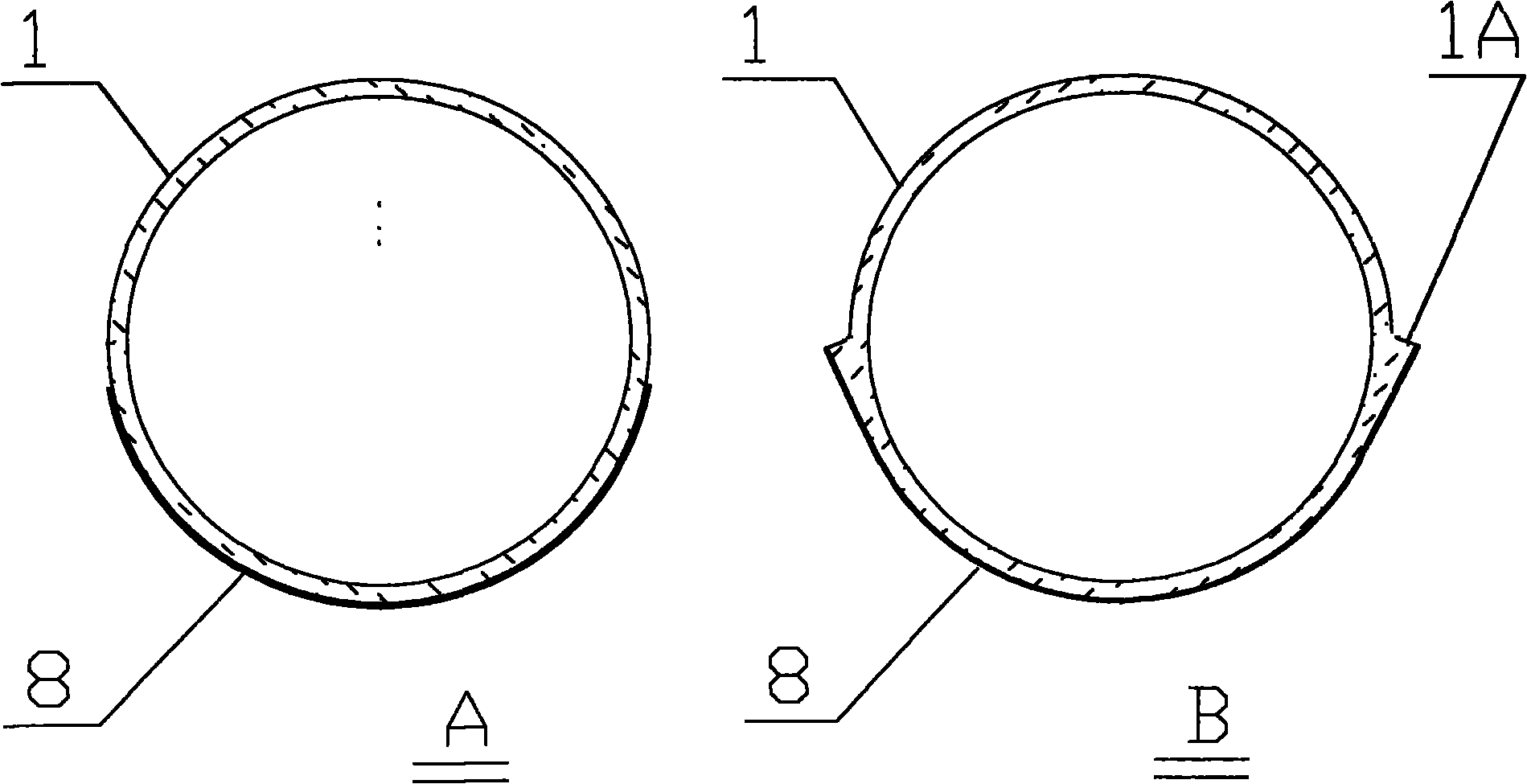

A piston for a cylinder for an internal combustion engine

ActiveUS20190128213A1Satisfactory bondingEqually distributedMolten spray coatingInternal combustion piston enginesExternal combustion engineEngineering

A piston for a cylinder for an internal combustion engine has a piston bowl surface adapted for facing a combustion chamber of the cylinder, the piston bowl surface being provided with a thermal barrier coating layer, wherein the thermal barrier coating layer is provided on a plurality of circumferentially spaced surface parts of the piston bowl surface. A method for producing a piston for a cylinder for an internal combustion engine includes the steps of providing a piston for a cylinder for an internal combustion engine, the piston having a piston bowl surface adapted for facing a combustion chamber of the cylinder, and providing the piston bowl surface with a thermal barrier coating layer, wherein the step of providing the thermal barrier coating layer is made on a plurality of circumferentially spaced surface parts of the piston bowl surface.

Owner:VOLVO LASTVAGNAR AB

Heated hair styling clip for rapid setting of informal hair styles

A heated hairstyling clip, optionally with heat-transfer accessories, is provided for rapid informal (“scrunch”-type) hair styling. (To “scrunch” is to crumple, crush or squeeze something tightly together; for example, a handful of hair.) In one embodiment the clip is a pair of concave jaws, optionally with interlocking fingers, held together by a spring mechanism. The hair is set and secured within the heated hairstyling clip, optionally with accessories supplying additional heat, and the clip is then allowed to cool before being removed. The clip is heated by a device, which may be a microwave oven, a conventional oven, a heated bath, or a resistive heating element. Heating of the clip may be supplemented or replaced by a heatable clip liner, held between the clip and the hair being treated, or a heatable clip pad supplying heat to the clip and the hair, or a reservoir within the clip, or a styling element in contact with the hair. The heated clip can be used for the purpose of creating natural looking scrunched styles, tousled body, informal waves or curls, or similar configuration or formation of hair.

Owner:DALEY TINA

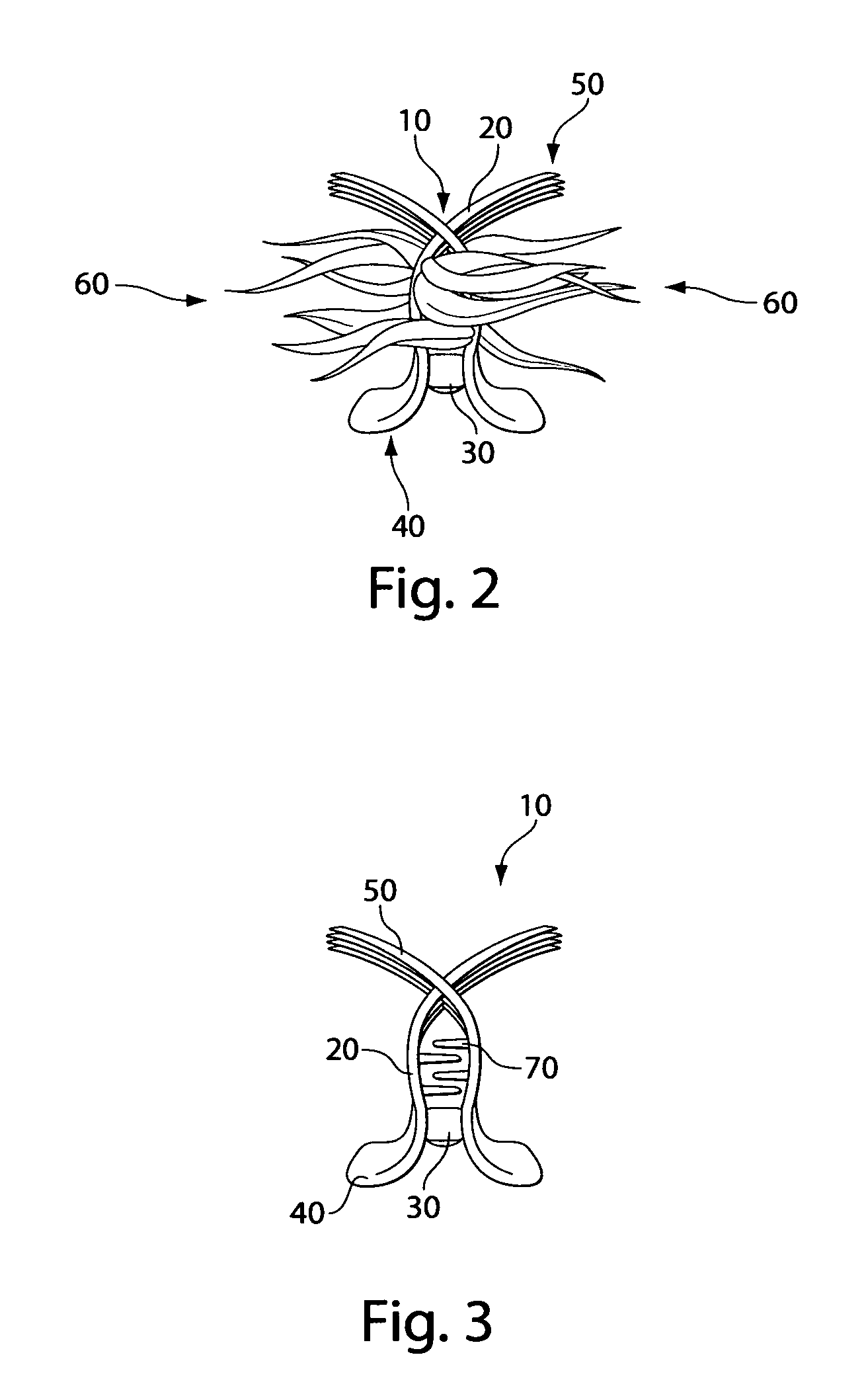

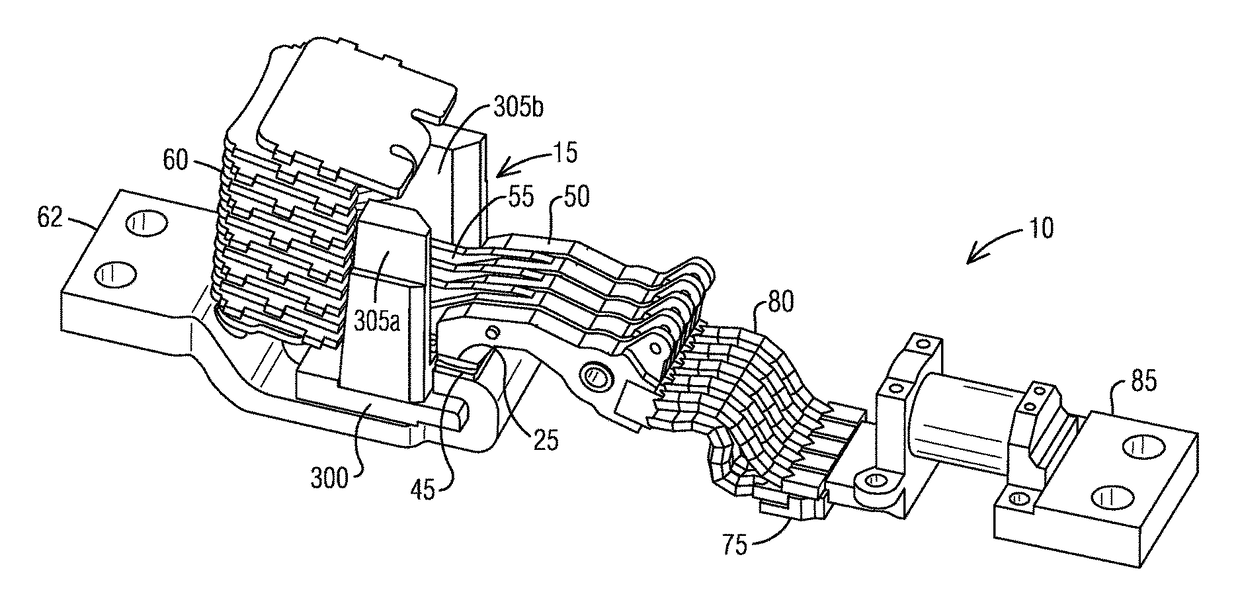

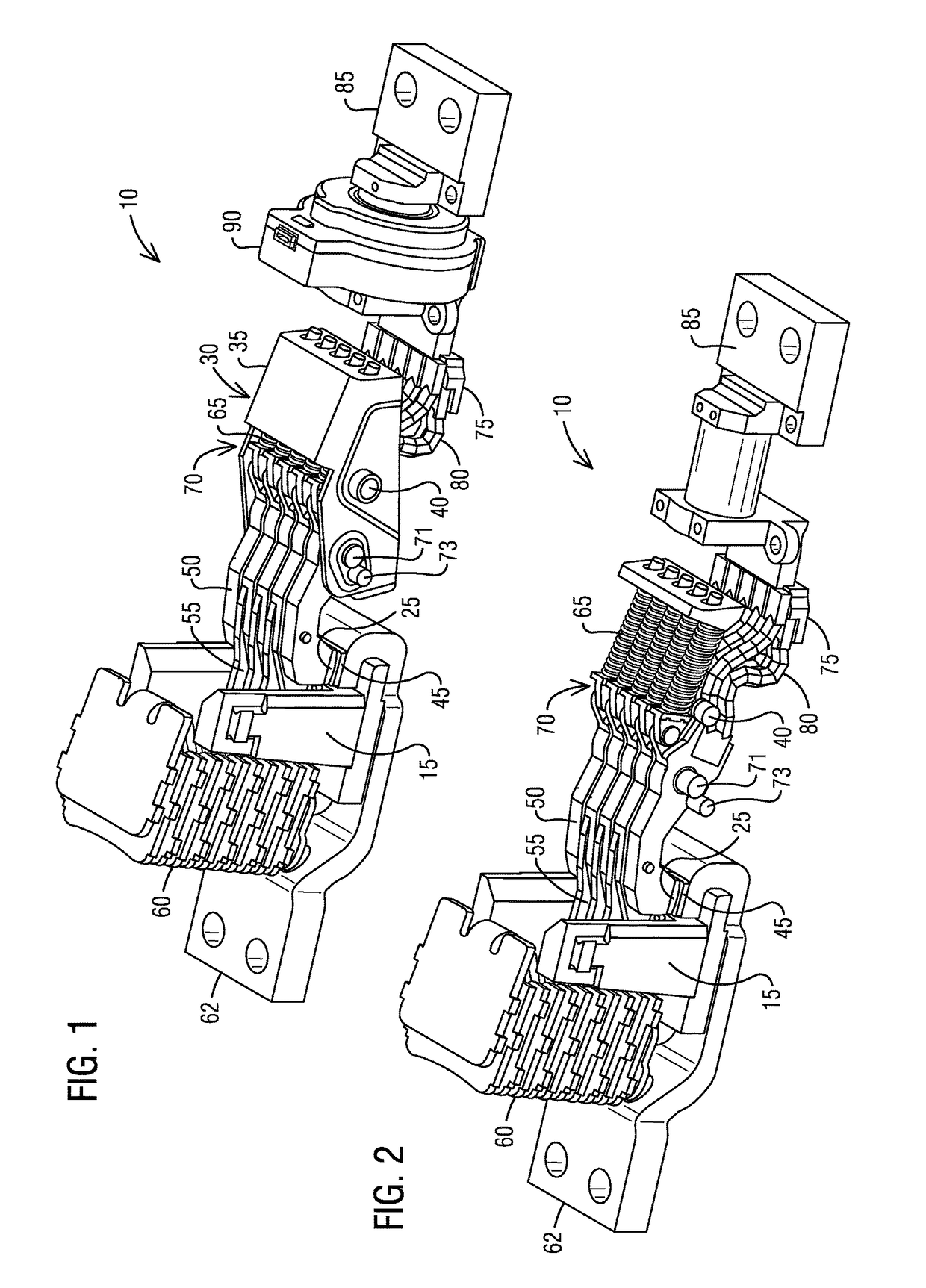

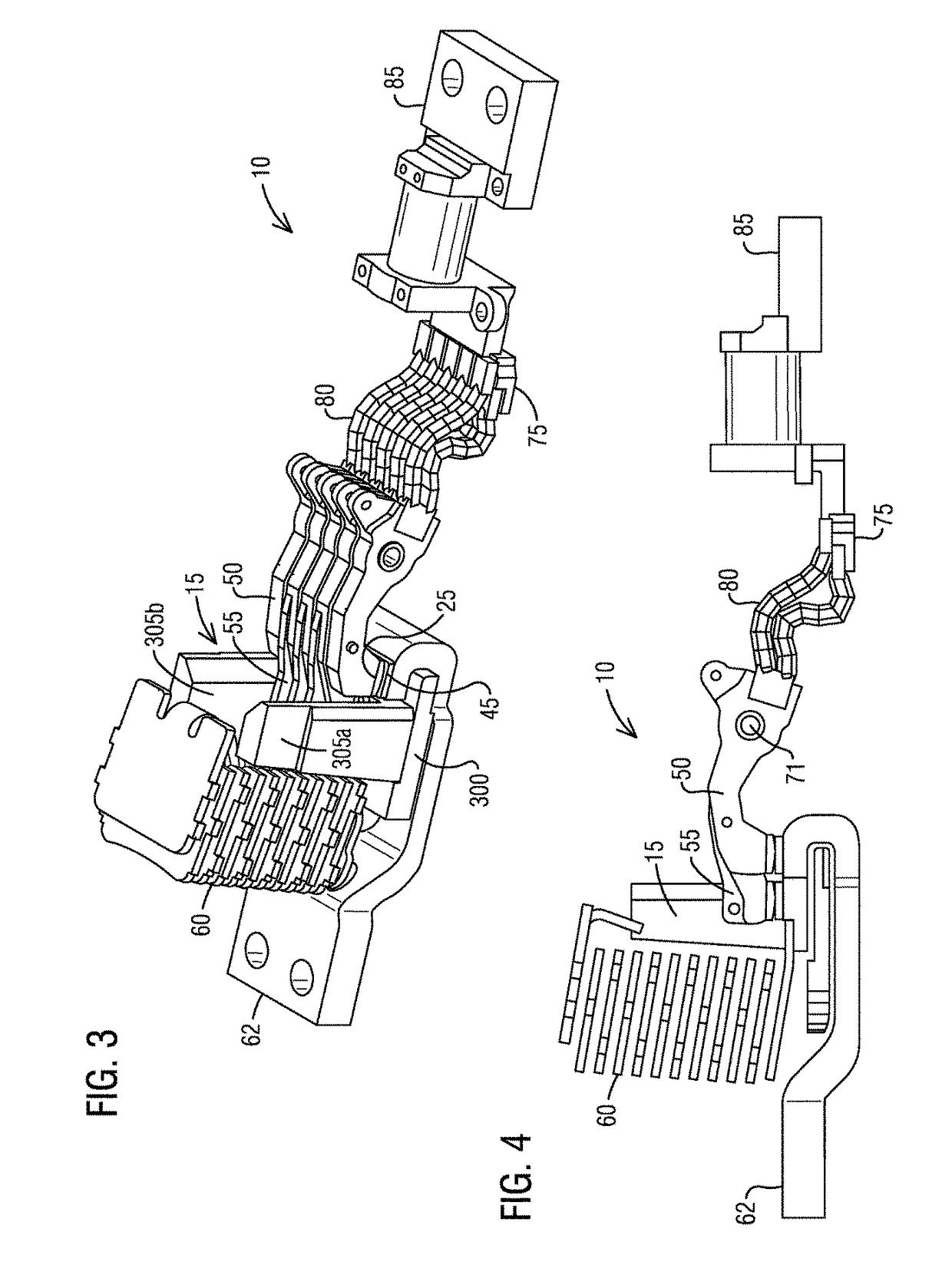

Slot motor configuration for high amperage multi-finger circuit breaker

ActiveUS9805887B2Magnetic force longExtinguishing the arc quicklyEmergency springsHigh-tension/heavy-dress switchesElectrical currentCircuit breaker

A multi-finger circuit breaker includes a moving contact assembly having a carrier body, a first plurality of fixed breaking contacts, a first plurality of movable contacts, a plurality of first fingers, at least one second finger longer in length to a length of a first finger of the plurality of first fingers, a plurality of splitter plates disposed adjacent to the plurality of first fingers and the at least one second finger and a slot motor disposed adjacent to the plurality of first fingers and the at least one second finger. The slot motor is configured to provide a first magnetic field force to amplify a second magnetic field force being applied on the second finger to influence an arc between the first plurality of fixed breaking contacts and the first plurality of movable contacts during a short circuit such that to move the arc away from between the first plurality of fixed breaking contacts and the first plurality of movable contacts and dissipate energy of the arc.

Owner:SIEMENS AG

Applying heating liquid to fix toner

InactiveUS8824944B2Effectively fixedReduce probabilityElectrographic process apparatusEngineeringGlass transition

A method for fixing toner onto a receiver medium includes depositing a pattern of toner onto a surface of the receiver medium. The toner has a toner glass transition temperature. At least one surface of the receiver medium is brought into contact with a heating liquid, the heating liquid being at a temperature greater than the toner glass transition temperature. Heat is transferred from the heating liquid to the toner, thereby raising a temperature of the toner to a level above the toner glass transition temperature.

Owner:EASTMAN KODAK CO

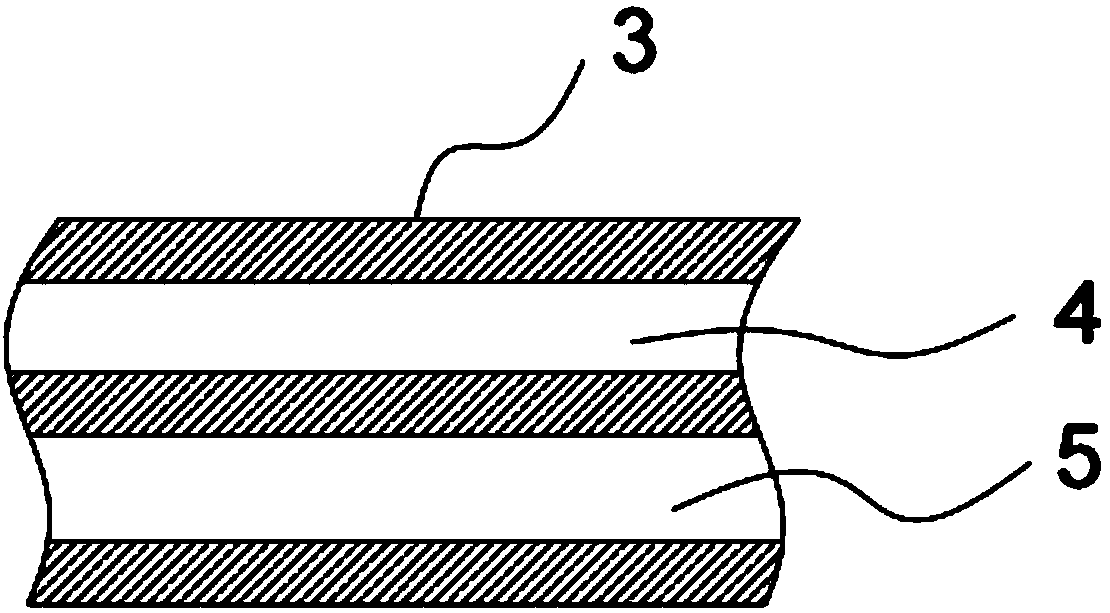

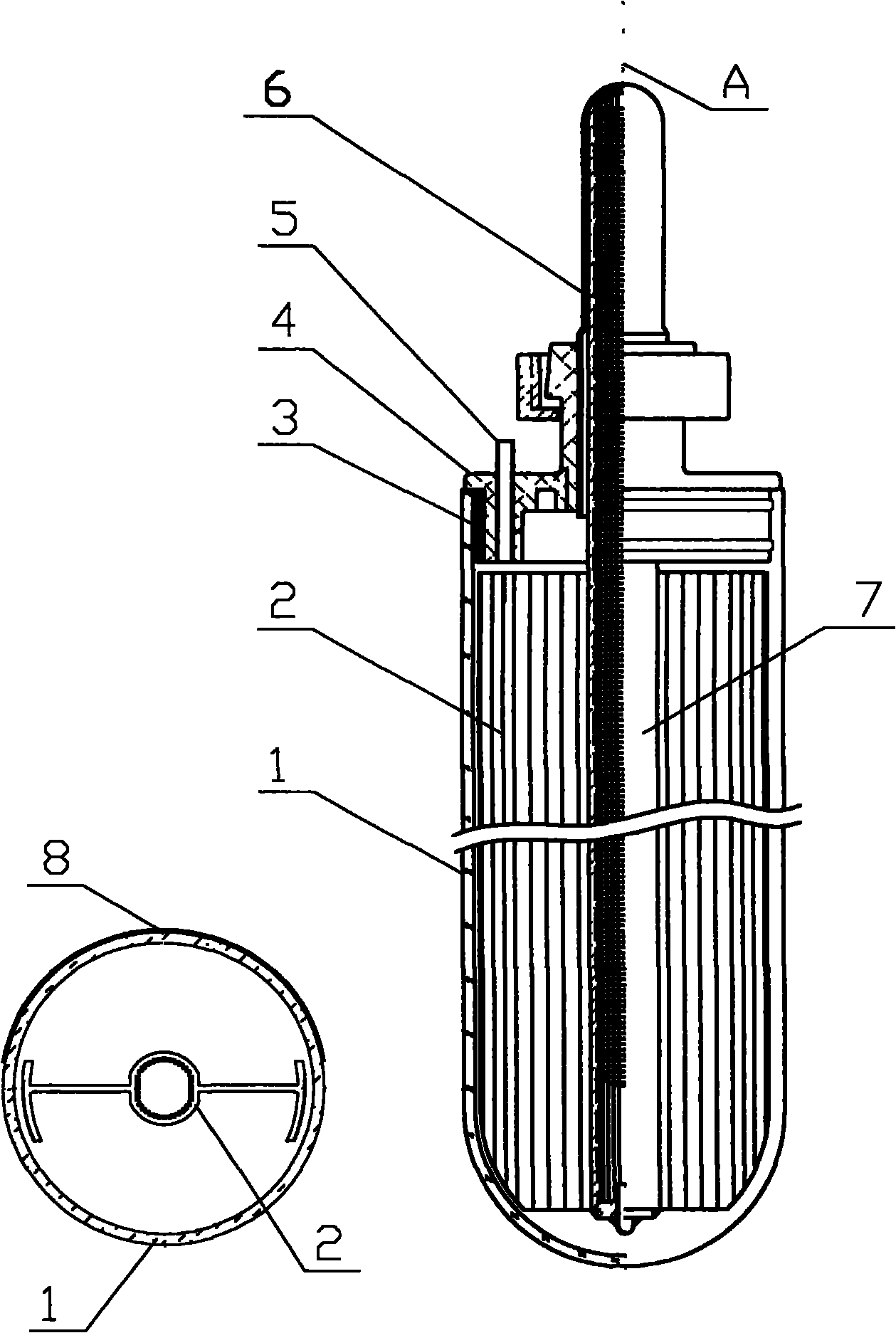

Solar transparent heat insulation pipe

InactiveCN102072573AIncreased effective heat collection areaReduced diffusion lossSolar heat devicesSolar thermal energy generationHeat conductingSolar water

The invention discloses a solar transparent heat insulation pipe, which mainly comprises a heat conducting pipe, wind surf fins, a rubber sealing ring, a suction and exhaust pipe, a sealing cover, a transparent heat insulation pipe and a reflective diaphragm. Through vacuum heat insulation of a single-layer transparent heat insulation pipe, the heat conducting pipe and the fins are directly used for collecting heat of a radiated surface, a heat collection and heat transfer mode that solar radiation energy is collected by a metal heat absorbing coating on a vacuum glass collector pipe in the conventional technical route is changed, a status that various heat conducting pipes are only taken as intermediate heat transfer tools is changed, the intermediate low-effect and redundant heat transfer links are eliminated, and the structure is simplified, so respective heat transfer advantages of various heat conducting pipes can be fully exerted, and various techniques capable of obviously improving heat collecting energy efficiency, such as the wind surf fins, a heat absorbing channels, reflective heat gathering and suboptical blackbody are applied; therefore, the energy efficiency of collecting the solar radiation energy can be greatly improved, and the solar transparent heat insulation pipe has the characteristics of reasonable structural design, simple process, low cost, high reliability, high heat collecting efficiency, small diffusion loss of heat radiation, convenience of installation and use, and suitability for U tube and heat pipe type solar water heaters.

Owner:南京绿盾电气设备有限公司

Piston for a cylinder for an internal combustion engine

ActiveUS10801439B2Equally distributedIncrease pressureMolten spray coatingInternal combustion piston enginesCombustion chamberInternal combustion engine

A piston for a cylinder for an internal combustion engine has a piston bowl surface adapted for facing a combustion chamber of the cylinder, the piston bowl surface being provided with a thermal barrier coating layer, wherein the thermal barrier coating layer is provided on a plurality of circumferentially spaced surface parts of the piston bowl surface. A method for producing a piston for a cylinder for an internal combustion engine includes the steps of providing a piston for a cylinder for an internal combustion engine, the piston having a piston bowl surface adapted for facing a combustion chamber of the cylinder, and providing the piston bowl surface with a thermal barrier coating layer, wherein the step of providing the thermal barrier coating layer is made on a plurality of circumferentially spaced surface parts of the piston bowl surface.

Owner:VOLVO TRUCK CORP

Internal combustion engine and operation method

InactiveCN109139237ASimple structureEasy to operateExhaust apparatusSilencing apparatusCombustionExternal combustion engine

The invention provides an internal combustion engine and an operation method. The internal combustion engine comprises a device body, a first working device and a pressurizing and discharging device,wherein the first working device and the pressurizing and discharging device are arranged in the device body. The first working device comprises a cylinder arranged in the device body, a combustion cavity with a downward opening is formed in the cylinder, and a first sliding block capable of sliding up and down is arranged in the combustion cavity. A second sliding block is fixedly connected to the lower end of the first sliding block, and a first groove with a downward opening is formed in the second sliding block. In the operation process of the internal combustion engine, the air entering amount can be automatically increased for the combustion cavity, waste gas discharging can be accelerated, the gas discharging process is more effective, and the space occupation rate of the engine isfar smaller than that of a common engine and a turbocharging device.

Owner:何海燕

Solenoid valve

InactiveUS7866796B2Aid rapid rise and fallMore heat energyInking apparatusOperating means/releasing devices for valvesSolenoid valveDiameter ratio

A solenoid valve making use of certain materials which is capable of operation at high frequencies and which can be made as a compact unit. The plunger (1) is made from a material having a saturation flux density greater than 1.4 Tesla preferably more than 1.6 Tesla, a coercivity at less than 0.25 ampere per centimeter and a relative magnetic permeability in excess of 10.000; and the nozzle bore leading from the valve head chamber (14) to the nozzle orifice (12) has a length to diameter ratio of less than 8:1 preferably between 2:1 to 4:1 and the nozzle orifice (12) has a diameter substantially the same as that of the nozzle bore. The invention also relates to method for operating a drop on demand ink jet printer incorporating such a valve.

Owner:WILLETT INT

Method and device for the production of an optimized neck contour on preforms

ActiveUS20200307045A1Better overall contouringMore heat energyDomestic articlesBlow moldingPolymer science

A method and device for producing an optimized neck contour on preforms below the neck which is optimal for subsequent stretch blow molding. The geometry has a significantly thinner wall thickness than the neck itself. The preform can only be produced in the injection molding tool, when axial channels are used on the point or the vanes produce the thin points on the preform during injection molding. The thin-walled geometry on the preform can be produced outside of the mold during post-cooling by embossing. The preform is then removed in a cooled receiving sleeve and is cooled in the body by intensive contact cooling while no cooling contact is made with the preform neck due to the initial position of the embossing element. Due to the reheating of the neck they can be mechanically deformed into a new geometry advantageous for blow molding and thus wall thickness can be influenced.

Owner:AKTAS MAHIR

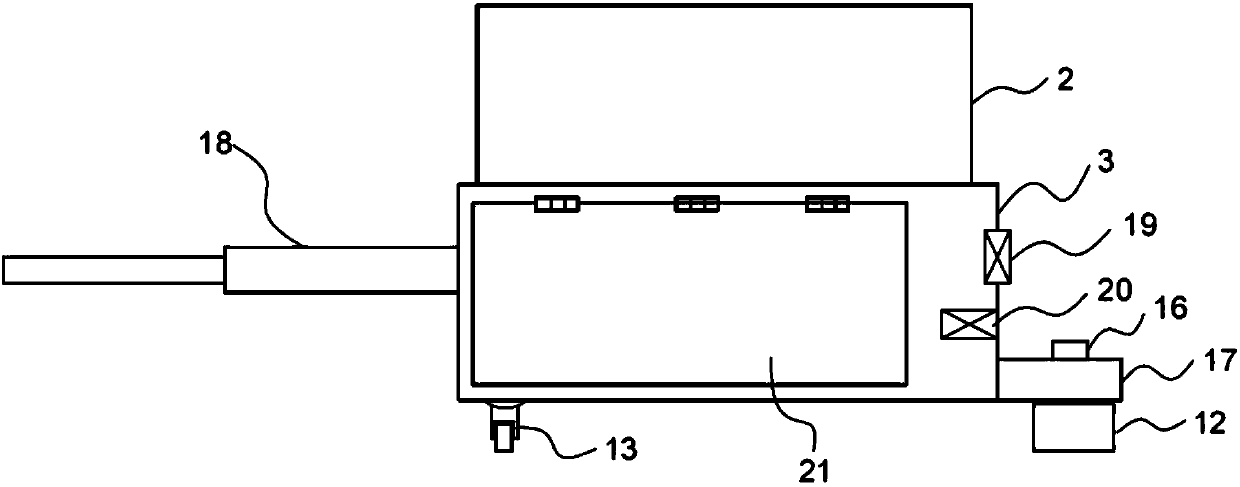

Lower energy consumption pneumatic motor

InactiveCN102410047AIncrease in sizeIncrease pressureInduction heatingMachines/enginesDrive shaftEngineering

The invention discloses a low energy consumption pneumatic motor which comprises a high-pressure air source, a pneumatic pipeline, a generator and a pneumatic converter, wherein the high-pressure air source is connected with pneumatic pipeline; the pneumatic converter is connected with the pneumatic pipeline; the pneumatic converter simultaneously drives a driving shaft of the generator and a driving shaft connected with a target device; a heating device is arranged on the pneumatic pipeline; and the generator supplies power to the heating device. The low energy consumption pneumatic motor can increase the kinetic energy conversion and output under the condition that the reserve volume of the own compressed gas of the pneumatic motor is not increased.

Owner:陈亦虎

Multifunctional Four Seasons Mat

The invention relates to a multifunctional four-season cushion, which belongs to the field of an electric blanket, and solves the problems that the existing electric blanket is likely to generate static electricity, the surface is easy to contaminate and difficult to clean, the fire resistance is poor, harmful electromagnetic waves are likely to produce, the heat utilization rate is low, and the electric blanket cannot be applicable to the hot season. The multifunctional four-season cushion comprises a heating layer, a surface layer and a supporting layer; the top layer of the multifunctional four-season cushion is the surface layer, the lower surface of the surface layer is provided with the heating layer, and the supporting layer is arranged on the lower surface of the heating layer; the surface layer is made of one or more of vines, bamboo, grass, hemp, cotton, silk, paper fibers, timber and plant fibers. The multifunctional four-season cushion is applicable to households.

Owner:HARBIN QIANCHUAN TECH

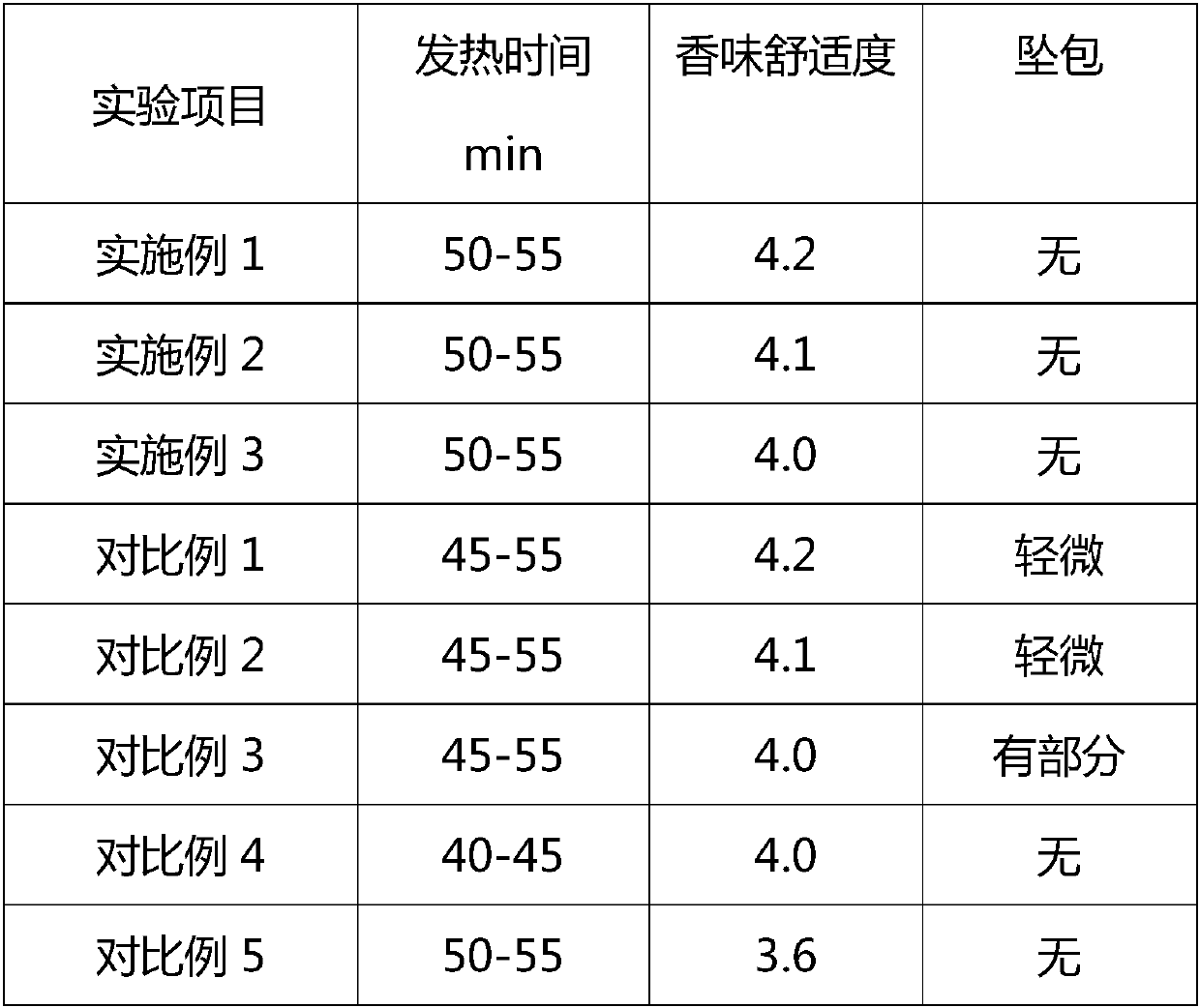

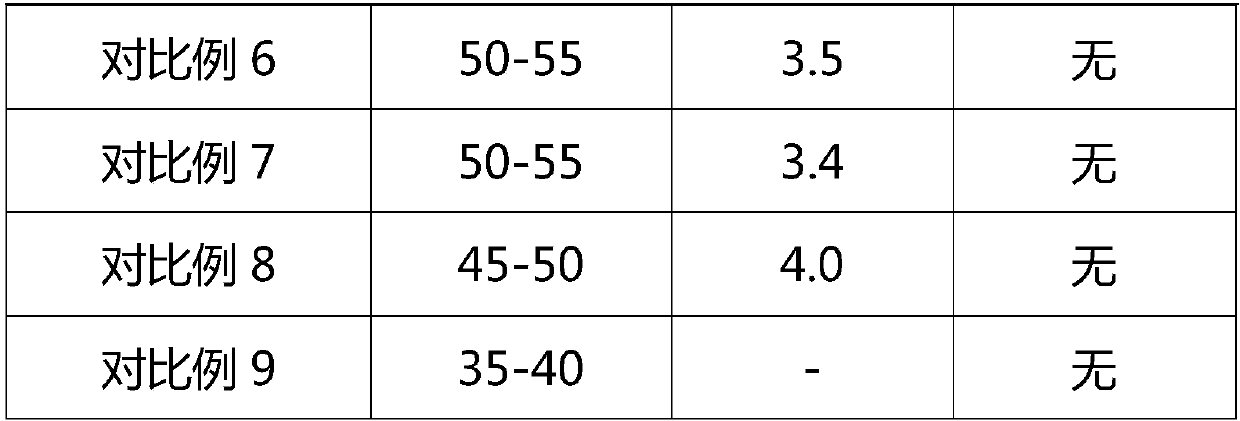

Novel eyeshade heating material and preparation process

ActiveCN111568641AGuaranteed stabilityReduce lossEye-masksTherapeutic coolingCelluloseCarboxymethyl cellulose

The invention discloses a novel eyeshade heating material and a preparation process. The novel eyeshade heating material comprises a plant aroma type layer, an upper non-woven fabric layer, an upper breathable film layer, a heating mixture, a lower breathable film layer and a lower non-woven fabric layer from outside to inside; and the heating mixture comprises two parts, the first part of the heating mixture comprises the following components in parts by mass: 45-65 parts of iron powder, 9-15 parts of carbon powder, 6-10 parts of vermiculite, 0.2-0.3 part of resin and 0.1-0.2 part of a deoxidizing agent, and the second part comprises the following components in parts by mass: 15 to 25 parts of water, 2 to 4 parts of a catalyst, 0.05 to 0.15 part of carboxymethyl cellulose and 0.03 to 0.07part of a plant adhesive.

Owner:刘子琛

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com