Steam ironing heat energy utilization system and heat energy utilization method thereof

A steam and heat energy technology, which is applied to a steam ironing heat energy utilization system and the heat energy utilization field thereof, can solve the problems of bad operating environment, low energy utilization rate, large power consumption, etc., and achieves improved operating environment, high heat energy utilization rate, and improved The effect of thermal energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below through specific examples.

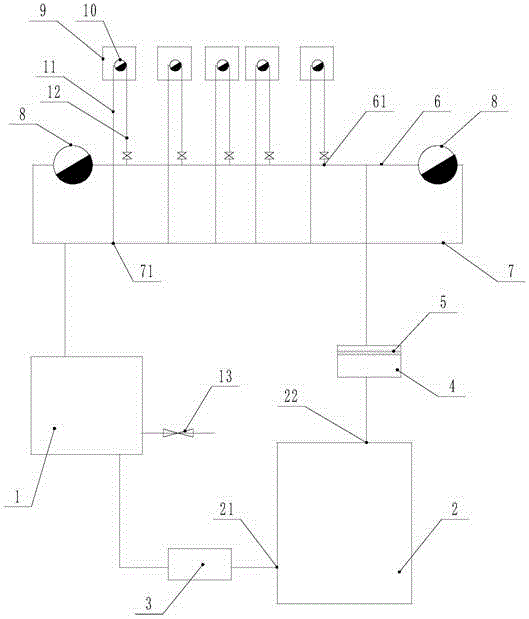

[0023] Such as figure 1 As shown, a heat energy utilization system for steam ironing includes an electric heating boiler 2, which is provided with a steam outlet 22 and a water injection port 21, and the heat energy utilization system also includes a steam main pipe 6, a liquid return main pipe 7 and several An ironing device 9, the steam main pipe 6 is connected to the steam outlet 22, and the steam main pipe 6 is provided with several steam distribution ports 61, and each steam distribution port 61 is connected with an air supply pipe 12; the liquid return main pipe 7 There are several liquid return ports 71 that match the steam distribution port 61, and the numbers of the steam distribution port 61 and the liquid return port 71 are generally selected according to actual usage conditions, but compared with the current heat energy utilization system, this 60% energy can be sav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com