Lower energy consumption pneumatic motor

A pneumatic machine, low energy consumption technology, applied in the direction of machine/engine, mechanical equipment, induction heating, etc., can solve the problems of inability to popularize and use, environmental pollution, short vehicle transportation journey, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

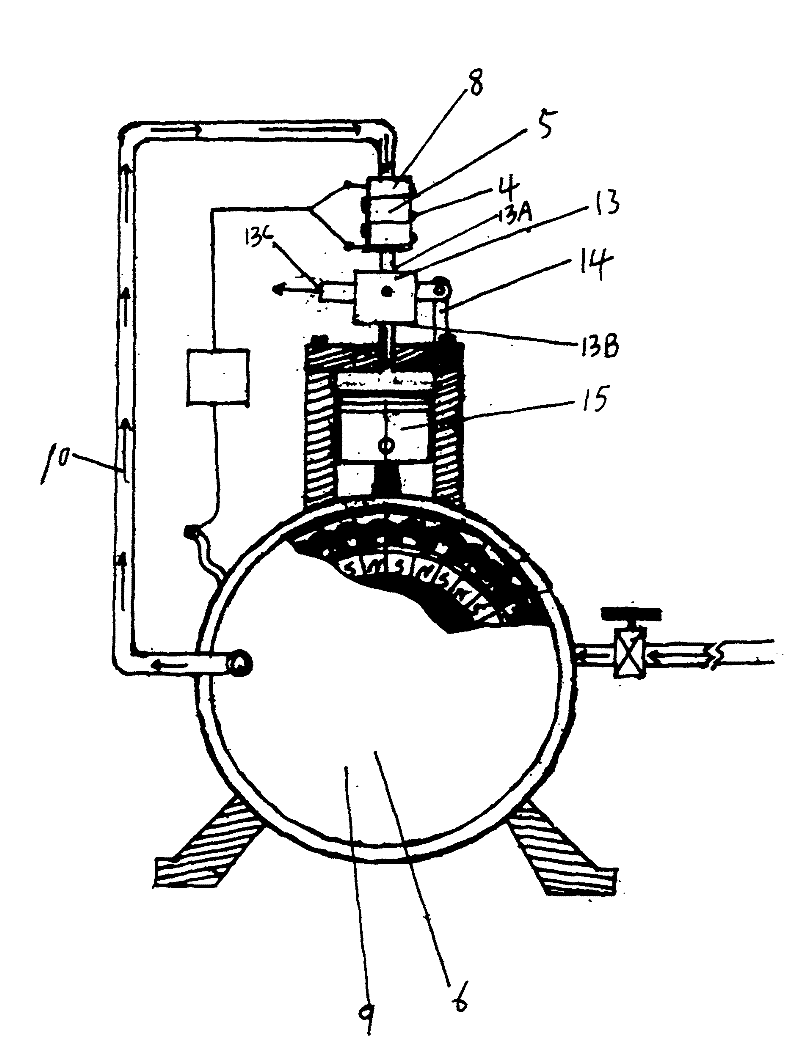

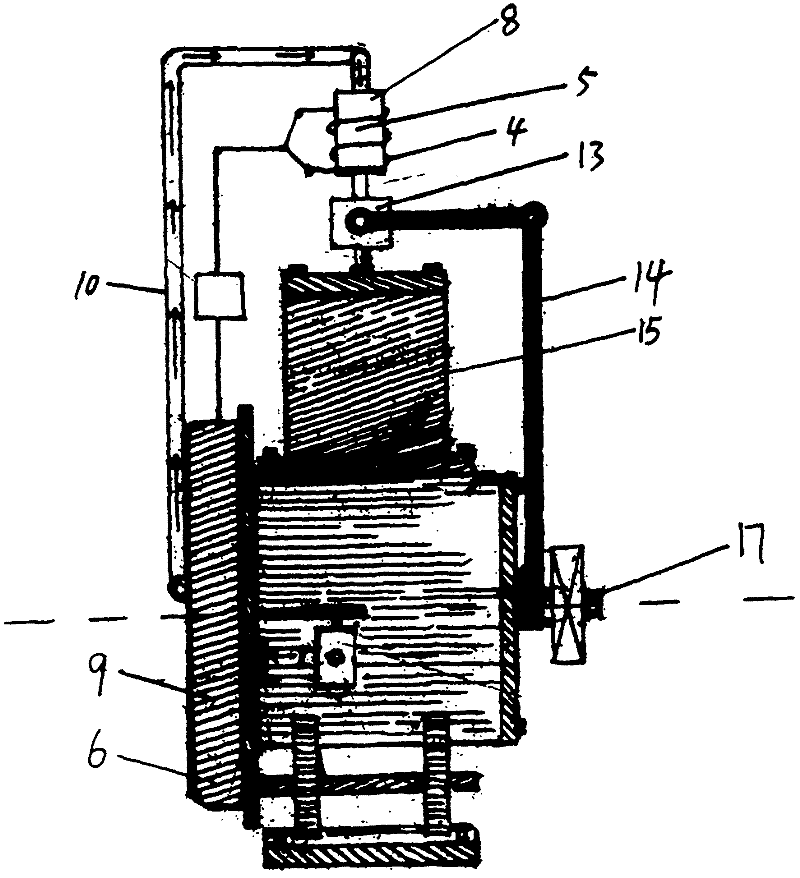

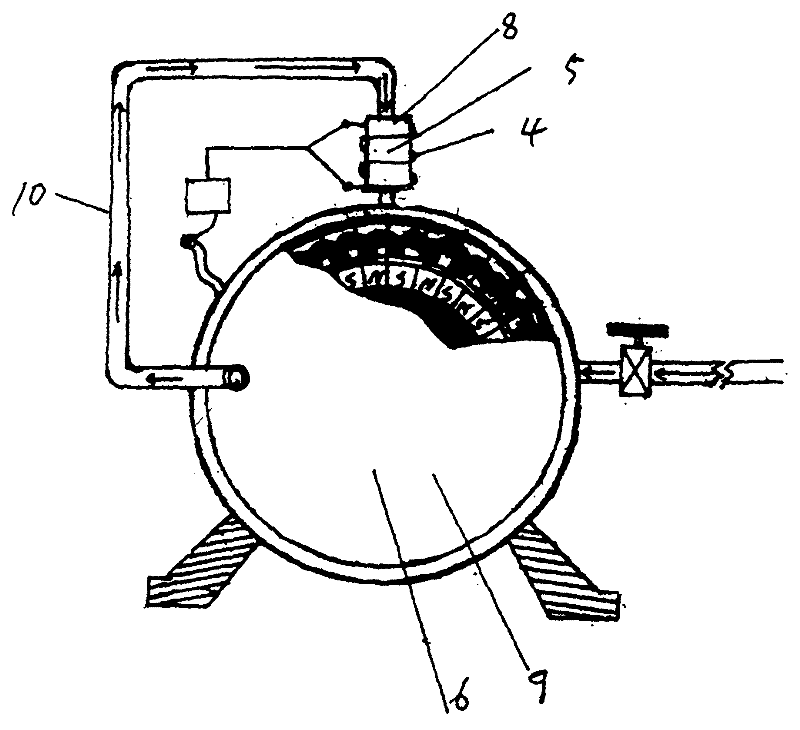

[0011] Such as figure 1 , figure 2 As shown, the low-energy pneumatic motor provided by the first embodiment of the present invention includes a high-pressure air source, a pneumatic pipeline 10, a generator 6 and a pneumatic converter, the high-pressure gas source is connected to the pneumatic pipeline 10, the pneumatic converter and the pneumatic tube 10, the pneumatic converter simultaneously drives the drive shaft of the generator and the drive shaft connected to the target device. Here, the target device refers to the device driven by the pneumatic motor, generally a running vehicle. 6 supply power to the heating device, where the heating device is generally an electromagnetic induction heating device 5, and the winding 4 in the electromagnetic induction heating device 5 and the winding of the generator 6 form an inductive closed loop, where the generator 6 is an alternator, and the generator 6 When the operating speed reaches a certain range, the rotating speed range o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com