Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56results about How to "Minimize thermal expansion differences" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

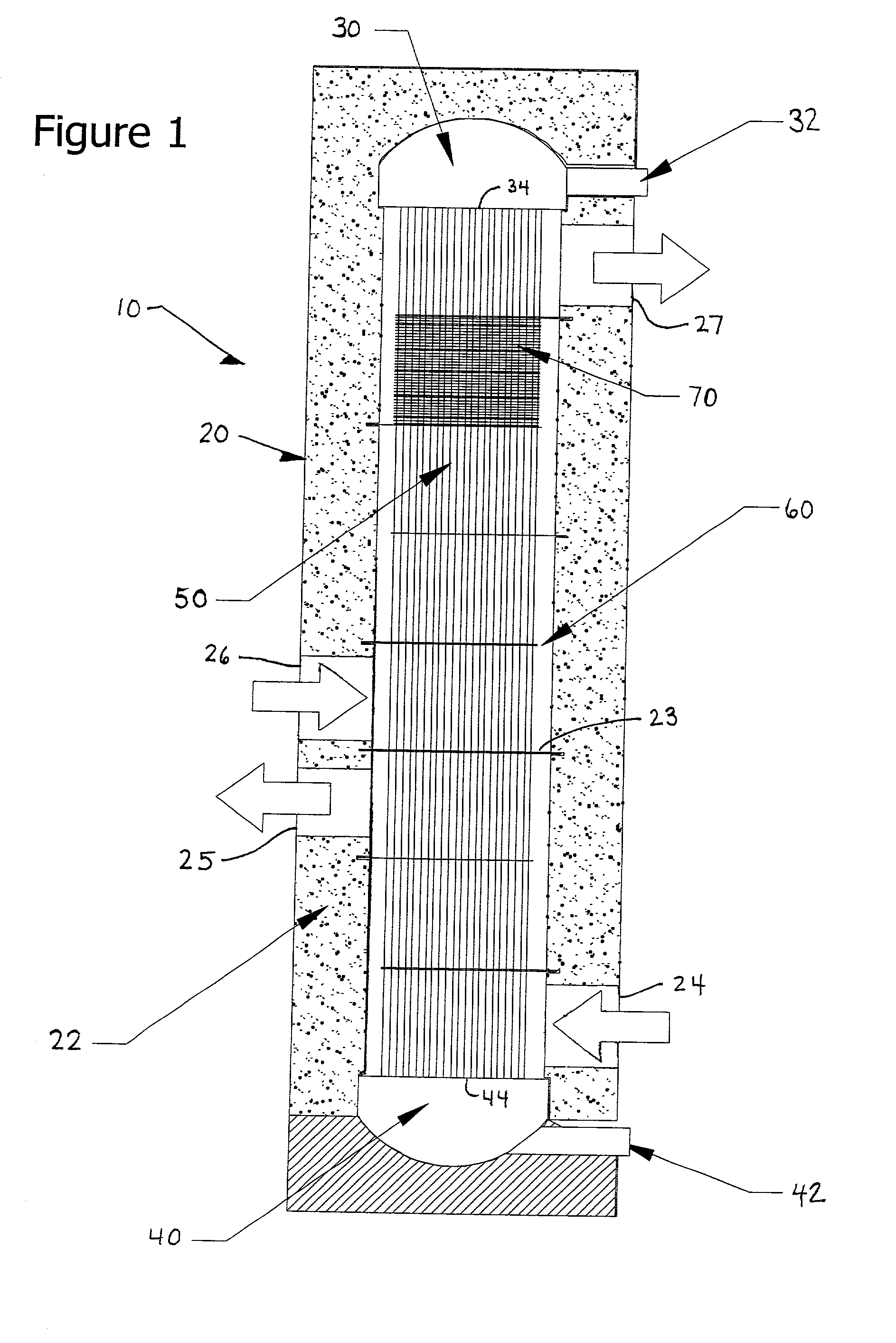

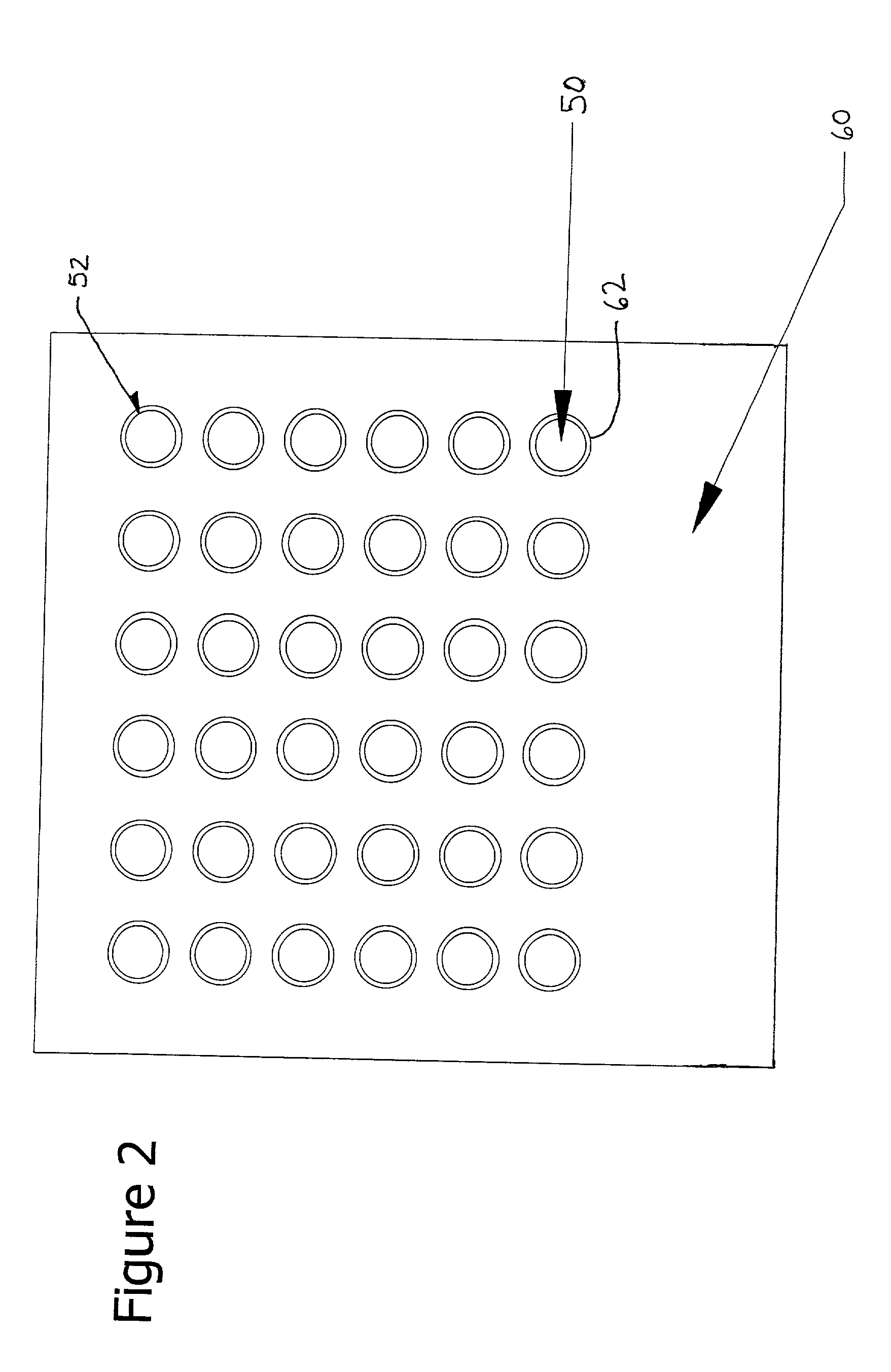

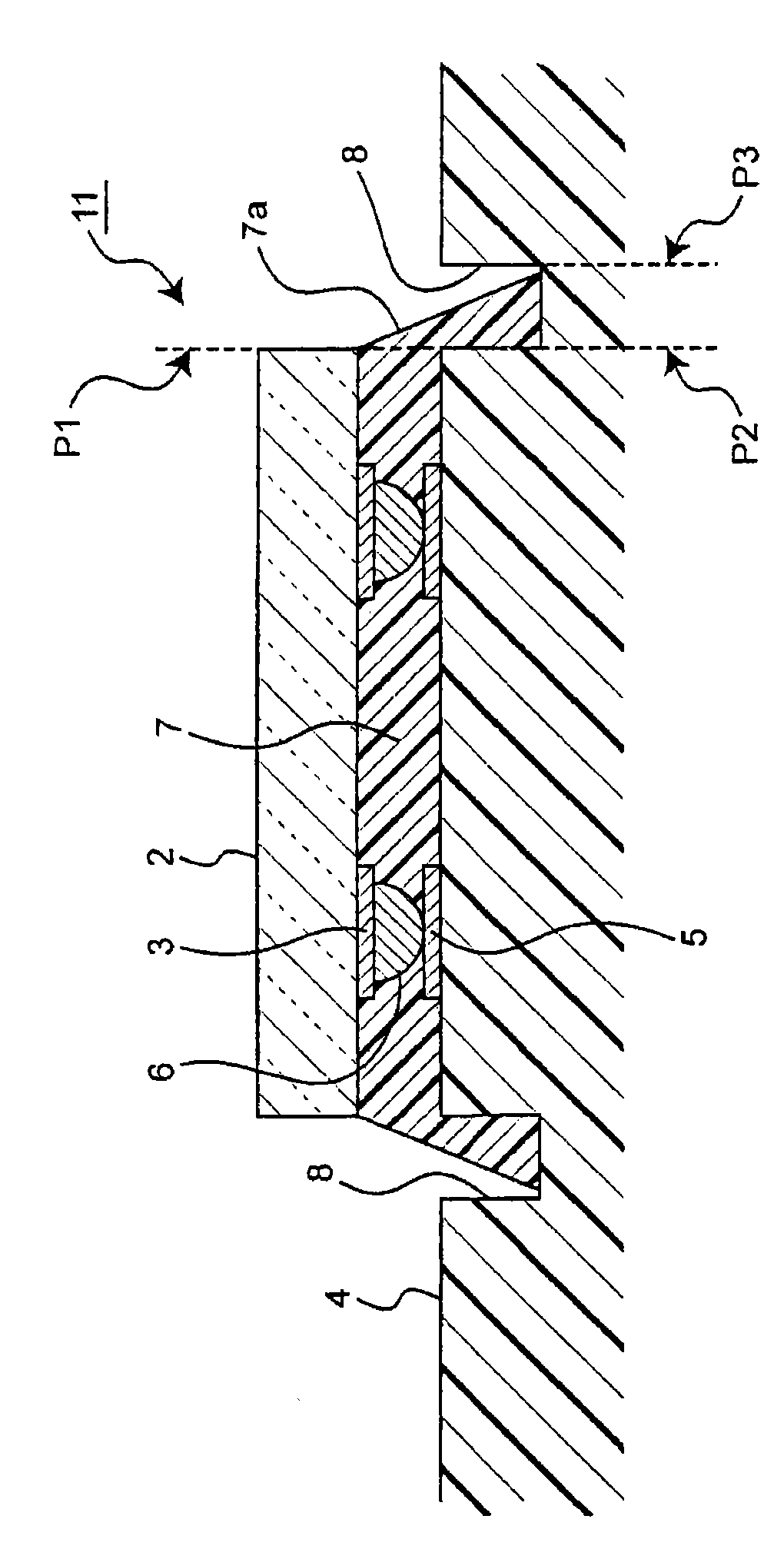

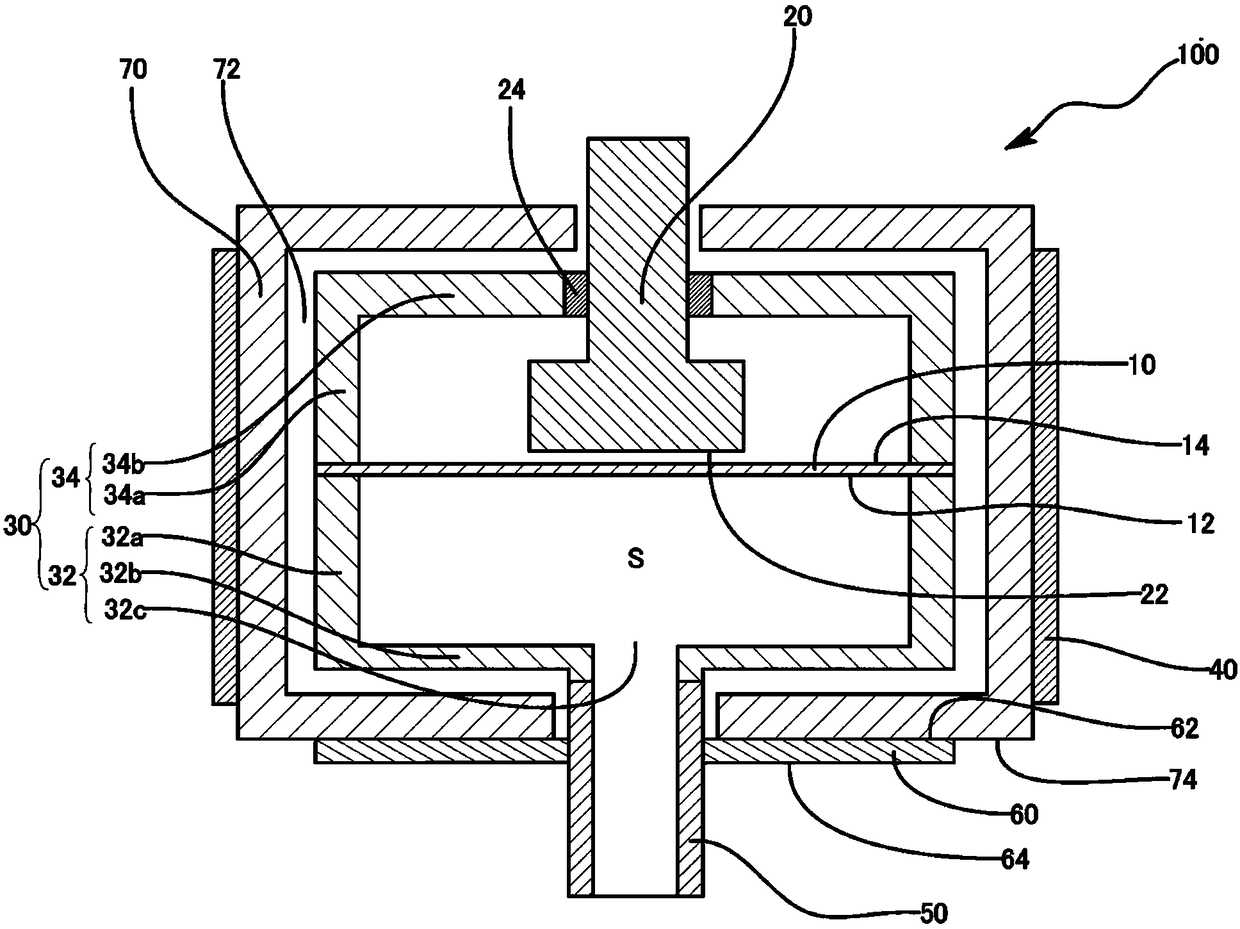

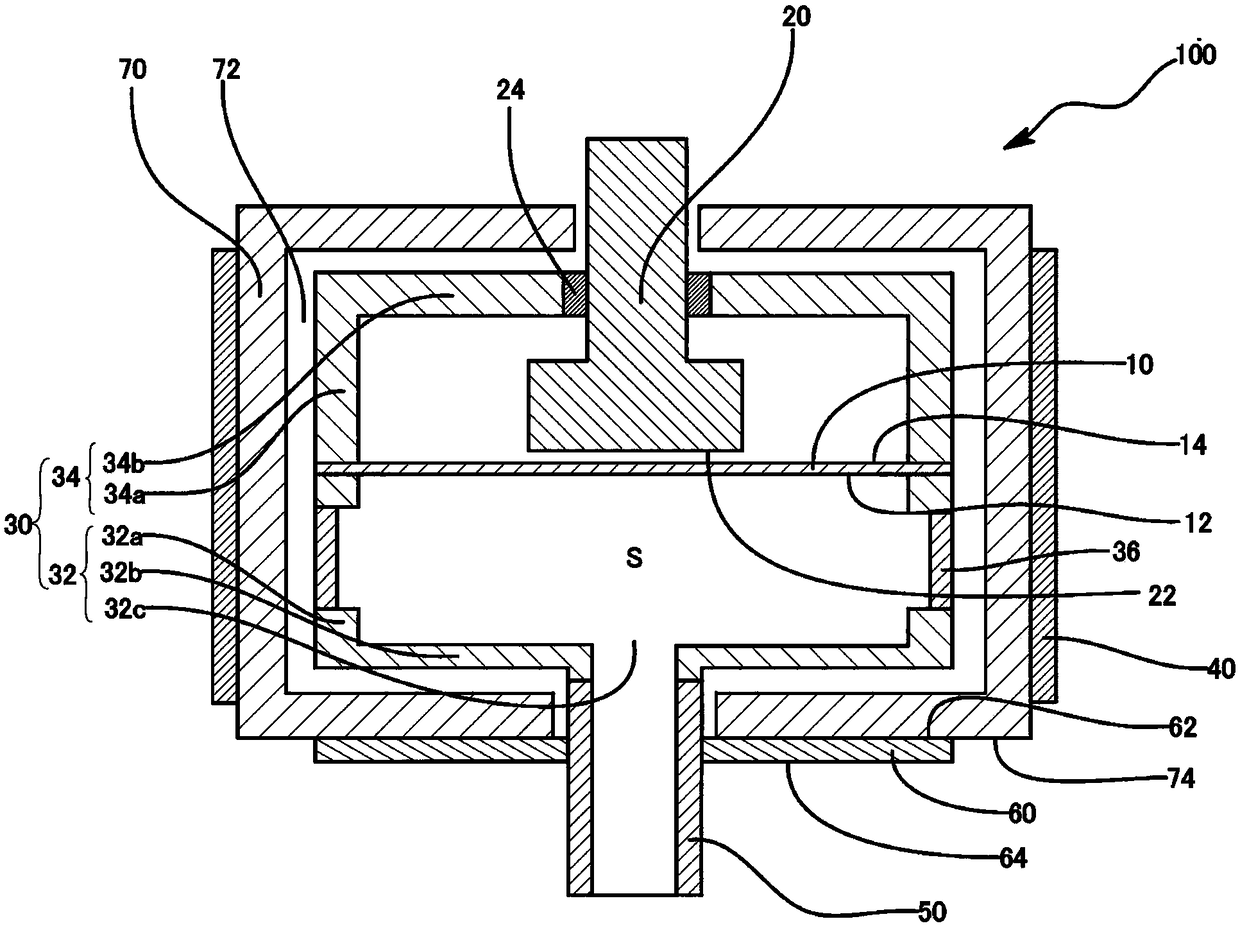

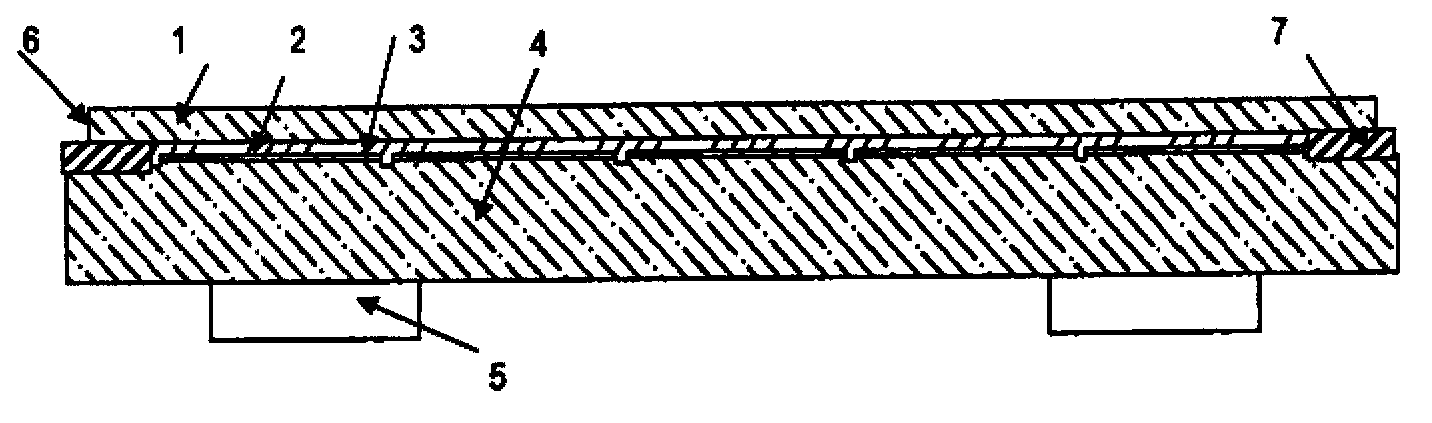

Method and apparatus for minimizing adverse effects of thermal expansion in a heat exchange reactor

InactiveUS7117934B2Improve corrosion resistanceHigh strengthChemical/physical/physico-chemical reactor detailsHydrogen/synthetic gas productionThermal expansionEngineering

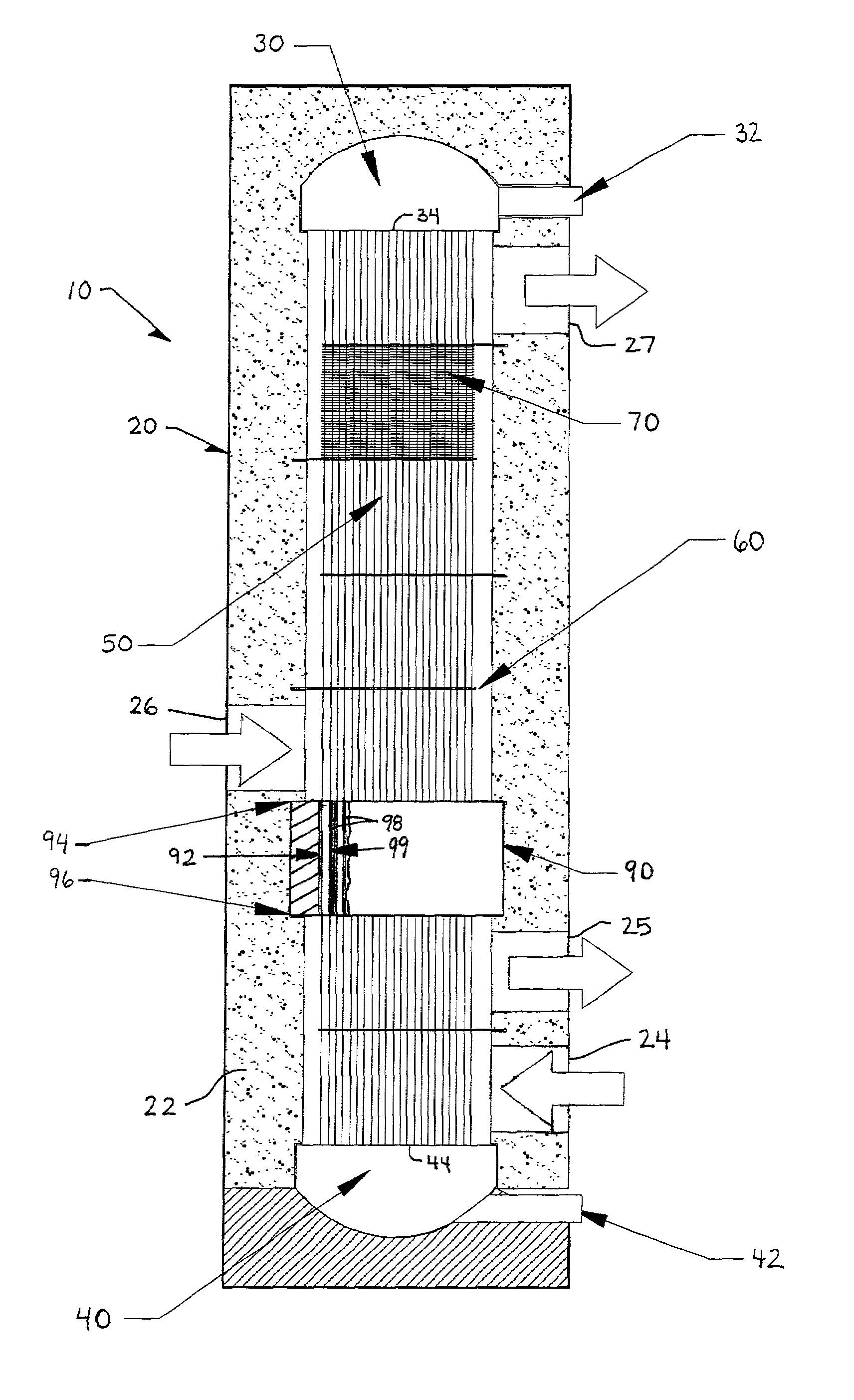

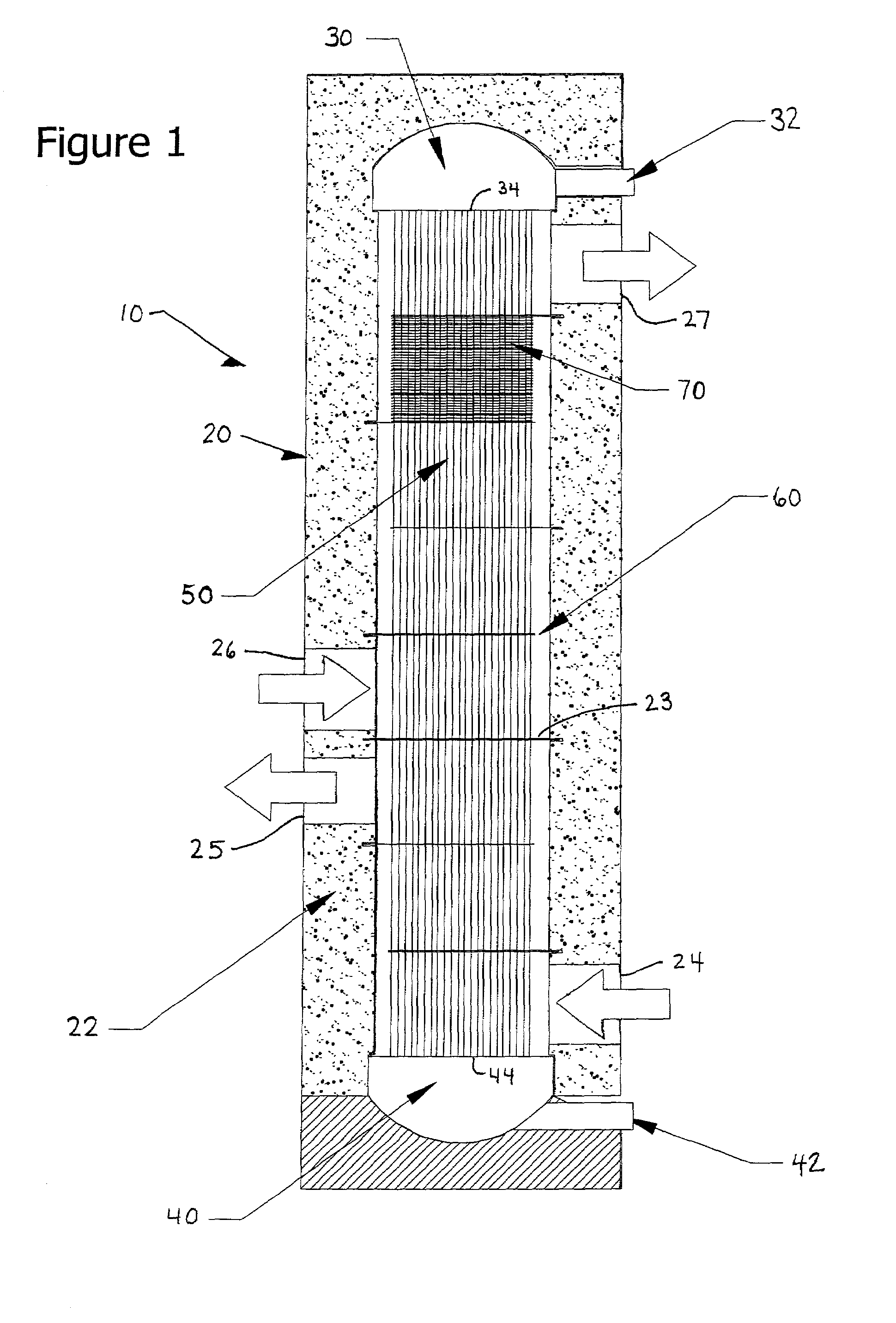

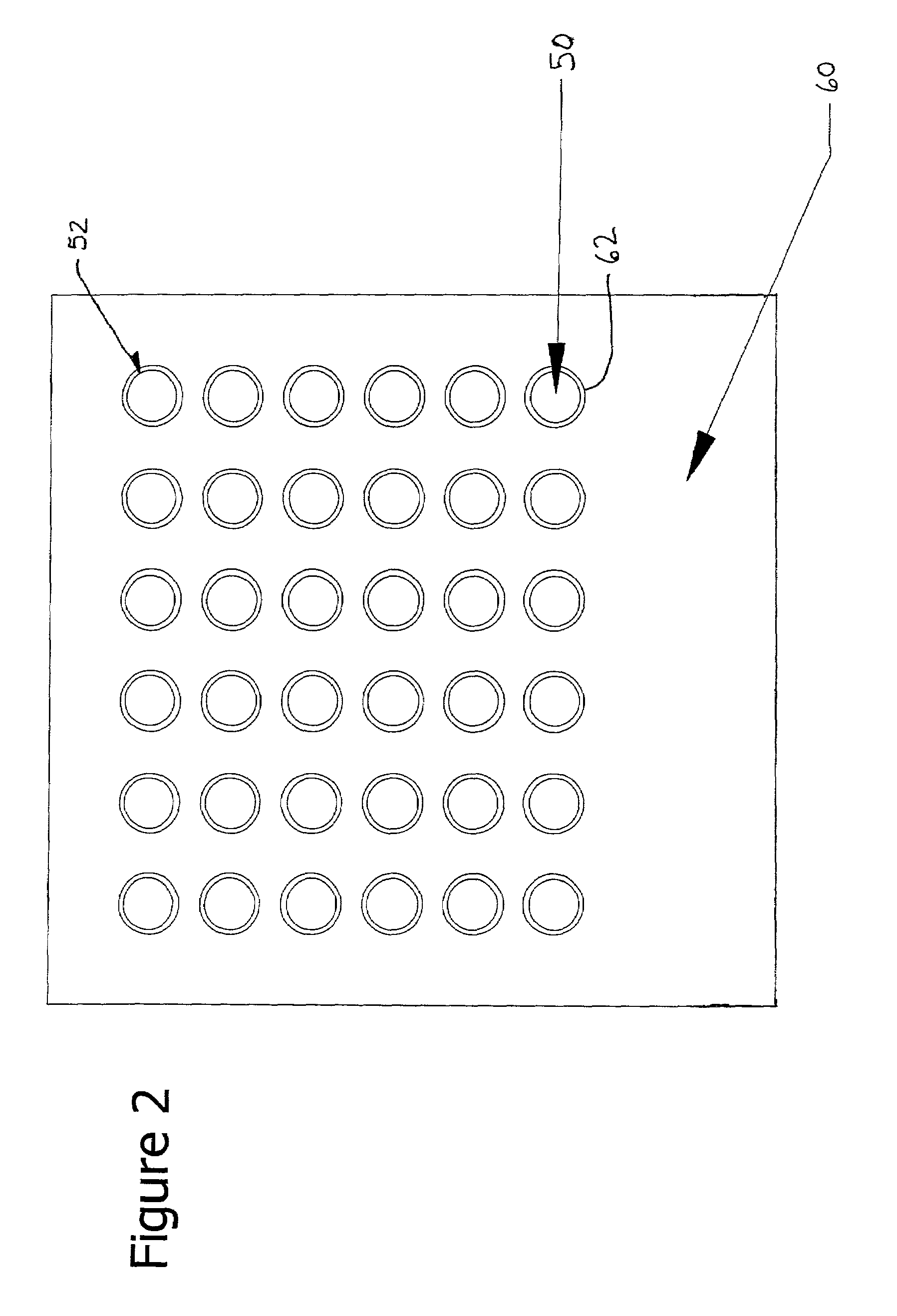

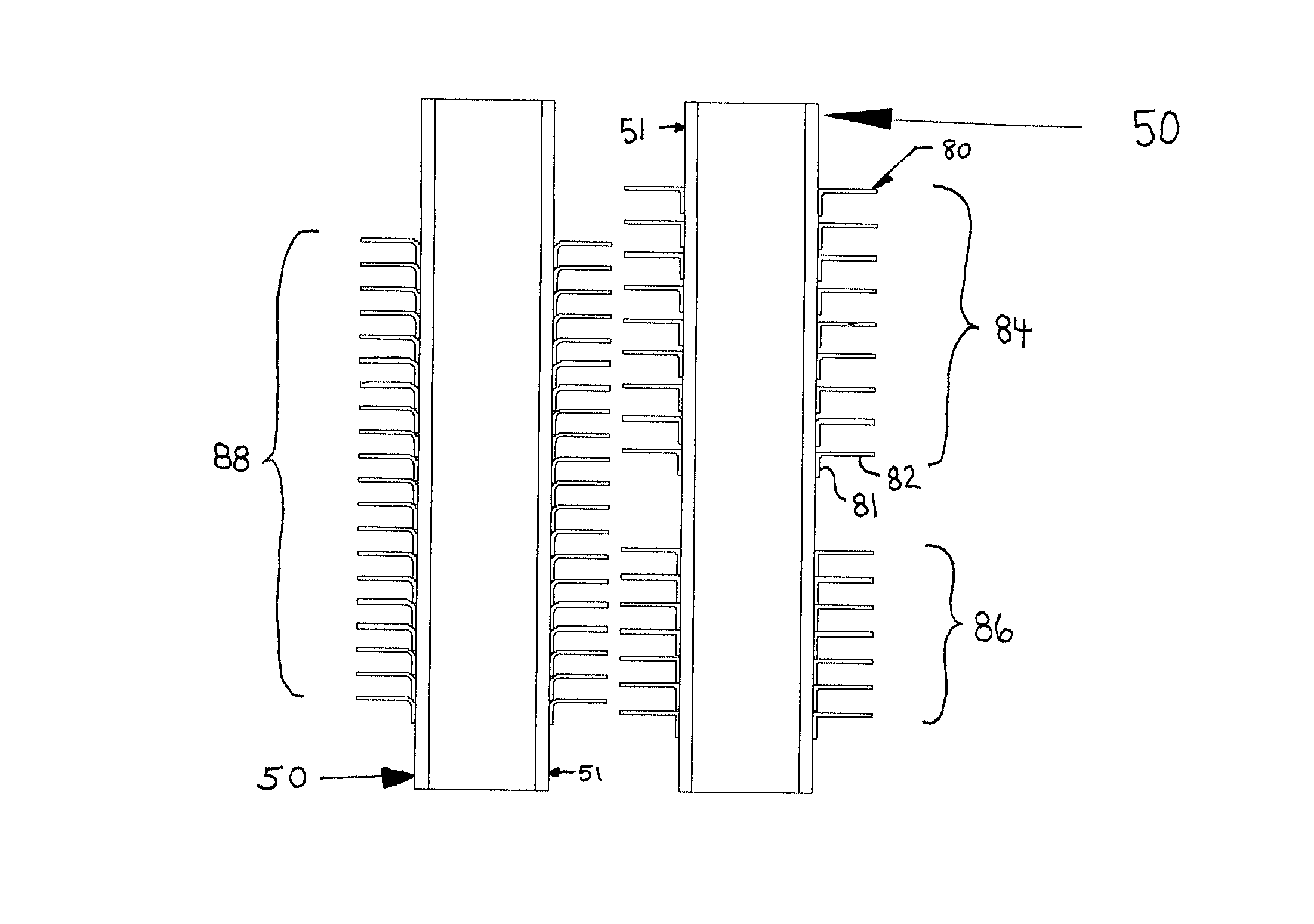

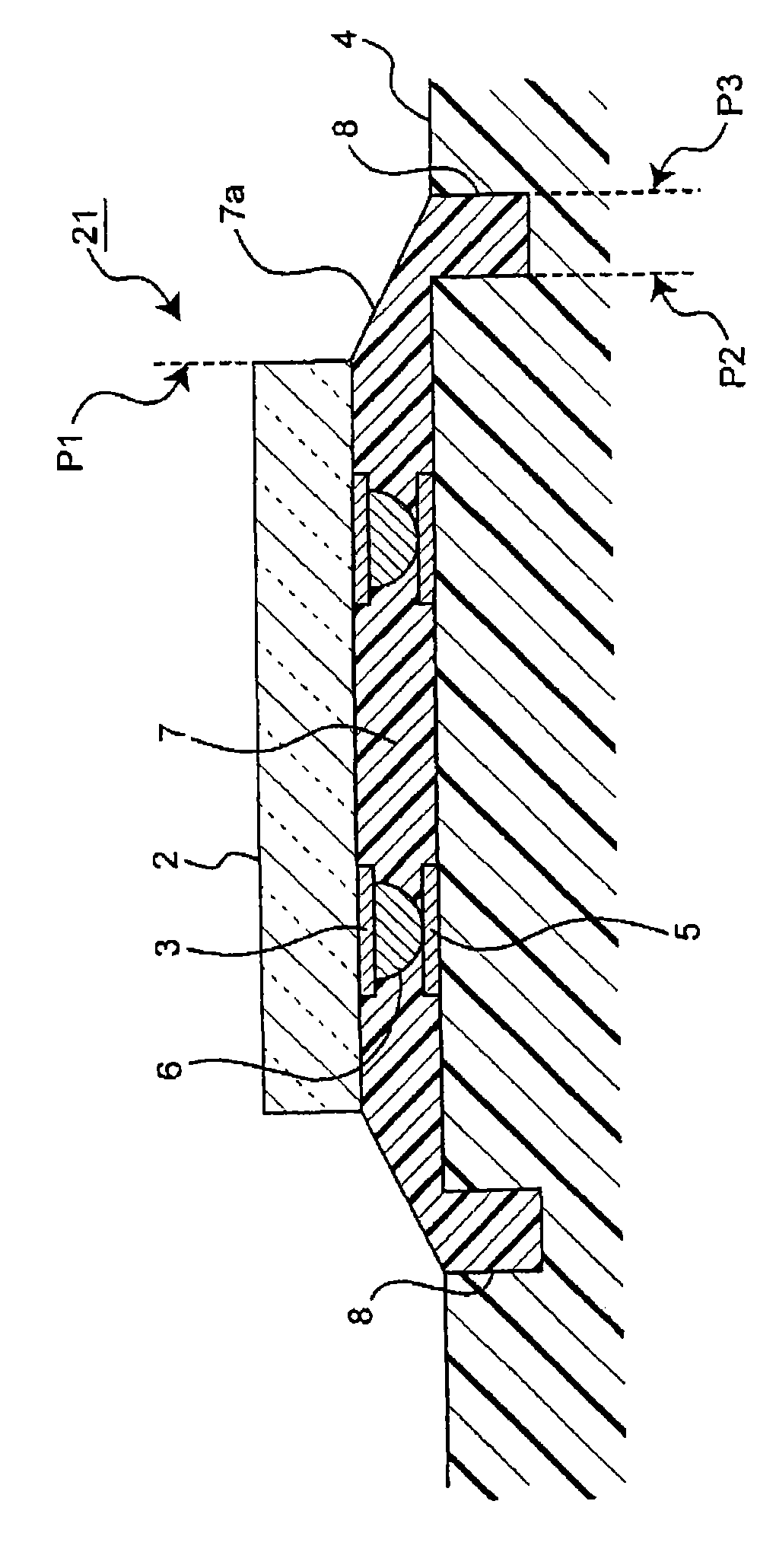

A heat exchange reactor including a housing, a plurality of tubes mounted in the housing and configured to carry a first fluid, and a baffle having a plurality of holes receiving the tubes. The baffle is configured to guide a second fluid provided within the housing to flow in a direction generally perpendicular to the tubes. The reactor includes various configurations for minimizing adverse effects of thermal expansion of the baffle and the tubes. The reactor is configured to minimize mechanical interference between the baffle and the tubes in both an operational state and a non-operational state, for example, by shaping the holes in the baffle to take into account thermal expansion. The reactor also includes a thermal insulator along a length of the tubes at a large temperature gradient zone within the reactor. The reactor further includes a heat transfer fin in contact with only one of the tubes.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

Method and apparatus for minimizing adverse effects of thermal expansion in a heat exchange reactor

InactiveUS20030173062A1Minimize adverse effectsMinimize thermal expansion differencesChemical/physical/physico-chemical reactor detailsHydrogen/synthetic gas productionThermal expansionEngineering

A heat exchange reactor including a housing, a plurality of tubes mounted in the housing and configured to carry a first fluid, and a baffle having a plurality of holes receiving the tubes. The baffle is configured to guide a second fluid provided within the housing to flow in a direction generally perpendicular to the tubes. The reactor includes various configurations for minimizing adverse effects of thermal expansion of the baffle and the tubes. The reactor is configured to minimize mechanical interference between the baffle and the tubes in both an operational state and a non-operational state, for example, by shaping the holes in the baffle to take into account thermal expansion. The reactor also includes a thermal insulator along a length of the tubes at a large temperature gradient zone within the reactor. The reactor further includes a heat transfer fin in contact with only one of the tubes.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

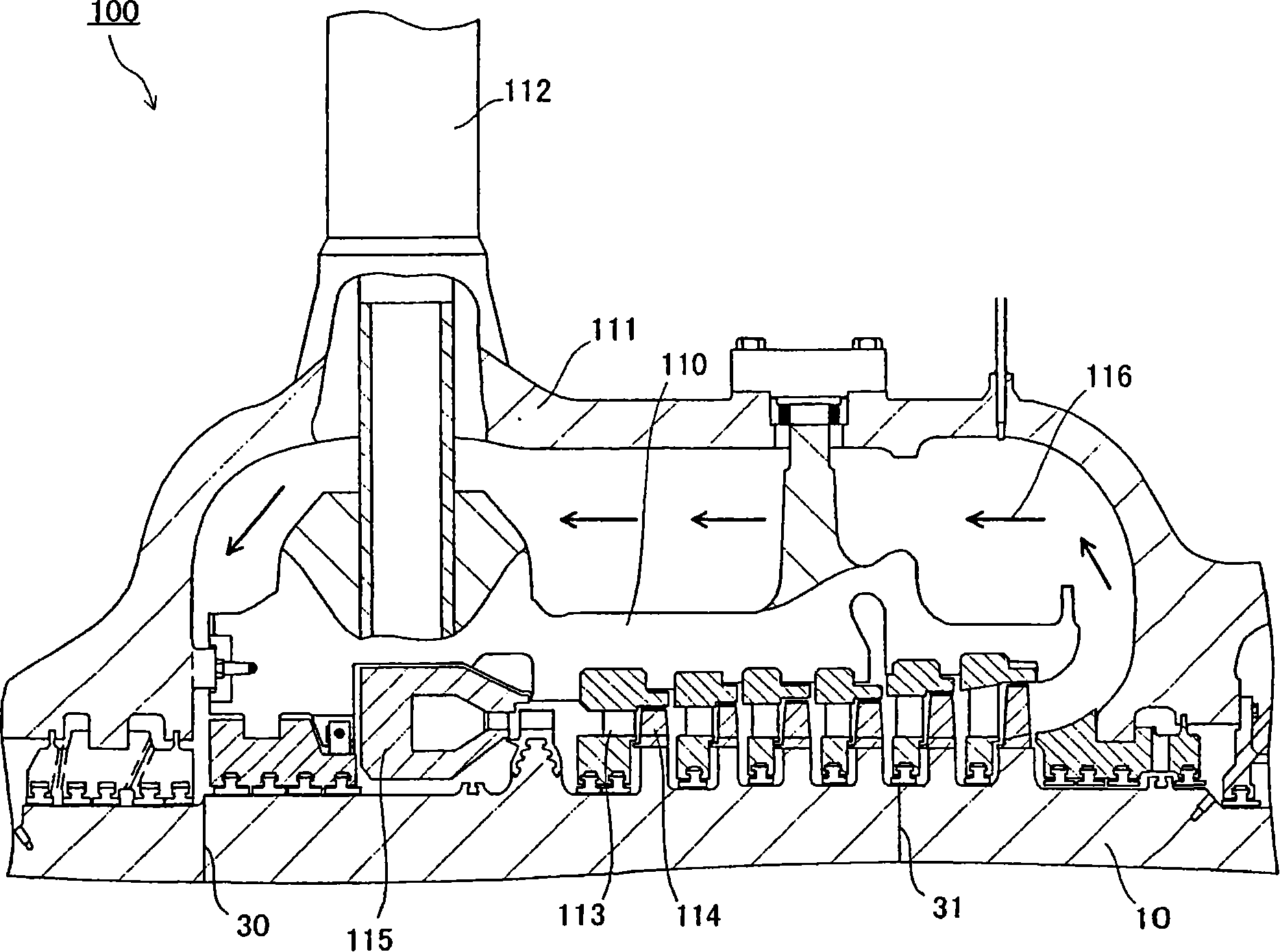

Steam turbine and method of cooling steam turbine

InactiveUS20100008756A1Reduce startup timeMinimize thermal expansion differencesPump componentsWind motor controlGas supplySteam turbine

A steam turbine 20 is provided with a casing 109, a turbine rotor 25 disposed through the casing 109, and labyrinth portions 50, 55 which are disposed at the boundary between the casing 109 and the turbine rotor 25. The steam turbine 20 is further provided with a sealing steam pipe 65 for supplying sealing steam to the labyrinth portions 50, 55 and a gas supply pipe 60 for supplying the labyrinth portions 50, 55 with a cooling gas for cooling the turbine rotor 25 or a heating gas for heating the turbine rotor 25.

Owner:KK TOSHIBA

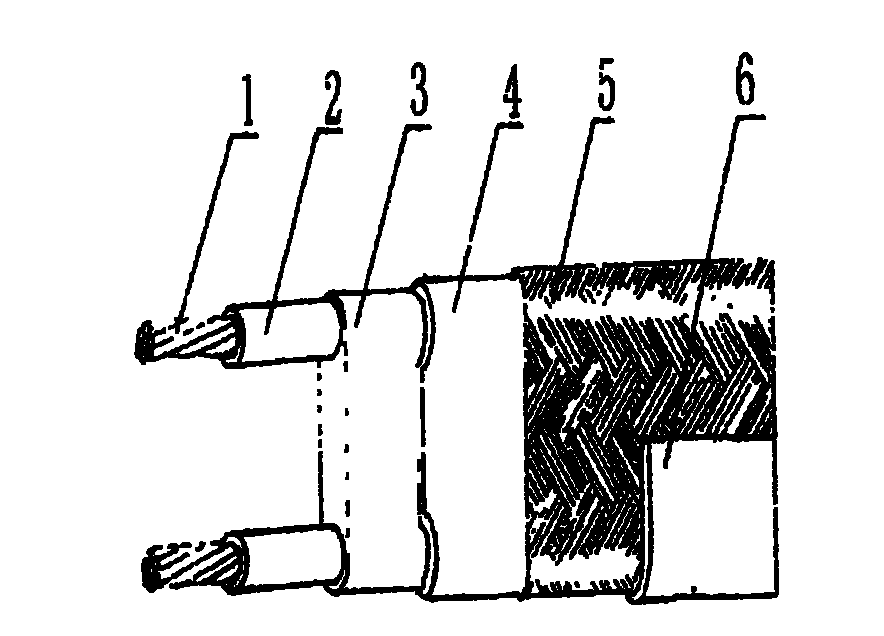

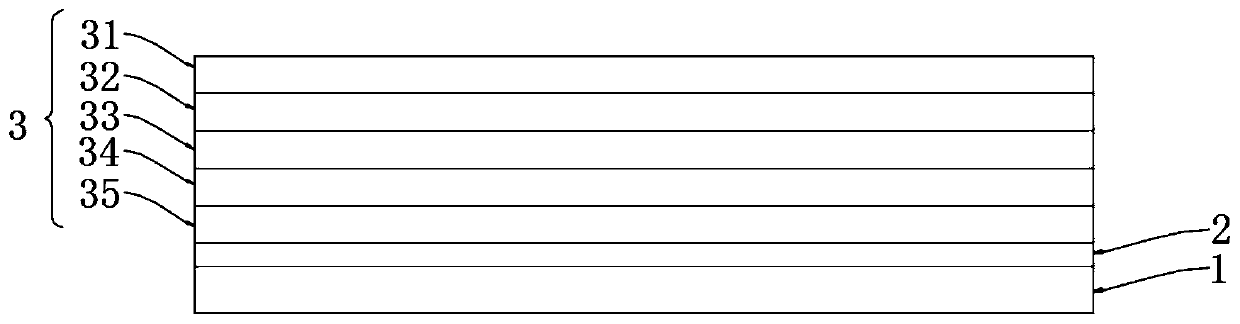

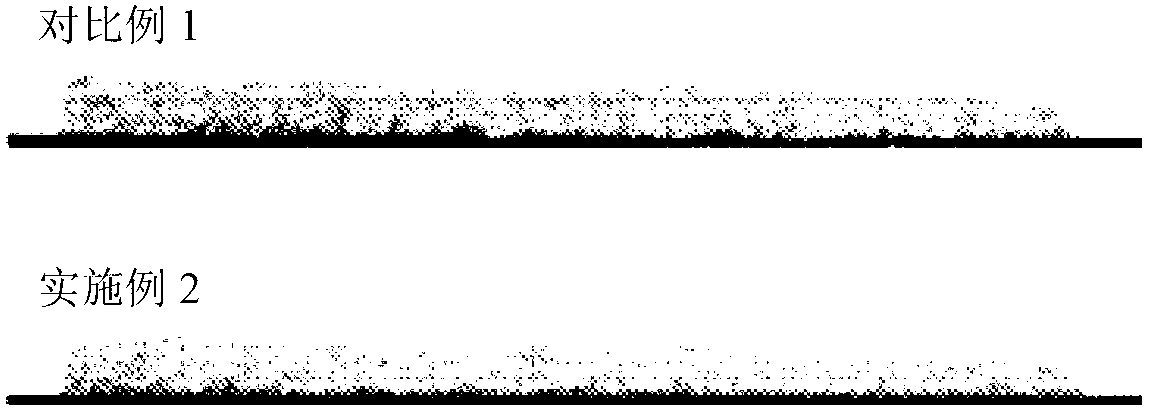

Self-temperature limiting heat tracing belt with dual-layer resin conductor and manufacturing method thereof

InactiveCN101977452AImprove interface contact resistanceExtend your lifeOhmic-resistance electrodesHeating element shapesUltrasound attenuationInsulation layer

The invention relates to a self-temperature limiting heat tracing belt with a dual-layer resin conductor and a manufacturing method thereof. The self-temperature limiting heat tracing belt is characterized by comprising a metal conductive electrode, a resin conductor layer, a heating element and an insulation layer. A shielding layer or a sheath can also be arranged outside the insulation layer. In the invention, the formulas of the resin conductor layer and the heating element are improved, and through the implementation of the technical scheme of the invention, and the problems existing in the aspects that the power attenuation of the traditional heat tracing belt is serious, the starting current of the traditional heat tracing belt becomes big, the heat tracing belt is burnt out frequently, the performance is not stable and the like can be well solved. The invention greatly improves the performance of the heat tracing belt, has the advantages of small starting current and high heat tracing belt temperature and is suitable for the industrial application.

Owner:王崇

Filter

InactiveCN102222811AMinimize thermal expansion differencesReduce crackingWaveguide type devicesThermal expansionEngineering

The invention discloses a filter relating to the field of communication equipment. The filter can reduce the possibility that a welding spot of a medium resonator is cracked owning to the difference of thermal expansion coefficient. The filter provided by the embodiment of the invention comprises a medium resonator, a chamber body and a connecting piece, wherein the medium resonator is arranged in the chamber body; the medium resonator is welded on the connecting piece that is connected with the chamber body together; the medium resonator is not directly contacted with the chamber body; the difference of the thermal expansion coefficient of the connecting piece and the thermal expansion coefficient of the medium resonator is less than that of the thermal expansion coefficient of the chamber body and the thermal expansion coefficient of the medium resonator, and / or the connecting piece is a deformation damping structural part with the elastic deformation capability higher than that of the chamber body. The filter is applied to the design concept on a novel filter and is mainly applied to a novel comb-shaped linear medium resonation mode.

Owner:HUAWEI MACHINERY

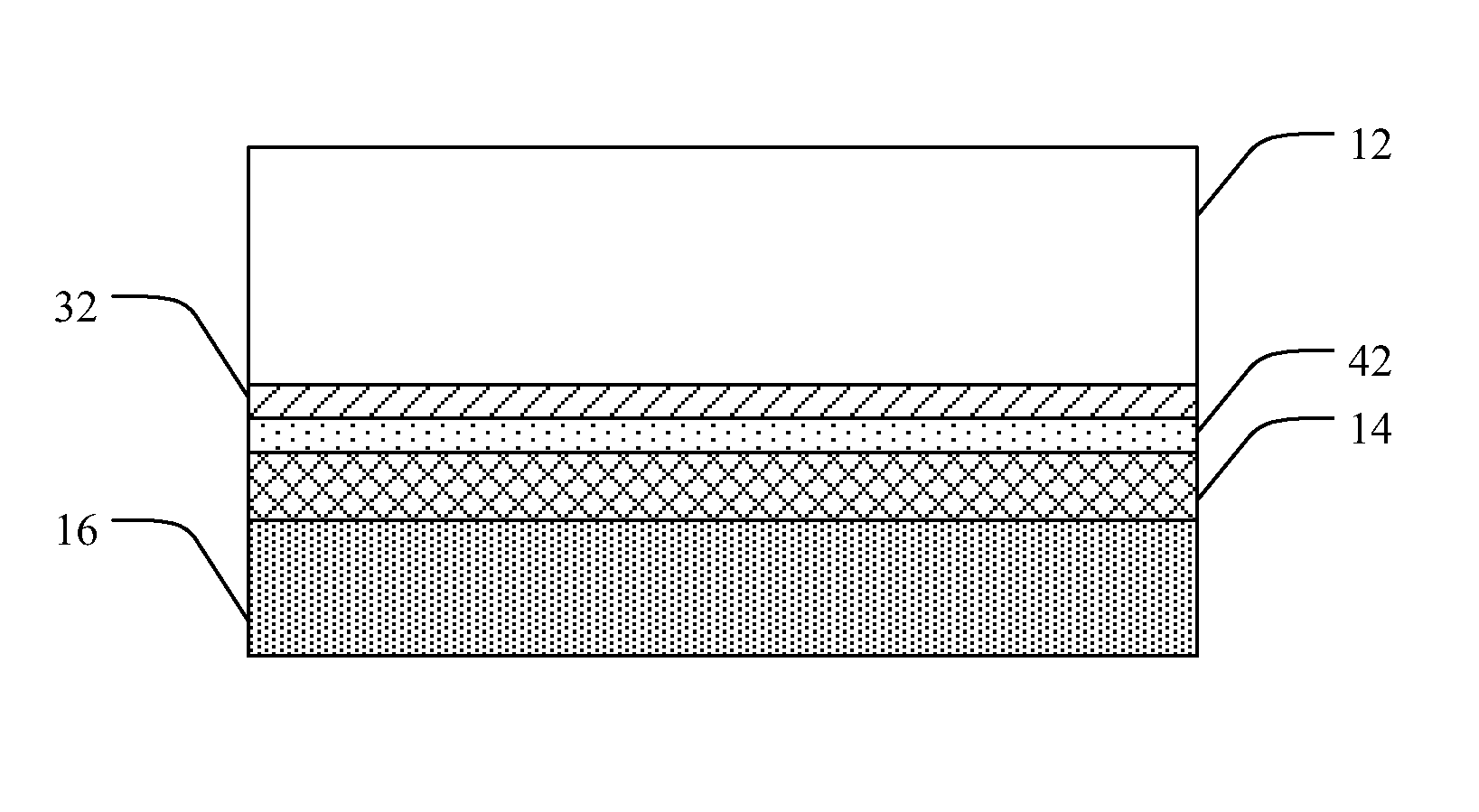

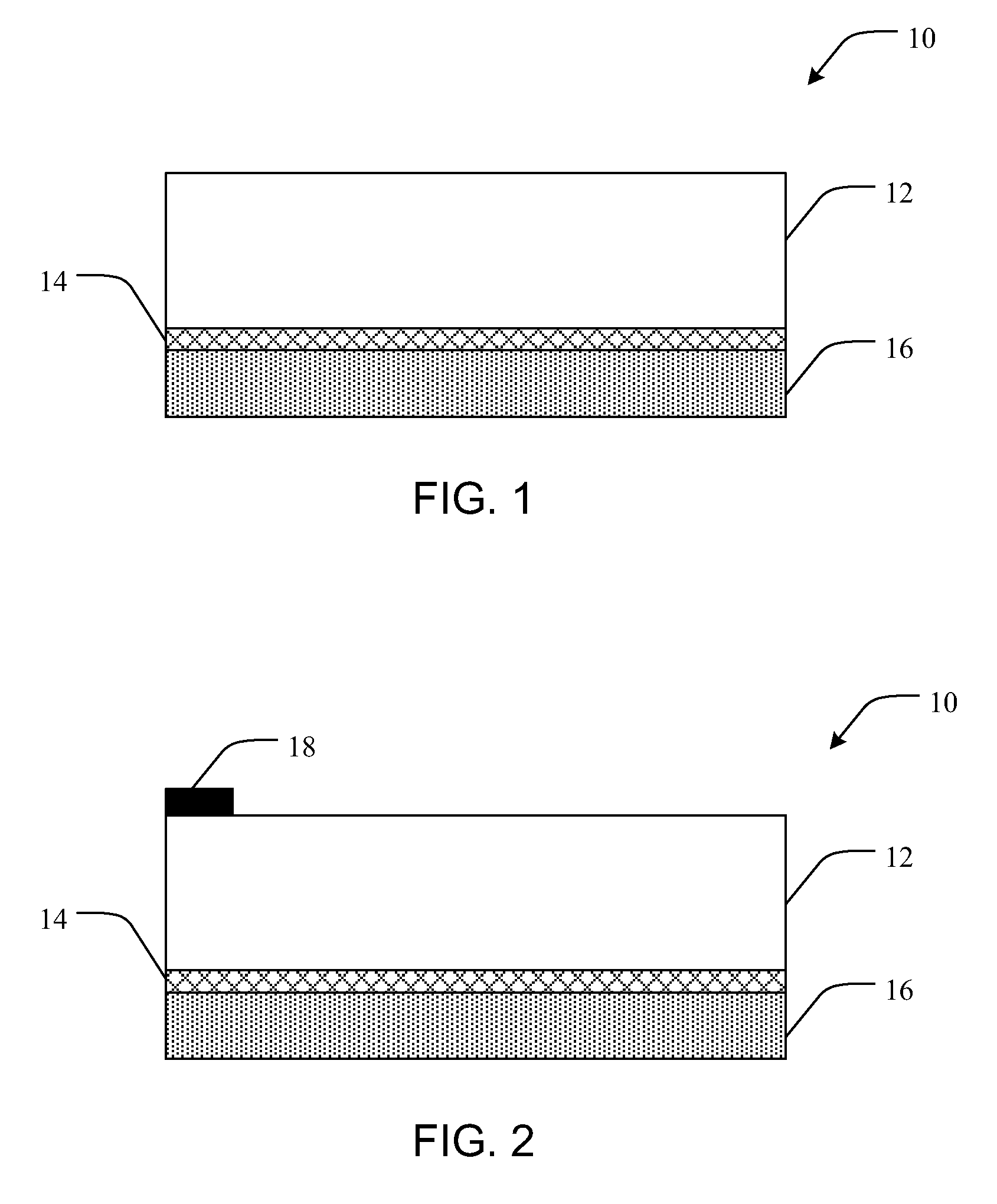

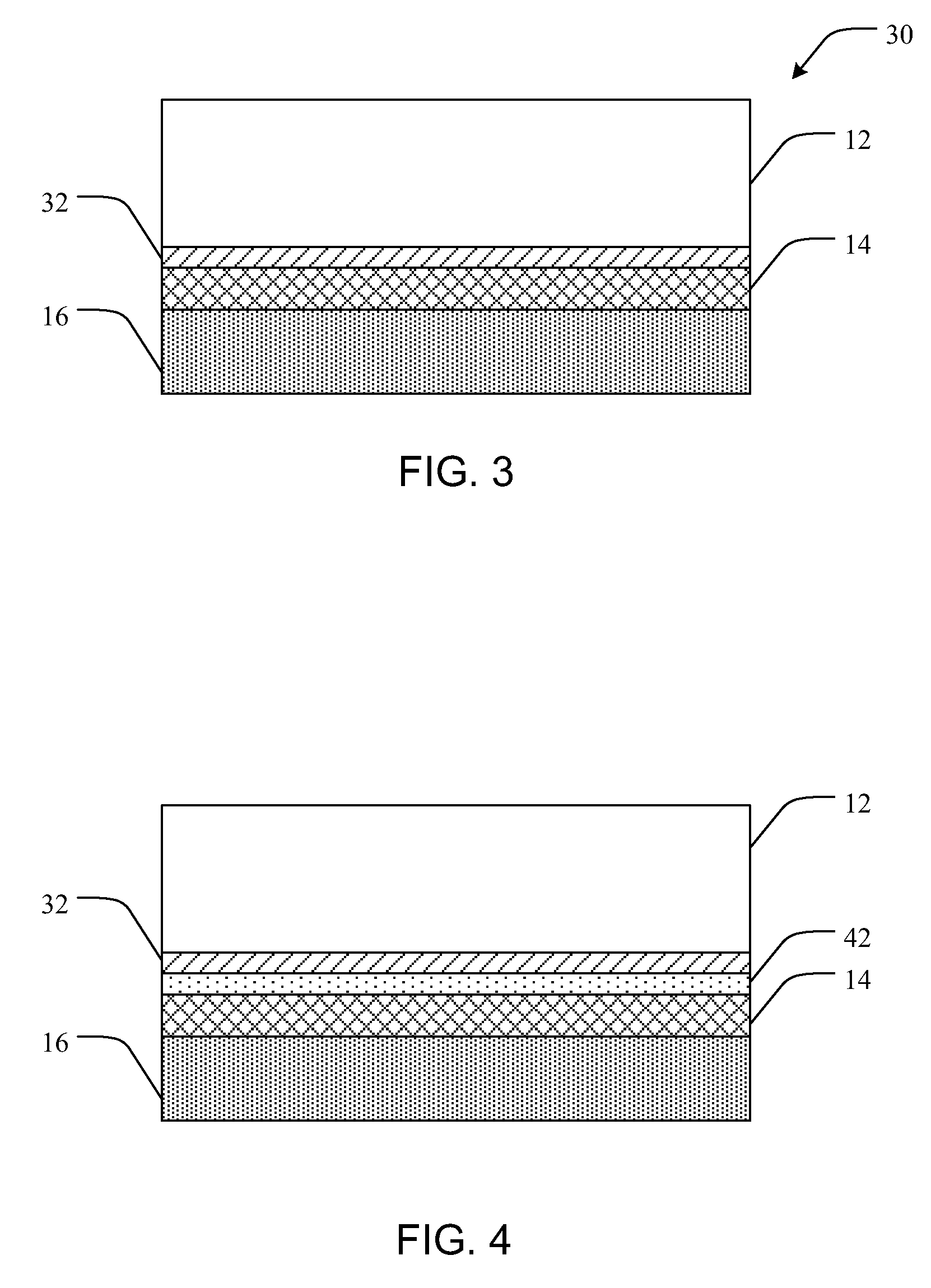

Stress Regulated Semiconductor Devices and Associated Methods

InactiveUS20120280253A1Minimize thermal expansion differencesReduce stressSemiconductor/solid-state device detailsSolid-state devicesCarbon layerSemiconductor package

Stress regulated semiconductor devices and associated methods are provided. In one aspect, for example, a stress regulated semiconductor device can include a semiconductor layer, a stress regulating interface layer including a carbon layer formed on the semiconductor layer, and a heat spreader coupled to the carbon layer opposite the semiconductor layer. The stress regulating interface layer is operable to reduce the coefficient of thermal expansion difference between the semiconductor layer and the heat spreader to less than or equal to about 10 ppm / ° C.

Owner:RITEDIA CORPORATION

High temperature roll

InactiveUS20100218559A1Minimize thermal expansion differencesReduce fiber contentGlass transportation apparatusGlass forming apparatusThermal dilatationMechanical engineering

The present invention describes a roll for use in glass manufacture, especially non-dusting TFT glass. The roll may include a hollow fused silica cylinder. End caps are mechanically fixed to the roll. Pulling flats are fixed in place by inner and outer end plates. A compression fitting secures at least the outer end plate to the roll. The roll may be reinforced with an internal metal rod that is secured to the shaft by a plurality of supports. The supports accommodate differences in thermal expansion.

Owner:VESUVIUS CRUCIBLE CO

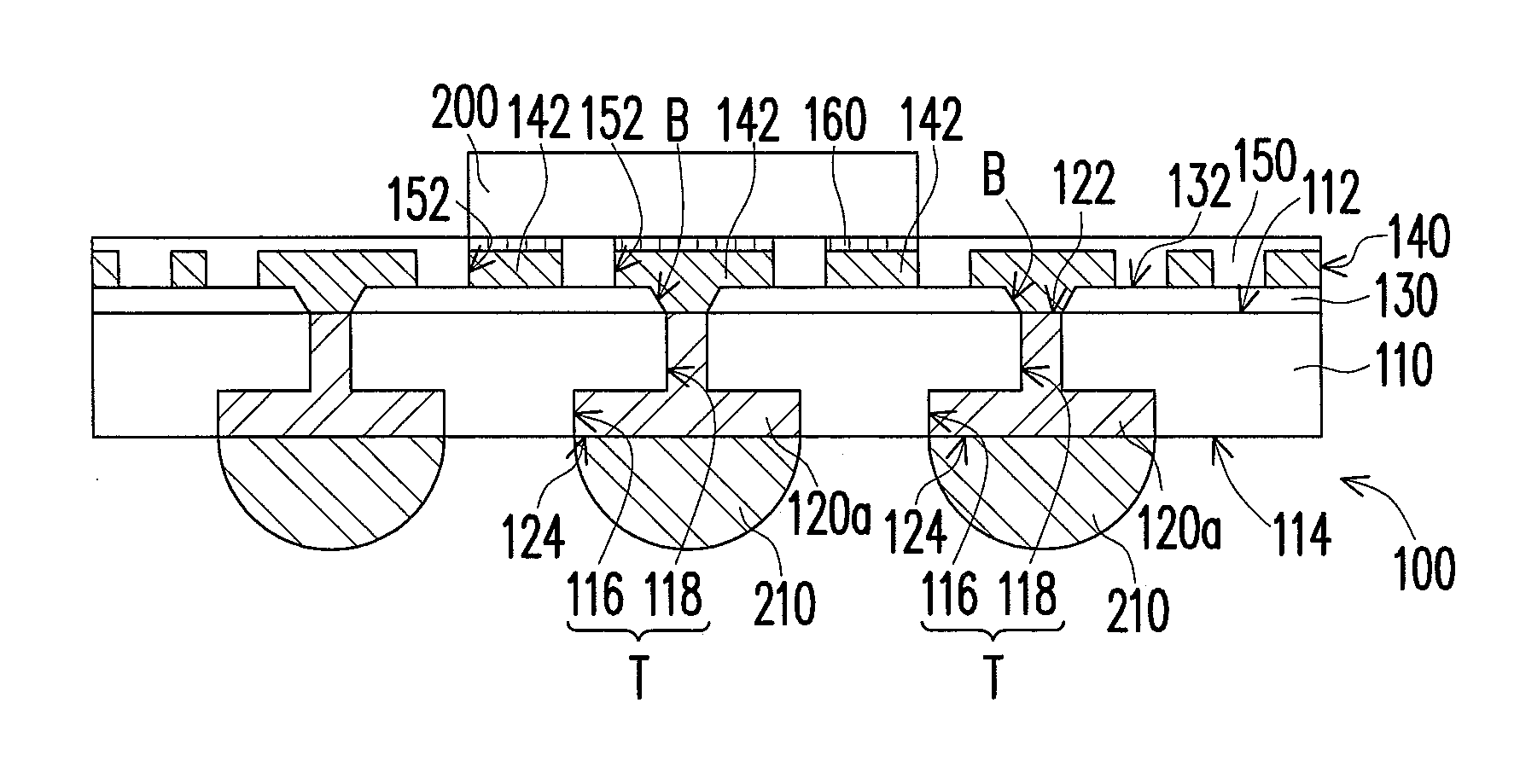

Semiconductor element mounting structure and semiconductor element mounting method

InactiveCN101578695AAvoid internal damageReduced extension areaSemiconductor/solid-state device detailsSolid-state devicesThermal expansionEngineering

On a substrate surface at a position facing an outer circumference end portion of a semiconductor element, a recessed section wherein a sealing adhesive resin is partially arranged is formed. Thus, while suppressing expansion of an arrangement region of a fillet portion (a portion spreading toward bottom) of the sealing adhesive resin, the inclination angle is increased. A stress load generated at the periphery of the semiconductor element due to thermal expansion differences and thermal shrinkage differences between members due to heating process and cooling process for mounting is reduced, and internal breakage of a semiconductor element mounting structure is eliminated.

Owner:PANASONIC CORP

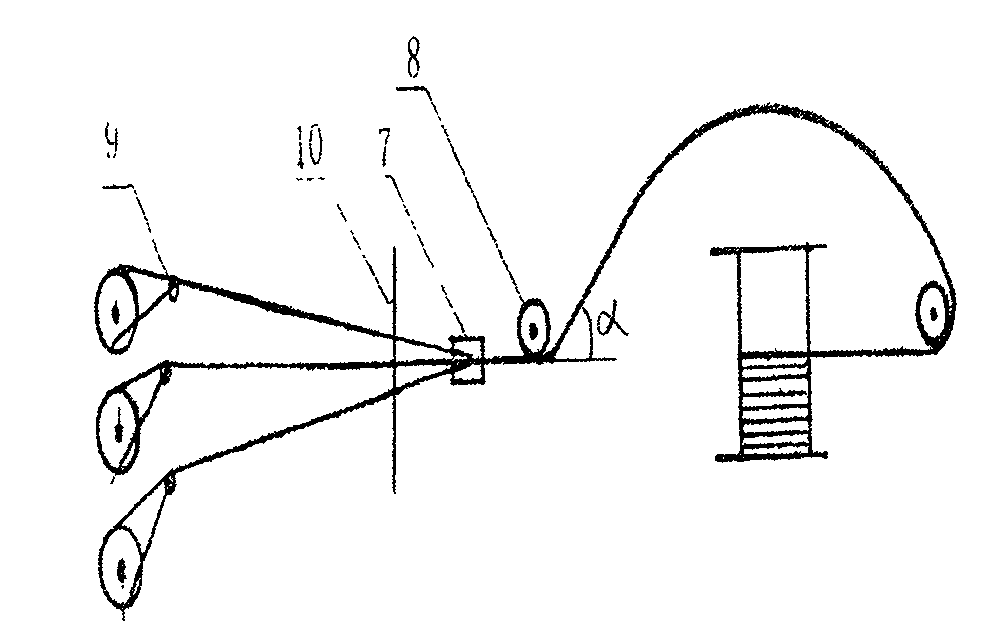

Laser processing method and corresponding laser machining apparatus

InactiveCN101134263AMinimize thermal expansion differencesRaise the temperature differenceGlass severing apparatusWelding/soldering/cutting articlesLaser processingLaser beam machining

The present invention relates to laser machining process and equipment. The laser machining process includes the following steps; setting the workpiece onto the working bench, heating the machined area of the workpiece to preset temperature, and machining the heated machined area with laser beam. The laser machining equipment includes one working bench for bearing the workpiece, one laser source to emit laser beam, and one heating source to preheat the machined area of the workpiece to preset temperature and reduce the temperature difference between the temperature of the machined area and the high temperature the laser beam generates.

Owner:FOXSEMICON INTEGRATED TECHNOLOGY (SHANGHAI) INC +1

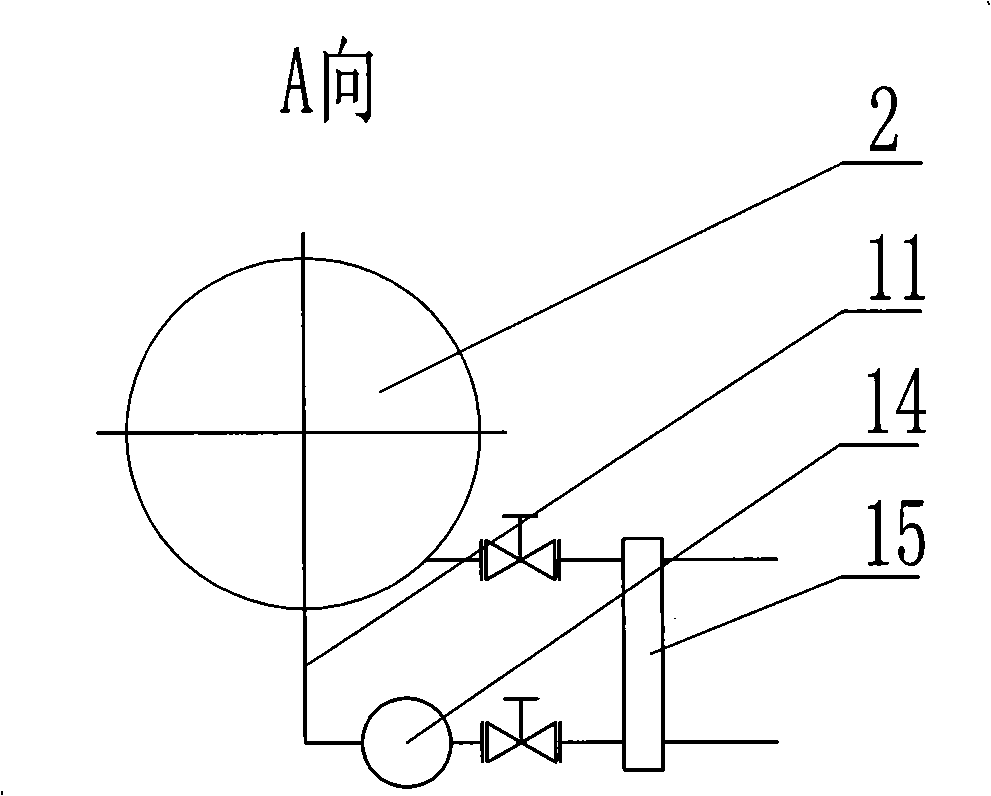

Discharging method and device of autoclave condensation water

InactiveCN101337170ASmall thermal deformationReduce corrosionPressure vessels for chemical processSteam trapProcess engineering

The invention relates to a method for discharging the condensation water of a still kettle, and the method belongs to the technical field of pressure containers. The still kettle is heated for temperature rise, when the temperature in the still kettle is equal to or lower than 100 DEG C, a controller outputs signals at intervals to open a pneumatic valve arranged on a header tank for discharging water according to the detected liquid level or the set discharge interval time of condensation water; when the temperature in the still kettle is larger than or equal to 100 DEG C, the controller output signals at intervals to open the pneumatic valve arranged on the header tank for discharging water according to the detected temperature difference between the upper and the lower parts of the kettle wall or the liquid level, at the same time, a thermal steam trap on a collecting pipe arranged between the bottom part of the still kettle and the header tank also discharges water. The method has the advantages that the condensation water of the still kettle can be completely and fast discharged; the use is safe and reliable; and the normal use of the still kettle can be ensured.

Owner:CHANGZHOU BOILER

Turbine rotor and steam turbine

ActiveCN101158289AMinimize thermal expansion differencesEngine manufactureBlade accessoriesEngineeringAlloy

A turbine rotor 10 is disposed in a steam turbine, into which high-temperature steam of 650°C or more is introduced, and separately configured of the portion made of the Ni-base alloy and the portion made of the CrMoV steel depending on a steam temperature and a metal temperature, and the individual portions having a small difference in coefficient of linear expansion are welded mutually.

Owner:KK TOSHIBA

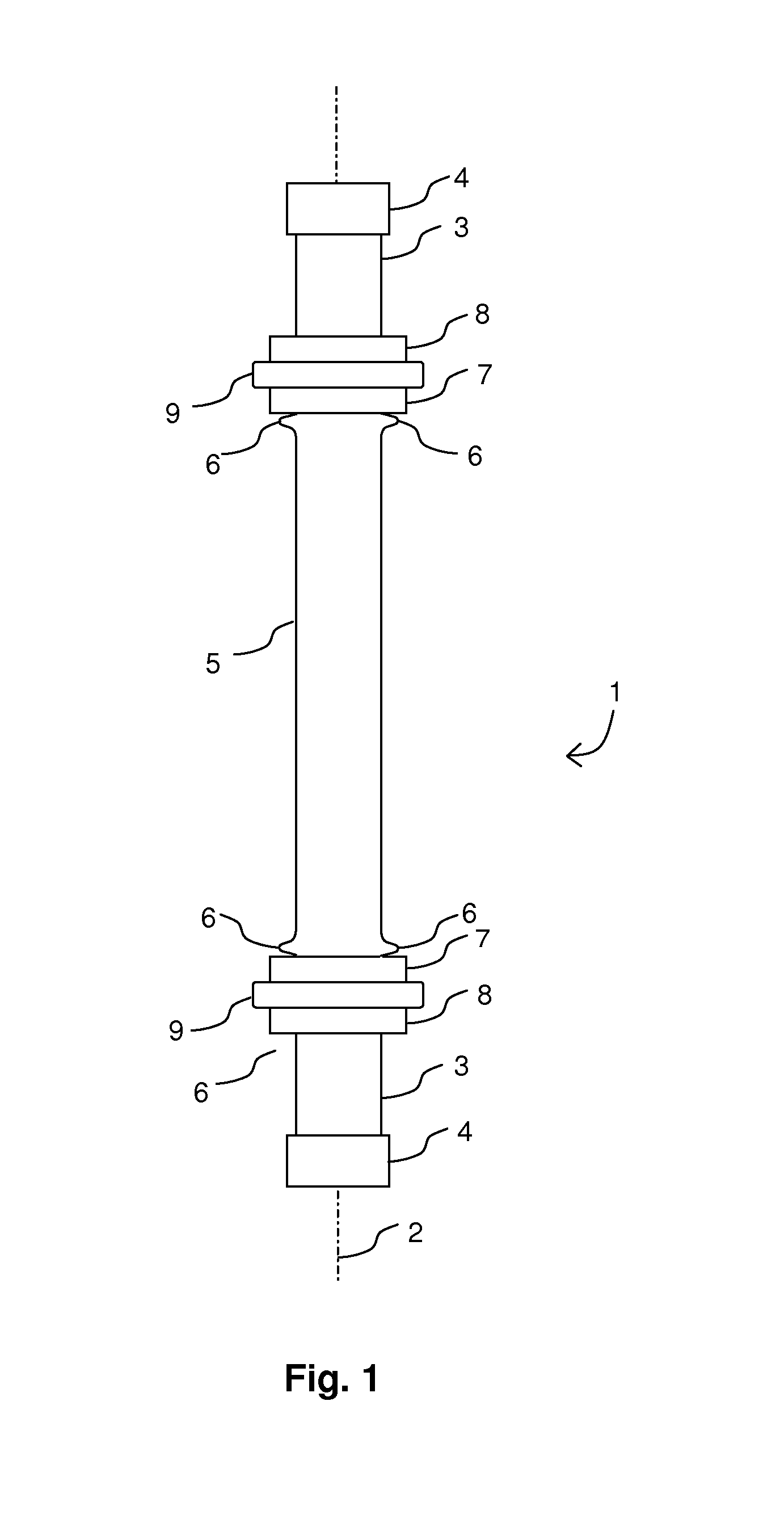

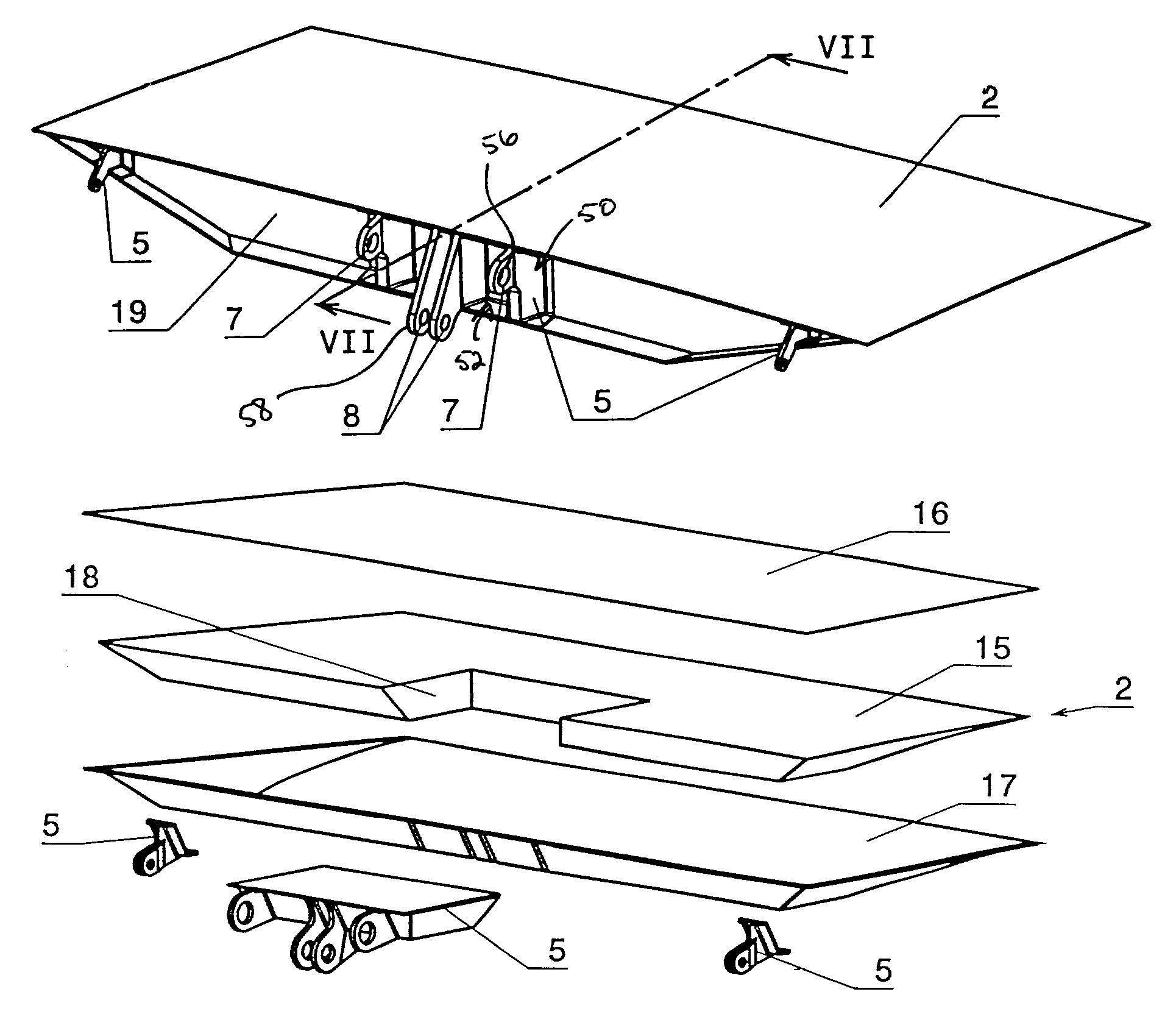

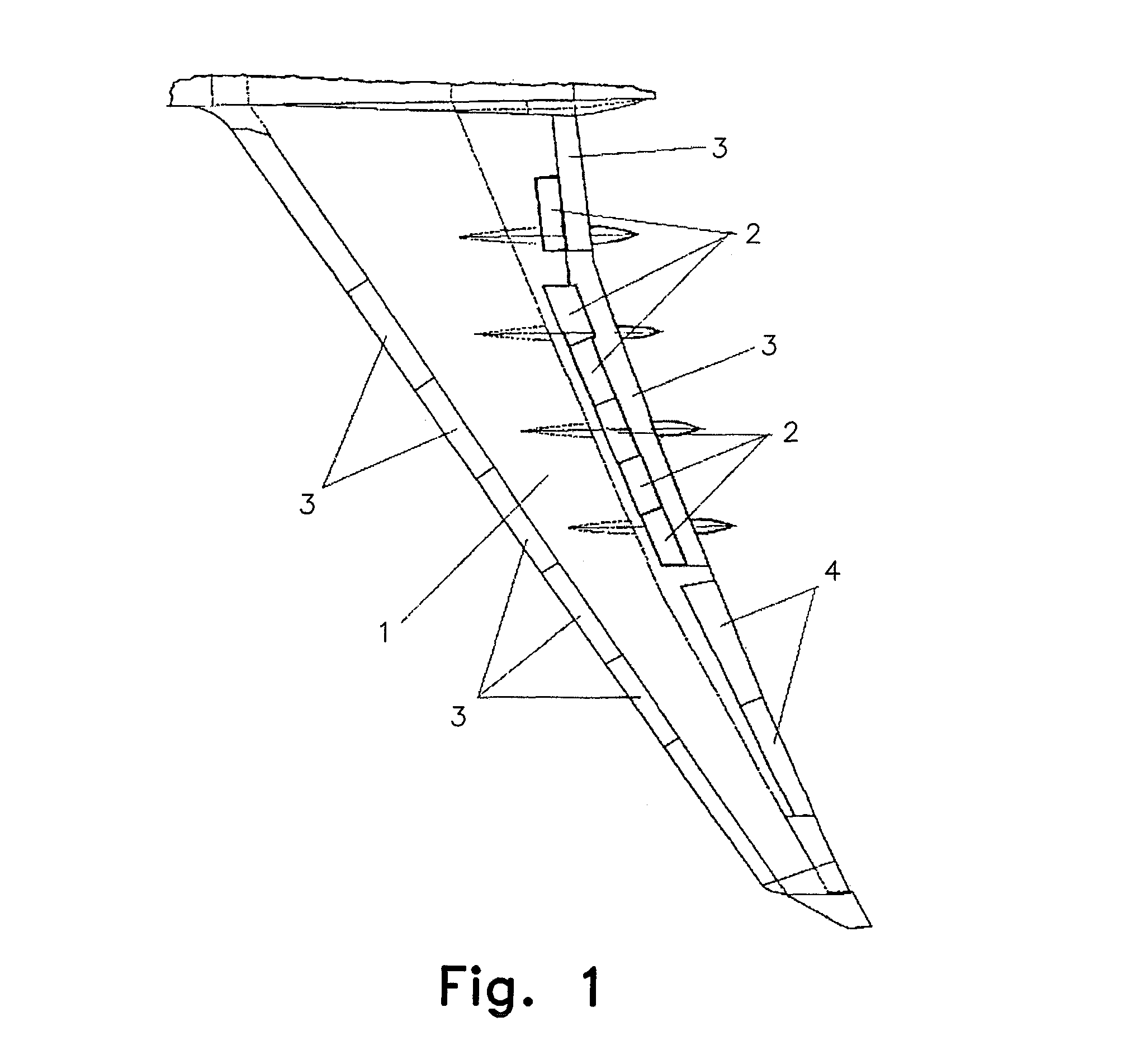

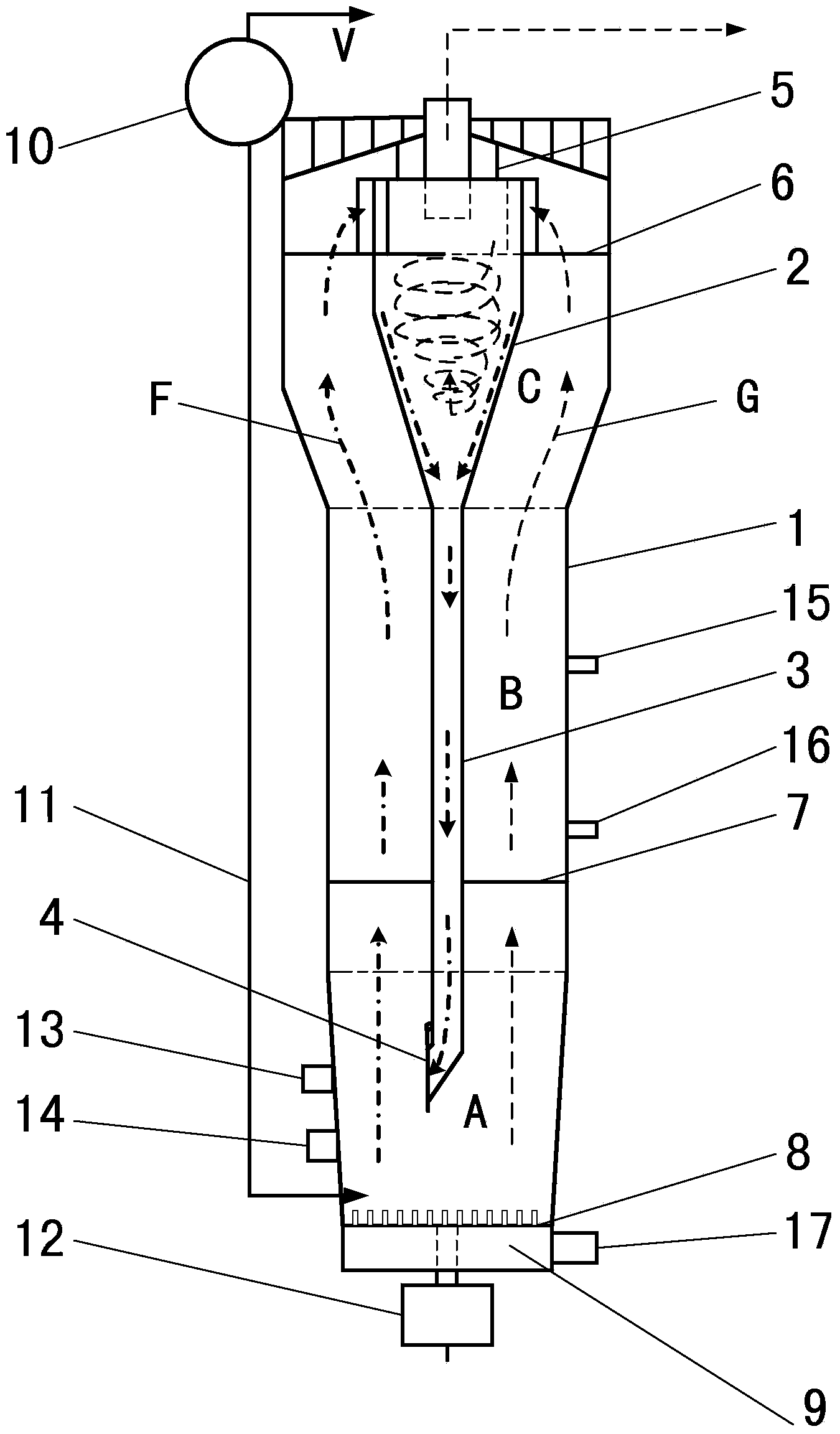

Device for connecting movable parts with structural elements of airplanes or the like

InactiveUS8453972B2Reduce weightGood for long termFuselage framesAircraft stabilisationJet aeroplaneSynthetic materials

A device for connecting movable parts with structural components of airplanes or other high-speed vehicles, including at least one fitting provided with at least one bearing. In order to provide such a device exhibiting low thermal stresses, a low weight, a high bearing capacity and a producibility as simple as possible, it is provided that the at least one fitting is made of a synthetic material and glued with the movable part. The resin transfer molding (RTM)-method is particularly suitable to produce the fitting.

Owner:FACC

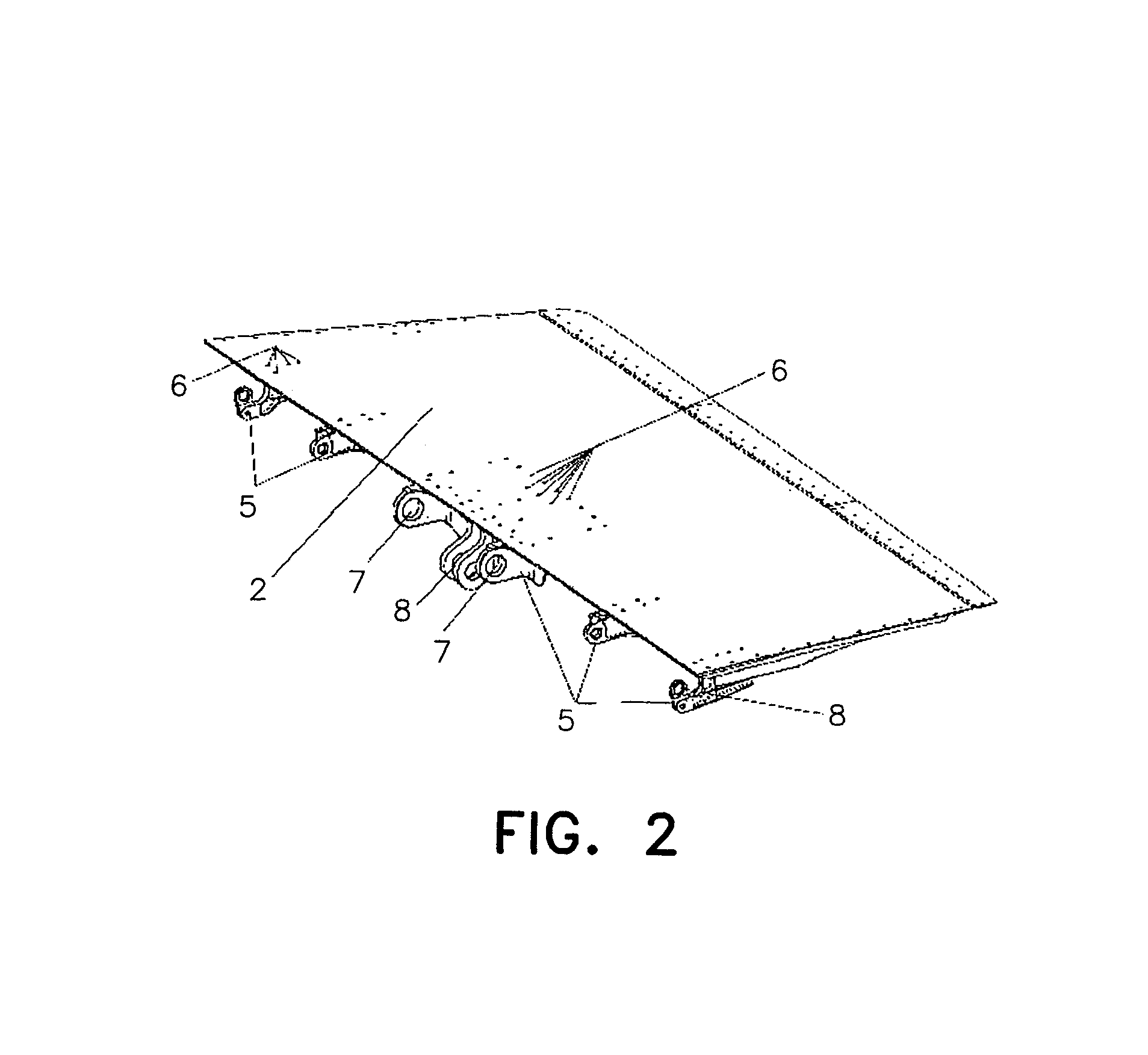

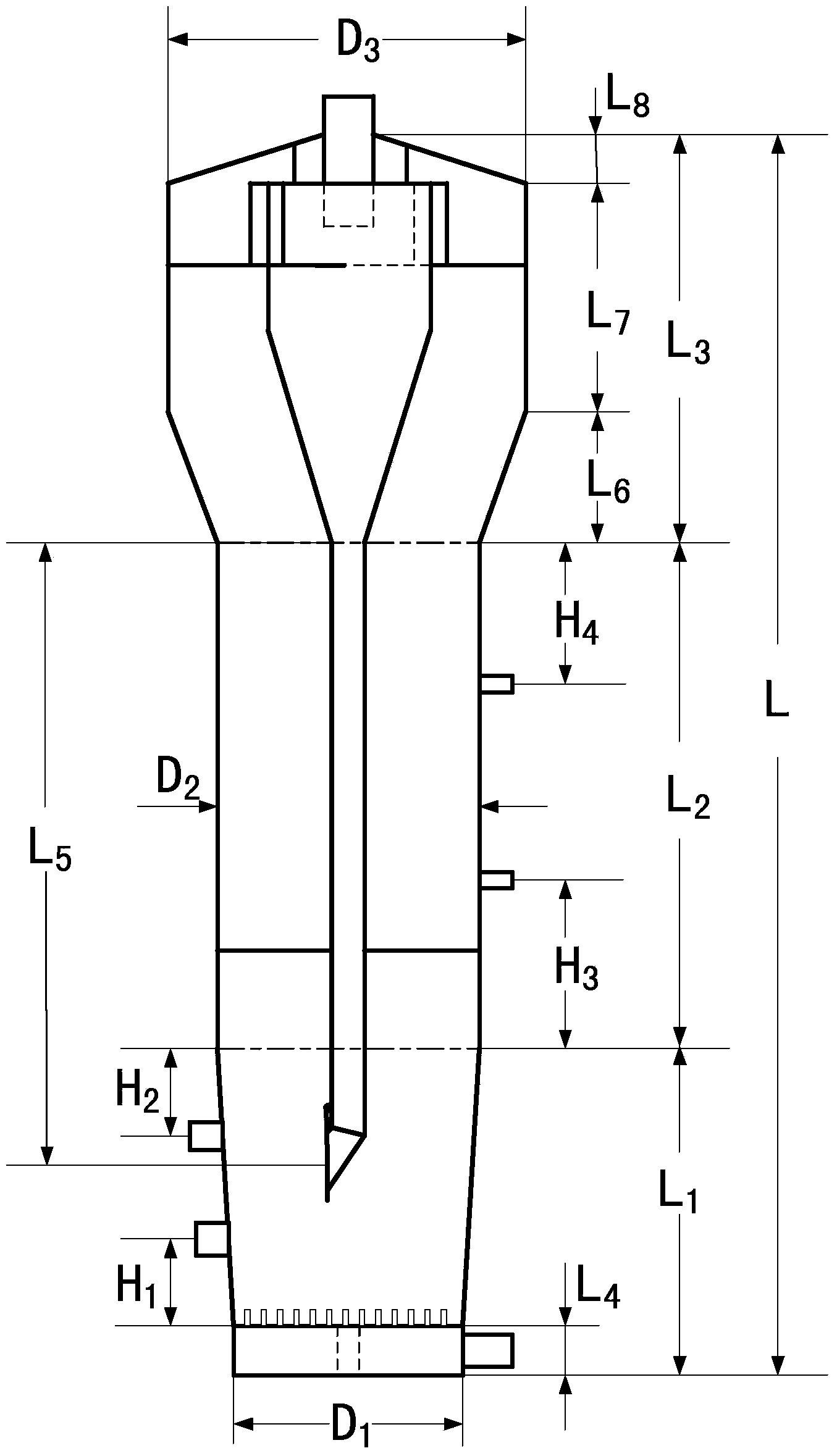

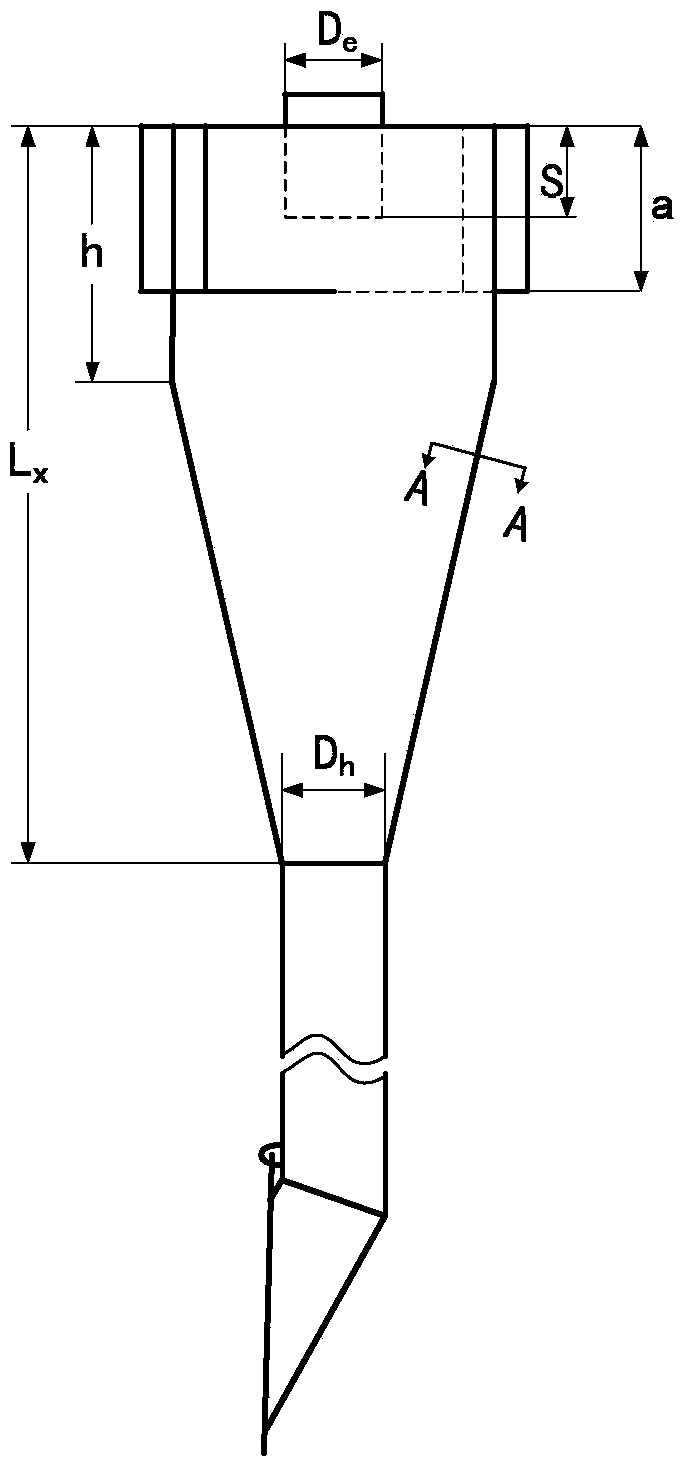

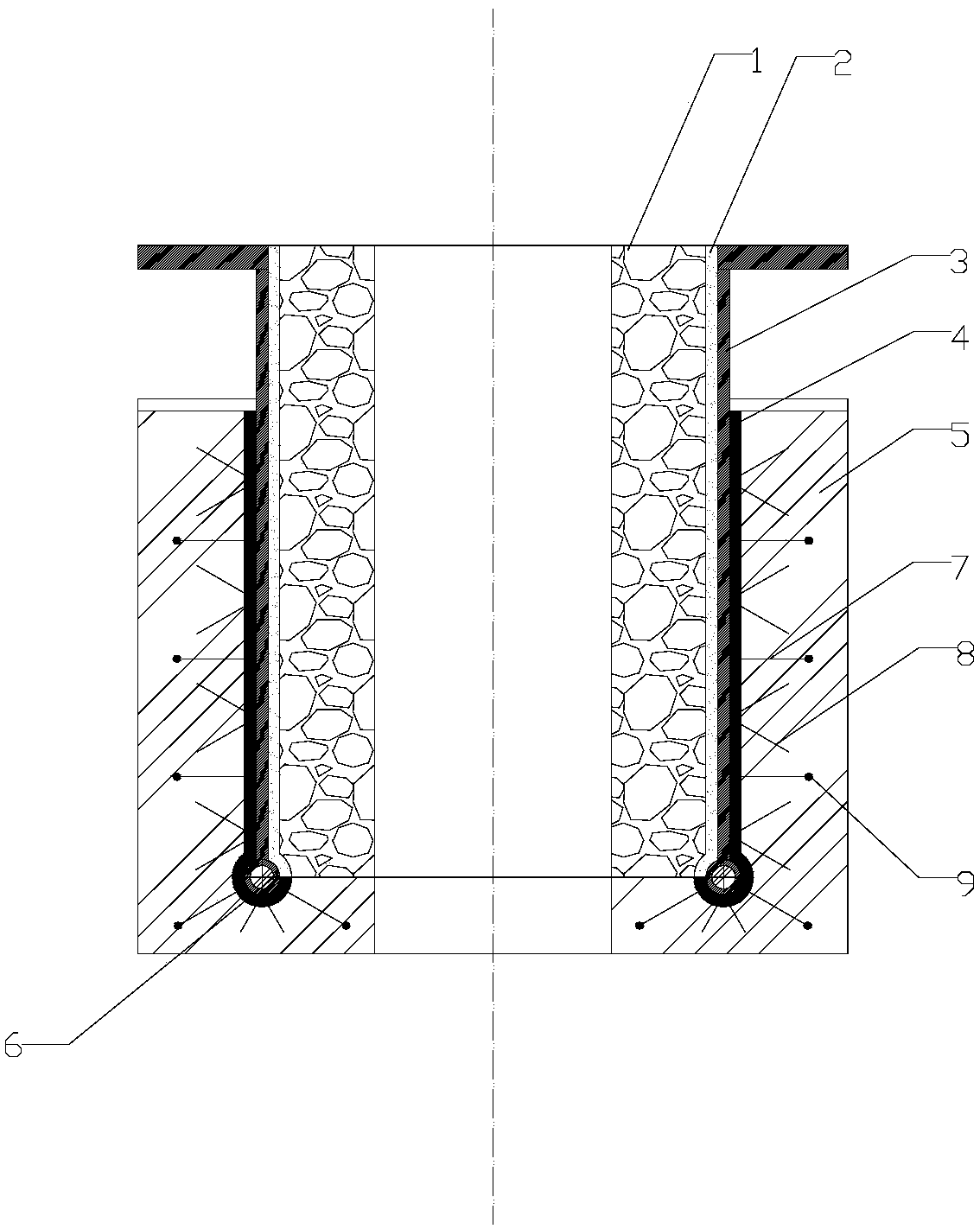

Circulating fluidized bed combustion device with internal double-inlet cyclone separator

ActiveCN103822205ACompact structureSmall footprintFluidized bed combustionApparatus for fluidised bed combustionCycloneFlue gas

The invention discloses a circulating fluidized bed combustion device with an internal double-inlet cyclone separator. The combustion device comprises a furnace chamber body (1), the double-inlet cyclone separator (2), a refeed downcomer (3) and a gas-water separator (10), wherein the inner wall of the vertically arranged furnace chamber body (1) is provided with a water wall; the furnace chamber body (1) comprises a furnace chamber dense-phase area (A), a furnace chamber lifting area (B) and a furnace chamber separating area (C) that are sequentially arranged from the bottom to up; the double-inlet cyclone separator (2) is coaxially arranged with a bed body in the furnace chamber separating area (C); the upper part of the flue gas inlet of the double-inlet cyclone separator (2) is arranged at the upper part of the furnace chamber separating area (C). According to the invention, gas-solid separating efficiency is improved, heat loss is reduced and boiler heat efficiency is improved.

Owner:SOUTHEAST UNIV

Steam Turbine Plant

InactiveUS20170254225A1Low efficiencyMinimize thermal expansion differencesLeakage preventionSteam engine plantsEngineeringFluid supply

A steam turbine plant of the present invention includes a heat source device that heats a low temperature fluid by a heat source medium to obtain a high temperature fluid, a steam generating device that generates steam by heat exchange with the high temperature fluid, a steam turbine that is driven by the steam, a heating flow path that is disposed on an outer surface of a casing of the steam turbine, a high temperature fluid supply passage that is branched from a flow path of the high temperature fluid in the steam generating device, is connected to the heating flow path, and supplies the high temperature fluid to the heating flow path, and a high temperature fluid flow rate regulating device that regulates a flow rate of the high temperature fluid flowing through the high temperature fluid supply passage.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

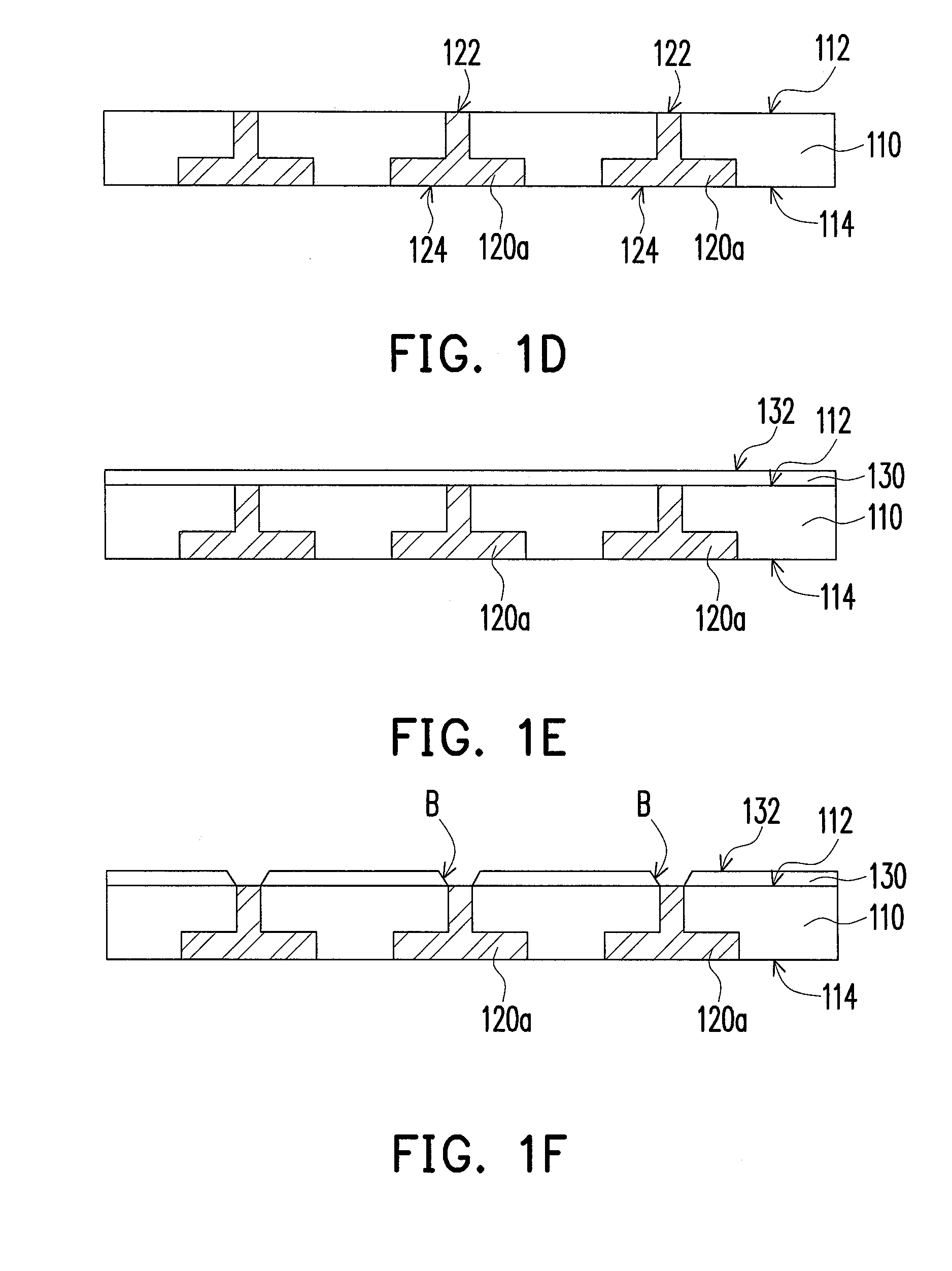

Package carrier and manufacturing method thereof

InactiveUS20140041922A1Decrease thermal expansion differenceIncrease use reliabilitySemiconductor/solid-state device detailsSolid-state devicesSolder maskEngineering

A manufacturing method of a package carrier is provided. An insulation substrate having an upper surface, a lower surface, plural cavities located at the lower surface and plural through holes passing through the insulation substrate and respectively communicating with the cavities is provided. Plural vias is defined by the cavities and the through holes. A conductive material filling up the vias is formed to define plural conductive posts. An insulation layer having a top surface and plural blind vias extending from the top surface to the conductive posts is formed on the upper surface. A patterned circuit layer filling up the blind vias, being connected to the conductive posts and exposing a portion of the top surface is formed on the top surface. A solder mask layer is formed on the patterned circuit layer and has plural openings exposing a portion of the patterned circuit layer to define plural pads.

Owner:SUBTRON TECH

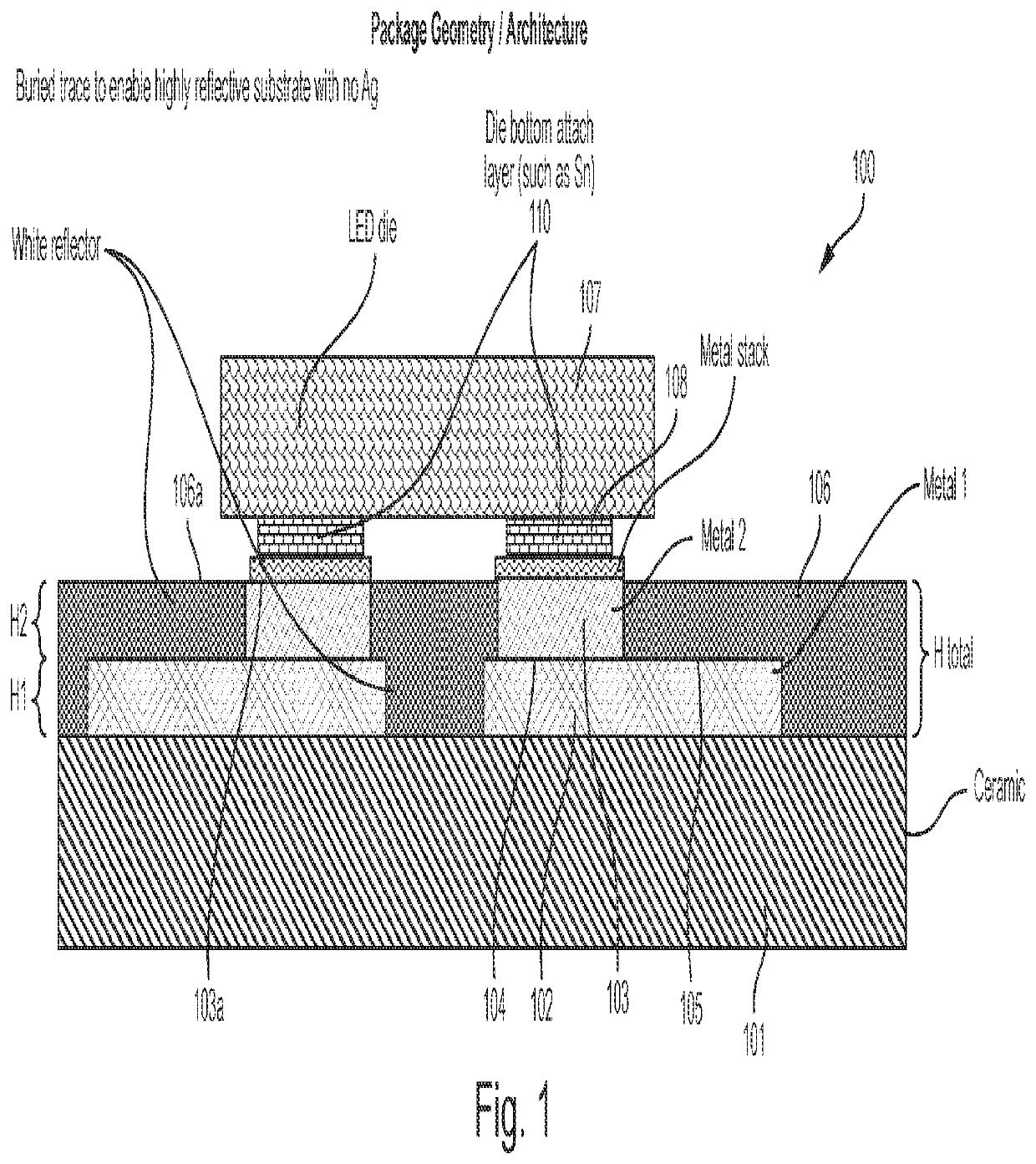

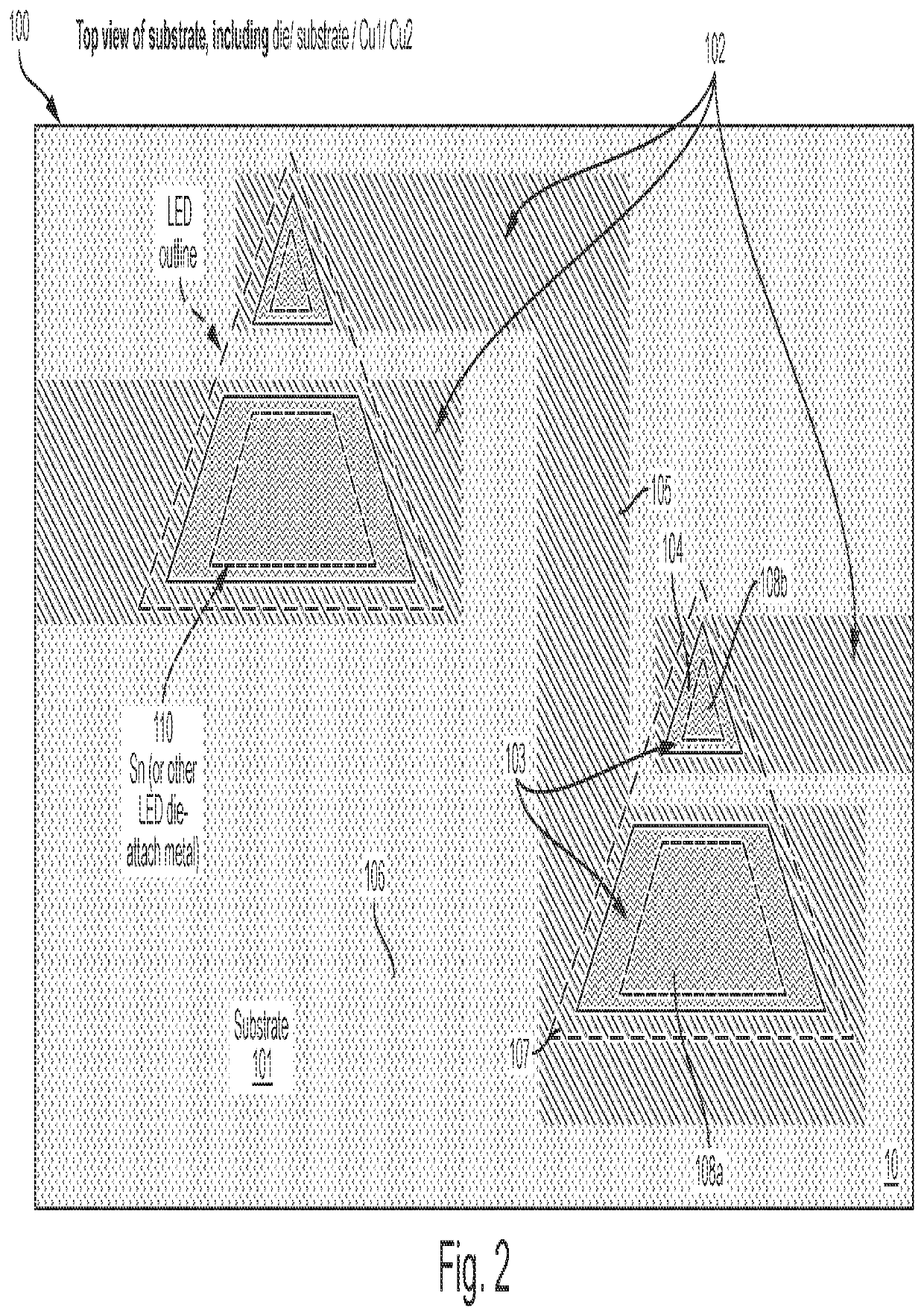

Light emitting diode package

InactiveUS20200313049A1Minimize exposureRobust bondingSolid-state devicesSemiconductor devicesLight-emitting diodeMaterials science

In one embodiment, the LED package comprises: (a) a submount comprising a substrate, at least one electrical interface, and a non-conductive reflective material disposed over substantially all of submount except for the at least one electrical interface; and (b) an LED chip having sides and at least one contact, the LED chip being flip-chip mounted to the submount such that the at least one contact is electrically connected to the at least one electrical interface, the LED chip covering a substantial portion of the at least one electrical interface, substantially all of the chip extending above the reflective material.

Owner:KORRUS INC

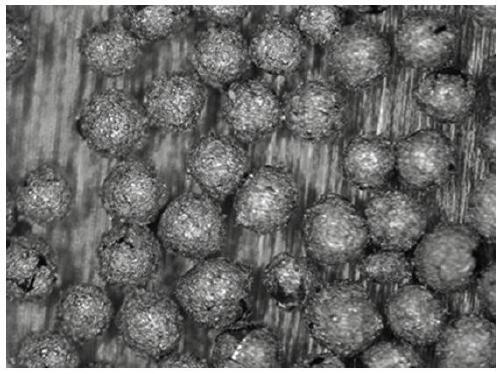

Preparation method for diamond embedded tool with high holding force

InactiveCN111318710AImprove gripNot easy to fall offTransportation and packagingMetal-working apparatusMetallurgyMetal powder

The invention provides a preparation method for a diamond embedded tool with high holding force. The preparation method comprises the following steps of first, wrapping a diamond, namely, taking soldering powder, metal powder and hard material powder in proportion, uniformly mixing to prepare a substrate, and wrapping the diamond using the mixed powder substrate by a diamond granulating method; second, pre-sintering; third, preparing a base body, namely, weighing and mixing body metal powder in proportion, granulating, weighing and uniformly mixing the body and the diamond fired in the secondstep in a certain proportion, and granulating to form the base body; fourth, performing cold pressing and forming; and fifth, sintering. According to the preparation method for the diamond embedded tool with the high holding force, excellent diamond holding force can be obtained the base body of a wrapping layer; the body, with different physical properties, not affecting the holding force of thediamond can be obtained by adjusting by utilizing great adjusting degree of freedom of the base body, and finally, the diamond tool with the high holding force is obtained; during working, the diamonddoes not fall off easily; the diamond protrudes high; and the improvement of the cutting efficiency and the prolonging of the service life of the diamond tool are facilitated.

Owner:CHANGSHA BAICHUAN SUPERHARD MATERIAL TOOLS

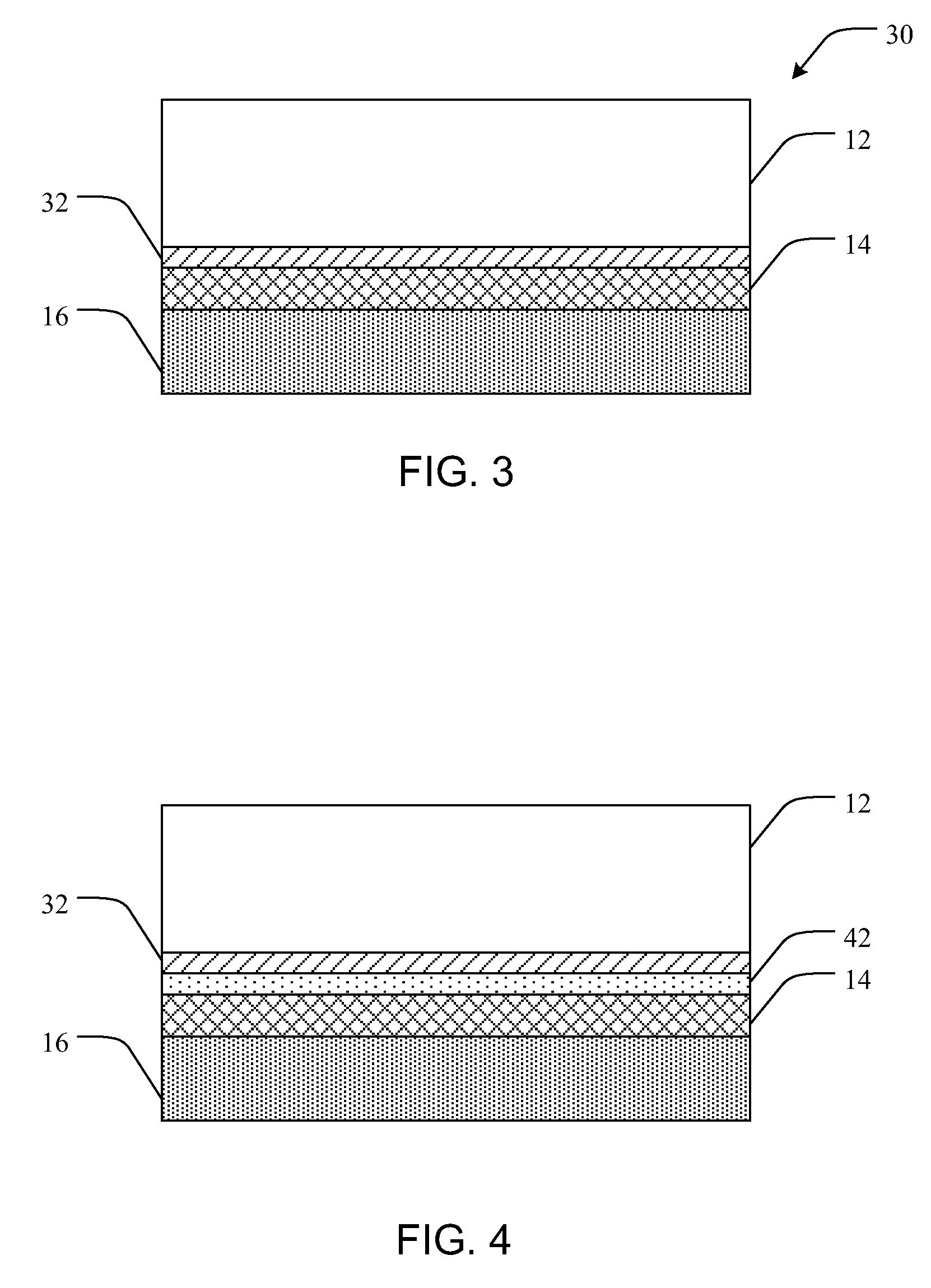

Metal surface heat protecting coating structure and preparation method and composite material thereof

PendingCN111593348AImprove stabilityMinimize thermal expansion differencesAnodisationAlkali metal silicate coatingsMicro arc oxidationThermal conductivity

The invention provides a metal surface heat protecting coating structure and a preparation method and composite material thereof. The metal surface heat protecting coating structure comprises a micro-arc oxidization transition layer and a ceramic coating, wherein the micro-arc oxidization transition layer and the ceramic coating are sequentially arranged on the surface of a metal base body from inside to outside. The ceramic coating comprises multiple subsidiary layers with the thermal expansion coefficient and the heat conductivity descending in a gradient manner from inside to outside. According to the heat protecting coating structure, the outer layer ceramic coating is designed into a multi-layer composite structure with the thermal expansion coefficient and the heat conductivity changing in a gradient manner, thus the thermal expansion difference between the coatings is reduced, the interface stress between a base body and the coatings is relieved, and the stability of the coatingoverall structure is improved. In addition, the micro-arc oxidization transition layer is guided between the metal base body and the ceramic coating, the stress between the metal base body and the ceramic coating can be relieved effectively, and meanwhile, the binding force between the ceramic coating and the metal base body is further increased.

Owner:HARBIN INST OF TECH +1

Manufacturing method of package carrier

ActiveUS20150068034A1Minimize thermal expansion differencesEasy to useSemiconductor/solid-state device detailsSolid-state devicesInsulation layerSolder mask

A manufacturing method of a package carrier is provided. An insulation substrate having an upper surface, a lower surface, plural cavities located at the lower surface and plural through holes passing through the insulation substrate and respectively communicating with the cavities is provided. Plural vias is defined by the cavities and the through holes. A conductive material filling up the vias is formed to define plural conductive posts. An insulation layer having a top surface and plural blind vias extending from the top surface to the conductive posts is formed on the upper surface. A patterned circuit layer filling up the blind vias, being connected to the conductive posts and exposing a portion of the top surface is formed on the top surface. A solder mask layer is formed on the patterned circuit layer and has plural openings exposing a portion of the patterned circuit layer to define plural pads.

Owner:SUBTRON TECH

Pressure sensor

ActiveCN108692854AAvoid temperature risePrevent localized thermal expansionFluid pressure measurement using capacitance variationMechanical engineeringHeat capacity

The present invention provides a pressure sensor capable of suppressing bending of a diaphragm caused by a sudden temperature change of a fluid introduction tube provided on a fluid conduit. The pressure sensor comprises the diaphragm, an electrode body, a housing, an inlet pipe, and a thermal buffer member. The diaphragm includes a pressure receiving surface configured to receive a pressure of ameasured target fluid. The electrode body includes an electrode surface facing a rear surface of the pressure receiving surface with a gap interposed therebetween. The housing supports the diaphragm so as to form a measuring chamber by surrounding the pressure receiving surface. The inlet pipe is coupled to the housing and configured to guide the measured target fluid into the measuring chamber. The thermal buffer member is disposed on the inlet pipe and has a predetermined heat capacity.

Owner:HORIBA STEC CO LTD

Steam turbine and method of cooling steam turbine

InactiveUS8356974B2Minimize thermal expansion differencesReduce startup timeWind motor controlPump componentsGas supplyTurbine rotor

A steam turbine 20 is provided with a casing 109, a turbine rotor 25 disposed through the casing 109, and labyrinth portions 50, 55 which are disposed at the boundary between the casing 109 and the turbine rotor 25. The steam turbine 20 is further provided with a sealing steam pipe 65 for supplying sealing steam to the labyrinth portions 50, 55 and a gas supply pipe 60 for supplying the labyrinth portions 50, 55 with a cooling gas for cooling the turbine rotor 25 or a heating gas for heating the turbine rotor 25.

Owner:KK TOSHIBA

Stress regulated semiconductor devices and associated methods

InactiveUS9006086B2Minimize thermal expansion differencesStress induced defectSemiconductor/solid-state device detailsSolid-state devicesCarbon layerInterface layer

Stress regulated semiconductor devices and associated methods are provided. In one aspect, for example, a stress regulated semiconductor device can include a semiconductor layer, a stress regulating interface layer including a carbon layer formed on the semiconductor layer, and a heat spreader coupled to the carbon layer opposite the semiconductor layer. The stress regulating interface layer is operable to reduce the coefficient of thermal expansion difference between the semiconductor layer and the heat spreader to less than or equal to about 10 ppm / ° C.

Owner:RITEDIA CORPORATION

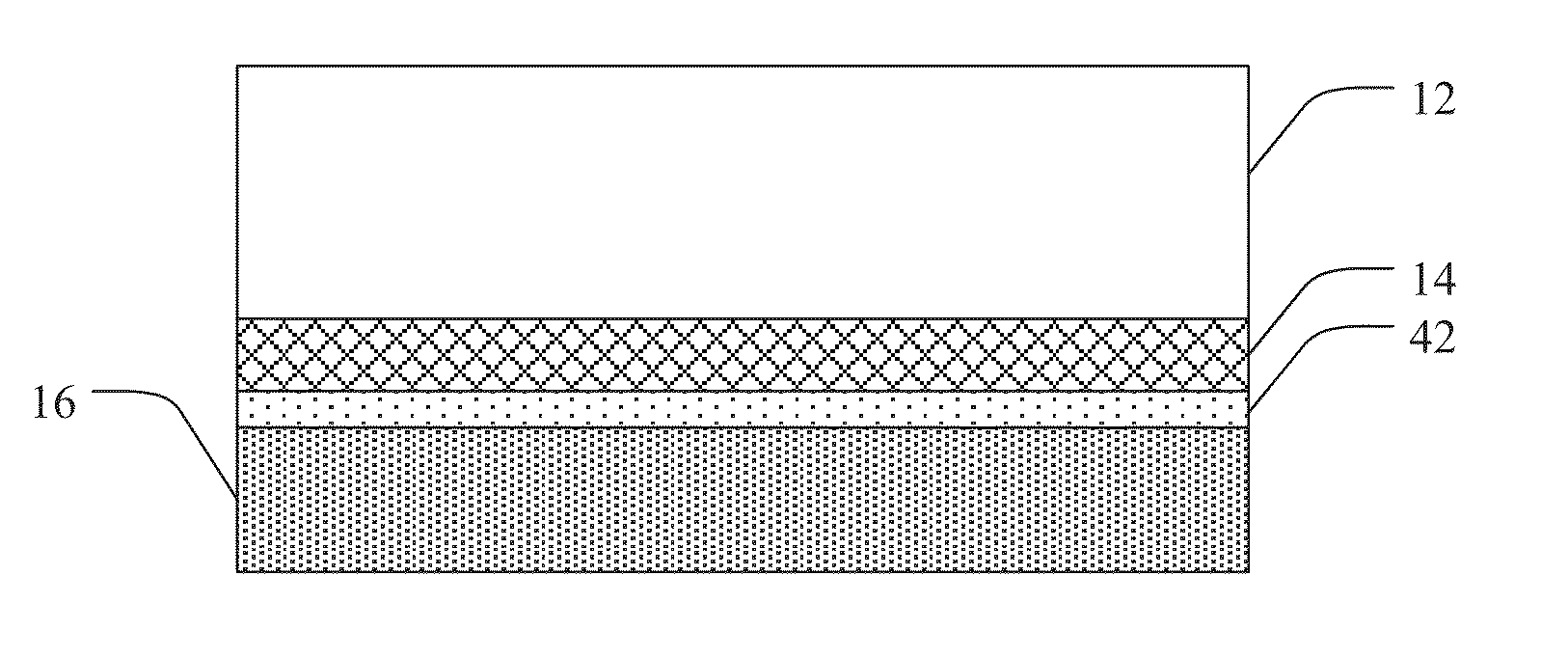

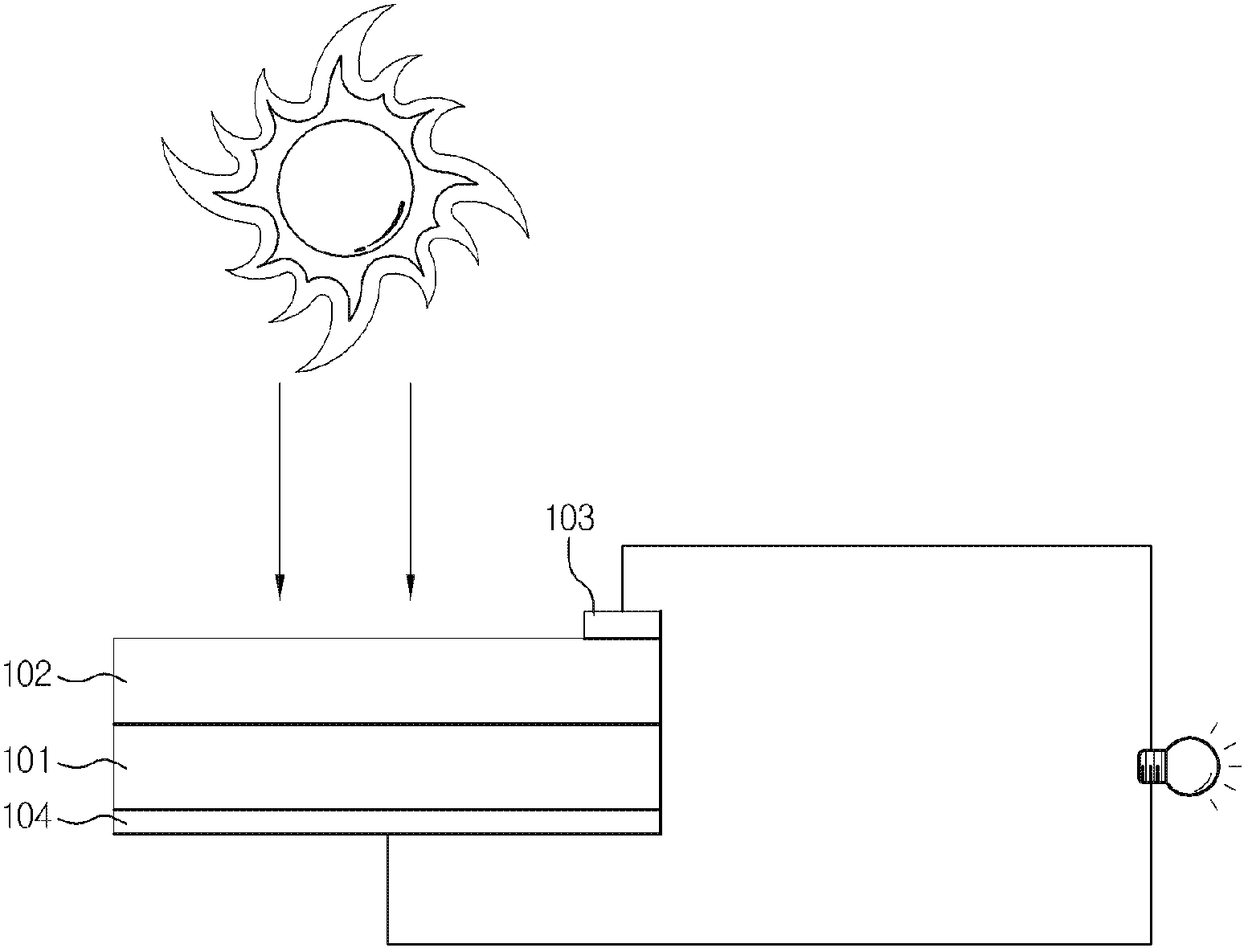

Photovoltaic concentrator receiver and use thereof

InactiveCN103430325AMinimize thermal expansion differencesPhotovoltaic energy generationSemiconductor devicesElectricityEngineering

The present invention relates to a photovoltaic (PV) concentrator receiver for concentrated illumination which comprises a substrate with at least one solar cell, wherein on the front surface of the substrate and the at least one solar cell an encapsulation material and a cover plate are disposed. The edges of the receiver are protected by a frame. The inventive PV concentrator receiver can be used for producing electricity from concentrated solar radiation.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

Stress regulated semiconductor devices and associated methods

InactiveUS8778784B2Minimize thermal expansion differencesStress induced defectSemiconductor/solid-state device detailsSolid-state devicesCarbon layerInterface layer

Stress regulated semiconductor devices and associated methods are provided. In one aspect, for example, a stress regulated semiconductor device can include a semiconductor layer, a stress regulating interface layer including a carbon layer formed on the semiconductor layer, and a heat spreader coupled to the carbon layer opposite the semiconductor layer. The stress regulating interface layer is operable to reduce the coefficient of thermal expansion difference between the semiconductor layer and the heat spreader to less than or equal to about 10 ppm / ° C.

Owner:RITEDIA CORPORATION

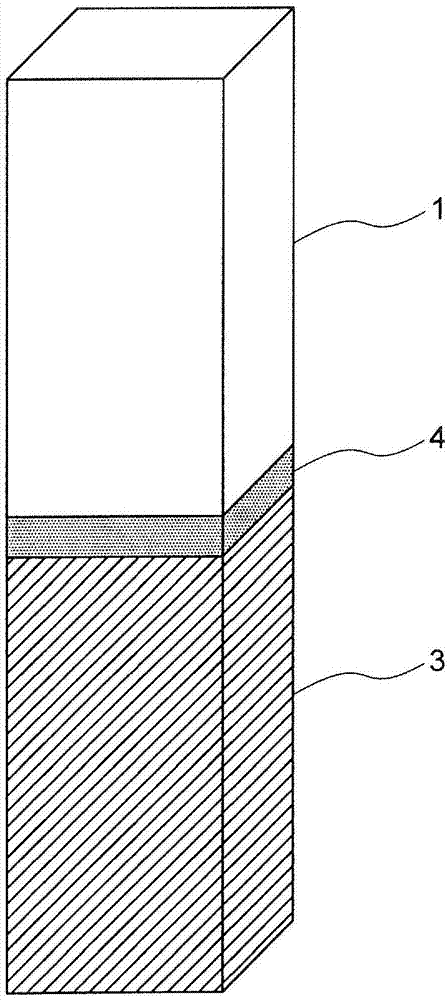

Composite body

ActiveCN107530780AMinimize thermal expansion differencesImprove joint strengthTransportation and packagingMetal-working apparatusInter layerCeramic metal

The present invention addresses the problem of providing a composite body of a metal member and a cermet member, which exhibits sufficient joining strength. The solution is a composite body having a cermet member, a metal member and an intermediate member. The cermet member includes a cermet oxide phase and a cermet metal phase. The cermet oxide phase contains a Ni-containing oxide or an Fe-containing oxide. The cermet metal phase contains Ni. The intermediate layer contains Cu. The mass proportions of Cu in the cermet metal phase at points which are spaced apart by 10, 50, 100 and 1000 [mu]mfrom the interface between the cermet member and the intermediate layer to the cermet member side are denoted by C10, C50, C100 and C1000 (mass%). When the mass proportions of Cu in the cermet oxide phase at points which are spaced apart by 10 and 100 [mu]m from the interface to the cermet member side are denoted by M10 and M100 (mass%), C10 > C50 > C100 > C1000, and 5 > M10-M100 > -5.

Owner:TDK CORPARATION

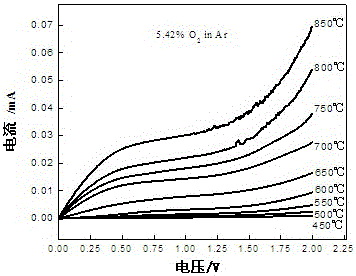

Method for preparing dense diffusion barrier of limiting current type oxygen sensor with co-permeation method

ActiveCN105948747AImprove bindingMinimize thermal expansion differencesMaterial electrochemical variablesThermal expansionPermeation

The invention belongs to the technical field of sensors, and particularly relates to a method for preparing a dense diffusion barrier of a limiting current type oxygen sensor with a co-permeation method. The method comprises steps as follows: La2O3, SrCO3, Ga2O3 and MgO are taken as raw materials, a La0.8Sr0.2Ga0.83Mg0.17O2.815 sheet is prepared with a solid-phase synthesis method, the La0.8Sr0.2Ga0.83Mg0.17O2.815 sheet is arranged at the lower part of a forming die, the upper part of the forming die is filled with transition metal oxide powder, pressure is kept for 5-10 min under the pressure intensity of 6-10 MPa, then sintering is performed for 5-50 h at the temperature of 1,400-1,600 DEG C, and after natural cooling, the dense diffusion barrier of the limiting current type oxygen sensor is obtained. The dense diffusion barrier prepared with the method is dense, uniform and pore-free in structure and firm in combination, the thermal expansion difference between a matrix and the dense diffusion barrier is reduced to the minimum, and the dense diffusion barrier has the advantages of short preparation period and high sensitivity.

Owner:NORTHEASTERN UNIV

Laminate, electronic device, and production method for laminate

InactiveCN108712965AImprove thermal conductivityImprove controllabilityLiquid crystal compositionsSemiconductor/solid-state device detailsHeat resistanceCoupling

The present invention is a laminate: with which differences in the thermal expansion coefficient at interfaces between different materials in the interior of a semiconductor element or the like can bekept small; which has high heat resistance; and which has high thermal conductivity. The laminate is provided with at least two layers of thermal expansion-controlling members, the thermal expansion-controlling members including a thermally conductive first inorganic filler joined to one end of a first coupling agent, and a thermally conductive second inorganic filler joined to one end of a second coupling agent; the other end of the first coupling agent and the other end of the second coupling agent are respectively joined to a polymerizable compound, or joined to one another; and the thermal expansion-controlling members have thermal expansion coefficients that are respectively different.

Owner:JNC CORP +1

High-temperature roll

InactiveUS20140245795A1Minimize thermal expansion differencesReduce fiber contentGlass transportation apparatusGlass rolling apparatusEngineeringThermal expansion

A roll for use in glass manufacture, such as in the production of non-dusting TFT glass, includes a hollow silica cylinder. A rod extends through the interior of the silica cylinder. A cooling volume is contained within the cylinder and extends around the rod. End caps are mechanically fixed to the roll. Pulling flats are fixed in place by inner and outer end plates. A compression fitting secures at least the outer end plate to the roll. The rod may serve to reinforce the roll and may be secured to the shaft by a plurality of supports. The supports accommodate differences in thermal expansion.

Owner:VESUVIUS CRUCIBLE CO

Silver paste composition and solar cell using same

ActiveCN102763172AImprove rolling effectImprove the level ofNon-conductive material with dispersed conductive materialPhotovoltaic energy generationSilver pasteFrit

The present invention relates to a silver paste composition and to a solar cell using the same. The silver paste composition of the present invention is applied onto an anti-reflective film, and comprises silver powder, glass frit powder, an organic binder and a plasticizer. The silver paste composition for the formation of a front electrode of a solar cell according to the present invention can be printed into a uniform pattern, and has superior bonding force to a substrate.

Owner:LG CHEM LTD

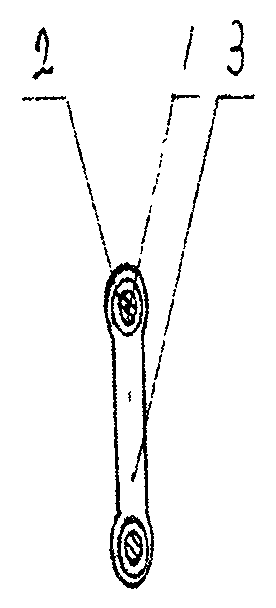

Rh Vacuum Furnace Low Stress Dip Tube

ActiveCN106011389BExtended service lifeImprove high temperature deformation resistanceBrickHeat stress

The invention discloses a low-stress dipping pipe for an RH vacuum furnace. The low-stress dipping pipe sequentially comprises a refractory brick lining, a filling layer and a steel barrel from inside to outside. No hole is formed in the wall surface of the steel barrel. An annular round metal pipe or an annular round metal rod is welded to the bottom surface of the steel barrel. The outer wall of the lower portion of the top of the steel barrel and the outer wall of the annular round metal pipe or the outer wall of the annular round metal rod are each paved with a buffer layer. V-shaped metal anchoring pieces and double-V-shaped metal anchoring pieces are uniformly welded to the outer wall of the steel barrel or the outer wall of the annular round metal rod in the axial spaced layered circumferential direction of the steel barrel and penetrate through the buffer layers. According to the low-stress dipping pipe for the RH vacuum furnace, the problem that damage and deterioration are caused due to the fact that the difference of the material performances of all components in a dipping pipe complex structure is remarkable is effectively solved, and the comprehensive purposes of reducing the structural stress and the heat stress of the dipping pipe, improving the dipping pipe resistance to crack, stripping and damage and the integrality and the structural stability of the dipping pipe, prolonging the service life of the dipping pipe and the like are achieved.

Owner:武汉钢铁有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com