Composite body

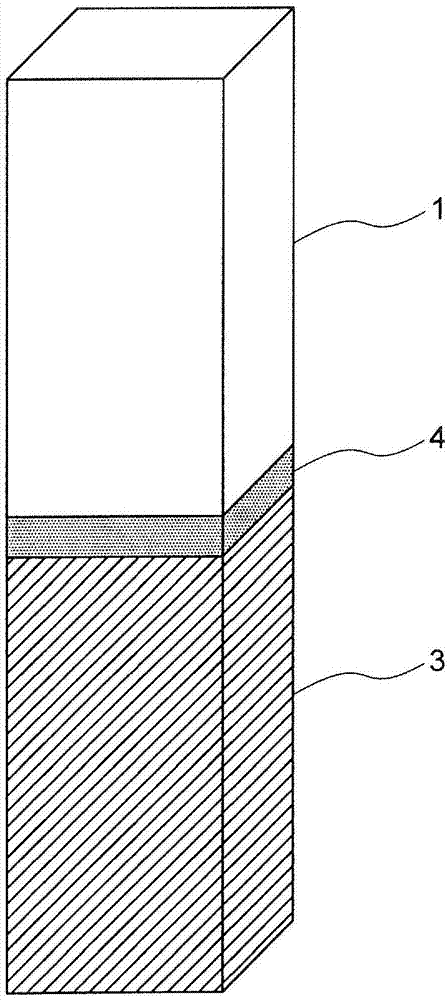

A technology of assembly and intermediate layer, which is used in electrolytic components, transportation and packaging, electrodes, etc., can solve the problems of reduced bonding strength and different thermal expansion coefficients between cermet components and metal components, and achieve the effect of high bonding strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~45 and comparative example 1~24

[0211] Combine commercially available NiO powder and Fe 2 O 3 Powder with NiO and Fe 2 O 3 The molar ratio becomes 70:30, and the ball mill is used for mixing. The mixed powder obtained by mixing was maintained in the atmosphere at a temperature of 1000° C. for 3 hours to perform calcining. The calcined powder obtained by calcination was pulverized with a ball mill to prepare ferrite oxide powder.

[0212] The obtained ferrite oxide powder and metal powder are mixed. Here, as the metal powder, Ni powder, mixed powder of Ni powder and Cu powder, mixed powder of Ni powder and Ag powder, and mixed powder of Ni powder, Cu powder and Ag powder are prepared. Regarding the mixed powder of Ni powder and Cu powder, the mass ratio of Ni and Cu satisfies the mixing ratio of 45<Ni<100 (mass%) and 0<Cu<55 (mass%). The mixing ratio of Ni powder and Ag powder was Ni=98 (mass%) and Ag=2 (mass%). Regarding the mixed powder of Ni powder, Cu powder and Ag powder, the mass ratio of Ni, Cu and Ag ...

Embodiment 50~75

[0249] In Experimental Example 2, different from Experimental Example 1, the NiO powder and Fe 2 O 3 The mixing ratio of the powder is set to NiO and Fe 2 O 3 The molar ratio of is 50:50. In addition, the joining time has also changed. Furthermore, intermediate members of the materials shown in Table 2 were prepared (only the first intermediate member was used in Example 50, the first intermediate member and the second intermediate member were used in Examples 51 to 69, and the first intermediate member was excluded in Examples 70 to 75. An intermediate member, the second intermediate member is also a third intermediate member). The thickness of each intermediate member was set to 0.02 cm.

[0250] Furthermore, when the third intermediate member was not used (Examples 51 to 69), the first intermediate member was placed on the cermet member, the second intermediate member was placed on the first intermediate member, and the metal member was placed on the On the second intermedia...

Embodiment 80~92

[0260] In Experimental Example 3, as in Experimental Example 2, the NiO powder and Fe 2 O 3 The mixing ratio of the powder is set to NiO and Fe 2 O 3 The molar ratio of is 50:50. Furthermore, as the intermediate member, a hybrid molded body produced by the production method shown below was used. Except for the aforementioned points and certain conditions described in Table 5, in the same manner as in Example 50 of Experimental Example 2, Examples 81 to 92 shown in Table 5 were obtained. Furthermore, various characteristics shown in Table 5 and Table 6 were measured. In all the examples, no cracks occurred, and the void ratio on the intermediate member was less than 5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com