Discharging method and device of autoclave condensation water

A technology of discharge device and autoclave, which is applied in the methods of chemically changing substances by using atmospheric pressure, chemical instruments and methods, and pressure vessels used in chemical processes, etc. Small and other problems, to ensure normal use, safe and reliable use, and reduce thermal deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

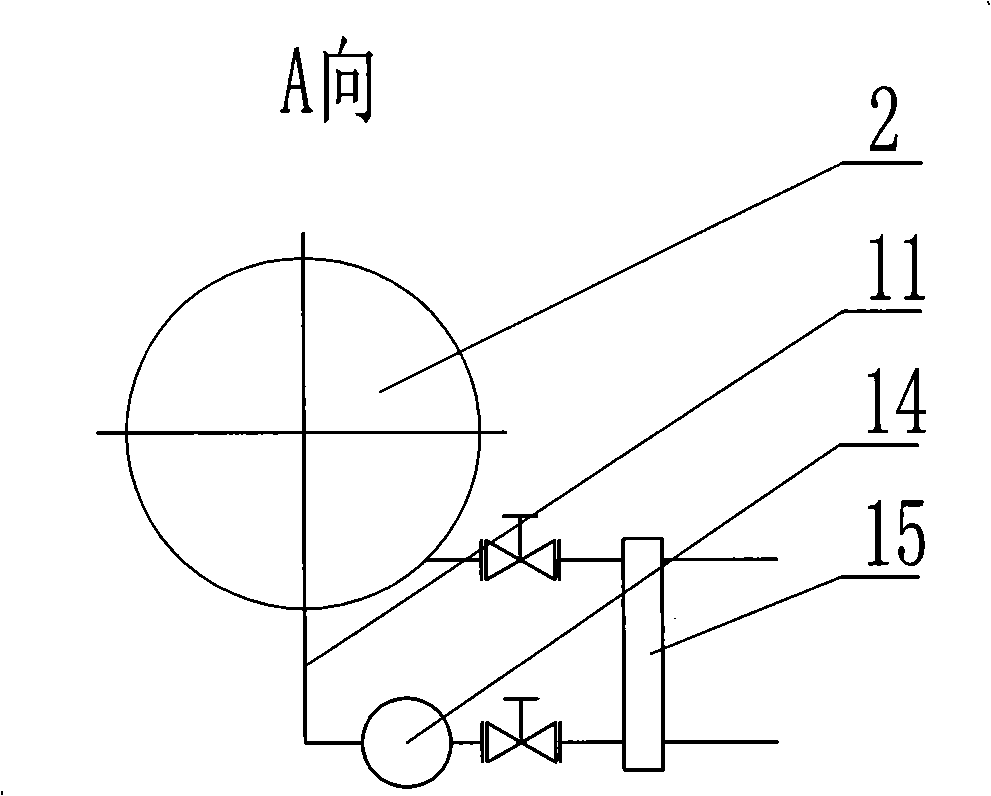

[0021] The discharge method of the condensed water in the autoclave of the present invention, the temperature of the autoclave is raised to discharge in sections, and the temperature in the autoclave is ≤ 100 ° C, and the liquid level gauge installed between the lower part of the autoclave and the water collection box will detect The liquid level signal is sent to the controller, the controller according to whether the detected liquid level exceeds the set liquid level, when the detected liquid level exceeds the set liquid level, or the controller evaporates according to the set The interval time for discharge of condensed water in the autoclave, the interval output signal makes the pneumatic valve act, and the condensed water is removed at intervals. The invention controls the action of the actuator of the pneumatic valve through the controller to control the air source control valve. The actuator is opened or closed and installed in the water collection Pneumatic valve on hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com