Non-gas metal arc welding 3 D adding material repair device and repair method

A gas shielded welding and non-melting electrode technology, applied in the field of additive repair, can solve problems such as insufficient bonding strength of the coating and its own strength, unsatisfactory repair effect, stress concentration in the transition zone, etc., to improve the welding effect and improve the welding efficiency , Reduce the effect of lack of welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Non-melting electrode gas shielded welding is a kind of arc welding that uses pure tungsten or non-activated tungsten as non-melting electrode and inert gas (CO2, Ar) as shielding gas. The invention discloses a repairing device and a repairing method for solving the deficiencies in the prior art.

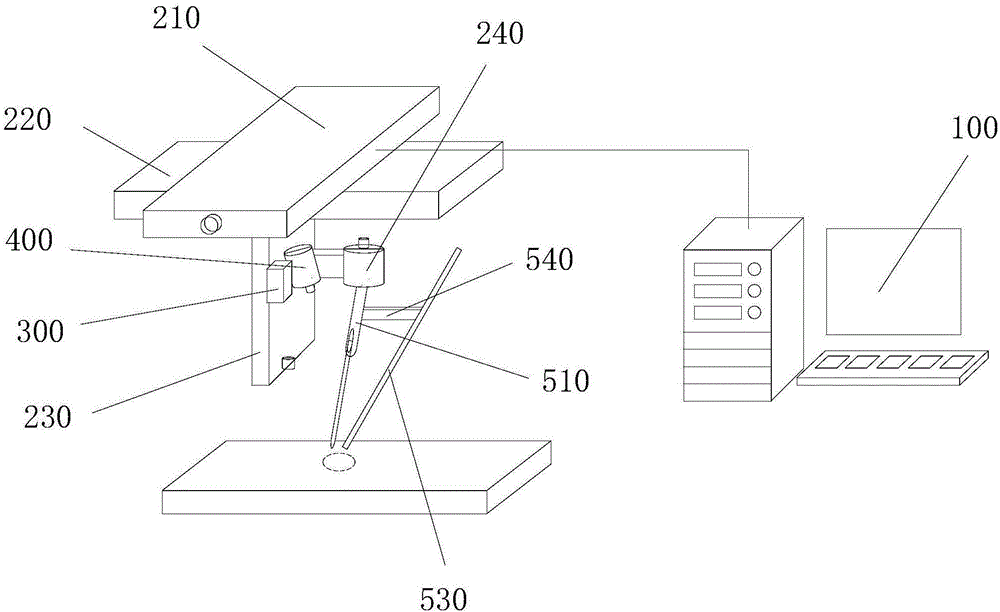

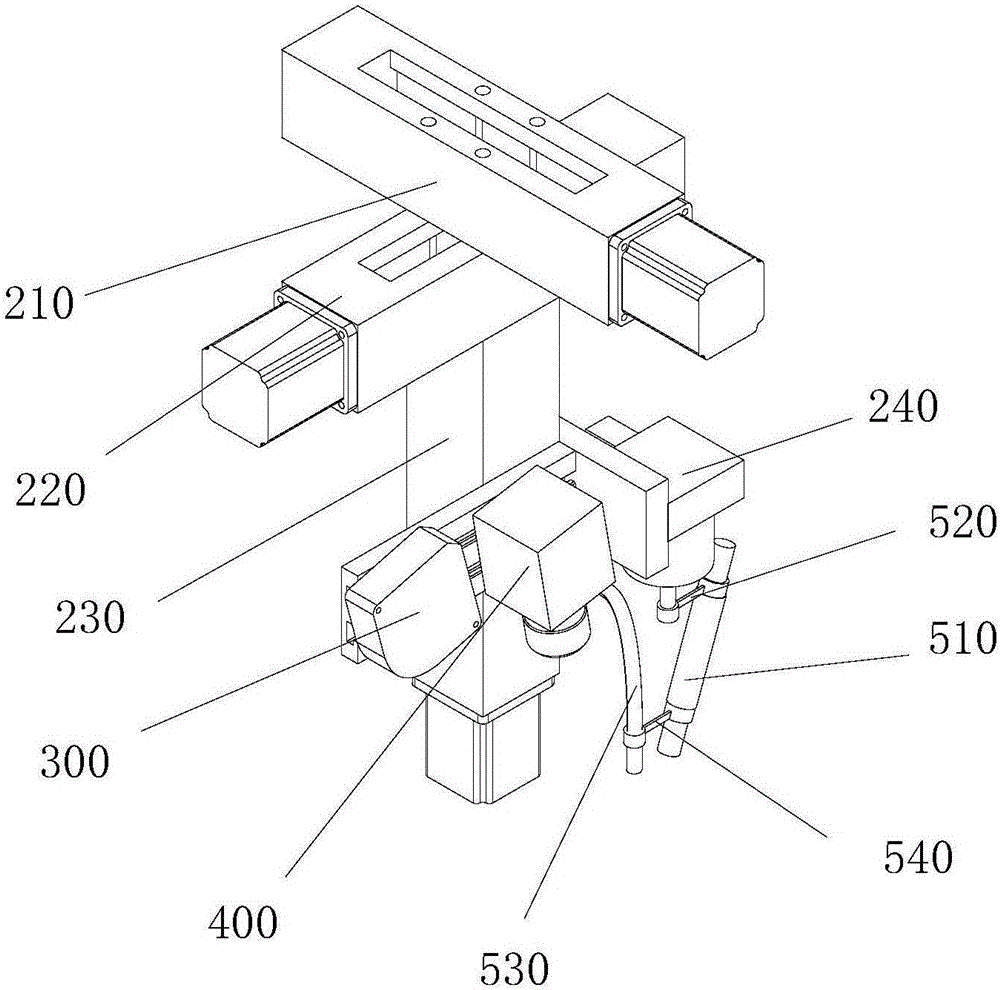

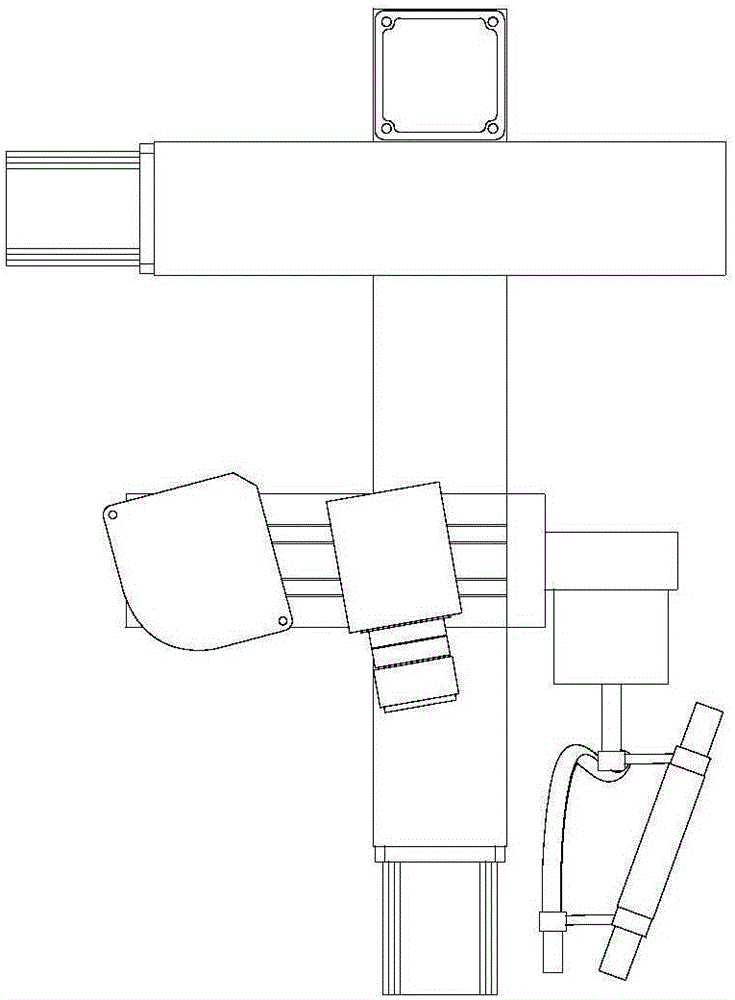

[0052] Among them, such as figure 1 As shown in the figure, the repairing device is a 3D additive repairing device for NGAW, and the repairing device mainly includes a controller 100, a four-axis linkage platform located above the repaired workpiece, and a linkage platform arranged on the linkage platform for obtaining the workpiece The laser vision sensor 300 for the three-dimensional information of the defect contour, the infrared vision sensor 400 for obtaining the state information of the molten pool 6, the fixture 520, the non-melting electrode torch 510, the wire feeding unit and the wire reel. The controller 100 is connected with the four-axis linkage platform, the la...

Embodiment 2

[0074] like figure 1 As shown, the laser vision sensor 300 and the near-infrared vision sensor 400 are installed on the Z-axis motion platform of the four-axis (X-Y-Z-A axis) motion control platform, and the non-melting electrode shielding gas welding torch 510 is installed on the A-axis rotating platform. The device can be installed on the end of the robot or on the gantry frame, and cooperate with the movement of the robot or the gantry to the corresponding position to repair defective specimens or equipment in different occasions.

[0075] The working process of the 3D additive repairing device provided by the present invention is as follows: first, the non-melting electrode welding torch 510 is moved to the corresponding position with the four-axis motion platform, and under the control of the computer controller 100, the laser vision sensor 300 is driven to scan for defects (complex Geometric shape) profile to get structured light signal.

[0076] Then, the semiconductor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com