Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

61results about How to "Lower Reynolds number" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

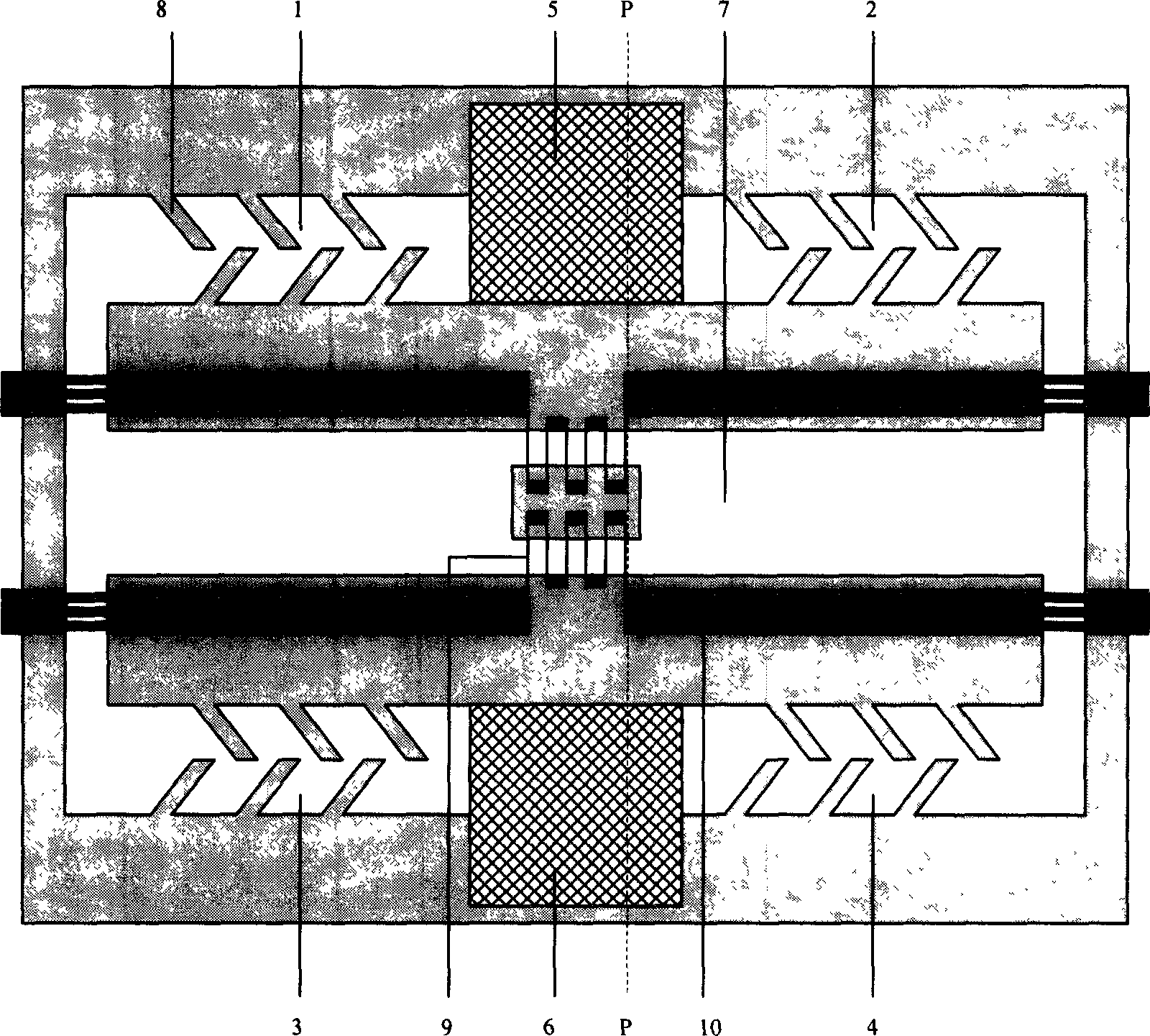

Microfluidic apparatus and methods for performing blood typing and crossmatching

ActiveUS20100112723A1Small dimensionIncrease ratingsBiocideBioreactor/fermenter combinationsAntigenGroup A - blood

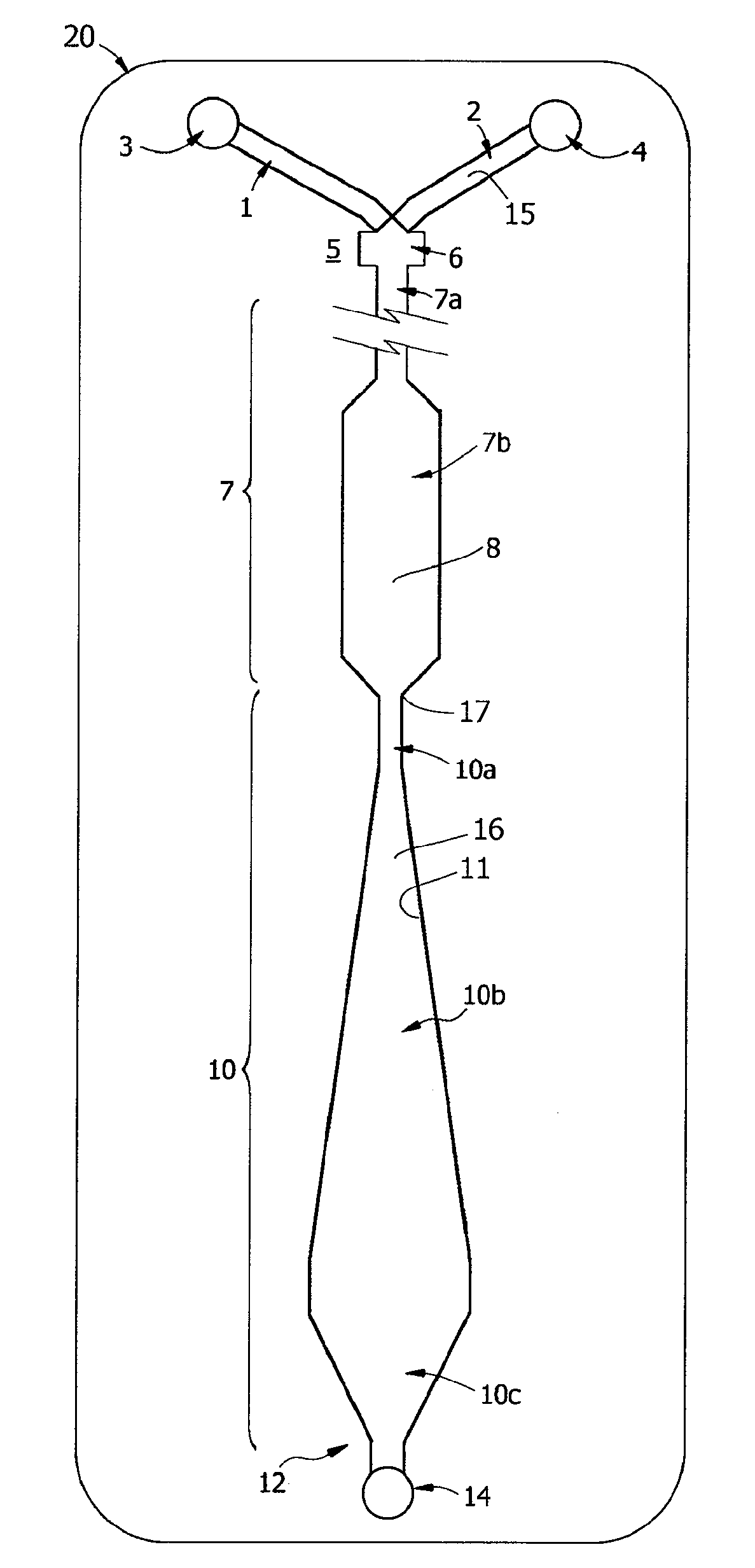

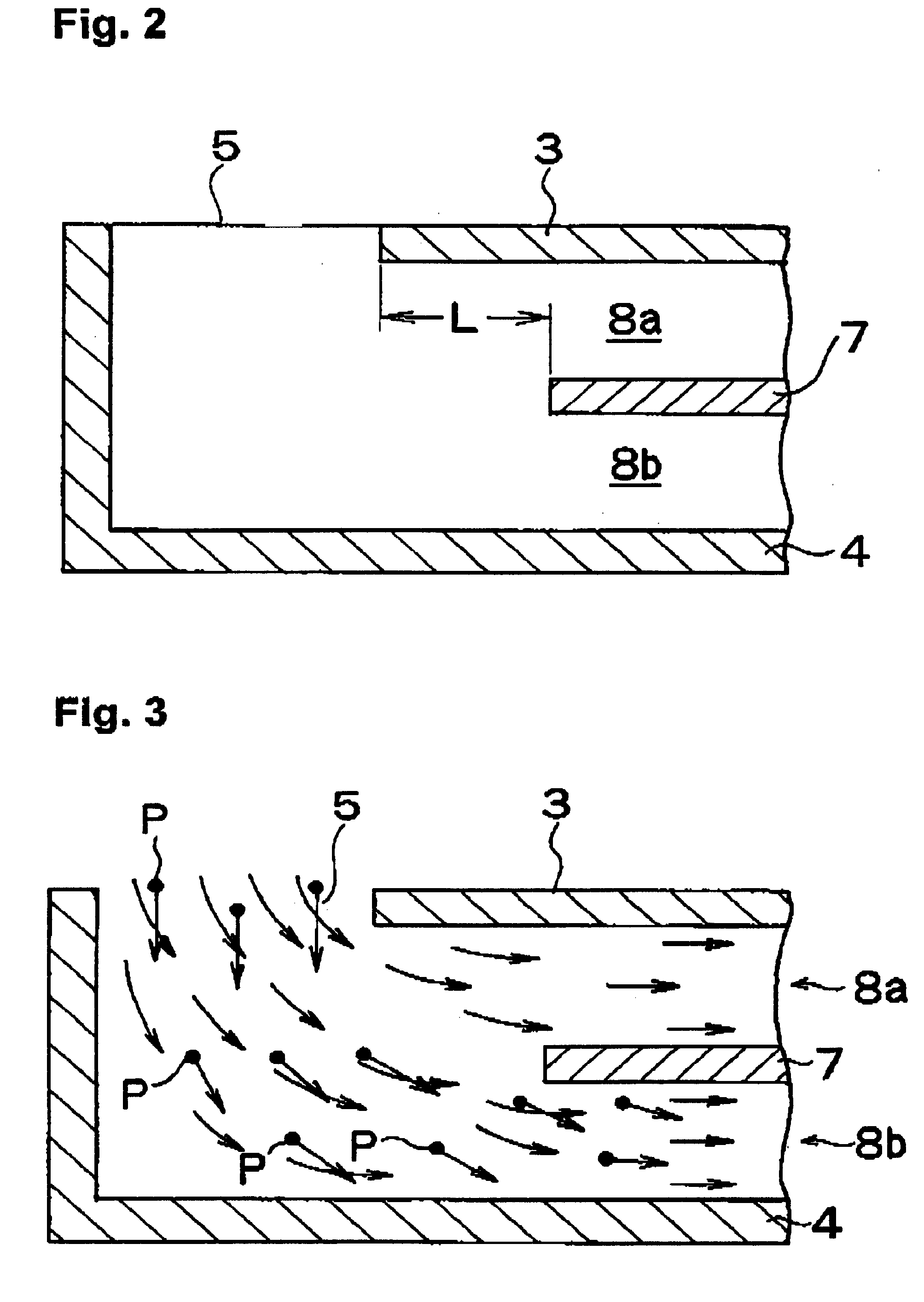

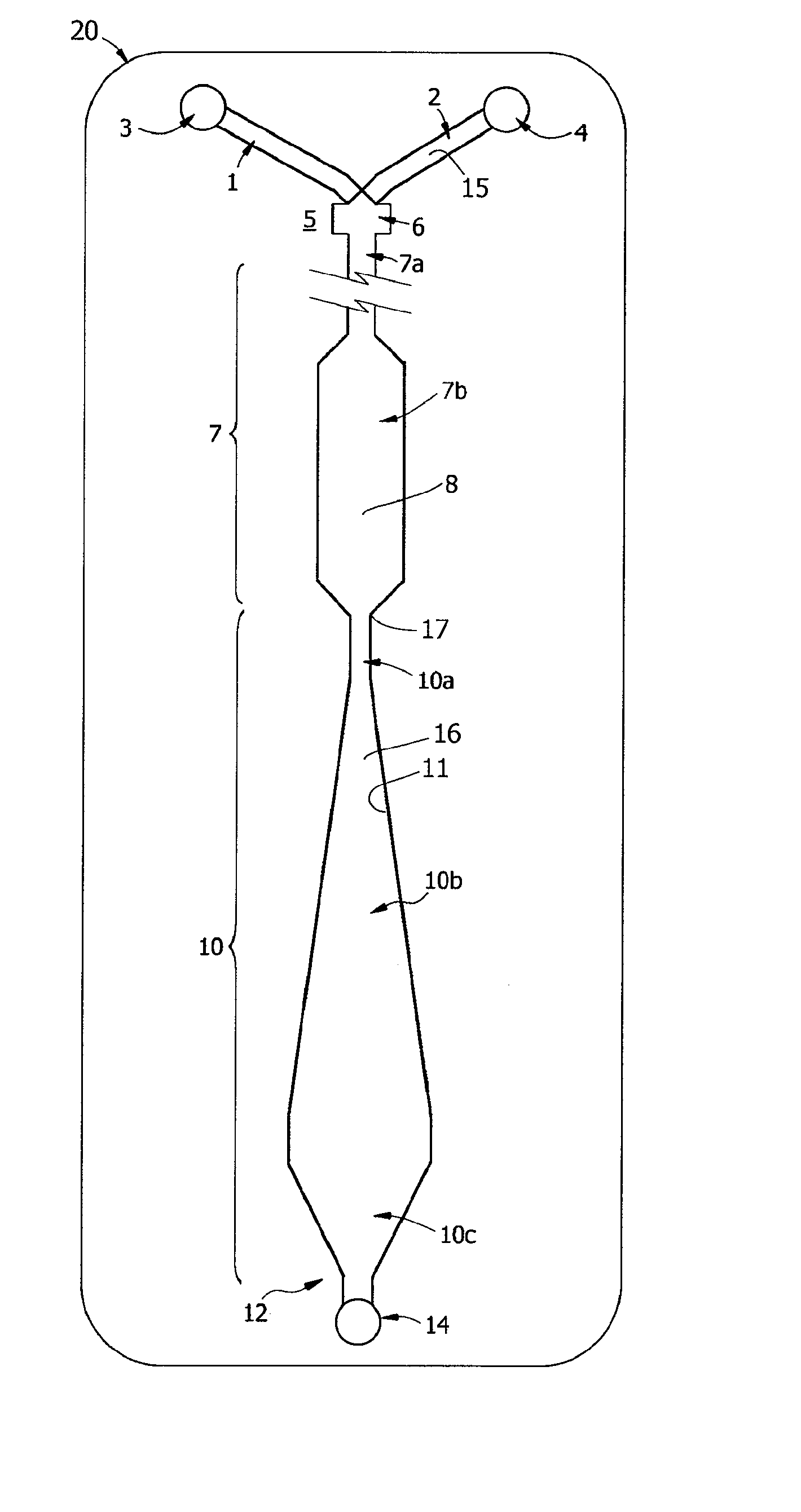

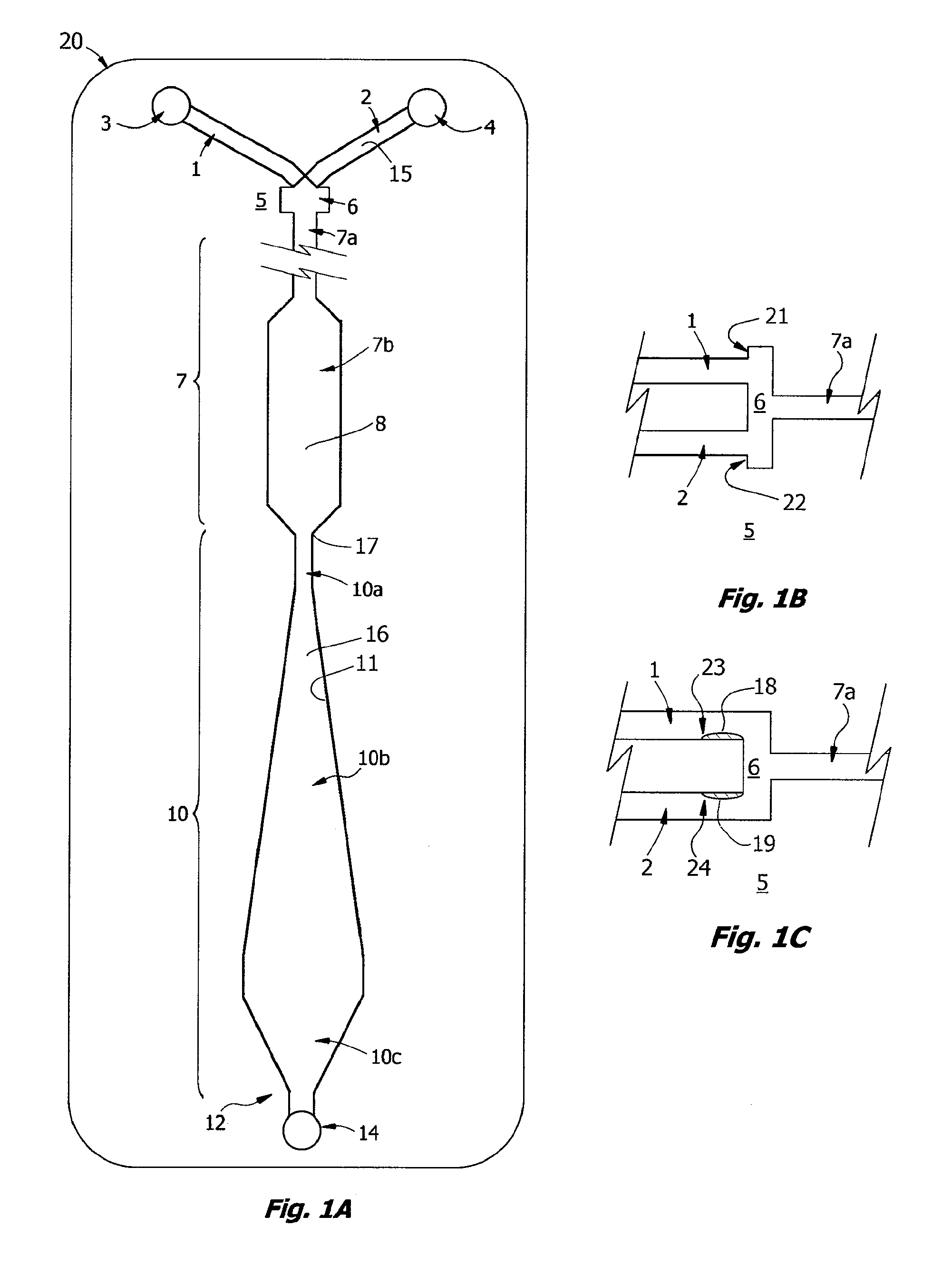

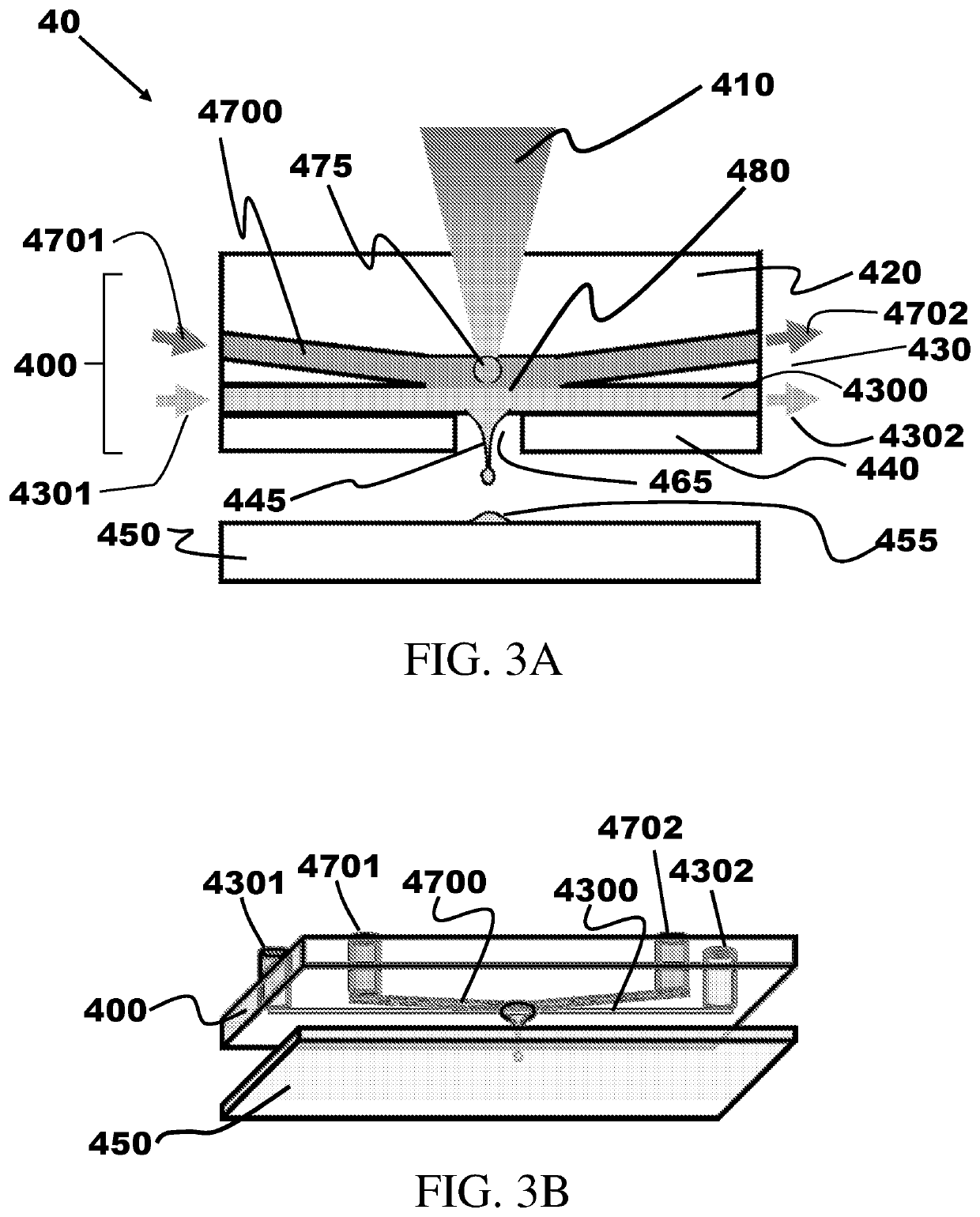

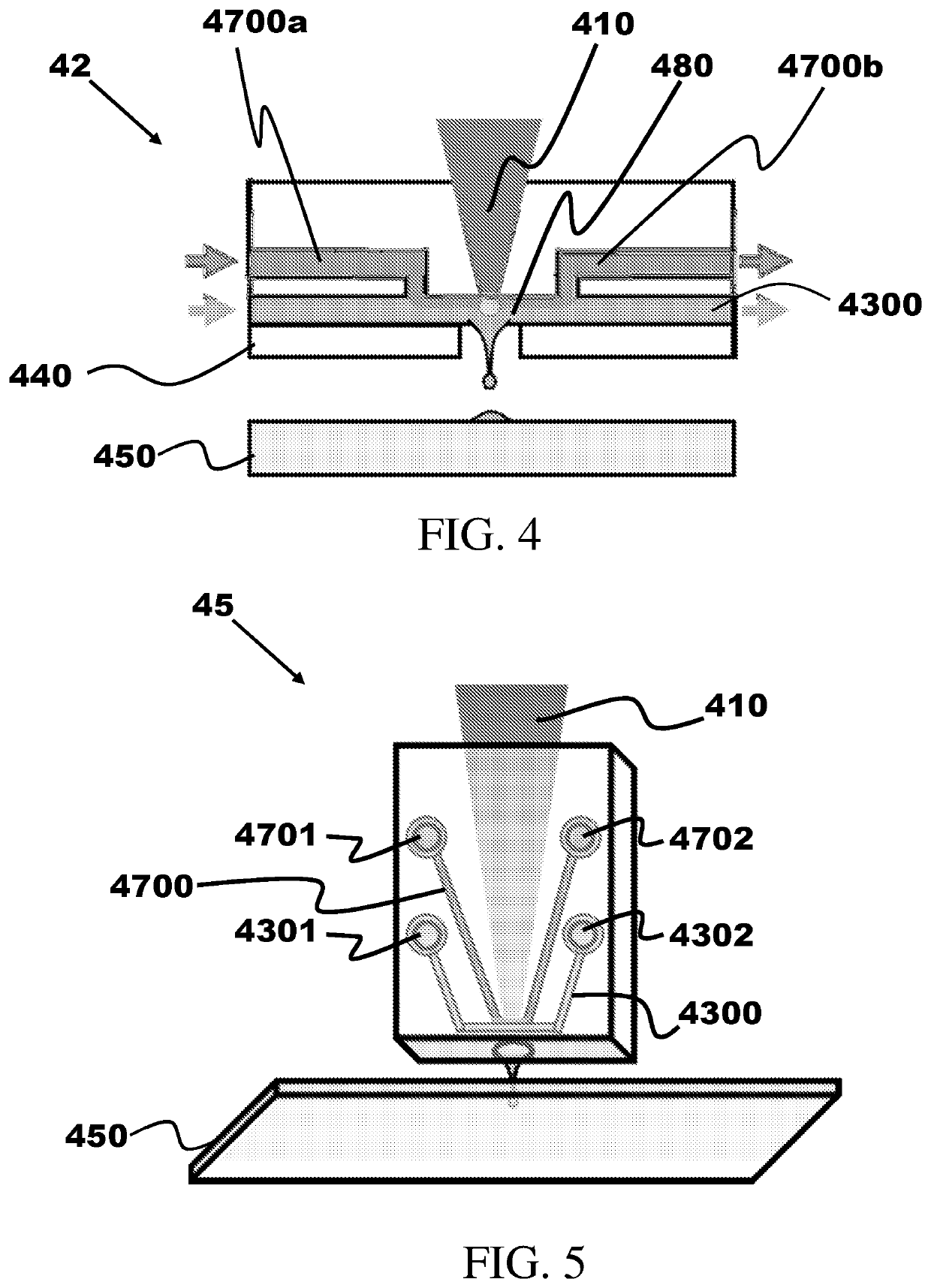

Microfluidic cartridges for agglutination reactions are provided. The cartridges include a microfluidic reaction channel with at least two intake channels, one for an antigen-containing fluid and the other for an antibody-containing fluid, conjoined to a reaction channel modified by incorporation of a downstream flow control channel. At low Reynolds Number, the two input streams layer one on top of the other in the reaction channel and form a flowing, unmixed horizontally-stratified laminar fluid diffusion (HLFD) interface for an extended duration of reaction. Surprisingly, the design, surface properties, and flow regime of microfluidic circuits of the present invention potentiate detection of antibody mediated agglutination at the stratified interface. Antigen:antibody reactions involving agglutination potentiated by these devices are useful in blood typing, in crossmatching for blood transfusion, and in immunodiagnostic agglutination assays, for example.

Owner:PERKINELMER HEALTH SCIENCES INC

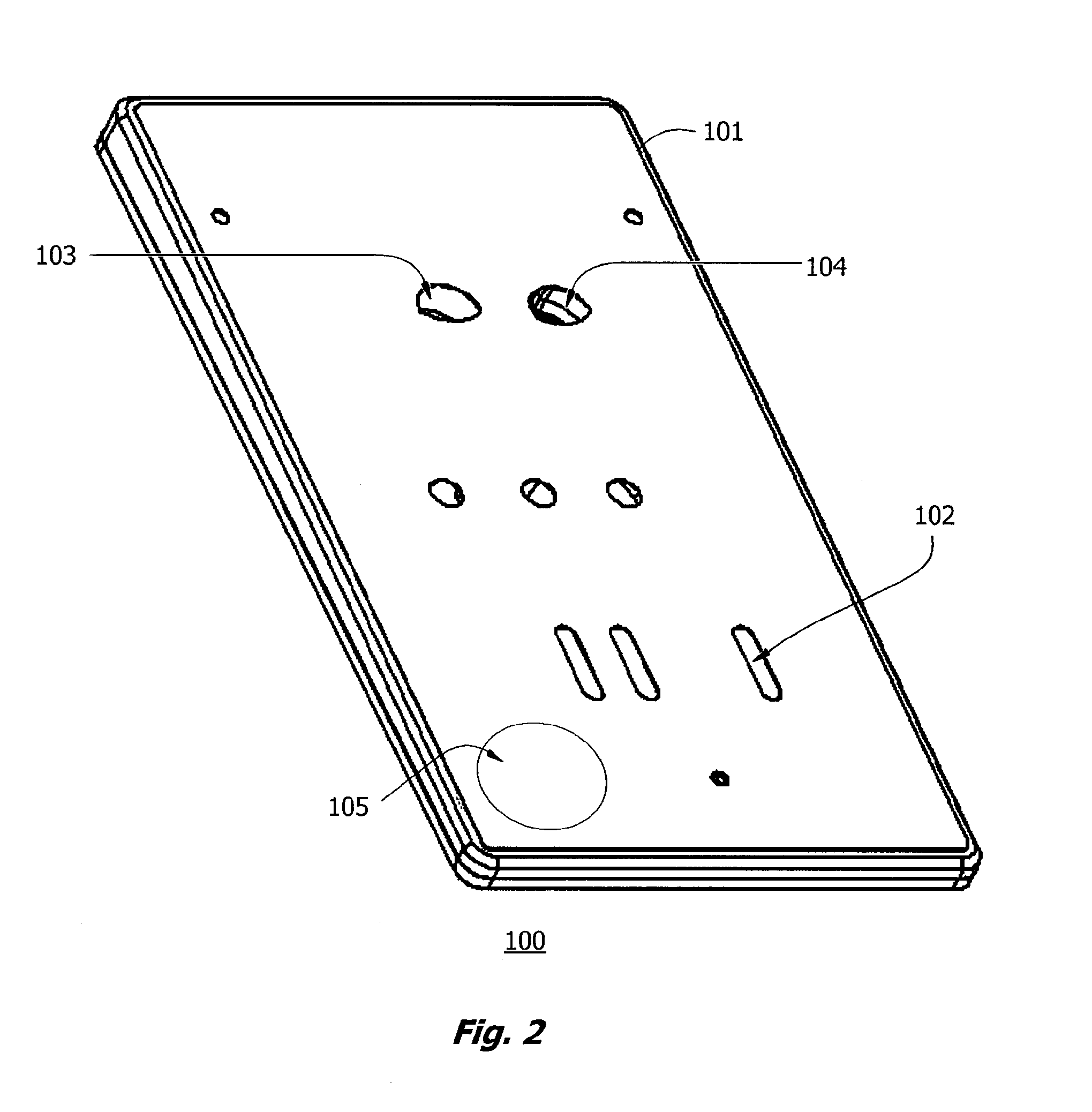

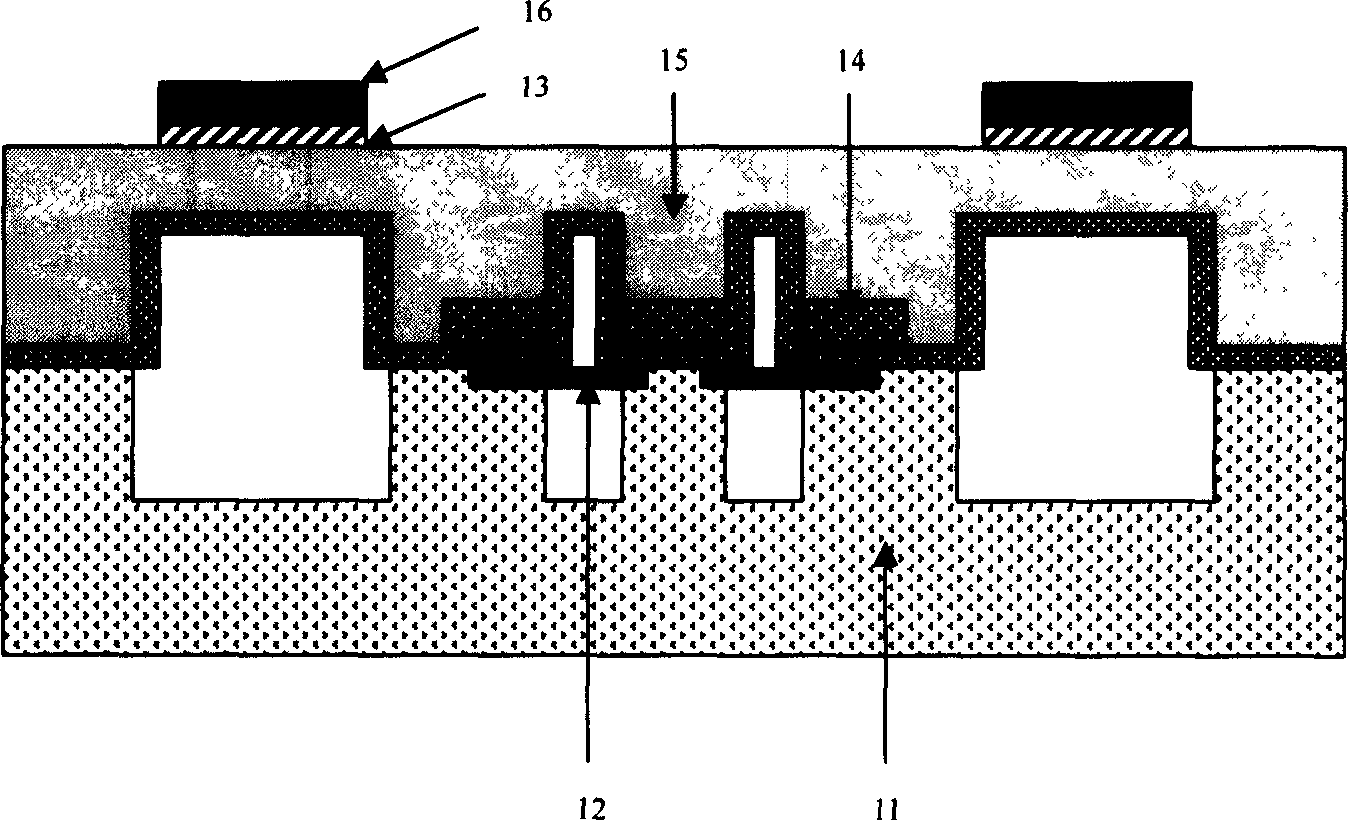

Flow rate and flow velocity measurement device

InactiveUS6526822B1Good pollution resistanceEasy to detectVolume/mass flow by thermal effectsVolume/mass flow by differential pressureMeasurement deviceEngineering

A flow measurement device is disclosed, in which an accumulation of pollution substance onto a detection element is prevented, and which can measure a reverse flow similarly to a normal flow. On both ends of an outer wall 23 outer peripheral portion of a divided flow pipe 20 having a OMEGA-shape pipe passage, there are oppositely formed an inlet port 25 and an outlet port 26, which open in faces orthogonal to a flow direction of a main flow M that is a detection object. Within the divided flow pipe 20, by a curved partition 27, plural branch flow passages 28a, 28b mutually branching and joining in the divided flow pipe 20 are formed. Inside both end portions of the outer wall 23, undulation portions 32, 33 are formed so as to clog an inlet and an outlet of the outer peripheral side branch flow passage 28a and, by this, throttles are formed respectively in a flow passage between the inlet port 25 and the inlet of the branch flow passage 28a and a flow passage between the outlet port 26 and the outlet of the branch flow passage 28a. In a bottom portion of the outer wall 23 of the divided flow pipe 20, a detection element 31 is attached so as to be exposed to a flow in the outer peripheral side branch flow passage 28a and, against its detection face, a down flow DW further divided from a divided flow D obliquely impinges.

Owner:NGK SPARK PLUG CO LTD

Microfluidic apparatus and methods for performing blood typing and crossmatching

ActiveUS8318439B2Increase ratingsEasy to distinguishBioreactor/fermenter combinationsBiocideAntigenAntibody-mediated agglutination

Owner:PERKINELMER HEALTH SCIENCES INC

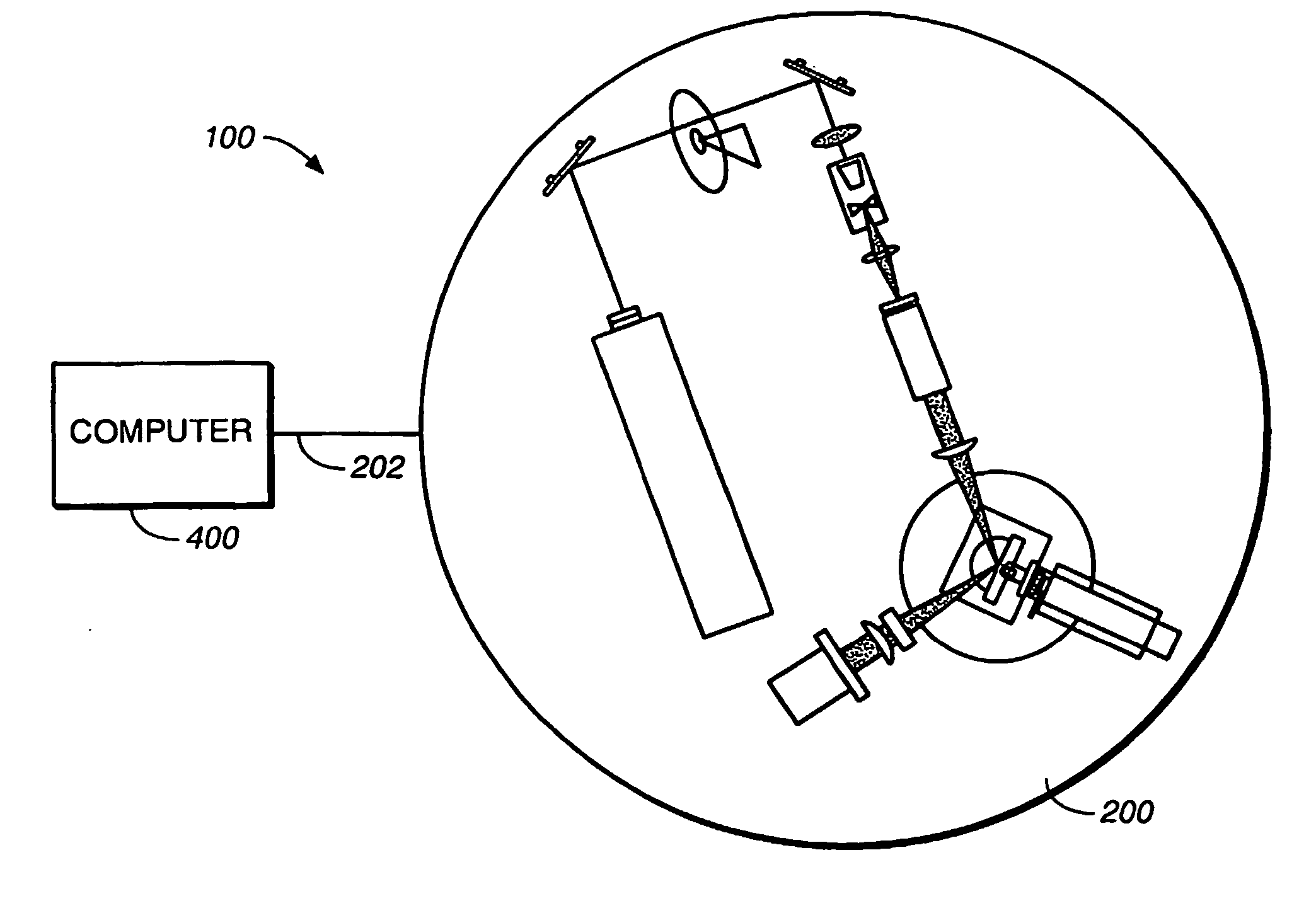

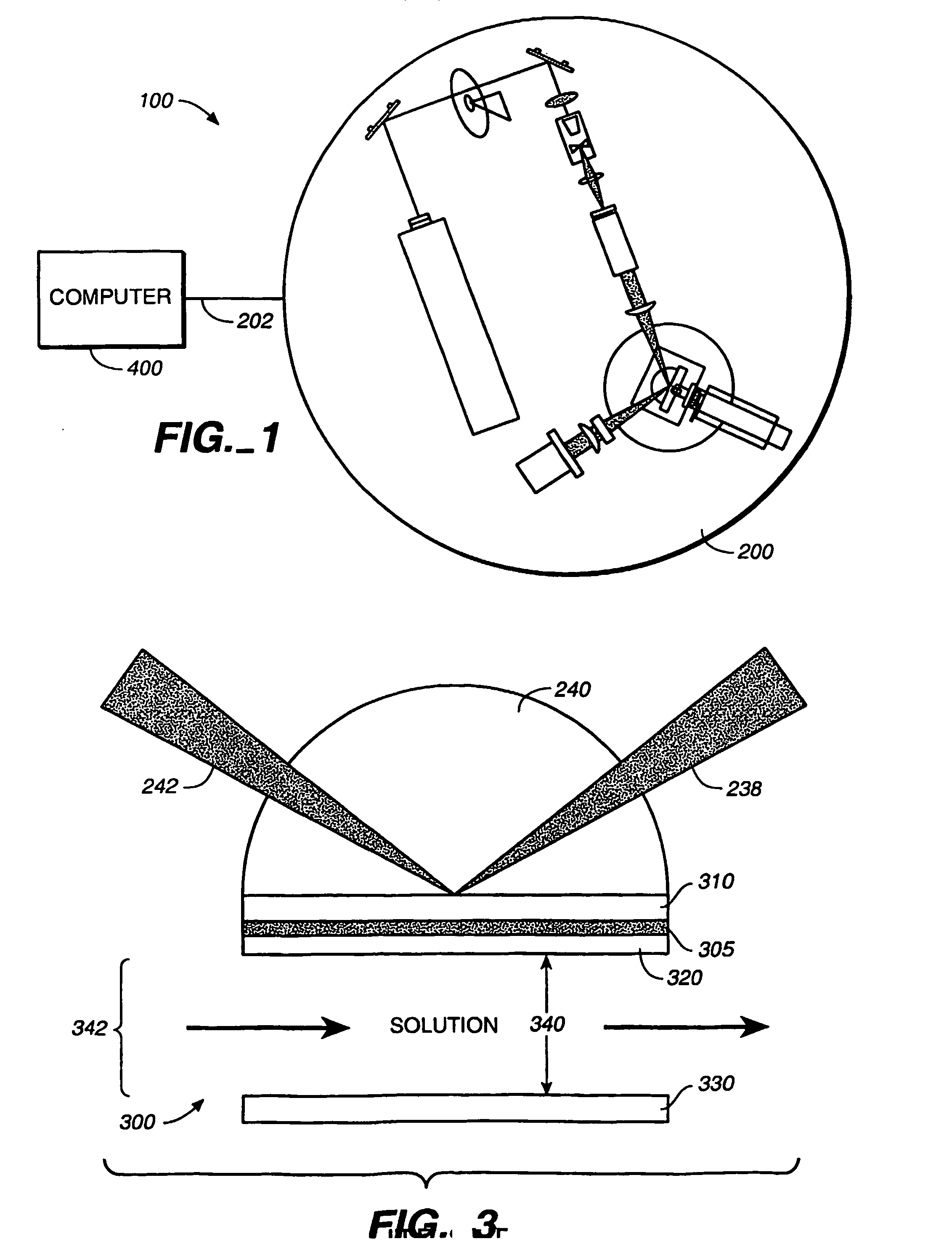

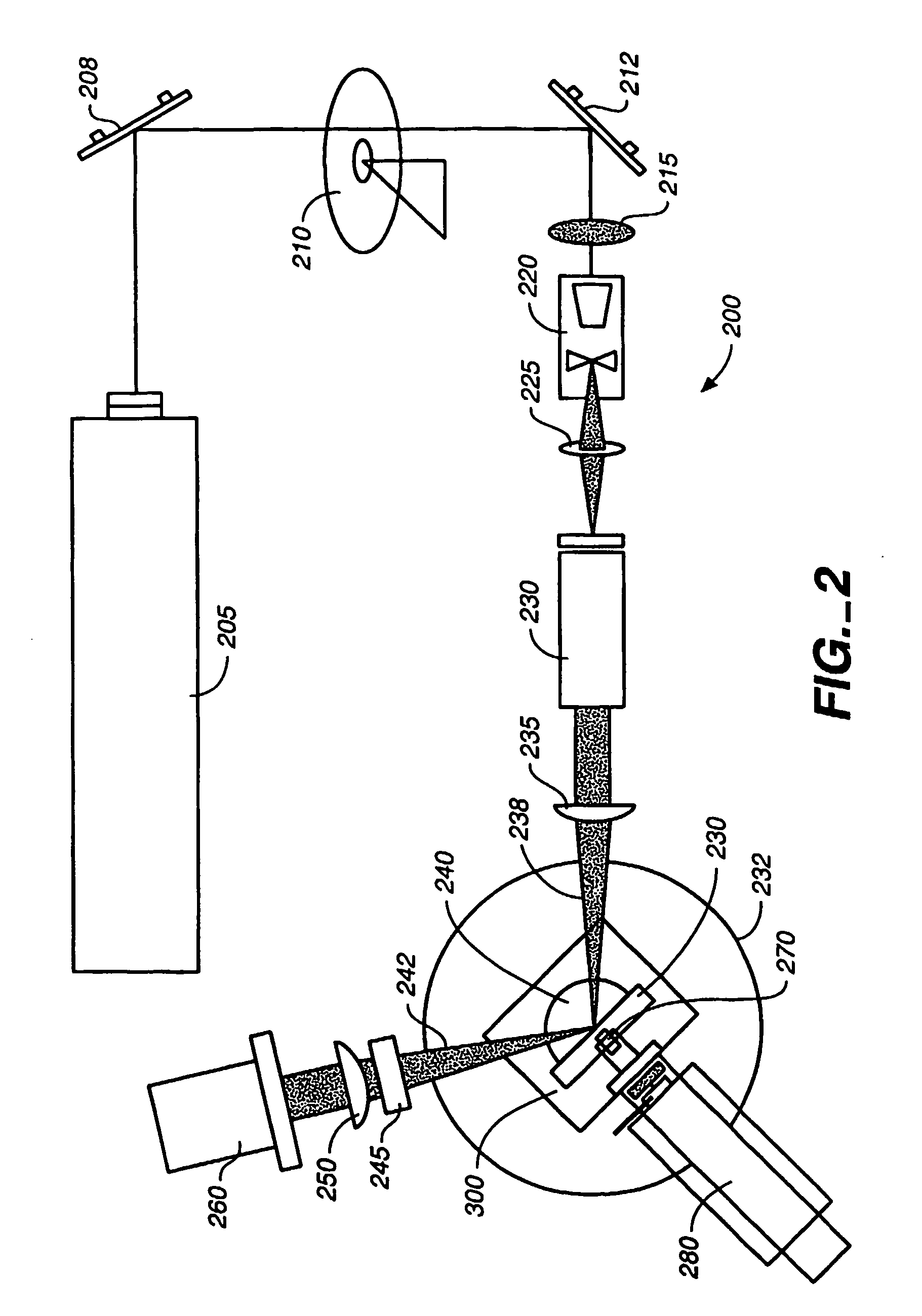

System and method of measuring molecular interactions

InactiveUS20060127278A1Lower Reynolds numberMaterial nanotechnologyBioreactor/fermenter combinationsDiffusionFluorescence

The present disclosure relates to a device for measuring surface plasmon resonance and fluorescence of a sample, a system for determining the rate of catalytic activity of an enzyme, a method of determining the rate of catalytic activity of an enzyme, and a method of measuring the adsorption and reactivity of a substance, all of which use SPR and SPEF methods simultaneously. This invention also relates generally to systems and methods for measuring diffusion and reactivity of macromolecules on a surface.

Owner:GAST ALICE P +4

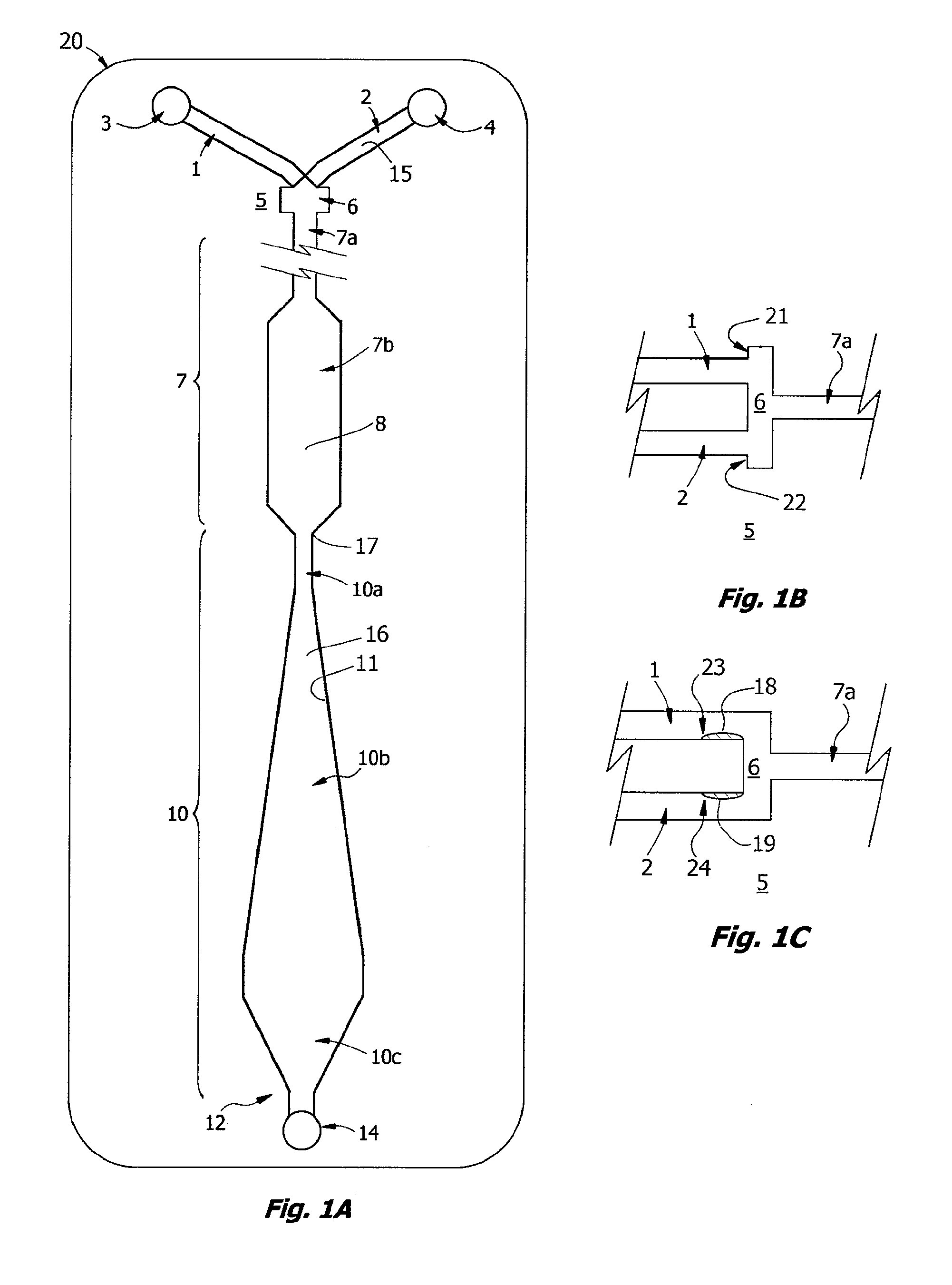

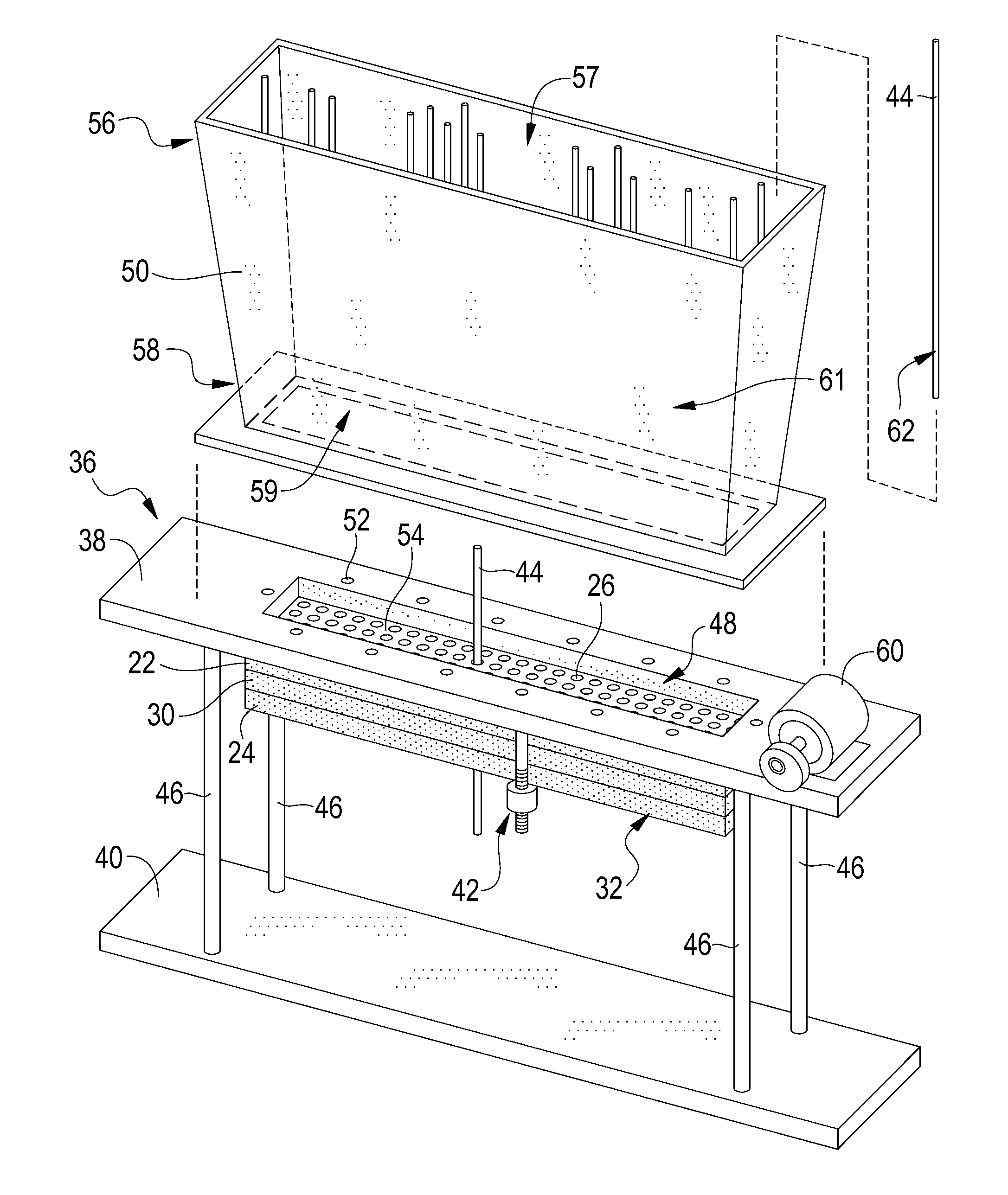

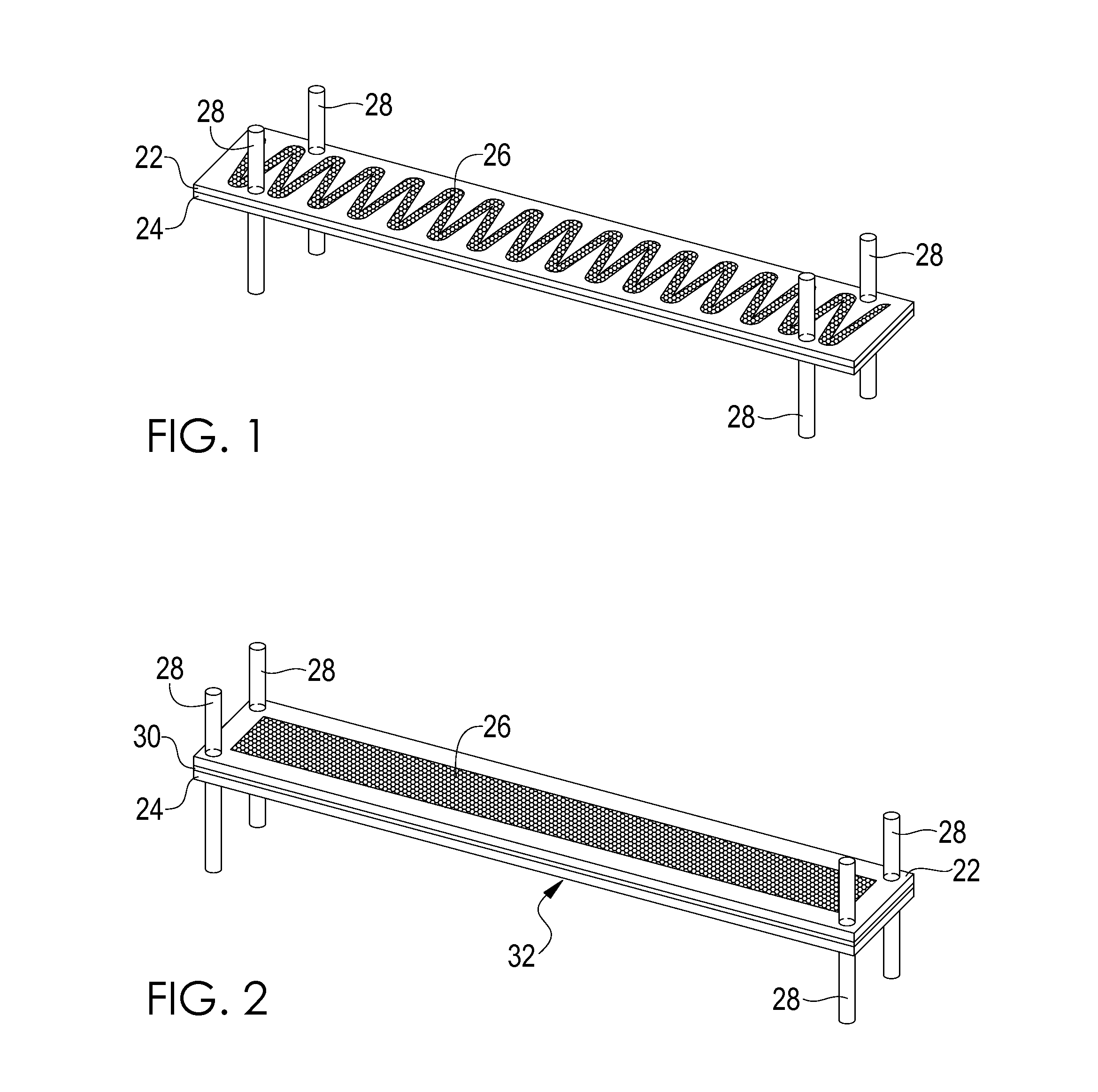

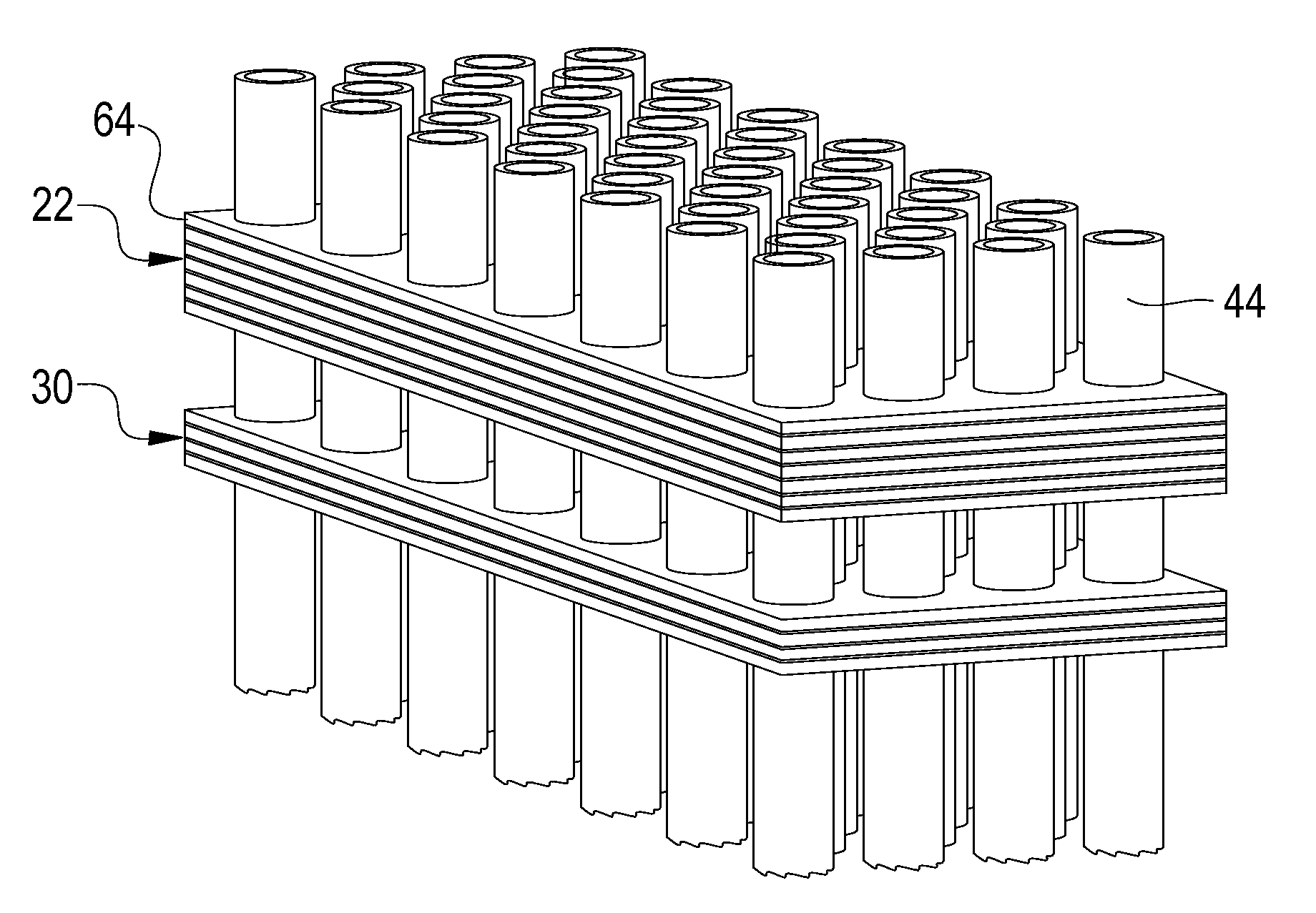

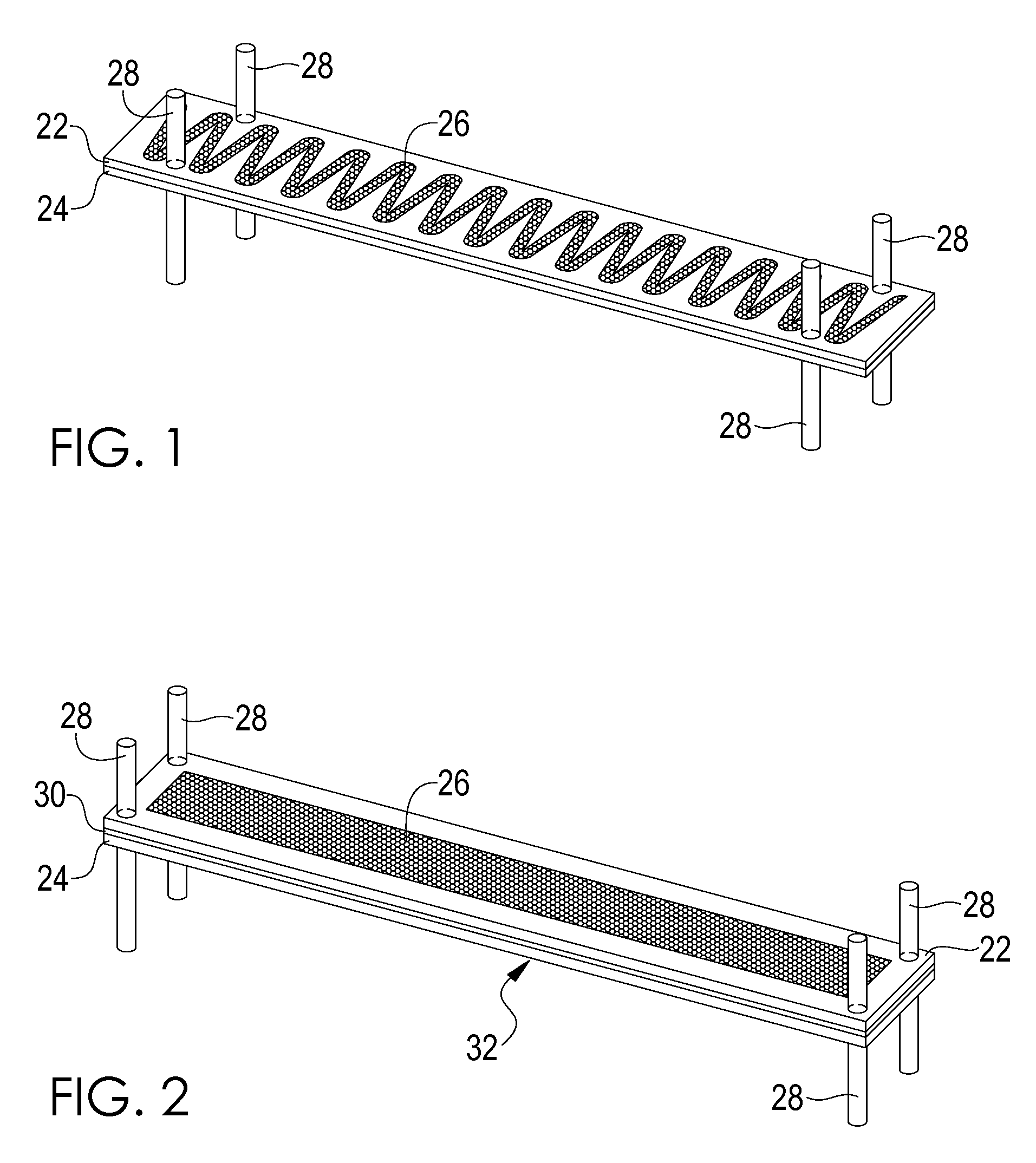

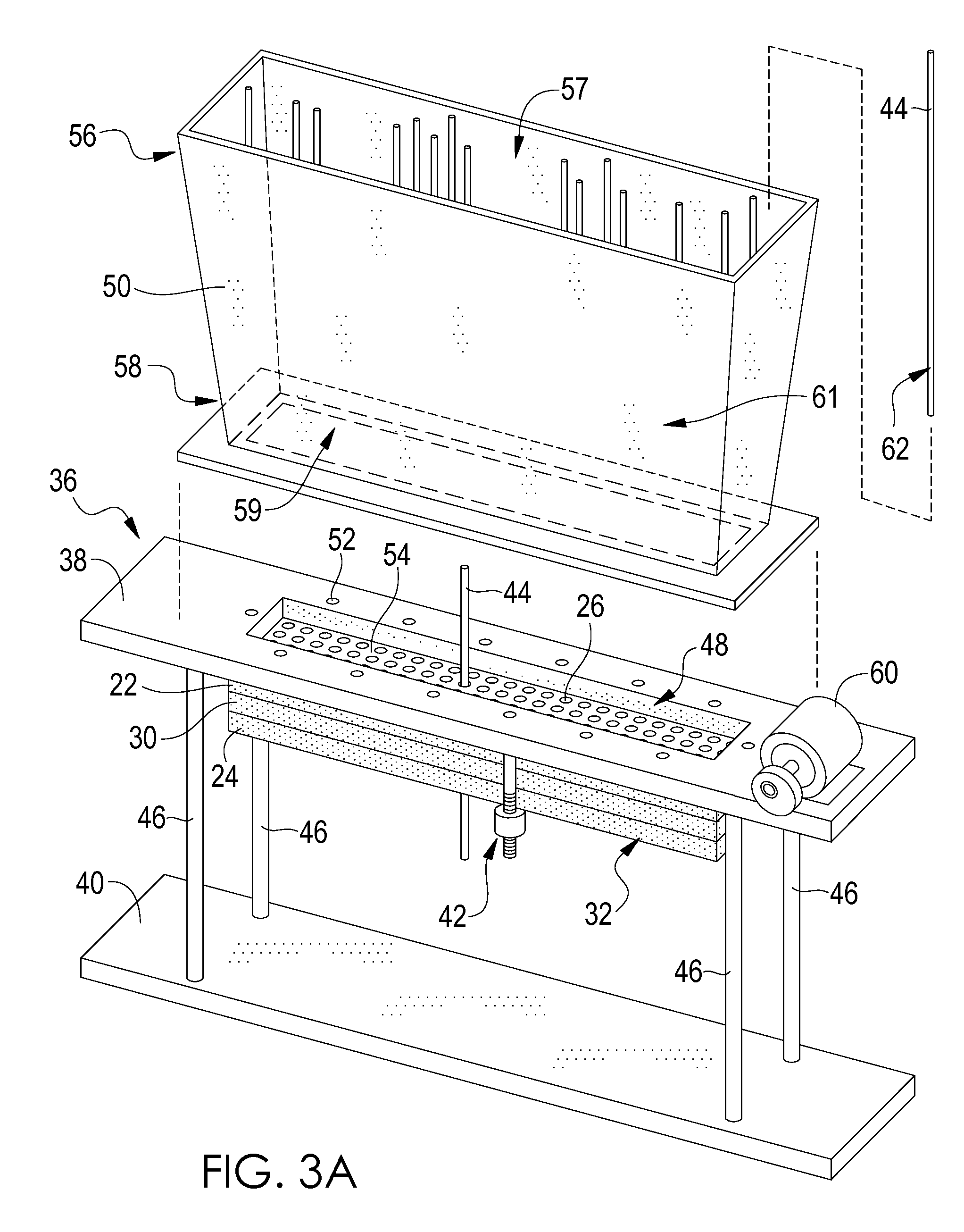

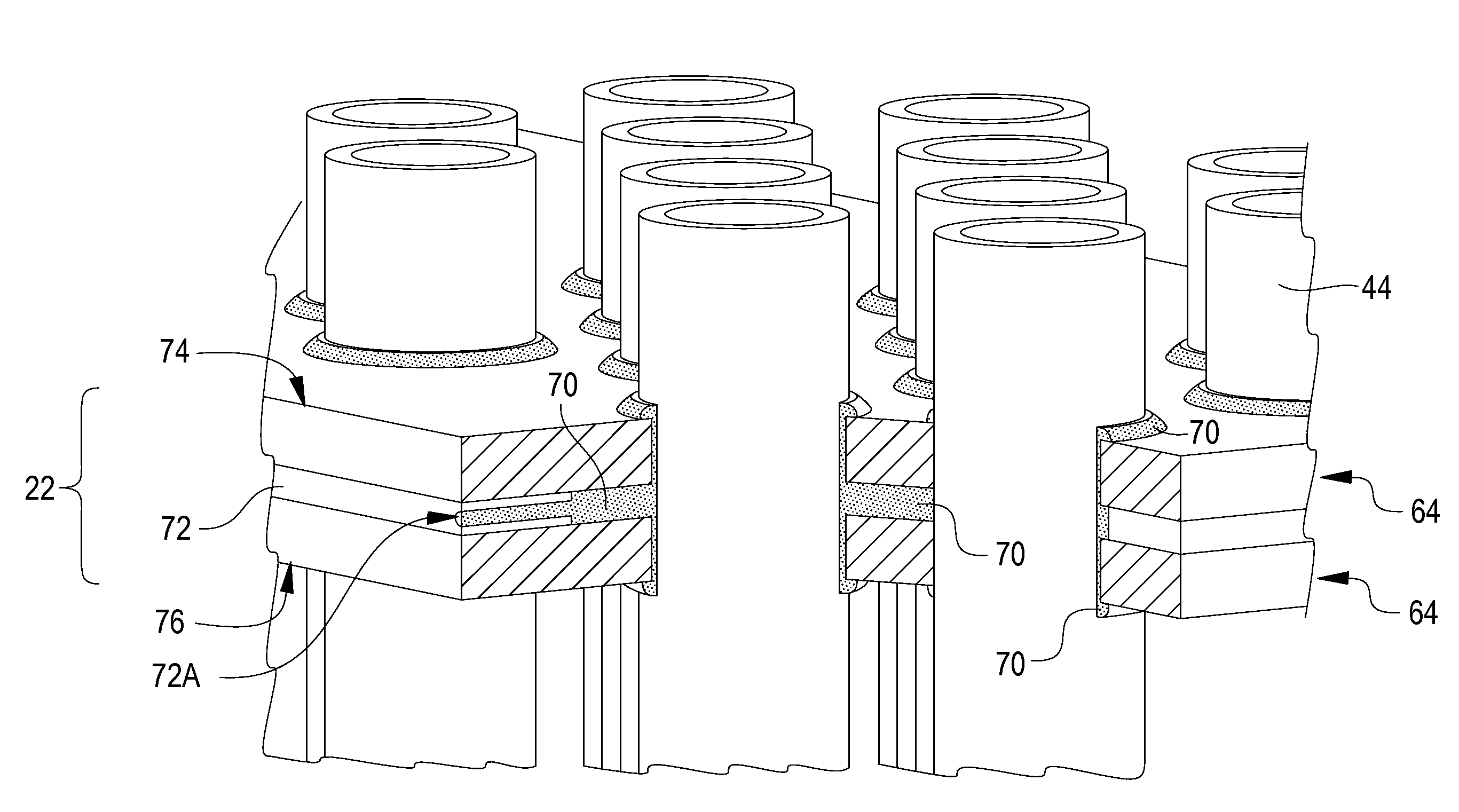

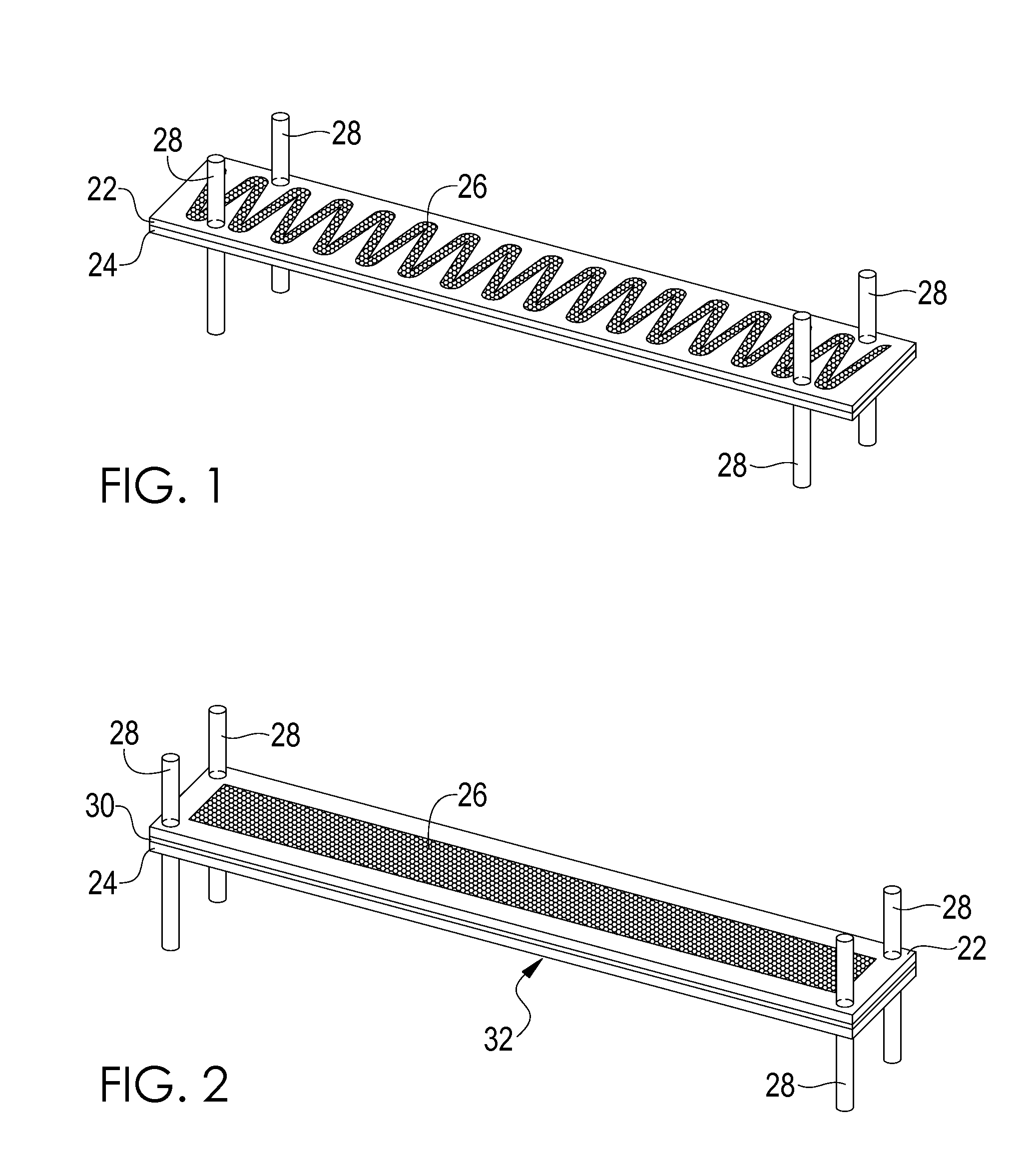

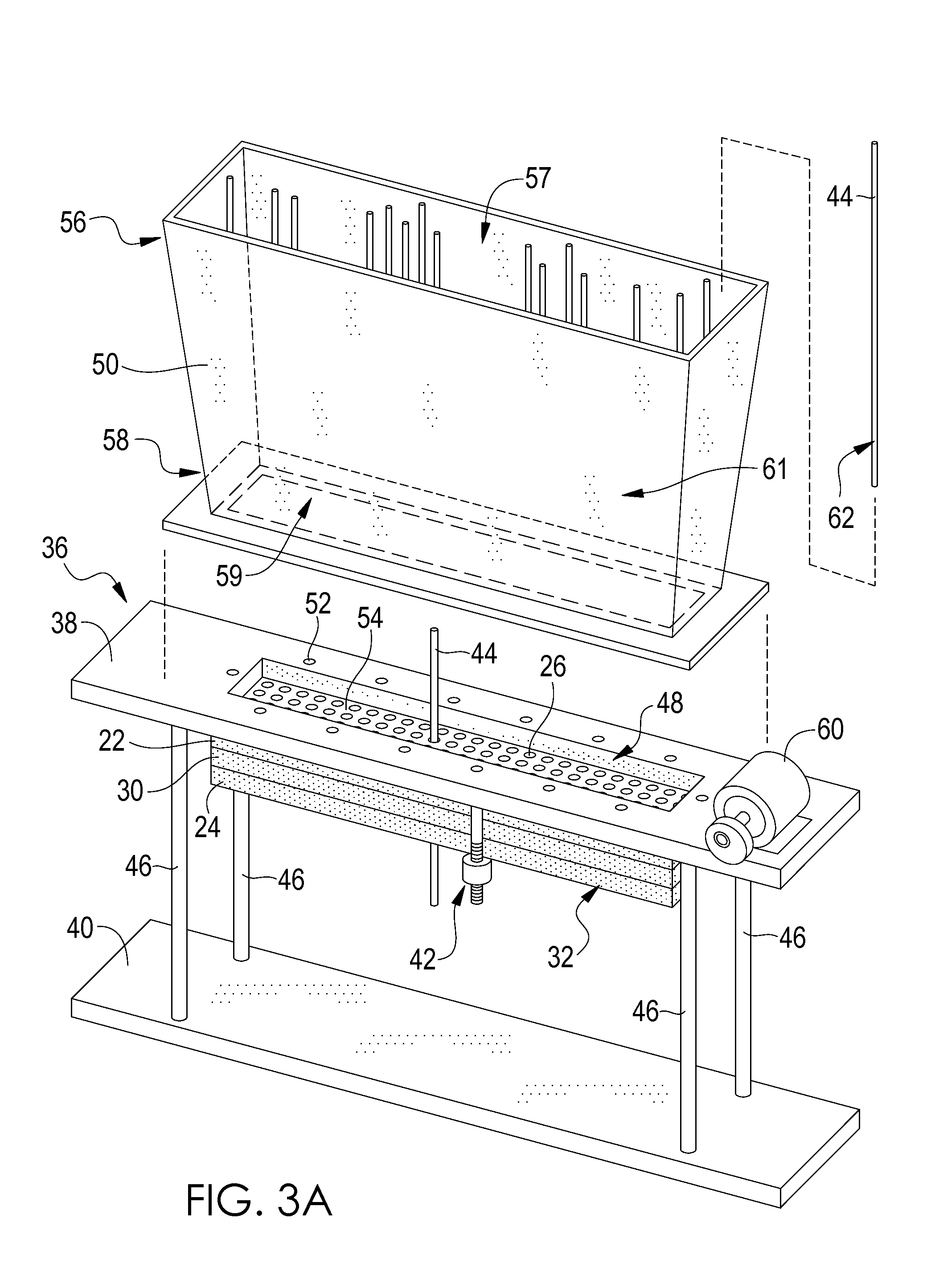

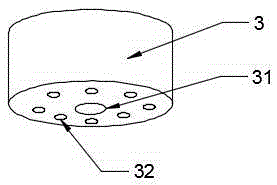

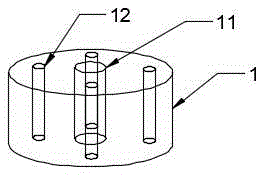

Method for Manufacturing A Micro Tube Heat Exchanger

ActiveUS20110024037A1More volumeImprovement factorAdhesive processes with surface pretreatmentLaminationEngineeringMechanical engineering

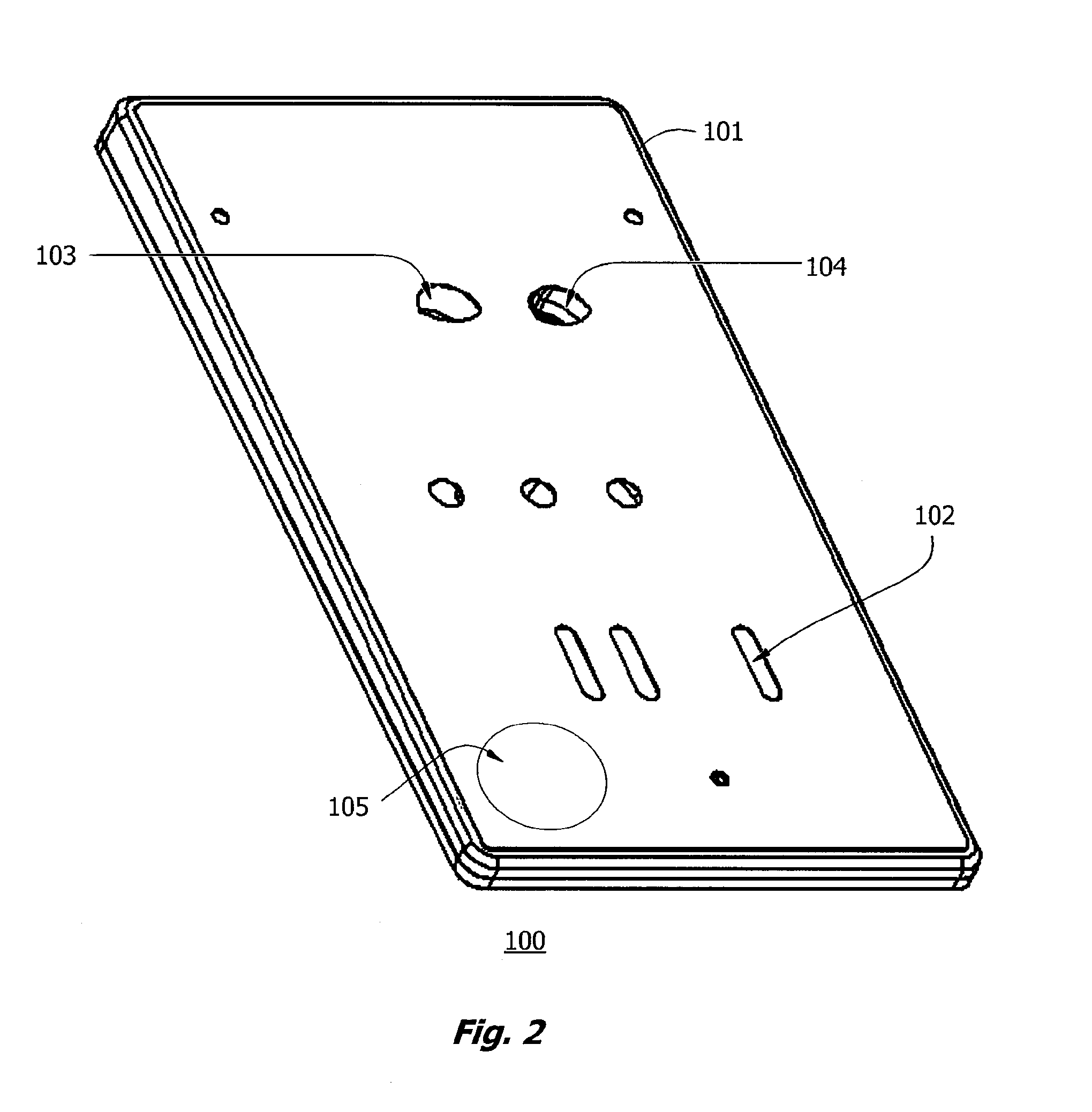

A method including disposing a first end plate adjacent to a second end plate, wherein the first end plate and second end plate each define a pattern of apertures. The first end plate is aligned with the second end plate such that the pattern of apertures in the first end plate is substantially aligned with the pattern of apertures in the second end plate. The method includes placing an end portion of each of a plurality of micro tubes in contact with the first end plate, the micro tubes being substantially vertically disposed and substantially perpendicular to a top surface of the first end plate, so as to place the micro tubes on the first end plate, and vibrating at least one of the micro tubes while the micro tubes are on the first end plate, thereby causing the micro tubes to insert into and through respective aligned apertures of the patterns of apertures in the first end plate and the second end plate. The method further includes separating the first end plate from the second end plate while the micro tubes extend therethrough, until the first end plate and the second end plate are disposed proximate to respective end portions of the micro tubes extending therethrough, and affixing each end portion of the micro tubes to a respective end plate, thereby forming a pathway in a micro tube heat exchanger component for the flow of an internal fluid to be heated or cooled by external flow of an external fluid.

Owner:INT MEZZO TECH

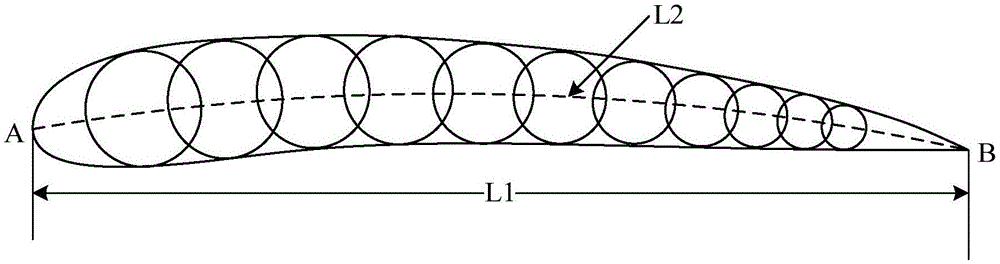

Low-Reynolds-number wing section matched with full-wing solar unmanned aerial vehicle

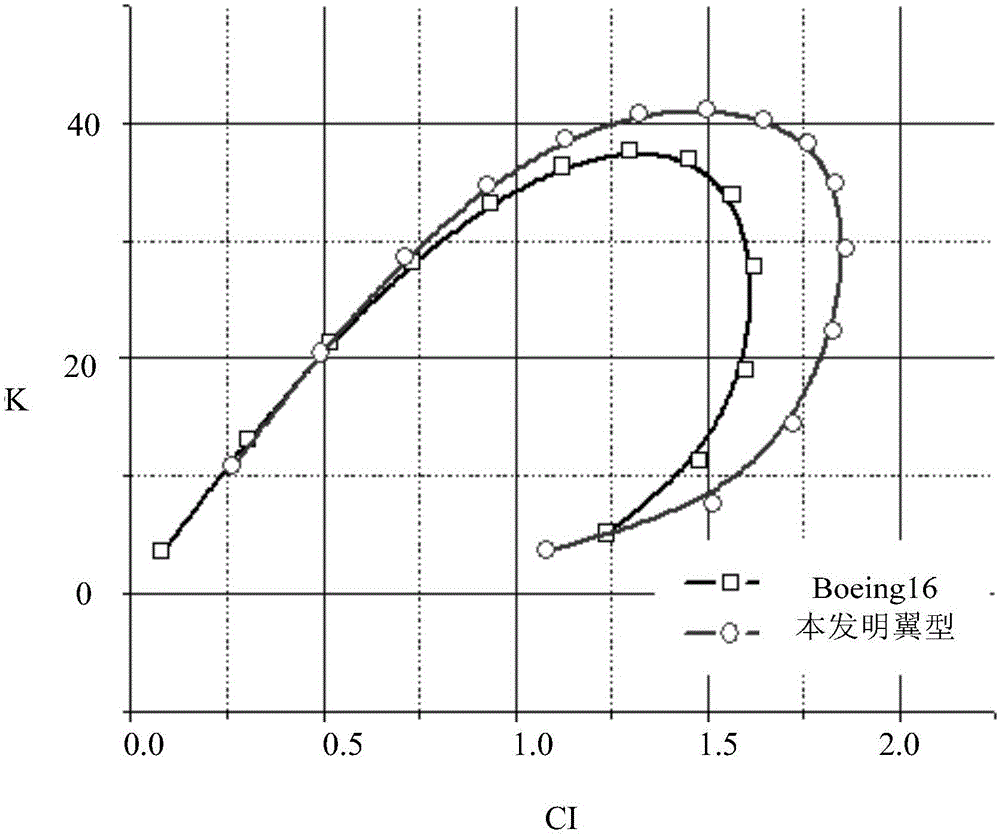

ActiveCN103482054AImprove the lift-to-drag ratioAchieve self-levelingWing shapesHeat reducing structuresHigh liftFront edge

The invention provides a low-Reynolds-number wing section matched with a full-wing solar unmanned aerial vehicle. The low-Reynolds-number wing section is characterized in that the relative thickness of the wing section is 11%-13%, the maximum camber of the wind section is 2%-4%, and a chordwise position with the maximum camber is 25%-30%; the wing section has a single bent outline in a 70% chordwise range from a front edge. With a full-aircraft matching design, the checking of pneumatic characteristics of a pair of wing sections is finished by checking the corresponding pneumatic characteristics of the wing sections and applying the two wing sections to the full-wing solar unmanned aerial vehicle, and the low-Reynolds-number wing section shows good pneumatic characteristics and engineering enforceability and can meet application demands on low Reynolds number, high lift force and lift-to-drag ratio and large relative thickness of the full-wing solar unmanned aerial vehicle.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method for manufacturing a micro tube heat exchanger

ActiveUS8177932B2More volumeImprovement factorAdhesive processes with surface pretreatmentLaminationEngineeringMechanical engineering

Owner:INT MEZZO TECH

Method for Manufacturing A Micro Tube Heat Exchanger

InactiveUS20120211158A1More volumeImprovement factorSoldering apparatusLaminationMechanical engineeringHeat exchanger

Method for fabricating a heat exchanger which, in one aspect, includes providing a stack of a plurality of lamina each of which defines a pattern of lamina apertures, the apertures being substantially alignable in the stack; disposing a plurality of microtubes through respective aligned lamina apertures extending through and defined by the stack of lamina so as to form a subassembly, a clearance existing between each of the microtubes and their respective aligned apertures when the microtubes are so disposed; and adhering together the lamina in the stack and the plurality of microtubes so disposed while forming a seal at the clearances.

Owner:INT MEZZO TECH

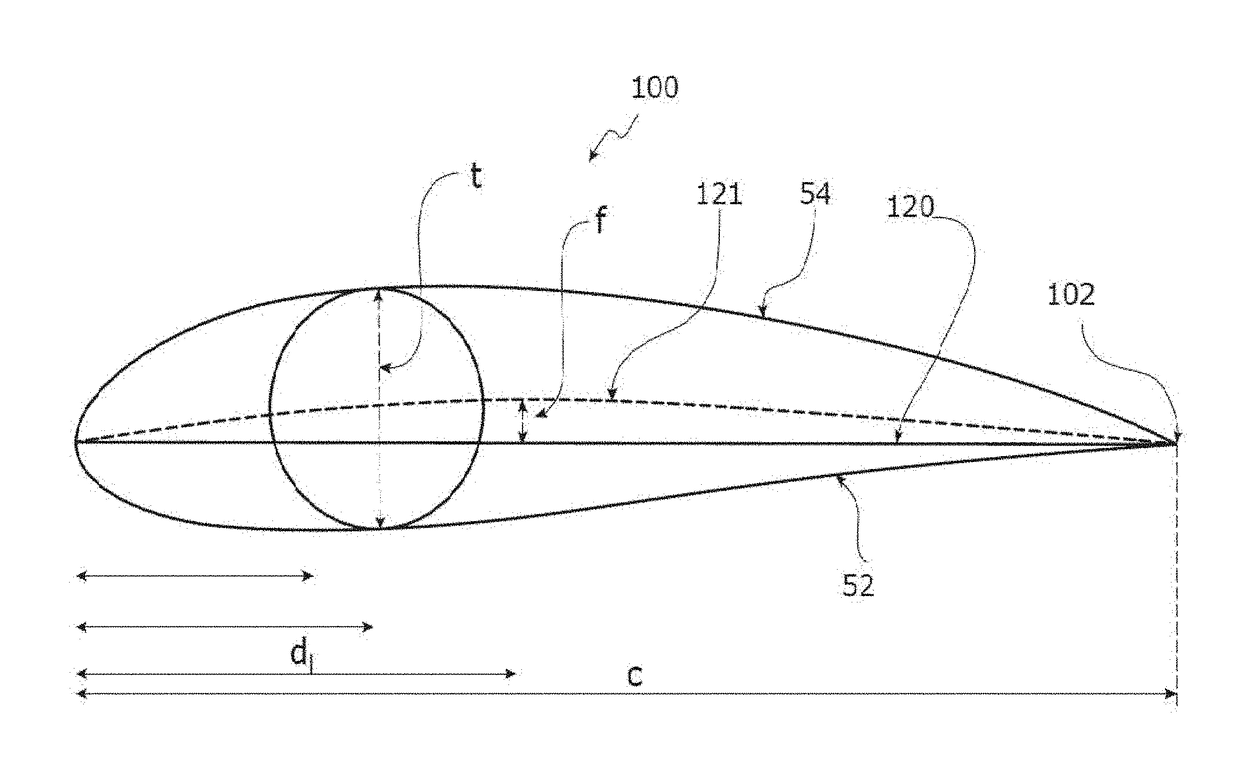

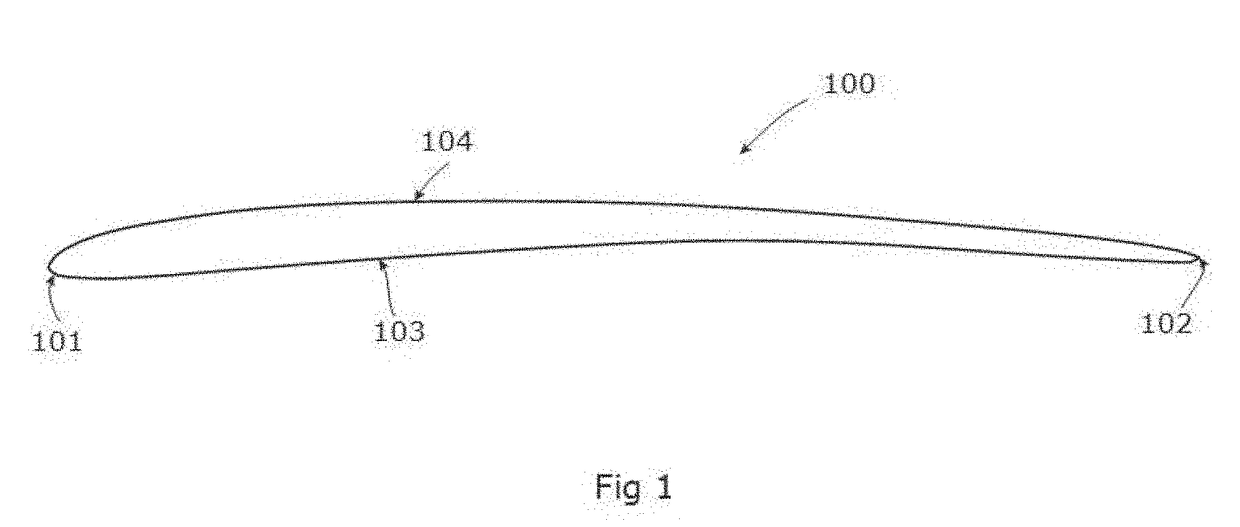

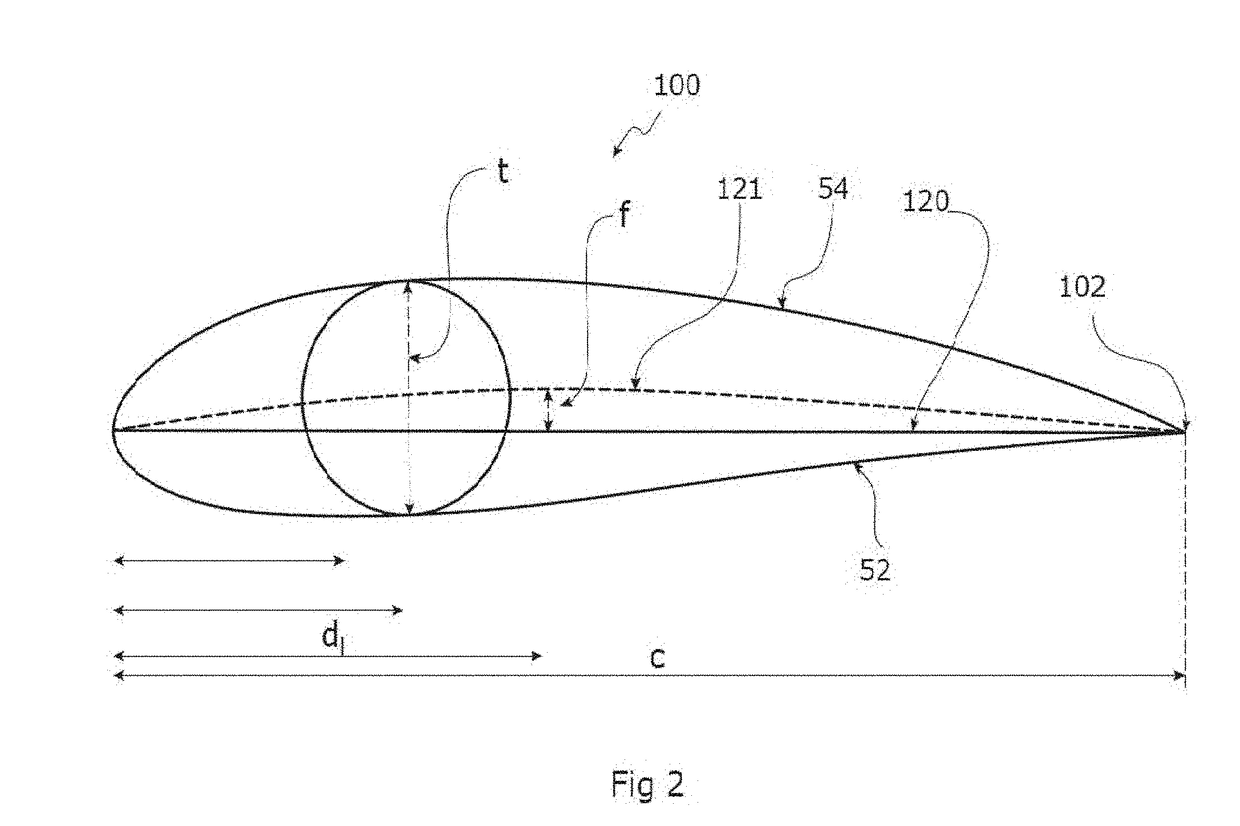

Low Reynolds Number Airfoil for a Wind Turbine Blade and Method Thereof

ActiveUS20180135593A1Lower Reynolds numberMachines/enginesWind energy generationLeading edgeTurbine blade

A low Reynolds number airfoil for a wind turbine blade, the airfoil having a leading edge 101, a trailing edge spaced from the leading edge 101, a chord 120 defined as a straight line joining the leading edge 101 and the trailing edge, a chord 120 length defined as distance between the trailing edge and the point on the leading edge 101 where the chord 120 intersects the leading edge 101 wherein the airfoil comprises a camber 121 between 5% to 7% of the chord 120 length, the camber 121 is disposed within a distance of 17% of the chord 120 length from the leading edge 101 and a thickness of the airfoil not greater than 7% of the chord 120 length. In an embodiment, it discloses A method of designing blade for low wind speed turbine for a site location, the method comprising obtaining time series data for the site location, computing a Weibull shape factor (K) and scale factor (C)corresponding to a Weibull distribution function based on the time series data for the site location, using K and C to identify energy intensive wind speed at the site location, determining blade length based on the energy intensive wind speed, K, C, a design power (PD) of the turbine, a design power coefficient (Cpd), and a density of the air (Ro), wherein the rated power of the turbine depends on load to be connected of the turbine, selecting a generator for use with the turbine, computing a design tip speed ratio based on a rated speed of the generator (NGD), a gear ratio (GR), the design power (PD), K, and C, identifying number of blades (B) depending on the design tip speed ratio and an end-use of the power being produced by the turbine; and identifying a chord 120 length and twist of the blade from root-to-tip.

Owner:UNIVERSITI BRUNEI DARUSSALAM

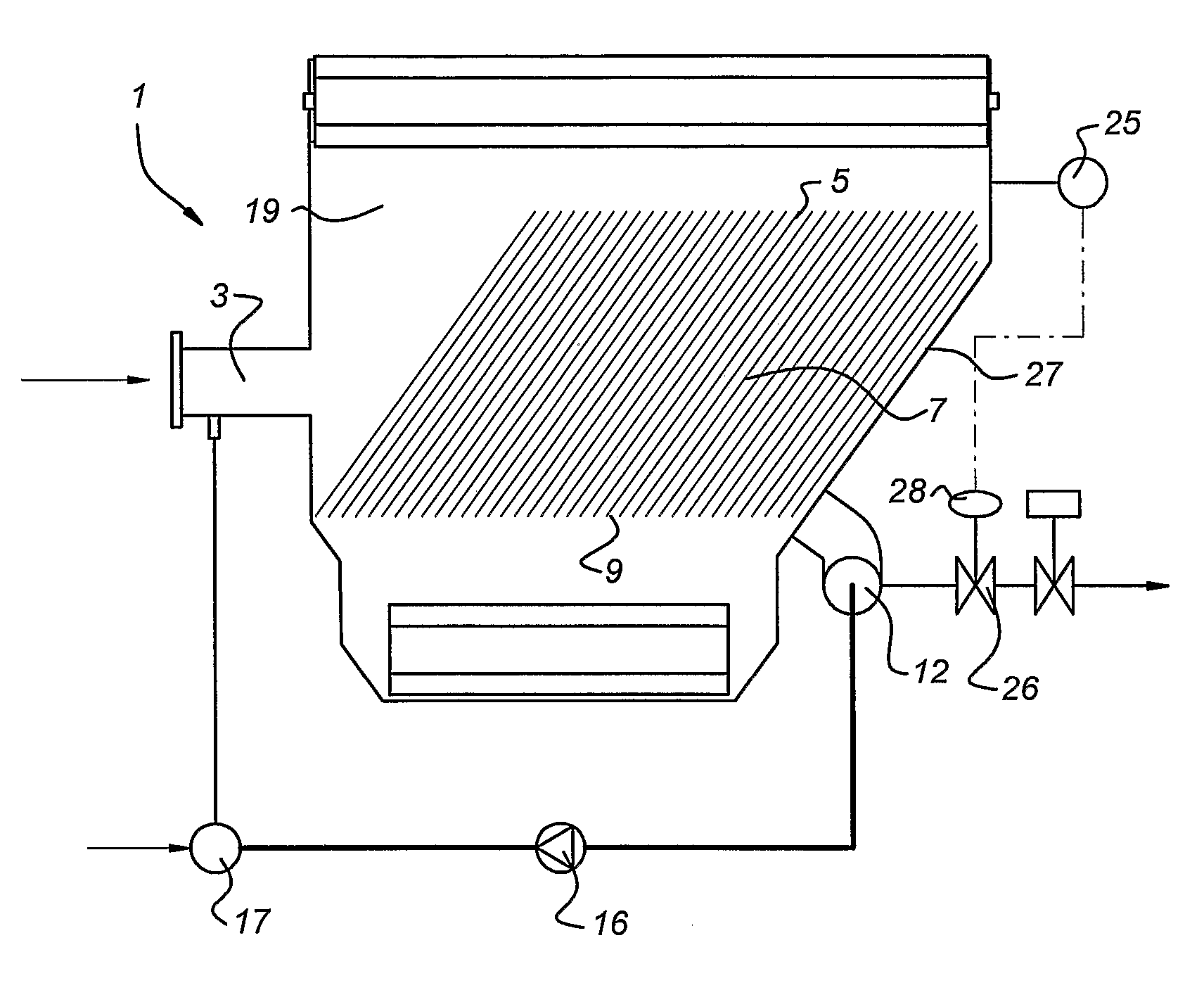

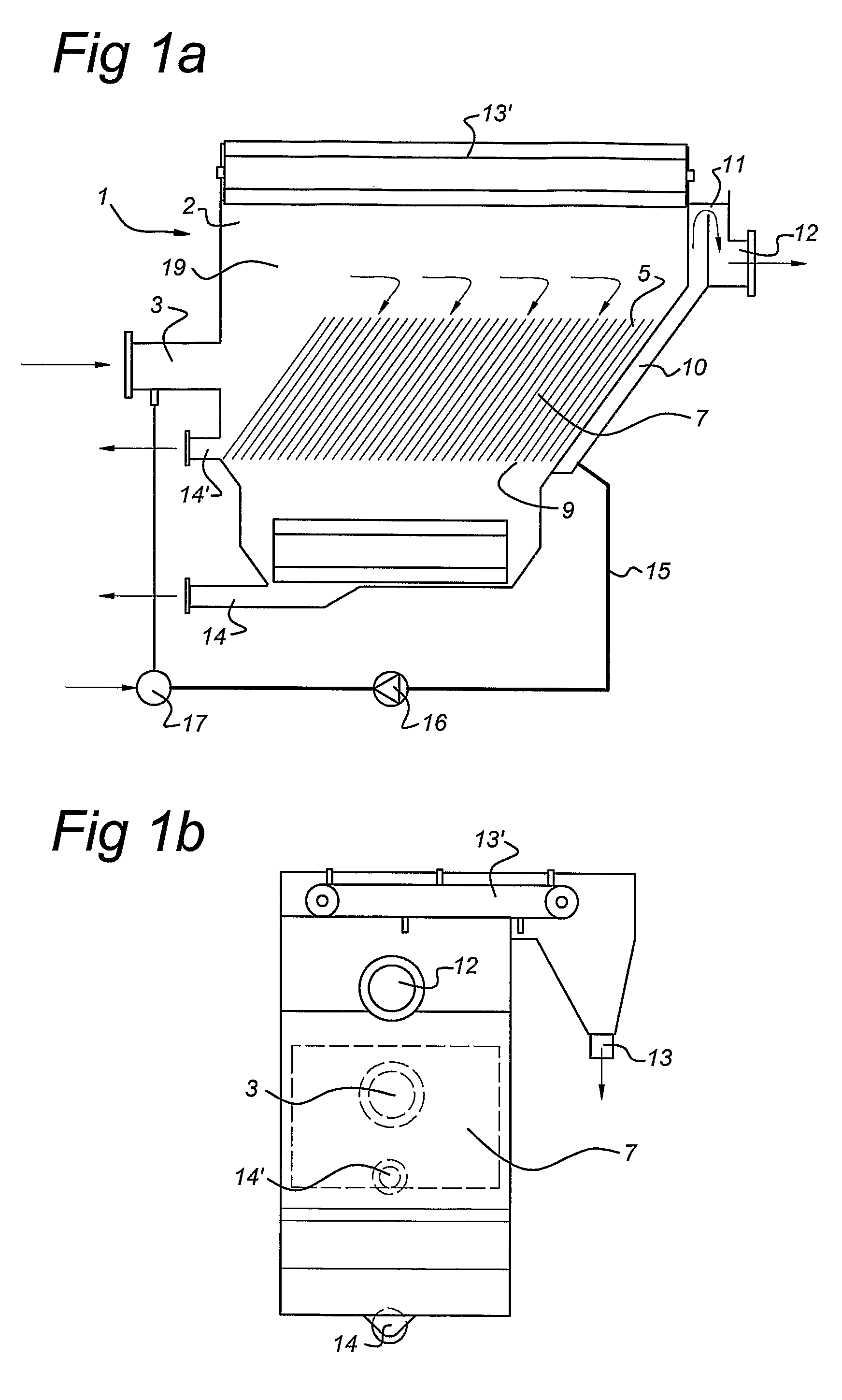

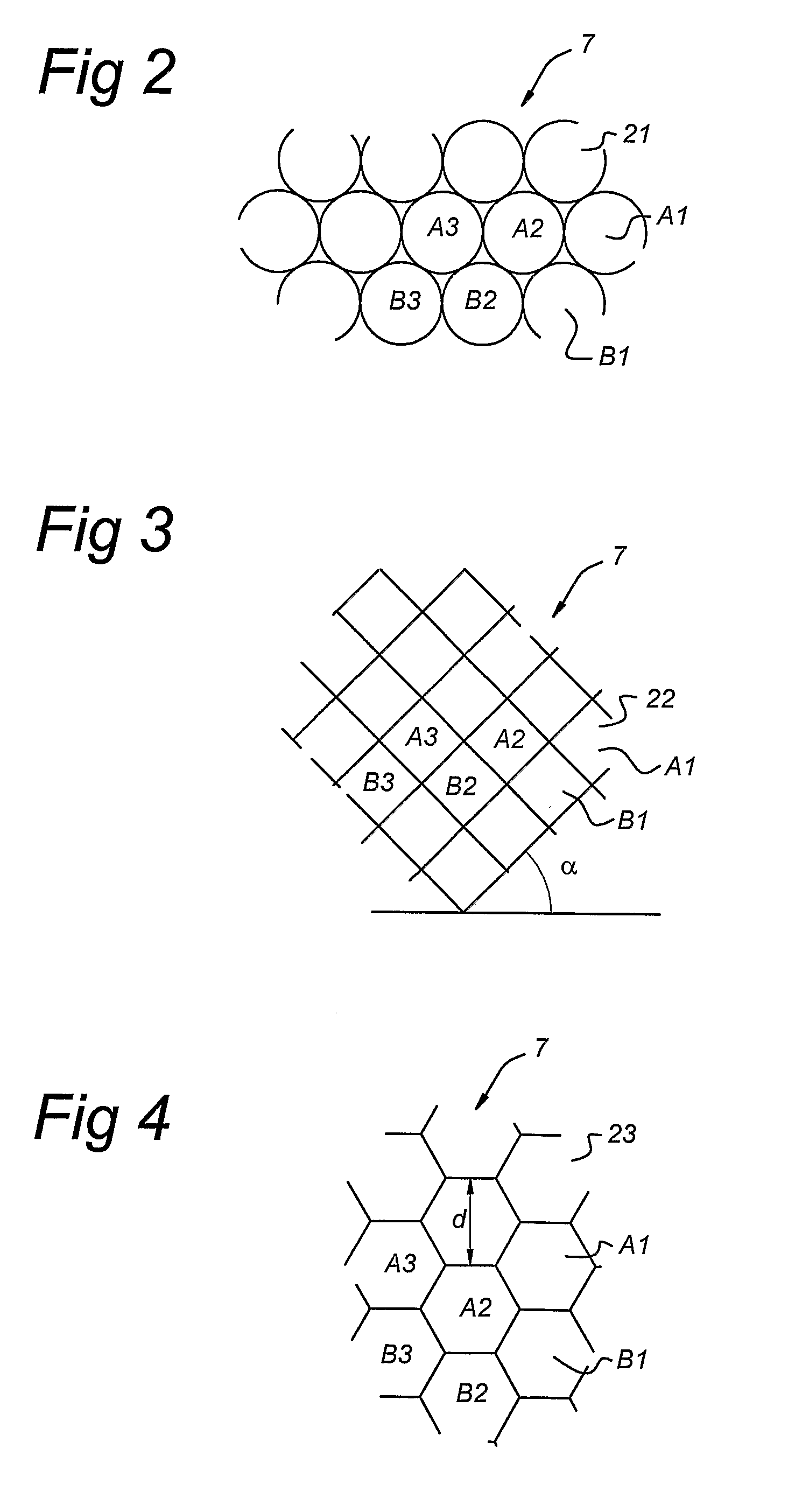

Separator device

ActiveUS7485223B2Increase capacityHigh levelLiquid separation auxillary apparatusLiquid displacementEngineeringClosed cell

The invention relates to a separator device for separating a first liquid substance from a second substance, the two substances forming a mixture. The apparatus comprises a vessel with an inlet for receiving the mixture, a first outlet for discharge of a first fraction of the mixture, a second outlet for discharge of a second fraction of the mixture and a flow element. The flow element comprises a number of parallel tubular channels defining a flow path for the mixture, the channels having an gilet end for receiving the mixture and an outlet end for discharge of the first fraction, a length direction of the channels being inclined with respect to a horizontal direction, wherein in a transverse cross section through the flow element, the channels form a two-dimensional array of closed cells, each cell defining a boundary of a flow channel, the cells being arranged in at least two rows, each cell in a first row contacting with its perimeter a cell in the second row. The device comprises a return duct from a first outlet to the inlet via a gas mixing device.

Owner:NIJHUIS WATER TECH

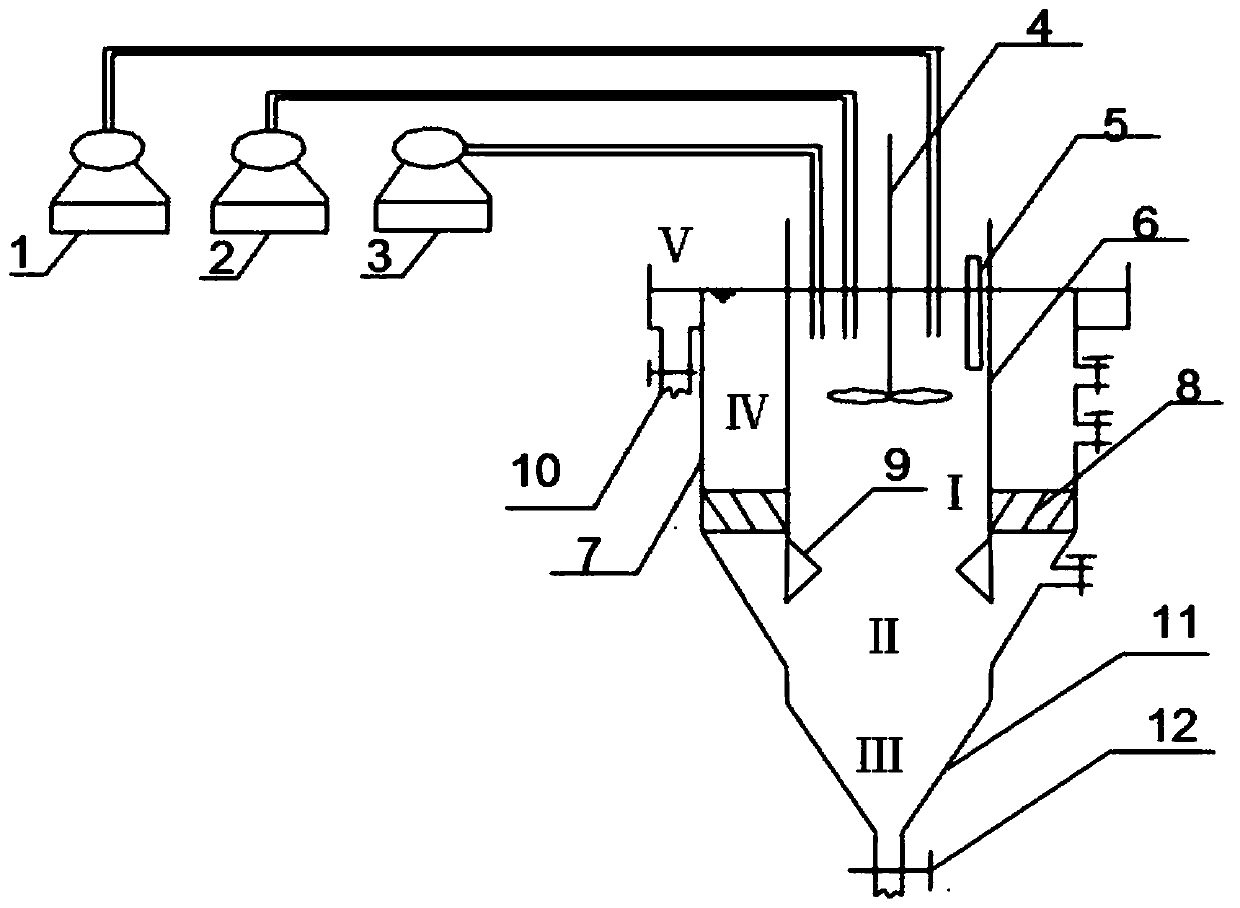

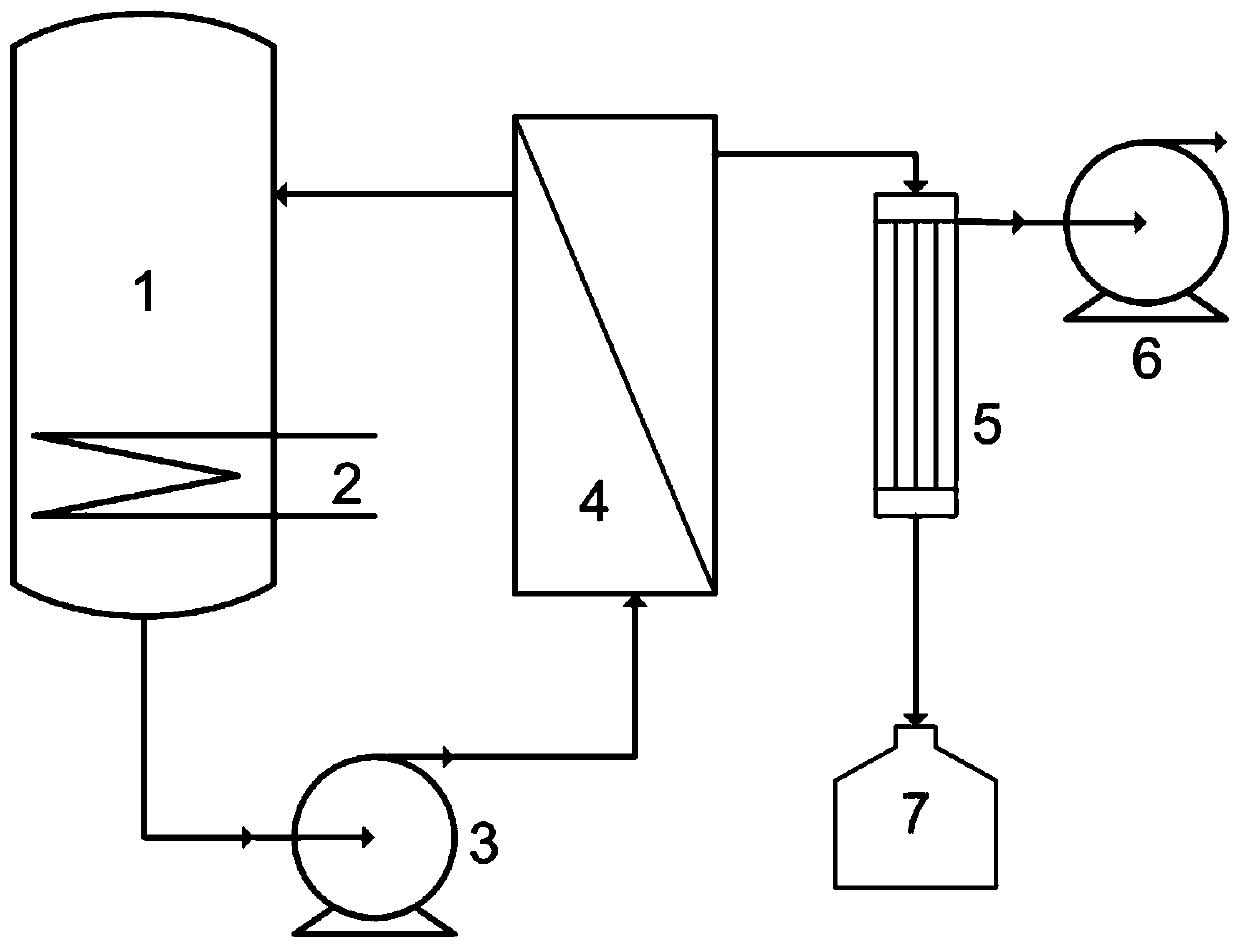

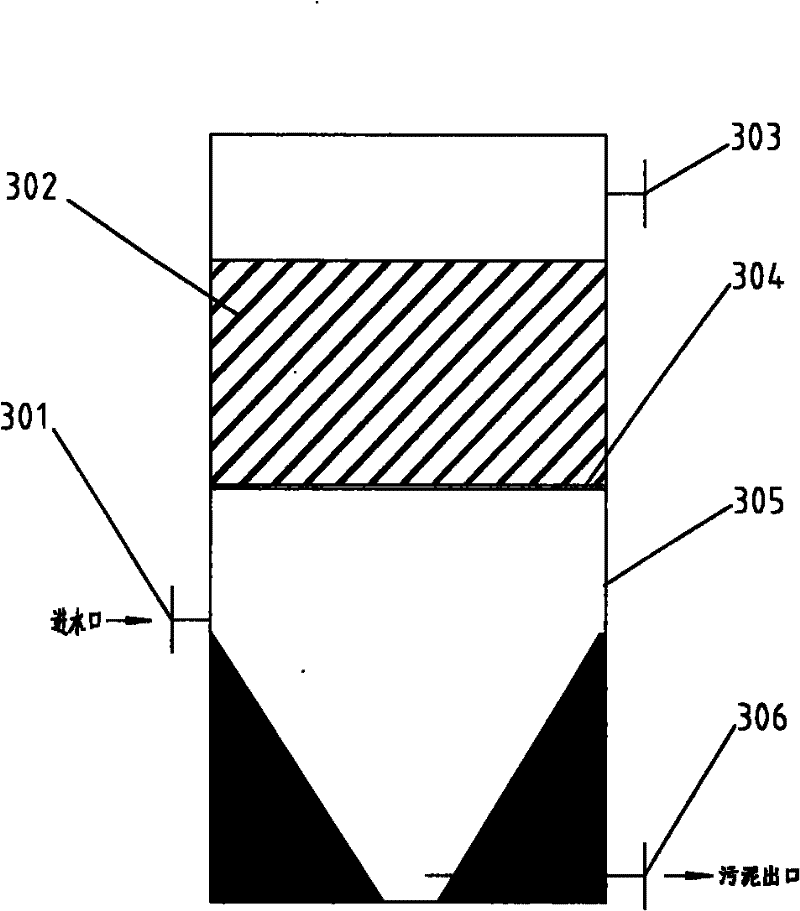

Integrated device and method for efficient magnesium ammonium phosphate crystallization and solid-liquid separation

InactiveCN109928542AEfficient crystallizationEasy to separateSedimentation separationMultistage water/sewage treatmentWater dischargeSludge

Belonging to the technical field of sewage recycling treatment, the invention relates to an integrated device and method for efficient magnesium ammonium phosphate crystallization and solid-liquid separation. A mixed reaction crystallization zone is connected to water intake pumps; a solid-liquid separation zone is disposed between an inner cylinder and an outer cylinder; a buffer zone is under the mixed reaction crystallization zone; an MAP sludge zone is disposed in a cone at the bottom of a reactor, and the bottom is connected to a large aperture valve; a water outlet zone is arranged at the top of the reactor, and employs an overflow water discharge way. The reactor operation includes crystallization reaction and solid-liquid separation processes. The reactor device adopts rapid mechanical stirring way to accelerate crystallization reaction, thus improving the reactor treatment capacity; at the same time, a baffled continuous flow treatment way with the same inflow and outlet waterdirection is employed to prolong the flow path of materials in the reactor, so that the crystallization reaction and solid-liquid separation process can be more complete; by setting an inclined platein the solid-liquid separation zone, efficient solid-liquid separation can be achieved, and MAP loss and secondary pollution can be avoided during water discharge.

Owner:BEIJING UNIV OF TECH

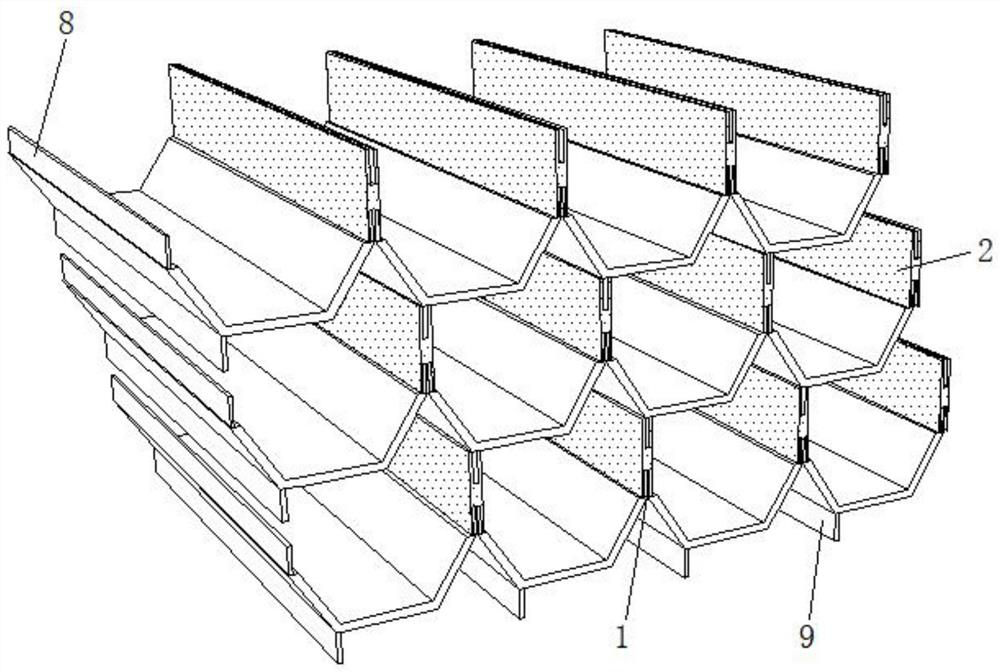

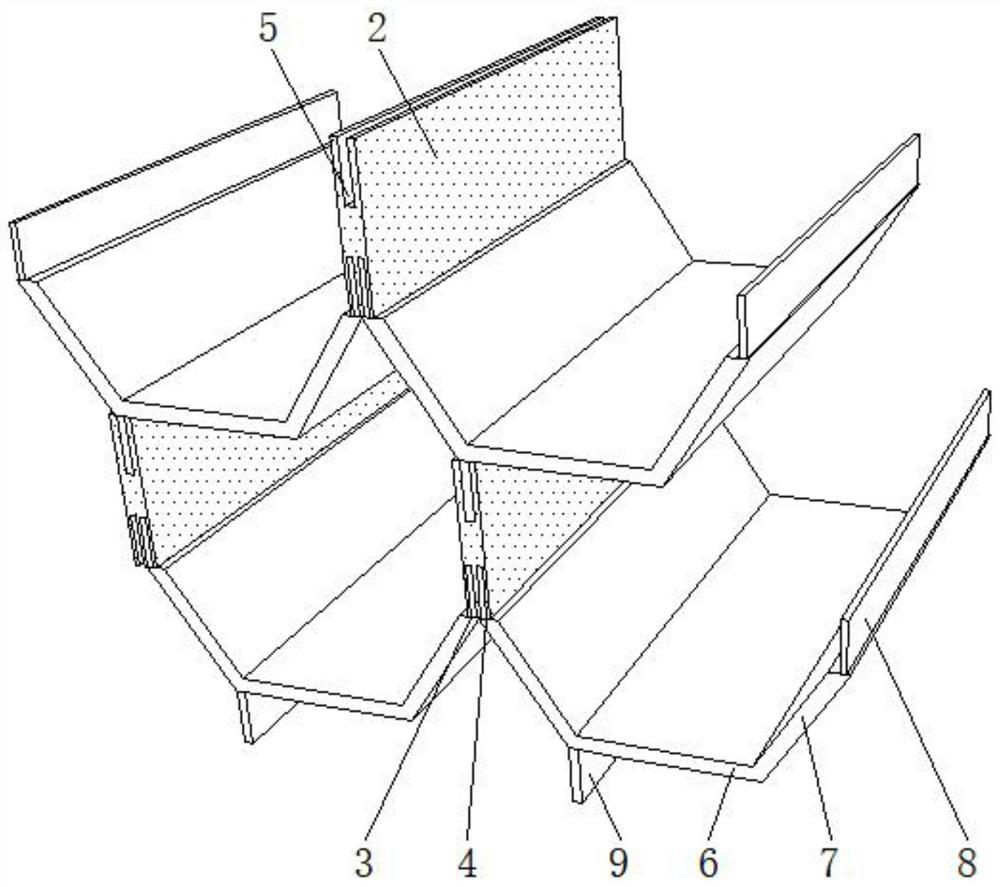

Heat exchanger

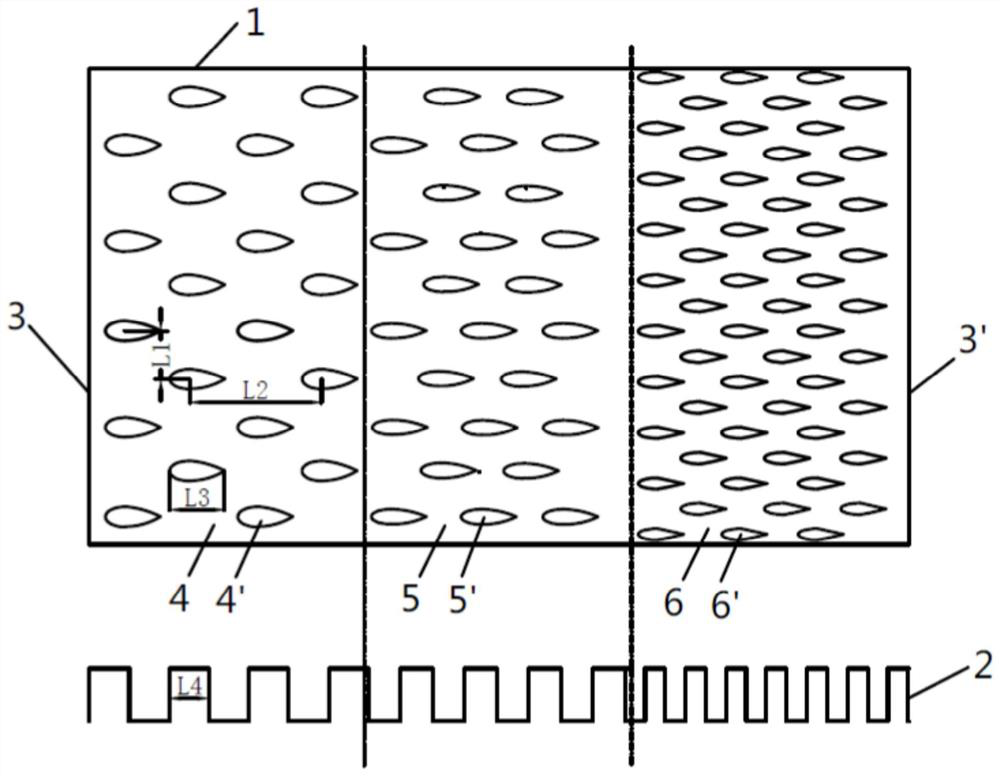

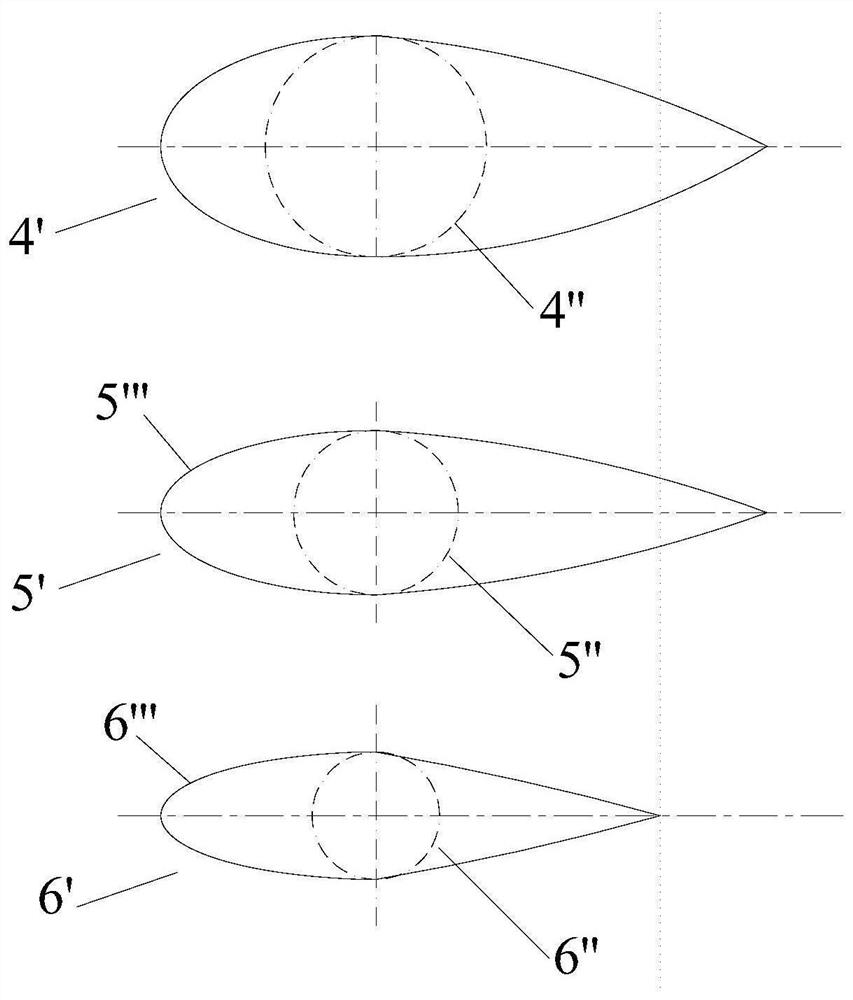

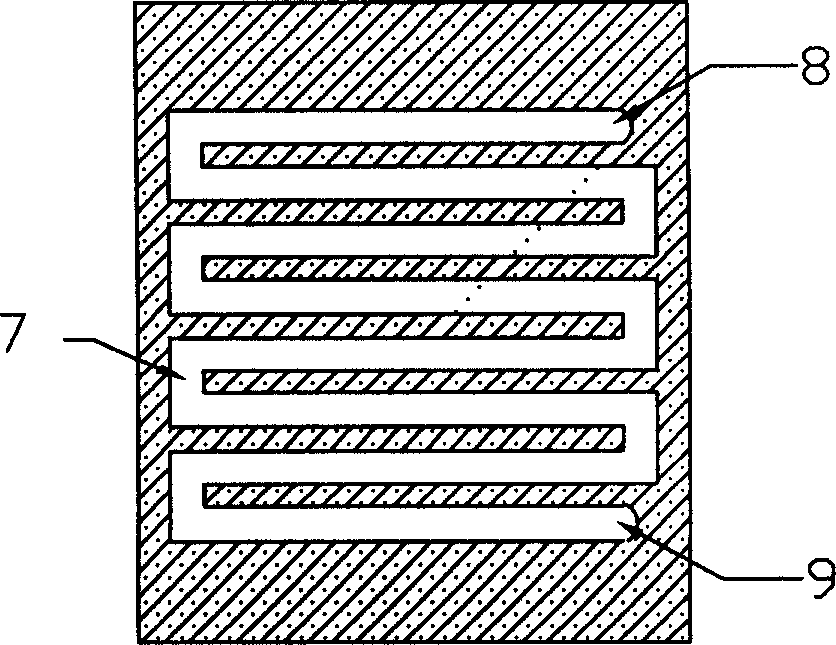

PendingCN111735328AReduce flow rateLower Reynolds numberHeat exchanger casingsHeat exchanger fasteningEngineeringMechanical engineering

The invention discloses a heat exchanger. The heat exchanger comprises multiple heat exchange plates and multiple rectangular wavy fins. The multiple heat exchange plates and the multiple rectangularwavy fins are alternately stacked and closely connected. Each heat exchange plate comprises an upper plate and a lower plate. A heat exchange plate inlet, an ordinary heat exchange region, two-stage or higher-stage enhanced heat exchange regions and a heat exchange plate outlet are arranged in the lower surface of each upper plate and the upper surface of the corresponding lower plate in the working medium flowing direction. Multiple discontinuous wing type ribs are arranged in each heat exchange region. Compared with the density of the wing type ribs of each ordinary heat exchange region, thedensity of the wing type ribs of the corresponding first-stage enhanced heat exchange region is increased. Compared with the density of the wing type ribs of each previous-stage heat exchange region,the density of the wing type ribs of the corresponding later-stage enhanced heat exchange region is increased. According to the heat exchanger, each heat exchange plate comprises the multiple corresponding heat exchange regions, different arrangement forms of the wing type ribs are arranged in each heat exchange region, the corresponding rectangular wavy fins are set to be of an unequal-intervalfin structure, the purpose that the heat exchange areas and the flow disturbance of the heat exchange plates and the fins are gradually increased from line to plane in the working medium flowing direction is achieved, and the improvement of the whole heat exchange performance is achieved.

Owner:浙江高晟光热发电技术研究院有限公司

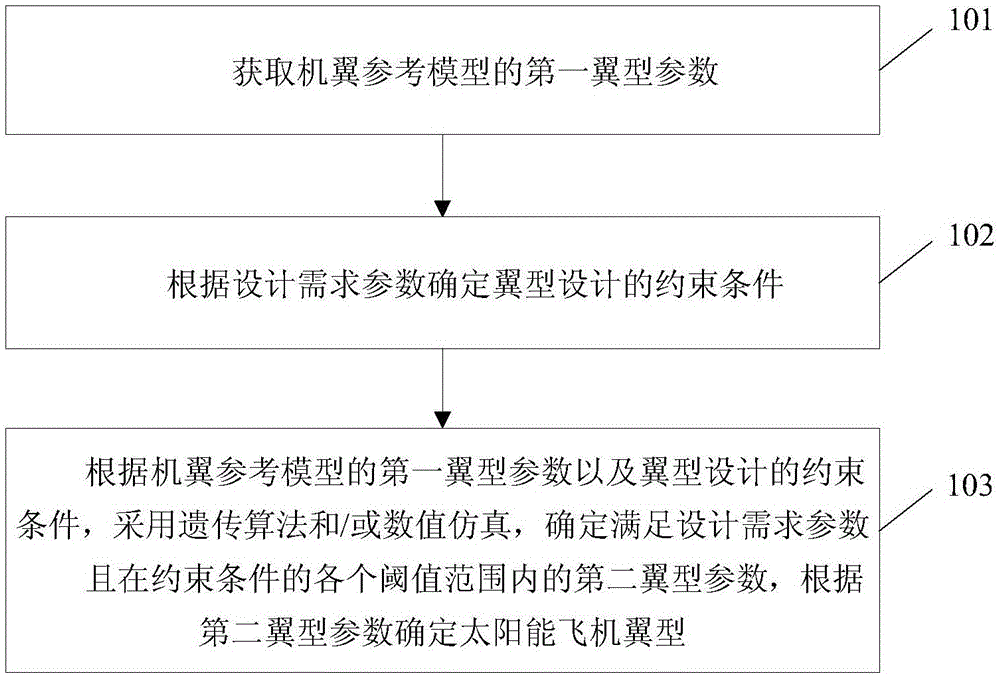

Solar-powered airplane airfoil profile design method and solar-powered airplane airfoil profile

ActiveCN105129071AIncrease lift coefficientImprove aerodynamic efficiencyWing shapesJet aeroplaneReference model

The invention provides a solar-powered airplane airfoil profile design method and a solar-powered airplane airfoil profile, wherein the method includes the steps: first airfoil profile parameters of an airfoil reference model are acquired, wherein the first airfoil profile parameters include a first airfoil profile maximum relative thickness, a relative position of the first airfoil profile maximum relative thickness, a first airfoil profile maximum relative camber, a relative position of the first airfoil profile maximum relative camber, and a first airfoil profile head radius; constraint conditions of an airfoil profile design are determined according to design demand parameters, wherein the design demand parameters include the flight speed, the elevating force coefficient and the Reynolds number, and the constraint conditions include a maximum relative thickness threshold, and an airfoil profile thickness threshold having the distance in the range of 20%-60% of the chord length away from an airfoil profile front edge; according to the first airfoil profile parameters of the airfoil reference model and the constraint conditions of the airfoil profile design and with use of a genetic algorithm and / or numerical simulation, second airfoil profile parameters meeting the design demand parameters and in the range of all the thresholds of the constraint conditions are determined, and the solar-powered airplane airfoil profile is determined according to the second airfoil profile parameters.

Owner:BEIJING CHANGYUAN TECH

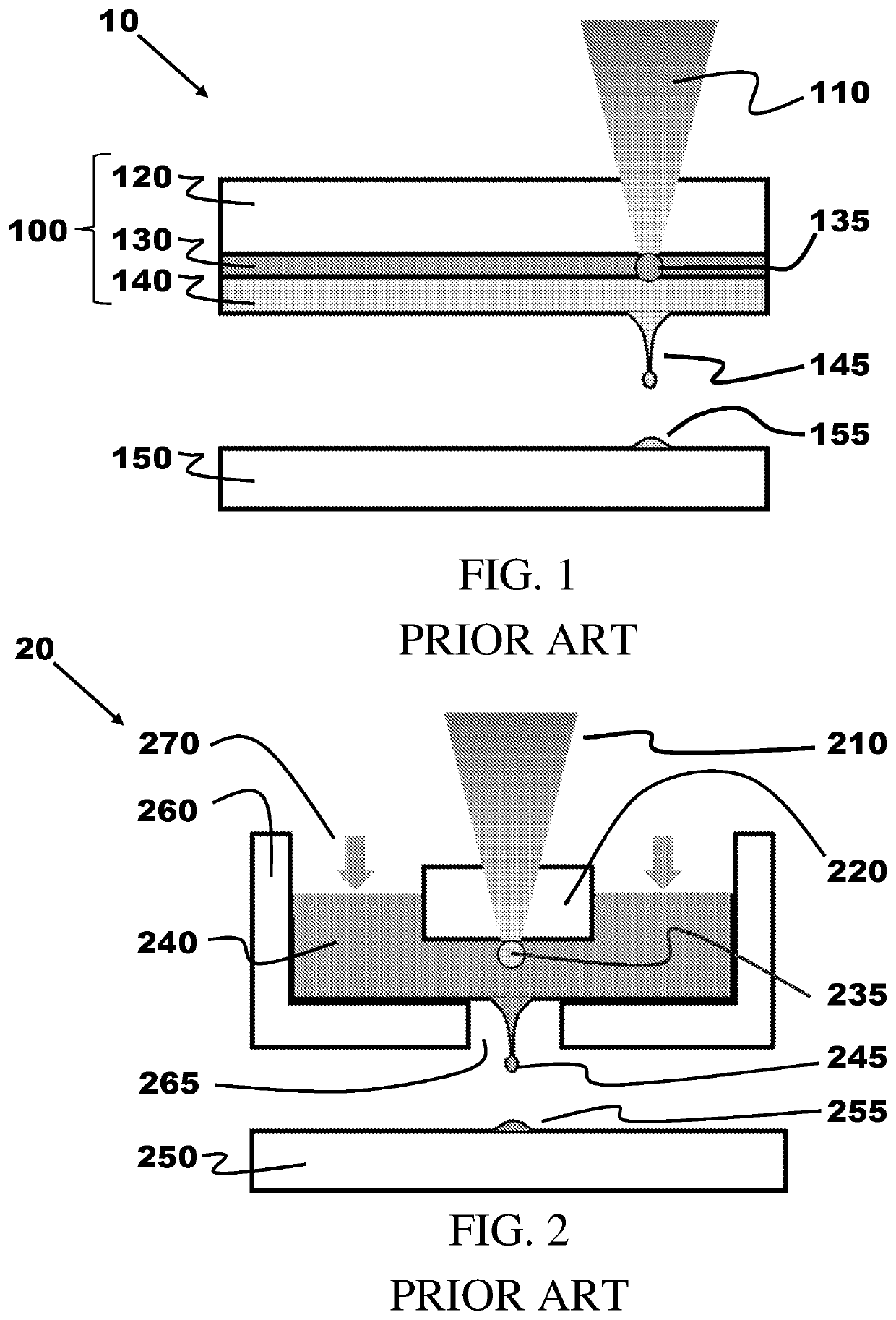

System and Method for Laser Induced Forward Transfer Comprising a Microfluidic Chip Print Head with a Renewable Intermediate Layer

ActiveUS20200070514A1Lower Reynolds numberSuppressing turbulence within flowInking apparatus3D object support structuresVapor bubblePulsed laser irradiation

Methods and systems for Laser-Induced Forward Transfer are disclosed in which a microfluidic chip is used as the printing head. The head comprises a transparent upper region, a middle region comprising an intermediate layer channel and an ink channel in fluid connection with said intermediate layer channel, and a lower layer with an orifice in fluid contact with the ink channel. When material in the intermediate layer channel is irradiated by an energy source (typically a pulsed laser) at a spot opposite the orifice, the material is partially evaporated, creating a vapor bubble that creates a transient pressure increase when it collapses, thereby forcing ink out of the orifice and onto a receiving substrate.

Owner:PRECISE BIO INC +1

Recovery method of N-methyl pyrrolidone

PendingCN110759844AReduce concentration polarizationReduce or even eliminate concentration polarizationOrganic chemistryPyrrolidinonesMethyl palmoxirate

The invention provides a recovery method of N-methyl pyrrolidone. The method is characterized by comprising the following steps: heating an N-methyl pyrrolidone material liquid with the water contentof 1-50 wt.% in a circulating tank to 30-190 DEG C; introducing the heated N-methyl pyrrolidone material liquid into a pervaporation membrane assembly to make water in the material liquid be separatedfrom the material liquid side of the pervaporation membrane and enter the permeation side, wherein the pervaporation membrane assembly comprises 1-3000 organic-inorganic or inorganic-organic hybrid membrane single-pass pipes or multi-pass pipes, an absolute pressure of the permeation side is set to be 100-15000 Pa, and a membrane feeding speed of the material liquid is set to be 0.15-1.6 m / s; after the material liquid passes through the pervaporation membrane assembly, making the material liquid on the material liquid side return to the circulating tank, and making the water on the permeationside be condensed and recovered; and performing circulation for multiple times on the material liquid in the circulating tank to obtain recovered N-methyl pyrrolidone.

Owner:HYLEIN ENERGY & ENVIRONMENT TECH CO LTD

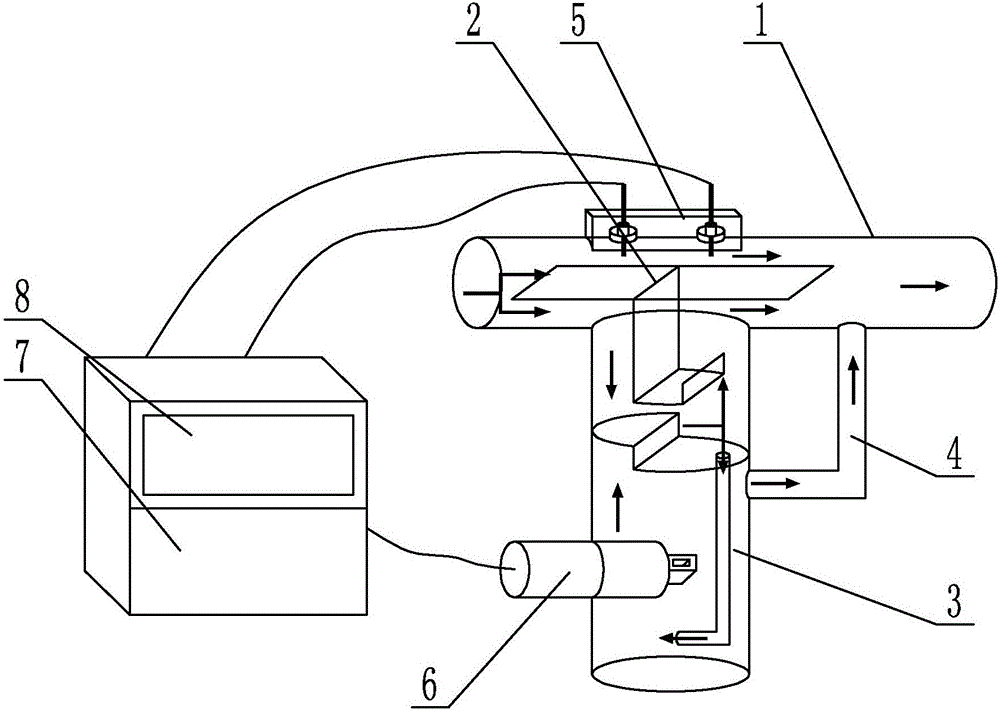

Household drinking water quality online detection device

InactiveCN106442415ALower Reynolds numberImprove water flow stabilityScattering properties measurementsTransmissivity measurementsProgrammable logic controllerEnvironmental geology

The invention discloses a household drinking water quality online detection device, relates to a water quality detection device, and aims to solve the problems that an existing water quality detection device is single in detection index and inflexible to disassemble, and online detection cannot be directly achieved in a pipeline. The household drinking water quality online detection device comprises a shell, a partition component, a flow guide pipe, a backflow pipe, an electrode detection sensor, a photoelectric detection sensor, a PLC (programmable logic controller) and a display, the upper end of the shell is a horizontal end, a water inlet is formed on end of the horizontal end, a water outlet is formed in the other end of the horizontal end, the partition component is arranged in the shell, the inside of the shell is divided into a first detection chamber, a flow guide chamber and a second detection chamber by the partition component, the electrode detection sensor is arranged in the first detection chamber, the photoelectric detection sensor is arranged in the second detection chamber, the electrode detection sensor and the photoelectric detection sensor are respectively connected with the PLC, and the PLC is connected with the display. The detection device is used for online detection of quality of household drinking water.

Owner:HARBIN INST OF TECH

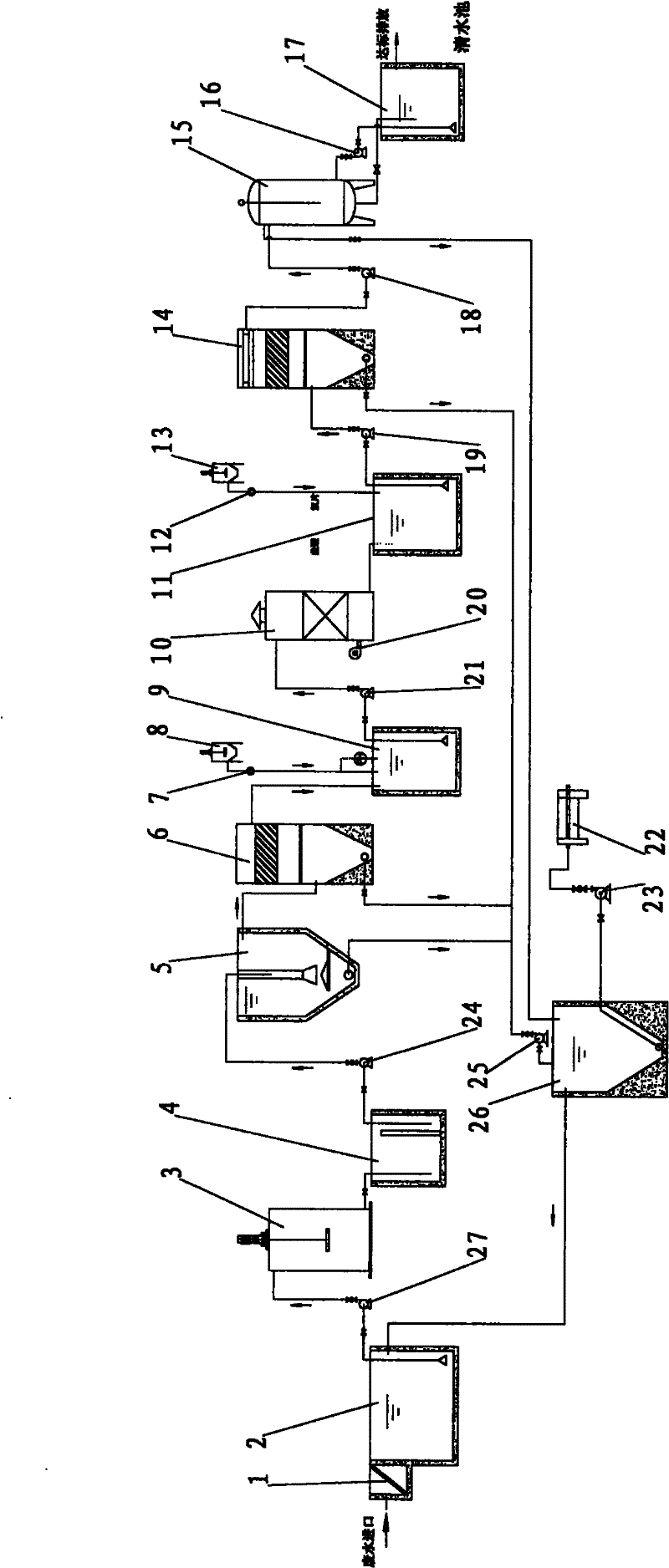

Vanadium and titanium industrial wastewater treatment device

InactiveCN102190390AReduce turbulenceShorten the precipitation distanceWater contaminantsMultistage water/sewage treatmentIndustrial wastewater treatmentHexavalent chromium

The invention relates to a hexavalent chromium- and ammonia nitrogen element-containing vanadium and titanium production wastewater treatment device, and provides a vanadium and titanium industrial wastewater treatment device, which can make hexavalent chromium, ammonia nitrogen, chemical oxygen demand (CODcr), pH, suspended matters, chroma, and biochemical oxygen demand (BOD) generated in the vanadium and titanium production wastewater meet standards and discharged. The device is provided with a grate, an adjusting tank, a first dosing box, a second dosing box, a third dosing box, a sedimentation tank, a vertical flow sedimentation tank, a first inclined tube sedimentation tank, a second inclined tube sedimentation tank, a first water pump, a second water pump, a third water pump, a fourth water pump, a fifth water pump, a sixth water pump, a recoil pump, a slurry pump, an intermediate water tank, an aeration tower, an air blower, a dosing water tank, a double filtration tower, a filter press, a screw pump, a sludge concentration tank, a sludge pump and the like. The wastewater containing overproof hexavalent chromium, ammonia nitrogen elements, CODcr, pH, suspended matters, chroma, and BOD in the vanadium and titanium production process is subjected to homogeneous adjustment, acid-alkali neutralization, solution sedimentation, biochemical reaction, aeration for ammonia removal, double filtration, sludge concentration, pressure filtration for dehydration and the like; and the treated sludge is transported outwards, and the treated wastewater meets standard to be discharged or recycled.

Owner:张步芳

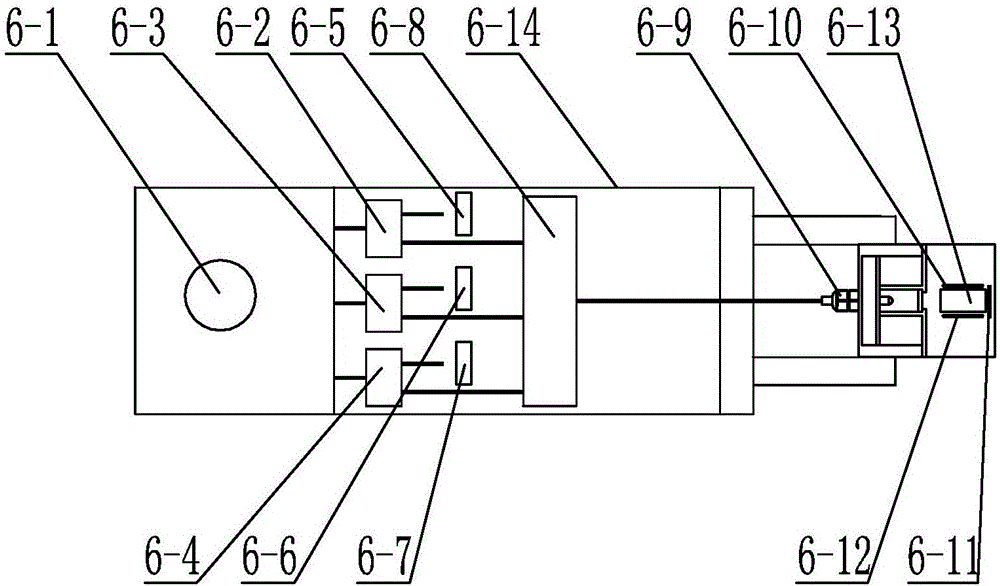

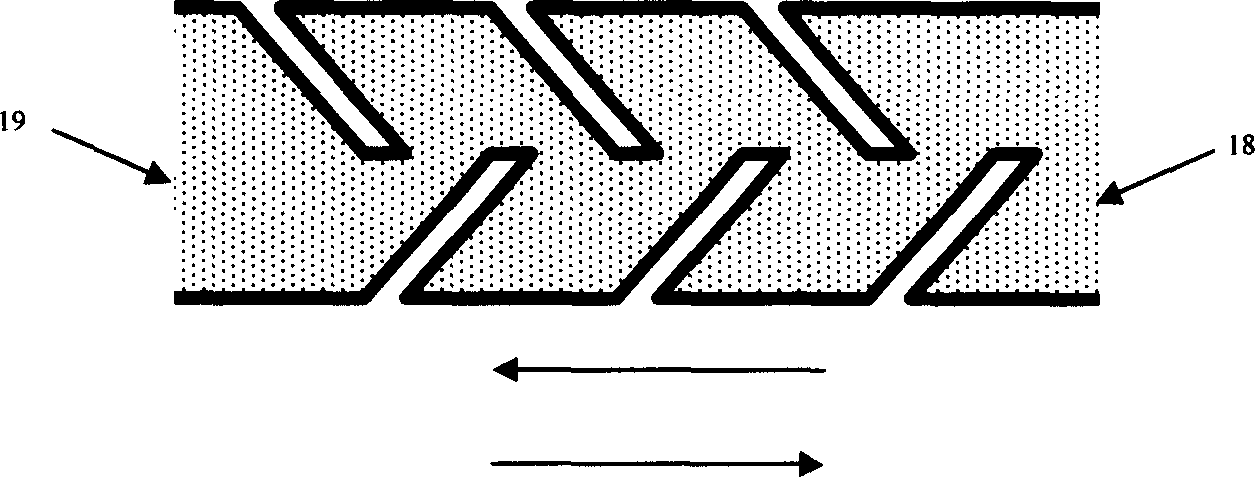

Jet flow angle velocity transducer and method for making same

This invention provides a fluidic angular velocity sensor and its process and belongs to micro electron mechanical system design and its process field. The sensor comprises two vibration chambers; four commute chambers and one detection chamber. The gas in the vibration chamber is driven and recycled and each vibration chamber two sides are located with two commute chambers and the driven gas flows into the detection chamber through the commute chamber and the recycled gas always moves along one direction in the detection chamber. The said detection chamber is symmetrically located with two pieces of heat sensitive resistance wires, which is connected with a Wheatstone bridge. The said commute chamber is needle teeth flow diode, which is composed of several orderly distributed needle teeth block bar.

Owner:PEKING UNIV

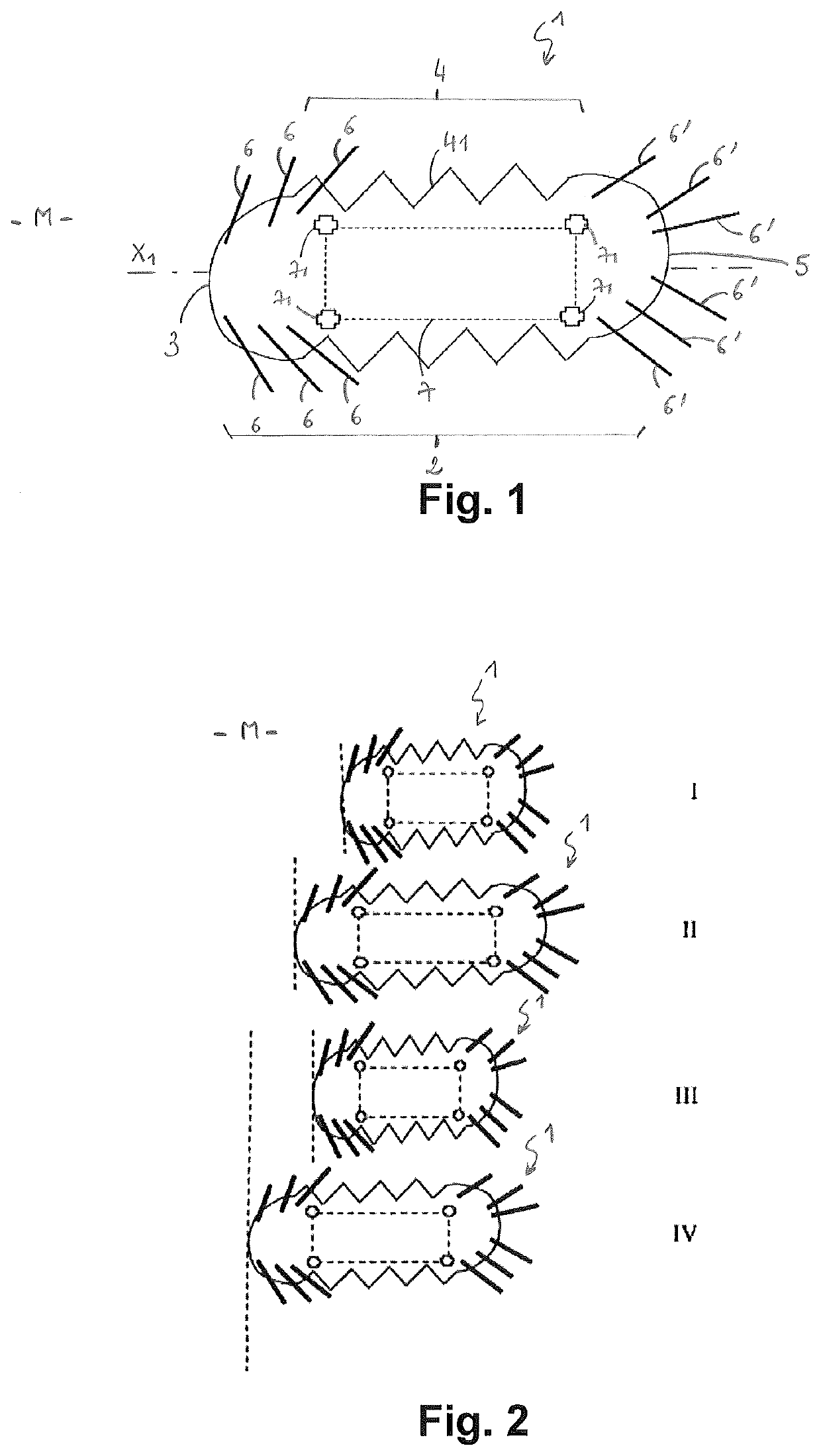

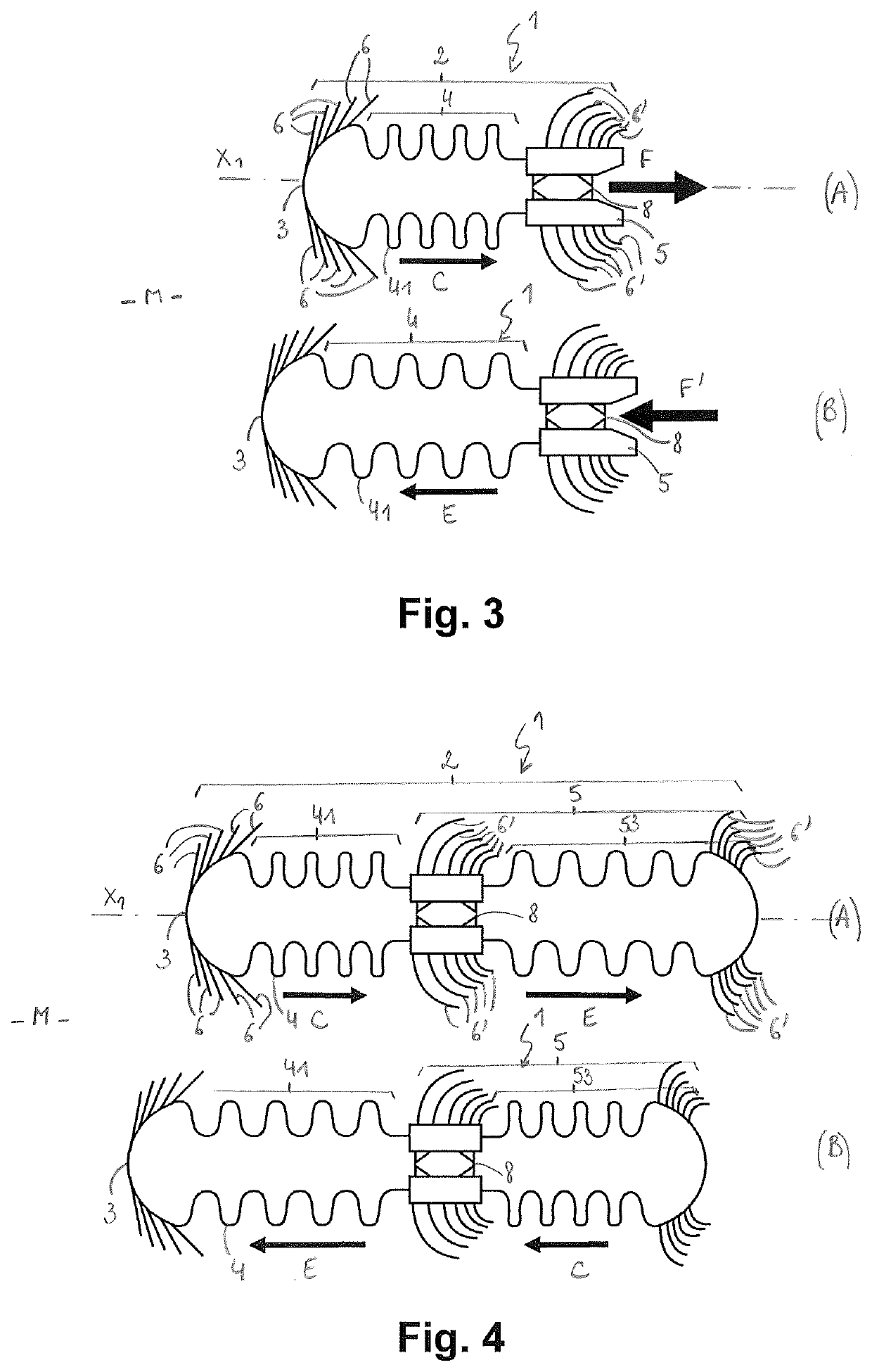

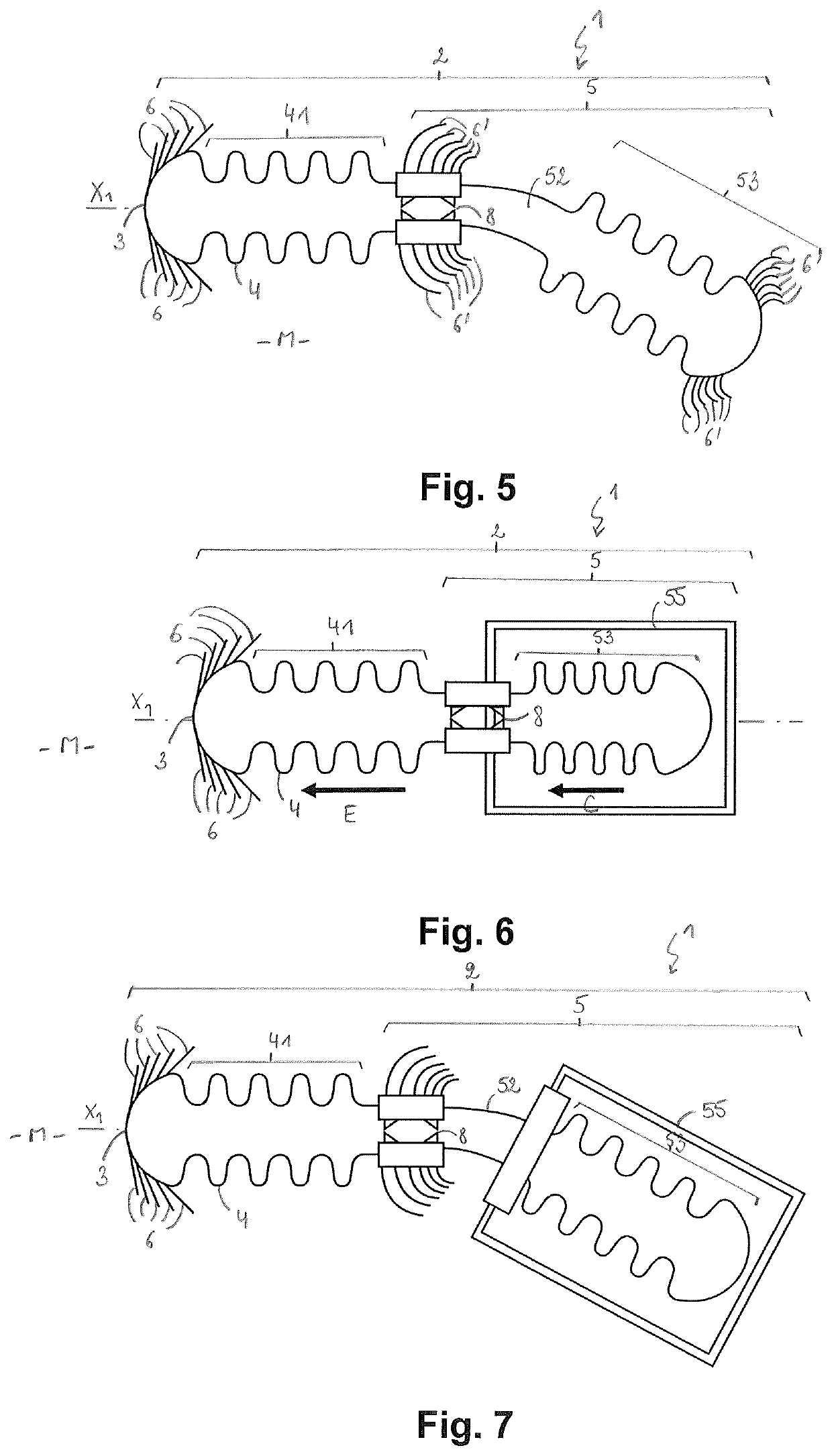

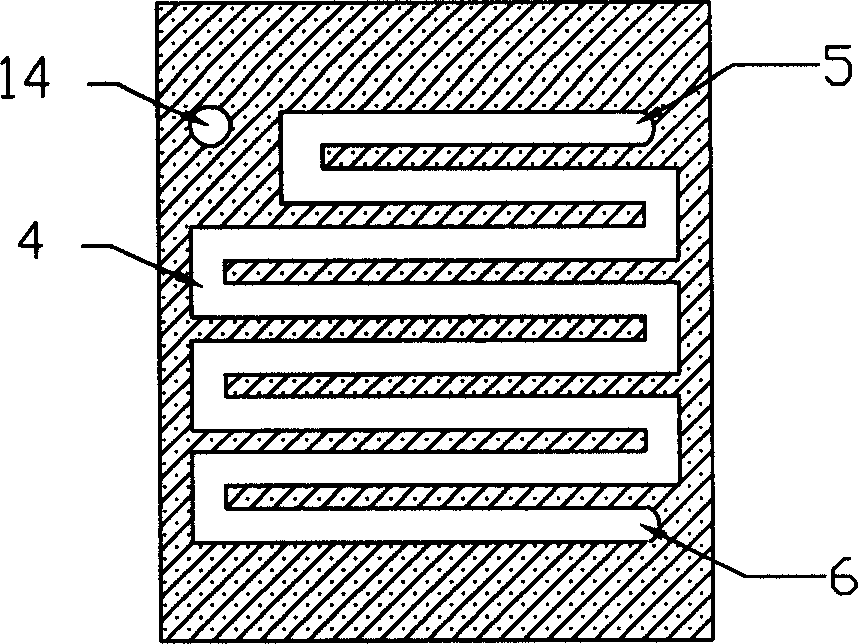

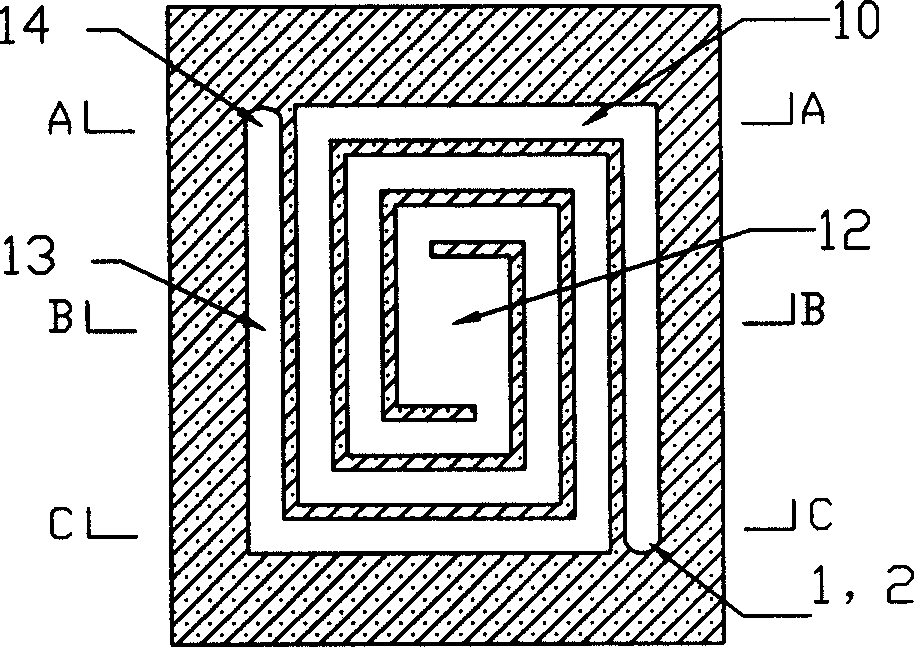

Microrobot configured to move in a viscous material

InactiveUS20200305796A1Effective exerciseLower Reynolds numberMicromanipulatorCatheterPhysicsEngineering

A microrobot configured to move in a viscous material, in particular in an organ of a subject such as a brain, the microrobot having a propulsion structure including a head portion, a rear portion and a deformable portion connecting the head portion and the rear portion. The deformable portion is deformable in elongation / contraction along a main axis connecting the head portion and the rear portion. The head portion includes at its surface at least one propulsion cilium, one end of the at least one propulsion cilium being attached to the head portion and the other end of the at least one propulsion cilium being a free end configured to move freely in the viscous material. The propulsion structure further comprises a motor configured to actuate sequentially elongation / contraction cycles of the deformable portion.

Owner:ROBEAUTE

Micro-internal mixed catalytic burner

InactiveCN1752518AReduce external structureReduce volumeIndirect carbon-dioxide mitigationGaseous fuel burnerCombustion chamberEngineering

The invented catalytic combustor includes combustion chamber of monocrystal silicon material, upper preheating chamber and lower preheating chamber, its upper and lower surfaces are bonded and formed into three-layer structure; in the upper and lower preheating chambers respectively an etched preheating channel is set, and the combustion chamber interior is successively equipped with mutually-communicated etched premixing channel, combustion zone space and exhausting channel. Its structure is compact and can raise combustion efficiency.

Owner:ZHEJIANG UNIV

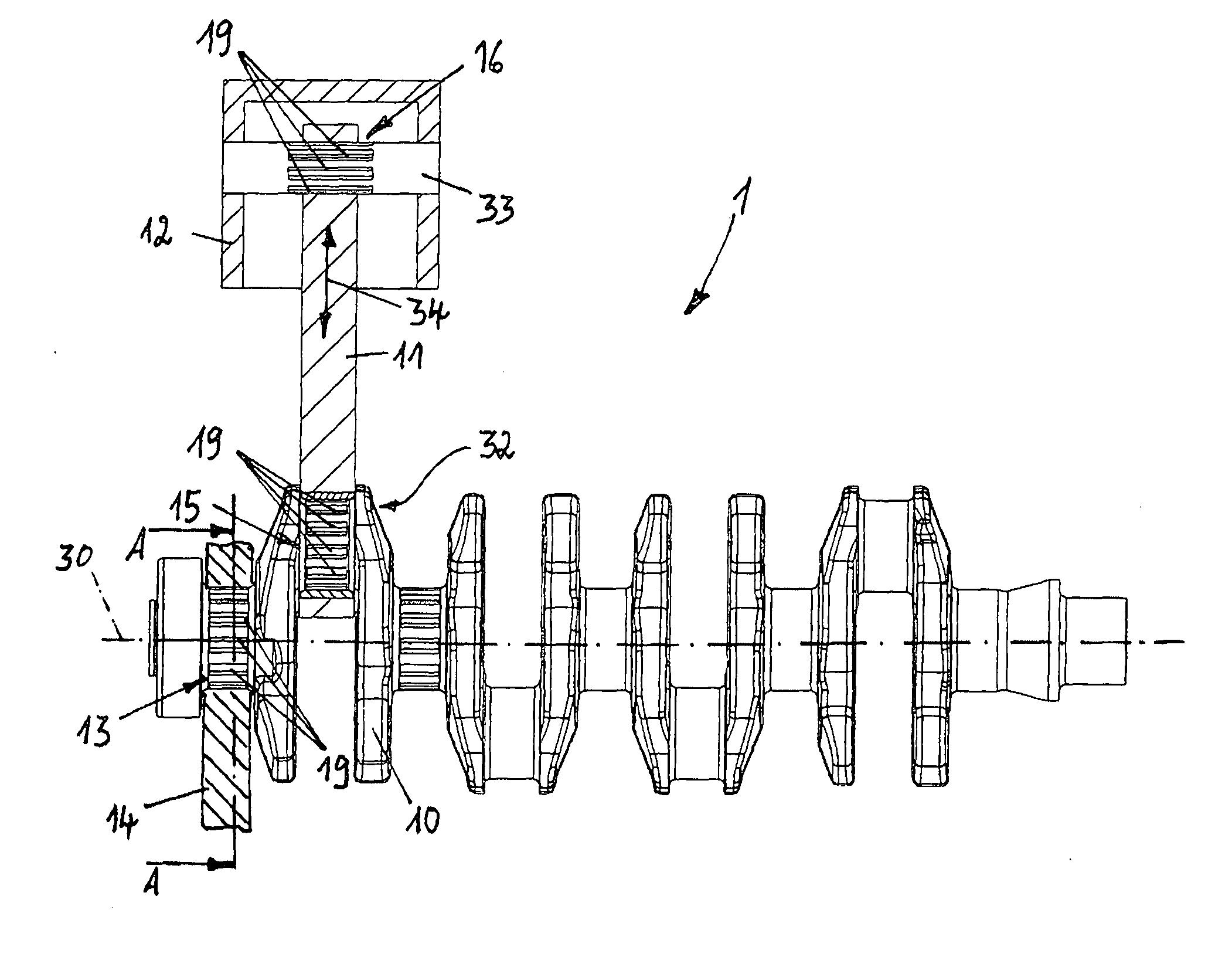

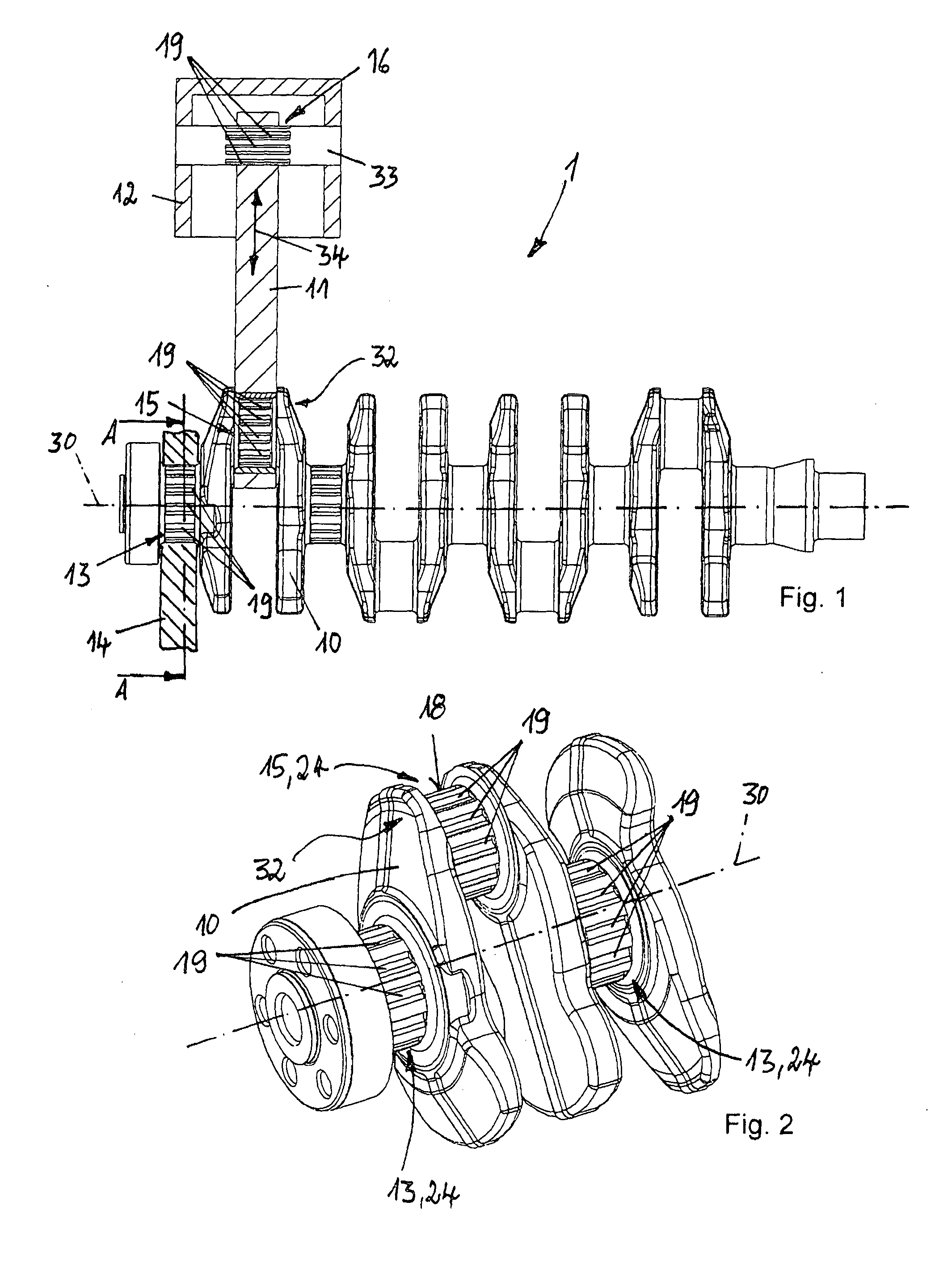

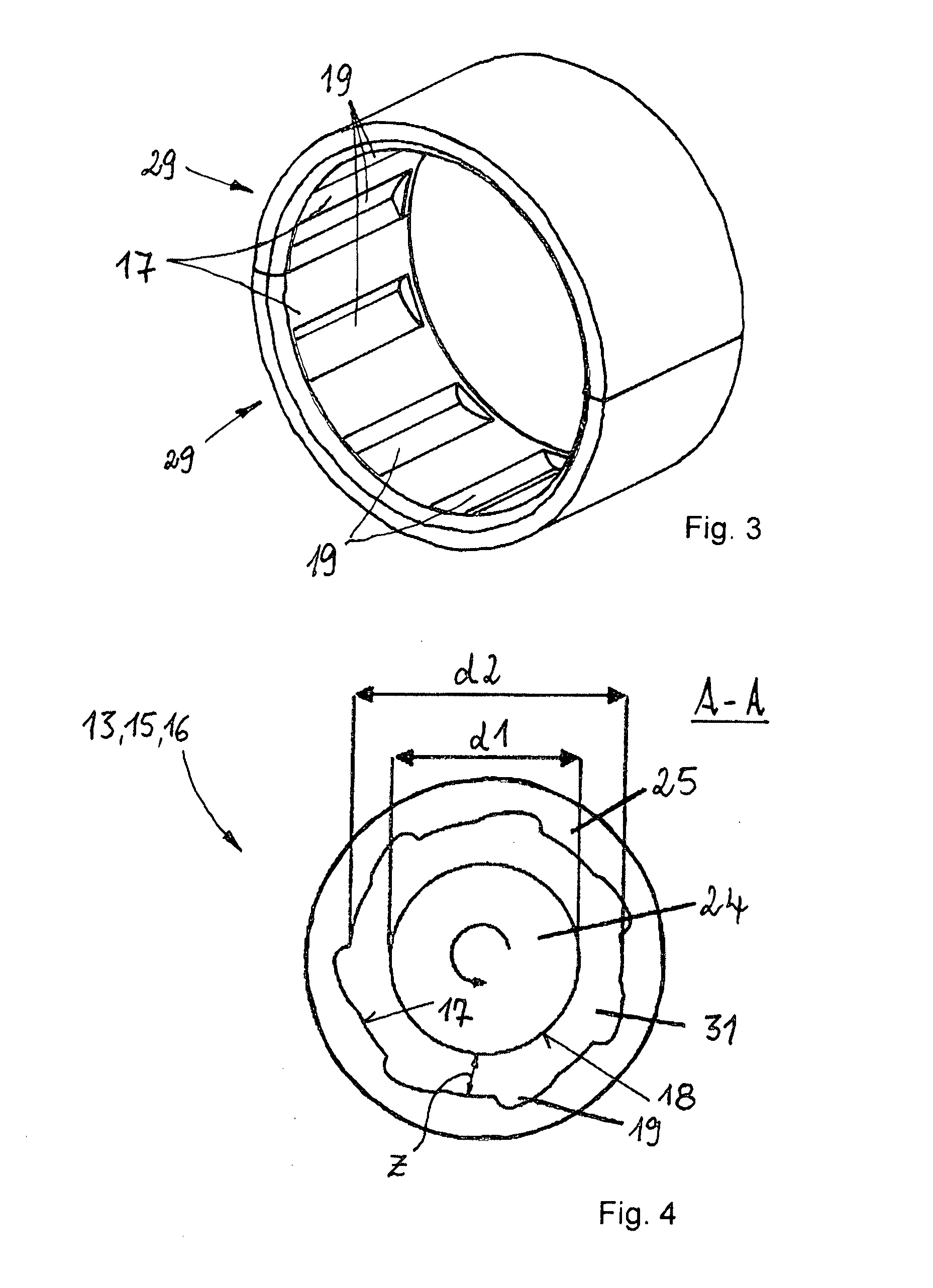

Crank-drive with bearings having micro -ramp structures of asymmetric form

InactiveUS20150204377A1Increase fluid pressureLower Reynolds numberConnecting rod bearingsConnecting rodsCrankEngineering

The present invention relates to a crank-drive with a crank-shaft, at least one connecting rod and at least one piston, in particular a crank-drive of an internal combustion engine, whereas the crank-shaft features at least one radial bearing (13) for supporting the crank-shaft in a crank-housing, at least one radial bearing for connecting the connecting rod to the crank-shaft, and the connection of the connecting rod to the piston features at least one radial bearing and whereas the bearings feature a bearing inner surface and / or a bearing outer surface. According to the invention in at least one of the bearing surfaces are arranged micro-ramp structures with an asymmetric form having a first concave section between the bearing surface and a bottom point of the micro-ramp structure and a second concave section between the bottom point and the bearing surface, whereas between the micro-ramp structures are arranged sections of the bearing surface.

Owner:THYSSENKRUPP METALURGICA CAMPO LIMPO

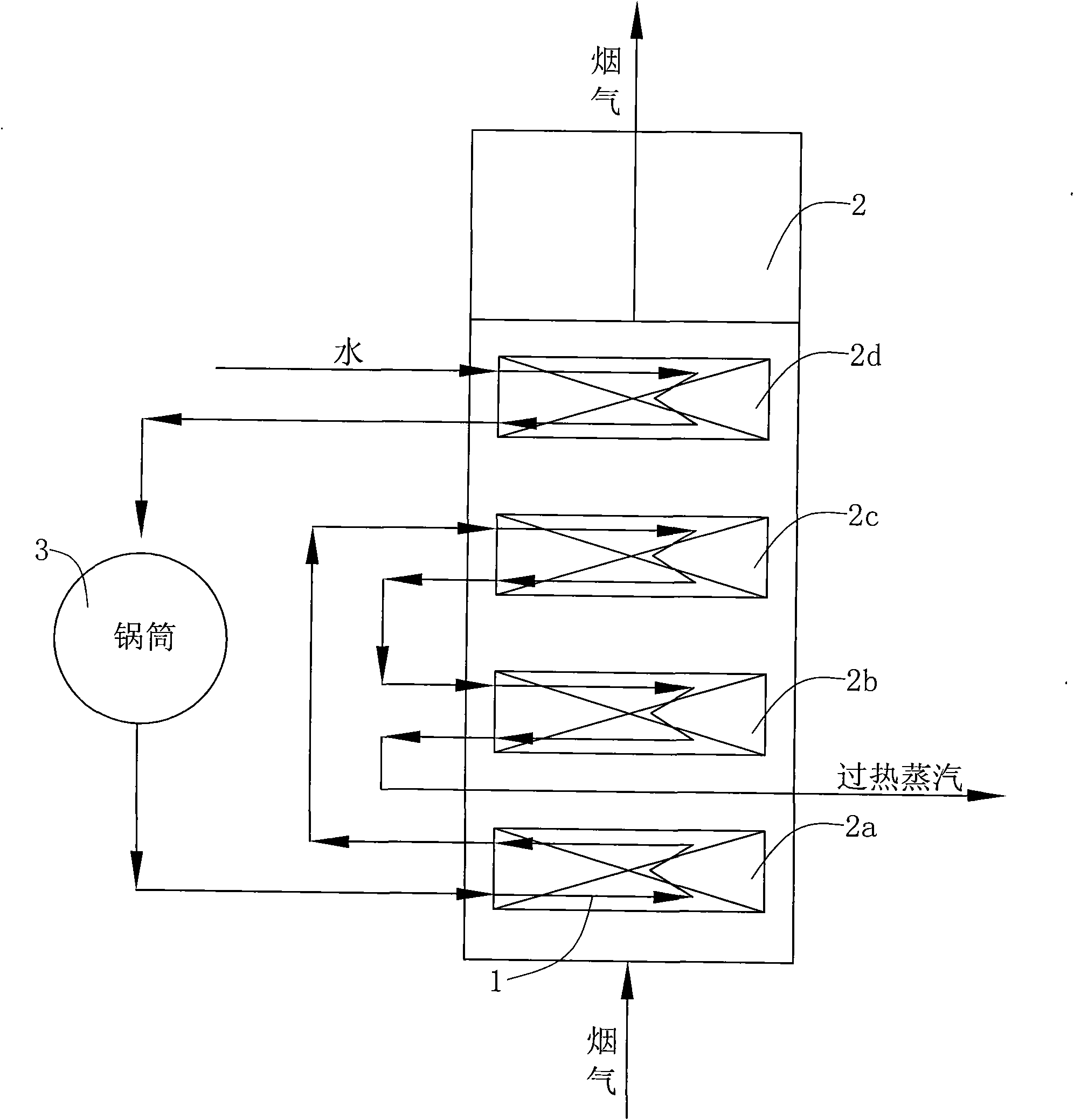

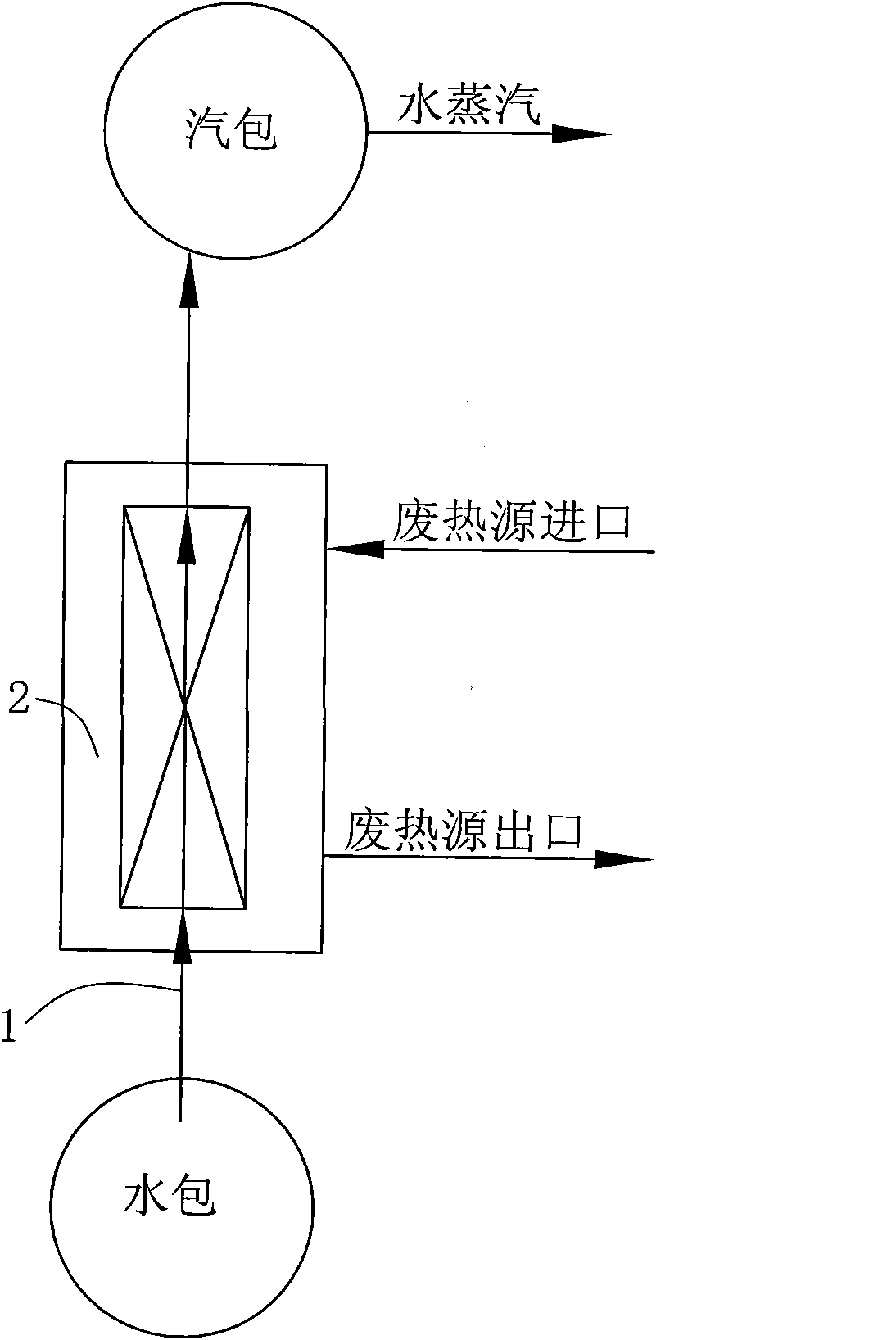

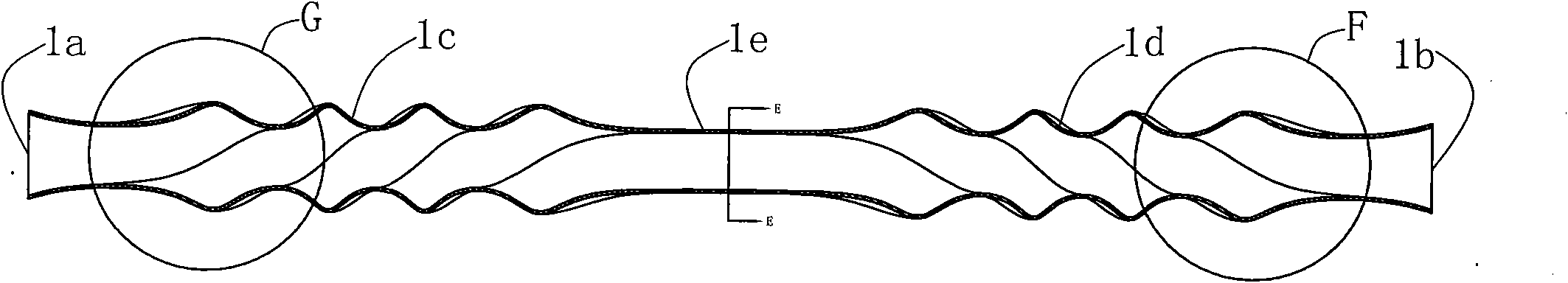

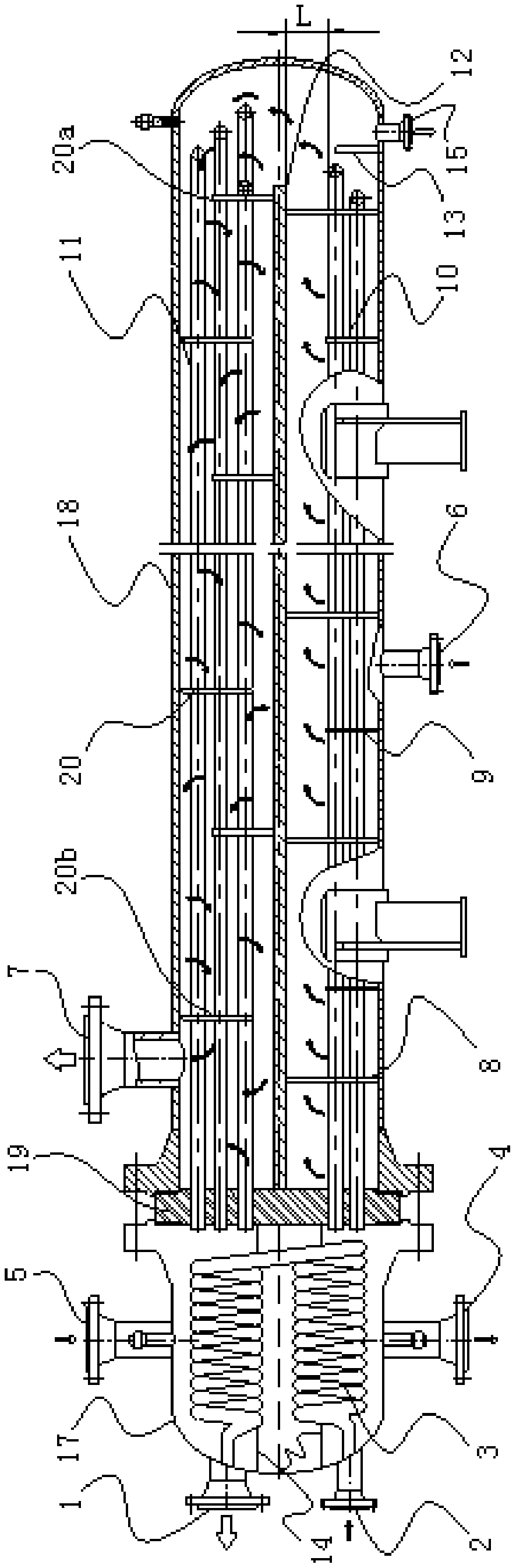

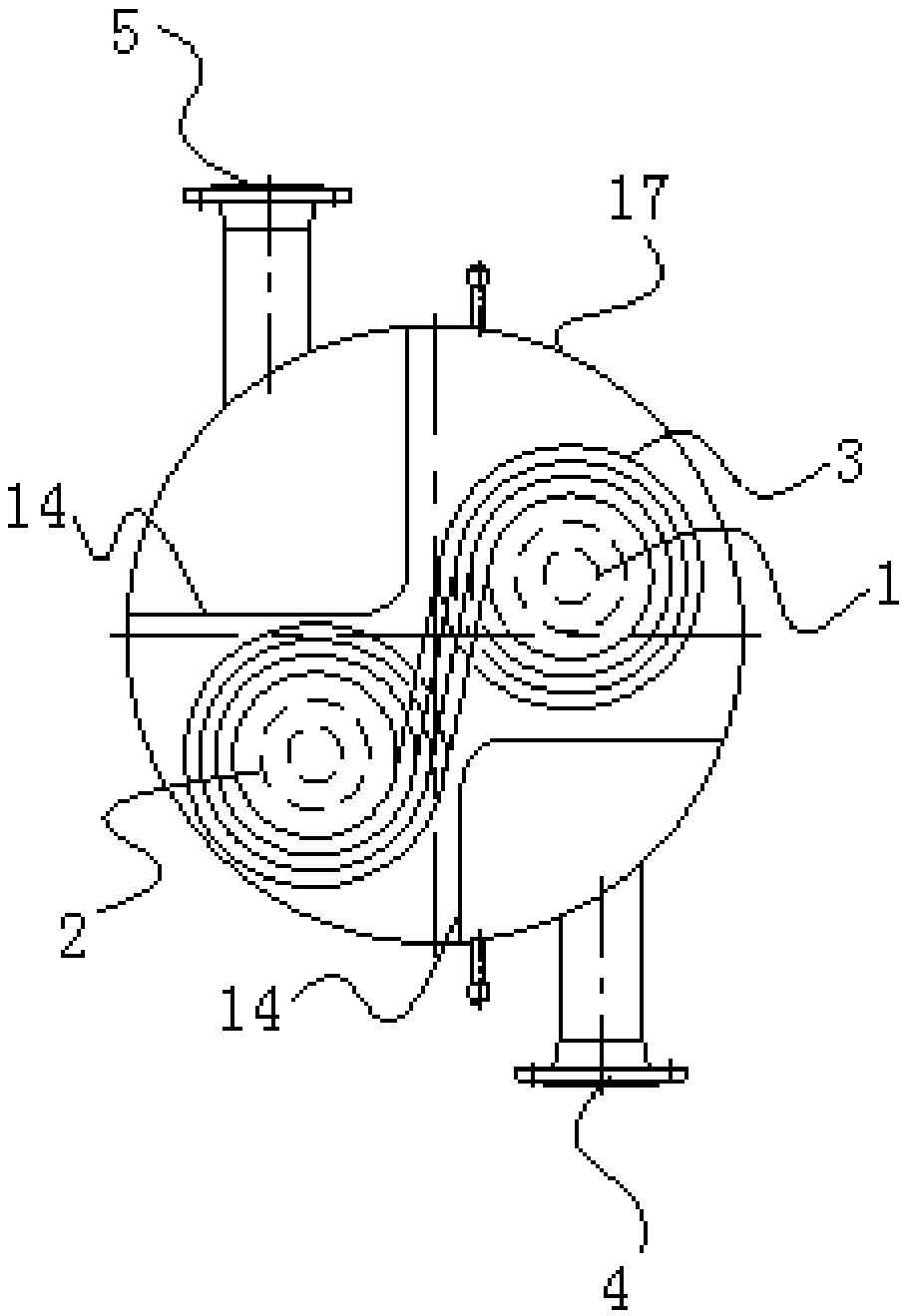

Helical flat pipe for waste heat boiler

ActiveCN101865623ACompact structureReduce volumeChemical industryTubular elementsChemical industryPetrochemical

The invention discloses a helical flat pipe for a waste heat boiler. The helical flat pipe comprises a flat pipe body, a first pipe port and a second pipe port, wherein the first pipe port and the second pipe port are positioned at the two ends of the flat pipe body; the first pipe port is also used as an inlet; the second pipe port is also used as an outlet; the flat pipe body is fixedly arranged in a heat exchange surface in the shape of a circle or regular curve and comprises at least one helical part; and the cross section at any mass point of the helical part along the axial line is an elliptical or long circular section with gradient helix. By using the helical flat pipe, the waste heat boiler has the advantages of compact structure, small size, convenient hanging, material saving, low manufacturing cost and the capability of greatly increasing the heat exchange efficiency; and thus the helical flat pipe can be widely applied to the industries such as petrochemical industry, power, steel and iron, non-ferrous metal, chemical industry, cement, building material, light industry, coal and the like.

Owner:NINGBO LIANTONG EQUIP MFG

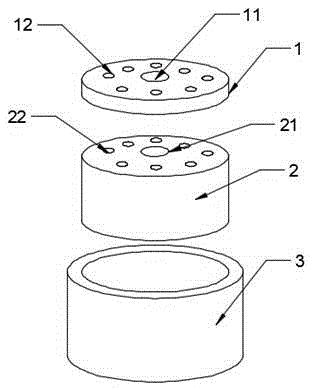

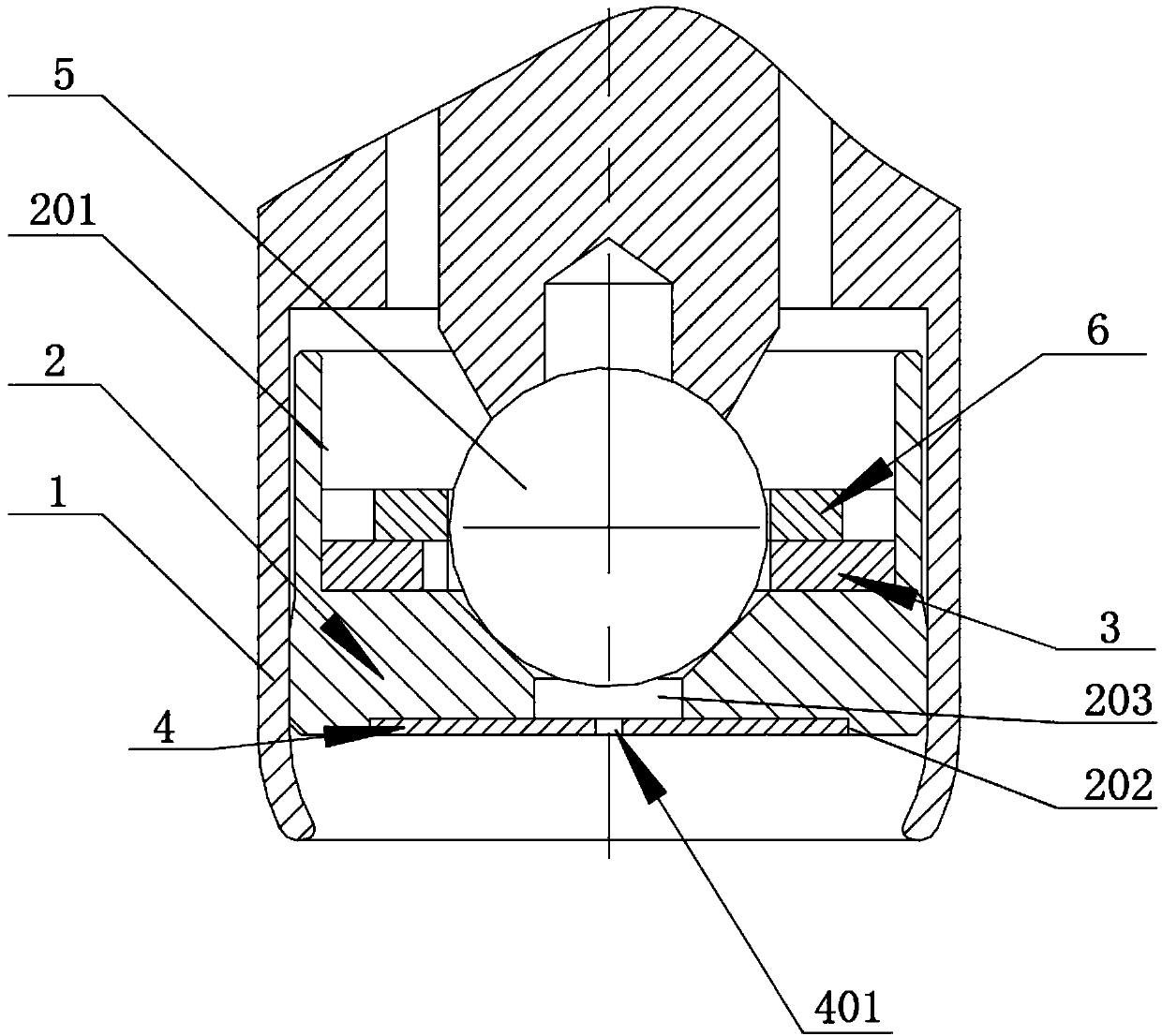

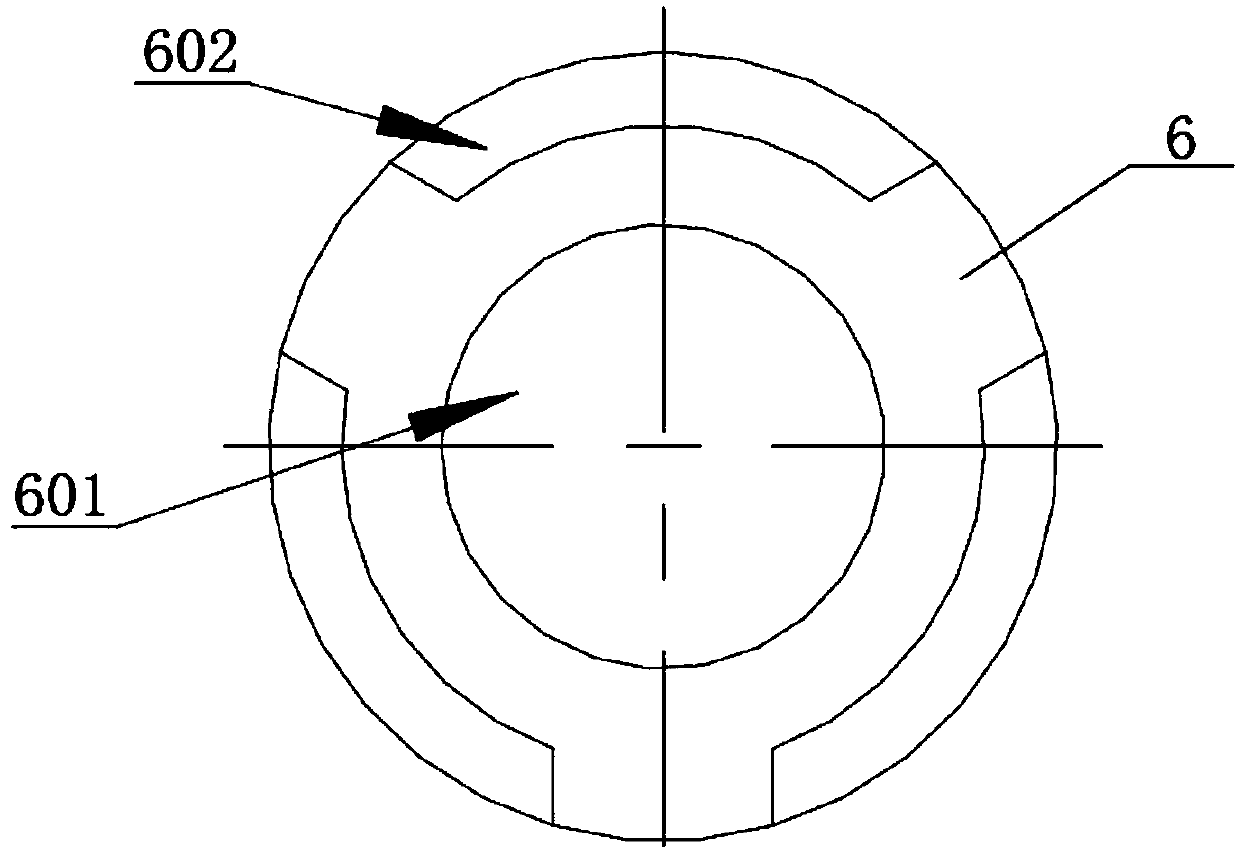

Inner-magnet moving-coil speaker multi-channel magnetic circuit system

InactiveCN106686502AImprove cooling effectUniform cooling areaElectrical transducersMagnetic stabilityPunching

The invention discloses an inner-magnet moving-coil speaker multi-channel magnetic circuit system. The system comprises a multi-channel magnetic plate, a multi-channel magnet, and a multi-channel magnetic bowl. The multi-channel magnetic plate is shaped as a round disk made of a magnetic material and punching through multiple channels. The multi-channel magnet is shaped as a cylinder made of a magnetic material and punching through multiple channels. The multi-channel magnetic bowl is shaped as a round cup made of a magnetic material and punching through multiple channels. The multi-channel magnet is arranged in the multi-channel magnetic bowl. The multi-channel magnetic plate is arranged on the multi-channel magnet. The multi-channel magnetic plate, the multi-channel magnet and the multi-channel magnetic bowl are provided with multiple punch-through channels of the same coordinate and same diameter. The heat dissipation area of the magnetic circuit system is uniform. The magnetic stability is improved. The interference of the reflected sound wave of surface area of the magnetic circuit system to normal movement of a vibrating diaphragm is reduced. The Reynolds number caused by air disorder of the magnetic circuit system is reduced. Therefore, the causes of turbulent flow are reduced greatly.

Owner:王卫平

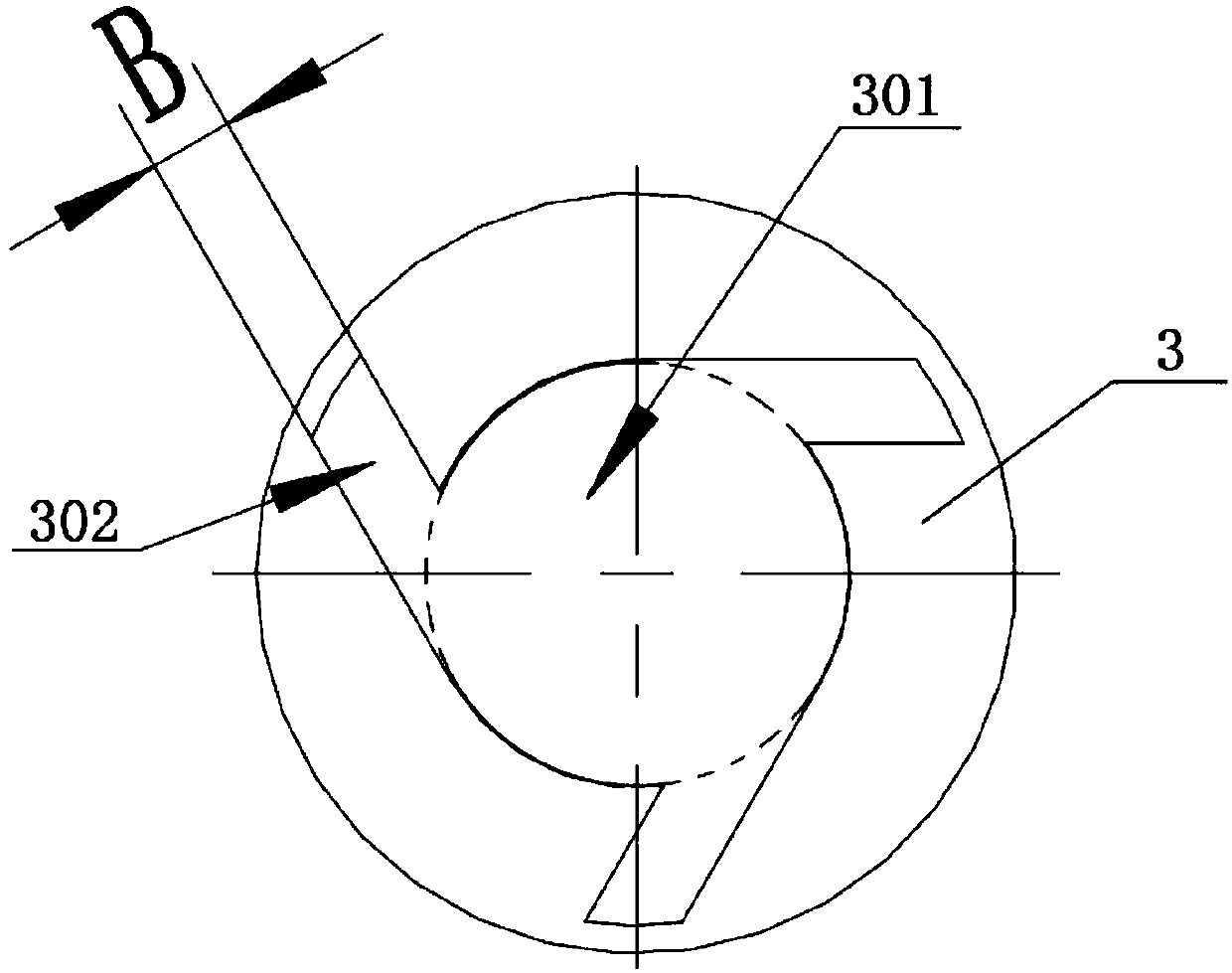

Single-hole atomizing injector and post atomizing structure thereof

InactiveCN107725243ALower Reynolds numberFine granularityFuel injection apparatusMachines/enginesCombustionEngineering

The invention discloses a single-hole atomizing injector and a post atomizing structure thereof. The post atomizing structure comprises a tube body, a valve base, splitters, swirling flow plates and ameasuring piece, a first mounting groove is formed in the top of the valve base, a second mounting groove is formed in the bottom of the valve base, the first mounting groove is communicated with thesecond mounting groove through valve openings, the measuring piece is attached to the bottom surface of the second mounting groove, the swirling flow plates are attached to the bottom surface of thefirst mounting groove, and the splitters are tightly attached to the surfaces of the swirling flow plates; through-flow holes and splitter grooves are formed in the splitters; swirling flow holes andswirling flow grooves are formed in the swirling flow plates; a measuring hole is formed in the measuring piece. Projections of the swirling flow grooves and the splitter grooves on the water level are overlapped, fluid is split and then enters the swirling flow grooves, a turbulent flow or a swirling flow is formed at the bottom of each swirling flow groove, the atomization effect is obviously improved when the fluid passes through the measuring hole, atomization is more thorough, the particle size of atomized particles is finer, fuel oil atomization effect is improved, and mixing with air and sufficient combustion are facilitated. The invention further discloses the single-hole atomizing injector. The single-hole atomizing injector has the above mentioned advantages.

Owner:GUANGXI CARTIER TECH CO LTD

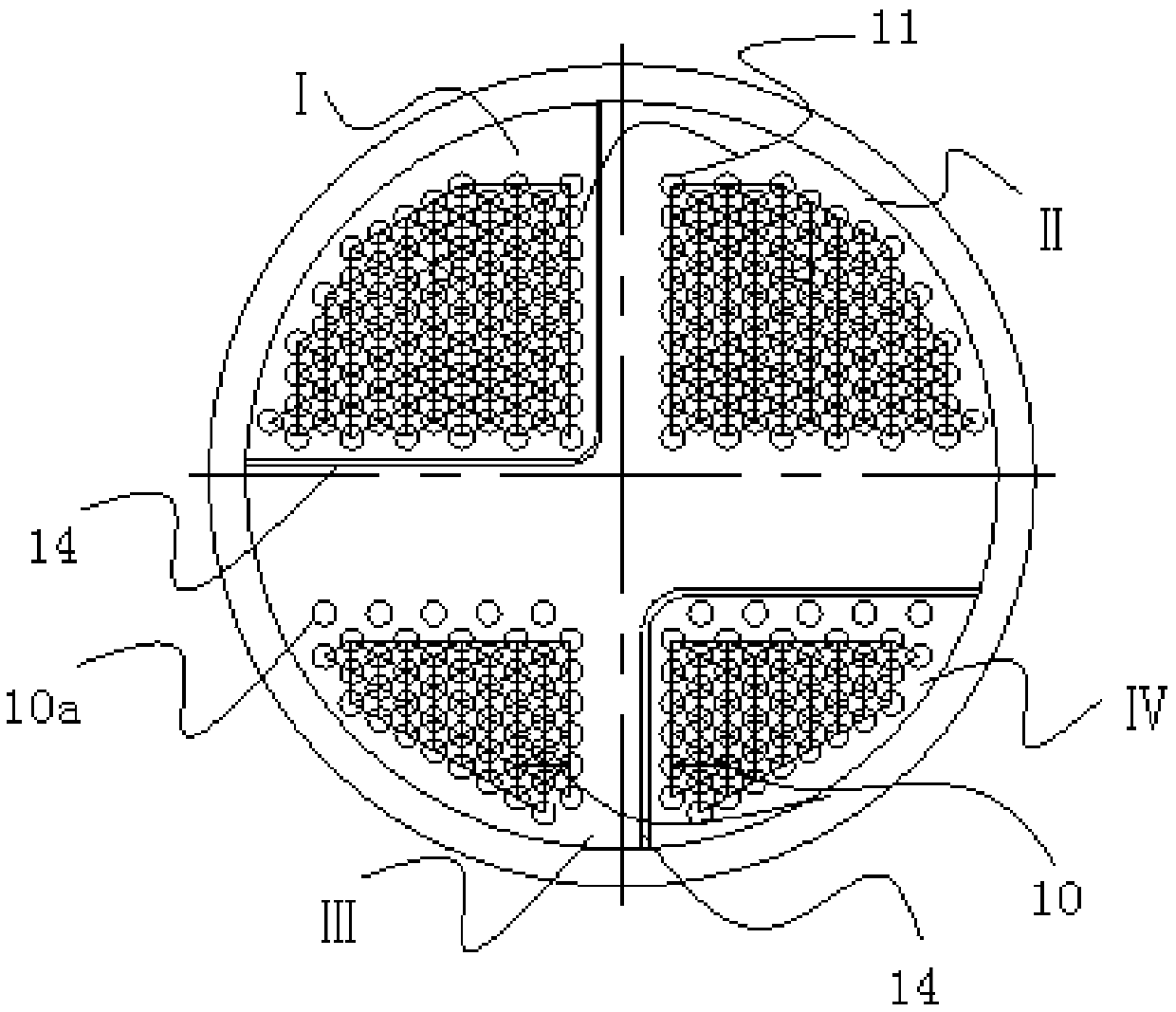

Integrated combined heat exchanger

ActiveCN107606974BImprove heat transfer efficiencyIncrease profitStationary tubular conduit assembliesPlate heat exchangerStraight tube

The invention discloses an integrated combined heat exchanger. The integrated combined heat exchanger comprises a tube box, a shell and a U-shaped heat exchange tube bundle. The tube box is divided bytube pass partition plates into four tube passes, and a tube winding tube bundle is arranged. The shell is connected with the rear end of the tube box through a tube plate, and a tube pass dividing partition plate with the length smaller than the length of the shell is transversely arranged in the shell. The U-shaped heat exchange tube bundle comprises overheating section tube bundles and evaporation section tube bundles, all of which are arranged in an overheating section area and an evaporation section area in a one-to-one correspondence manner, the total length of the evaporation section tube bundles is equal to the length of the tube pass dividing partition plate, and the length of straight tube sections of the overheating section tube bundles is equal to the length of the tube pass dividing partition plate. The vertical distance between a row of tube bundles on the tops of the evaporation section tube bundles and the tube pass dividing partition plate is not smaller than 125 mm,at least one row of heat exchange tubes in the evaporation section tube bundles are higher than the liquid level in the shell, and the vertical distance between the row of heat exchange tubes and thenext row of heat exchange tubes is larger than the normal tube distance of the evaporation section tube bundles. The heat exchanger can be used for multiple occasions, and the utilization rate and heat transfer efficiency are improved.

Owner:SHANGHAI KAIREN GAS ENG CO LTD

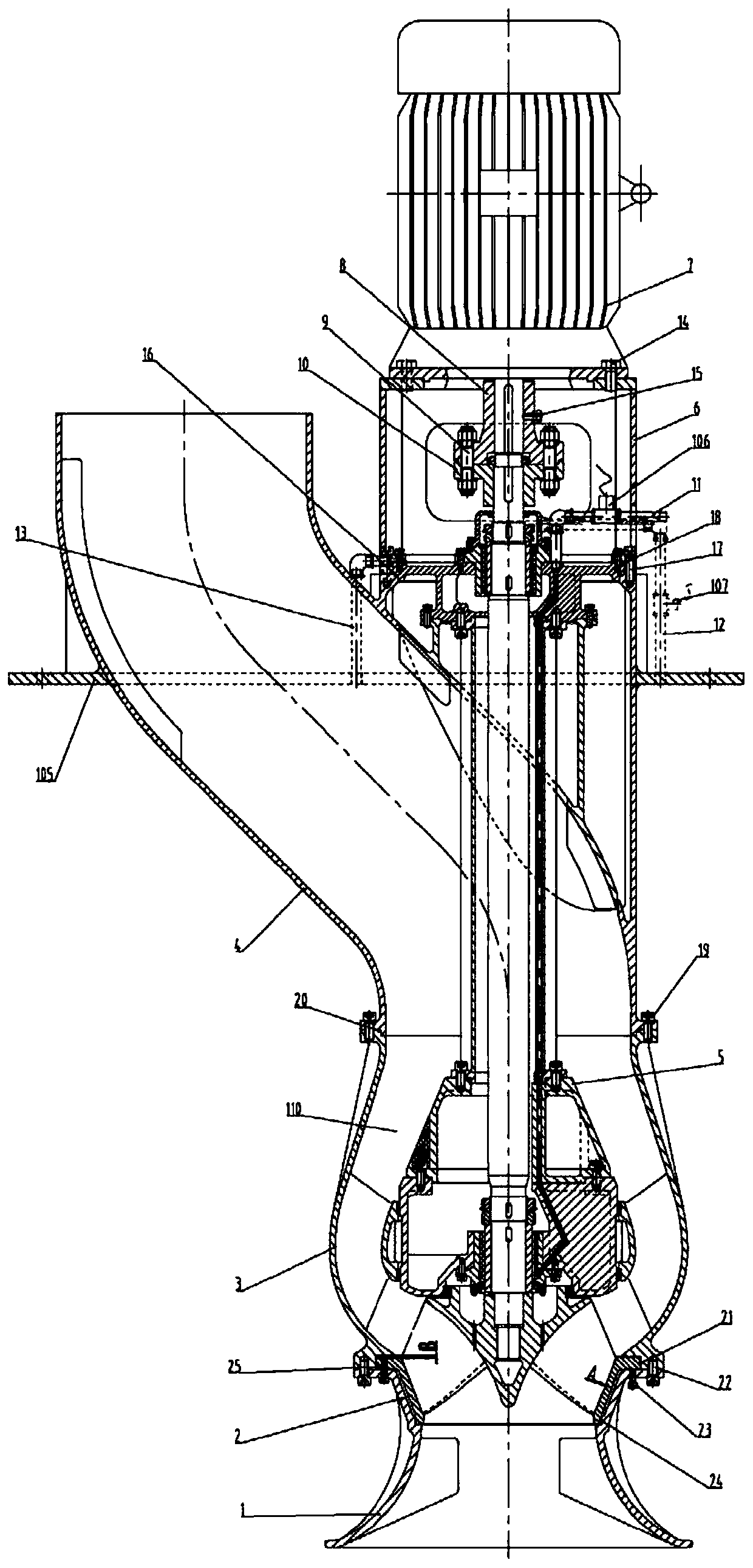

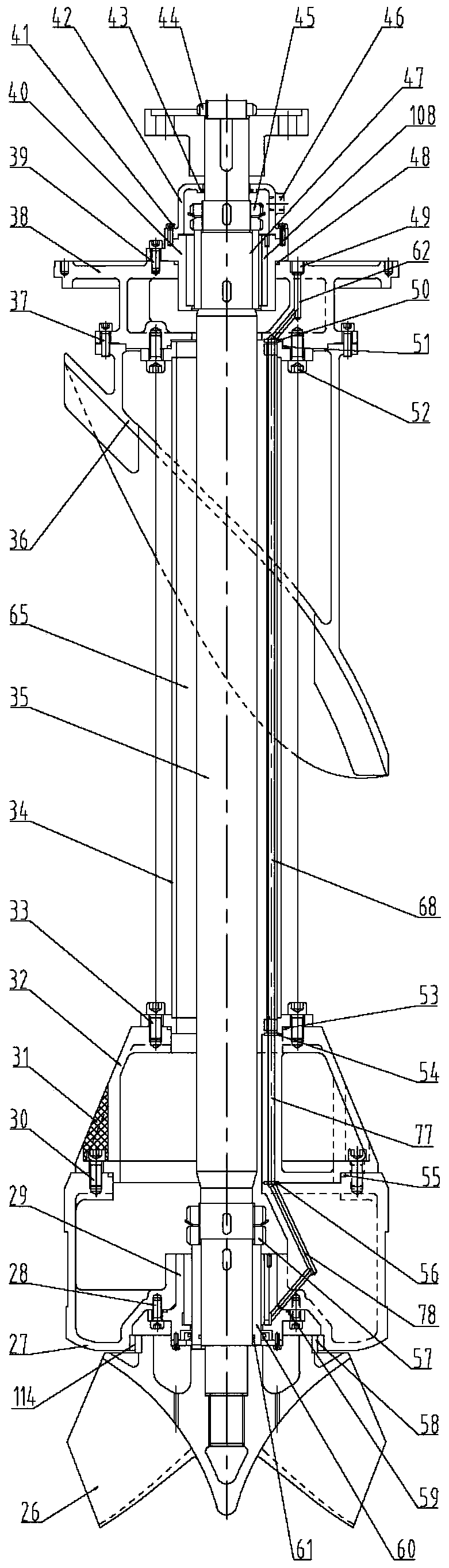

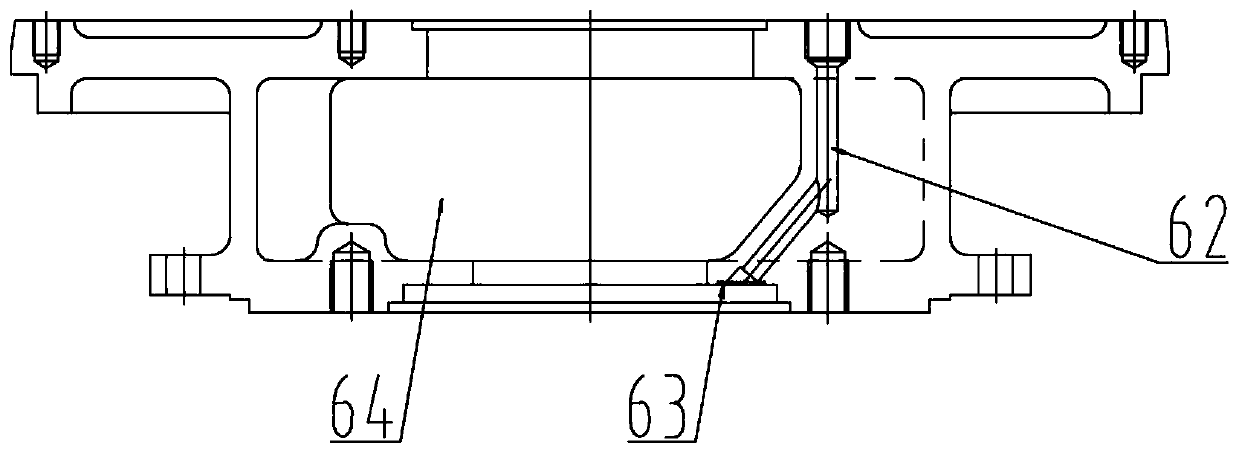

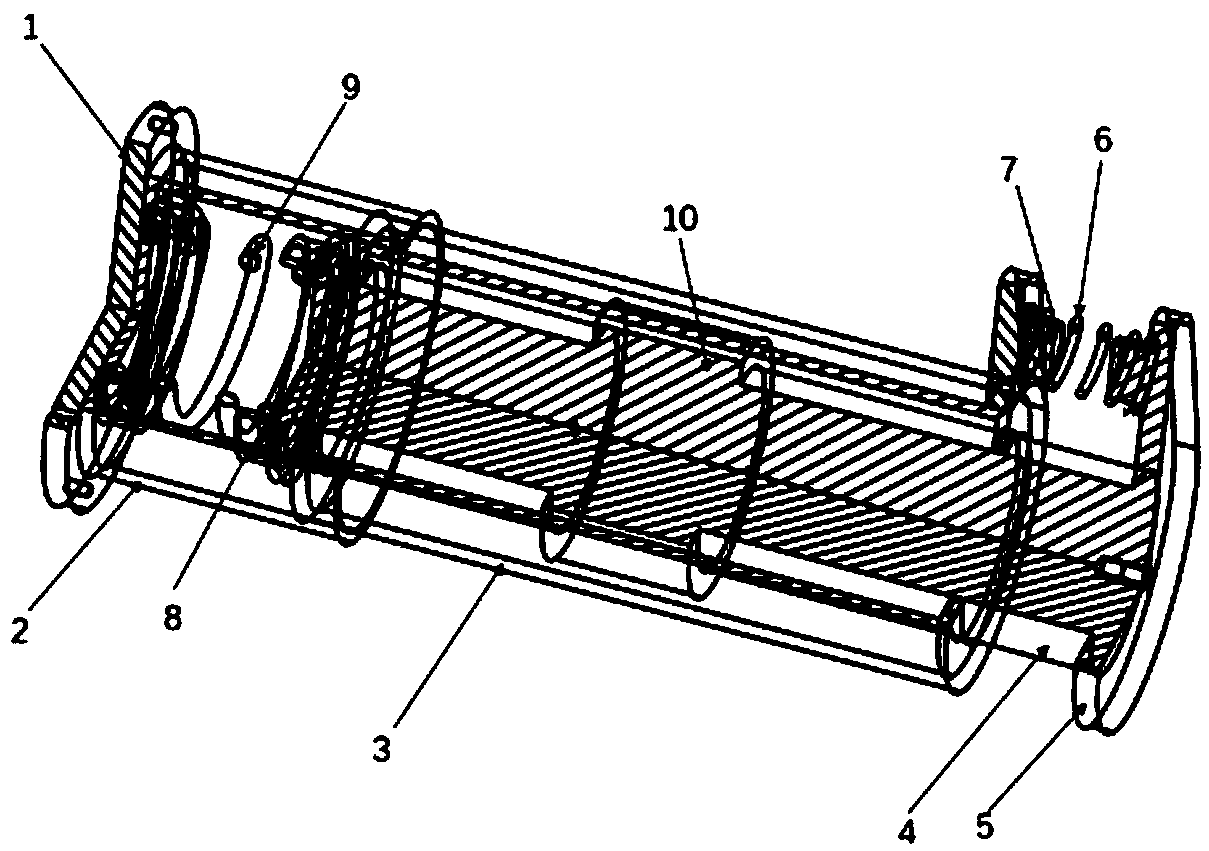

Environment-friendly reliable type pump for water treatment system

PendingCN110145469AExtended service lifeLower Reynolds numberPump componentsPump controlWater treatment systemEngineering

The invention provides an environment-friendly reliable type pump for a water treatment system. The environment-friendly reliable type pump comprises a rotor part, wherein a first through hole is formed in the upper end cover of the rotor part; a cooling tube which extends along length of a protective tube is arranged in the protective tube; a second through hole is formed in a guide shell; a third through hole is formed in a lower bearing base; a ring of ring-shaped slots is formed in the inner side surface of the lower bearing base; a fourth through hole is formed in a lower bearing; the first through hole, the cooling tube, the second through hole, the third through hole, the ring-shaped slots and the fourth through hole are in communication in sequence; the guide shell, the protectivetube, the upper end cover and the inner part of a sealing cover are in communication; a fifth through hole which communicates with the inner part of the sealing cover is formed in the sealing cover; alubricating / cooling / flushing cavity capable of circulating liquid independently is formed, so that the pump has effects of independently isolating, lubricating, flushing and cooling, and different media can be pumped, and therefore, the environment-friendly reliable type pump is safe, clean, multi-purpose, energy-saving and long in service life; moreover, the water pump is a structure capable ofdrawing a core, and facilitates mounting and dismounting; and a pump mounting plate is arranged outside a water outlet section in a sleeving mode, and a mounting position of the motor bracket is arranged on the water outlet section, so that length of a pump shaft is effectively reduced.

Owner:GUANGZHOU XINHENG PUMP MFG

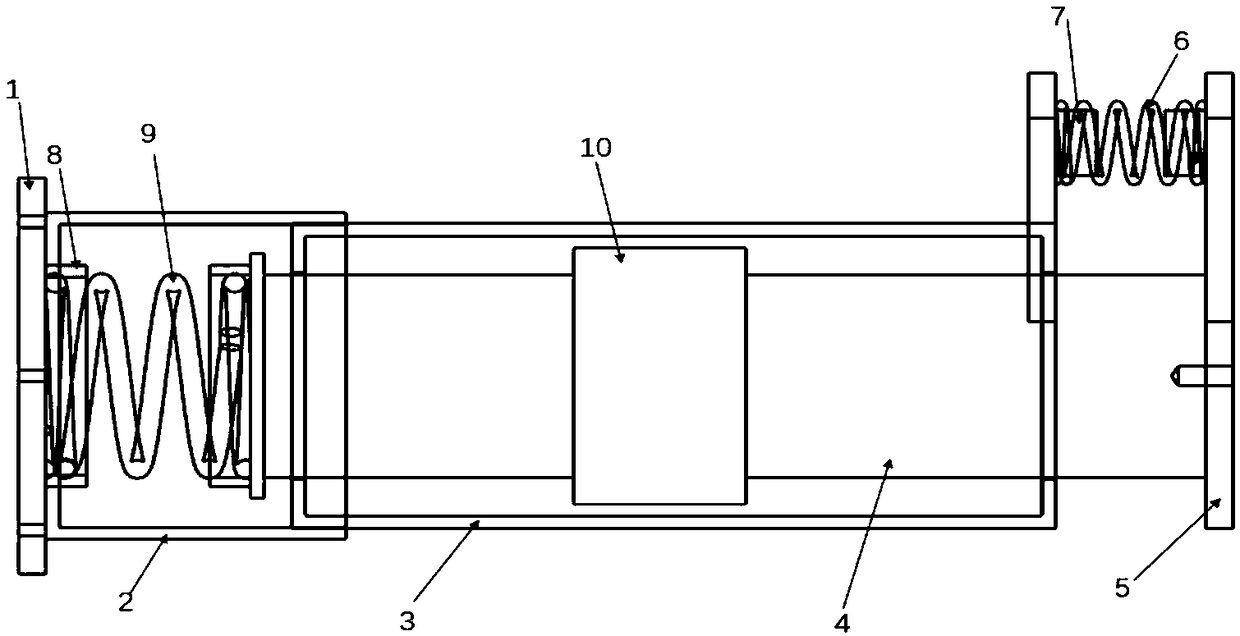

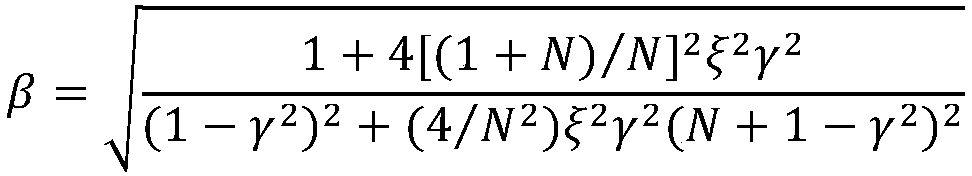

A thrust transducer for a pulse detonation engine

ActiveCN109264003AIncrease high frequencyGood periodicityPower plant constructionIntermittent jet plantsAxial displacementPulse detonation engine

The invention discloses a thrust converting device of a pulse detonation engine, comprising an aircraft mount, a spring cavity, a linear viscous damper, an engine mount, a parallel spring and a seriesspring; the thrust converting device comprises an aircraft mount, a spring cavity, a linear viscous damper, an engine mount, a parallel spring and a series spring. The thrust conversion device is connected with the aircraft and the pulse detonation engine through an aircraft mount and an engine mount. The linear viscous damper is designed as a symmetrical double-output rod clearance damper, so that the damping property thereof does not change with the change of the motion direction, and is convenient to control. Adopting the structure design of two springs mounted side by side not only improves its ability to isolate high frequency, periodic, pulse-type and large peak-to-peak thrust, but also reduces the axial displacement of the engine. Pulse detonation engine produces periodic, pulsed,large peak-to-peak thrust transfer to the engine mount, through the spring storage energy, damper energy consumption, and ultimately converted into a small fluctuation of the quasi-steady force, through the mount transfer to the aircraft.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

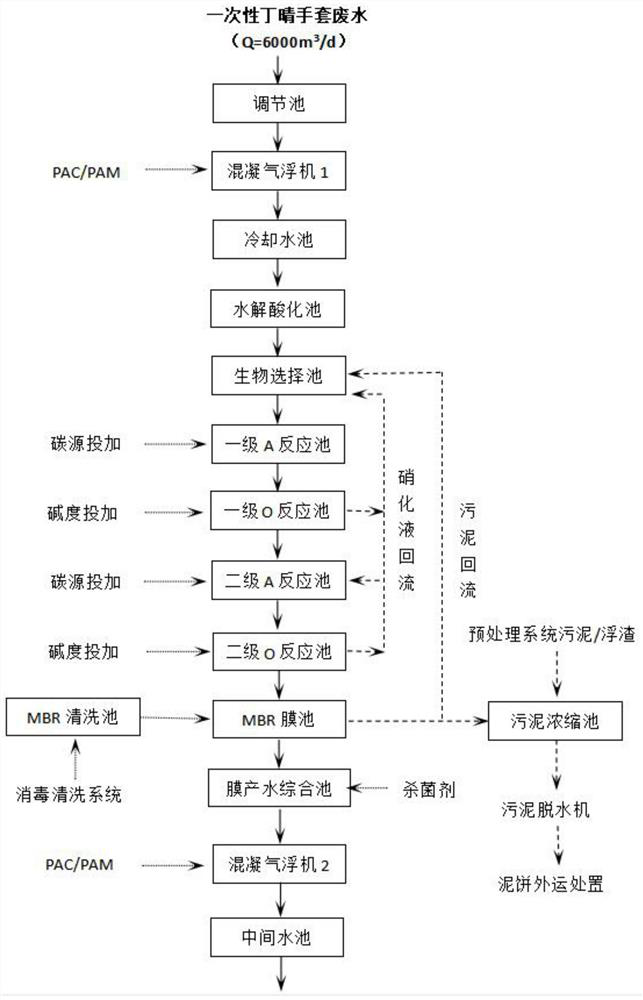

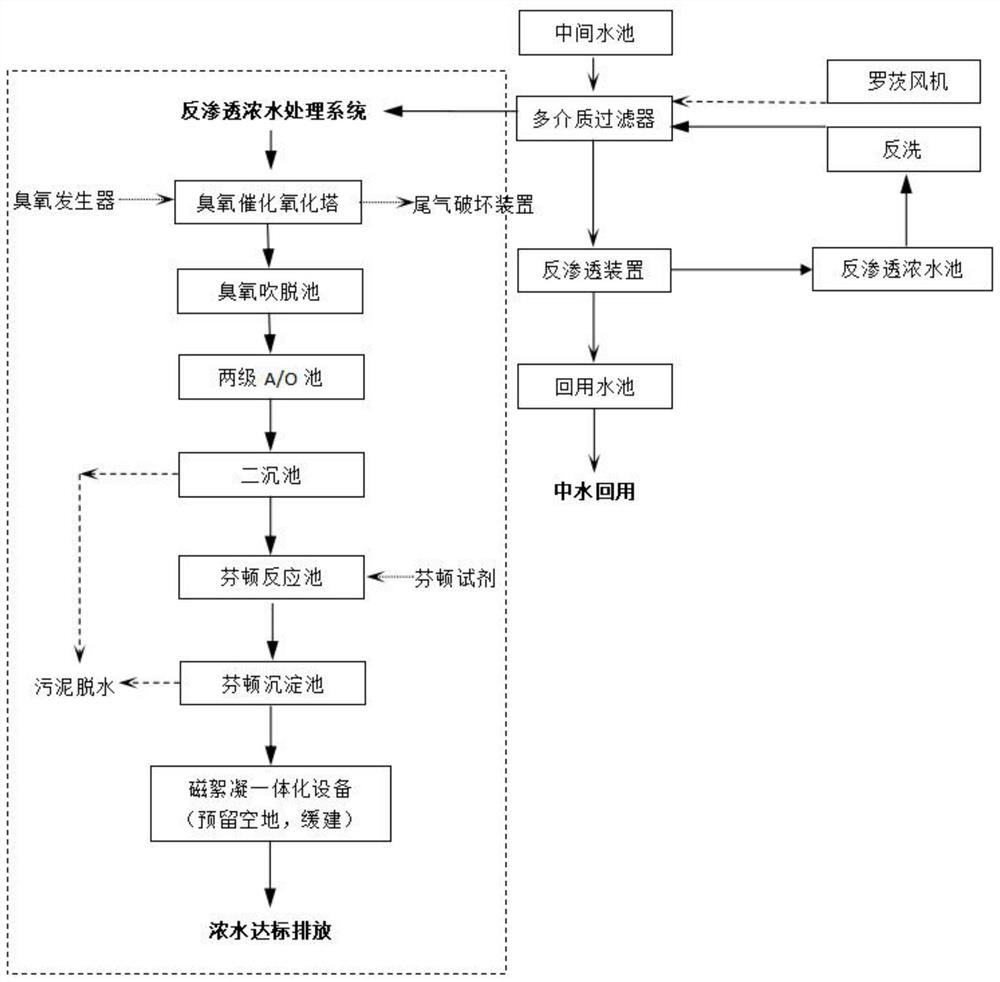

Disposable butyronitrile glove production wastewater treatment method and reuse water treatment process

ActiveCN113277677AImprove water qualitySmall footprintWater treatment compoundsWater contaminantsEnvironmental geologySewage

The invention discloses a disposable butyronitrile glove production wastewater treatment method. The method comprises the following steps: collecting incoming water through an adjusting tank; removing slag through a coagulation air flotation machine 1; cooling through a cooling tower; enabling the wastewater to pass through a hydrolysis acidification tank and a biological selection tank, and sequentially pass through a first-stage A reaction tank, a first-stage O reaction tank, a second-stage A reaction tank and a second-stage O reaction tank for treatment; separating the sludge from water through an MBR membrane tank; and sterilizing the sewage, carrying out deslagging and discharged, and pressing the sludge into sludge cakes to be transported outwards. The invention relates to a disposable butyronitrile glove production reuse water treatment process, which comprises: filtering incoming water through a multi-medium filter; pumping to a reverse osmosis device, and treating the generated concentrated water through a catalytic ozonation tower and a two-stage A / O tank; and feeding the sewage enters a Fenton reaction tank to be treated. According to the present invention, after the two-stage RO filtration concentration, 70% of the purified water is reused for production, and 30% of the concentrated water is further deeply treated to achieve the emission requirement and then is discharged.

Owner:JINAN GUANGBO ENVIRONMENTAL PROTECTION TECHCO

Low-Reynolds-number wing section matched with full-wing solar unmanned aerial vehicle

ActiveCN103482054BImprove the lift-to-drag ratioAchieve self-levelingWing shapesHeat reducing structuresHigh liftFront edge

The invention provides a low-Reynolds-number wing section matched with a full-wing solar unmanned aerial vehicle. The low-Reynolds-number wing section is characterized in that the relative thickness of the wing section is 11%-13%, the maximum camber of the wind section is 2%-4%, and a chordwise position with the maximum camber is 25%-30%; the wing section has a single bent outline in a 70% chordwise range from a front edge. With a full-aircraft matching design, the checking of pneumatic characteristics of a pair of wing sections is finished by checking the corresponding pneumatic characteristics of the wing sections and applying the two wing sections to the full-wing solar unmanned aerial vehicle, and the low-Reynolds-number wing section shows good pneumatic characteristics and engineering enforceability and can meet application demands on low Reynolds number, high lift force and lift-to-drag ratio and large relative thickness of the full-wing solar unmanned aerial vehicle.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

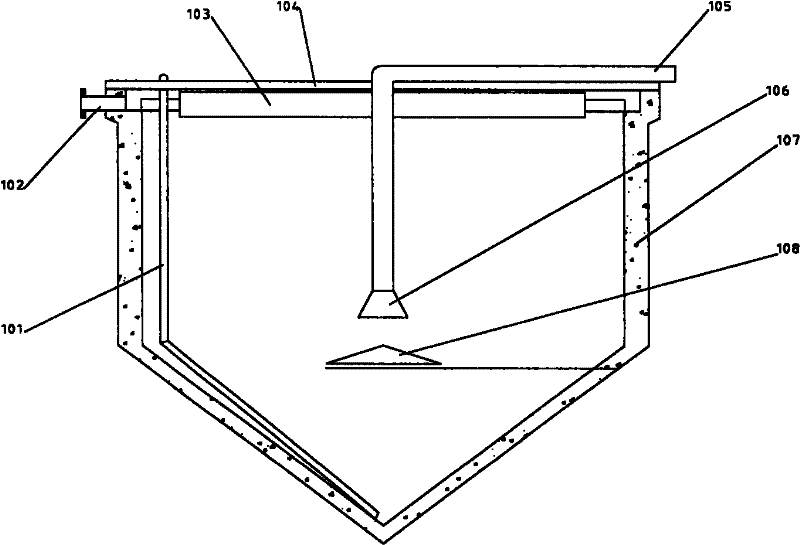

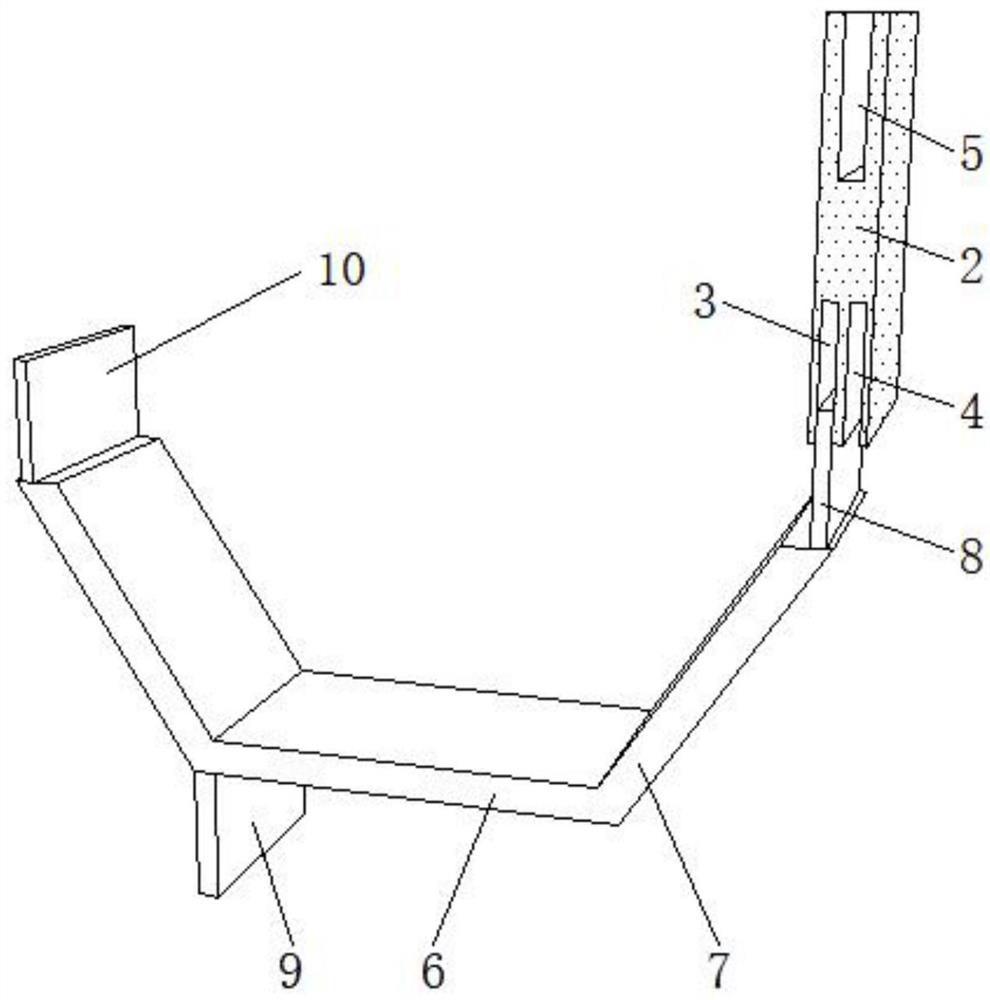

U-shaped inclined tube for inclined tube thickener and splicing method of U-shaped inclined tube

ActiveCN112791455AQuick assemblyAvoid overlappingSedimentation settling tanksStructural engineeringMechanics

The invention relates to a U-shaped inclined tube for an inclined tube thickener and a splicing method of the U-shaped inclined tube, belongs to the technical field of underground coal preparation, and solves the problems that the precipitation efficiency is low and the combination mode is complicated due to sheet overlapping during installation of the existing inclined tube. The U-shaped inclined tube comprises a plurality of layers of waveform sheets and a plurality of parallel sheets. Each layer of waveform sheet comprises a plurality of U-shaped sheets, and a first plug and a third plug are arranged at the two ends of each U-shaped sheet respectively. One end of each parallel sheet is provided with a first groove and a second groove, and the first plugs and the third plugs of the adjacent U-shaped sheets are respectively clamped to and connected with the first groove and the second groove of the same parallel piece to form a waveform sheet. A second plug is arranged at the bottom of each U-shaped sheet. A third groove is formed in the other end of each parallel sheet. The second plugs are connected with the third grooves in a clamped mode, and connection between the multiple layers of waveform sheets is achieved. Rapid splicing of the U-shaped inclined tube is achieved through mutual clamping of the waveform sheets and the parallel sheets.

Owner:ZHENGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com