Helical flat pipe for waste heat boiler

A waste heat boiler and flat tube technology, which is applied to tubular elements, heat exchange equipment, lighting and heating equipment, etc., can solve the problems of large potential for improvement of waste heat utilization efficiency and low utilization ratio of waste heat resources, and achieve compact structure and heat exchange efficiency. Improve and save material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

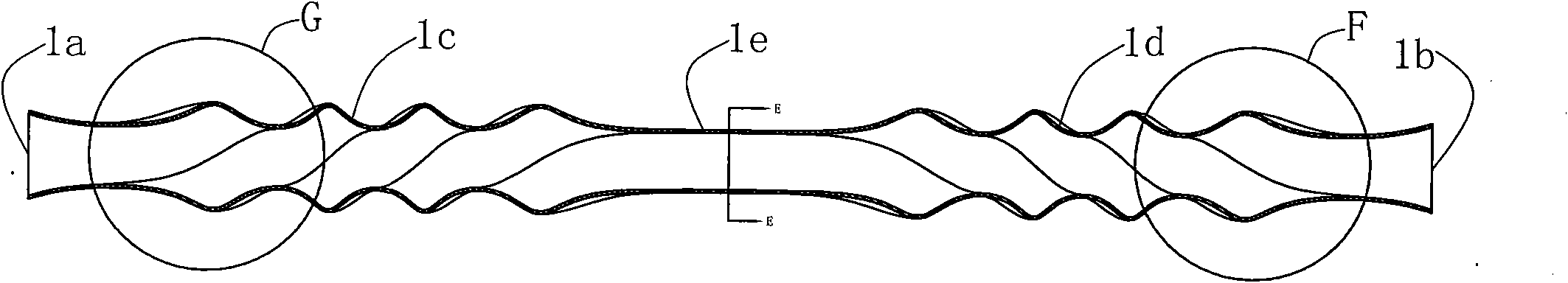

[0039] The spiral flat tube used in the waste heat boiler of the present invention includes a flat tube body 1, a first tube interface 1a that doubles as an inlet and a second tube interface 1b that doubles as an outlet located at both ends of the flat tube body 1, wherein: the flat tube body 1 It is fixedly installed in the heat exchange surface 2 in a ring or regular curve shape, and the flat tube body 1 includes at least one helical part, and the cross section of the helical part along the axis at any point is an ellipse or oval with a spiral gradient.

[0040] The spiral portion may be a left-handed portion 1c or a right-handed portion 1d. The helical part is based on a circular tube, which is twisted and shaped after being flattened. The cross-section of the helical part along the axis at any point is an ellipse or oval with a spiral gradient. A plurality of spiral parts can be arranged on the flat tube body 1 .

[0041] A transition section 1e can be provided between ea...

Embodiment 2

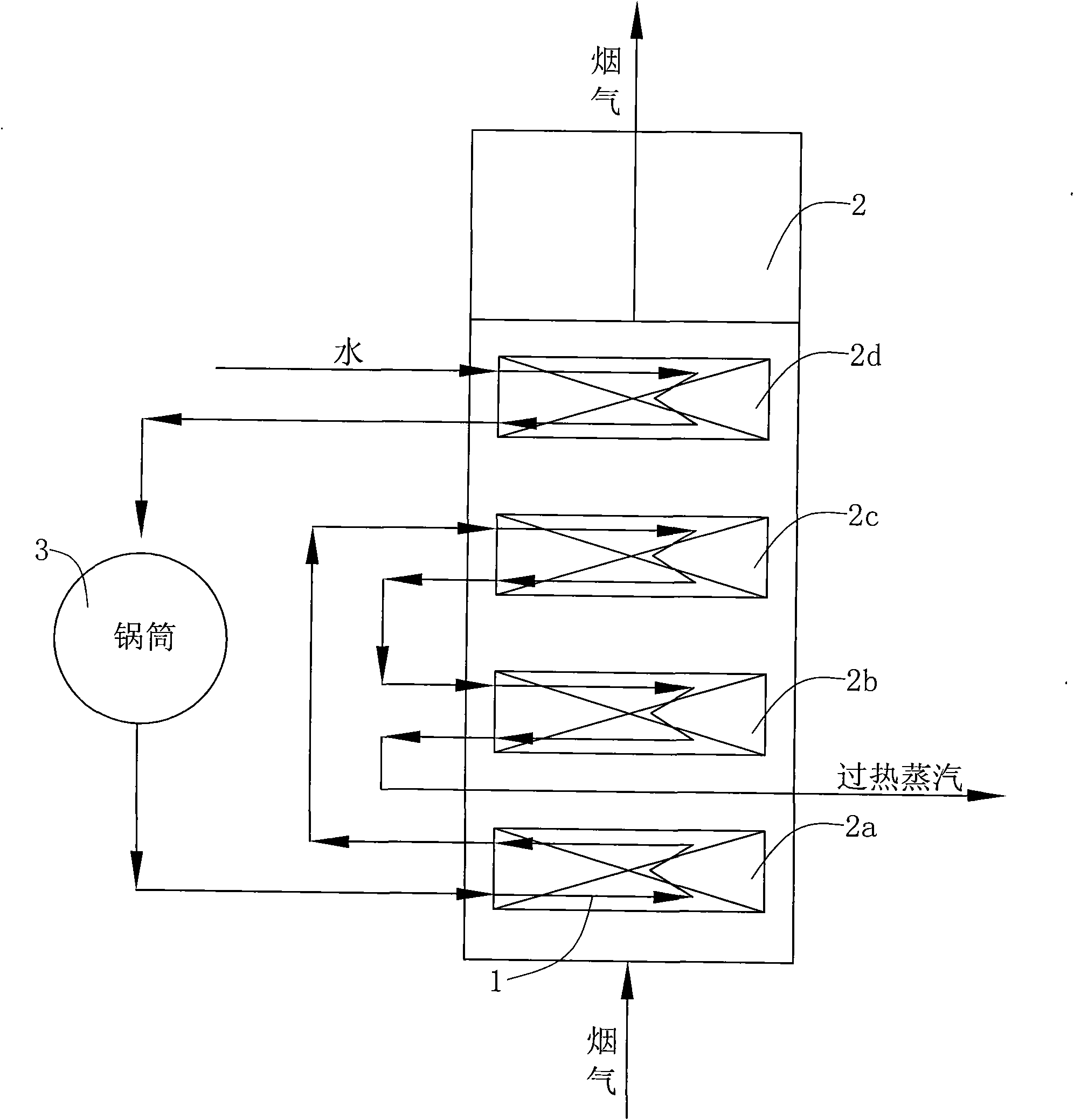

[0050] Figure 10 It is a structural schematic diagram of the application of the spiral flat tube in this embodiment to a flue-type waste heat boiler.

[0051] Such as Figure 10 As shown, the flue-type waste heat boiler is mainly composed of an economizer, a riser, a drum, a downcomer, a water protection section, an evaporator, a superheater and a chimney. The flue boiler is a water tube boiler. Water or steam flows in the furnace tube, and the flue gas flows in the flue outside the furnace tube. A coil composed of spiral flat tubes is installed in the economizer, water protection section, evaporator and superheater. tube group. The flue gas transfers heat to the water or steam inside the tube by scouring the outer surface of the tube.

[0052] During the working process, the water enters the economizer through the water supply pipe, and after being heated, it is sent to the drum, mixed with the pot water, and then goes down the downcomer to pass through the water protecti...

Embodiment 3

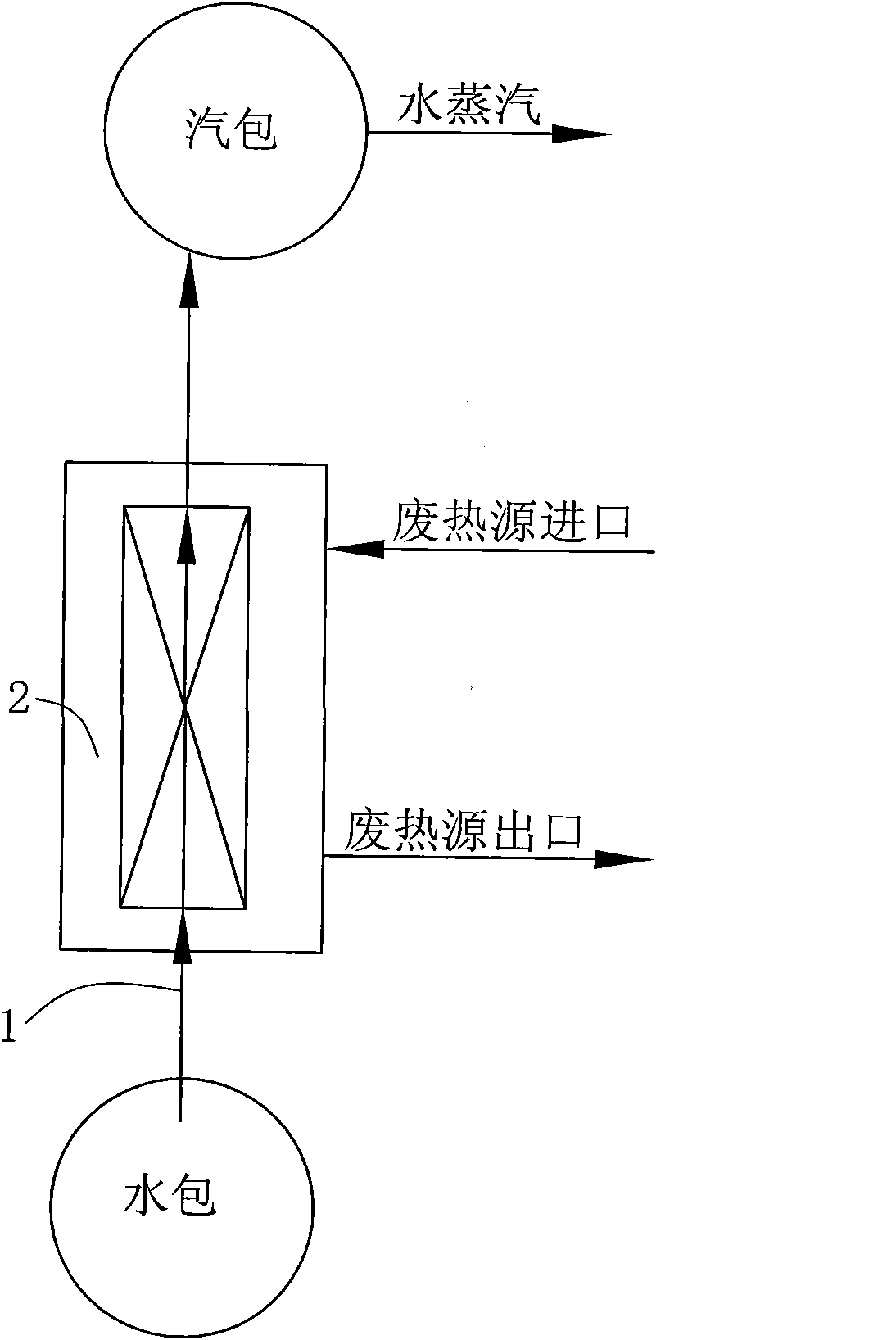

[0055] Figure 11 It is a structural schematic diagram of the application of the spiral flat tube in this embodiment to a shell-and-tube waste heat boiler.

[0056] Such as Figure 12 As shown, the shell-and-tube waste heat boiler body is mainly composed of front-end tube box 6, flue gas outlet 7, fixed tube plate 8, steam outlet 9, shell 10, baffle plate 11, tube bundle 12, floating tube plate 13, floating head cover 14 , Outer head cover 15, water inlet 16 and flue gas inlet 17 etc. are formed. The shell and tube waste heat boiler is a fire tube boiler, the flue gas flows in the furnace tube, and the water flows in the shell outside the tube. Heat is transferred through the tube wall to the water outside the tube.

[0057] The water enters the pot shell through the water supply pipe, and the water absorbs heat in the pot shell to form a steam-water mixture, which reaches the steam drum through the rising pipe, and the steam drum separates the water and steam. The separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com