Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Low in Tea Polyphenols" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Honeysuckle tea and processing method thereof

InactiveCN103190498AOvercome the defect of long-term drinking injury to the stomachMaintain the efficacy of the drugPre-extraction tea treatmentBitter tasteTea leaf

The invention provides a processing method of the honeysuckle tea, and relates to the technical field of tea processing. The method mainly comprises the following steps of: picking up and treating the honeysuckle, picking up fresh tea, withering tea green, cutting up the honeysuckle, evenly mixing honeysuckle with the tea, rolling, fermenting, extracting fragrance in a drying way, carrying out vacuum package and the like. According to a 'curing' process, the honeysuckle tea provided by the invention is weak in irritation, more gentle and temperate, can play the functions of the red tea for effectively promoting the stomach digestion, promoting the appetite, carrying out detumescence and diuresis, strengthening the heart and the like, can keep the pesticide effect action of the honeysuckle, and keeps the health protection effect of the honeysuckle. The juice of the honeysuckle can be sufficiently absorbed by the tea according to the rolling and fermenting of both of the red tea and the honeysuckle, and the taste of the honeysuckle and that of the tea are mediated with each other, so that the mouth feel is more delicious, the bitter taste of the honeysuckle disappears, and the tea has better sweet aftertaste.

Owner:福建省柘荣县天康茶业有限公司

Processing method of white tea

InactiveCN103583725AQuality improvementRegular shapePre-extraction tea treatmentProcess engineeringAir blower

The invention provides a processing method of white tea, and belongs to the technical field of tea processing. The processing method comprises the steps of tea picking, green airing, withering, rolling, shaping, roasting and purifying, wherein the key procedures are green airing, withering, rolling and roasting; the tea is aired for 10-20 minutes under the sunlight until the tea temperature is 38-40 DEG C; firstly, the tea is naturally withered indoors, then is processed by a blower for 3-4 hours; the air outlet temperature is controlled within 45-60 DEG C. Finished tea prepared by the processing method has the characteristics of full pekoe, spiral tea as silver balls, needle tea as silver pins, tidy shape, mellow smell, lasting flavor, sweet taste, smooth feel when entering mouths, yellow green bright soup color, brewing resistance, pure taste and no bitterness.

Owner:GUANGXI LUOCHENG XINKE SHUANGQUAN ORGANIC FOOD

Green tea processing technology in summer

InactiveCN106035773AImprove qualityAmino acid highPre-extraction tea treatmentCooking & bakingPolyphenol

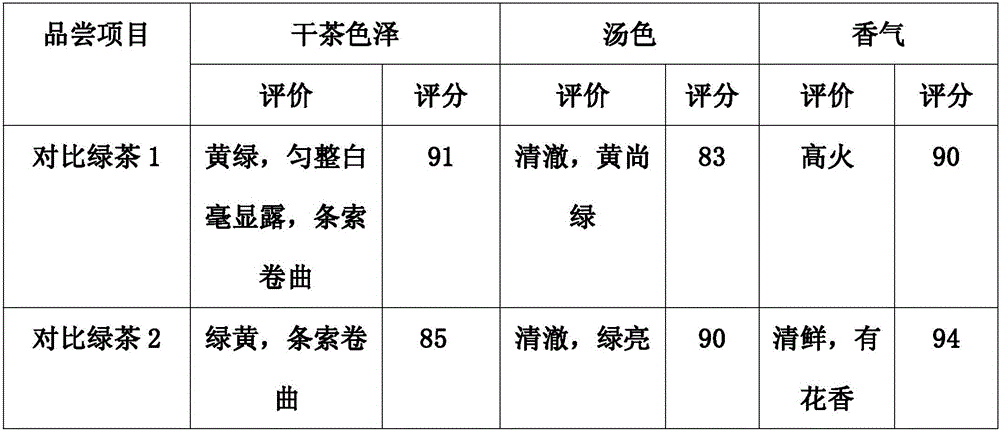

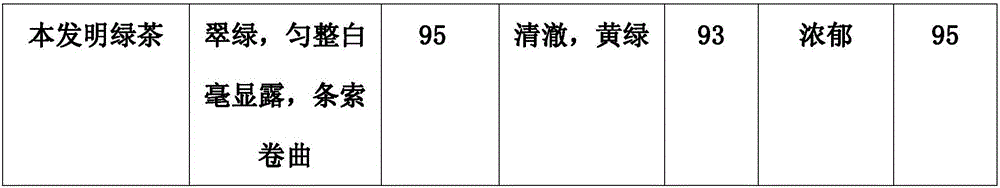

The invention provides a processing technology of green tea, which specifically includes picking, green tea spreading, killing green tea, spreading cold, rolling, initial frying, re-frying, drying, aroma enhancer to enhance the aroma, and the green tea produced has good quality and amino acid The higher the content, the lower the content of tea polyphenols, and the smaller the ratio of phenol to ammonia. The aroma of the finished finished tea lasts for a long time, the water content of the tea leaves is less than 5%, that is, the water content is low, the storage time is long, the color is emerald green, the appearance is even and the pekoe is exposed, the cord is curled, and the tea quality is good; the taste is mellow, the aftertaste is sweet, The soup is clear, and the bottom of the leaves is bright green.

Owner:遵义凤龙茶业有限公司

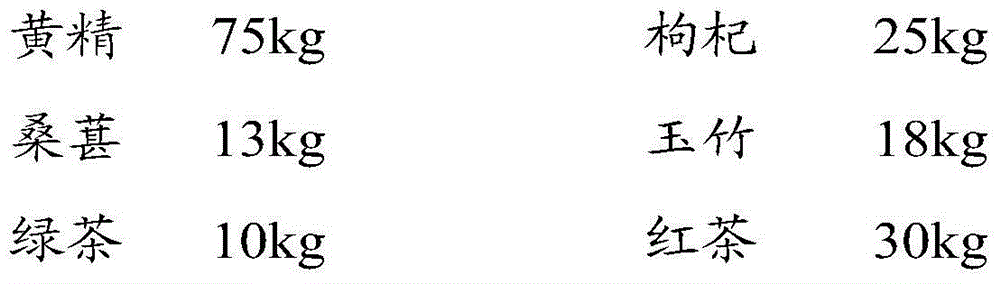

Substitutional tea with polygonatum and method for manufacturing same

InactiveCN104886322AGreat tasteFully absorbedPre-extraction tea treatmentTea substituesPolygonum odoratumAbsorption effect

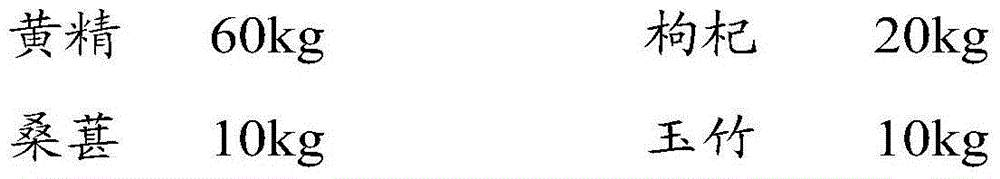

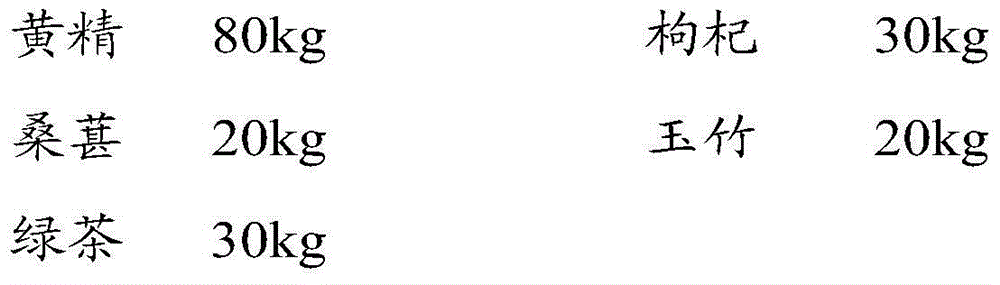

The invention provides substitutional tea with polygonatum and a method for manufacturing the same. The substitutional tea mainly comprises, by weight, 60-80 parts of the polygonatum, 20-30 parts of lycium barbarum, 10-20 parts of mulberries and 10-20 parts of polygonatum odoratum. The method for manufacturing the substitutional tea includes steps of mixing raw materials; smashing the raw materials; sieving the raw materials; concentrating and extracting the raw materials; drying and granulating the raw materials to obtain grains. The substitutional tea can be obtained after the grains are packaged. The substitutional tea with the polygonatum and the method in an embodiment of the invention have the advantages that excellent absorption effects can be realized by the substitutional tea, the substitutional tea is suitable for people of all ages and low in cost, and people can drink the substitutional tea conveniently without time constraints.

Owner:福建德广中草药有限公司

White tea liquor production method

InactiveCN105199891APromote the secretion of interferonImprove the ability to resist external aggressionMetabolism disorderDigestive systemChemistryDistillation

The invention discloses a white tea liquor production method. The method comprises 1, selecting a white tea finished product, carrying out rinsing by clear water to remove impurities and carrying out airing for next use, 2, extracting active ingredients of white tea and collecting the extract and white tea residues for next use, 3, cleaning and immersing liquor production raw materials, adding the white tea residues obtained by the step 2 into the raw materials, carrying out stewing, carrying out spreading cooling, mixing the mixture and distiller's yeast, putting the mixture into a jar and carrying out preliminary fermentation, 4, adding water and the extract obtained by the step 2 into the raw materials subjected to preliminary fermentation and carrying out secondary fermentation, 5, carrying out distillation extraction on the fermented mixture to obtain a white tea liquor stock solution, and 6, filtering the distillation product, clarifying the filtrate, and carrying out sterilization, ageing and blending to obtain a white tea liquor finished product.

Owner:徐小芹

Making technology of fermented edible mushroom tea and fermented edible mushroom tea

InactiveCN107593955ALow in Tea PolyphenolsHave a weight loss effectPre-extraction tea treatmentFiberCooking & baking

The invention relates to a making technology of fermented edible mushroom tea and the fermented edible mushroom tea. Fermented tea leaves or fermented finished product tea is used as a raw material, and through the spawn running working procedure of edible mushrooms, the fermented edible mushroom tea is obtained. The making technology comprises the following steps of adding edible mushroom culturematerials to the fermented tea leaves, performing humidity conditioning, performing steaming, and performing tea leaf shaping; performing bagging and / or bottling, performing high-temperature sterilization, performing heat dissipation, performing inoculation with edible mushroom strains, and performing spawn running; performing heat preservation on tea bags and / or tea bottles, and performing electrothermal baking; and packaging finished products. According to the making technology disclosed by the invention, rich microorganism fungus nutritive protein and nutrient components, which can be eaten by human bodies or can be directly absorbed, are increased through fermentation and transformation with edible mushrooms, in stems and leaves of the fermented tea leaves mainly comprising crude fibers and lignin, the fermented edible mushroom tea has low calorie, high mycoprotein, polysaccharide amino acids, unsaturated fatty acid, various trace elements necessary for human bodies, and the like,the fermented edible mushroom mycelium and sclerotium tea not only has the characteristics of fermented tea but also has specific nutrient value of edible mushroom mycelia and edible mushroom sclerotium, and the medical value and the health-care functions of the fermented edible mushroom tea are increased.

Owner:于葵 +1

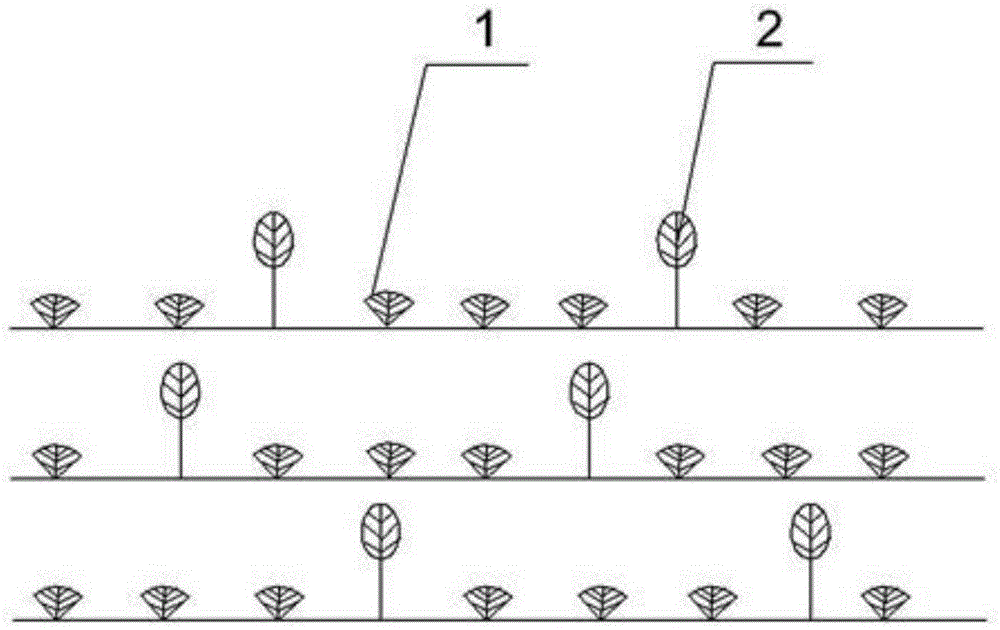

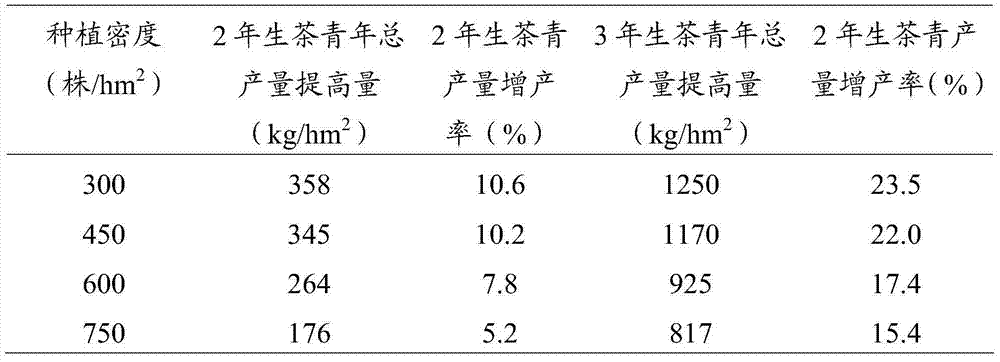

Tableland tea garden shading method

ActiveCN105248235AImprove tendernessImprove qualityCultivating equipmentsPlant protective coveringsEconomic benefitsSeedling

The invention discloses a tableland tea garden shading method. Multiple rows of tea trees are planted in a tableland tea garden, one tea tree is taken as a shading tree every other 5-10 m in each row, the shading trees are not sheared during plantation and grow naturally to 2-4 m, the shading tress in every two adjacent rows are planted alternately, and the shading trees are not located at the two ends of the corresponding row. Tea tree seedlings are shaded by means of original ecology tea seedlings, the tenderness keeping ability of tea can be improved, the quality of tableland tea is improved, high-grade camellia arborescens products are obtained, and the economic benefit of the tea garden is improved greatly; the negative effect that tea fragrance is affected due to odor taint caused by interplanting with other kinds of trees is avoided; insect and disease prevention of the tea garden is facilitated, and field management is facilitated.

Owner:GUANGXI POLYTECHNIC

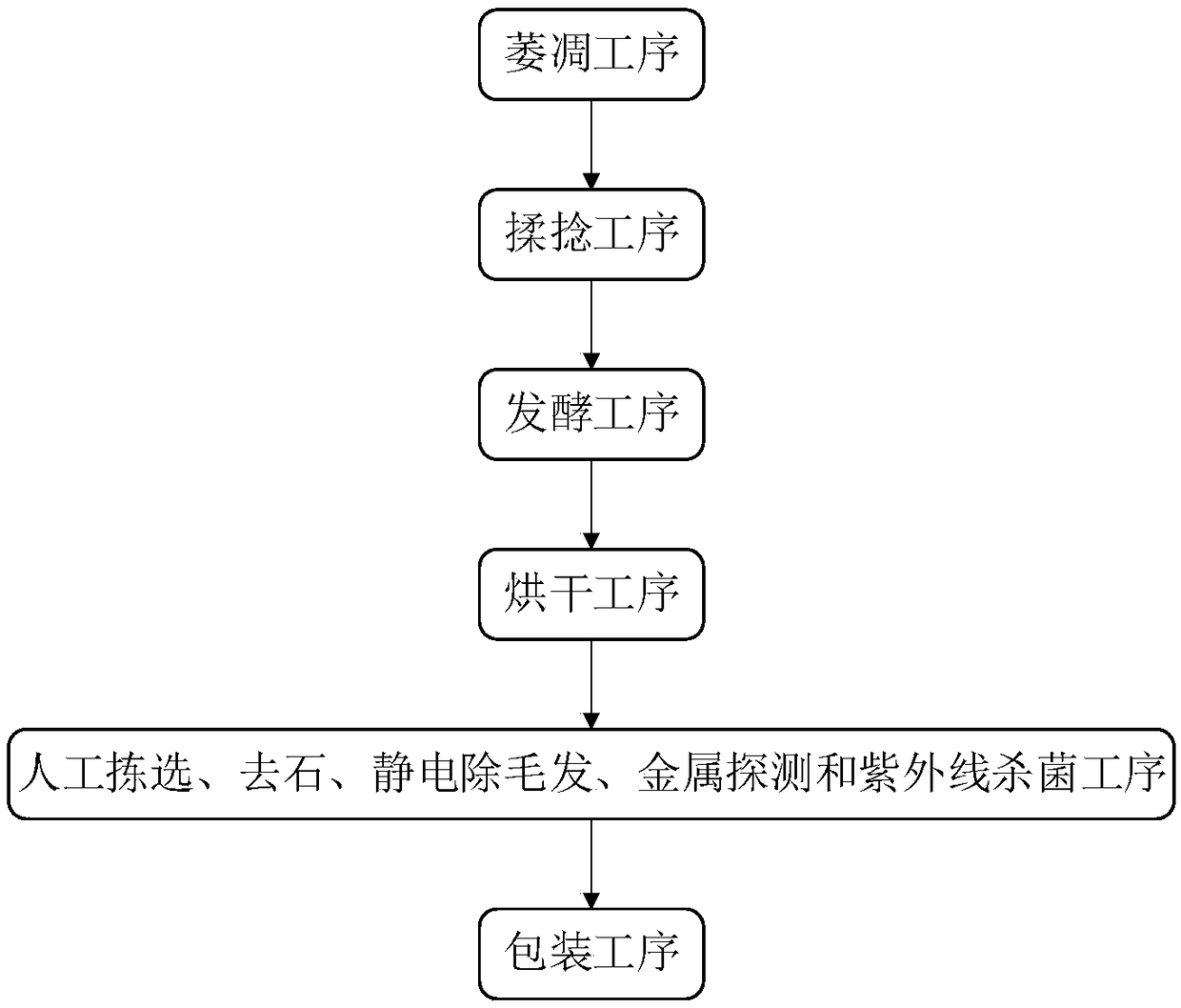

Processing technology of Chinese wolfberry bud tea and Chinese wolfberry leaf tea

The invention relates to the technical field of tea beverage processing, and especially relates to a processing technology of Chinese wolfberry bud tea and Chinese wolfberry leaf tea. The processing technology of the Chinese wolfberry bud tea and the Chinese wolfberry leaf tea orderly comprises the following processes of performing withering, rolling, fermenting and drying on Chinese wolfberry buds and Chinese wolfberry leaves. The process of performing fermenting includes the steps of respectively and uniformly spreading Chinese wolfberry buds and Chinese wolfberry leaves to be fermented on fermentation frames in a fermentation chamber, wherein the spread thickness is 2.5-3.0 centimeters; maintaining the temperature of the fermentation chamber at 28-30 DEG C and the humidity of the fermentation chamber at 80-90%; carrying out fermentation for 6-8 hours, and determining whether the Chinese wolfberry buds and the Chinese wolfberry leaves are appropriately fermented by observing superficial characteristic changes, as well as color and luster indexes; and ending the process of performing fermenting when the Chinese wolfberry buds and the Chinese wolfberry leaves are appropriately fermented. The processing technology of Chinese wolfberry bud tea and Chinese wolfberry leaf tea provided by the invention is high in automation degree; moreover, stimulation of the Chinese wolfberry budsand the Chinese wolfberry leaves can be effectively improved after the process of performing fermenting. The Chinese wolfberry bud tea and the Chinese wolfberry leaf tea processed by the processing technology have good stomach-nourishing and stomach-protecting functions.

Owner:宁夏润德生物科技有限责任公司

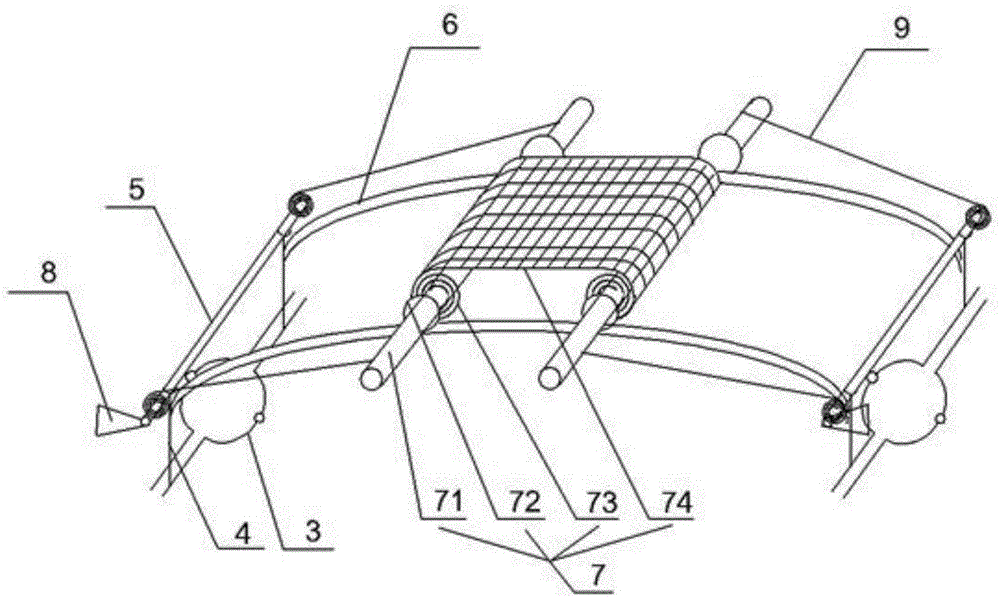

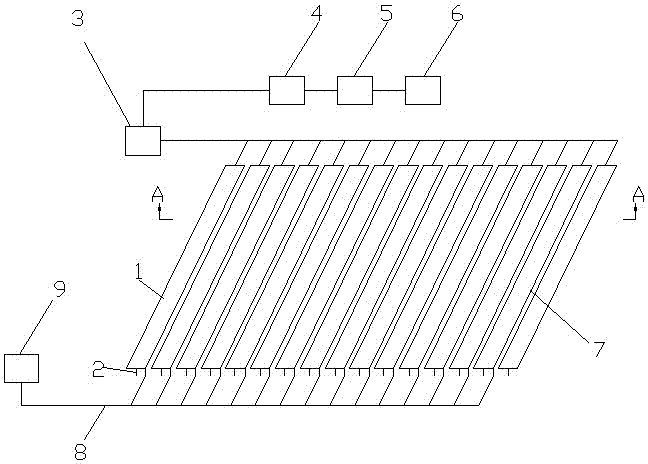

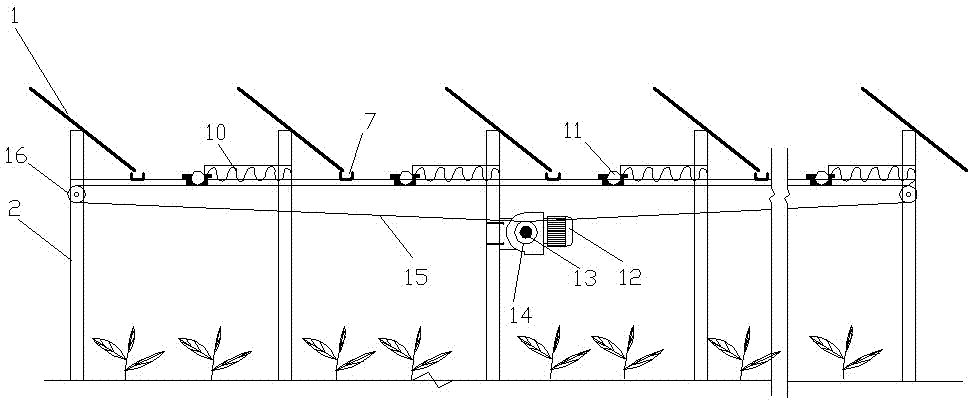

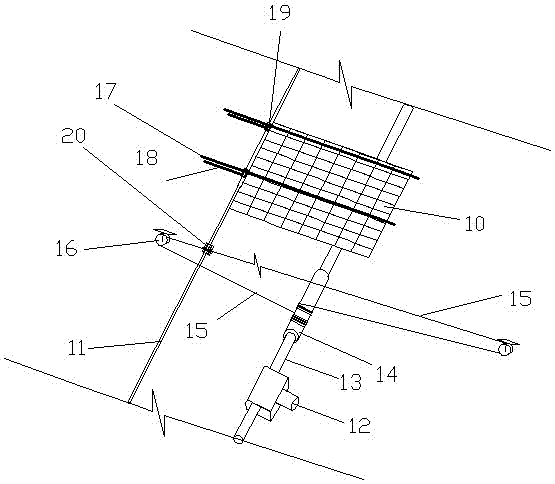

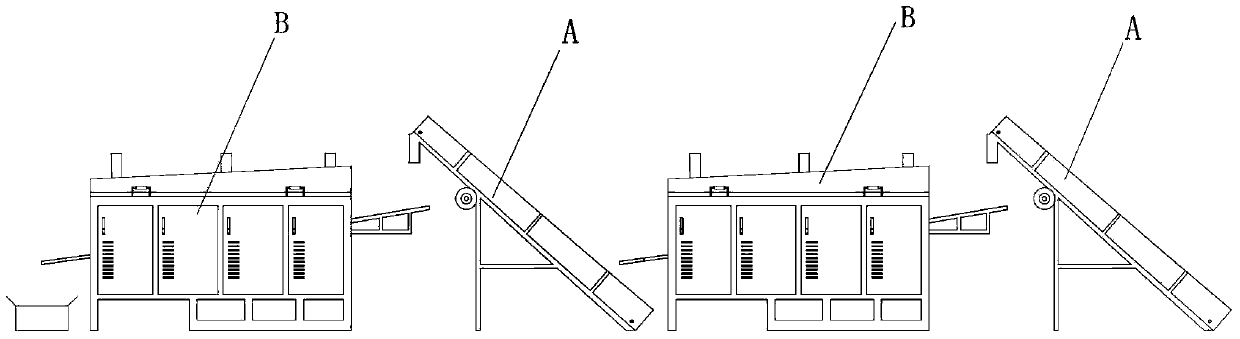

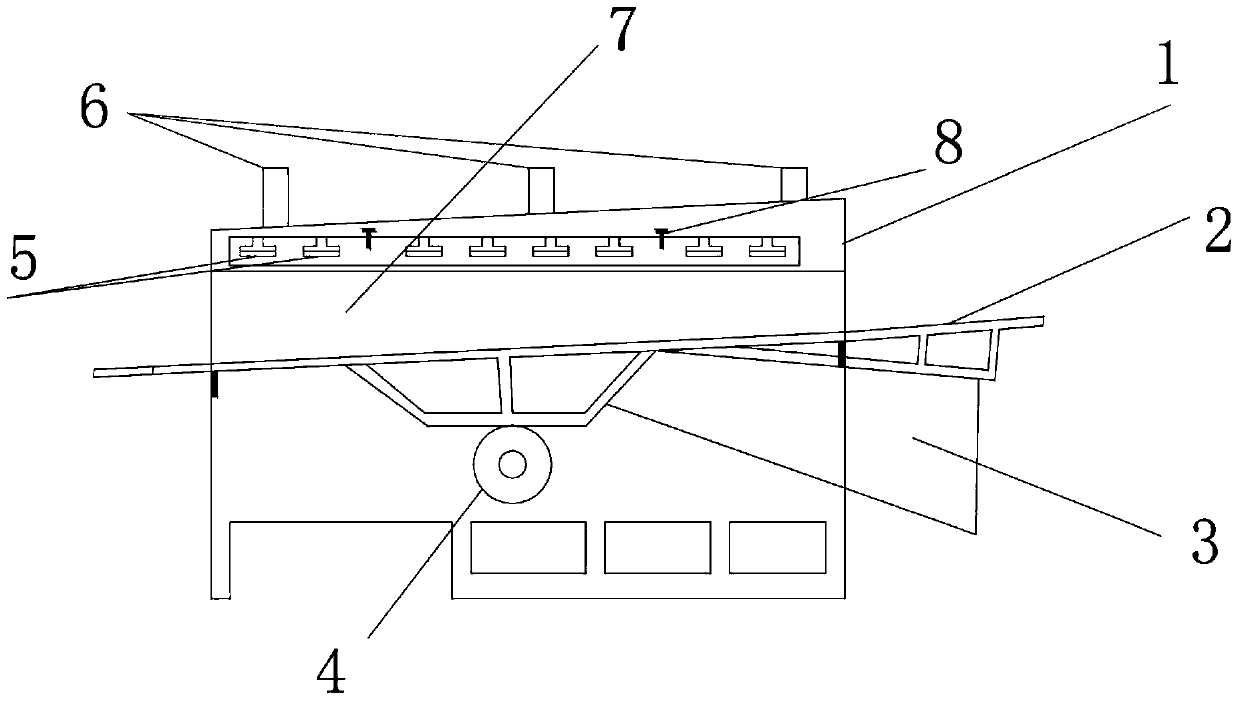

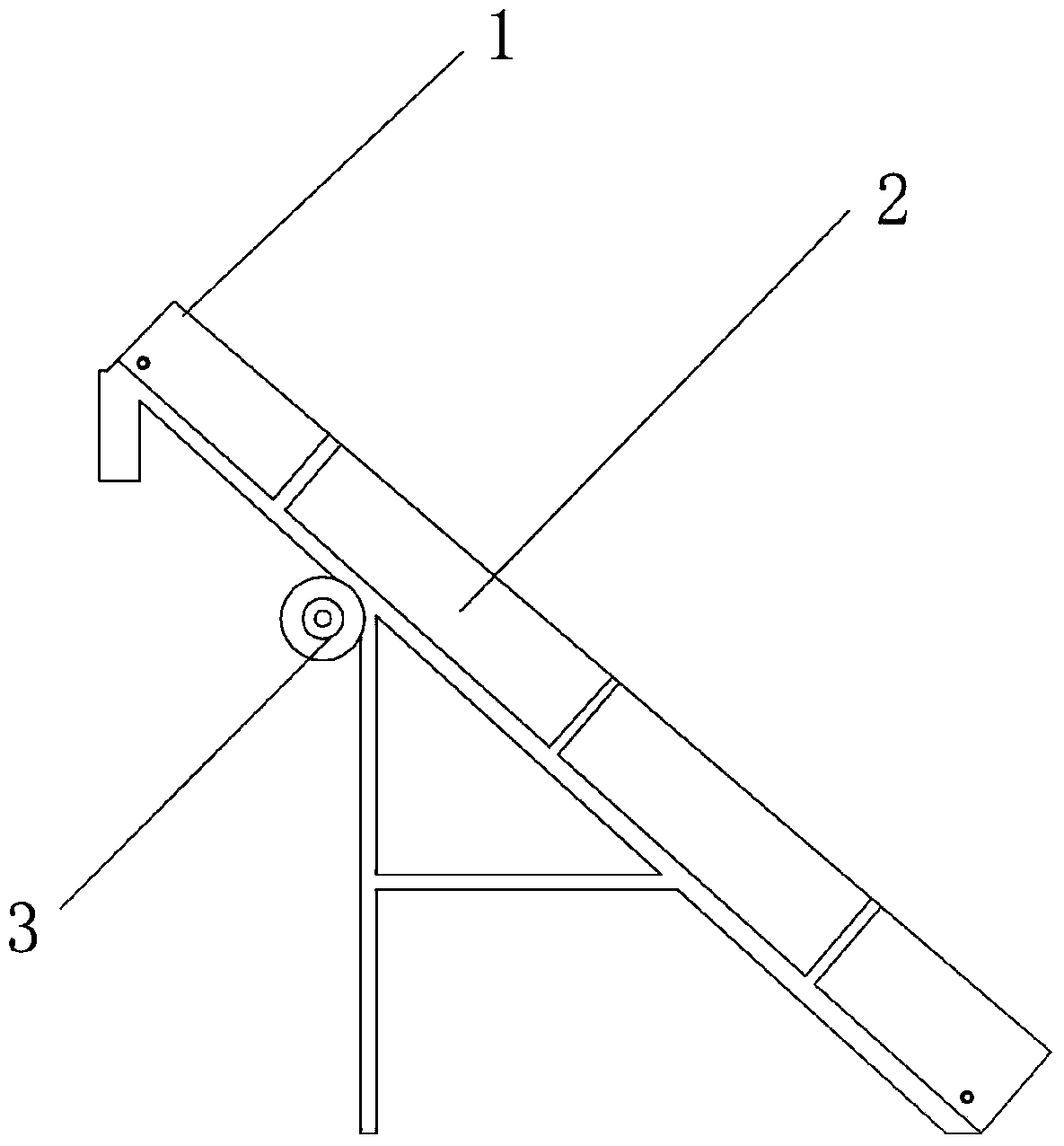

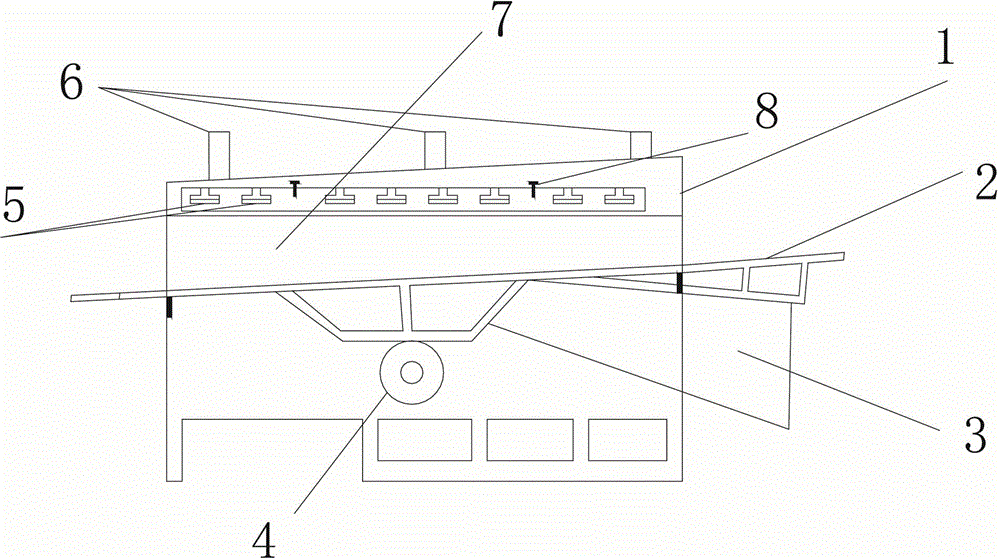

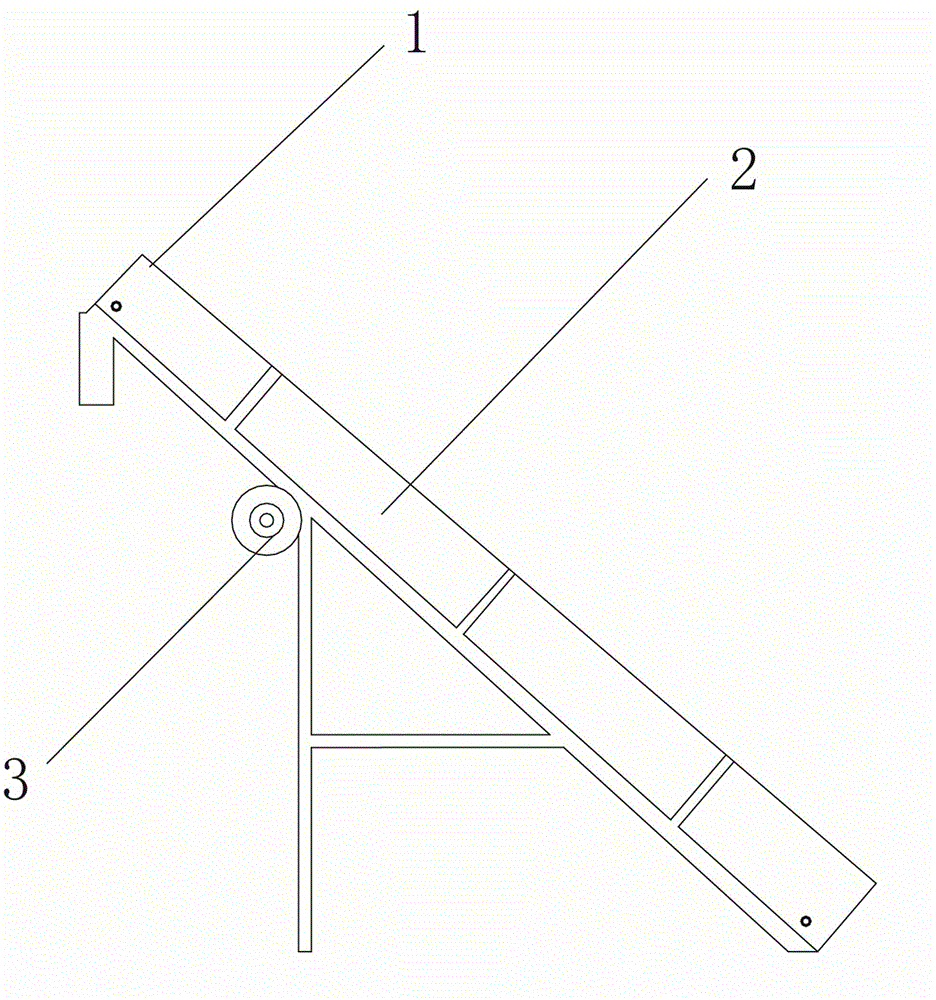

Large-area shading device of tea gardens based on photovoltaic panel power generation

ActiveCN106973731APromote early germinationIncrease productionPhotovoltaic supportsGeneral water supply conservationElectricityDrive shaft

The invention discloses a large-area shading device of tea gardens based on photovoltaic panel power generation. The device comprises a plurality of vertical supports. Solar power photovoltaic panels are arranged on the top of the vertical supports, and the lower ends of the vertical supports are provided with water collection channels. A drive cable is surrounded on a reversing wheel located at two sides. Drive shafts are arranged on the vertical supports, and reel sleeves are arranged on the drive shafts. Sunshade nets are arranged between the adjacent vertical supports. The right end of the sunshade nets is connected to the upper part of the corresponding vertical support; the left end is connected to sliding bars. The sliding bars are fixed on the cable through the respective pulling rod in a clamped mode. Curtain-supporting lines are arranged below the sunshade nets, and curtain-pressing lines are arranged on the sunshade nets. Clips of the middle part of positioning guide clips are arranged on the sliding bars in a clamping mode; holes in the upper part are arranged on the curtain-pressing lines in a penetrating mode and holes in the lower part are arranged on the curtain-supporting lines in a penetrating mode. The device has the advantages of being suitable for large-area use, flexible and quick in deploying and retracting, using sun to generate electricity effectively, and collecting rainwater for tea garden irrigation.

Owner:杭州建荣新能源有限公司

Interplanting method in tea garden

ActiveCN104838955AImprove the ecological environmentImprove qualityCultivating equipmentsEcological environmentEconomic benefits

The invention discloses an interplanting method in a tea garden. The interplanting method includes steps of interplanting dalbergia odorifera and agilawood in the tea garden. The tea garden comprises at least two rows of ridges for planting tea trees. The dalbergia odorifera and the agilawood are alternatively planted along the inter-row length extending direction between the adjacent ridges. By interplanting the dalbergia odorifera and the agilawood in the tea garden, the ecological environment of the tea garden is beneficial to synthesis and accumulation of amino acid and caffeine of the tea trees, chlorophyll content of leaves is remarkably increased, tea polyphenol content is somewhat reduced, and phenol ammonia is decreased, so that quality of tea leaves is improved. In addition, yield of the tea trees can be increased and economic benefits of the tea garden are added.

Owner:ZHANGZHOU GUANGZHAOREN TEA CO LTD

Tea preparation method

InactiveCN104839357AEvenly heatedHigh collection valuePre-extraction tea treatmentBiotechnologyGreen teas

The present invention discloses a tea preparation method which includes the following steps: air-drying and withering, aroma conserving, enzyme deactivating, rolling, low temperature drying, baking with fire to keep aroma, uniformly pushing, and screening. The whole process is conducted without complete fermentation, and thus the tea has original ecological fresh mouth feel of green tea. Meanwhile, the tea produced by the process also has the characteristics of pu'er raw tea as "more mature pu'er raw tea is more fragrant", and has enhanced fresh mouth feel and higher collection value compared to black tea. The soup color of the tea is different from that of black tea, pu 'er raw tea and pu 'er ripe tea. With the increasing of soaking times, the tea soup color changes from golden yellow and transparent to orange red and bright and then to golden yellow and transparent.

Owner:云南龙润茶业集团有限公司

Ion repair liquid preparation method

InactiveCN110894174AEasy to prepareImprove production efficiencyBio-organic fraction processingAlkali orthophosphate fertiliserWater solubleDigested food

The invention provides an ion repair liquid preparation method, which comprises the following steps: raw material weighing, acidifying, fermenting, aging and enzyme spraying, wherein an acidifying agent is adopted in the acidifying, the addition amount of the acidifying agent is 8.3%, the acidifying temperature is 48 DEG C, the fermenting temperature is 58 DEG C, the PH value of the fermenting is6.2, the stirring rotating speed is 60 r / min, aerobic fermentation is carried out for 30 hours, anaerobic fermentation is carried out for 15 hours, the pressure of the aging is 82.5-84.7 MPa, qualityconditioning is performed with steam for 73 seconds at 122 DEG C, and the viscosity of the sprayed enzyme is 896 mPa.s. According to the ion repair liquid obtained by the method disclosed by the invention, macromolecules are changed into micromolecules so as to increase the permeability, the diffusivity and the dissolving capacity of the repair liquid, so that various water-soluble amino acids, vitamins and trace elements are easily absorbed, the soil water stable aggregate content can be increased, the permeation regulating substances in the leaves of planted crops can be increased, the photosynthesis and the transpiration of newly transplanted plants can be regulated, and the rooting and the survival of plants can be promoted.

Owner:蔡敬海

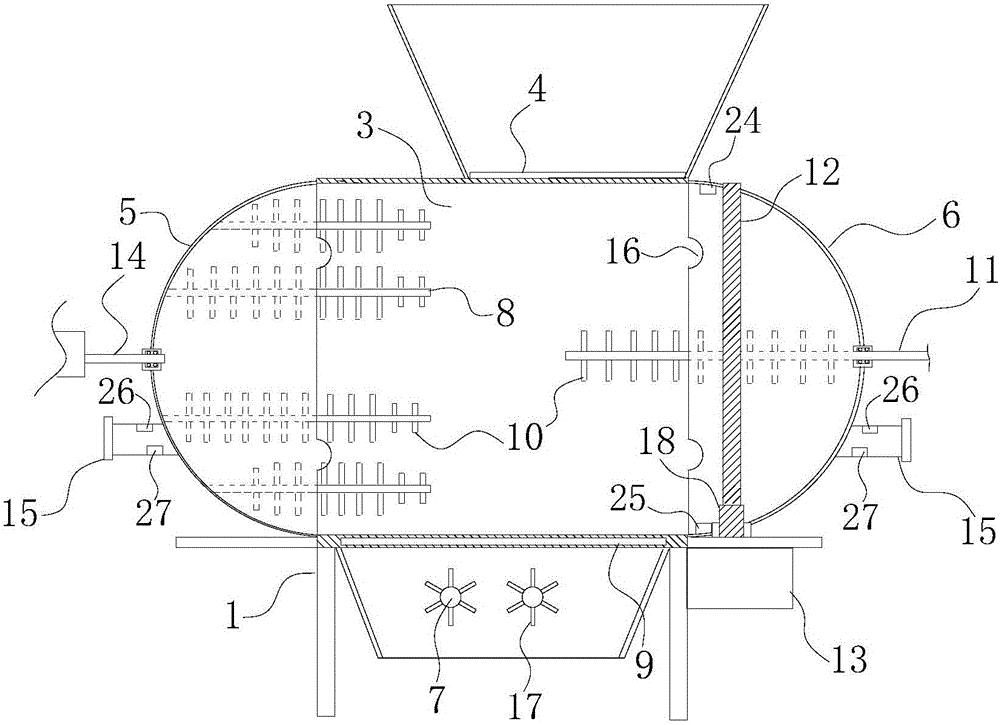

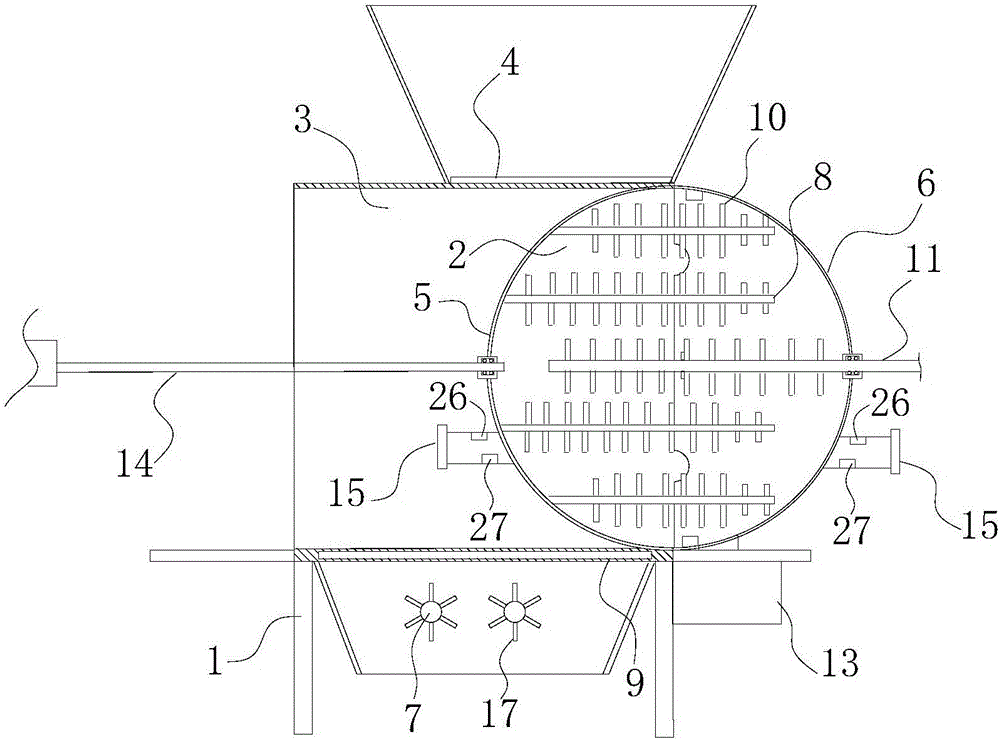

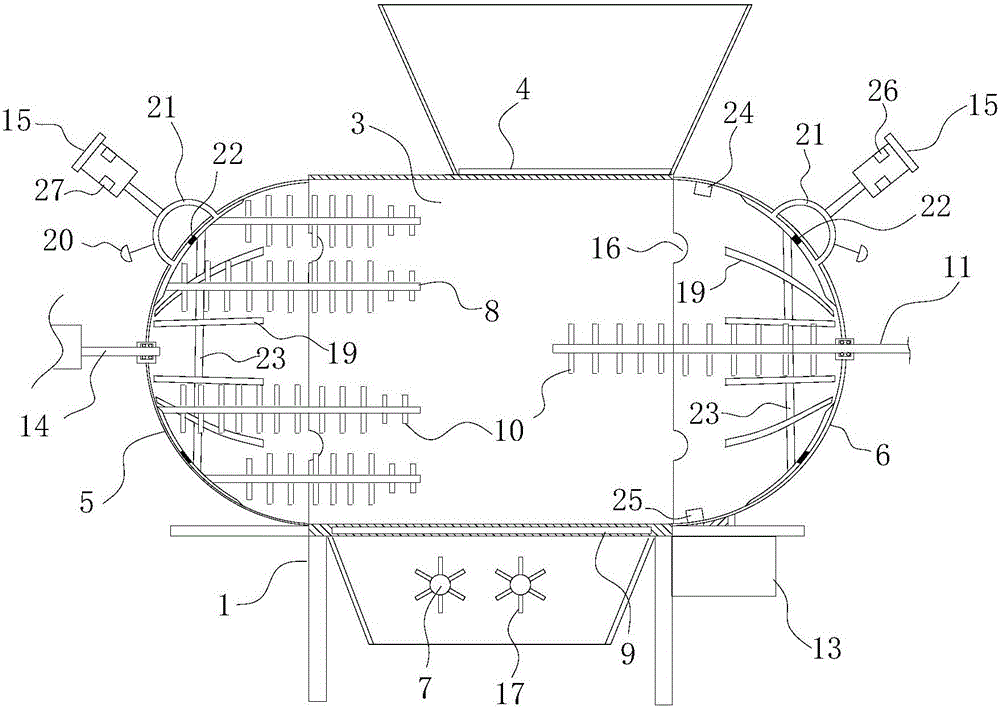

Far infrared fixation set for tea leaves and fixation method of far infrared fixation set

InactiveCN104171076AEnsure consistencyTemperature controlPre-extraction tea treatmentHorticultureInfrared

The invention discloses a far infrared fixation set for tea leaves and a fixation method of the far infrared fixation set. The far infrared fixation set is characterized by comprising at least two sets of far infrared fixation machines and two sets of automatic tea leaf feeding machines, which are alternatively arrayed. Far infrared rays are used for carrying out automatic fixation and the tea leaves can be cooled and moistened again after being subjected to fixation carried out by the far infrared fixation machines, so that the effect of carrying out efficient fixation on the tea leaves is achieved.

Owner:柳州市自动化科学研究所

Processing method for reducing bitterness of summer green tea

PendingCN110742139APromote conversionImprove freshnessPre-extraction tea treatmentHorticultureAgricultural engineering

The invention relates to a processing method for reducing bitterness of summer green tea in the field of tea processing. The processing method comprises the following steps: (1) picking: picking freshleaves of big-leaf tea; (2) spreading: spreading the fresh leaves on a spreading tank at the thickness of 5-10 cm and the temperature of 20-32 DEG C, lightly turning the fresh leaves once every 3 h,and spreading the fresh leaves for 12-16 h; (3) fixation: putting the fresh leaves into a continuous steam fixation machine for fixation for 120-150 s at the speed of 200-250 kg / h; (4) cooling: blowing the tea leaves natural wind for cooling; 5) spreading and airing: lightly turning the leaves once every 2-3 h at the thickness of 5-12 cm for 6-9 h until leaf tips and leaf edges are completely wetand soft; (6) shaping: performing carding and rolling according to shaping requirements; and (7) drying: reducing the water content of the tea leaves to 7% or below to obtain a finished product. The method reduces the content of part of tea polyphenols mainly by changing the spreading degree and the spreading time after fixation or rolling in the tea processing process, so that the green tea tastes mellow but not bitter.

Owner:凤冈县苏贵茶业旅游发展有限公司

Processing technology of golden buds

PendingCN112293504AIncreased amino acid contentQuality assurancePre-extraction tea treatmentGreen teasPhenolic content in tea

The invention discloses a processing technology of golden buds (a kind of green tea). The technology ensures the quality of fresh leaves and improves the quality of tea leaves by cleaning the fresh leaves, the mellowness of the taste of the golden buds can be increased by indoor withering and sunlight withering, and the golden buds baked by adopting the technology disclosed by the invention are high in theanine content and more sufficient in fresh and cool taste of finished tea; and the tea polyphenol content is low, finished tea is light in bitter taste, and market prospect is promising.

Owner:安徽宏云制茶有限公司

Processing method of white tea

InactiveCN108514033AQuality improvementRegular shapePre-extraction tea treatmentAnti virusAnti viral immunity

The invention discloses a processing method of white tea. The method comprises the following steps: (1) tea picking; (2) cooling; (3) withering; (4) rolling; (5) shaping; (6) stoving; and (7) purification: subjecting crude tea to winnowing and sieving to pick out non-tea impurities so as to obtain a finished product. The method ensures the high quality and efficiency of white tea processing, particularly improves the color, aroma, taste and appearance of ''green leaf yellow-green soup'' of the white tea and improves the quality of leaf bases, increases the yield of prepared tea, and improves the quality of the white tea. The white tea processed by the method is regular in shape; the dried tea is full of pekoe; the snail-shaped tea is similar to silver pearls; the needle-shaped tea is similar to silver needles; the white tea is rich in aroma, pure in taste, lasting in fragrance, mellow in taste and sweet in aftertaste; the tea water is smooth in mouth, yellow green, bright and clear insoup color and durable in brewing; the white tea has the characteristics of high amino acid content and low tea polyphenol content, also contains active enzymes necessary for human body, has good anti-virus immune functions, and can be preserved at normal temperature for 10 years without deterioration.

Owner:胡琴其

Jasmine flower micro-fermented tea and preparation process thereof

InactiveCN104782811AGlycol retentionLess theophyllinePre-extraction tea treatmentTea flavoringBiotechnologyPhenolic content in tea

The invention discloses jasmine flower micro-fermented tea and a preparation process thereof. The jasmine flower micro-fermented tea is obtained through stacking, high-temperature roasting, cooling, and bagging and natural fermentation for a semi-finished tea base; the jasmine flower micro-fermented tea prepared by the method furthest reserves the sweetness and the mellowness of fermented tea, and has the faint scent of jasmine flower; moreover, the contents of theophylline and tea polyphenols are low; the product achieves an elegant appearance, excellent taste and fragrance, a bright soup colour, a strong and natural fragrance, a pure and sweet state, a delicious aroma after drinking, and a strong aftertaste.

Owner:赵容 +1

Compound Maojian tea and preparation method thereof

InactiveCN105594906AFull of nutritionImprove drinking valuePre-extraction tea treatmentSurface moistureBlood pressure

The invention relates to the field of tea leaf manufacturing, in particular to compound Maojian tea and a preparation method thereof. Preprocessed Maojian is impregnated in hydroxypropyl methylcellulose liquid; then, the impregnated Maojian is softened in vacuum environment; next, mixed extraction juice of apples, ponkans and cherries is sprayed to the Maojian; then, microwave heating is performed until the surface moisture content of the Maojian is 50 to 65 percent; the Maojian is transferred into a kneading and twisting machine and is uniformly mixed with lemon oil; kneading and twisting are performed under the condition that the rotating speed is 300 to 500 r / min; the mixture is then transferred into a stir-frying machine and is mixed with L-lactamine to be baked until the moisture content of the Maojian is 7 to 10 percent; through cooling and screening, the compound Maojian tea is obtained. The compound Maojian tea has the characteristics of rich nutrition, high drinking value, good mouthfeel, good quality, blood pressure reduction and skin whitening.

Owner:GUIZHOU LINGFENG TECH IND PARK CO LTD

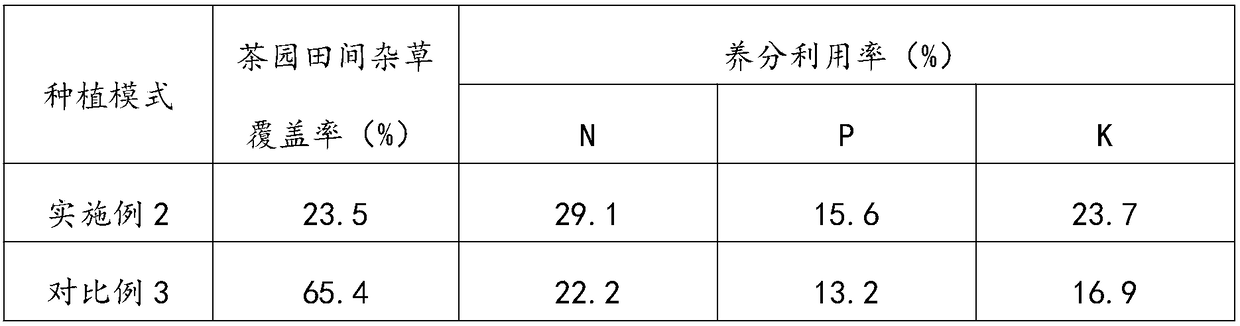

Compound planting method of ecological tea garden

InactiveCN109328837AStrong vine coverageSuitable shade coverageCultivating equipmentsFruit crop cultivationLand resourcesPassion fruit

The invention discloses a compound planting method of an ecological tea garden, and belongs to the technical field of garden planting. The method includes the following steps of firstly, planting teatrees; secondly, digging planting ditches to plant passion fruits; thirdly, establishing a shed frame; fourthly, conducting daily management. By compound planting the passion fruits in the ecologicaltea garden, the content of amino acids in summer fresh tea leaves can be increased by 0.3% or above, the content of tea polyphenol is reduced by 2% or above, and the freshness of the tea leaves is improved; the ripe passion fruits can be picked, and the yield can be increased by 1500 RMB or above in each mu; no additional land resources are occupied, weeds growing in the tea garden are reduced by60% or above, the illumination utilization rate is improved by 25% or above, and the nutrient utilization rate in the tea garden is increased by 15% or above.

Owner:GUANGXI GUILIN TEA RES INST

A kind of interplanting planting method of tea garden

ActiveCN104838955BImprove the ecological environmentImprove qualityCultivating equipmentsAquilaria rostrataEcological environment

The invention discloses an interplanting method in a tea garden. The interplanting method includes steps of interplanting dalbergia odorifera and agilawood in the tea garden. The tea garden comprises at least two rows of ridges for planting tea trees. The dalbergia odorifera and the agilawood are alternatively planted along the inter-row length extending direction between the adjacent ridges. By interplanting the dalbergia odorifera and the agilawood in the tea garden, the ecological environment of the tea garden is beneficial to synthesis and accumulation of amino acid and caffeine of the tea trees, chlorophyll content of leaves is remarkably increased, tea polyphenol content is somewhat reduced, and phenol ammonia is decreased, so that quality of tea leaves is improved. In addition, yield of the tea trees can be increased and economic benefits of the tea garden are added.

Owner:ZHANGZHOU GUANGZHAOREN TEA CO LTD

White tea processing method

InactiveCN107751447AQuality improvementRegular shapePre-extraction tea treatmentCooking & bakingEngineering

The invention provides a processing method of white tea, which belongs to the technical field of tea processing. Including tea picking, drying, withering, rolling, shaping, baking and cleaning, the key process is drying, withering, rolling and baking, drying the tea leaves in the sun for 30‑60 minutes until the temperature of the tea leaves is 38‑40 °C , wither first in the room, and then use a blower for 3-4 hours to control the temperature of the air outlet at 45-60°C. Features of the finished tea produced by the white tea processing method of the present invention: the finished dry tea is filled with pekoe, snail tea looks like silver beads, needle tea looks like silver needles, neat in shape, rich and mellow in taste, long-lasting in fragrance, full-bodied in taste, sweet in aftertaste, lubricated at the entrance of the tea, clear in soup color Yellow-green bright and clear, durable to foam, pure taste, no bitterness.

Owner:贵州绿视野绿色开发有限公司

Yellow tea and preparation method thereof

PendingCN112806449ALow in Tea PolyphenolsHigh in caffeinePre-extraction tea treatmentBiotechnologyPhenolic content in tea

The invention relates to the technical field of tea leaf processing, in particular to yellow tea and a preparation method thereof. The yellow tea is prepared by adopting tea leaves with specific quality as raw materials through primary spreading, green leaf rocking, secondary spreading, fixation, two-time rolling, dehydration, staged heaping for yellowing, drying, spreading for airing and aroma enhancement, so that the obtained yellow tea is low in tea polyphenol content and high in caffeine content, the theaflavin content is high, the thearubigin content is low, the taste is improved, the bitterness of tea soup is reduced, besides, the tea has rich flower fragrance, and the tea soup is apricot yellow and bright in color, and sweet and mellow in taste. Through experimental research, the caffeine content of the yellow tea is maintained at 2.4 mg / ml or above, the tea polyphenol content is reduced to 11 mg / ml or below, the theaflavin content reaches 11% or above, and the thearubigin content reaches 2% or below.

Owner:GUIZHOU TEA RES INST

Processing technology for white tea

InactiveCN108617802AQuality improvementRegular shapePre-extraction tea treatmentClimate change adaptationActive enzymeAmino acid content

The invention discloses a processing technology for white tea. The processing technology comprises the following steps: firstly, picking tea leaves; secondly, airing green leaves; thirdly, withering;fourthly, rolling; fifthly, shaping; sixthly, drying; seventhly, purifying: winnowing and screening raw tea and picking out non-tea inclusions to obtain a finished product. According to the processingtechnology disclosed by the invention, high quality and high efficiency of white tea processing are ensured, particularly the qualities of green leaf yellow green soup in color, fragrance, taste, shape and leaf bottom are improved, and the yield of produced tea and the quality of the white tea are improved. The white tea processed by the method disclosed by the invention has the advantages of neat shape, rich fragrance, mellow taste, long last fragrance, mellow flavor, sweet aftertaste, smoothness of tea soup in mouth, yellow and green bright clear soup color and long-time making endurance; dry tea is covered with pekoe, spiral tea resembles silver beads, and needle tea resembles a silver needle; the white tea has the characteristics of higher content of amino acid and low content of teapolyphenol; moreover, the white tea also contains active enzymes essential for a human body, has a good anti-viral immune function and can be preserved at a normal temperature for 10 years without spoilage.

Owner:胡琴其

Production method of white tea

InactiveCN108477323AQuality improvementRegular shapePre-extraction tea treatmentCooking & bakingRoom temperature

The invention discloses a production method of white tea. The production method comprises the following steps of (1) picking tea leaves; (2) performing fresh leaf airing; (3) performing withering; (4)performing rolling; (5) performing tidying; (6) performing baking; and (7) performing clean substance extraction: performing air separation and sieving on semi-finished tea, and picking out non-tea foreign bodies to obtain finished products. According to the production method disclosed by the invention, superior efficient processing of the white tea is guaranteed, particularly the color, fragrance, taste, shape and leaf base quality of green leaf yellowish green soup of the white tea can be improved, the tea yield is increased, and the quality of the white tea is improved. The white tea processed by the method disclosed by the invention is tidy in shape, dried white tea is covered with white fine long hairs, spiral tea is similar to silver pearls, and needle tea is similar to silver needles; the white tea is rich in fragrance, mellow in taste, long in delicate fragrance, mellow in taste, and sweet in aftertaste; tea soup is smooth after being drunk in mouths, and soup color is yellowish green, bright and clear; and the white tea is resistant to soak, has the characteristics of being high in amino acid content and low in tea polyphenol content, besides, further contains active enzymes necessary by human bodies, has good antiviral immunity functions, and cannot deteriorate after being preserved for 10 years at room temperature.

Owner:胡琴其

Tea leaf far-infrared fixation machine unit and fixation method thereof

InactiveCN104782809ATemperature controlOptimization of operating parametersPre-extraction tea treatmentEngineeringFar infrared

The invention discloses a tea leaf far-infrared fixation machine unit and a fixation method thereof. The tea leaf far-infrared fixation machine unit is characterized by at least comprising two groups of far-infrared fixation machines and two groups of automatic tea leaf charge machines which are ranked alternately; far infrared rays are utilized for automatic fixation, and tea leaves are subjected to cooling and moisture regaining after being subjected to fixation by the far-infrared fixation machines, so that efficient fixation of tea leaves is realized.

Owner:柳州市自动化科学研究所

Process for preparing white tea wine

ActiveCN100445358CHigh nutritional valueSimple processTea extractionAlcoholic beverage preparationAdditive ingredientEucommia

the invention discloses a manufacturing method of wine within white tea, which comprises the following steps: 1. rinsing product white-tea; drying; 2. extracting effective ingredient in the white tea; collecting extracted liquid and residuals; 3. immersing raw material; adding the materials in the residual white tea and glossy ganoderma as well as eucommia in the step 2 to boil; stirring to add barm; fermenting; 4. adding water in the raw material; fermenting the materials with extracted liquid in the step 2; 5. distilling the fermented composition to form white tea wine liquid; 6. filtering; clearing; sterilizing; aging; allocating to obtain the product.

Owner:王称兴

Puer tea processing process for reducing bitterness degree of summer and fall tea

InactiveCN108850305AImprove qualityRemove bitter tastePre-extraction tea treatmentTurbidityLiquid color

The invention relates to the technical field of puer tea processing, in particular to a puer tea processing process for reducing the bitterness degree of summer and fall tea. The processing process comprises the following steps of (1) selecting high-quality withering primary tea with the moisture content being 10 to 11 percent; controlling the pile fermentation temperature to be 50 to 55 DEG C; performing pile fermentation for certain time for use; (2) putting withered primary tea subjected to pile fermentation treatment into material mixing equipment; adding beta-cyclodextrine, tannase and OPanimal albumin powder; uniformly mixing the materials for use; (3) putting the product treated in the step 2 into a round mold paved with a cloth liner; adding 0.1 times of quantity of water; then, performing steam-hot air fixation treatment on the round mold for certain time; (4) pressing tea leaves subjected to steam-hot air fixation treatment into a tea cake; then, drying the tea cake; controlling the moisture to a certain value; obtaining the tea. The processing process disclosed by the invention effectively overcomes the defects of high bitterness degree and liquid color turbidity of theproduct obtained by the existing puer tea processing process.

Owner:郝连奇

Huangshan local oolong making method

ActiveCN106172919AFully fermentedReduce bitternessPre-extraction tea treatmentClimate change adaptationPositive pressureBiology

The invention belongs to the technical field of tea processing, particularly relates to a Huangshan local oolong making method and aims to provide a making method for Huangshan local oolong. The method includes the steps of fresh leaf picking, sun-withering, rocking, cooling, parching, red side removal, spreading, dampening, rolling, secondary fermentation and drying. The method is characterized in that in the rolling and secondary fermentation process, temperature is controlled to be 30+ / -2 DEG C, humidity is controlled to be 65-75%, the mass concentration of carbon dioxide in a rolling environment is controlled to be 0.06%-0.066%, and tea leaves are in a positive pressure environment, rolled into strips and compacted. According to the making method, rolling technology can be simplified, processing efficiency is improved, processing quality is ensured, both the quality and the taste of the oolong made by the making method are improved, tea color is green, smooth and bright yellow, and tea soup is clear and bright.

Owner:黄山职业技术学院

Tea processing method

InactiveCN108308300AQuality improvementRegular shapePre-extraction tea treatmentAmino acid contentAnti viral immunity

The invention discloses a tea processing method. The tea processing method comprises the following steps that (1) tea leaves are picked; (2) the tea leaves are subjected to airing; (3) the tea leavesare withered; (4) rolling is carried out; (5) shaping is carried out; (6) drying is carried out; and (7) purifying is carried out, specifically, primary tea is subjected to winnowing and screening, and non-tea inclusions are picked out so as to obtain a finished product. The method has the advantages that high-quality and high-efficiency tea processing is guaranteed, especially the quality of thecolor (specifically referring to green tea leaves and yellowish green tea soup), the fragrance, the taste, the shape and infused leaves of tea is improved, the tea making yield is increased, and the quality of the tea is improved. The tea processed by adopting the method has the advantages that the shape is regular, the dried tea is full of pekoe, the snail tea is like silver pearls, the needle tea is like silver needles, the aroma is delicate, the fragrance is lasting, the taste is mellow, the aftertaste is sweet, the tea soup is smooth in the mouth, the color of the tea soup is yellowish green, bright and clear, the tea is enduring and can be infused repeatedly, the amino acid content is relatively high, the tea polyphenol content is relatively low, meanwhile, active enzymes necessary for human bodies are contained, a good antiviral immunity function can be achieved, and the tea can be stored for 10 years at normal temperature without going bad.

Owner:胡琴其

A method for changing temperature and frequency of needle-shaped famous tea

ActiveCN108260678BReduce noiseTight and thinPre-extraction tea treatmentThermodynamicsConstant frequency

Owner:CHONGQING ACAD OF AGRI SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com