A method for changing temperature and frequency of needle-shaped famous tea

A technology for strip and famous tea, applied in the direction of tea treatment before extraction, etc., can solve the problems of large difference in quality of tea leaves, deterioration of quality, yellowing of tea leaves, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

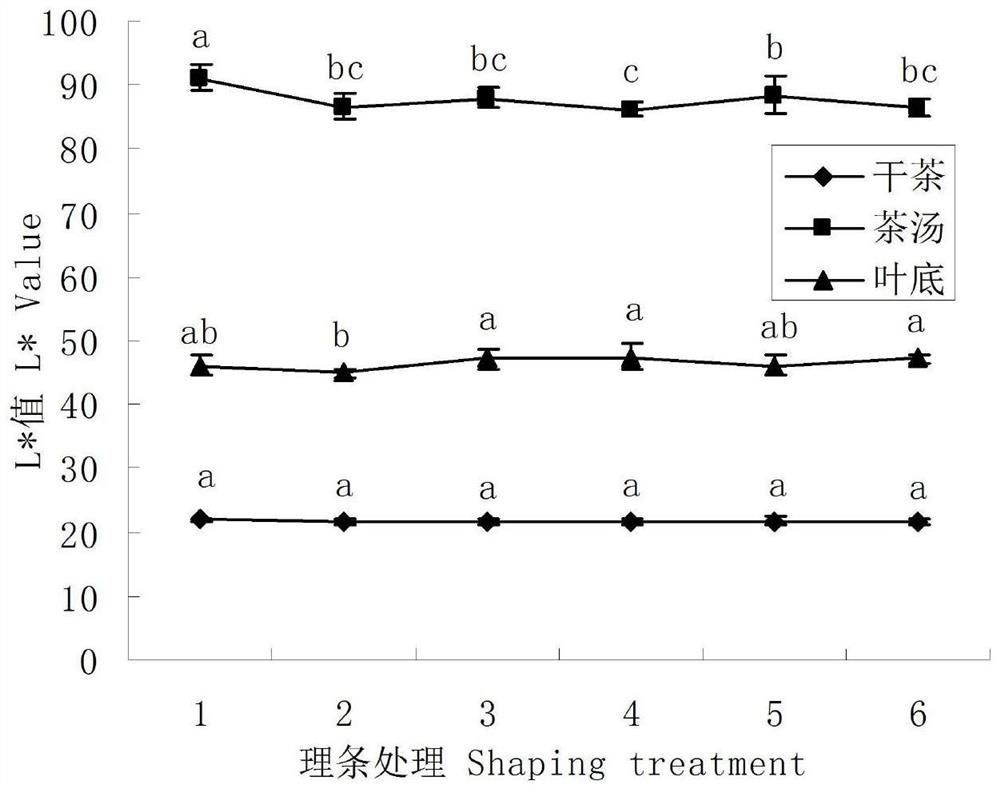

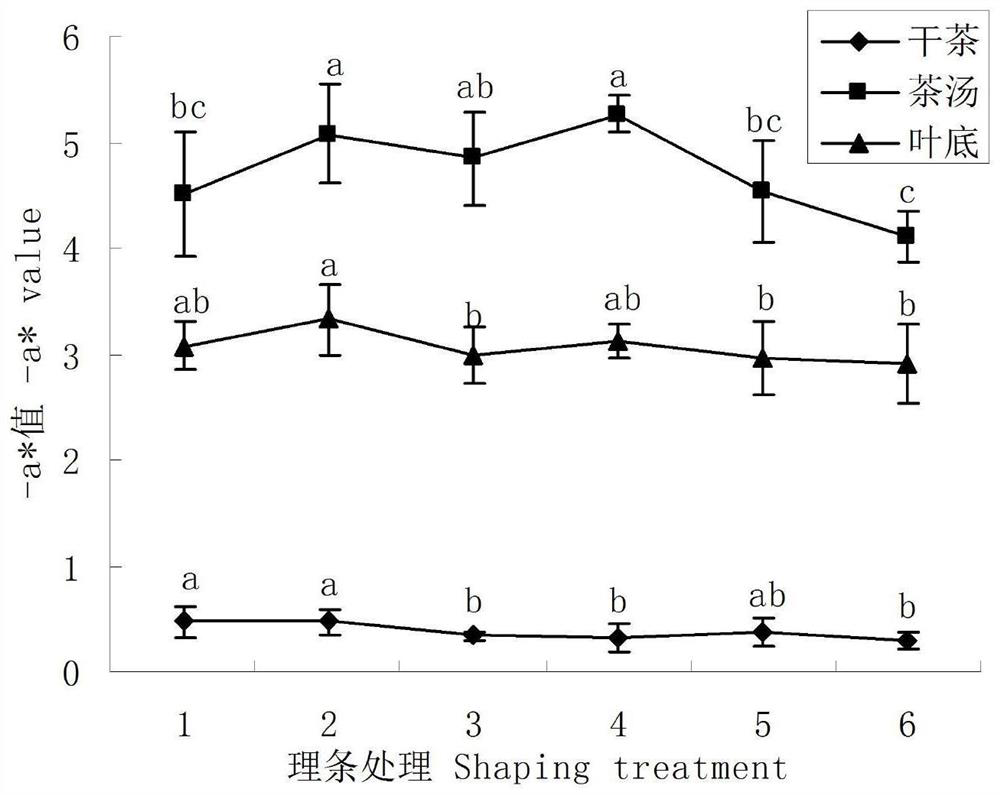

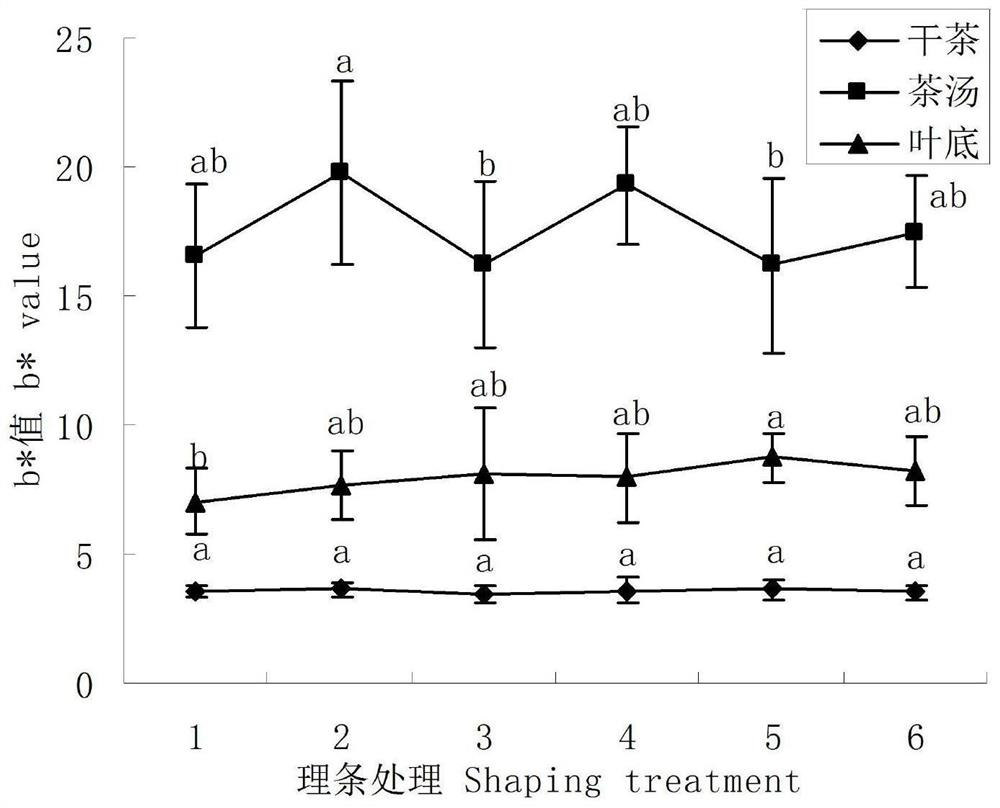

Image

Examples

Embodiment

[0033] process flow

[0034] Fresh leaves—spreading—finishing—primary kneading—second greening—re-kneading—organization—drying.

[0035] The fresh tea leaves used for the study of stripping technology were collected from the experimental tea garden of the Tea Research Institute of Chongqing Academy of Agricultural Sciences (29°75′N, 105°71′E, 440m above sea level) on March 30, 2016. One bud of the Fuding Dabai tea tree variety One leaf is carried out, and the needle-shaped famous tea is processed according to the above-mentioned technological process, and the specific parameters are shown in Table 1.

[0036] Table 1 Processing parameters of famous needle-shaped tea

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com