Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Less time and energy consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pollution-free low-cost technology for preparing monolayer graphene oxide

The invention discloses a pollution-free low-cost technology for preparing graphene oxide. The technology comprises the following steps: 1, mixing graphite with a strong acid to infiltrate graphite, adding a strong oxidant, and continuously stirring to oxidize and exfoliate graphite layers; 2, centrifuging the obtained reaction solution, recovering the strong acid to be used in a next reaction, slowly pouring the obtained muddy product into deionized water, stirring, washing by using dilute hydrochloric acid, repeatedly cleaning by using deionized water, and centrifuging to obtain monolayer graphene oxide; 3, introducing ammonia gas into wastewater until the pH value approaches 7 to obtain an inorganic fertilizer containing nitrogen, potassium, iron and phosphorus; and 4, concentrating an aqueous solution of graphene oxide, and drying to obtain graphene oxide with high density and high specific surface area. The technology has the advantages of simple, safe and controllable preparation process, less time and energy consumption, no explosion danger and no pollution. The cycle use of concentrated sulfuric acid in the raw material-to-fertilizer process makes all raw materials and elements fully used, so the preparation cost of graphene oxide is greatly reduced.

Owner:ZHEJIANG TANGUSHANGXI MATERIAL SCI & TECH

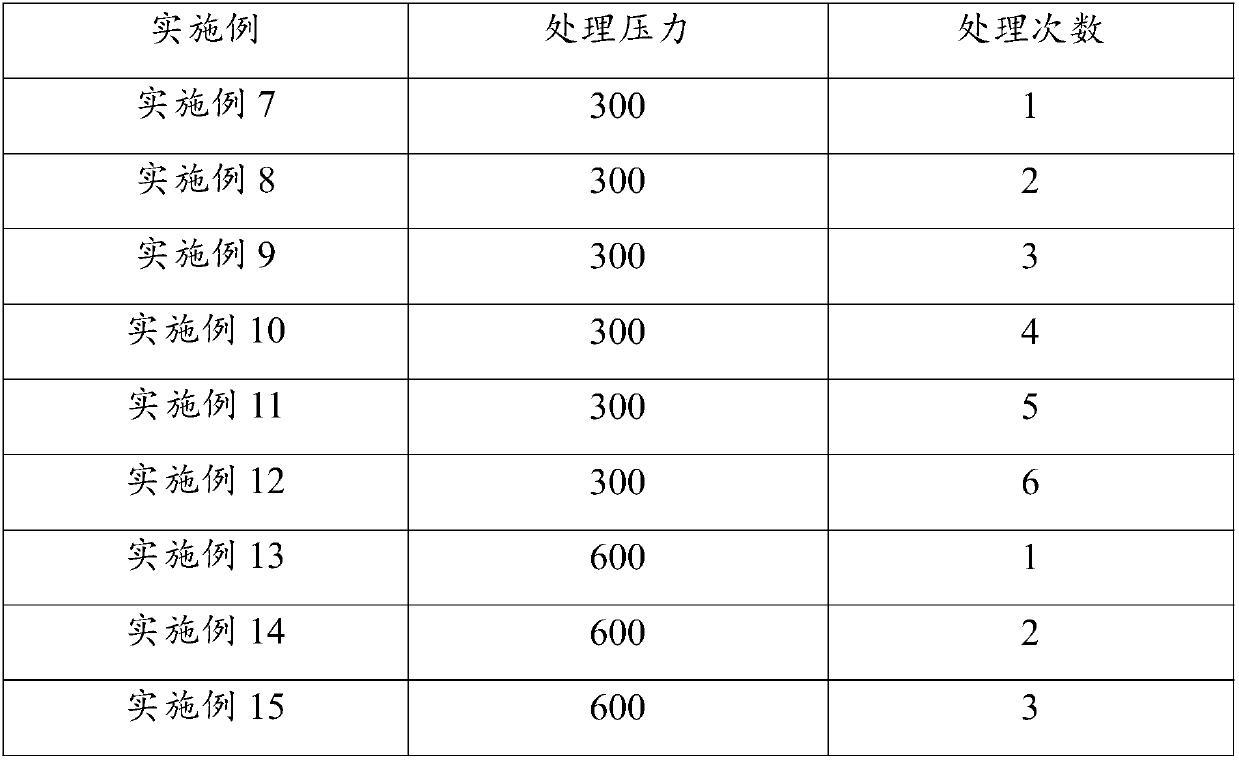

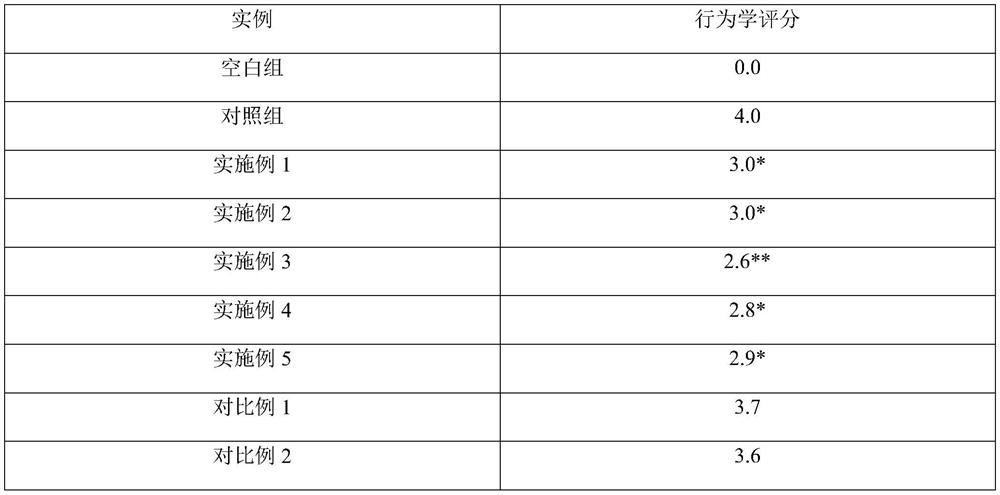

Polysaccharide degradation method and low-molecular-weight polysaccharide

The invention discloses a polysaccharide degradation method and low-molecular-weight polysaccharide, and relates to the field of degradation of a polysaccharides compound. The polysaccharide degradation method comprises the following step: treating a polysaccharide solution by adopting a high-pressure cell crushing device to obtain the low-molecular-weight polysaccharide. The polysaccharide degradation method disclosed by the invention overcomes the shortcomings that a conventional ultrasonic method is long in time and low in efficiency, a chemical method is low in reaction regularity and hasa hardly controlled process, and an enzyme hydrolysis method is low in applicability and high in cost and can hardly realize large-scale production. According to the method, the high-pressure cell crushing device is adopted to degrade polysaccharide, so that the polysaccharide which has a relatively low molecular weight is obtained by shearing and collision at high pressure; the molecular weight of the polysaccharide can be precisely controlled by adjusting the treatment pressure and the number of times; the polysaccharide degradation method has the advantages of small noise, zero pollution and high speed, and the physiological activity of the polysaccharide cannot be destroyed.

Owner:GUANGDONG MARUBI BIOLOGICAL TECH CO LTD

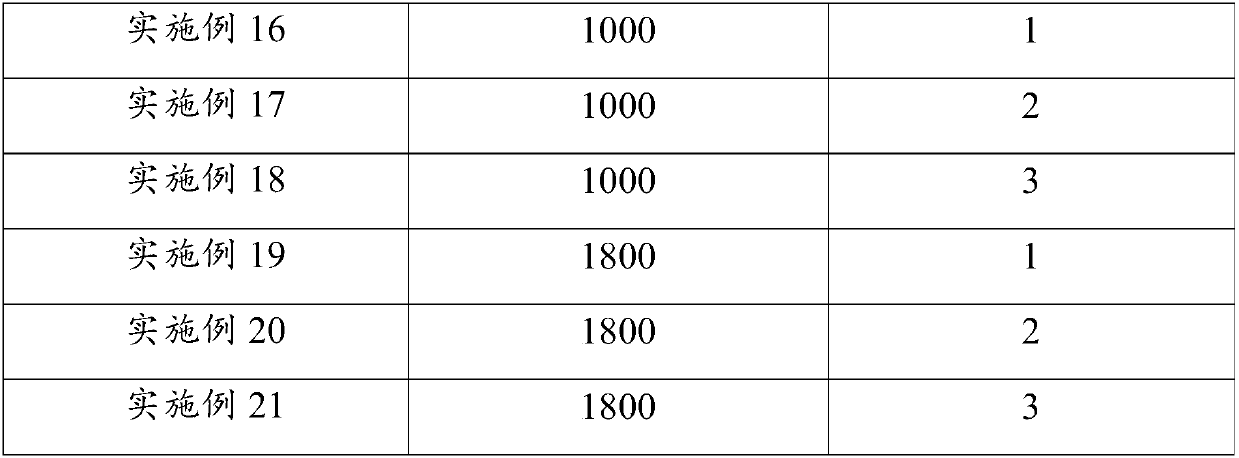

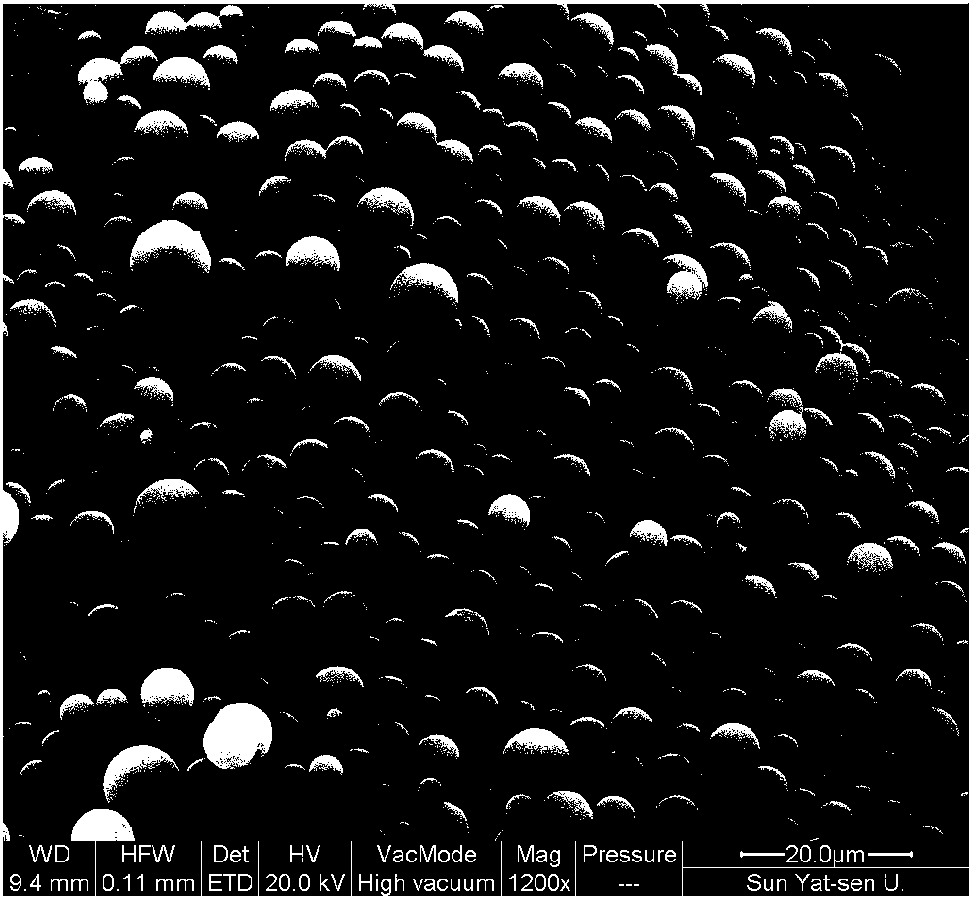

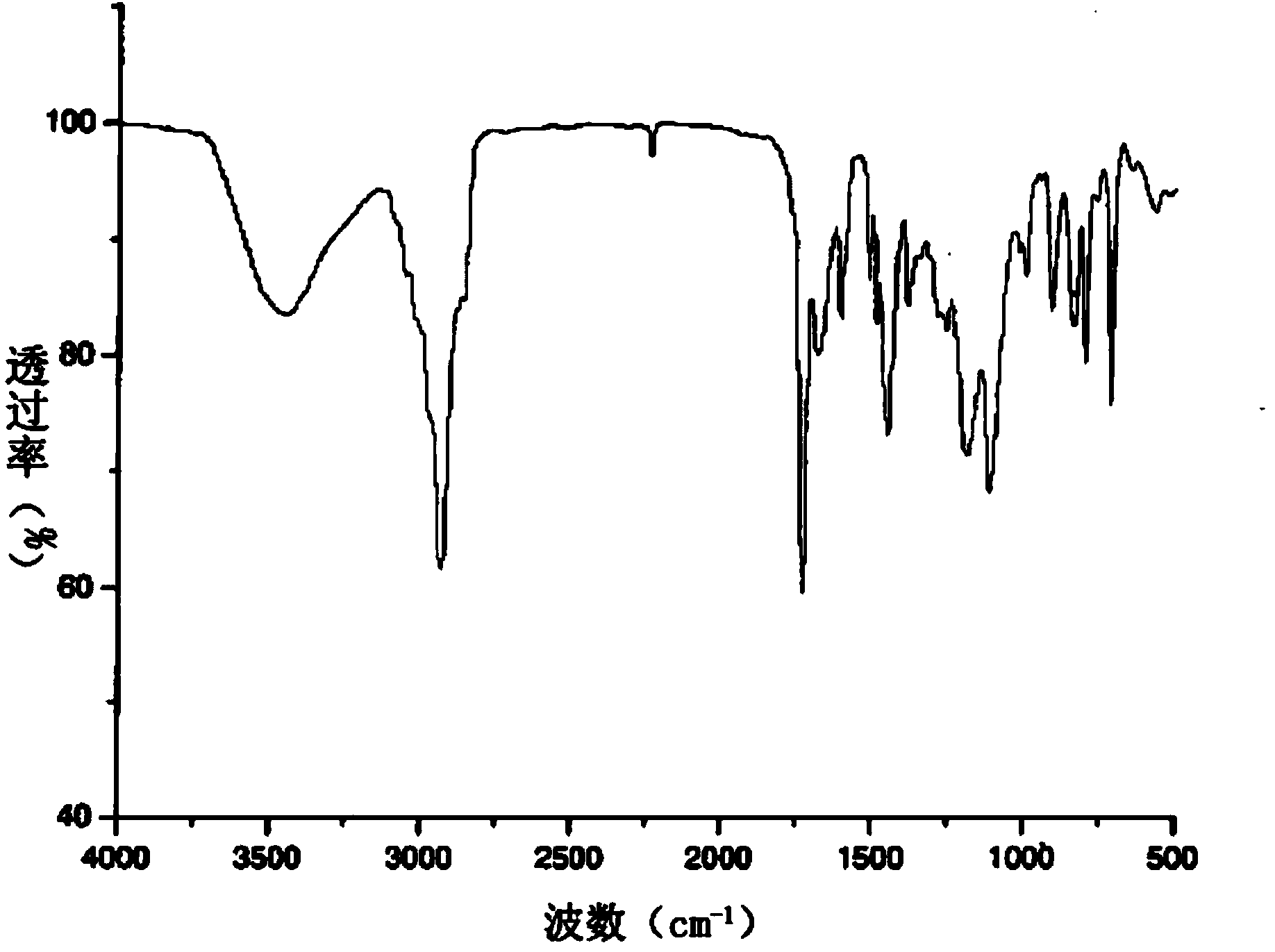

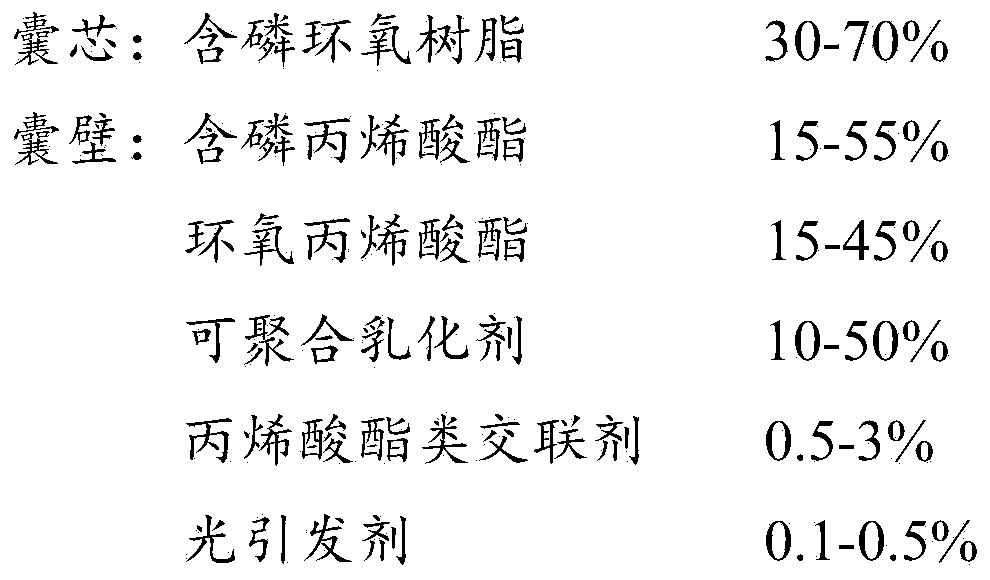

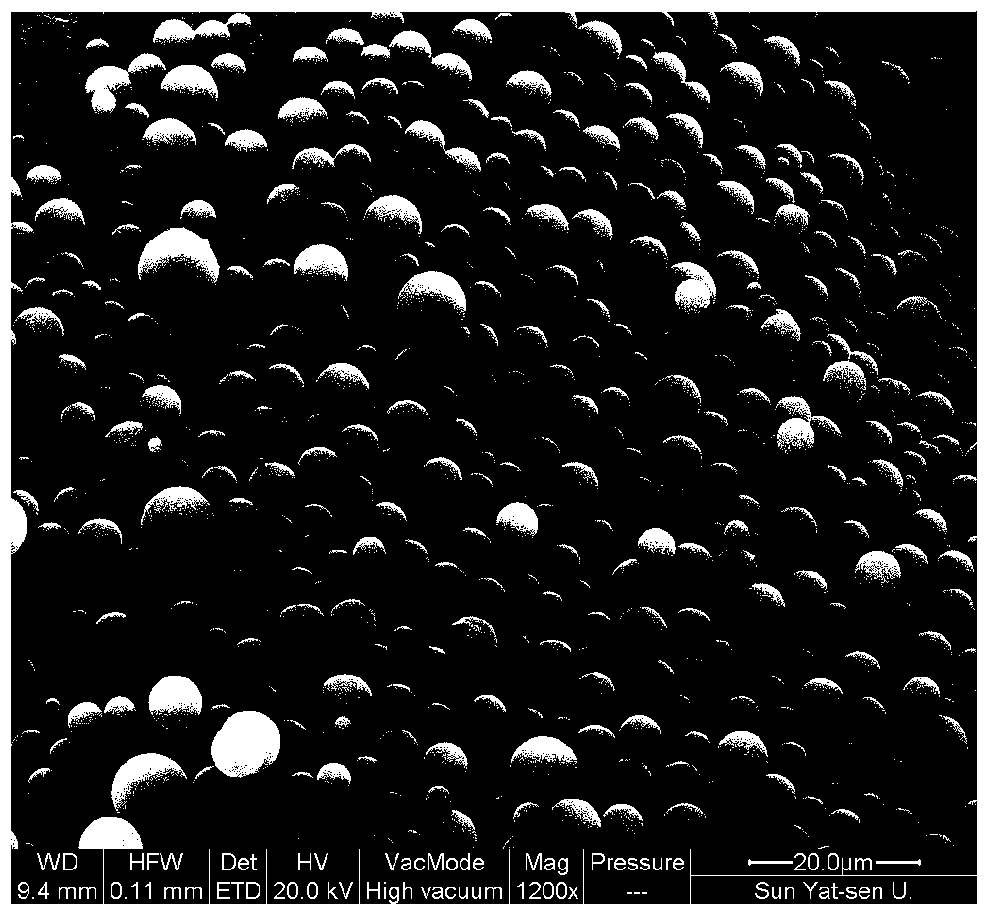

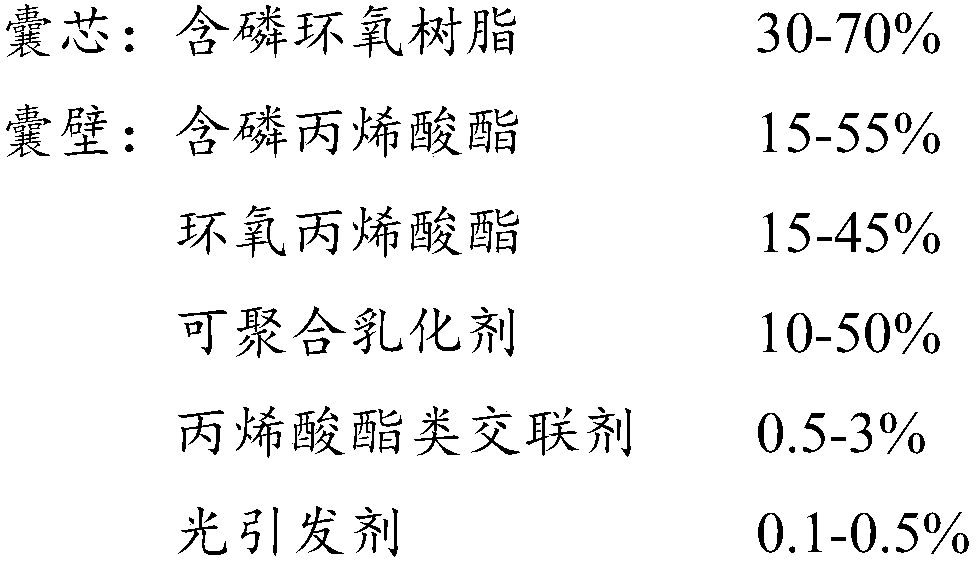

Reaction-type flame-retardant epoxy resin microcapsule and preparation method thereof

ActiveCN104226216AWith self-healing functionEnsure self-healing capabilitiesMicroballoon preparationMicrocapsule preparationEpoxyIn situ polymerization

The invention discloses a reaction-type flame-retardant epoxy resin microcapsule. The reaction-type flame-retardant epoxy resin microcapsule comprises a capsule core and a capsule wall, wherein the capsule core is 30 to 70 percent by mass of phosphorus-containing epoxy resin, and the capsule wall consists of the following ingredients by mass percent: 15 to 55 percent of phosphorus-containing acrylate, 15 to 45 percent of epoxy acrylate, 10 to 50 percent of a polymerizable emulsifier, 0.5 to 3 percent of an acrylate crosslink agent and 0.1 to 0.5 percent of a photoinitiator. The invention also discloses a method for preparing the microcapsule. The microcapsule has the following advantages that the flame resistance and self-repairing function are good, so that the microcapsule can be widely applied to the fields such as thermosetting self-repairing resin-based composite materials and coatings. The method for preparing the microcapsule adopts an ultraviolet interface in-situ polymerization method, so that not only is the process simple and less time consumed, but also the method is controllable, the safety of the prepared composite material can be improved, and the service life of the composite material can be prolonged.

Owner:广东润昌南星新材料有限公司

Environment-friendly synthesis method of two-dimensional transition metal carbide or nitride nanosheets

InactiveCN106744732AThe synthesis process is green and environmentally friendlyRich synthesis methodsNitrogen-metal/silicon/boron binary compoundsTitanium carbideTransition metal carbidesIntercalation reaction

The invention discloses an environment-friendly synthesis method of two-dimensional transition metal carbide or nitride nanosheets. The environment-friendly synthesis method comprises the following steps: mixing a corrosion intercalation agent and a ternary layered ceramic material, performing a corrosion intercalation reaction, and then performing shearing dispersion treatment to obtain the two-dimensional transition metal carbide nanosheets or the two-dimensional transition metal nitride nanosheets. The synthesis method of the two-dimensional transition metal carbide or nitride nanosheets, provided by the invention, is environment-friendly, simple in process, easy to operate, safe and controllable in process and low in time consumption and energy consumption; and by the synthesis method, the synthesizing way of the two-dimensional transition metal carbide or nitride nanosheets is enriched and popularization and application of the two-dimensional transition metal carbide or nitride nanosheets can be effectively promoted.

Owner:SUZHOU UNIV

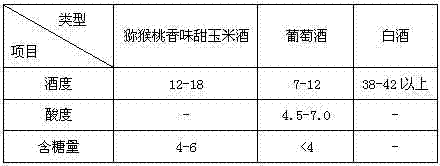

Brewing method of kiwi-flavored sweet corn wine

InactiveCN102586057ATaste and texture are mellow and harmoniousHigh alcohol contentMicroorganism based processesAlcoholic beverage preparationBiotechnologyKiwi fruit

The invention discloses a brewing method of kiwi-flavored sweet corn wine. The brewing method comprises the steps as follows: selecting fresh brewing sweet corn ears which are pollinated 25 days before, adding water, homogenizing to obtain sweet corn juice, and cleaning and homogenizing green kiwi fruit to obtain kiwi raw juice; mixing 75-85% of brewing sweet corn juice with 25-15% of pea juice to obtain a distiller's yeast culture medium, inoculating with yeast subjected to slant culture, and carrying out progressive amplification culture in distiller's yeast seeding tanks to obtain liquid distiller's yeast; adding the kiwi raw juice, the brewing sweet corn juice and the liquid distiller's yeast into a fermentation tank, fermenting at 15-20 DEG C for 21-14 days, harrowing and supplementing white granulated sugar with a ratio of 8.5-17% on the 7th -10th day of fermentation, filtering, and carrying out microwave treatment on the filtrate to obtain kiwi-flavored sweet corn wine base; pumping the kiwi-flavored sweet corn wine base into an aging tank to be stored at 16 DEG C below for more than 18 months; and adding sweet corn Brandy of which the amount accounts for 3-5% the weight ofthe aged sweet corn wine to obtain the kiwi-flavored sweet corn wine. The obtained kiwi-flavored sweet corn wine has kiwi fruit aroma and rice wine mellowness, is moderate in alcohol degree, mellow, elegant and nutrient, and satisfies the fashion of health-care driving.

Owner:窦秉德

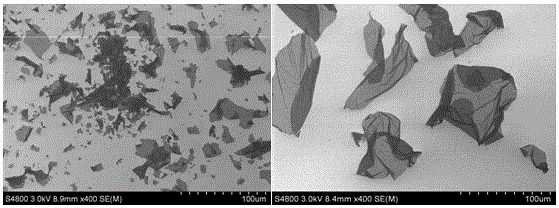

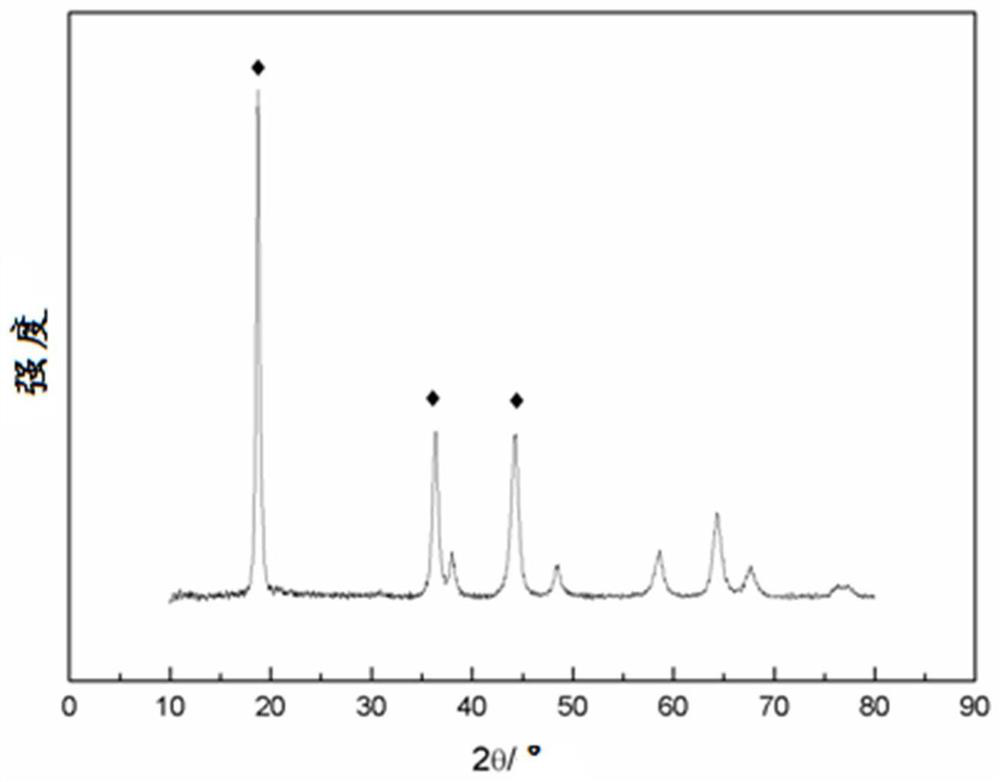

Novel crystal form of cefazolin sodium and preparation method thereof

The invention relates to a novel crystal form of cefazolin sodium and a crystallization preparation method thereof. An X-ray powder diffraction pattern is used for defining at the characteristic peaks of a diffraction angle of 2-theta degrees and DSC. The preparation method comprises the following steps: adding a cefazolin sodium solid into a solvent to prepare a suspension of 0.3-0.7g / mL; heating the suspension to 30-45 DEG C under a stirring condition; stirring for 0.5-12 hours at a constant temperature; cooling to 0-20 DEG C, and growing a crystal at a constant temperature for 0.5-2 hours; then filtering to obtain crystal slurry; and drying the filter cake obtained by filtering to obtain a product of the novel crystal form of cefazolin sodium. The novel crystal form has a higher heat-absorption temperature, the product purity, color and shape do not change after the product is stored for 100 days under a normal-temperature and dry condition, and the crystal form has relatively good stability. Compared with already reported crystal forms, the short-bar shaped novel crystal form has the advantages of relatively high dissolving speed and relatively high fluidity and bulk density, and is easy for commercially industrial large-scale implementation.

Owner:SHENYANG SANJIU PHARMA

Method for brewing grape-flavor sweet corn sake

InactiveCN103666956AGreat tasteBest Technical ParametersAlcoholic beverage preparationBiotechnologyYeast

A method for brewing a grape-flavor sweet corn sake comprises the following steps: selecting fresh brewing sweet corn clusters pollinated 25 days ago, adding water and homogenizing to obtain sweet corn juice, cleaning, airing and homogenizing grape with seeds to prepare grape neat juice, mixing sweet corn juice of 75%-85% and pea juice of 25%-15% to serve as a distiller's yeast culture medium, adding a yeast subjected to slant culture, expanding the cultivation step by step through a distiller's yeast seeding tank to obtain a liquid distiller's yeast, adding the grape neat juice, the sweet corn juice and the liquid distiller's yeast into a fermentation tank, fermenting at 15-20 DEG C for 21-14 days, adding water after fermentation for 7-10 days, supplementing white granulated sugar, filtering, conducting microwave treatment on the filtrate to obtain a grape-flavor sweet corn raw wine, pumping the grape-flavor sweet corn raw wine into an ageing tank, reserving at the temperature of below 16 DEG C for more than 18 months, adding sweet corn brandy of which the weight is 3-8 % of that of the aged sweet corn wine into the aged sweet corn wine to obtain the grape-flavor sweet corn sake. The grape-flavor sweet corn sake is naturally golden in color, has the fruity flavor of grape and the faint scent of corn and is unique in style and moderate in alcohol content.

Owner:ENZYME ENG INST SHAANXI PROVINCE ACAD OF SCI

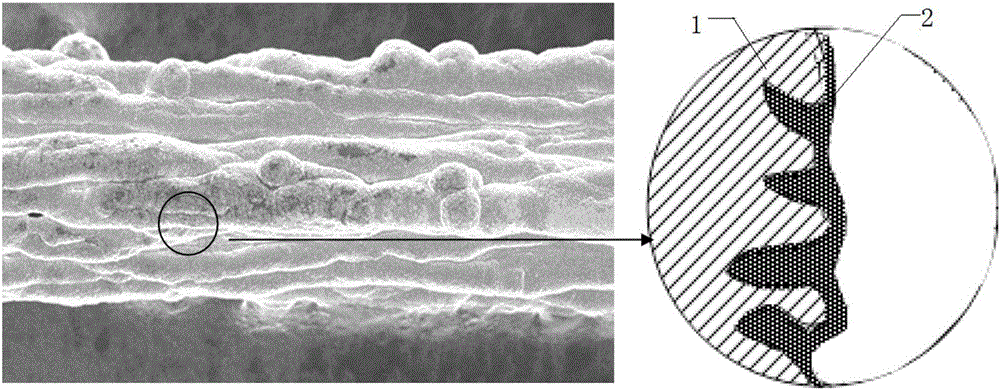

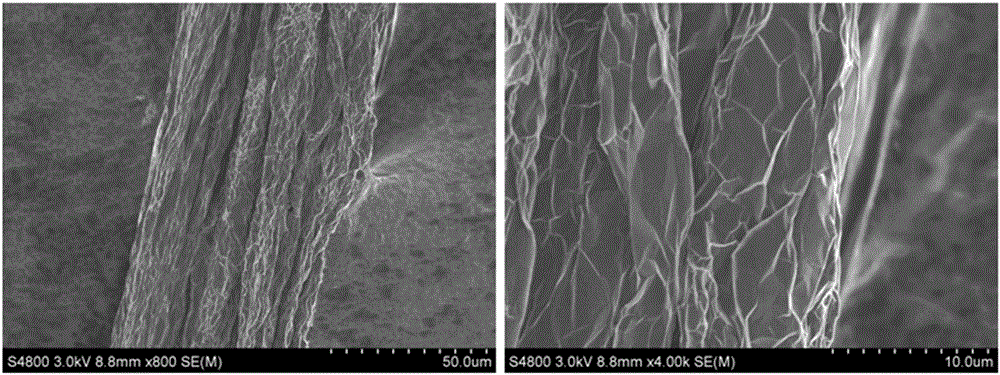

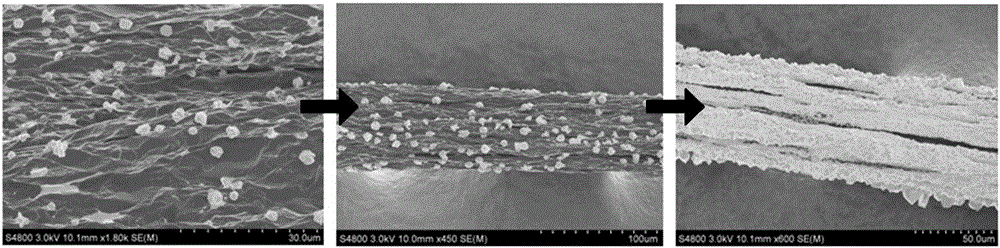

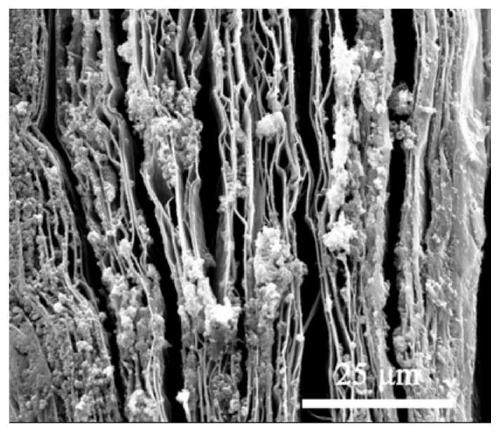

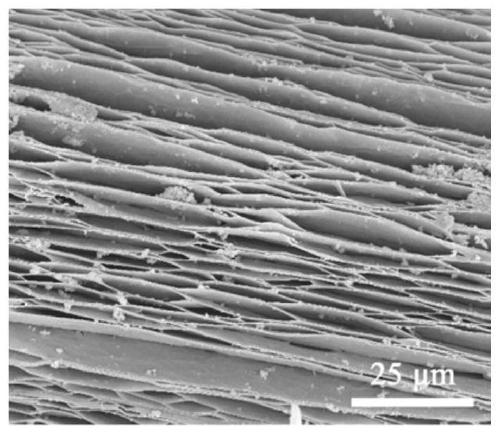

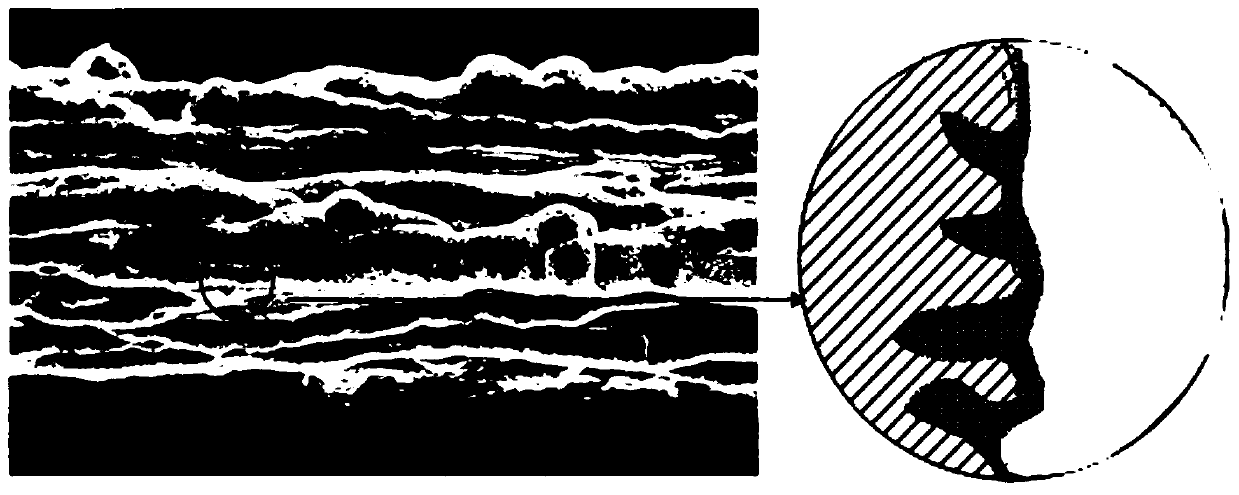

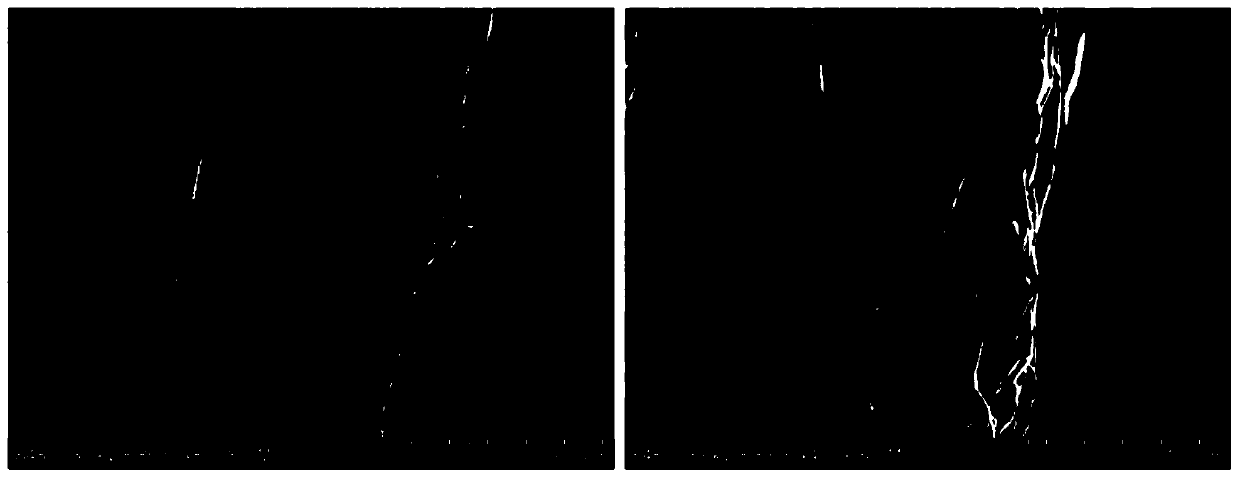

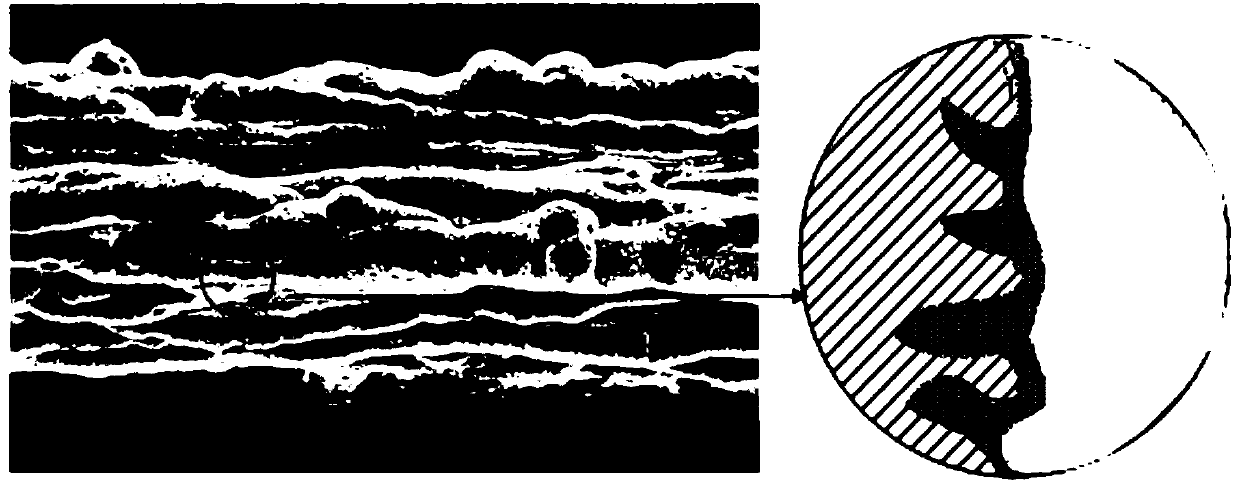

Graphene-silver composite fiber and preparation method thereof

ActiveCN106702731AWide variety of sourcesCompact structureElectroconductive/antistatic filament manufactureCarbon fibresCopperElectroplating

The invention discloses a graphene-silver composite fiber and a preparation method thereof. The method comprises the steps of firstly preparing a graphene oxide fiber of which the diameter is 1-50 microns by adopting a wet spinning method, and then putting the graphene oxide fiber into a high-temperature furnace for heating and reducing to obtain a continuous pure graphene fiber. Due to a special treatment mode, the fiber surface is provided with multi-stage wrinkles, the pure graphene fiber is fixed on a negative electrode of a plating bath for electroplating, and a copper layer has an extension structure embedded into the wrinkles. Graphene is tightly combined with silver crystals, a hole defect is avoided, the electrical properties of the material are greatly improved, and the fiber is stable in structure and constant in electric conductivity after being bent for 100 times.

Owner:杭州德烯科技集团有限公司

Sodium vanadium fluorophosphate/graphene composite, preparation method thereof and use thereof

ActiveCN110247037AImprove conductivityImprove permeabilityMaterial nanotechnologyCell electrodesPhosphoric acidSodium-ion battery

The invention discloses a sodium vanadium fluorophosphate / graphene composite, a preparation method thereof and use thereof. The sodium vanadium fluorophosphate / graphene composite is a porous submicron sphere structure which comprises a plurality of nanosheets, and gaps are between the nanosheets. The preparation method comprises a step of dispersing graphene oxide in deionized water to obtain a graphene oxide aqueous solution, a step of uniformly mixing vanadium acetylacetonate, phosphoric acid, sodium fluoride, ethanol and acetone in a predetermined ratio to obtain a mixed solution, a step of mixing the graphene oxide aqueous solution and the mixed solution in a set ratio and then placing the graphene oxide aqueous solution and the mixed solution in an autoclave at a temperature of 120 DEG C for hydrothermal reaction, a step of sequentially washing, centrifuging and drying a hydrothermally reacted product to obtain the sodium vanadium fluorophosphate / graphene composite. Since the sodium vanadium fluorophosphate / graphene composite has good electrical conductivity and stable structure, the sodium vanadium fluorophosphate / graphene composite is suitable for being applied as a positive electrode material for a sodium-ion battery.

Owner:HUAZHONG UNIV OF SCI & TECH

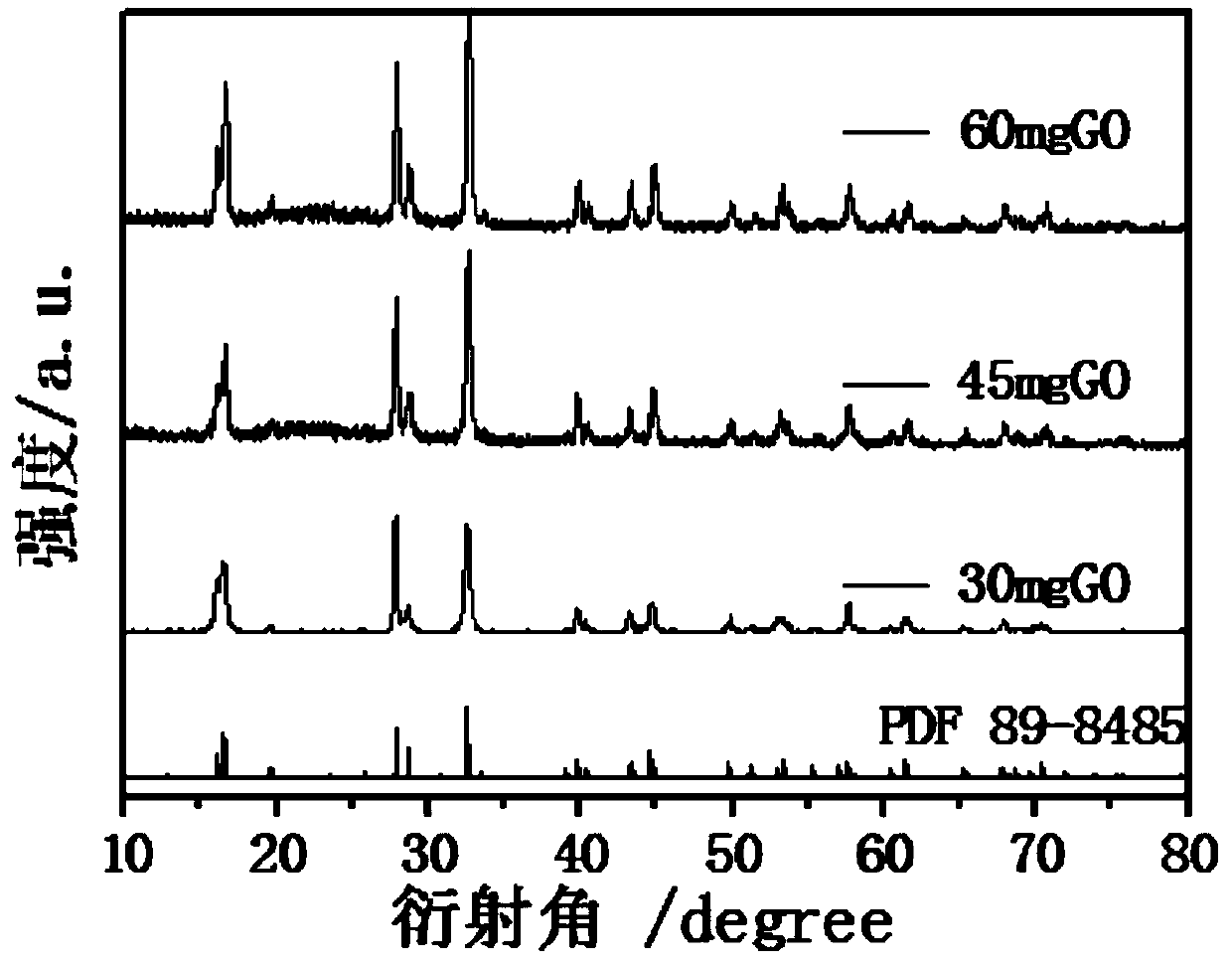

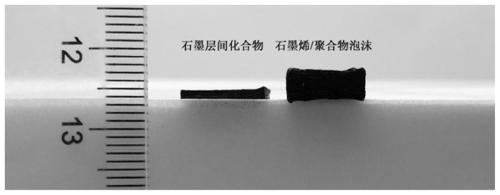

Batched preparation method of interlayer in-situ polymerization of graphene/polymer foams

The invention discloses a batched preparation method of interlayer in-situ polymerization of graphene / polymer foams. The method mainly comprises the following steps of 1, preparing a graphitic layer compound, wherein an oxidizing agent and concentrated sulfuric acid are mixed and added into graphite, after standing is performed, solid parts are separated out, and dilute sulfuric acid is used for washing repeatedly; 2, performing monomer interlayer in-situ polymerization, wherein the graphitic layer compound obtained in step 1 and monomers are mixed and react with each other under the proper temperature; 3, cleaning and drying the product, wherein the product obtained in step 2 is subjected to water and alcohol repeated washing and dried under the temperature of 30-200 DEG C, and graphene / polymer foams are obtained. The preparation process is simple, safe and controllable, graphene in the product is dispersed uniformly, and the method has the advantages that the preparation flow is short, little time and energy are consumed, control is easy, and the cost is low.

Owner:SOUTHWEST JIAOTONG UNIV

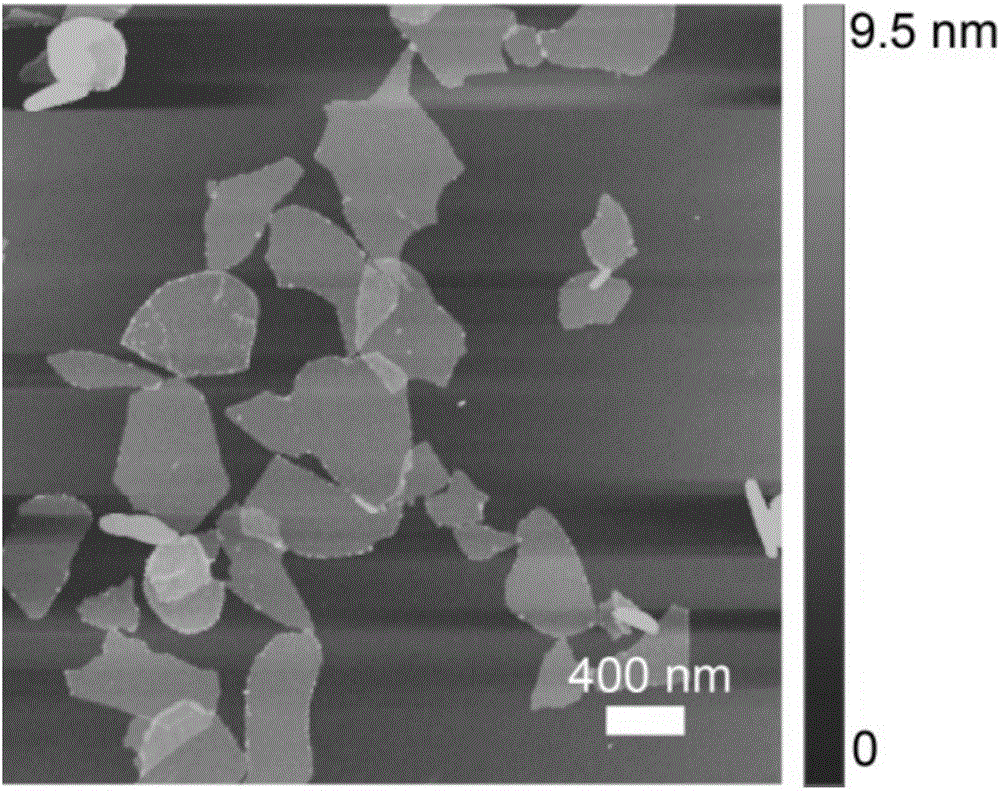

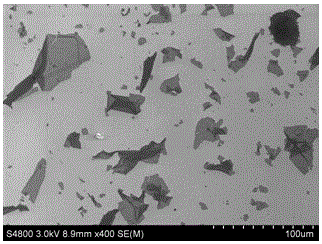

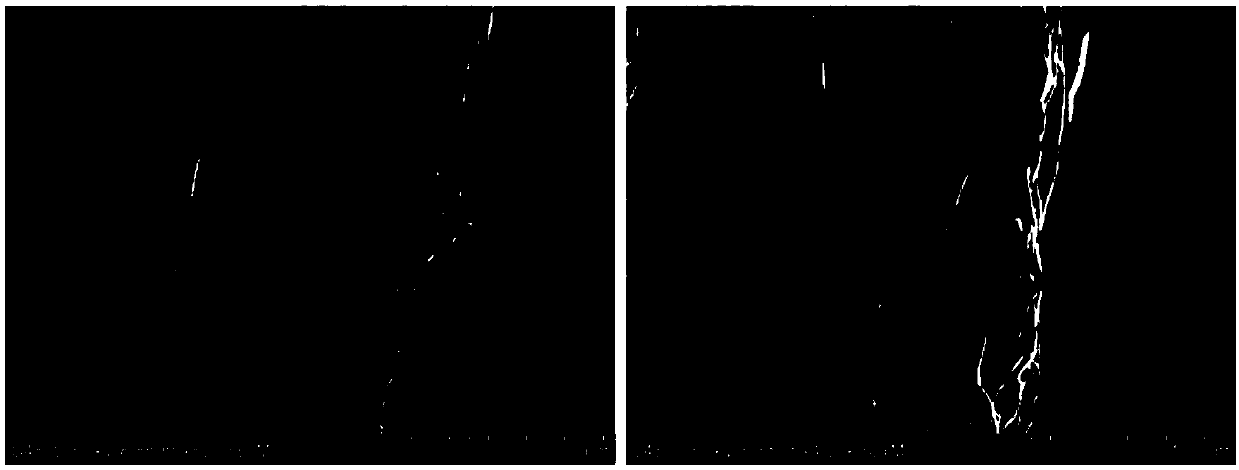

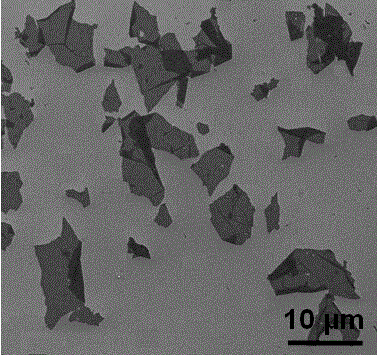

Preparation method of fragment-free super-large graphene oxide sheet

ActiveCN105692599AThe preparation process is simple, safe and controllableLess time and energy consumptionGrapheneIce waterLarge fragment

The invention discloses a preparation method of a super-large fragment-free graphene oxide sheet. According to the method, before a graphite oxide crystal is washed by water, a fragment is separated out by adopting a mesh screen separation method. The graphite oxide crystal is diluted by adopting ice water of above 10 times of volume, so that a wafer of the graphite oxide crystal cannot be destroyed due to the solution heat of sulfuric acid. The wafer is further shocked and washed by adopting a shaking table, so that a graphene oxide sheet layer is prevented from being broken by mechanical force when being stripped. The preparation method of the super-large fragment-free graphene oxide sheet is simple, safe and controllable in preparation process and little in time consumption and energy consumption; the fragment-free super-large graphene oxide sheet is obtained by one step through simple separation operation before a product.

Owner:ZHEJIANG TANGUSHANGXI MATERIAL SCI & TECH

Mixing and coating technology for production of positive and negative pole pieces of lithium ion battery

InactiveCN103579582ARaise your temperatureShorten the lengthElectrode extrusionComing outEngineering

The invention relates to a mixing and coating technology for production of positive and negative pole pieces of a lithium ion battery. Compared with the traditional technology, the technology can simplify a mixing process, and can reduce the production time and the production energy consumption. A mixing procedure is that various raw materials are mixed simply, and then the roughly mixed raw materials are subjected to high-temperature short-time fine mixing by an extrusion machine. The materials coming out of the mixing procedure are sent to a high-temperature coating machine for coating, and then enter a shortened oven for solvent removal.

Owner:陈煜

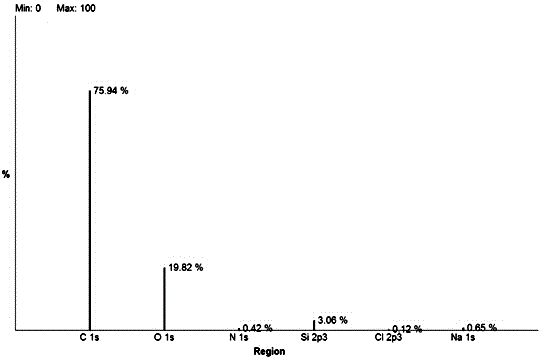

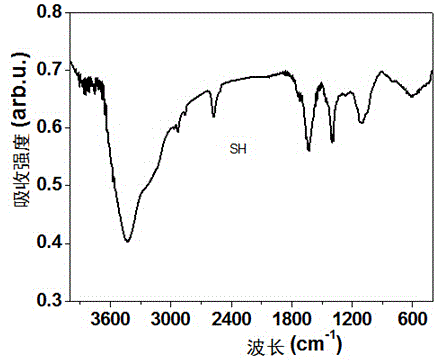

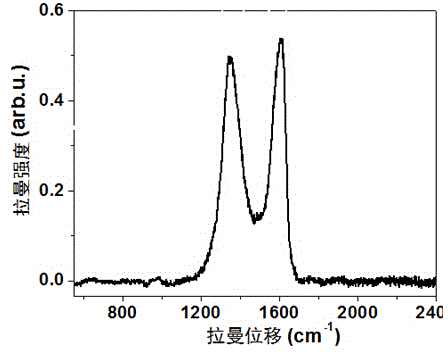

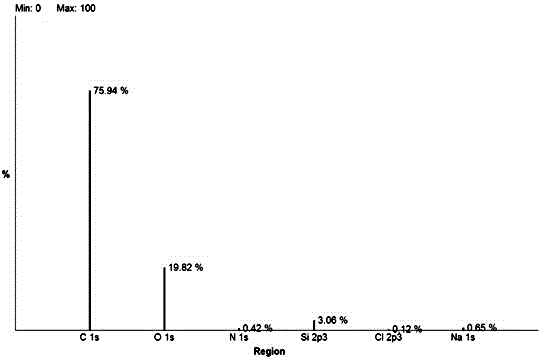

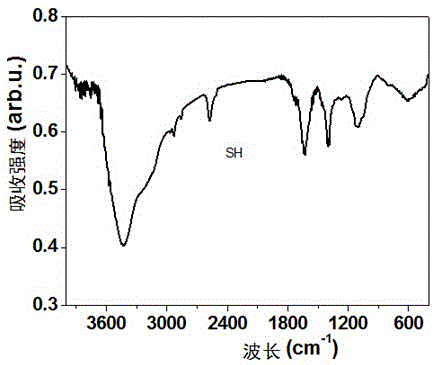

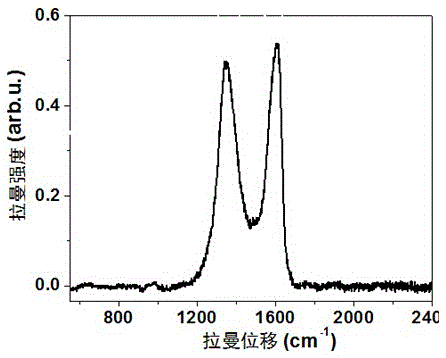

Sulfydryl-modified graphene oxide and preparation method thereof

The invention discloses a sulfydryl-modified graphene oxide and a preparation method thereof. According to the sulfydryl-modified graphene oxide, a modified graphene oxide product is obtained by introducing sulfydryl to a graphene oxide lamellar structure. The preparation method comprises the following steps: mixing a graphene oxide solution, a solvent and triethylamine evenly; adding thiocarboxylic acid or sulfo-carboxylate under argon protection and reacting at 10-70 DEG C for 1-7 days to obtain a sulfydryl-modified latent sulfur graphene oxide; centrifugally washing the sulfydryl-modified latent sulfur graphene oxide with deionized water to obtain the sulfydryl-modified graphene oxide; or mixing the sulfydryl-modified latent sulfur graphene oxide with diluted hydrochloric acid evenly, and centrifugally washing with the deionized water to obtain the sulfydryl-modified graphene oxide. The sulfydryl-modified graphene oxide is simple in preparation process, safe, controllable, and low in time consumption and energy consumption; and according to the prepared sulfydryl-modified graphene oxide, the synthesis means and the application field of graphene derived materials and sulfocompounds are further expanded.

Owner:ZHEJIANG TANGUSHANGXI MATERIAL SCI & TECH

A kind of mercapto-modified graphene oxide and preparation method thereof

The invention discloses a thiol-modified graphene oxide and a preparation method thereof. The mercapto-modified graphene oxide is a modified graphene oxide product obtained by introducing mercapto groups into the graphene oxide sheet structure. The preparation method is: after mixing graphene oxide solution, solvent and triethylamine evenly, add thiocarboxylic acid or thiocarboxylate under nitrogen protection; react at 10-70 degrees Celsius for 1-7 days to obtain thioester Modified latent sulfur graphene oxide; the thioester modified latent sulfur graphene is centrifugally washed with deionized water to obtain thiol-modified graphene oxide; or the thioester modified latent sulfur graphene is mixed with dilute After the hydrochloric acid is mixed evenly, it is centrifuged and washed with deionized water to obtain mercapto-modified graphene oxide. The preparation process of the present invention is simple, safe and controllable, less time-consuming and energy-consuming, and the mercapto-modified graphene oxide is prepared, which further broadens the synthesis means and application fields of graphene-derived materials and sulfur-containing compounds.

Owner:ZHEJIANG TANGUSHANGXI MATERIAL SCI & TECH

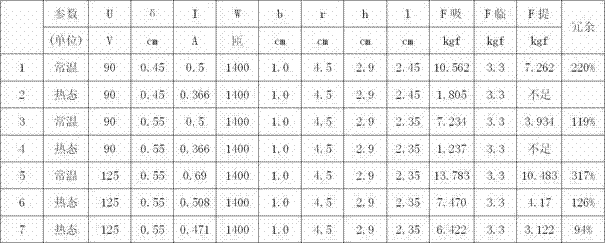

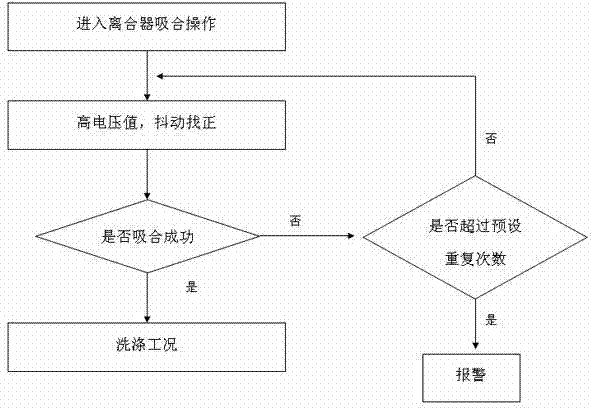

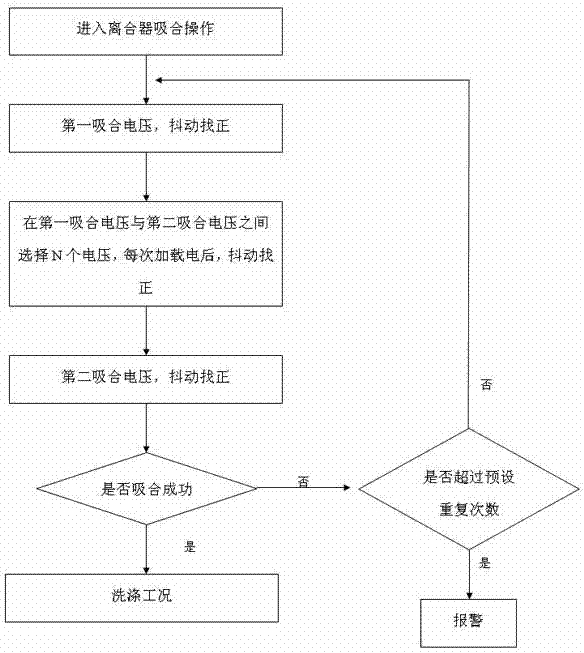

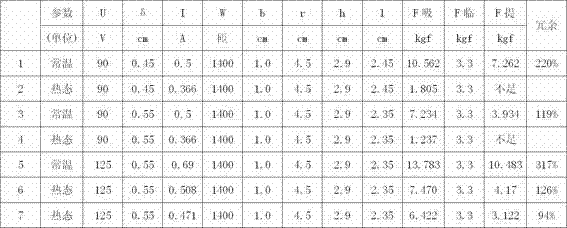

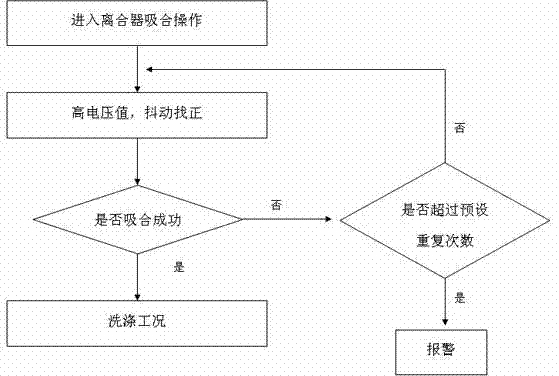

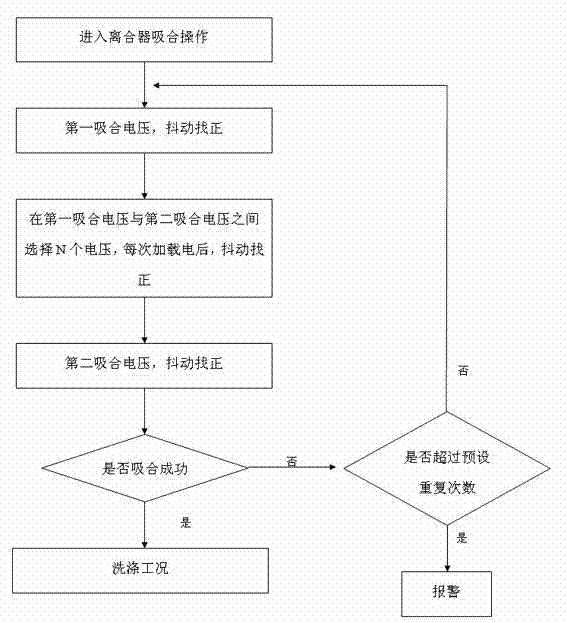

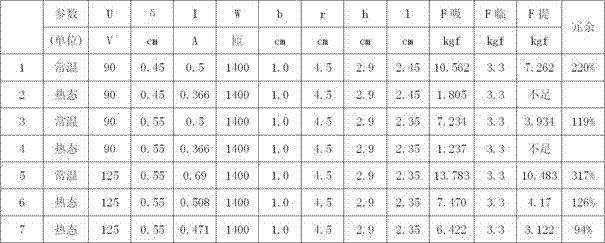

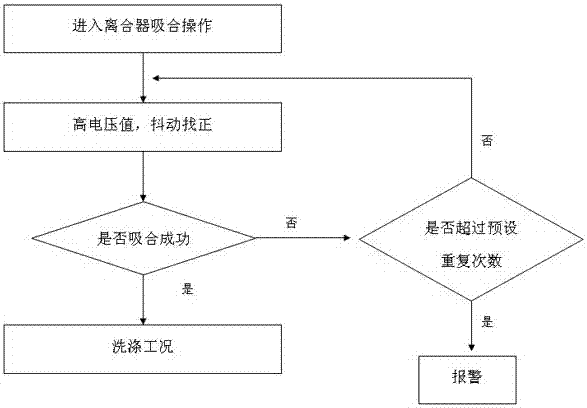

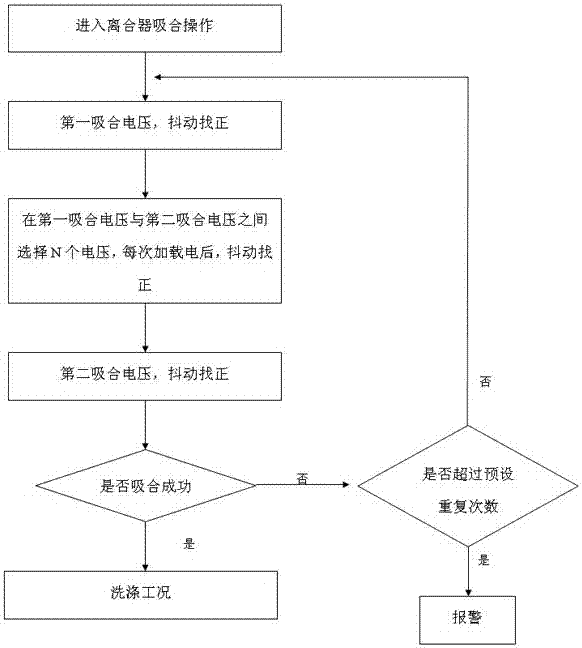

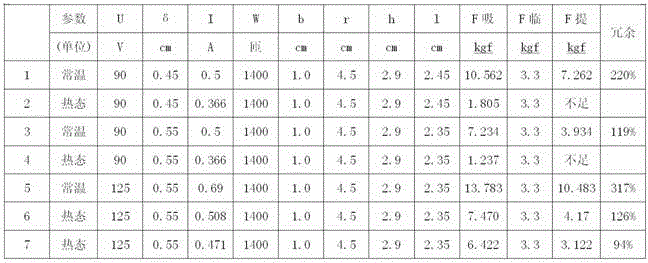

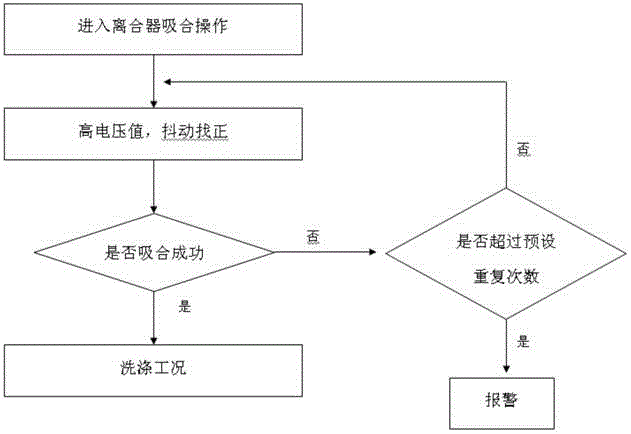

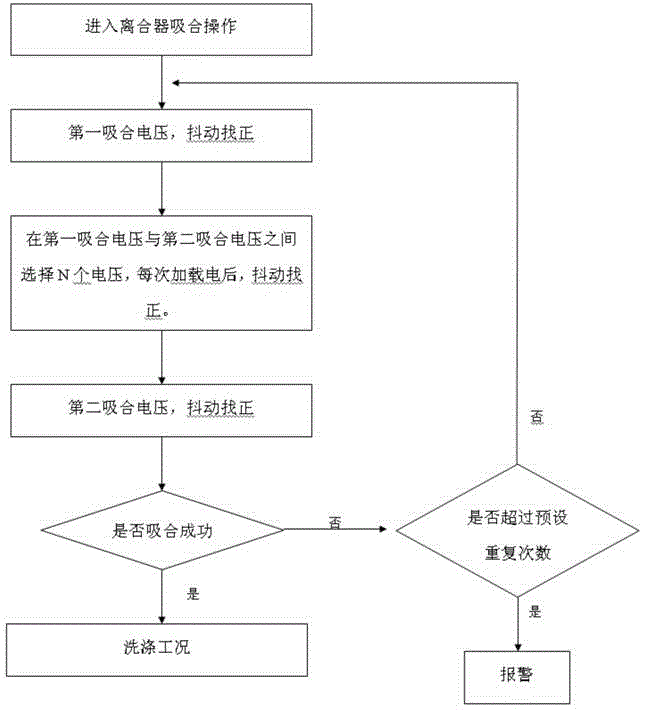

Clutch reliability improving system and using method thereof

The invention provides a clutch reliability improving system. The main reason of failure of a clutch includes that the clutch with a clutch ring is used continuously and an electromagnetic coil is over hot. By the clutch reliability improving system, a loaded pull-in voltage can be adjusted, and the pull-in reliability of the clutch is ensured by guaranteeing a redundant value of an electromagnet on the improving ability of the clutch ring.

Owner:NINGGUO JULONG IND

A kind of graphene-silver composite fiber and preparation method thereof

ActiveCN106702731BWide variety of sourcesCompact structureElectroconductive/antistatic filament manufactureCarbon fibresCopperElectroplating

The invention discloses a graphene-silver composite fiber and a preparation method thereof. The method comprises the steps of firstly preparing a graphene oxide fiber of which the diameter is 1-50 microns by adopting a wet spinning method, and then putting the graphene oxide fiber into a high-temperature furnace for heating and reducing to obtain a continuous pure graphene fiber. Due to a special treatment mode, the fiber surface is provided with multi-stage wrinkles, the pure graphene fiber is fixed on a negative electrode of a plating bath for electroplating, and a copper layer has an extension structure embedded into the wrinkles. Graphene is tightly combined with silver crystals, a hole defect is avoided, the electrical properties of the material are greatly improved, and the fiber is stable in structure and constant in electric conductivity after being bent for 100 times.

Owner:杭州德烯科技集团有限公司

Method for preparing lithium ionic sieve adsorbent

ActiveCN109012564AImprove adsorption capacityStable structureOther chemical processesManganese oxides/hydroxidesMicrowaveLithium metal

The invention provides a method for preparing a lithium ionic sieve adsorbent. The method comprises the following steps: co-acting a raw material which is an aqueous solution of a lithium salt and a manganese salt by microwaves and ultrasonic waves to obtain a co-precipitation product, calcining the co-precipitation product to obtain a lithium ionic sieve precursor, and carrying out acid leachingon the lithium ionic sieve precursor to obtain the lithium ionic sieve adsorbent. The lithium salt and manganese salt mixed aqueous solution is used as the raw material, and precipitates under the co-action of the microwaves and the ultrasonic waves, the precipitate is calcined to obtain the lithium ionic sieve precursor with an ideal structure, a high purity and a high lithium content, and the lithium ionic sieve precursor is processed to obtain the lithium ionic sieve adsorbent. The lithium ionic sieve adsorbent has the advantages of stable structure and high adsorption capacity, and the method has the advantages of short time, low energy consumption and high controllability, and is of great significance to recycling lithium metal resources.

Owner:BEIJING UNIV OF TECH

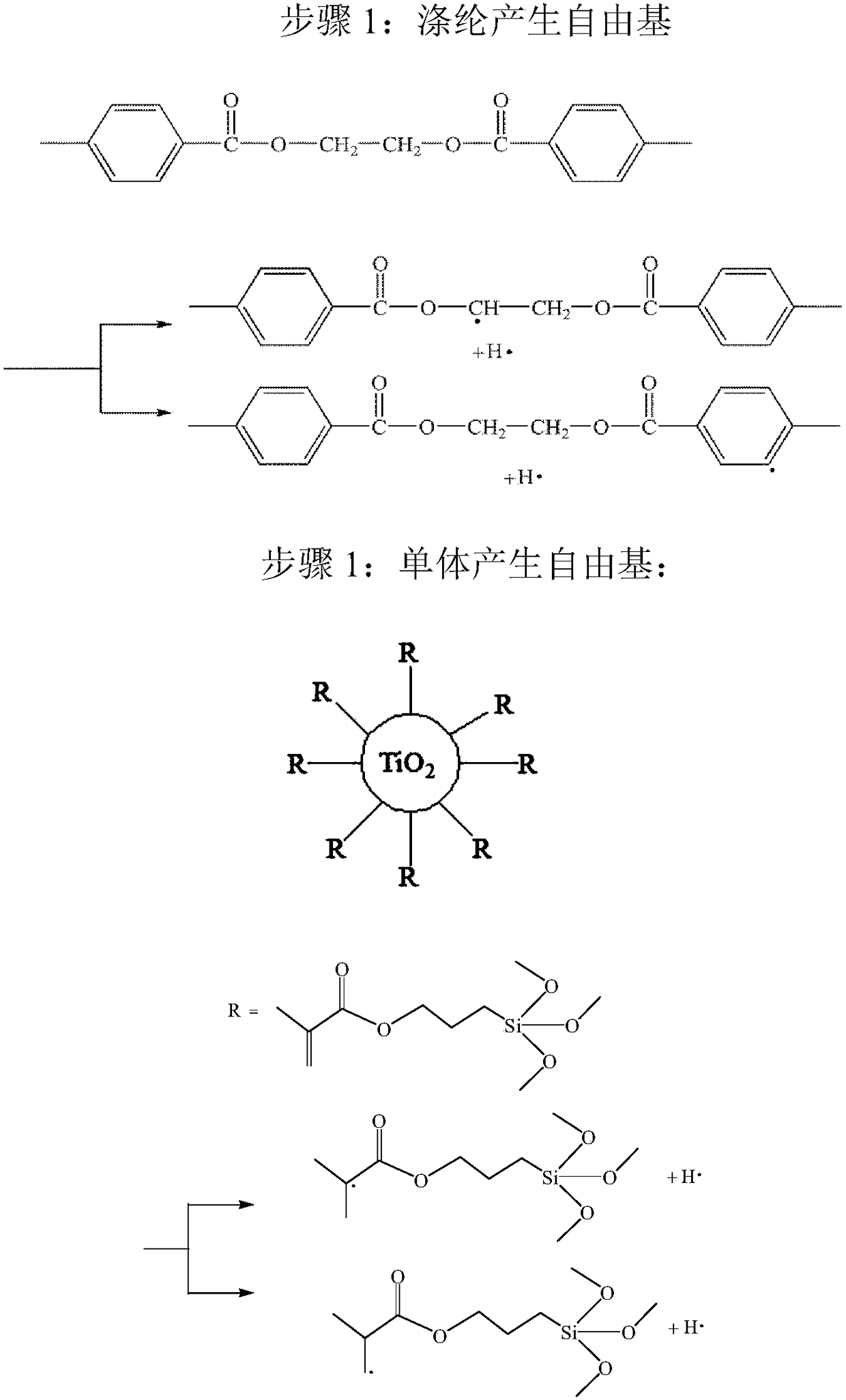

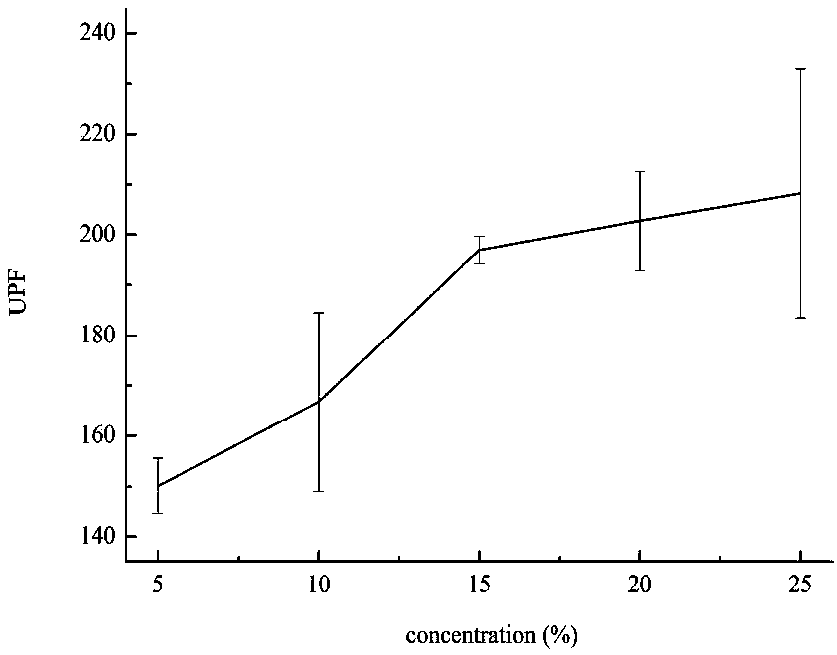

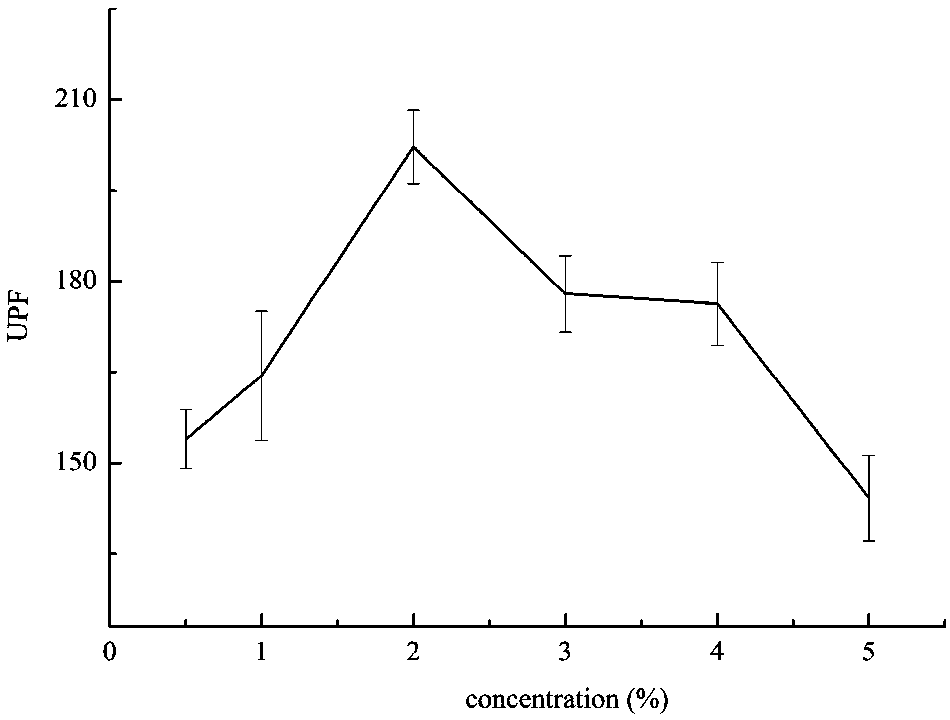

Preparation method and application of nano titanium dioxide organic and inorganic hybridized anti-ultraviolet finishing agent

The invention provides a preparation method of an organic and inorganic hybridized anti-ultraviolet finishing agent based on nano titanium dioxide. The preparation method comprises the following steps: mixing absolute ethyl alcohol and de-ionized water; adjusting the pH (Potential of Hydrogen) value of the solution to 8 to 9; adding rutile type nano titanium dioxide; after carrying out ultrasonicdispersion, dropwise adding an ethanol solution of gamma-(methacryloyloxy)propyltrimethoxysilane (KH570); stirring to react at room temperature; after finishing reaction, washing sediment with alcoholfor three times and centrifuging at a high speed; drying to obtain the KH570-TiO2 hybridized anti-ultraviolet finishing agent. According to the preparation method provided by the invention, a monomeris finished on a polyester fabric, and two finishing manners including a traditional rolling and roasting technology (PDC) and an electron beam radiation technology (EB) are adopted to prepare a fabric with excellent anti-ultraviolet performance.

Owner:JIANGNAN UNIV

Clutch reliability improving system and using method thereof

ActiveCN104727084AAvoid failurePull-in power dropOther washing machinesTextiles and paperControl engineeringControl theory

The invention provides a clutch reliability improving system. The main reason of failure of a clutch includes that the clutch with a clutch ring is used continuously and an electromagnetic coil is over hot. By the clutch reliability improving system, a loaded pull-in voltage can be adjusted, and the pull-in reliability of the clutch is ensured by guaranteeing a redundant value of an electromagnet on the improving ability of the clutch ring.

Owner:NINGGUO JULONG IND

A kind of graphene-copper composite fiber and preparation method thereof

The invention discloses a graphene-copper composite fiber and a preparation method thereof. The method comprises the steps of firstly preparing a graphene oxide fiber of which the diameter is 1-50 microns by adopting a wet spinning method, and then putting the graphene oxide fiber into a high-temperature furnace for heating and reducing to obtain a continuous pure graphene fiber. Due to a special treatment mode, the fiber surface is provided with multi-stage wrinkles, the pure graphene fiber is fixed on a negative electrode of a plating bath for electroplating, and a copper layer has an extension structure embedded into the wrinkles. Graphene is tightly combined with copper crystals, a hole defect is avoided, the electrical properties of the material are greatly improved, the fiber is stable in structure and constant in electric conductivity after being bent for 100 times.

Owner:杭州德烯科技集团有限公司

Preparation method of medium-and long-chain structured lipid composition for nutritional treatment of breast diseases

ActiveCN110419736AReduce energy consumptionReduce consumptionFood homogenisationFood shapingDiseasePhytosterol

The invention provides a preparation method of medium-and long-chain structured lipid composition for nutritional treatment of breast diseases, and relates to the field of lipid synthesis. The preparation method includes the steps that conjugated linoleic acid, medium-chain triglycerides, long-chain triglycerides, conjugated linoleic acid glyceride and phytosterol are used as raw materials, an ester exchange reaction is carried out in a reactor, the pretreatment step is carried out, and medium-and long-chain triglyceride is obtained; after further treatment, the medium-and long-chain triglyceride is mixed with silica, N-acetylneuraminic acid, beta-hydroxy-beta- methylbutyrate calcium, konjac glucomannan, mangosteen extracts, elderberry and yeast beta- glucan, and the medium-and long-chainstructured lipid composition is prepared. The preparation method is simple, convenient and cheap; and meanwhile, the medium-and long-chain structured lipid composition prepared by the preparation method can be used for nutritional treatment of breast diseases.

Owner:河北康睿达脂质有限公司

A kind of method for preparing lithium ion sieve adsorbent

ActiveCN109012564BImprove adsorption capacityStable structureOther chemical processesManganese oxides/hydroxidesLithium metalPhysical chemistry

The invention provides a method for preparing a lithium ion sieve adsorbent, comprising: using an aqueous solution of lithium salt and manganese salt as a raw material, using microwaves and ultrasonic waves to obtain a co-precipitation product, and then roasting the co-precipitation product to obtain lithium ions The sieve precursor is finally obtained by acid leaching the lithium ion sieve precursor. The method of the present invention uses the mixed aqueous solution of lithium salt and manganese salt as raw material, produces precipitation under the joint action of microwave and ultrasonic wave, and then obtains a lithium ion sieve precursor with ideal structure through roasting, which has high purity and high lithium content. The lithium ion sieve adsorbent finally obtained after the treatment of the ion sieve precursor has a stable structure and high adsorption capacity, and the method of the present invention consumes less time and energy and has high controllability, which is of great significance to the recycling and utilization of lithium metal resources.

Owner:BEIJING UNIV OF TECH

A kind of reactive flame retardant epoxy resin microcapsule and preparation method thereof

ActiveCN104226216BWith self-healing functionEnsure self-healing capabilitiesMicroballoon preparationMicrocapsule preparationEpoxyPolymer science

The invention discloses a reactive flame-retardant epoxy resin microcapsule, which includes a capsule core and a capsule wall, wherein the capsule core is 30-70% phosphorus-containing epoxy resin, and the capsule wall is 15-55% phosphorus-containing epoxy resin. Phosphorus-containing acrylate, 15-45% epoxy acrylate, 10-50% polymerizable emulsifier, 0.5-3% acrylate crosslinker, 0.1-0.5% photoinitiator. The invention also discloses a method for preparing the microcapsule. The microcapsule of the present invention has the following advantages: good flame retardancy and self-repairing function, so that it can be widely used in various fields such as thermosetting self-repairing resin-based composite materials and coatings. The method for preparing the microcapsules of the present invention adopts an ultraviolet light interface in-situ polymerization method, which not only has a simple process, consumes less time and energy, but is also controllable, and can improve the safety of the prepared composite material and prolong its service life.

Owner:广东润昌南星新材料有限公司

A pollution-free and low-cost process for preparing single-layer graphene oxide

The invention discloses a pollution-free low-cost technology for preparing graphene oxide. The technology comprises the following steps: 1, mixing graphite with a strong acid to infiltrate graphite, adding a strong oxidant, and continuously stirring to oxidize and exfoliate graphite layers; 2, centrifuging the obtained reaction solution, recovering the strong acid to be used in a next reaction, slowly pouring the obtained muddy product into deionized water, stirring, washing by using dilute hydrochloric acid, repeatedly cleaning by using deionized water, and centrifuging to obtain monolayer graphene oxide; 3, introducing ammonia gas into wastewater until the pH value approaches 7 to obtain an inorganic fertilizer containing nitrogen, potassium, iron and phosphorus; and 4, concentrating an aqueous solution of graphene oxide, and drying to obtain graphene oxide with high density and high specific surface area. The technology has the advantages of simple, safe and controllable preparation process, less time and energy consumption, no explosion danger and no pollution. The cycle use of concentrated sulfuric acid in the raw material-to-fertilizer process makes all raw materials and elements fully used, so the preparation cost of graphene oxide is greatly reduced.

Owner:ZHEJIANG TANGUSHANGXI MATERIAL SCI & TECH

Clutch reliability improvement system and method of use thereof

The present invention firstly finds that the clutch with a clutch ring is overheated due to continuous use of the electromagnetic coil, which is the main reason for the failure of the clutch. And for this purpose, a clutch reliability improvement system is proposed, the system can adjust the loaded pull-in voltage, and ensure the reliability of the clutch pull-in by ensuring the redundant value of the lifting force of the electromagnet to the clutch ring.

Owner:NINGGUO JULONG IND

Clutch reliability improving system and using method thereof

ActiveCN104452190ASave electricityReduce use costOther washing machinesTextiles and paperPull in voltageElectromagnet

As it is firstly found that the main reason for failure of a clutch is overheating of an electromagnetic coil due to the fact that the clutch with a clutch ring is used contentiously, the invention provides a clutch reliability improving system. By the system, loaded pull-in voltage can be adjusted, and reliability of clutch pull-in is ensured by guaranteeing redundancy of lifting force of an electromagnet on the clutch ring.

Owner:NINGGUO JULONG IND

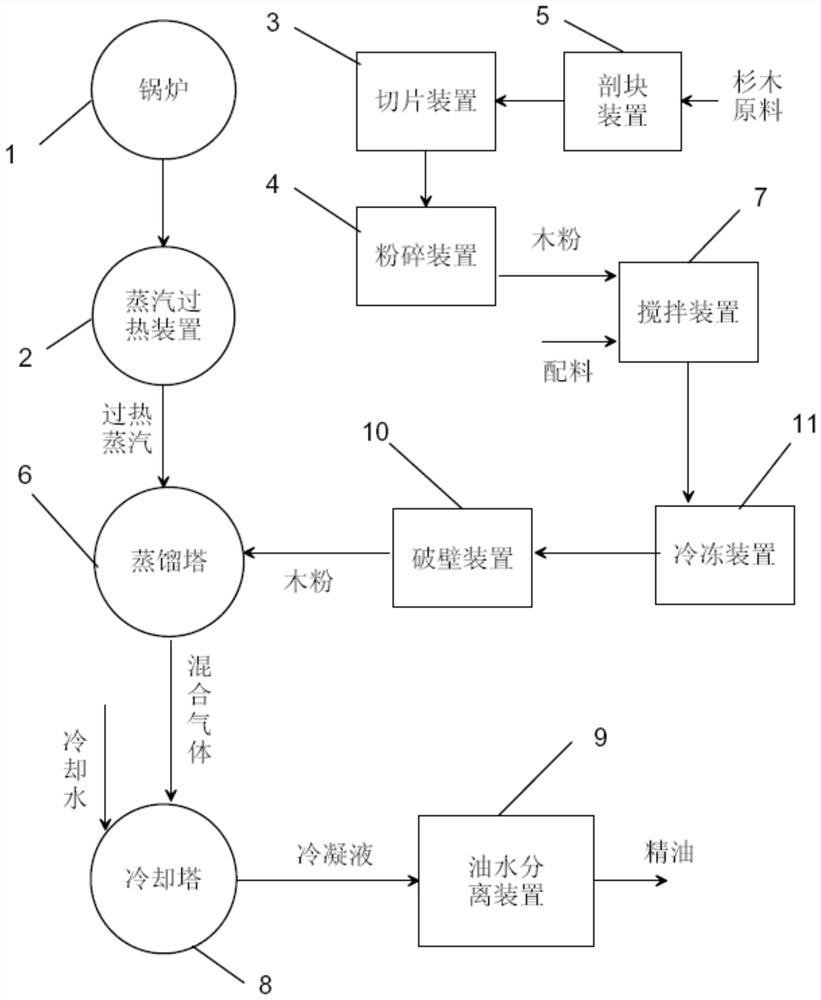

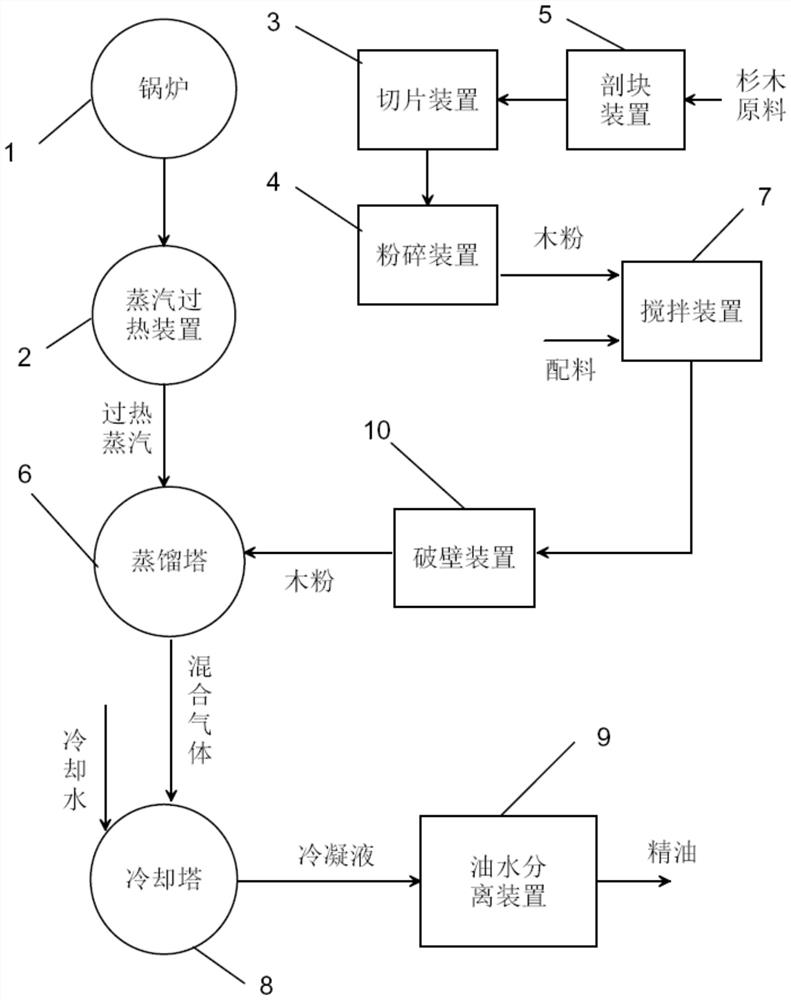

Optimized production method and production line of cedarwood essential oil

PendingCN114395445ALess time and energy consumptionHigh yieldEssential-oils/perfumesProcess engineeringManufacturing line

The invention discloses an optimized production method and production line of cedarwood essential oil. The production line comprises a boiler, a steam overheating device, a block cutting device, a slicing device, a smashing device, a stirring device, a wall breaking device, a distillation tower, a cooling tower and an oil-water separation device. The steam pipeline is communicated with a steam inlet of the distillation tower after being heated by the steam overheating device; the cutting device, the slicing device, the crushing device and the stirring device are sequentially connected through a conveying device; a gas outlet of the distillation tower is communicated with a gas inlet of the cooling tower; a condensate outlet of the cooling tower is communicated with an inlet of the oil-water separation device; the wall breaking device is a popcorn machine; the output end of the stirring device is connected with the feeding end of the corn popper through a conveying device; the discharging end of the corn popper is connected with the feeding hole of the distillation tower through a conveying device. The production method is carried out by adopting the production line, and a finished product is prepared through the steps of powder preparation, mixing, wall breaking, distillation, cooling and oil-water separation. Wall breaking is more thorough, working hours are shorter, energy consumption and production cost are lower, and the yield is higher.

Owner:FUJIAN XINLYULIN PROD DEV

Brewing method of kiwi-flavored sweet corn wine

InactiveCN102586057BTaste and texture are mellow and harmoniousHigh alcohol contentMicroorganism based processesAlcoholic beverage preparationBiotechnologyKiwi fruit

The invention discloses a brewing method of kiwi-flavored sweet corn wine. The brewing method comprises the steps as follows: selecting fresh brewing sweet corn ears which are pollinated 25 days before, adding water, homogenizing to obtain sweet corn juice, and cleaning and homogenizing green kiwi fruit to obtain kiwi raw juice; mixing 75-85% of brewing sweet corn juice with 25-15% of pea juice to obtain a distiller's yeast culture medium, inoculating with yeast subjected to slant culture, and carrying out progressive amplification culture in distiller's yeast seeding tanks to obtain liquid distiller's yeast; adding the kiwi raw juice, the brewing sweet corn juice and the liquid distiller's yeast into a fermentation tank, fermenting at 15-20 DEG C for 21-14 days, harrowing and supplementing white granulated sugar with a ratio of 8.5-17% on the 7th -10th day of fermentation, filtering, and carrying out microwave treatment on the filtrate to obtain kiwi-flavored sweet corn wine base; pumping the kiwi-flavored sweet corn wine base into an aging tank to be stored at 16 DEG C below for more than 18 months; and adding sweet corn Brandy of which the amount accounts for 3-5% the weight ofthe aged sweet corn wine to obtain the kiwi-flavored sweet corn wine. The obtained kiwi-flavored sweet corn wine has kiwi fruit aroma and rice wine mellowness, is moderate in alcohol degree, mellow, elegant and nutrient, and satisfies the fashion of health-care driving.

Owner:窦秉德

A kind of preparation method of cranial neurotrophic treatment composition

ActiveCN110038018BReduce energy consumptionReduce consumptionNervous disorderEster active ingredientsDiseaseNutrition

The present invention provides a preparation method of a cerebral nerve nutritional therapeutic composition and relates to the field of synthesis of oils and fats. Fatty acid triglyceride, conjugatedlinoleic acid glyceride and phytosterol are used as raw materials, the raw materials are subjected to transesterification with 435 lipase, IM lipase and DF15 lipase, cooling, decolorization, deodorization, distillation and fine-filtration are conducted, then emulsification, embedding and spray-drying are conducted to obtain dry powder, then the dry powder is mixed with phosphatidylserine, N-acetylneuraminic acid, beta-hydroxy-beta-methylbutyrate calcium, konjac glucomannan, a mangosteen extract, elderberries and yeast beta-glucan, and homogenizing is conducted to obtain the medium-long chain structure lipid composition. The technology is simple, convenient and inexpensive, and can produce precise nutritional composition suitable for clinical rehabilitation of diseases of stroke, Alzheimer's disease, depression, Parkinson's disease, epilepsy, etc.

Owner:河北康睿达脂质有限公司

A kind of preparation method of composition for rehabilitation of prostatic urinary disease

ActiveCN109875050BReduce energy consumptionReduce consumptionFood shapingFermentationLipidomePalmitates

The invention provides a method for preparing a composition for the rehabilitation of prostate and urinary diseases, and relates to the field of oil synthesis. Carry out transesterification with phytosterols as raw materials, add vitamin E and ascorbyl palmitate after cooling, decolorization, deodorization, distillation and fine filtration to obtain 6‑24 carbon medium and long chain triglycerides; then emulsification, homogenization, coating Embedded and spray-dried, and mixed with a functional mixture to prepare a medium-long chain structure lipid composition. The method is simple, convenient and cheap, and the prepared composition can be used for rehabilitation of diseases such as prostatic urology and the like.

Owner:河北康睿达脂质有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com