A kind of preparation method of cranial neurotrophic treatment composition

A therapeutic composition and cranial nerve technology, applied in the field of oil synthesis, can solve the problems of untimely energy supply, slow metabolism of long-chain fatty acids, increased burden, etc., reduce energy and time consumption, simple preparation process, and low price The effect of time-consuming and energy-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

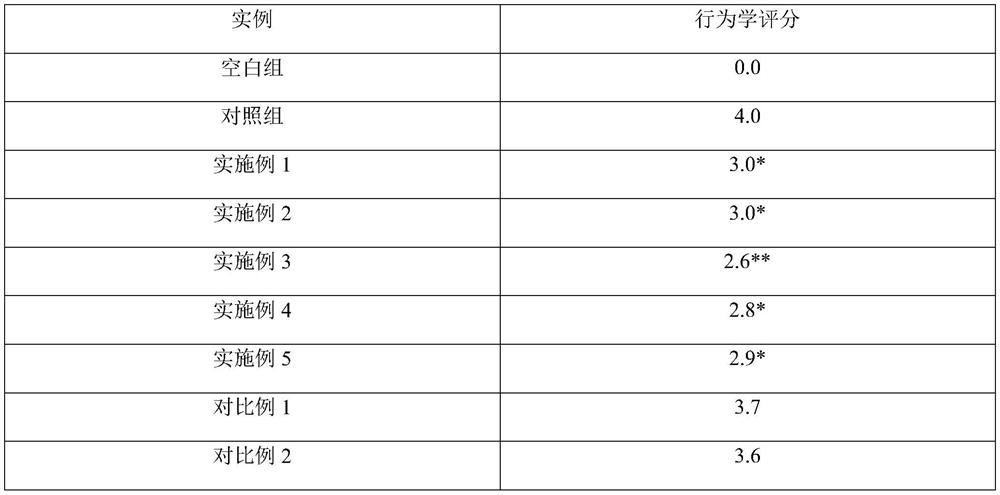

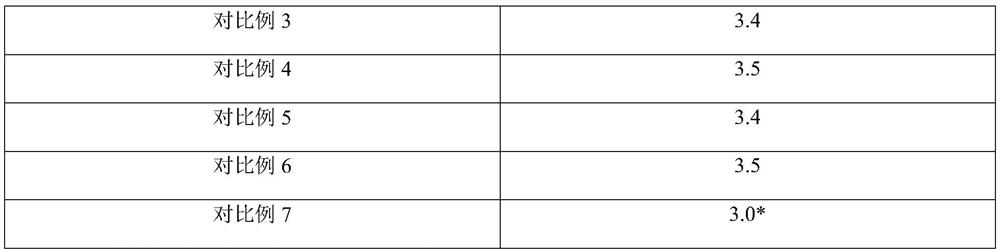

Examples

Embodiment 1

[0022] A preparation method of a brain neurotrophic treatment composition: adding fatty acid triglycerides, conjugated linoleic acid glycerides and β-sitosterol to a lipase collecting machine equipped with 435 lipase, IM lipase and DF15 lipase The transesterification reaction is carried out in the closed reactor of the device, the reaction temperature is 40° C., and the reaction time is 15 hours. Among them, fatty acid triglycerides are 8-10 carbon fatty acid triglycerides extracted from palm kernel oil and 16-24 carbon fatty acid triglycerides extracted from linseed oil, 8-10 carbon fatty acid triglycerides, 16- The weight ratio of 24 carbon fatty acid triglycerides, conjugated linoleic acid glycerides and β-sitosterol is 15:16:2:4; the addition of 435 lipase is 1.5% of the total weight of fatty acid triglycerides %, the addition of IM lipase is 0.6% of the total weight of fatty acid triglycerides, and the addition of DF15 lipase is 0.2% of the total weight of fatty acid trig...

Embodiment 2

[0024] A preparation method of a brain neurotrophic treatment composition: adding fatty acid triglycerides, conjugated linoleic acid glycerides and stigmasterol to a lipase collecting device equipped with 435 lipase, IM lipase and DF15 lipase The transesterification reaction was carried out in a closed reactor, the reaction temperature was 60° C., and the reaction time was 12 hours. Among them, fatty acid triglycerides are 8-10 carbon fatty acid triglycerides extracted from coconut oil and 16-24 carbon fatty acid triglycerides extracted from salamander oil, 8-10 carbon fatty acid triglycerides, 16-24 carbon fatty acid triglycerides The weight ratio of fatty acid triglycerides, conjugated linoleic acid glycerides and stigmasterol is 65:75:12:10; the addition of 435 lipase is 7% of the total weight of fatty acid triglycerides, IM fat The added amount of the enzyme is 1% of the total weight of the fatty acid triglyceride, and the added amount of the DF15 lipase is 2% of the total...

Embodiment 3

[0026] A preparation method of a brain neurotrophic treatment composition: adding fatty acid triglycerides, conjugated linoleic acid glycerides and campesterol to a lipase collecting device equipped with 435 lipase, IM lipase and DF15 lipase The transesterification reaction was carried out in a closed reactor, the reaction temperature was 55° C., and the reaction time was 13.5 hours. Among them, the fatty acid triglycerides are 8-10 carbon fatty acid triglycerides extracted from palm kernel oil and 16-16-carbon fatty acid triglycerides extracted from garlic oil, sorbifolia oil and linseed oil with a weight ratio of 1:1:2. The weight ratio of 24-carbon fatty acid triglyceride, 8-10 carbon fatty acid triglyceride, 16-24 carbon fatty acid triglyceride, conjugated linoleic acid glyceride and campesterol is 34:42:8:6 ; The addition of 435 lipase is 4.5% of the total weight of fatty acid triglycerides, the addition of IM lipase is 2% of the total weight of fatty acid triglycerides, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com