Preparation method and application of nano titanium dioxide organic and inorganic hybridized anti-ultraviolet finishing agent

An anti-ultraviolet and finishing agent technology, which is applied in fiber treatment, textiles and papermaking, light-resistant fibers, etc., can solve the problems of incompatibility and complexity, and achieve excellent anti-ultraviolet performance, simple process and high yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

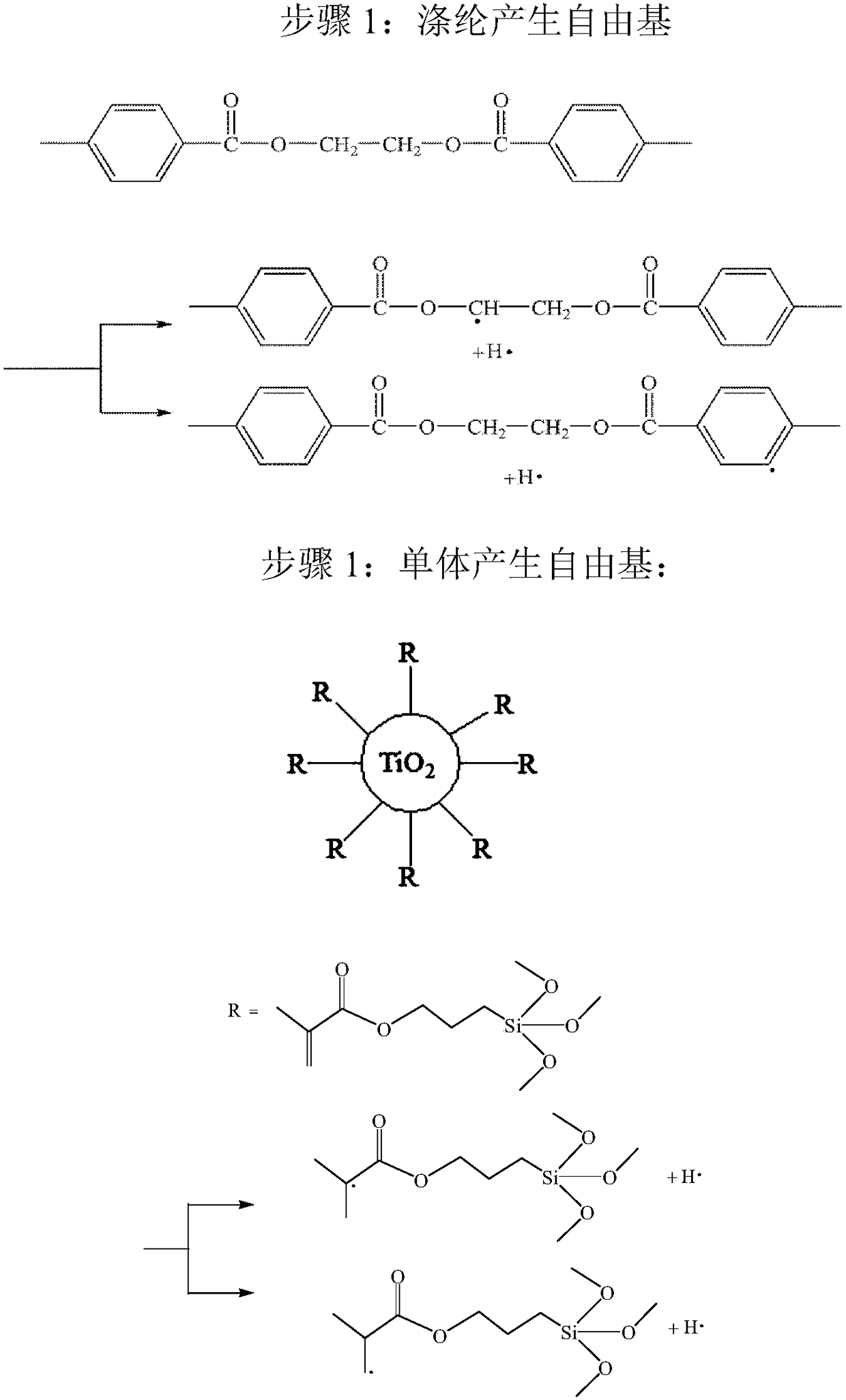

Method used

Image

Examples

Embodiment 1

[0033] Mix 90mL of absolute ethanol and 10mL of deionized water in a 250mL beaker, adjust the pH value of the solution to 8 with a pH meter, add 10g of rutile nano-titanium dioxide, and pour it into a 250mL flat-bottomed flask after ultrasonic dispersion, and drop in 2g of γ -(Methacryloyloxy)propyltrimethoxysilane (KH570) in ethanol (10mL) solution, stirred and reacted at room temperature for 11 hours. After the reaction, the precipitate was washed three times with ethanol and centrifuged at high speed, and placed in a dry Drying in the oven gave 8.04 g of white product, yield 80.40%.

Embodiment 2

[0035] Mix 95mL absolute ethanol and 10mL deionized water in a 250mL beaker, adjust the pH value of the solution to 8.5 with a pH meter, add 9g of rutile nano-titanium dioxide, and pour it into a 250mL flat-bottomed flask after ultrasonic dispersion, and drop in 3g of γ -(Methacryloyloxy)propyltrimethoxysilane (KH570) in ethanol (5mL) solution, stirred and reacted at room temperature for 12 hours. After the reaction, the precipitate was washed three times with ethanol and centrifuged at high speed, and placed in a dry After drying in the box, 8.04 g of white product was obtained, with a yield of 82.35%.

Embodiment 3

[0037] Mix 100mL absolute ethanol and 10mL deionized water in a 250mL beaker, adjust the pH value of the solution to 9 with a pH meter, add 8g of rutile nano-titanium dioxide, and pour it into a 250mL flat-bottomed flask after ultrasonic dispersion, and drop 4g of γ -(Methacryloyloxy)propyltrimethoxysilane (KH570) solution, stirred and reacted at room temperature for 13 hours. After the reaction, washed the precipitate three times with ethanol and centrifuged at high speed, placed in a drying oven to dry, 8.04 g of white product was obtained, with a yield of 81.60%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com